steering JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 194 of 3039

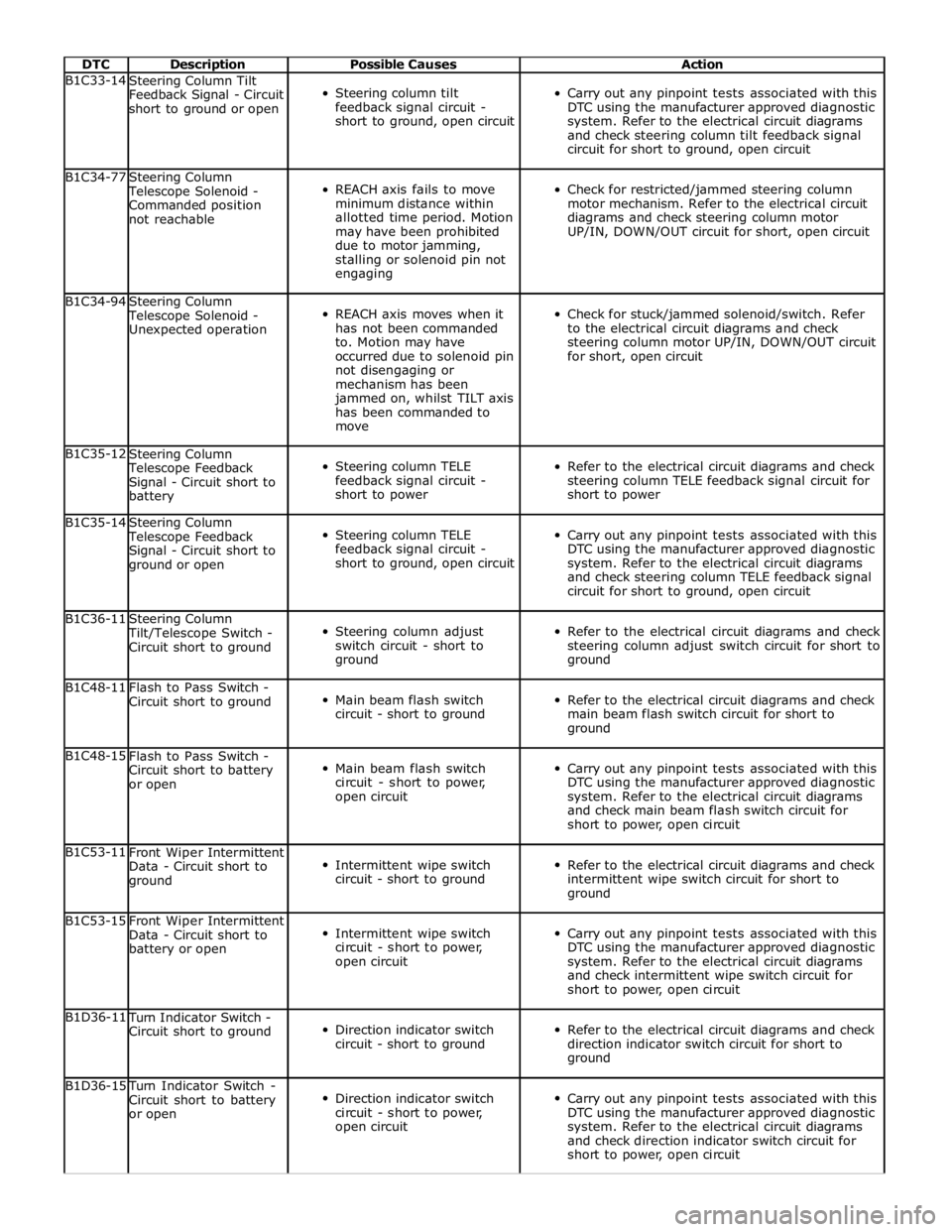

DTC Description Possible Causes Action B1C33-14

Steering Column Tilt

Feedback Signal - Circuit

short to ground or open

Steering column tilt

feedback signal circuit -

short to ground, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check steering column tilt feedback signal

circuit for short to ground, open circuit B1C34-77

Steering Column Telescope Solenoid -

Commanded position

not reachable

REACH axis fails to move

minimum distance within

allotted time period. Motion

may have been prohibited

due to motor jamming,

stalling or solenoid pin not

engaging

Check for restricted/jammed steering column

motor mechanism. Refer to the electrical circuit

diagrams and check steering column motor

UP/IN, DOWN/OUT circuit for short, open circuit B1C34-94

Steering Column Telescope Solenoid -

Unexpected operation

REACH axis moves when it

has not been commanded

to. Motion may have

occurred due to solenoid pin

not disengaging or

mechanism has been

jammed on, whilst TILT axis

has been commanded to

move

Check for stuck/jammed solenoid/switch. Refer

to the electrical circuit diagrams and check

steering column motor UP/IN, DOWN/OUT circuit

for short, open circuit B1C35-12

Steering Column Telescope Feedback

Signal - Circuit short to

battery

Steering column TELE

feedback signal circuit -

short to power

Refer to the electrical circuit diagrams and check

steering column TELE feedback signal circuit for

short to power B1C35-14

Steering Column Telescope Feedback

Signal - Circuit short to

ground or open

Steering column TELE

feedback signal circuit -

short to ground, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check steering column TELE feedback signal

circuit for short to ground, open circuit B1C36-11

Steering Column Tilt/Telescope Switch -

Circuit short to ground

Steering column adjust

switch circuit - short to

ground

Refer to the electrical circuit diagrams and check

steering column adjust switch circuit for short to

ground B1C48-11

Flash to Pass Switch -

Circuit short to ground

Main beam flash switch

circuit - short to ground

Refer to the electrical circuit diagrams and check

main beam flash switch circuit for short to

ground B1C48-15

Flash to Pass Switch -

Circuit short to battery

or open

Main beam flash switch

circuit - short to power,

open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check main beam flash switch circuit for

short to power, open circuit B1C53-11

Front Wiper Intermittent

Data - Circuit short to

ground

Intermittent wipe switch

circuit - short to ground

Refer to the electrical circuit diagrams and check

intermittent wipe switch circuit for short to

ground B1C53-15

Front Wiper Intermittent

Data - Circuit short to

battery or open

Intermittent wipe switch

circuit - short to power,

open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check intermittent wipe switch circuit for

