Fuse box JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1288 of 3039

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Intake Air

Distribution and Filtering - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) (EMS high current relay) 4 Tuning valve 5 ECM (engine control module)

Page 1358 of 3039

Published: 11-May-2011

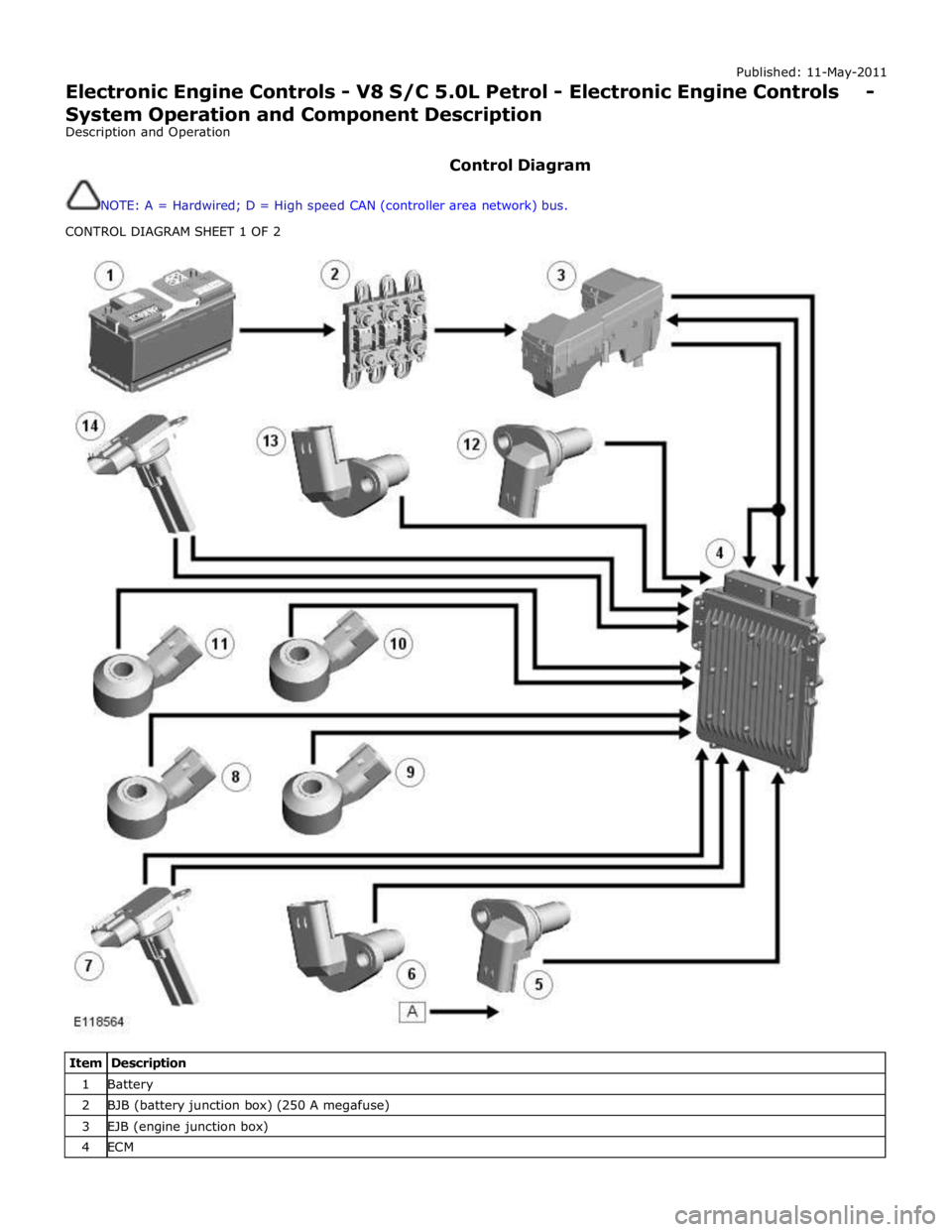

Electronic Engine Controls - V8 S/C 5.0L Petrol - Electronic Engine Controls - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus.

