Can bus JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 195 of 3039

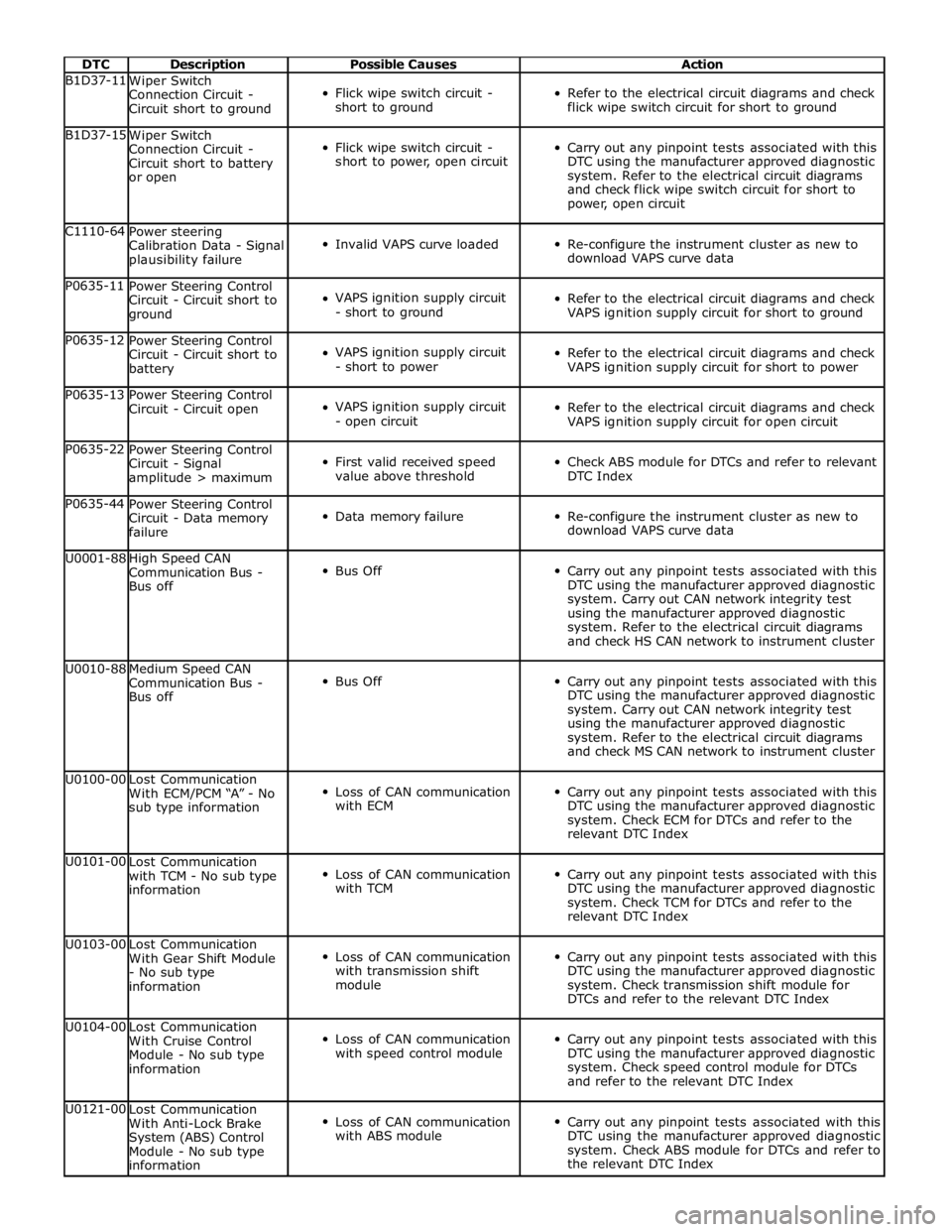

DTC Description Possible Causes Action B1D37-11

Wiper Switch

Connection Circuit -

Circuit short to ground

Flick wipe switch circuit -

short to ground

Refer to the electrical circuit diagrams and check

flick wipe switch circuit for short to ground B1D37-15

Wiper Switch

Connection Circuit -

Circuit short to battery

or open

Flick wipe switch circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check flick wipe switch circuit for short to

power, open circuit C1110-64

Power steering

Calibration Data - Signal

plausibility failure

Invalid VAPS curve loaded

Re-configure the instrument cluster as new to

download VAPS curve data P0635-11

Power Steering Control

Circuit - Circuit short to

ground

VAPS ignition supply circuit

- short to ground

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for short to ground P0635-12

Power Steering Control

Circuit - Circuit short to

battery

VAPS ignition supply circuit

- short to power

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for short to power P0635-13

Power Steering Control

Circuit - Circuit open

VAPS ignition supply circuit

- open circuit

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for open circuit P0635-22

Power Steering Control

Circuit - Signal

amplitude > maximum

First valid received speed

value above threshold

Check ABS module for DTCs and refer to relevant

DTC Index P0635-44

Power Steering Control

Circuit - Data memory

failure

Data memory failure

Re-configure the instrument cluster as new to

download VAPS curve data U0001-88

High Speed CAN

Communication Bus -

Bus off

Bus Off

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test

using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check HS CAN network to instrument cluster U0010-88

Medium Speed CAN

Communication Bus -

Bus off

Bus Off

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test

using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check MS CAN network to instrument cluster U0100-00

Lost Communication

With ECM/PCM “A” - No

sub type information

Loss of CAN communication

with ECM

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for DTCs and refer to the

relevant DTC Index U0101-00

Lost Communication

with TCM - No sub type

information

Loss of CAN communication

with TCM

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Module

- No sub type

information

Loss of CAN communication

with transmission shift

module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for

DTCs and refer to the relevant DTC Index U0104-00

Lost Communication

With Cruise Control

Module - No sub type

information

Loss of CAN communication

with speed control module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check speed control module for DTCs

and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-Lock Brake

System (ABS) Control

Module - No sub type

information

Loss of CAN communication

with ABS module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS module for DTCs and refer to

the relevant DTC Index

Page 202 of 3039

DTC Description Possible Causes Action B11A9-23 Tone Button - Signal stuck

low

Button stuck

down/jammed

Integrated control

panel failure

Check for stuck down/jammed button. Check and

install a new integrated control panel as required B121F-23

Climate Switch - Signal

stuck low

Button stuck

down/jammed

Integrated control

panel failure

Check for stuck down/jammed button. Check and

install a new integrated control panel as required U0010-88

Medium Speed CAN

Communication Bus - Bus

off

Bus off

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U0140-00

Lost Communication With

Body Control Module - No

sub type information

Missing message

from CJB

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U0142-00

Lost Communication With

Body Control Module "B" -

No sub type information

Missing message

from RJB

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U0155-00

Lost Communication With

Instrument Panel Cluster

(IPC) Control Module - No

sub type information

Missing message

from instrument

cluster

Carry out any pinpoint tests associated to this DTC

using the manufacturer approved diagnostic system U0156-00

Lost Communication With

Information Center "A" -

No sub type information

Missing message

from information and

entertainment control

module

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U0300-00

Internal Control Module

Software Incompatibility -

No sub type information

Invalid car

configuration data

received

Re-configure the integrated control panel as new.