short to power, open circuit B1D36-11 Turn Indicator Switch -

Circuit short to ground

Direction indicator switch

circuit - short to ground

Refer to the electrical circuit diagrams and check

direction indicator switch circuit for short to

ground B1D36-15 Turn Indicator Switch -

Circuit short to battery

or open

Direction indicator switch

circuit - short to power,

open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check direction indicator switch circuit for

short to power, open circuit

Page 195 of 3039

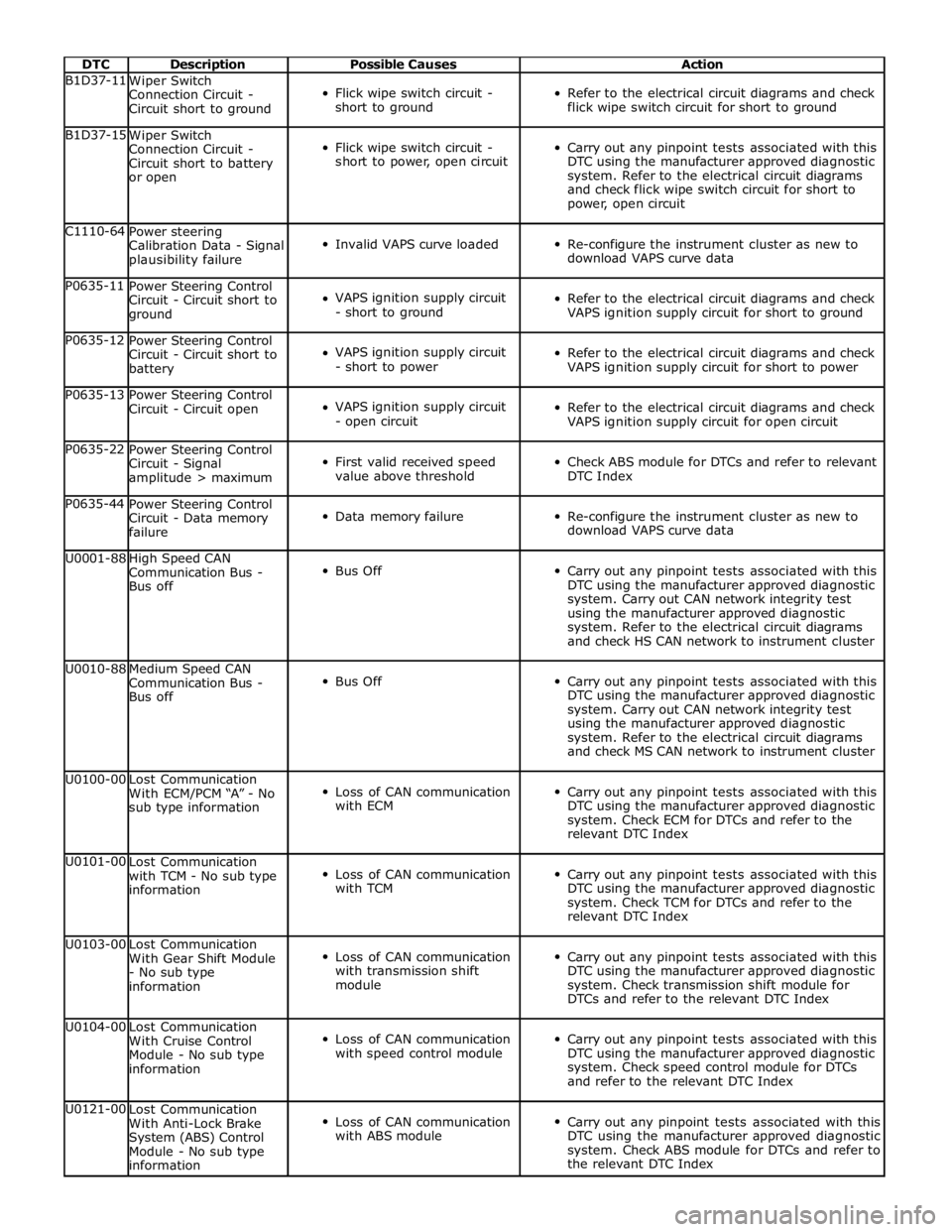

DTC Description Possible Causes Action B1D37-11

Wiper Switch

Connection Circuit -

Circuit short to ground

Flick wipe switch circuit -

short to ground

Refer to the electrical circuit diagrams and check

flick wipe switch circuit for short to ground B1D37-15

Wiper Switch

Connection Circuit -

Circuit short to battery

or open

Flick wipe switch circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check flick wipe switch circuit for short to

power, open circuit C1110-64

Power steering

Calibration Data - Signal

plausibility failure

Invalid VAPS curve loaded

Re-configure the instrument cluster as new to

download VAPS curve data P0635-11

Power Steering Control

Circuit - Circuit short to

ground

VAPS ignition supply circuit

- short to ground

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for short to ground P0635-12

Power Steering Control

Circuit - Circuit short to

battery

VAPS ignition supply circuit

- short to power

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for short to power P0635-13

Power Steering Control

Circuit - Circuit open

VAPS ignition supply circuit

- open circuit

Refer to the electrical circuit diagrams and check

VAPS ignition supply circuit for open circuit P0635-22

Power Steering Control

Circuit - Signal

amplitude > maximum

First valid received speed

value above threshold

Check ABS module for DTCs and refer to relevant

DTC Index P0635-44

Power Steering Control

Circuit - Data memory

failure

Data memory failure

Re-configure the instrument cluster as new to

download VAPS curve data U0001-88

High Speed CAN

Communication Bus -

Bus off

Bus Off

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test

using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check HS CAN network to instrument cluster U0010-88

Medium Speed CAN

Communication Bus -

Bus off

Bus Off

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test

using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check MS CAN network to instrument cluster U0100-00

