hand brake JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 632 of 3039

BRAKE CALIPERS System Operation

When hydraulic pressure is supplied to the caliper, the pistons extend to force the inner pad against the brake disc. The caliper

reacts and slides along two guide pins to bring the outer pad into contact with the brake disc.

BRAKE PAD WEAR SENSORS

When a brake pad incorporating a brake pad wear sensor is approximately 75% worn, the sensor wire within the pad material

is worn through and the brake pad wear sensor goes open circuit. When the instrument cluster detects the open circuit, it

illuminates the amber LED (light emitting diode) in the brake warning indicator, displays an appropriate warning in the

message center and sounds a warning chime.

Refer to: Instrument Cluster (413-01 Instrument Cluster, Description and Operation).

NOTE: A new pad wear sensor lead must be fitted whenever the brake pads are changed, irrespective of the brake pad

warning sensor being triggered.

BRAKE CALIPERS Component Description

Each caliper is mounted within a fixed carrier that is secured to the rear wheel knuckle with two bolts. Each outboard brake pad

is installed with a wire anti-rattle spring.

The brake calipers on SC (supercharger) vehicles are painted and also include a logo badge, secured with two screws, which

must be removed in order to change the brake pads.

The inboard brake pad of the RH (right-hand) brake incorporates a wear sensor.

BRAKE PAD WEAR SENSORS

The brake pad wear sensor is wired in series with a wear sensor on the LH (left-hand) front brake and the instrument cluster. If

the thickness of one of the brake pads connected to a wear sensor decreases to a predetermined limit, the instrument cluster

illuminates the brake warning indicator.