Clear DTC and re-test, if DTC remains suspect the

integrated control panel. Check and install a new

integrated control panel as required, refer to the new

module/component installation note at the top of the

DTC Index U3000-41

Control Module - General

checksum failure

Checksum error,

internal module

failure

Suspect the integrated control panel, check and

install a new integrated control panel as required,

refer to the new module/component installation note

at the top of the DTC Index

Page 204 of 3039

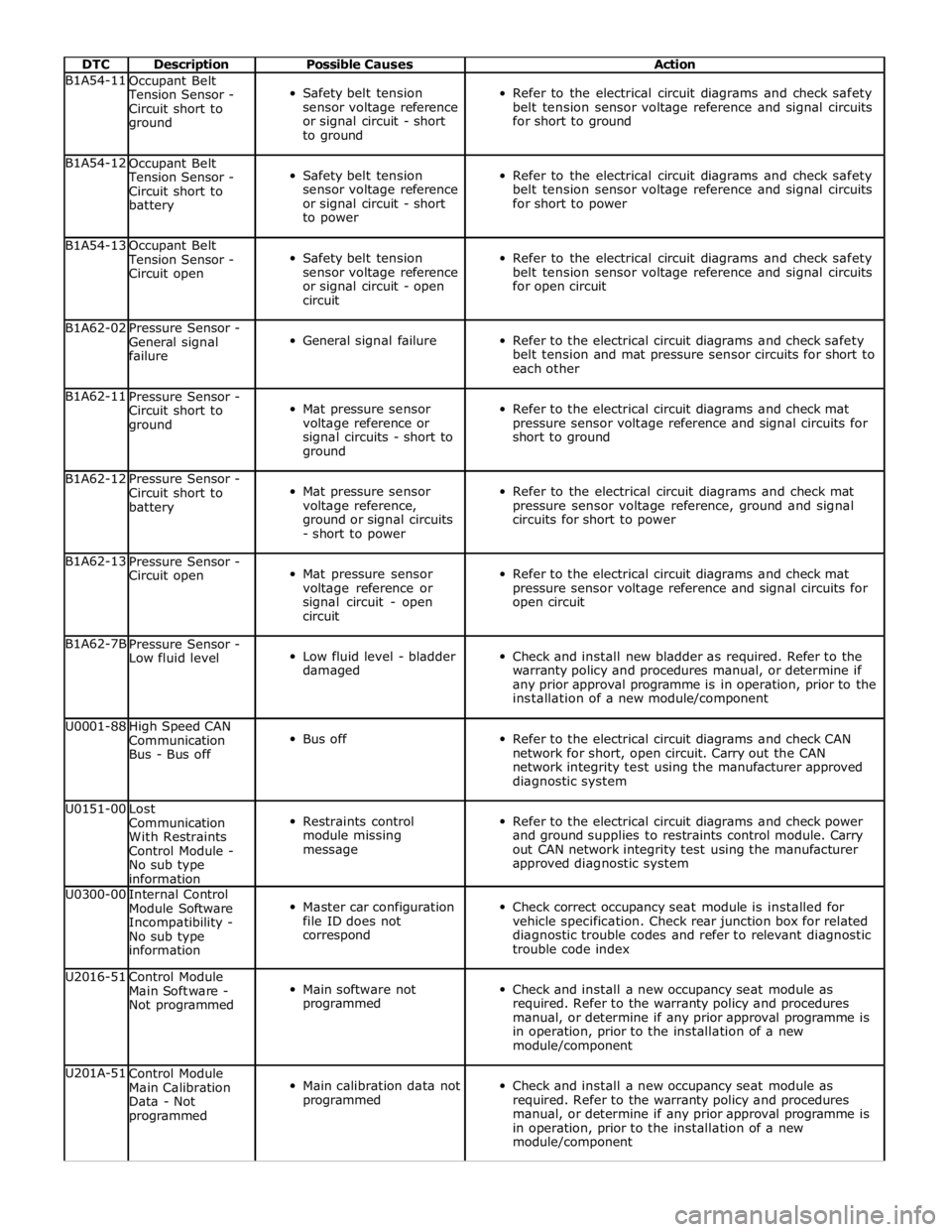

DTC Description Possible Causes Action B1A54-11

Occupant Belt Tension Sensor -

Circuit short to

ground

Safety belt tension

sensor voltage reference

or signal circuit - short

to ground

Refer to the electrical circuit diagrams and check safety

belt tension sensor voltage reference and signal circuits

for short to ground B1A54-12

Occupant Belt Tension Sensor -

Circuit short to

battery

Safety belt tension

sensor voltage reference

or signal circuit - short

to power

Refer to the electrical circuit diagrams and check safety

belt tension sensor voltage reference and signal circuits

for short to power B1A54-13

Occupant Belt Tension Sensor -

Circuit open

Safety belt tension

sensor voltage reference

or signal circuit - open

circuit

Refer to the electrical circuit diagrams and check safety

belt tension sensor voltage reference and signal circuits

for open circuit B1A62-02

Pressure Sensor -

General signal

failure

General signal failure

Refer to the electrical circuit diagrams and check safety

belt tension and mat pressure sensor circuits for short to

each other B1A62-11

Pressure Sensor -

Circuit short to

ground

Mat pressure sensor

voltage reference or

signal circuits - short to

ground

Refer to the electrical circuit diagrams and check mat

pressure sensor voltage reference and signal circuits for

short to ground B1A62-12

Pressure Sensor -

Circuit short to

battery

Mat pressure sensor

voltage reference,

ground or signal circuits

- short to power

Refer to the electrical circuit diagrams and check mat

pressure sensor voltage reference, ground and signal

circuits for short to power B1A62-13

Pressure Sensor -

Circuit open

Mat pressure sensor

voltage reference or

signal circuit - open

circuit

Refer to the electrical circuit diagrams and check mat

pressure sensor voltage reference and signal circuits for

open circuit B1A62-7B

Pressure Sensor -

Low fluid level

Low fluid level - bladder

damaged

Check and install new bladder as required. Refer to the

warranty policy and procedures manual, or determine if

any prior approval programme is in operation, prior to the

installation of a new module/component U0001-88

High Speed CAN

Communication

Bus - Bus off

Bus off

Refer to the electrical circuit diagrams and check CAN

network for short, open circuit. Carry out the CAN

network integrity test using the manufacturer approved

diagnostic system U0151-00

Lost

Communication

With Restraints

Control Module -

No sub type

information

Restraints control

module missing

message

Refer to the electrical circuit diagrams and check power

and ground supplies to restraints control module. Carry

out CAN network integrity test using the manufacturer

approved diagnostic system U0300-00

Internal Control

Module Software