Lost Communication

With ECM/PCM “A” - No

sub type information

Loss of CAN communication

with ECM

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for DTCs and refer to the

relevant DTC Index U0101-00

Lost Communication

with TCM - No sub type

information

Loss of CAN communication

with TCM

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Module

- No sub type

information

Loss of CAN communication

with transmission shift

module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for

DTCs and refer to the relevant DTC Index U0104-00

Lost Communication

With Cruise Control

Module - No sub type

information

Loss of CAN communication

with speed control module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check speed control module for DTCs

and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-Lock Brake

System (ABS) Control

Module - No sub type

information

Loss of CAN communication

with ABS module

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS module for DTCs and refer to

the relevant DTC Index

Page 220 of 3039

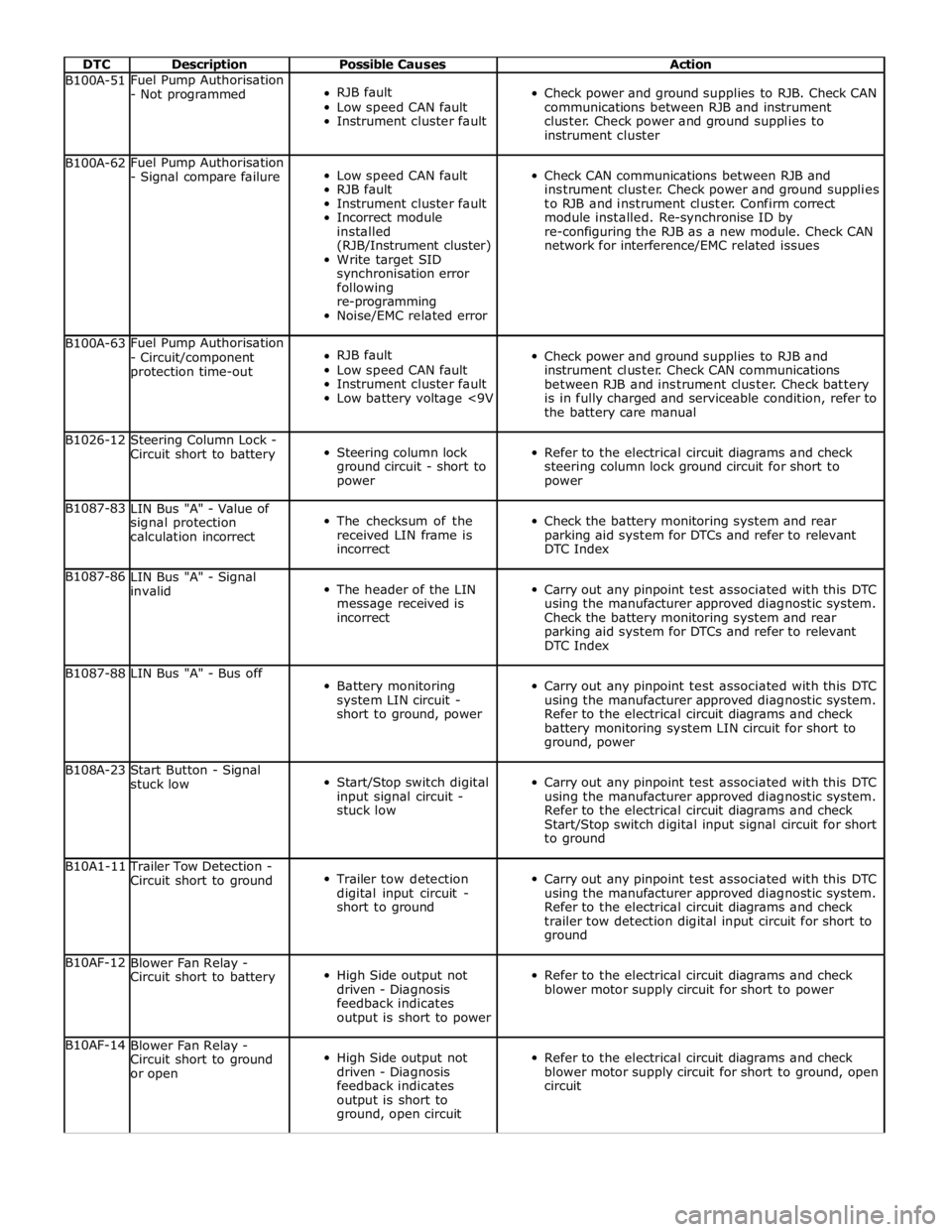

DTC Description Possible Causes Action B100A-51 Fuel Pump Authorisation

- Not programmed

RJB fault

Low speed CAN fault

Instrument cluster fault

Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument

cluster. Check power and ground supplies to

instrument cluster B100A-62 Fuel Pump Authorisation

- Signal compare failure

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed

(RJB/Instrument cluster)

Write target SID

synchronisation error

following

re-programming

Noise/EMC related error

Check CAN communications between RJB and

instrument cluster. Check power and ground supplies

to RJB and instrument cluster. Confirm correct

module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN

network for interference/EMC related issues B100A-63 Fuel Pump Authorisation

- Circuit/component

protection time-out

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V

Check power and ground supplies to RJB and

instrument cluster. Check CAN communications

between RJB and instrument cluster. Check battery

is in fully charged and serviceable condition, refer to

the battery care manual B1026-12

Steering Column Lock -

Circuit short to battery

Steering column lock

ground circuit - short to

power

Refer to the electrical circuit diagrams and check

steering column lock ground circuit for short to

power B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

The checksum of the

received LIN frame is

incorrect

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-86

LIN Bus "A" - Signal

invalid

The header of the LIN

message received is

incorrect

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-88 LIN Bus "A" - Bus off

Battery monitoring

system LIN circuit -

short to ground, power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

battery monitoring system LIN circuit for short to

ground, power B108A-23

Start Button - Signal

stuck low

Start/Stop switch digital

input signal circuit -

stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

Start/Stop switch digital input signal circuit for short

to ground B10A1-11 Trailer Tow Detection -

Circuit short to ground

Trailer tow detection

digital input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

trailer tow detection digital input circuit for short to

ground B10AF-12

Blower Fan Relay -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to power B10AF-14