Page 634 of 3039

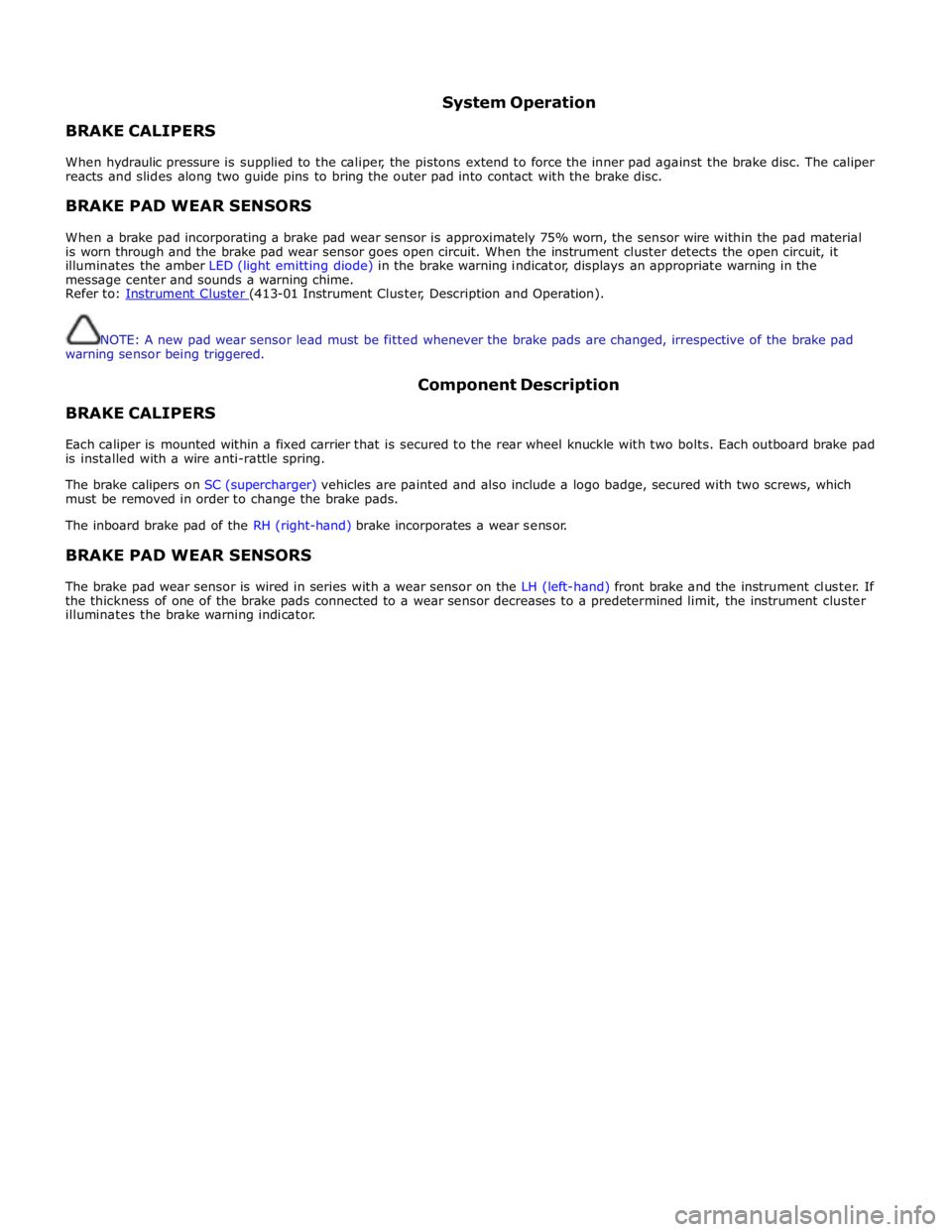

5. NOTE: Left-hand shown, right-hand similar.

Torque: 10 Nm

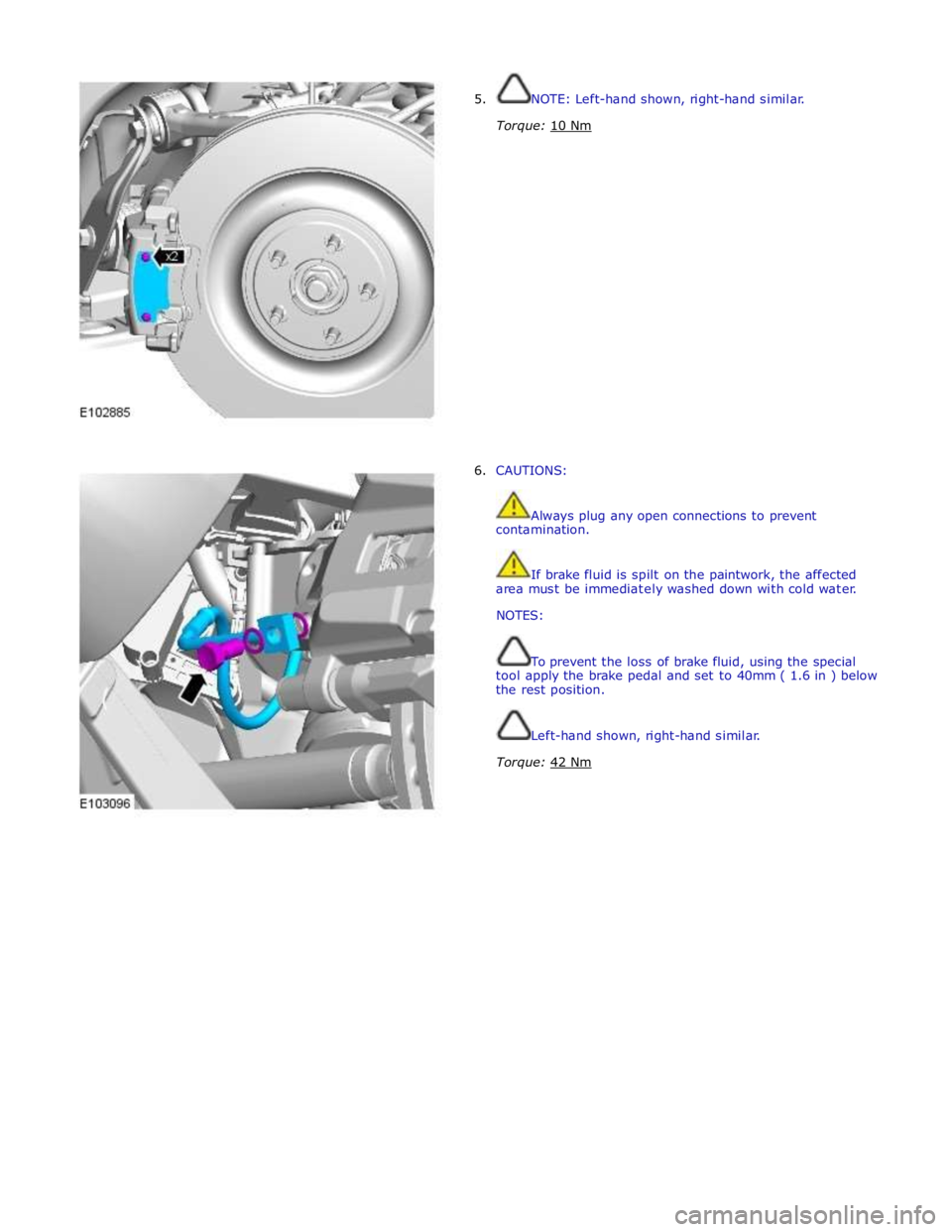

6. CAUTIONS:

Always plug any open connections to prevent

contamination.