Incompatibility -

No sub type

information

Master car configuration

file ID does not

correspond

Check correct occupancy seat module is installed for

vehicle specification. Check rear junction box for related

diagnostic trouble codes and refer to relevant diagnostic

trouble code index U2016-51

Control Module

Main Software -

Not programmed

Main software not

programmed

Check and install a new occupancy seat module as

required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is

in operation, prior to the installation of a new

module/component U201A-51

Control Module

Main Calibration

Data - Not

programmed

Main calibration data not

programmed

Check and install a new occupancy seat module as

required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is

in operation, prior to the installation of a new

module/component

Page 212 of 3039

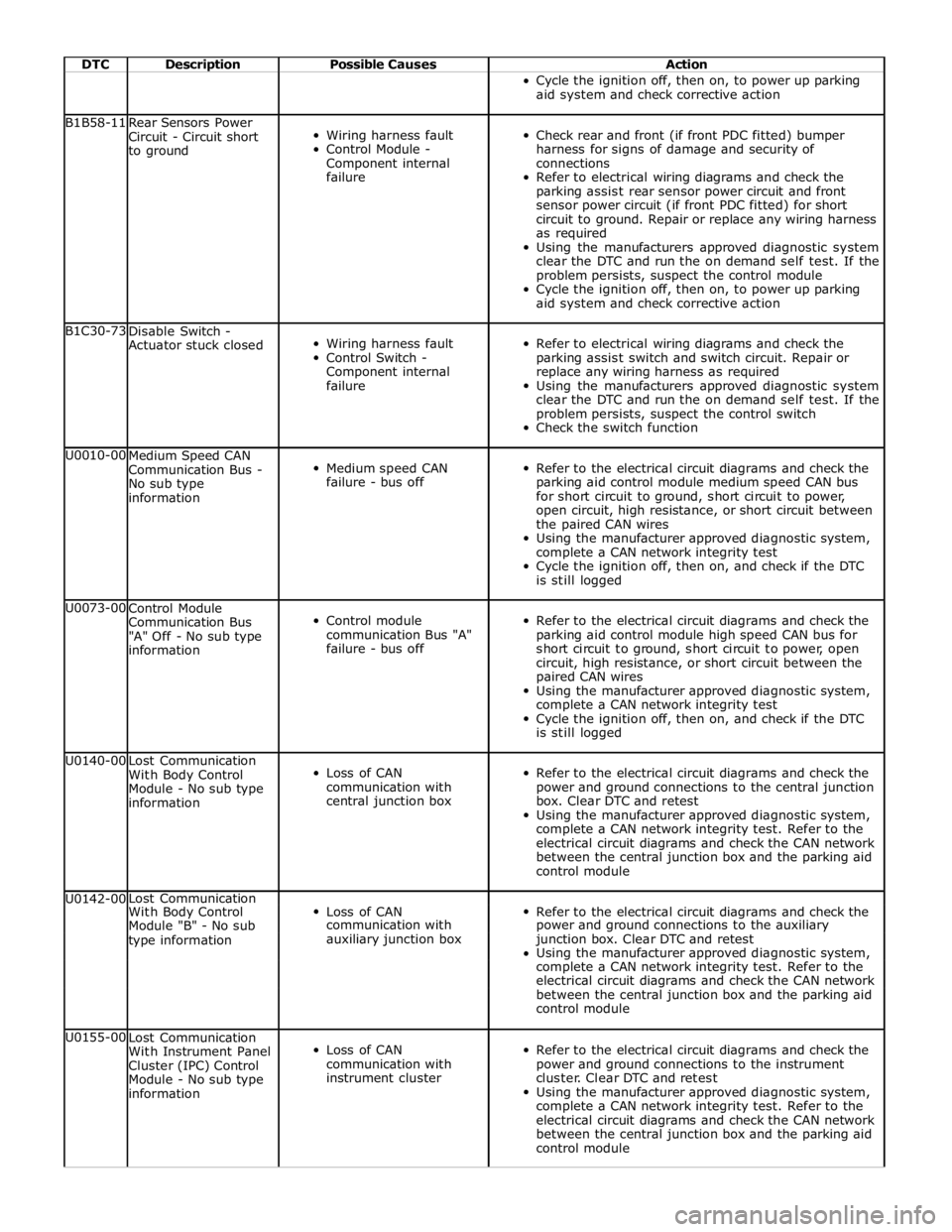

DTC Description Possible Causes Action Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1B58-11

Rear Sensors Power

Circuit - Circuit short

to ground

Wiring harness fault

Control Module -

Component internal

failure

Check rear and front (if front PDC fitted) bumper

harness for signs of damage and security of

connections

Refer to electrical wiring diagrams and check the

parking assist rear sensor power circuit and front

sensor power circuit (if front PDC fitted) for short

circuit to ground. Repair or replace any wiring harness

as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module

Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1C30-73

Disable Switch -

Actuator stuck closed

Wiring harness fault

Control Switch -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking assist switch and switch circuit. Repair or

replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control switch

Check the switch function U0010-00

Medium Speed CAN

Communication Bus -

No sub type

information

Medium speed CAN

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module medium speed CAN bus

for short circuit to ground, short circuit to power,

open circuit, high resistance, or short circuit between

the paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0073-00

Control Module

Communication Bus

"A" Off - No sub type

information

Control module

communication Bus "A"

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module high speed CAN bus for

short circuit to ground, short circuit to power, open

circuit, high resistance, or short circuit between the

paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Loss of CAN

communication with

central junction box

Refer to the electrical circuit diagrams and check the

power and ground connections to the central junction

box. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module U0142-00 Lost Communication

Loss of CAN

Refer to the electrical circuit diagrams and check the With Body Control Module "B" - No sub communication with power and ground connections to the auxiliary type information auxiliary junction box junction box. Clear DTC and retest Using the manufacturer approved diagnostic system, complete a CAN network integrity test. Refer to the electrical circuit diagrams and check the CAN network between the central junction box and the parking aid control module U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Loss of CAN