CONTROL DIAGRAM SHEET 1 OF 2

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 ECM

Page 1411 of 3039

Published: 11-May-2011

Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Description - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; B = K bus; D = High speed CAN (controller area network) bus; O = LIN (local interconnect

network) bus

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 CJB (central junction box)

Page 1529 of 3039

Published: 11-May-2011

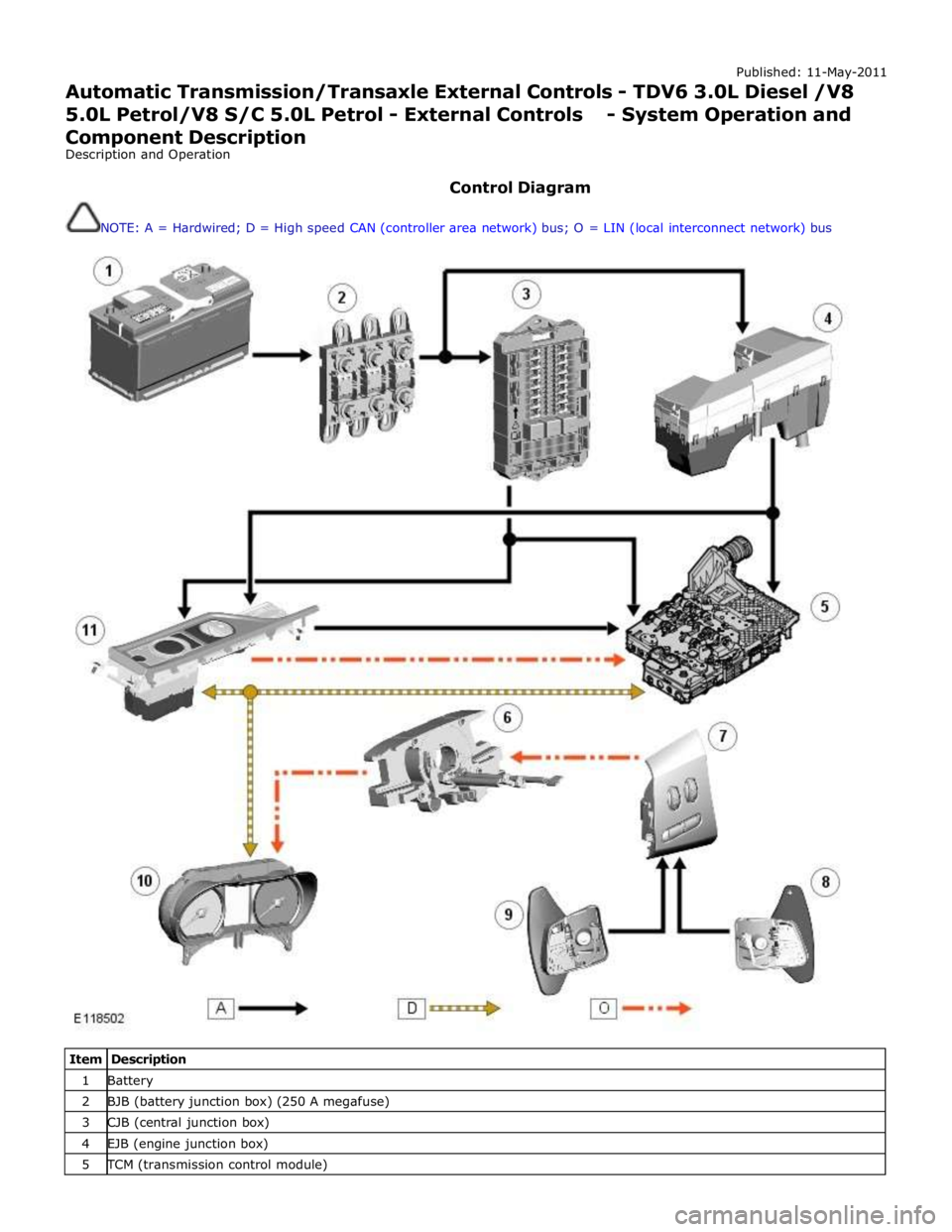

Automatic Transmission/Transaxle External Controls - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - External Controls - System Operation and

Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; O = LIN (local interconnect network) bus

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 CJB (central junction box) 4 EJB (engine junction box) 5 TCM (transmission control module)