If brake fluid is spilt on the paintwork, the affected

area must be immediately washed down with cold water.

NOTES:

To prevent the loss of brake fluid, using the special

tool apply the brake pedal and set to 40mm ( 1.6 in ) below

the rest position.

Left-hand shown, right-hand similar.

Torque: 42 Nm

Page 636 of 3039

Installation

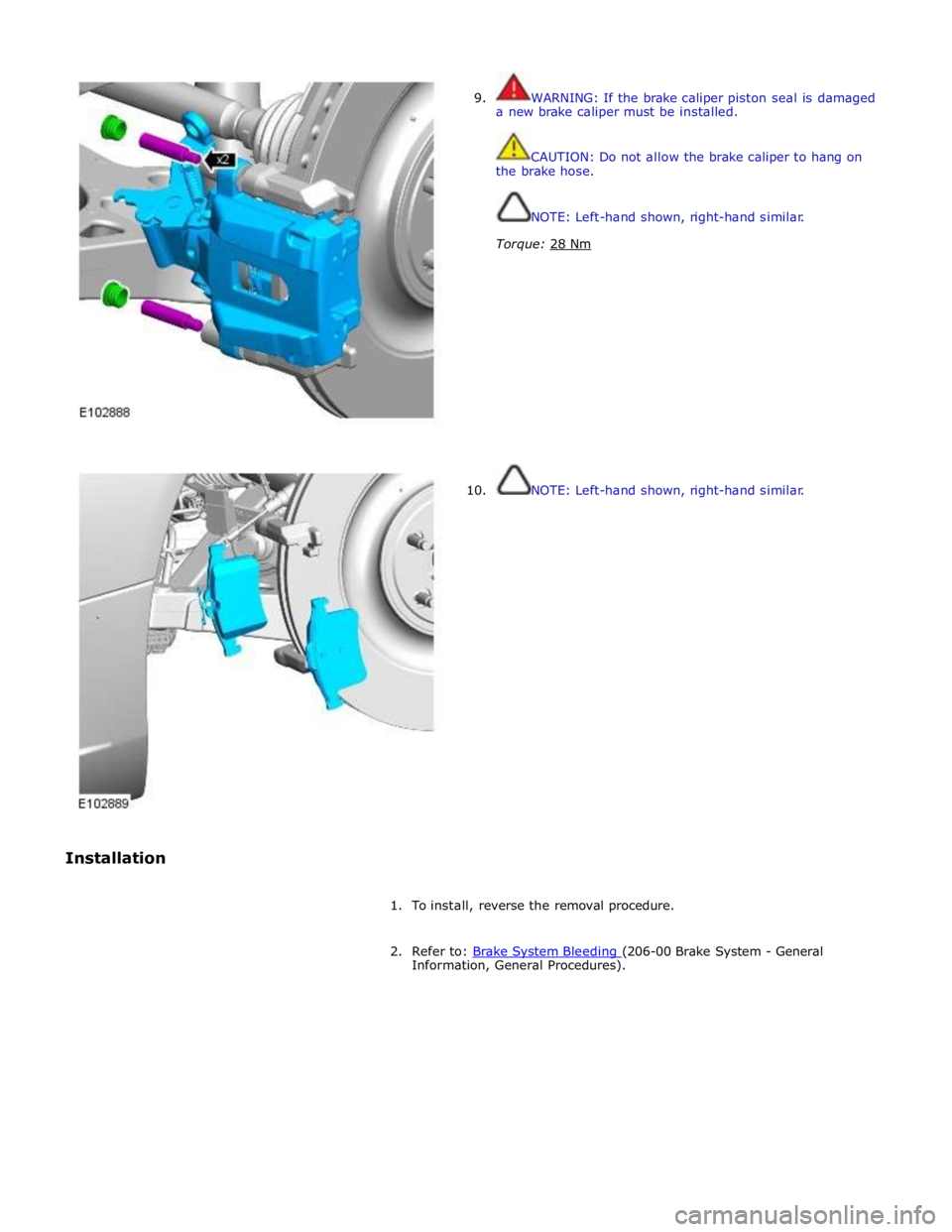

9.

10.

WARNING: If the brake caliper piston seal is damaged

a new brake caliper must be installed.

CAUTION: Do not allow the brake caliper to hang on

the brake hose.