communication with

instrument cluster

Refer to the electrical circuit diagrams and check the

power and ground connections to the instrument

cluster. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module

Page 220 of 3039

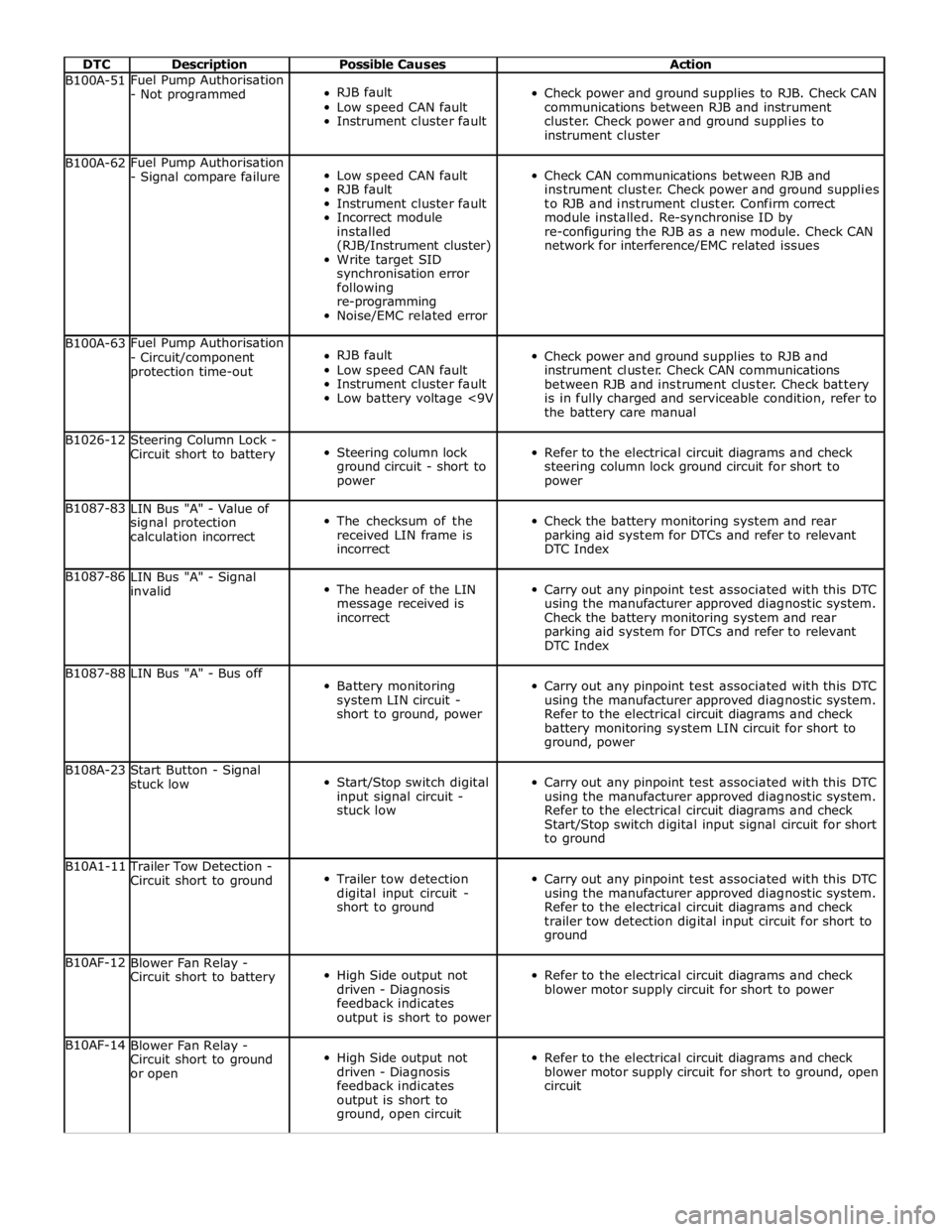

DTC Description Possible Causes Action B100A-51 Fuel Pump Authorisation

- Not programmed

RJB fault

Low speed CAN fault

Instrument cluster fault

Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument

cluster. Check power and ground supplies to

instrument cluster B100A-62 Fuel Pump Authorisation

- Signal compare failure

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed

(RJB/Instrument cluster)

Write target SID

synchronisation error

following

re-programming

Noise/EMC related error

Check CAN communications between RJB and

instrument cluster. Check power and ground supplies

to RJB and instrument cluster. Confirm correct

module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN

network for interference/EMC related issues B100A-63 Fuel Pump Authorisation

- Circuit/component

protection time-out

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V

Check power and ground supplies to RJB and

instrument cluster. Check CAN communications

between RJB and instrument cluster. Check battery

is in fully charged and serviceable condition, refer to

the battery care manual B1026-12

Steering Column Lock -

Circuit short to battery

Steering column lock

ground circuit - short to

power

Refer to the electrical circuit diagrams and check

steering column lock ground circuit for short to

power B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

The checksum of the

received LIN frame is

incorrect

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-86

LIN Bus "A" - Signal

invalid

The header of the LIN

message received is

incorrect

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-88 LIN Bus "A" - Bus off

Battery monitoring

system LIN circuit -

short to ground, power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

battery monitoring system LIN circuit for short to

ground, power B108A-23

Start Button - Signal

stuck low

Start/Stop switch digital

input signal circuit -

stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

Start/Stop switch digital input signal circuit for short

to ground B10A1-11 Trailer Tow Detection -

Circuit short to ground

Trailer tow detection

digital input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

trailer tow detection digital input circuit for short to

ground B10AF-12

Blower Fan Relay -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to power B10AF-14

Blower Fan Relay -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to ground, open

