engine light JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1317 of 3039

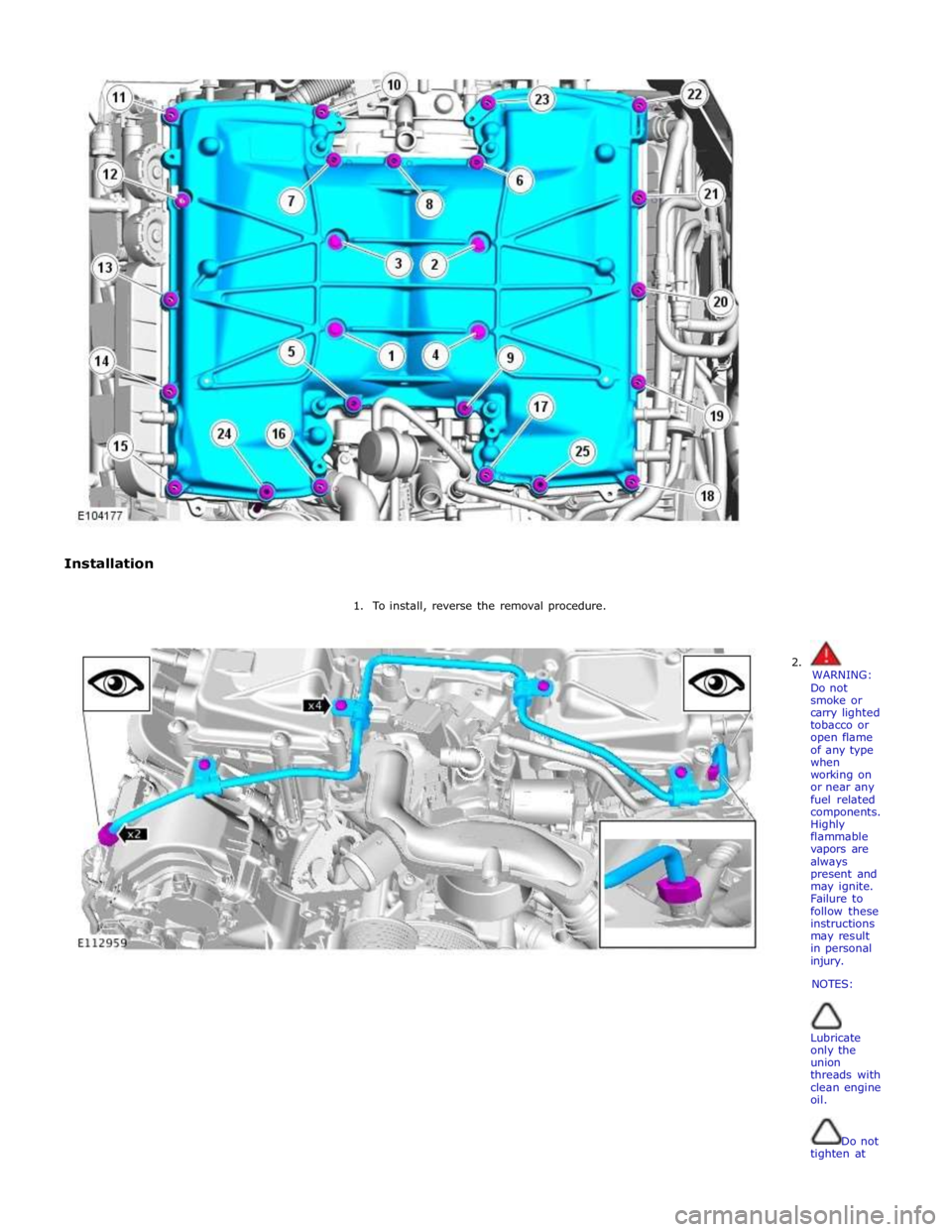

Installation

1. To install, reverse the removal procedure.

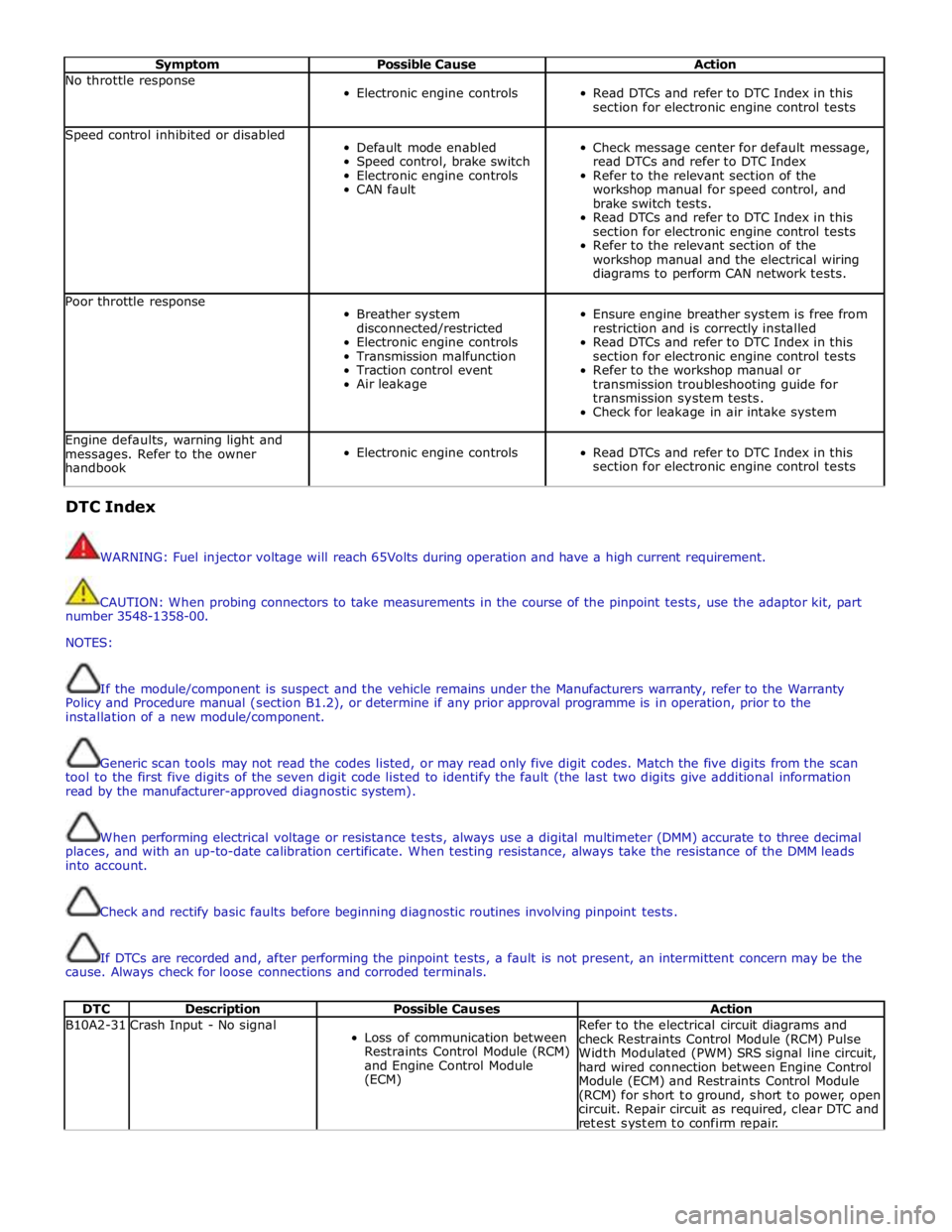

2.

WARNING:

Do not

smoke or

carry lighted

tobacco or

open flame

of any type

when

working on

or near any

fuel related

components.

Highly

flammable

vapors are

always

present and

may ignite.

Failure to

follow these

instructions

may result

in personal

injury.

NOTES:

Lubricate

only the

union

threads with

clean engine

oil.