NOTE: Left-hand shown, right-hand similar.

Torque: 28 Nm

NOTE: Left-hand shown, right-hand similar.

1. To install, reverse the removal procedure.

2. Refer to: Brake System Bleeding (206-00 Brake System - General Information, General Procedures).

Page 641 of 3039

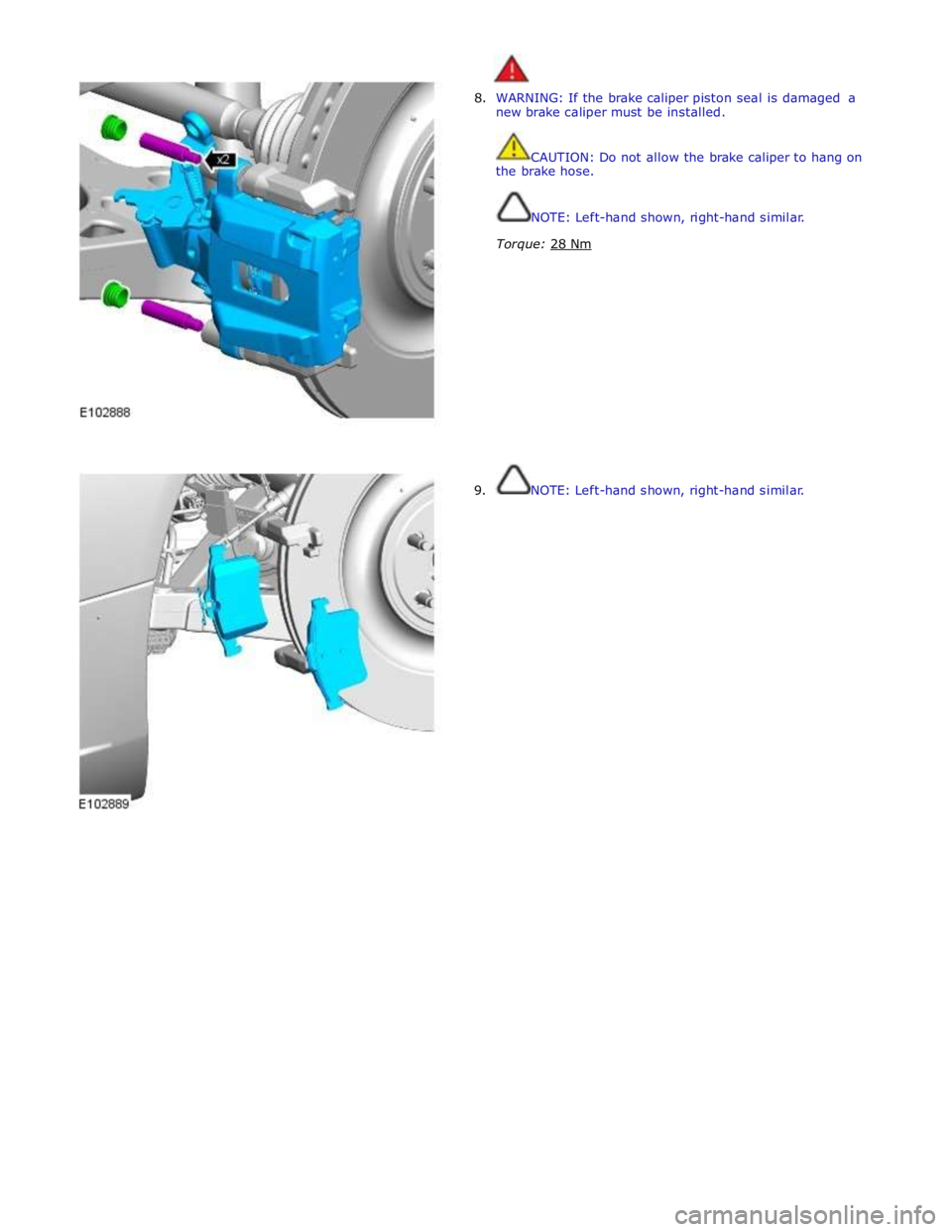

8. WARNING: If the brake caliper piston seal is damaged a

new brake caliper must be installed.

CAUTION: Do not allow the brake caliper to hang on

the brake hose.

NOTE: Left-hand shown, right-hand similar.

Torque: 28 Nm

9. NOTE: Left-hand shown, right-hand similar.

Page 642 of 3039

10.

11. NOTE: Left-hand shown, right-hand similar.

Special Tool(s): 303-588 Special Tool(s): 206-080 Special Tool(s): 206-081 Using the special tools, fully retract the brake

caliper piston.