circuit

Page 225 of 3039

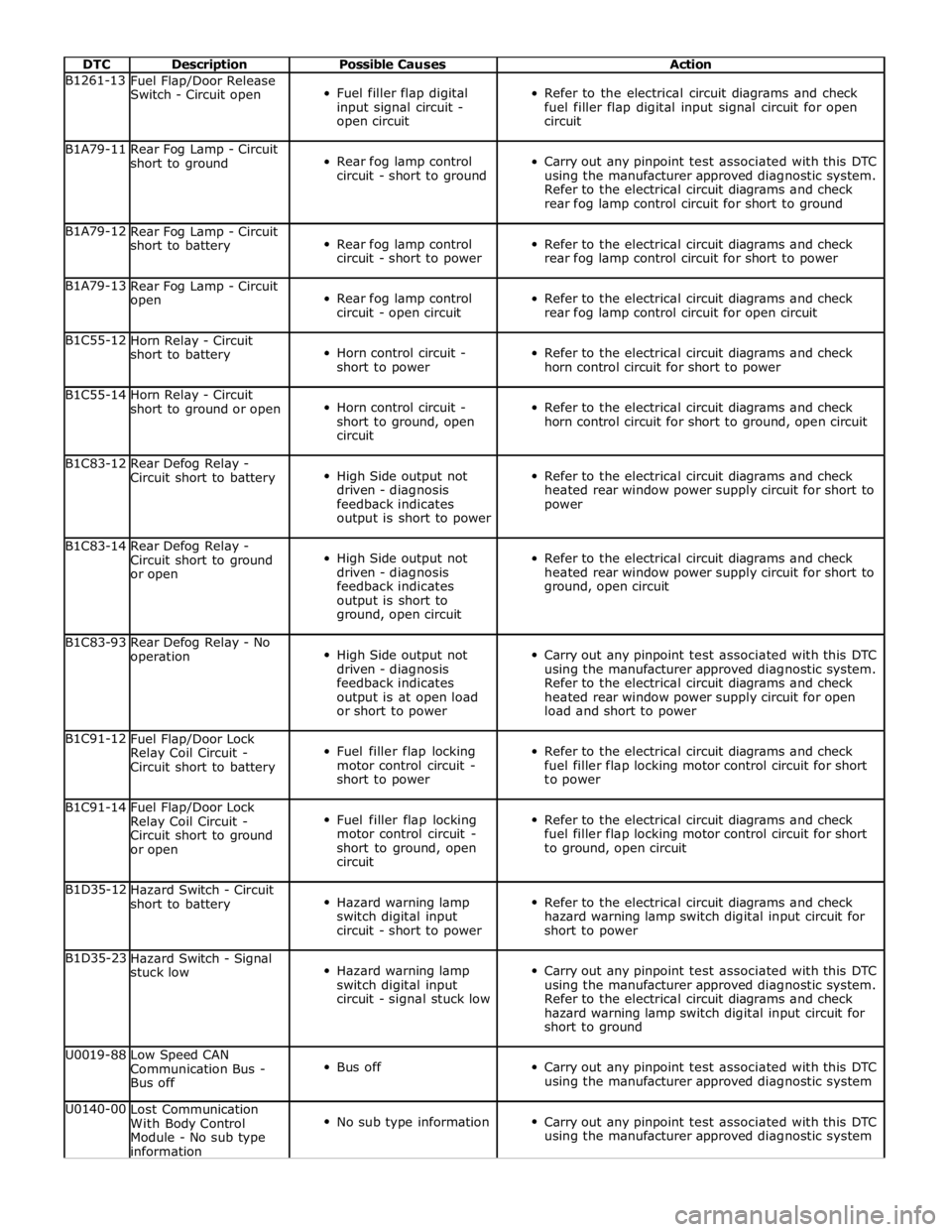

DTC Description Possible Causes Action B1261-13

Fuel Flap/Door Release

Switch - Circuit open

Fuel filler flap digital

input signal circuit -

open circuit

Refer to the electrical circuit diagrams and check

fuel filler flap digital input signal circuit for open

circuit B1A79-11

Rear Fog Lamp - Circuit

short to ground

Rear fog lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for short to ground B1A79-12

Rear Fog Lamp - Circuit

short to battery

Rear fog lamp control

circuit - short to power

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for short to power B1A79-13

Rear Fog Lamp - Circuit

open

Rear fog lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for open circuit B1C55-12

Horn Relay - Circuit

short to battery

Horn control circuit -

short to power

Refer to the electrical circuit diagrams and check

horn control circuit for short to power B1C55-14

Horn Relay - Circuit

short to ground or open

Horn control circuit -

short to ground, open

circuit

Refer to the electrical circuit diagrams and check

horn control circuit for short to ground, open circuit B1C83-12

Rear Defog Relay -

Circuit short to battery

High Side output not

driven - diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for short to

power B1C83-14

Rear Defog Relay -

Circuit short to ground

or open

High Side output not

driven - diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for short to

ground, open circuit B1C83-93

Rear Defog Relay - No

operation

High Side output not

driven - diagnosis

feedback indicates

output is at open load

or short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for open

load and short to power B1C91-12

Fuel Flap/Door Lock

Relay Coil Circuit -

Circuit short to battery

Fuel filler flap locking

motor control circuit -

short to power

Refer to the electrical circuit diagrams and check

fuel filler flap locking motor control circuit for short

to power B1C91-14

Fuel Flap/Door Lock

Relay Coil Circuit -

Circuit short to ground

or open

Fuel filler flap locking

motor control circuit -

short to ground, open

circuit

Refer to the electrical circuit diagrams and check

fuel filler flap locking motor control circuit for short

to ground, open circuit B1D35-12

Hazard Switch - Circuit

short to battery

Hazard warning lamp

switch digital input

circuit - short to power

Refer to the electrical circuit diagrams and check

hazard warning lamp switch digital input circuit for

short to power B1D35-23

Hazard Switch - Signal

stuck low

Hazard warning lamp

switch digital input

circuit - signal stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

hazard warning lamp switch digital input circuit for

short to ground U0019-88

Low Speed CAN

Communication Bus -

Bus off

Bus off

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system U0140-00

Lost Communication

With Body Control

Module - No sub type

information

No sub type information

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system

Page 229 of 3039

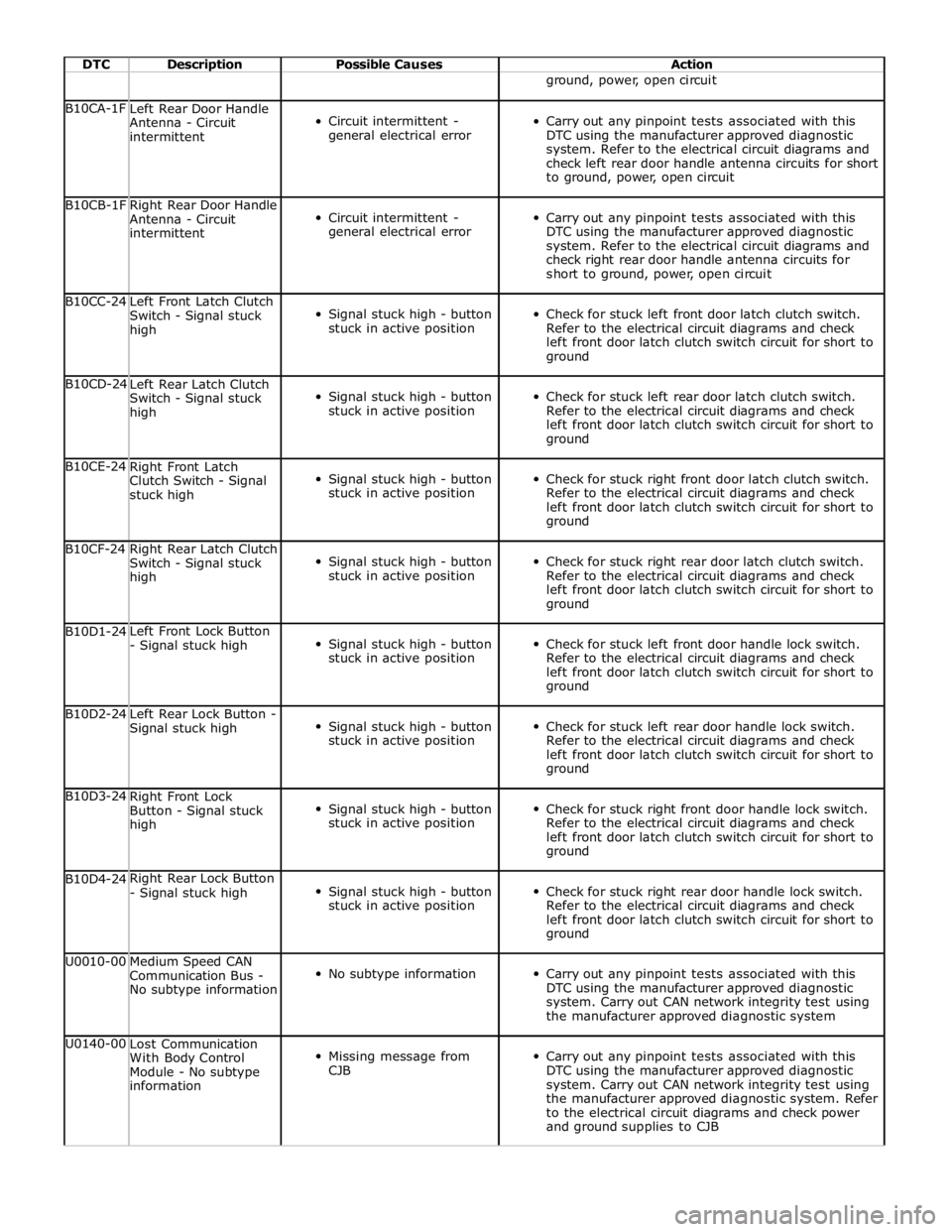

DTC Description Possible Causes Action ground, power, open circuit B10CA-1F

Left Rear Door Handle

Antenna - Circuit

intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check left rear door handle antenna circuits for short

to ground, power, open circuit B10CB-1F

Right Rear Door Handle

Antenna - Circuit

intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check right rear door handle antenna circuits for

short to ground, power, open circuit B10CC-24

Left Front Latch Clutch

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Check for stuck left front door latch clutch switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground B10CD-24