Page 1585 of 3039

Published: 11-May-2011

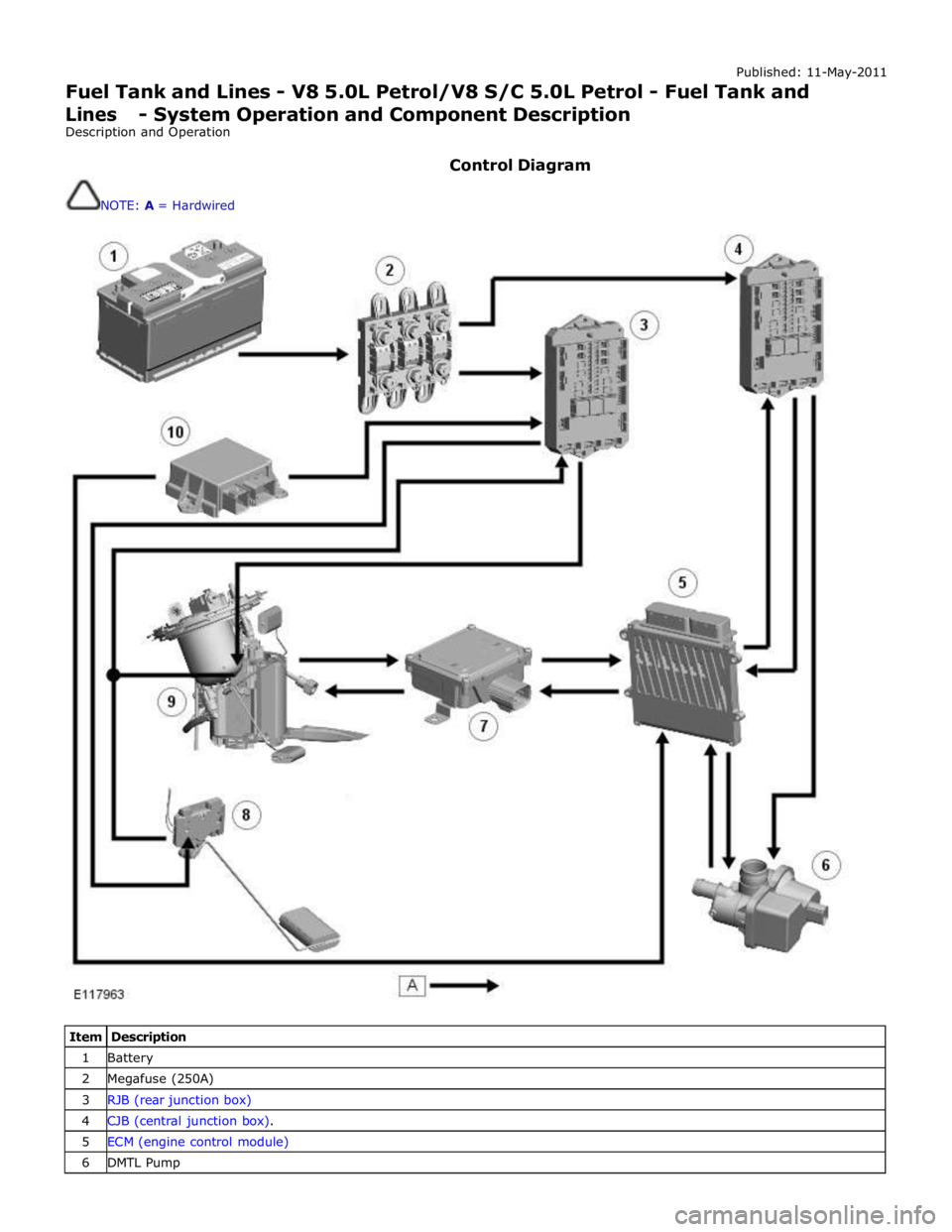

Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Fuel Tank and Lines - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 Megafuse (250A) 3 RJB (rear junction box) 4 CJB (central junction box). 5 ECM (engine control module) 6 DMTL Pump