12.

Repeat the above procedure on the opposite side.

Installation

1. NOTE: The brake pad wear sensor retaining tang must be

installed to the sensor prior to installation to the brake

pad.

2. To install, reverse the removal procedure.

3. Repeat the above procedure on the opposite side.

Page 657 of 3039

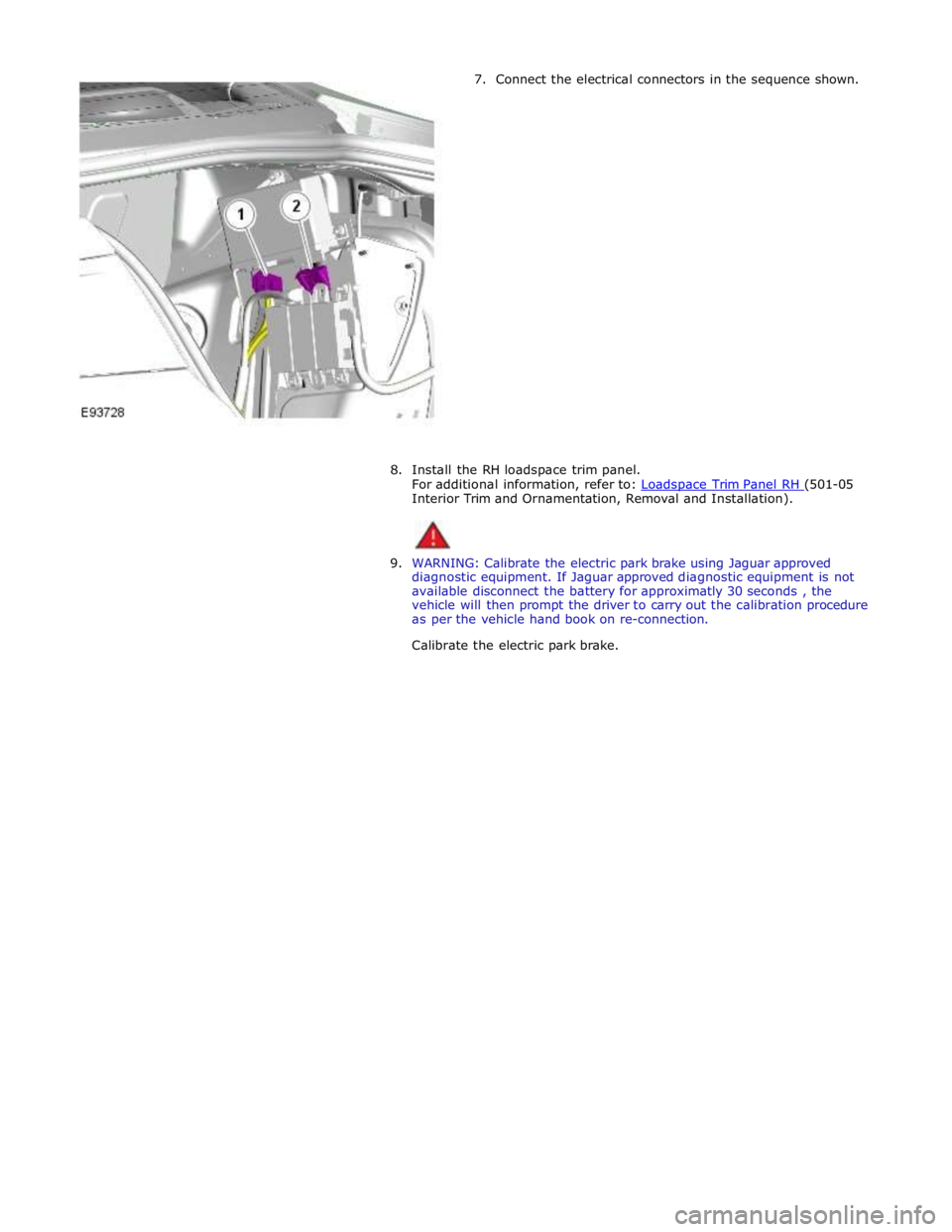

7. Connect the electrical connectors in the sequence shown.

8. Install the RH loadspace trim panel.

For additional information, refer to: Loadspace Trim Panel RH (501-05 Interior Trim and Ornamentation, Removal and Installation).

9. WARNING: Calibrate the electric park brake using Jaguar approved

diagnostic equipment. If Jaguar approved diagnostic equipment is not

available disconnect the battery for approximatly 30 seconds , the

vehicle will then prompt the driver to carry out the calibration procedure

as per the vehicle hand book on re-connection.