Blower Fan Relay -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to ground, open

circuit

Page 242 of 3039

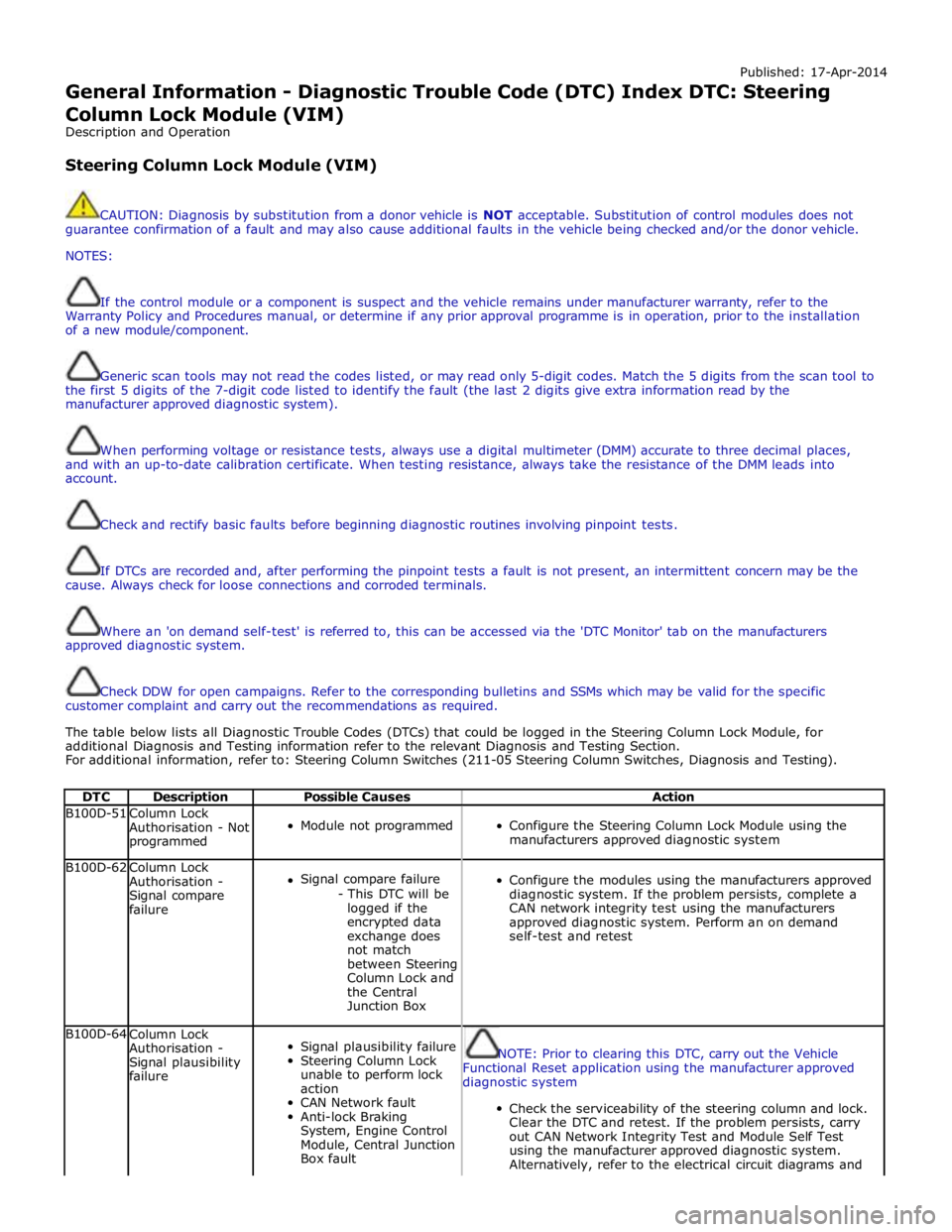

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Steering

Column Lock Module (VIM)

Description and Operation

Steering Column Lock Module (VIM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Steering Column Lock Module, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Steering Column Switches (211-05 Steering Column Switches, Diagnosis and Testing).