Do not

tighten at

Page 1372 of 3039

Symptom Possible Cause Action No throttle response

Electronic engine controls

Read DTCs and refer to DTC Index in this

section for electronic engine control tests Speed control inhibited or disabled

Default mode enabled

Speed control, brake switch

Electronic engine controls

CAN fault

Check message center for default message,

read DTCs and refer to DTC Index

Refer to the relevant section of the

workshop manual for speed control, and

brake switch tests.

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

Refer to the relevant section of the

workshop manual and the electrical wiring

diagrams to perform CAN network tests. Poor throttle response

Breather system

disconnected/restricted

Electronic engine controls

Transmission malfunction

Traction control event

Air leakage

Ensure engine breather system is free from

restriction and is correctly installed

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

Refer to the workshop manual or

transmission troubleshooting guide for

transmission system tests.

Check for leakage in air intake system Engine defaults, warning light and

messages. Refer to the owner

handbook

Electronic engine controls

Read DTCs and refer to DTC Index in this

section for electronic engine control tests DTC Index

WARNING: Fuel injector voltage will reach 65Volts during operation and have a high current requirement.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the module/component is suspect and the vehicle remains under the Manufacturers warranty, refer to the Warranty

Policy and Procedure manual (section B1.2), or determine if any prior approval programme is in operation, prior to the

installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Causes Action B10A2-31 Crash Input - No signal

Loss of communication between

Restraints Control Module (RCM)

and Engine Control Module

(ECM) Refer to the electrical circuit diagrams and

check Restraints Control Module (RCM) Pulse

Width Modulated (PWM) SRS signal line circuit,

hard wired connection between Engine Control

Module (ECM) and Restraints Control Module

(RCM) for short to ground, short to power, open

circuit. Repair circuit as required, clear DTC and

retest system to confirm repair.

Page 1486 of 3039

22.

23.

24.

Refer to: Catalytic Converter LH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

25. Refer to: Catalytic Converter RH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

26. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

27. Check and top up the cooling system as required.

28. Set the heater controls to HOT.

29. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Start the engine and allow to idle until hot air is emited at the face

registers.

Page 1487 of 3039

30. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Raise the engine speed to 2000 RPM and maintain at 2000 RPM until the

engine cooling fan operates.

31. CAUTION: Switch off the engine and allow the coolant temperature

to go cold.

Switch the engine off and allow to cool.

32. Visually check the engine and cooling system for signs of coolant

leakage.

33. WARNINGS:

When releasing the cooling system pressure, cover the coolant

expansion tank cap with a thick cloth.

Since injury such as scalding could be caused by escaping steam or

coolant, make sure the vehicle cooling system is cool prior to carrying

out this procedure.

CAUTIONS:

Make sure the coolant level remains above the "COLD FILL RANGE"

lower level mark.

Anti-freeze concentration must be maintained at 50%.

NOTE: When the cooling system is warm, the coolant will be

approximately 10mm above the upper level mark on the expansion tank

with the cap removed.

Check and top-up the coolant if required.

34. Refer to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, General Procedures).

Page 1502 of 3039

20.

21.

22.

Refer to: Catalytic Converter LH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

23. Refer to: Catalytic Converter RH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

24. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

25. Check and top up the cooling system as required.

26. Set the heater controls to HOT.

27. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Start the engine and allow to idle until hot air is emited at the face

registers. www.JagDocs.com

Page 1503 of 3039

28. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Raise the engine speed to 2000 RPM and maintain at 2000 RPM until the

engine cooling fan operates.

29. CAUTION: Switch off the engine and allow the coolant temperature

to go cold.

Switch the engine off and allow to cool.

30. Visually check the engine and cooling system for signs of coolant

leakage.

31. WARNINGS:

When releasing the cooling system pressure, cover the coolant

expansion tank cap with a thick cloth.

Since injury such as scalding could be caused by escaping steam or

coolant, make sure the vehicle cooling system is cool prior to carrying

out this procedure.

CAUTIONS:

Make sure the coolant level remains above the "COLD FILL RANGE"

lower level mark.

Anti-freeze concentration must be maintained at 50%.

NOTE: When the cooling system is warm, the coolant will be

approximately 10mm above the upper level mark on the expansion tank

with the cap removed.