Calibrate the electric park brake.

Page 666 of 3039

7.

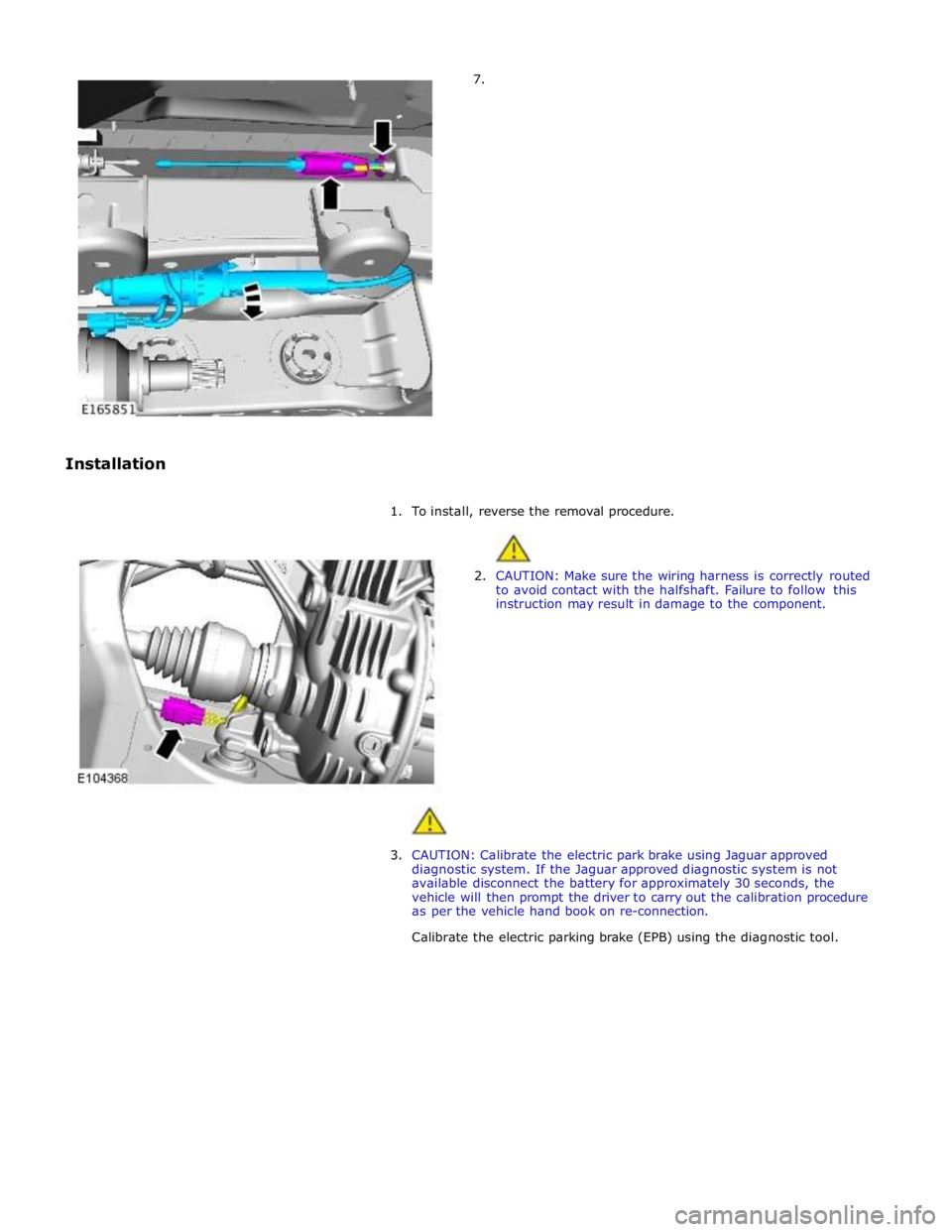

Installation

1. To install, reverse the removal procedure.

2. CAUTION: Make sure the wiring harness is correctly routed

to avoid contact with the halfshaft. Failure to follow this

instruction may result in damage to the component.

3. CAUTION: Calibrate the electric park brake using Jaguar approved

diagnostic system. If the Jaguar approved diagnostic system is not

available disconnect the battery for approximately 30 seconds, the

vehicle will then prompt the driver to carry out the calibration procedure

as per the vehicle hand book on re-connection.

Calibrate the electric parking brake (EPB) using the diagnostic tool.