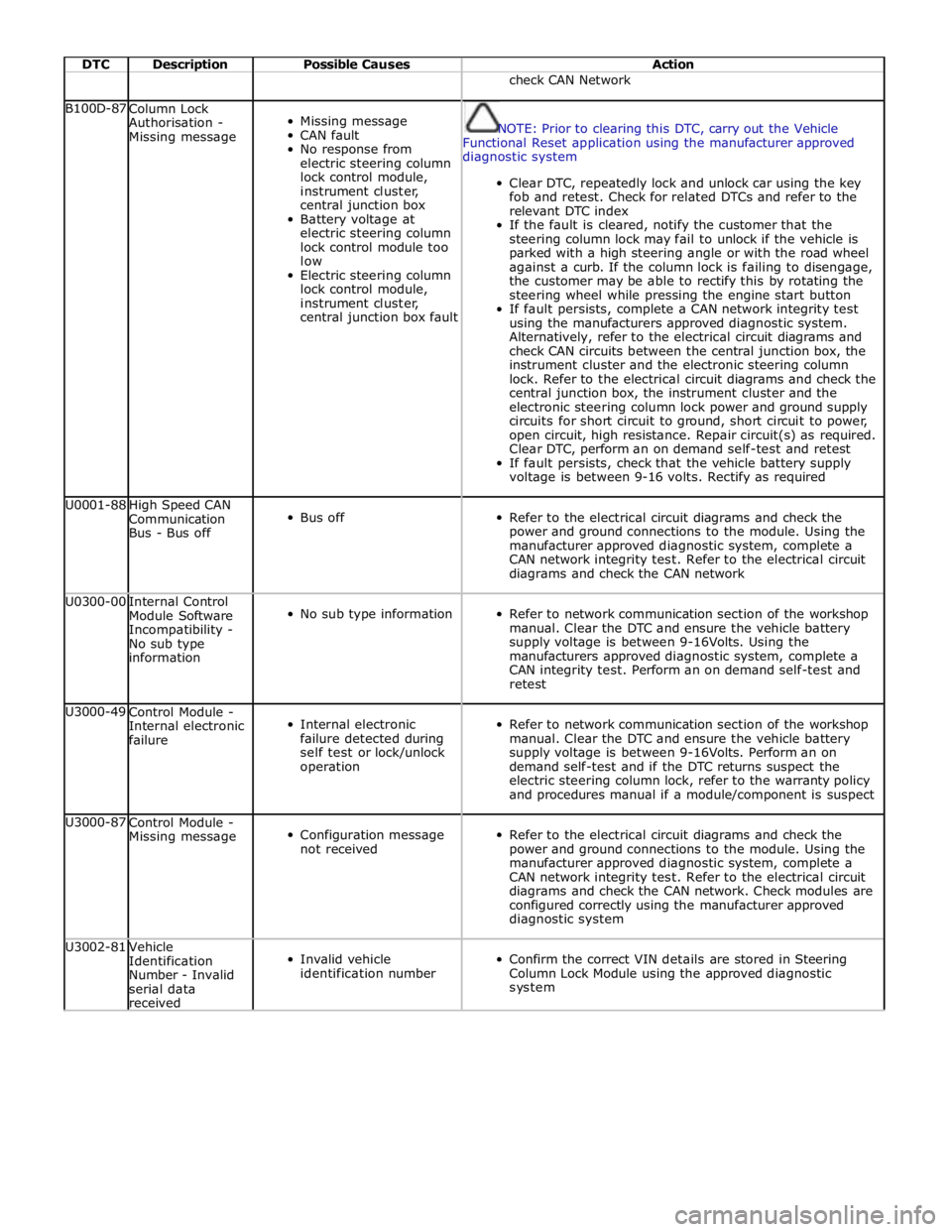

DTC Description Possible Causes Action B100D-51

Column Lock

Authorisation - Not

programmed

Module not programmed

Configure the Steering Column Lock Module using the

manufacturers approved diagnostic system B100D-62

Column Lock

Authorisation -

Signal compare

failure

Signal compare failure

- This DTC will be

logged if the

encrypted data

exchange does

not match

between Steering

Column Lock and

the Central

Junction Box

Configure the modules using the manufacturers approved

diagnostic system. If the problem persists, complete a

CAN network integrity test using the manufacturers

approved diagnostic system. Perform an on demand

self-test and retest B100D-64

Column Lock

Authorisation -

Signal plausibility

failure

Signal plausibility failure

Steering Column Lock

unable to perform lock

action

CAN Network fault

Anti-lock Braking

System, Engine Control

Module, Central Junction

Box fault

NOTE: Prior to clearing this DTC, carry out the Vehicle

Functional Reset application using the manufacturer approved

diagnostic system

Check the serviceability of the steering column and lock.

Clear the DTC and retest. If the problem persists, carry

out CAN Network Integrity Test and Module Self Test

using the manufacturer approved diagnostic system.

Alternatively, refer to the electrical circuit diagrams and

Page 243 of 3039

DTC Description Possible Causes Action check CAN Network B100D-87

Column Lock

Authorisation -

Missing message

Missing message

CAN fault

No response from

electric steering column

lock control module,

instrument cluster,

central junction box

Battery voltage at

electric steering column

lock control module too

low

Electric steering column

lock control module,

instrument cluster,

central junction box fault

NOTE: Prior to clearing this DTC, carry out the Vehicle

Functional Reset application using the manufacturer approved

diagnostic system

Clear DTC, repeatedly lock and unlock car using the key

fob and retest. Check for related DTCs and refer to the

relevant DTC index

If the fault is cleared, notify the customer that the

steering column lock may fail to unlock if the vehicle is

parked with a high steering angle or with the road wheel

against a curb. If the column lock is failing to disengage,

the customer may be able to rectify this by rotating the

steering wheel while pressing the engine start button

If fault persists, complete a CAN network integrity test

using the manufacturers approved diagnostic system.

Alternatively, refer to the electrical circuit diagrams and

check CAN circuits between the central junction box, the

instrument cluster and the electronic steering column

lock. Refer to the electrical circuit diagrams and check the

central junction box, the instrument cluster and the

electronic steering column lock power and ground supply

circuits for short circuit to ground, short circuit to power,

open circuit, high resistance. Repair circuit(s) as required.