Page 1596 of 3039

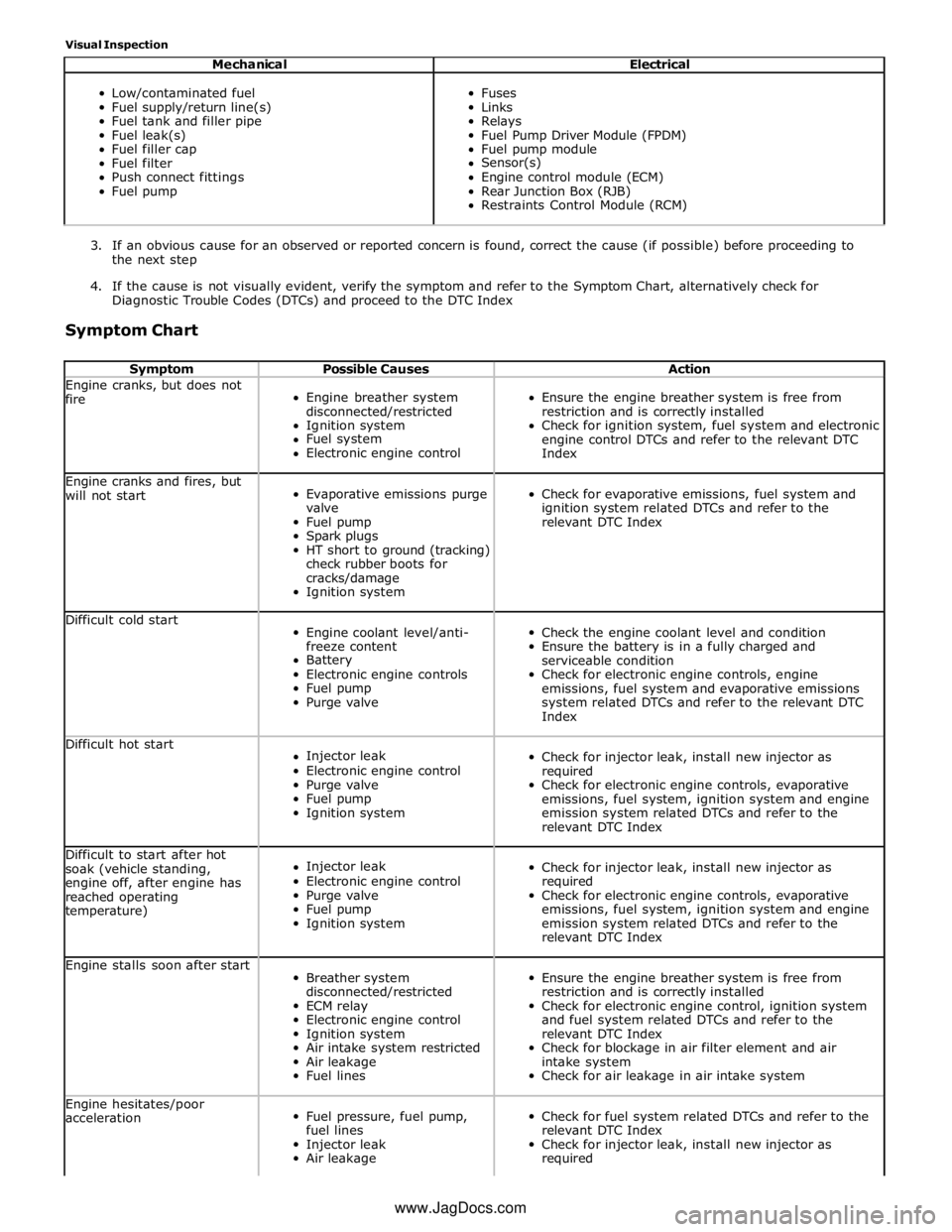

Visual Inspection

Mechanical Electrical

Low/contaminated fuel

Fuel supply/return line(s)

Fuel tank and filler pipe

Fuel leak(s)

Fuel filler cap

Fuel filter

Push connect fittings

Fuel pump

Fuses

Links

Relays

Fuel Pump Driver Module (FPDM)

Fuel pump module

Sensor(s)

Engine control module (ECM)

Rear Junction Box (RJB)

Restraints Control Module (RCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and proceed to the DTC Index

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control

Ensure the engine breather system is free from

restriction and is correctly installed

Check for ignition system, fuel system and electronic

engine control DTCs and refer to the relevant DTC

Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system

Check for evaporative emissions, fuel system and

ignition system related DTCs and refer to the

relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Fuel pump

Purge valve

Check the engine coolant level and condition

Ensure the battery is in a fully charged and

serviceable condition

Check for electronic engine controls, engine

emissions, fuel system and evaporative emissions

system related DTCs and refer to the relevant DTC

Index Difficult hot start

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Difficult to start after hot

soak (vehicle standing,

engine off, after engine has

reached operating

temperature)

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Engine stalls soon after start