Page 668 of 3039

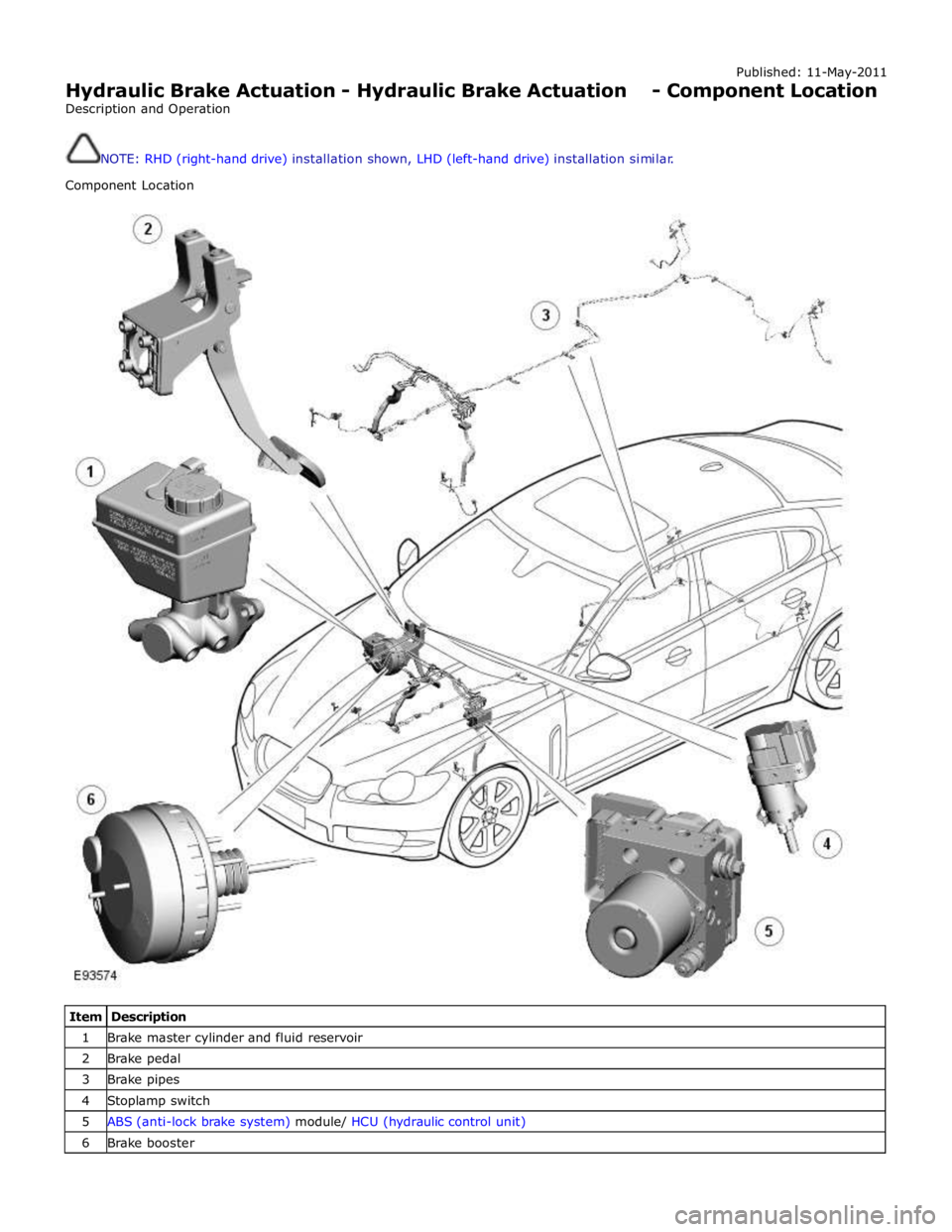

Published: 11-May-2011

Hydraulic Brake Actuation - Hydraulic Brake Actuation - Component Location

Description and Operation

NOTE: RHD (right-hand drive) installation shown, LHD (left-hand drive) installation similar.

Component Location

Item Description 1 Brake master cylinder and fluid reservoir 2 Brake pedal 3 Brake pipes 4 Stoplamp switch 5 ABS (anti-lock brake system) module/ HCU (hydraulic control unit) 6 Brake booster

Page 673 of 3039

1 LH (left-hand) front brake 2 RH (right-hand) rear brake 3 LH rear brake 4 RH front brake 5 Primary circuit inlet port 6 Secondary circuit inlet port The ABS module is located in the passenger side, rear engine bay and incorporates the HCU. The HCU is a four channel unit that modulates the supply of hydraulic pressure to the brakes under control of the ABS module.