Clear DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required U0001-88

High Speed CAN

Communication

Bus - Bus off

Bus off

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network U0300-00

Internal Control

Module Software

Incompatibility -

No sub type

information

No sub type information

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Using the

manufacturers approved diagnostic system, complete a

CAN integrity test. Perform an on demand self-test and

retest U3000-49

Control Module -

Internal electronic

failure

Internal electronic

failure detected during

self test or lock/unlock

operation

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Perform an on

demand self-test and if the DTC returns suspect the

electric steering column lock, refer to the warranty policy

and procedures manual if a module/component is suspect U3000-87

Control Module -

Missing message

Configuration message

not received

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network. Check modules are

configured correctly using the manufacturer approved

diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data

received

Invalid vehicle

identification number

Confirm the correct VIN details are stored in Steering

Column Lock Module using the approved diagnostic

system

Page 260 of 3039

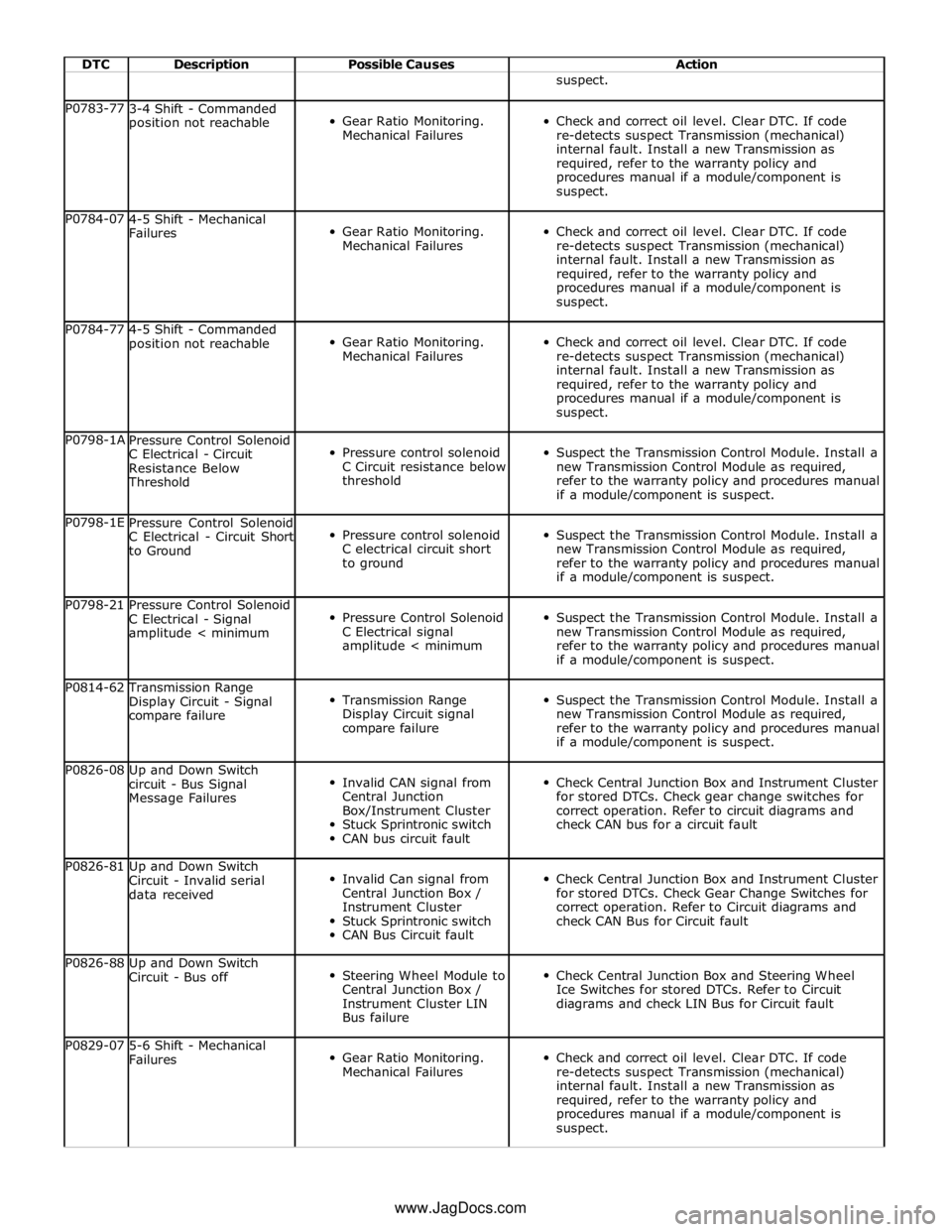

DTC Description Possible Causes Action suspect. P0783-77

3-4 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-07

4-5 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-77

4-5 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0798-1A

Pressure Control Solenoid

C Electrical - Circuit

Resistance Below Threshold

Pressure control solenoid

C Circuit resistance below

threshold

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-1E

Pressure Control Solenoid

C Electrical - Circuit Short

to Ground

Pressure control solenoid

C electrical circuit short

to ground

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-21

Pressure Control Solenoid

C Electrical - Signal

amplitude < minimum

Pressure Control Solenoid

C Electrical signal

amplitude < minimum

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0814-62 Transmission Range

Display Circuit - Signal

compare failure

Transmission Range

Display Circuit signal

compare failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0826-08

Up and Down Switch

circuit - Bus Signal

Message Failures

Invalid CAN signal from

Central Junction

Box/Instrument Cluster

Stuck Sprintronic switch

CAN bus circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check gear change switches for

correct operation. Refer to circuit diagrams and

check CAN bus for a circuit fault P0826-81

Up and Down Switch

Circuit - Invalid serial

data received

Invalid Can signal from

Central Junction Box /

Instrument Cluster

Stuck Sprintronic switch

CAN Bus Circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check Gear Change Switches for