Breather system

disconnected/restricted

ECM relay

Electronic engine control

Ignition system

Air intake system restricted

Air leakage

Fuel lines

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine control, ignition system

and fuel system related DTCs and refer to the

relevant DTC Index

Check for blockage in air filter element and air

intake system

Check for air leakage in air intake system Engine hesitates/poor

acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Check for fuel system related DTCs and refer to the

relevant DTC Index

Check for injector leak, install new injector as

required www.JagDocs.com

Page 1791 of 3039

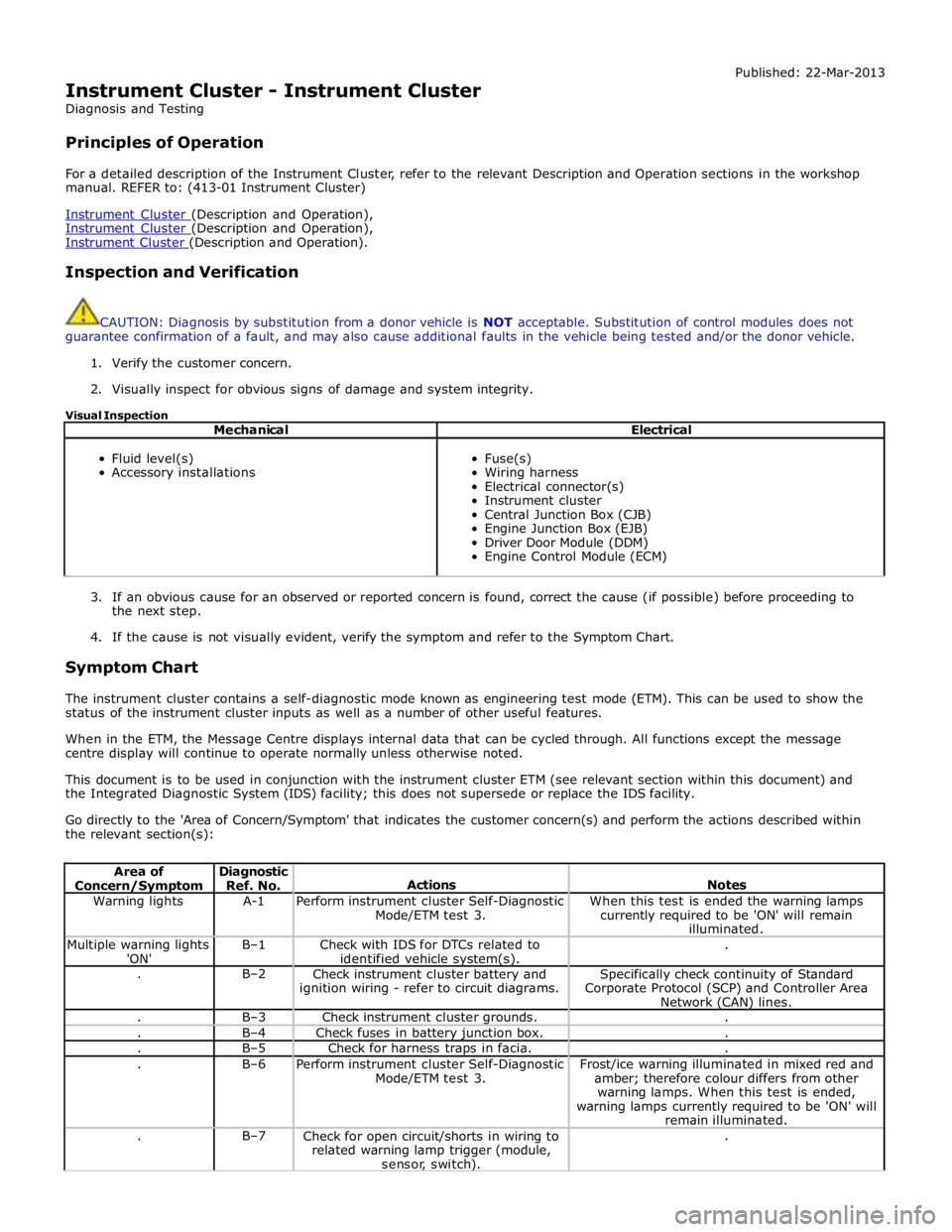

Instrument Cluster - Instrument Cluster

Diagnosis and Testing

Principles of Operation Published: 22-Mar-2013

For a detailed description of the Instrument Cluster, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (413-01 Instrument Cluster)

Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Fluid level(s)

Accessory installations

Fuse(s)

Wiring harness

Electrical connector(s)

Instrument cluster

Central Junction Box (CJB)

Engine Junction Box (EJB)

Driver Door Module (DDM)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

The instrument cluster contains a self-diagnostic mode known as engineering test mode (ETM). This can be used to show the

status of the instrument cluster inputs as well as a number of other useful features.