Check and top-up the coolant if required.

32. Refer to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, General Procedures).

Page 1614 of 3039

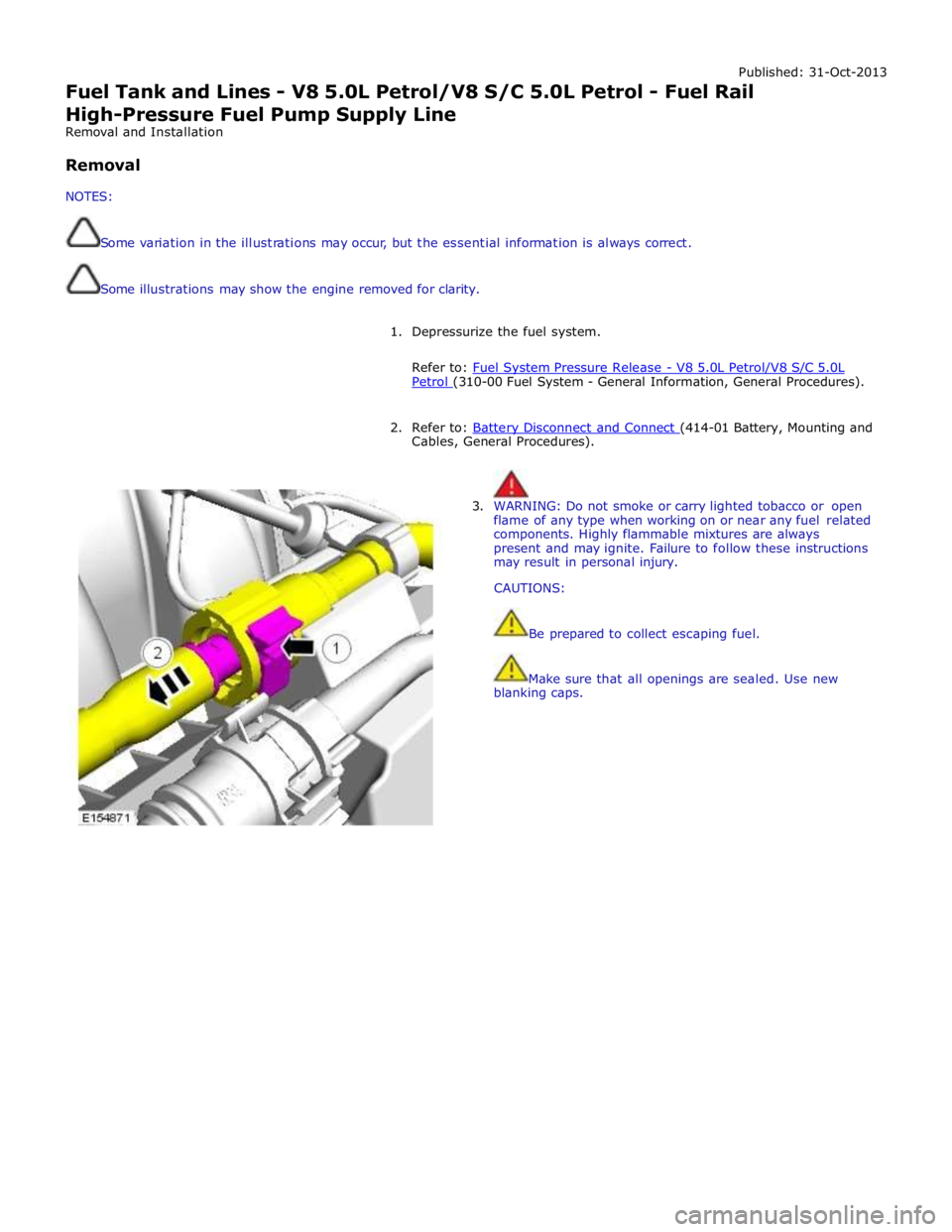

Published: 31-Oct-2013

Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Fuel Rail High-Pressure Fuel Pump Supply Line

Removal and Installation

Removal

NOTES:

Some variation in the illustrations may occur, but the essential information is always correct.