The primary and secondary outlets of the master cylinder are connected to the primary and secondary circuits within the HCU. The primary circuit in the HCU has separate outlet ports to the RH front and LH rear brakes. The secondary circuit in the HCU has separate outlet ports to the LH front and RH rear brakes.

Page 683 of 3039

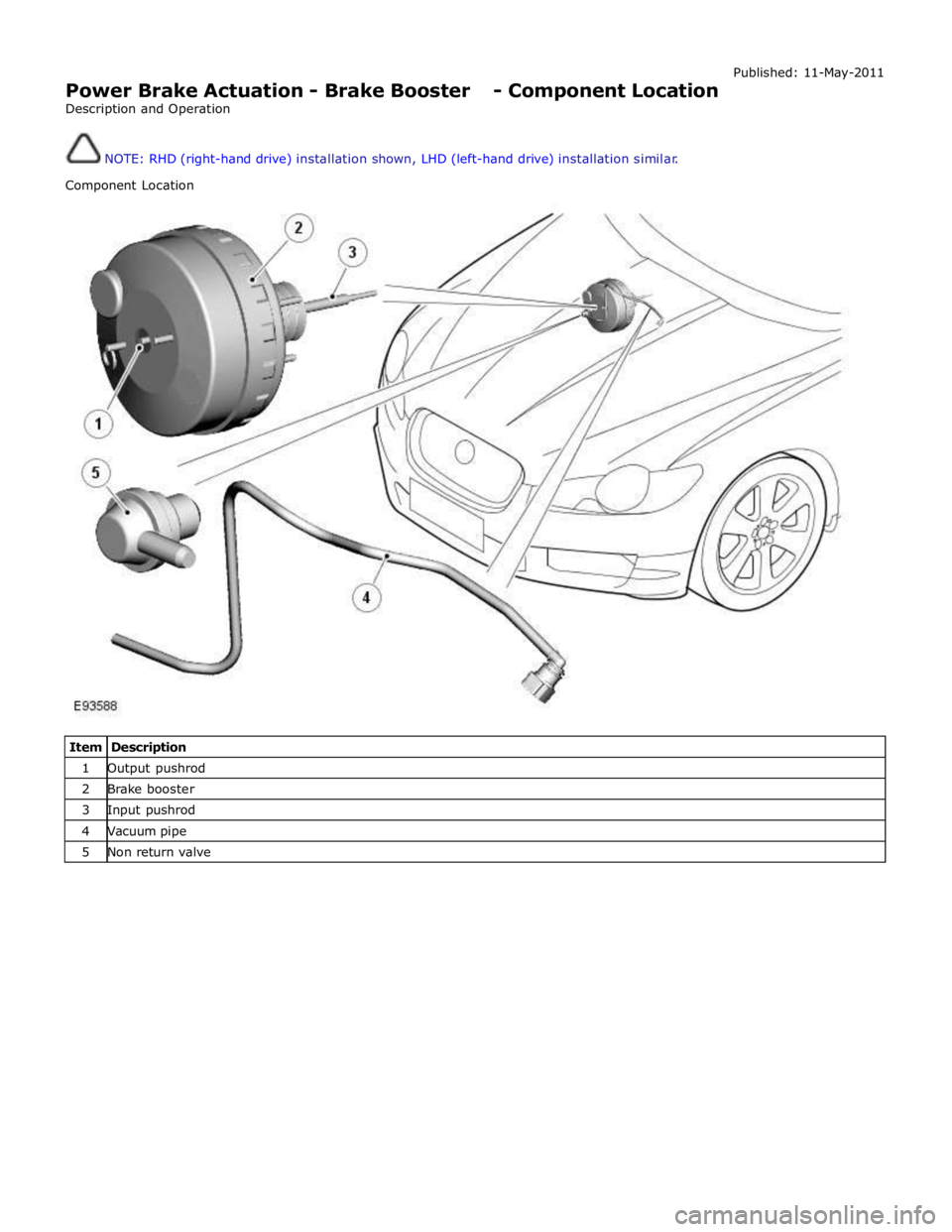

Power Brake Actuation - Brake Booster - Component Location

Description and Operation

NOTE: RHD (right-hand drive) installation shown, LHD (left-hand drive) installation similar.

Component Location Published: 11-May-2011

Item Description 1 Output pushrod 2 Brake booster 3 Input pushrod 4 Vacuum pipe 5 Non return valve