correct operation. Refer to Circuit diagrams and

check CAN Bus for Circuit fault P0826-88

Up and Down Switch

Circuit - Bus off

Steering Wheel Module to

Central Junction Box /

Instrument Cluster LIN

Bus failure

Check Central Junction Box and Steering Wheel

Ice Switches for stored DTCs. Refer to Circuit

diagrams and check LIN Bus for Circuit fault P0829-07

5-6 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. www.JagDocs.com

Page 267 of 3039

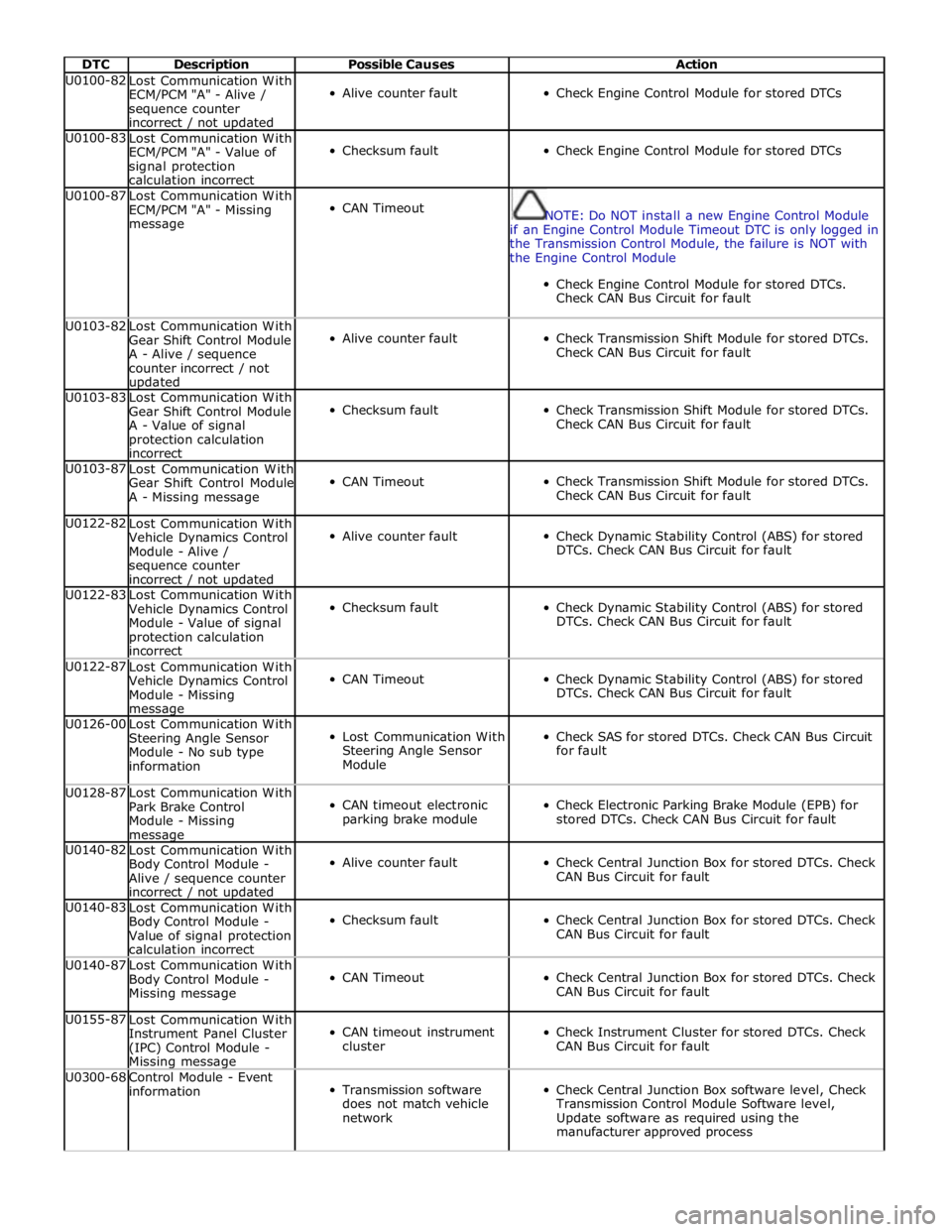

DTC Description Possible Causes Action U0100-82

Lost Communication With

ECM/PCM "A" - Alive /

sequence counter

incorrect / not updated

Alive counter fault

Check Engine Control Module for stored DTCs U0100-83

Lost Communication With

ECM/PCM "A" - Value of

signal protection

calculation incorrect

Checksum fault

Check Engine Control Module for stored DTCs U0100-87

Lost Communication With

ECM/PCM "A" - Missing

message

CAN Timeout

NOTE: Do NOT install a new Engine Control Module

if an Engine Control Module Timeout DTC is only logged in

the Transmission Control Module, the failure is NOT with

the Engine Control Module

Check Engine Control Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-82

Lost Communication With

Gear Shift Control Module

A - Alive / sequence

counter incorrect / not updated

Alive counter fault

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-83

Lost Communication With

Gear Shift Control Module

A - Value of signal

protection calculation

incorrect

Checksum fault

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0103-87

Lost Communication With

Gear Shift Control Module

A - Missing message

CAN Timeout

Check Transmission Shift Module for stored DTCs.