When in the ETM, the Message Centre displays internal data that can be cycled through. All functions except the message

centre display will continue to operate normally unless otherwise noted.

This document is to be used in conjunction with the instrument cluster ETM (see relevant section within this document) and

the Integrated Diagnostic System (IDS) facility; this does not supersede or replace the IDS facility.

Go directly to the 'Area of Concern/Symptom' that indicates the customer concern(s) and perform the actions described within

the relevant section(s):

Area of Concern/Symptom Diagnostic

Ref. No.

Actions

Notes Warning lights A-1

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. When this test is ended the warning lamps

currently required to be 'ON' will remain

illuminated. Multiple warning lights

'ON' B–1

Check with IDS for DTCs related to

identified vehicle system(s). . . B–2

Check instrument cluster battery and

ignition wiring - refer to circuit diagrams. Specifically check continuity of Standard

Corporate Protocol (SCP) and Controller Area

Network (CAN) lines. . B–3 Check instrument cluster grounds. . . B–4 Check fuses in battery junction box. . . B–5 Check for harness traps in facia. . . B–6

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. Frost/ice warning illuminated in mixed red and

amber; therefore colour differs from other

warning lamps. When this test is ended,

warning lamps currently required to be 'ON' will

remain illuminated. . B–7

Check for open circuit/shorts in wiring to

related warning lamp trigger (module,

sensor, switch). .

Page 1843 of 3039

1 Battery 2 Megafuses 3 RJB (rear junction box) 4 Entertainment system control module 5 Integrated audio module 6 Audio amplifier 7 Audio system speakers