Some illustrations may show the engine removed for clarity.

1. Depressurize the fuel system.

Refer to: Fuel System Pressure Release - V8 5.0L Petrol/V8 S/C 5.0L Petrol (310-00 Fuel System - General Information, General Procedures).

2. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. WARNING: Do not smoke or carry lighted tobacco or open

flame of any type when working on or near any fuel related

components. Highly flammable mixtures are always

present and may ignite. Failure to follow these instructions

may result in personal injury.

CAUTIONS:

Be prepared to collect escaping fuel.

Make sure that all openings are sealed. Use new

blanking caps.

Page 1651 of 3039

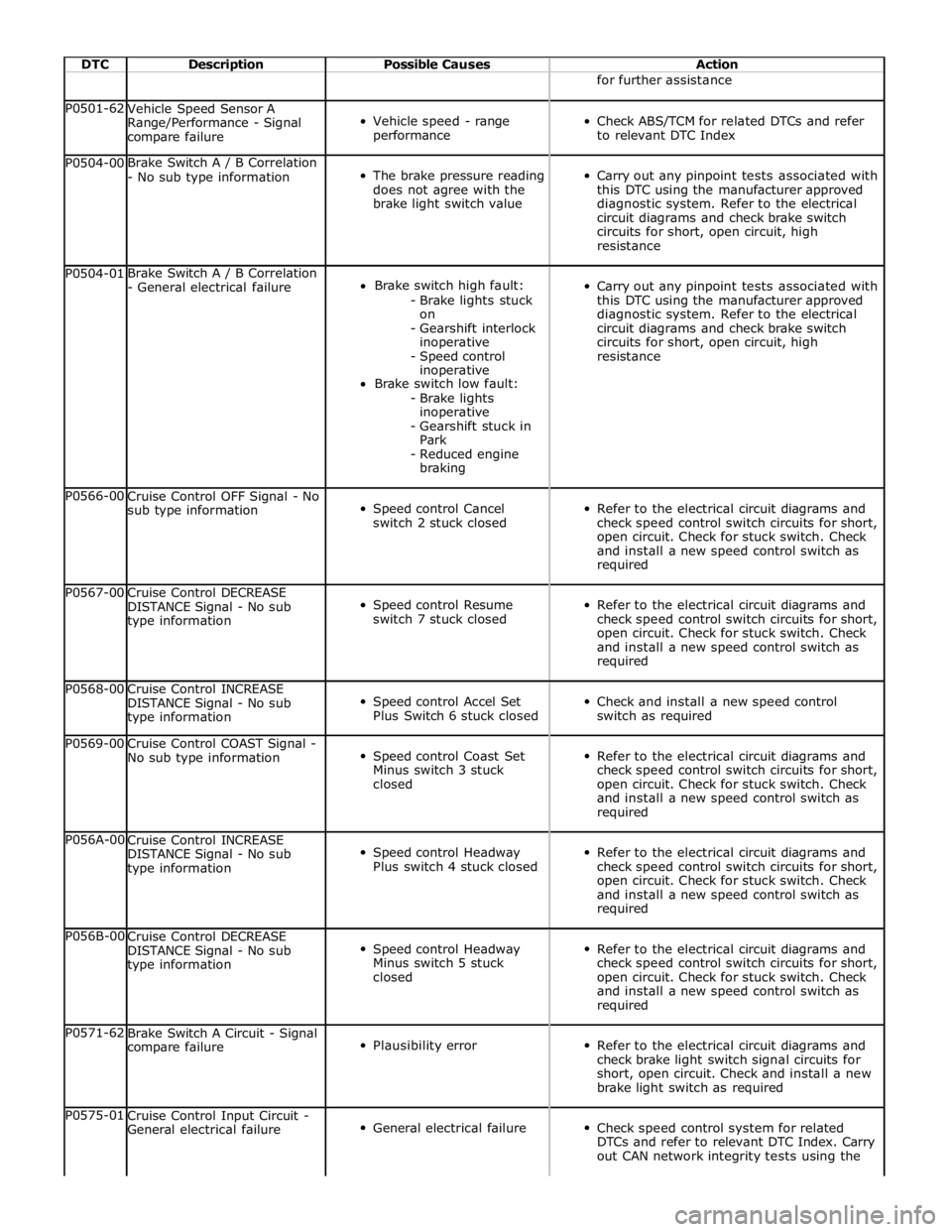

DTC Description Possible Causes Action for further assistance P0501-62

Vehicle Speed Sensor A

Range/Performance - Signal

compare failure

Vehicle speed - range

performance

Check ABS/TCM for related DTCs and refer

to relevant DTC Index P0504-00 Brake Switch A / B Correlation

- No sub type information

The brake pressure reading

does not agree with the

brake light switch value

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and check brake switch

circuits for short, open circuit, high

resistance P0504-01 Brake Switch A / B Correlation

- General electrical failure

Brake switch high fault:

- Brake lights stuck

on

- Gearshift interlock

inoperative

- Speed control

inoperative

Brake switch low fault:

- Brake lights

inoperative

- Gearshift stuck in

Park

- Reduced engine

braking

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and check brake switch

circuits for short, open circuit, high

resistance P0566-00

Cruise Control OFF Signal - No

sub type information

Speed control Cancel

switch 2 stuck closed

Refer to the electrical circuit diagrams and

check speed control switch circuits for short,

open circuit. Check for stuck switch. Check

and install a new speed control switch as

required P0567-00

Cruise Control DECREASE

DISTANCE Signal - No sub

type information

Speed control Resume

switch 7 stuck closed

Refer to the electrical circuit diagrams and

check speed control switch circuits for short,

open circuit. Check for stuck switch. Check

and install a new speed control switch as

required P0568-00

Cruise Control INCREASE

DISTANCE Signal - No sub

type information

Speed control Accel Set

Plus Switch 6 stuck closed

Check and install a new speed control

switch as required P0569-00

Cruise Control COAST Signal -

No sub type information

Speed control Coast Set

Minus switch 3 stuck

closed

Refer to the electrical circuit diagrams and

check speed control switch circuits for short,

open circuit. Check for stuck switch. Check

and install a new speed control switch as

required P056A-00

Cruise Control INCREASE

DISTANCE Signal - No sub

type information

Speed control Headway

Plus switch 4 stuck closed

Refer to the electrical circuit diagrams and

check speed control switch circuits for short,

open circuit. Check for stuck switch. Check

and install a new speed control switch as