Left Rear Latch Clutch

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Check for stuck left rear door latch clutch switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground B10CE-24

Right Front Latch

Clutch Switch - Signal

stuck high

Signal stuck high - button

stuck in active position

Check for stuck right front door latch clutch switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground B10CF-24

Right Rear Latch Clutch

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Check for stuck right rear door latch clutch switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground B10D1-24 Left Front Lock Button

- Signal stuck high

Signal stuck high - button

stuck in active position

Check for stuck left front door handle lock switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground B10D2-24

Left Rear Lock Button -

Signal stuck high

Signal stuck high - button

stuck in active position

Check for stuck left rear door handle lock switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground B10D3-24

Right Front Lock

Button - Signal stuck

high

Signal stuck high - button

stuck in active position

Check for stuck right front door handle lock switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground B10D4-24 Right Rear Lock Button

- Signal stuck high

Signal stuck high - button

stuck in active position

Check for stuck right rear door handle lock switch.

Refer to the electrical circuit diagrams and check

left front door latch clutch switch circuit for short to

ground U0010-00

Medium Speed CAN

Communication Bus -

No subtype information

No subtype information

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test using

the manufacturer approved diagnostic system U0140-00

Lost Communication

With Body Control

Module - No subtype

information

Missing message from

CJB

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test using

the manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check power

and ground supplies to CJB

Page 239 of 3039

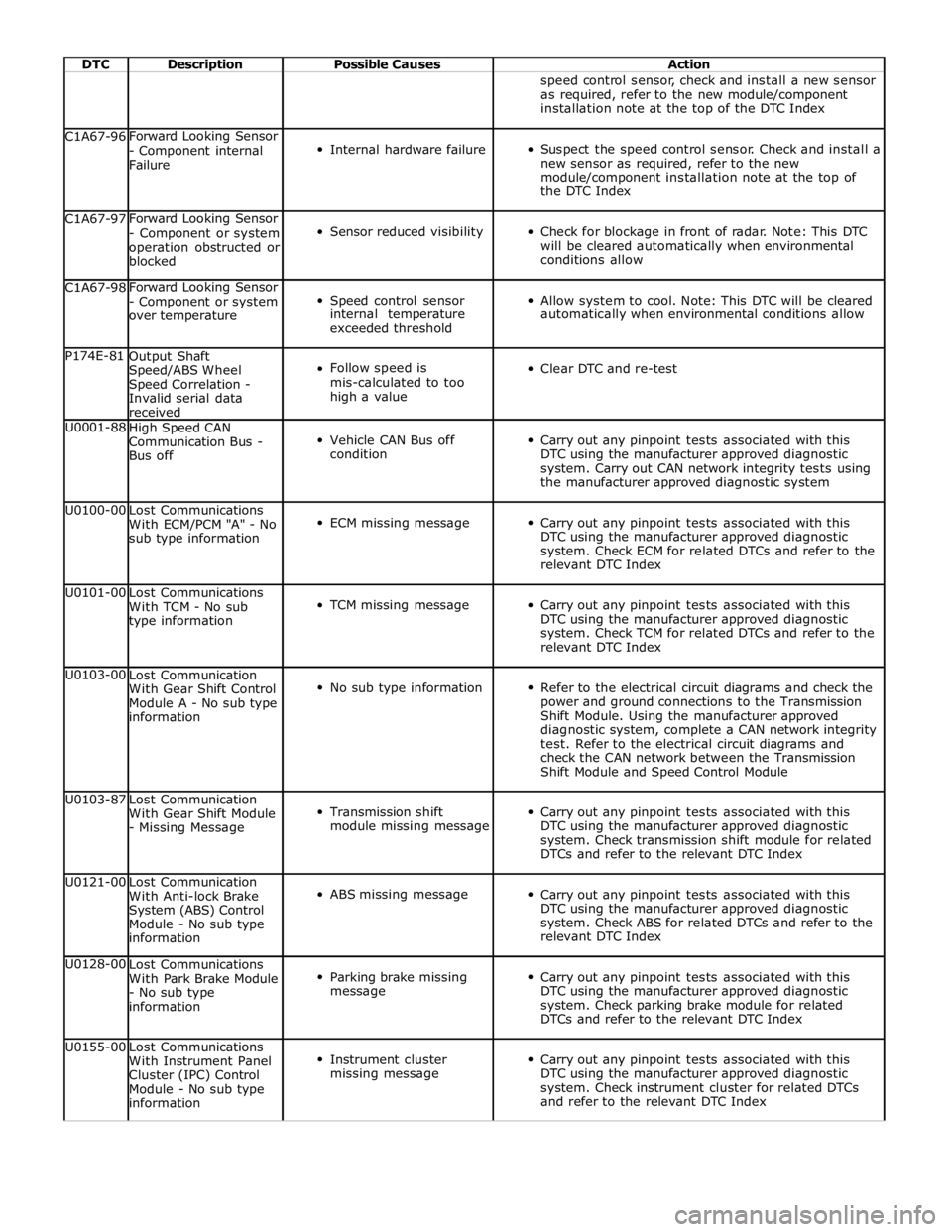

DTC Description Possible Causes Action speed control sensor, check and install a new sensor

as required, refer to the new module/component

installation note at the top of the DTC Index C1A67-96 Forward Looking Sensor

- Component internal

Failure

Internal hardware failure

Suspect the speed control sensor. Check and install a

new sensor as required, refer to the new

module/component installation note at the top of

the DTC Index C1A67-97 Forward Looking Sensor

- Component or system

operation obstructed or

blocked

Sensor reduced visibility

Check for blockage in front of radar. Note: This DTC

will be cleared automatically when environmental

conditions allow C1A67-98 Forward Looking Sensor

- Component or system

over temperature

Speed control sensor

internal temperature

exceeded threshold

Allow system to cool. Note: This DTC will be cleared

automatically when environmental conditions allow P174E-81

Output Shaft

Speed/ABS Wheel

Speed Correlation -

Invalid serial data

received

Follow speed is

mis-calculated to too

high a value

Clear DTC and re-test U0001-88

High Speed CAN

Communication Bus -

Bus off

Vehicle CAN Bus off

condition

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity tests using

the manufacturer approved diagnostic system U0100-00

Lost Communications

With ECM/PCM "A" - No

sub type information

ECM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for related DTCs and refer to the

relevant DTC Index U0101-00

Lost Communications

With TCM - No sub

type information

TCM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for related DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Control