Page 1856 of 3039

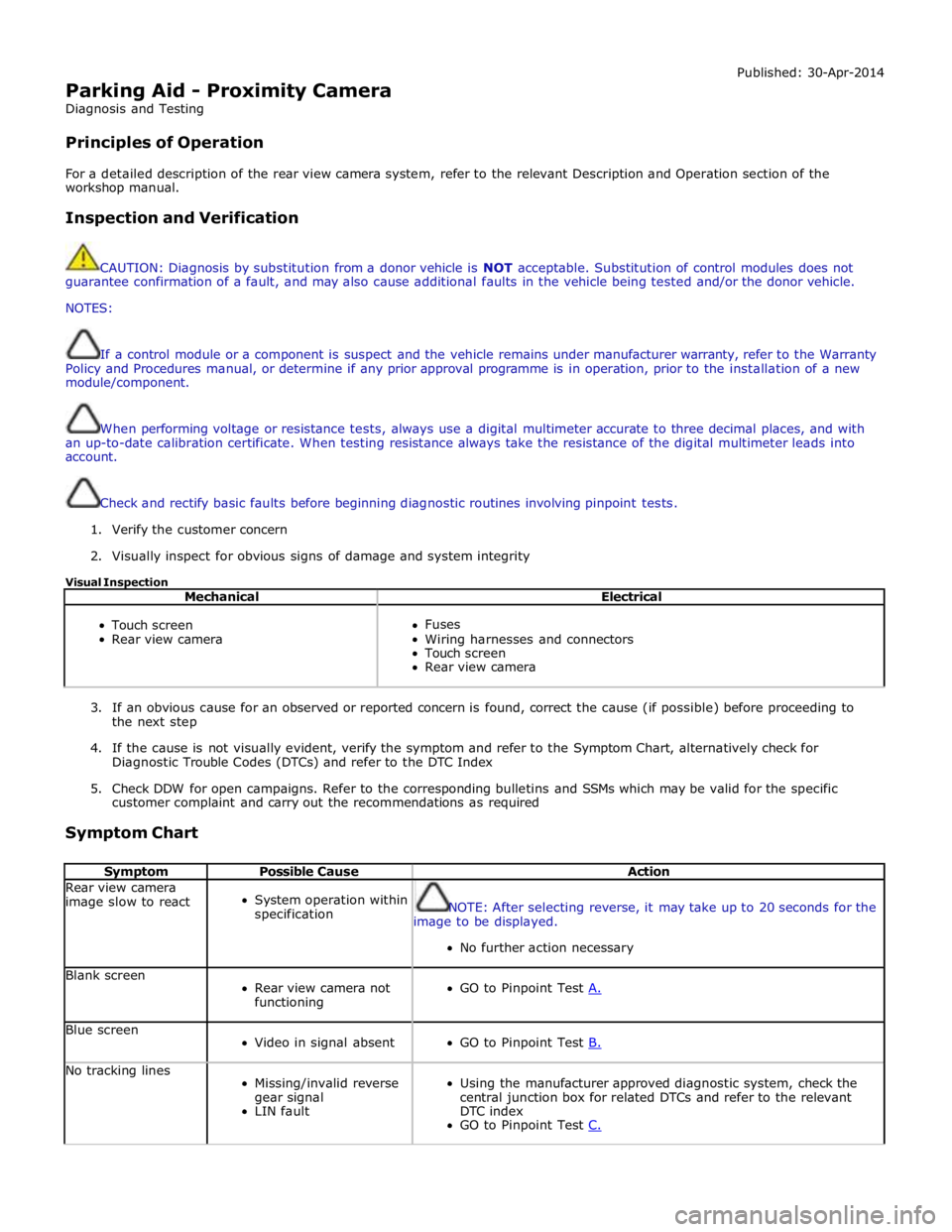

Parking Aid - Proximity Camera

Diagnosis and Testing

Principles of Operation Published: 30-Apr-2014

For a detailed description of the rear view camera system, refer to the relevant Description and Operation section of the

workshop manual.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Touch screen

Rear view camera

Fuses

Wiring harnesses and connectors

Touch screen

Rear view camera

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Possible Cause Action Rear view camera

image slow to react

System operation within

specification

NOTE: After selecting reverse, it may take up to 20 seconds for the

image to be displayed.

No further action necessary Blank screen

Rear view camera not

functioning

GO to Pinpoint Test A. Blue screen

Video in signal absent

GO to Pinpoint Test B. No tracking lines

Missing/invalid reverse

gear signal

LIN fault

Using the manufacturer approved diagnostic system, check the

central junction box for related DTCs and refer to the relevant

DTC index

GO to Pinpoint Test C.