required P056B-00

Cruise Control DECREASE

DISTANCE Signal - No sub

type information

Speed control Headway

Minus switch 5 stuck

closed

Refer to the electrical circuit diagrams and

check speed control switch circuits for short,

open circuit. Check for stuck switch. Check

and install a new speed control switch as

required P0571-62

Brake Switch A Circuit - Signal

compare failure

Plausibility error

Refer to the electrical circuit diagrams and

check brake light switch signal circuits for

short, open circuit. Check and install a new

brake light switch as required P0575-01

Cruise Control Input Circuit -

General electrical failure

General electrical failure

Check speed control system for related

DTCs and refer to relevant DTC Index. Carry

out CAN network integrity tests using the

Page 1783 of 3039

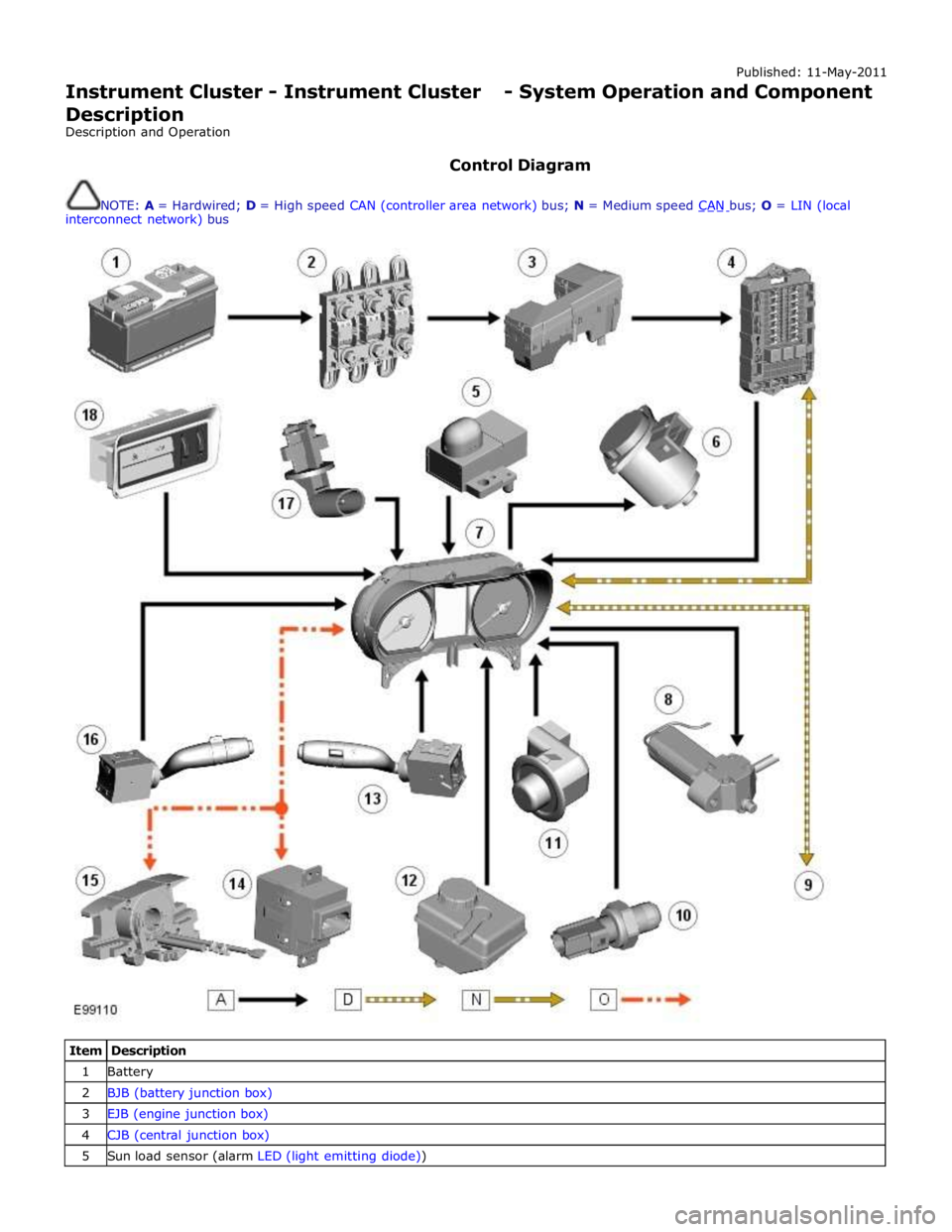

Published: 11-May-2011

Instrument Cluster - Instrument Cluster - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; N = Medium speed CAN bus; O = LIN (local interconnect network) bus

Item Description 1 Battery 2 BJB (battery junction box) 3 EJB (engine junction box) 4 CJB (central junction box) 5 Sun load sensor (alarm LED (light emitting diode))

Page 1784 of 3039

7 Instrument cluster 8 Steering column motor 9 High speed CAN bus connection to other vehicle systems 10 Engine oil pressure switch 11 Steering column adjustment switch 12 Brake fluid level switch 13 LH (left-hand) steering column multifunction switch 14 Start control module 15 Clockspring 16 RH (right-hand) steering column multifunction switch 17 Engine coolant level sensor 18 Auxiliary lighting switch