Module A - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check the

power and ground connections to the Transmission

Shift Module. Using the manufacturer approved

diagnostic system, complete a CAN network integrity

test. Refer to the electrical circuit diagrams and

check the CAN network between the Transmission

Shift Module and Speed Control Module U0103-87

Lost Communication

With Gear Shift Module

- Missing Message

Transmission shift

module missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for related

DTCs and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-lock Brake

System (ABS) Control

Module - No sub type

information

ABS missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS for related DTCs and refer to the

relevant DTC Index U0128-00

Lost Communications

With Park Brake Module

- No sub type

information

Parking brake missing

message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check parking brake module for related

DTCs and refer to the relevant DTC Index U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Instrument cluster

missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check instrument cluster for related DTCs

and refer to the relevant DTC Index

Page 240 of 3039

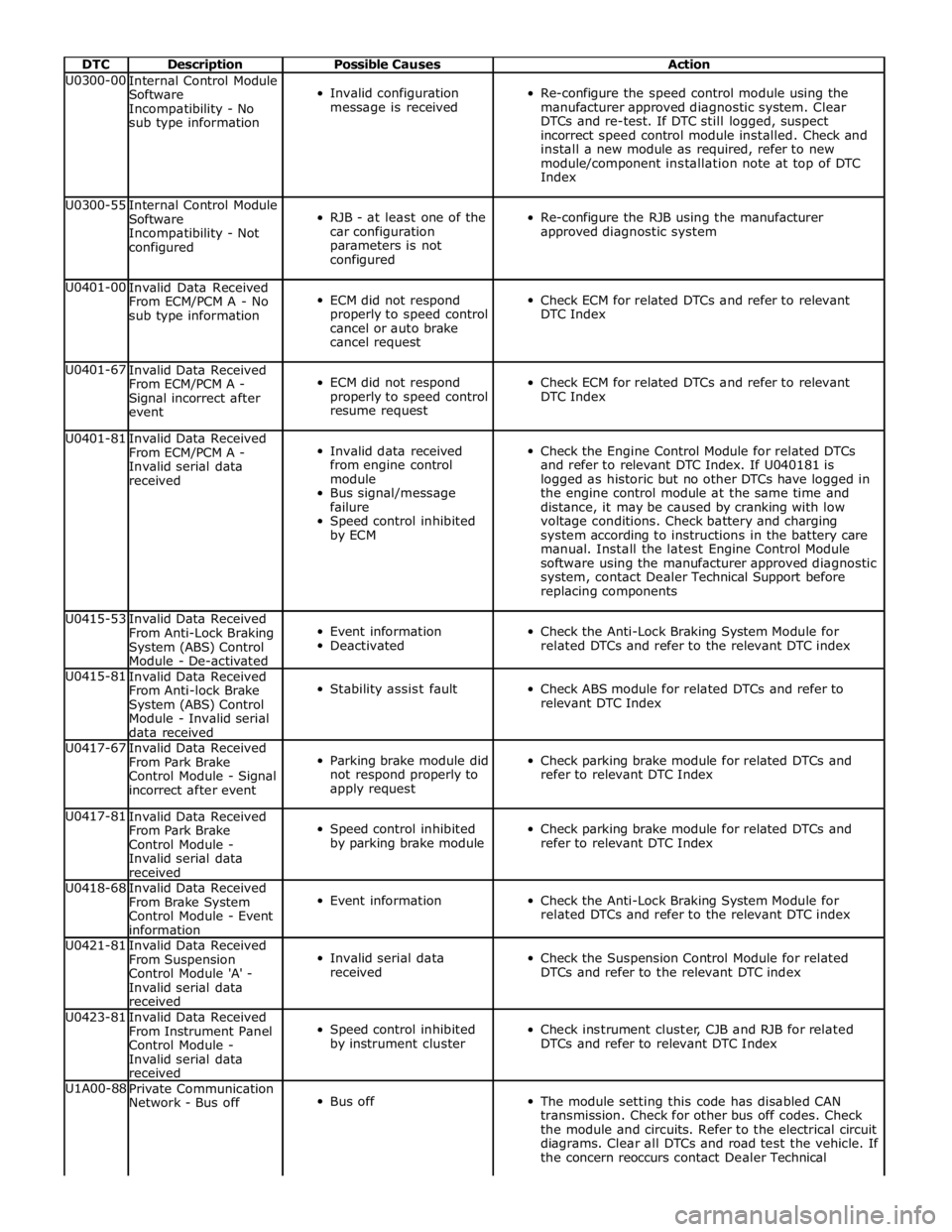

DTC Description Possible Causes Action U0300-00

Internal Control Module

Software

Incompatibility - No

sub type information

Invalid configuration

message is received

Re-configure the speed control module using the

manufacturer approved diagnostic system. Clear

DTCs and re-test. If DTC still logged, suspect

incorrect speed control module installed. Check and

install a new module as required, refer to new

module/component installation note at top of DTC

Index U0300-55

Internal Control Module

Software

Incompatibility - Not

configured

RJB - at least one of the

car configuration

parameters is not

configured

Re-configure the RJB using the manufacturer

approved diagnostic system U0401-00

Invalid Data Received

From ECM/PCM A - No

sub type information

ECM did not respond

properly to speed control

cancel or auto brake

cancel request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-67

Invalid Data Received

From ECM/PCM A -

Signal incorrect after

event

ECM did not respond

properly to speed control

resume request

Check ECM for related DTCs and refer to relevant

DTC Index U0401-81

Invalid Data Received

From ECM/PCM A -

Invalid serial data

received

Invalid data received

from engine control

module

Bus signal/message

failure

Speed control inhibited

by ECM

Check the Engine Control Module for related DTCs

and refer to relevant DTC Index. If U040181 is

logged as historic but no other DTCs have logged in

the engine control module at the same time and

distance, it may be caused by cranking with low

voltage conditions. Check battery and charging

system according to instructions in the battery care

manual. Install the latest Engine Control Module

software using the manufacturer approved diagnostic

system, contact Dealer Technical Support before

replacing components U0415-53

Invalid Data Received

From Anti-Lock Braking

System (ABS) Control

Module - De-activated

Event information

Deactivated

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0415-81

Invalid Data Received

From Anti-lock Brake

System (ABS) Control

Module - Invalid serial

data received

Stability assist fault

Check ABS module for related DTCs and refer to

relevant DTC Index U0417-67

Invalid Data Received

From Park Brake

Control Module - Signal

incorrect after event

Parking brake module did

not respond properly to

apply request

Check parking brake module for related DTCs and

refer to relevant DTC Index U0417-81

Invalid Data Received

From Park Brake

Control Module -

Invalid serial data

received

Speed control inhibited

by parking brake module

Check parking brake module for related DTCs and

refer to relevant DTC Index U0418-68