Page 1871 of 3039

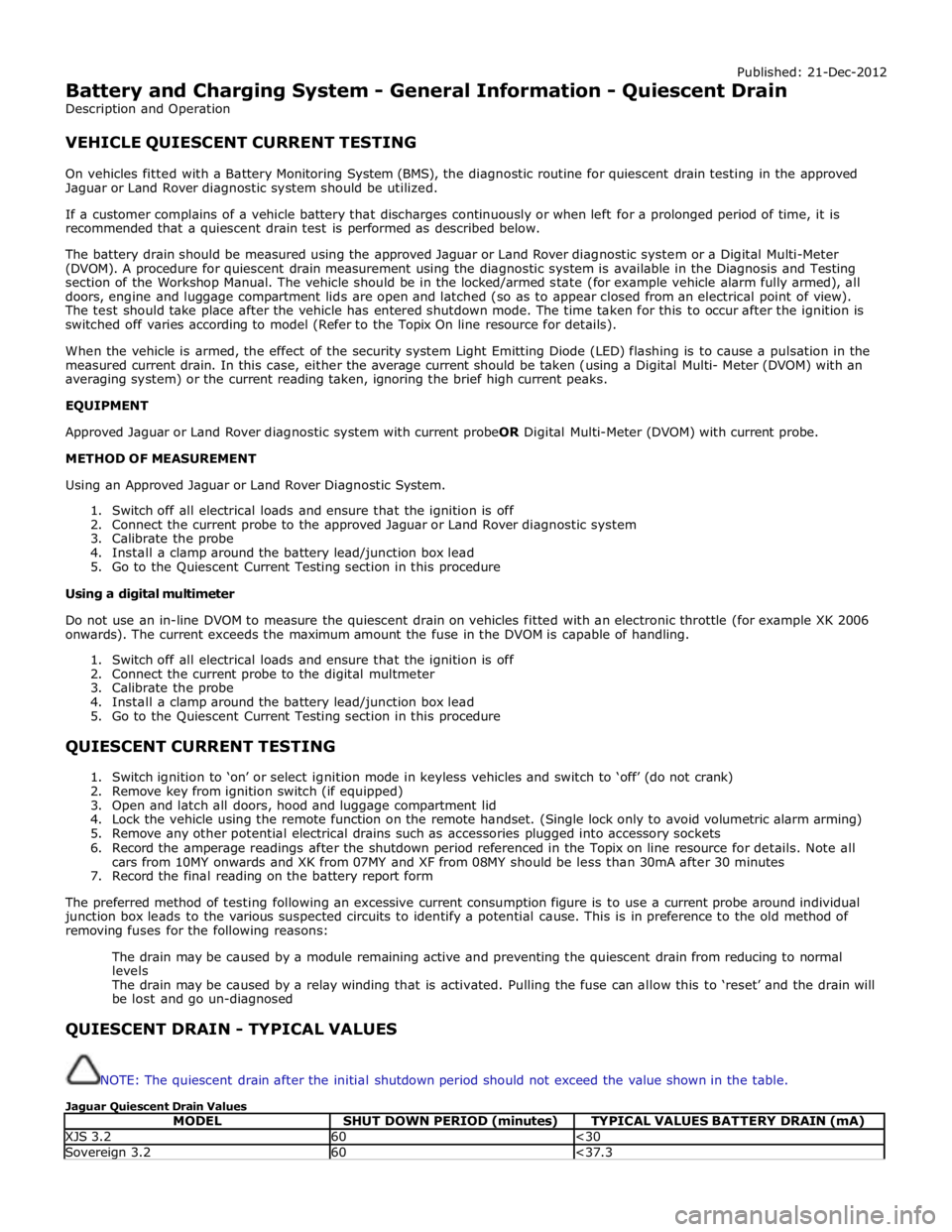

Published: 21-Dec-2012

Battery and Charging System - General Information - Quiescent Drain

Description and Operation

VEHICLE QUIESCENT CURRENT TESTING

On vehicles fitted with a Battery Monitoring System (BMS), the diagnostic routine for quiescent drain testing in the approved

Jaguar or Land Rover diagnostic system should be utilized.

If a customer complains of a vehicle battery that discharges continuously or when left for a prolonged period of time, it is

recommended that a quiescent drain test is performed as described below.

The battery drain should be measured using the approved Jaguar or Land Rover diagnostic system or a Digital Multi-Meter

(DVOM). A procedure for quiescent drain measurement using the diagnostic system is available in the Diagnosis and Testing

section of the Workshop Manual. The vehicle should be in the locked/armed state (for example vehicle alarm fully armed), all

doors, engine and luggage compartment lids are open and latched (so as to appear closed from an electrical point of view).

The test should take place after the vehicle has entered shutdown mode. The time taken for this to occur after the ignition is

switched off varies according to model (Refer to the Topix On line resource for details).

When the vehicle is armed, the effect of the security system Light Emitting Diode (LED) flashing is to cause a pulsation in the

measured current drain. In this case, either the average current should be taken (using a Digital Multi- Meter (DVOM) with an

averaging system) or the current reading taken, ignoring the brief high current peaks.

EQUIPMENT

Approved Jaguar or Land Rover diagnostic system with current probeOR Digital Multi-Meter (DVOM) with current probe.

METHOD OF MEASUREMENT

Using an Approved Jaguar or Land Rover Diagnostic System.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the approved Jaguar or Land Rover diagnostic system

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

Using a digital multimeter

Do not use an in-line DVOM to measure the quiescent drain on vehicles fitted with an electronic throttle (for example XK 2006

onwards). The current exceeds the maximum amount the fuse in the DVOM is capable of handling.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the digital multmeter

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

QUIESCENT CURRENT TESTING

1. Switch ignition to ‘on’ or select ignition mode in keyless vehicles and switch to ‘off’ (do not crank)

2. Remove key from ignition switch (if equipped)

3. Open and latch all doors, hood and luggage compartment lid

4. Lock the vehicle using the remote function on the remote handset. (Single lock only to avoid volumetric alarm arming)

5. Remove any other potential electrical drains such as accessories plugged into accessory sockets

6. Record the amperage readings after the shutdown period referenced in the Topix on line resource for details. Note all

cars from 10MY onwards and XK from 07MY and XF from 08MY should be less than 30mA after 30 minutes

7. Record the final reading on the battery report form

The preferred method of testing following an excessive current consumption figure is to use a current probe around individual

junction box leads to the various suspected circuits to identify a potential cause. This is in preference to the old method of

removing fuses for the following reasons:

The drain may be caused by a module remaining active and preventing the quiescent drain from reducing to normal

levels

The drain may be caused by a relay winding that is activated. Pulling the fuse can allow this to ‘reset’ and the drain will

be lost and go un-diagnosed

QUIESCENT DRAIN - TYPICAL VALUES

NOTE: The quiescent drain after the initial shutdown period should not exceed the value shown in the table.

Jaguar Quiescent Drain Values

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJS 3.2 60 <30 Sovereign 3.2 60 <37.3