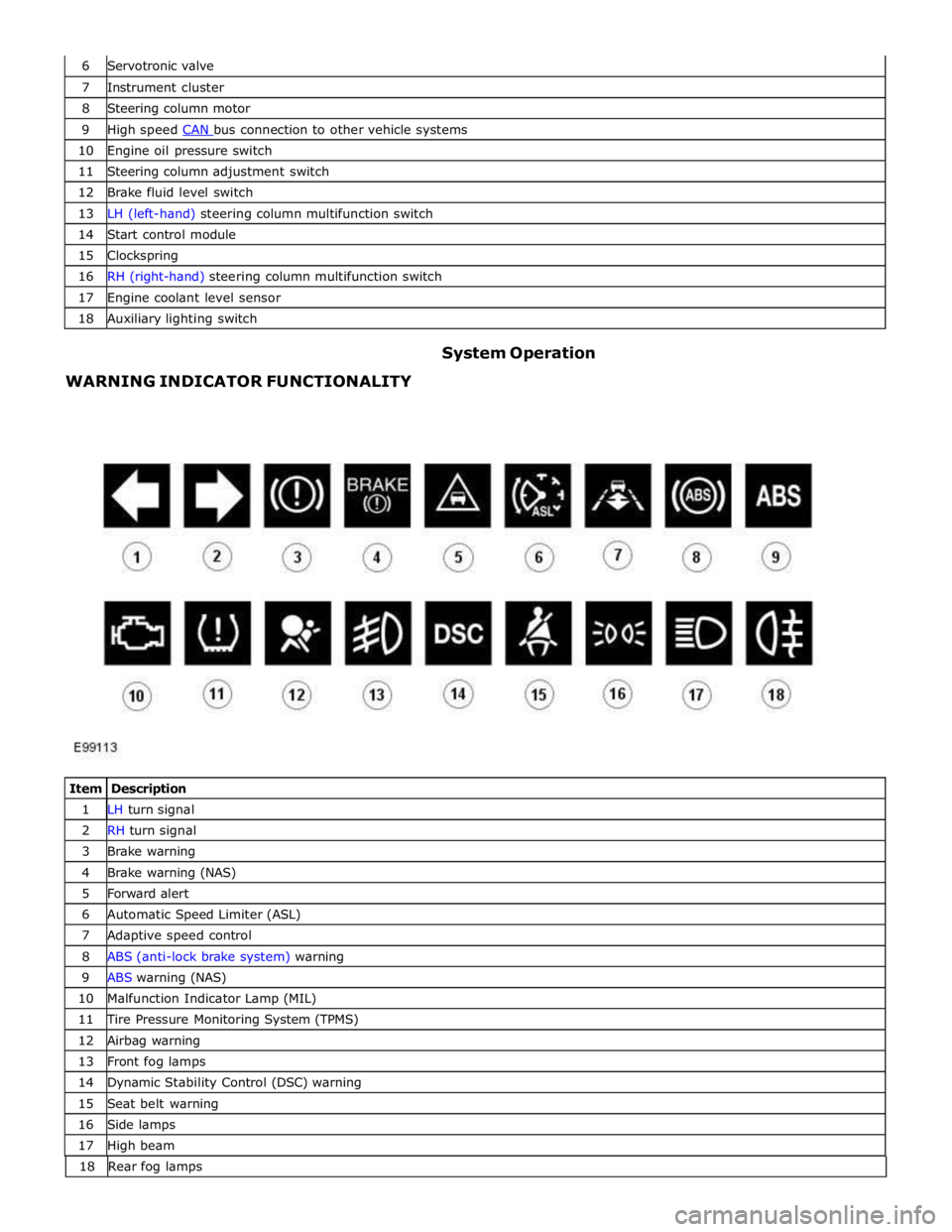

WARNING INDICATOR FUNCTIONALITY System Operation

Item Description 1 LH turn signal 2 RH turn signal 3 Brake warning 4 Brake warning (NAS) 5 Forward alert 6 Automatic Speed Limiter (ASL) 7 Adaptive speed control 8 ABS (anti-lock brake system) warning 9 ABS warning (NAS) 10 Malfunction Indicator Lamp (MIL) 11 Tire Pressure Monitoring System (TPMS) 12 Airbag warning 13 Front fog lamps 14 Dynamic Stability Control (DSC) warning 15 Seat belt warning 16 Side lamps 17 High beam 18 Rearfoglamps