Invalid Data Received

From Brake System

Control Module - Event

information

Event information

Check the Anti-Lock Braking System Module for

related DTCs and refer to the relevant DTC index U0421-81

Invalid Data Received

From Suspension

Control Module 'A' -

Invalid serial data

received

Invalid serial data

received

Check the Suspension Control Module for related

DTCs and refer to the relevant DTC index U0423-81

Invalid Data Received

From Instrument Panel

Control Module -

Invalid serial data

received

Speed control inhibited

by instrument cluster

Check instrument cluster, CJB and RJB for related

DTCs and refer to relevant DTC Index U1A00-88

Private Communication

Network - Bus off

Bus off

The module setting this code has disabled CAN

transmission. Check for other bus off codes. Check

the module and circuits. Refer to the electrical circuit

diagrams. Clear all DTCs and road test the vehicle. If

the concern reoccurs contact Dealer Technical

Page 243 of 3039

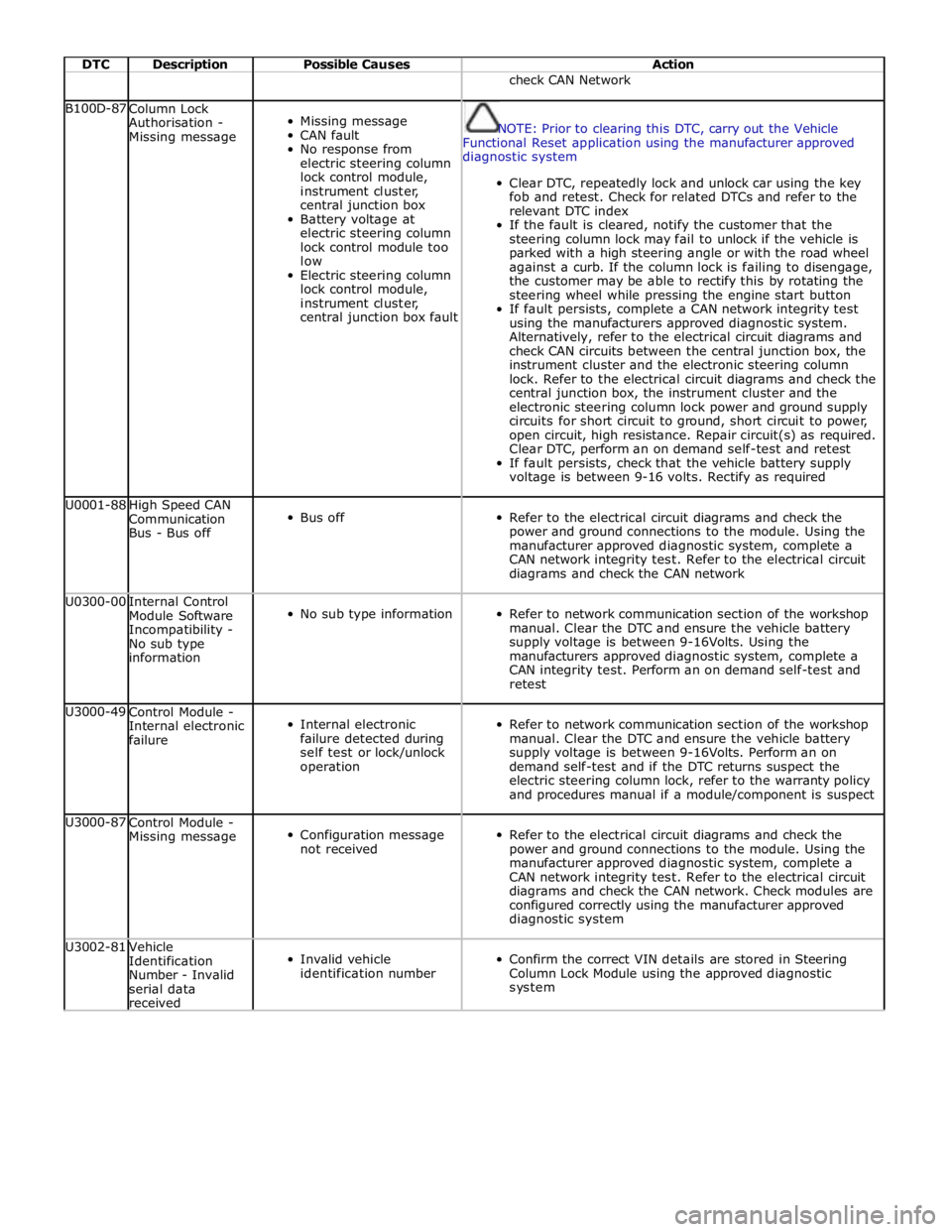

DTC Description Possible Causes Action check CAN Network B100D-87

Column Lock

Authorisation -

Missing message

Missing message

CAN fault

No response from

electric steering column

lock control module,

instrument cluster,

central junction box

Battery voltage at

electric steering column

lock control module too

low

Electric steering column

lock control module,

instrument cluster,

central junction box fault

NOTE: Prior to clearing this DTC, carry out the Vehicle

Functional Reset application using the manufacturer approved

diagnostic system

Clear DTC, repeatedly lock and unlock car using the key

fob and retest. Check for related DTCs and refer to the

relevant DTC index

If the fault is cleared, notify the customer that the

steering column lock may fail to unlock if the vehicle is

parked with a high steering angle or with the road wheel

against a curb. If the column lock is failing to disengage,

the customer may be able to rectify this by rotating the

steering wheel while pressing the engine start button

If fault persists, complete a CAN network integrity test

using the manufacturers approved diagnostic system.

Alternatively, refer to the electrical circuit diagrams and

check CAN circuits between the central junction box, the

instrument cluster and the electronic steering column

lock. Refer to the electrical circuit diagrams and check the

central junction box, the instrument cluster and the

electronic steering column lock power and ground supply

circuits for short circuit to ground, short circuit to power,

open circuit, high resistance. Repair circuit(s) as required.

Clear DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required U0001-88

High Speed CAN

Communication

Bus - Bus off

Bus off

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network U0300-00

Internal Control

Module Software

Incompatibility -

No sub type

information

No sub type information

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Using the

manufacturers approved diagnostic system, complete a

CAN integrity test. Perform an on demand self-test and

retest U3000-49

Control Module -

Internal electronic

failure

Internal electronic

failure detected during

self test or lock/unlock

operation

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Perform an on

demand self-test and if the DTC returns suspect the

electric steering column lock, refer to the warranty policy

and procedures manual if a module/component is suspect U3000-87

Control Module -

Missing message

Configuration message

not received

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network. Check modules are

configured correctly using the manufacturer approved

diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data

received

Invalid vehicle

identification number

Confirm the correct VIN details are stored in Steering

Column Lock Module using the approved diagnostic

system