Check CAN Bus Circuit for fault U0122-82

Lost Communication With

Vehicle Dynamics Control

Module - Alive /

sequence counter

incorrect / not updated

Alive counter fault

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0122-83

Lost Communication With

Vehicle Dynamics Control

Module - Value of signal

protection calculation

incorrect

Checksum fault

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0122-87

Lost Communication With

Vehicle Dynamics Control

Module - Missing message

CAN Timeout

Check Dynamic Stability Control (ABS) for stored

DTCs. Check CAN Bus Circuit for fault U0126-00

Lost Communication With

Steering Angle Sensor

Module - No sub type

information

Lost Communication With

Steering Angle Sensor

Module

Check SAS for stored DTCs. Check CAN Bus Circuit

for fault U0128-87

Lost Communication With

Park Brake Control

Module - Missing message

CAN timeout electronic

parking brake module

Check Electronic Parking Brake Module (EPB) for

stored DTCs. Check CAN Bus Circuit for fault U0140-82

Lost Communication With

Body Control Module -

Alive / sequence counter

incorrect / not updated

Alive counter fault

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0140-83

Lost Communication With

Body Control Module -

Value of signal protection

calculation incorrect

Checksum fault

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0140-87

Lost Communication With

Body Control Module -

Missing message

CAN Timeout

Check Central Junction Box for stored DTCs. Check

CAN Bus Circuit for fault U0155-87

Lost Communication With

Instrument Panel Cluster

(IPC) Control Module - Missing message

CAN timeout instrument

cluster

Check Instrument Cluster for stored DTCs. Check

CAN Bus Circuit for fault U0300-68

Control Module - Event

information

Transmission software

does not match vehicle

network

Check Central Junction Box software level, Check

Transmission Control Module Software level,

Update software as required using the

manufacturer approved process

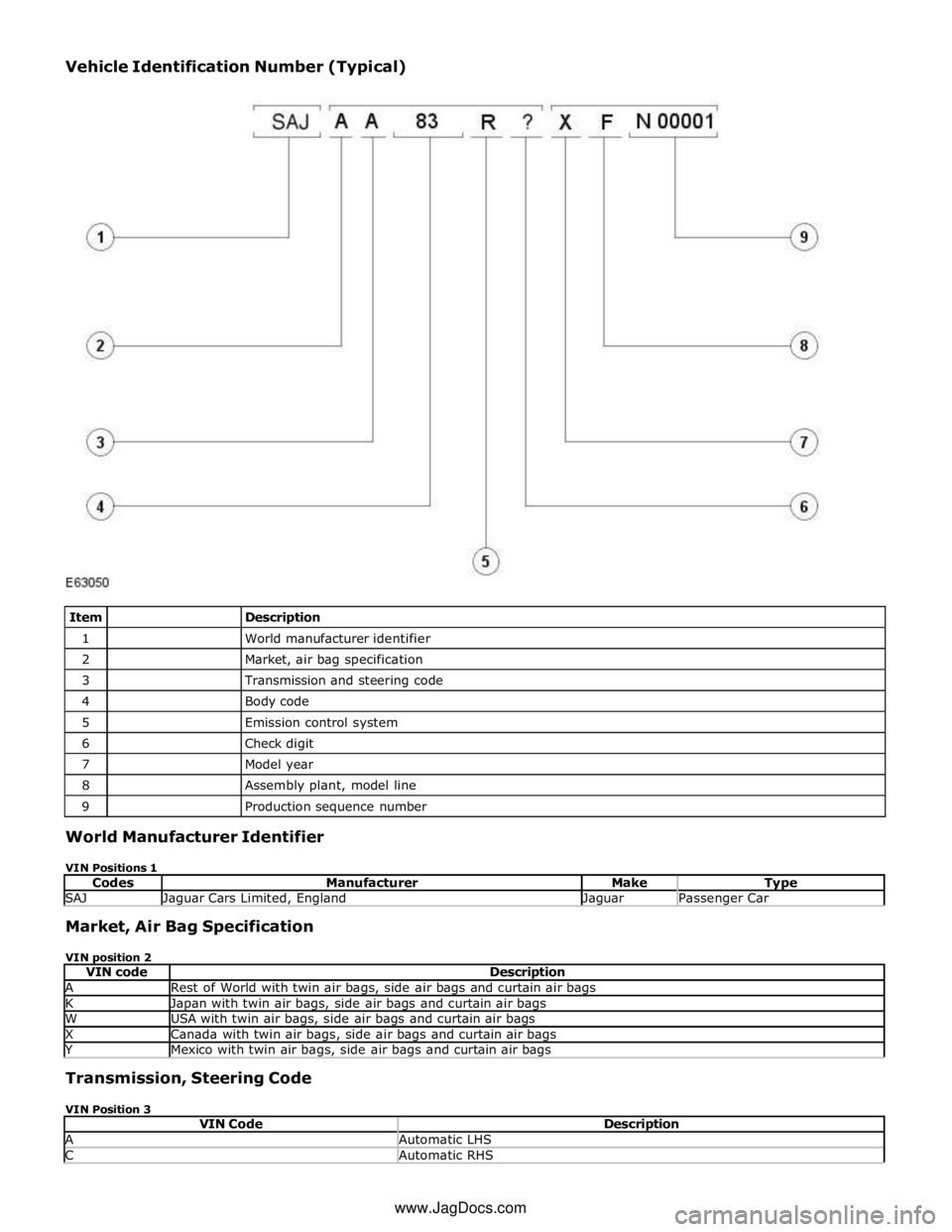

Page 282 of 3039

1

World manufacturer identifier 2

Market, air bag specification 3

Transmission and steering code 4

Body code 5

Emission control system 6

Check digit 7

Model year 8

Assembly plant, model line 9

Production sequence number World Manufacturer Identifier

VIN Positions 1

Codes Manufacturer Make Type SAJ Jaguar Cars Limited, England Jaguar Passenger Car Market, Air Bag Specification

VIN position 2

VIN code Description A Rest of World with twin air bags, side air bags and curtain air bags K Japan with twin air bags, side air bags and curtain air bags W USA with twin air bags, side air bags and curtain air bags X Canada with twin air bags, side air bags and curtain air bags Y Mexico with twin air bags, side air bags and curtain air bags Transmission, Steering Code

VIN Position 3

VIN Code Description A Automatic LHS C Automatic RHS www.JagDocs.com

Page 295 of 3039

Jacking and Lifting - Lifting

Description and Operation

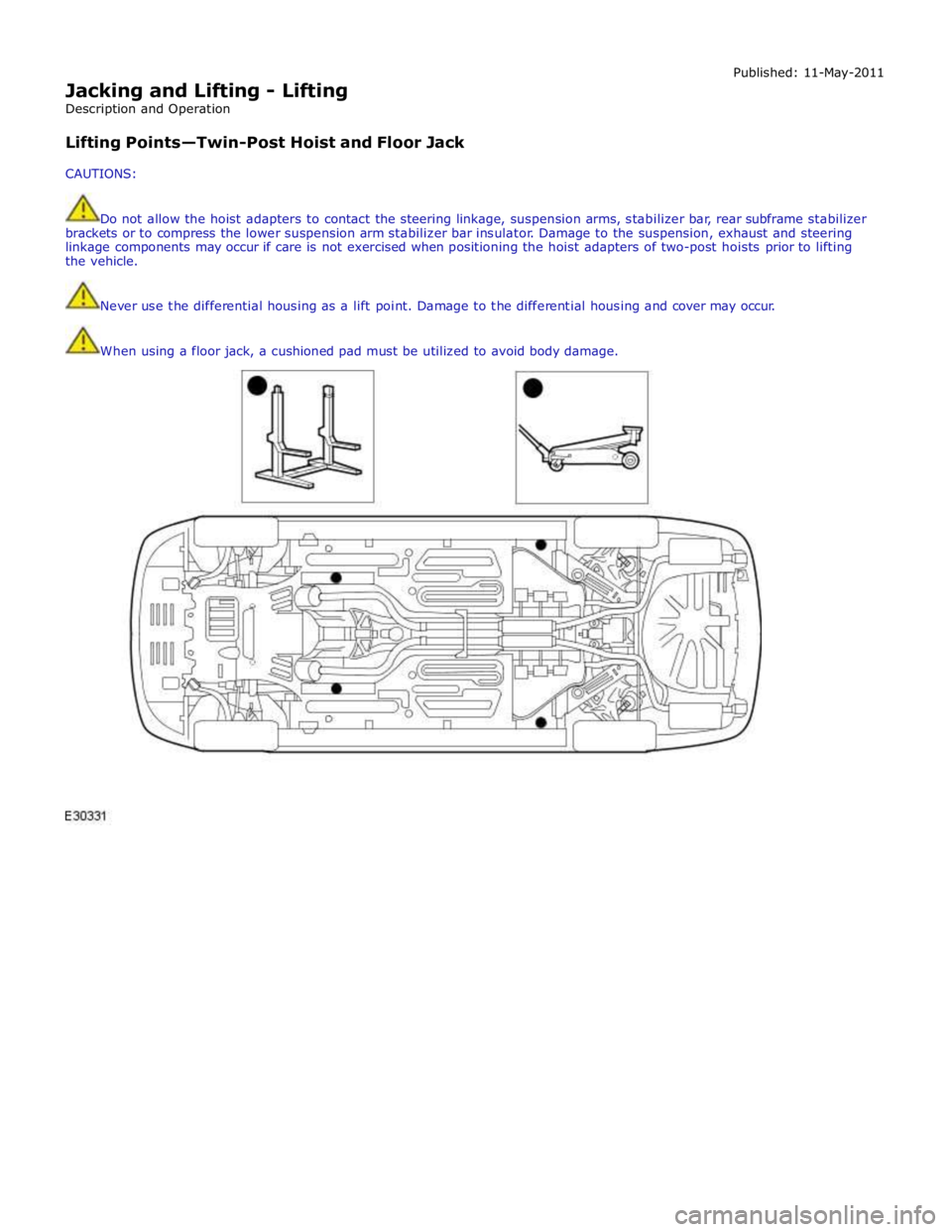

Lifting Points—Twin-Post Hoist and Floor Jack

CAUTIONS: Published: 11-May-2011

Do not allow the hoist adapters to contact the steering linkage, suspension arms, stabilizer bar, rear subframe stabilizer

brackets or to compress the lower suspension arm stabilizer bar insulator. Damage to the suspension, exhaust and steering

linkage components may occur if care is not exercised when positioning the hoist adapters of two-post hoists prior to lifting

the vehicle.

Never use the differential housing as a lift point. Damage to the differential housing and cover may occur.

When using a floor jack, a cushioned pad must be utilized to avoid body damage.

Page 297 of 3039

Rear Suspended Tow

When the vehicle is being recovered by rear suspended tow:

The ignition key must be removed from the ignition switch to lock the steering.

The rear wheels must be correctly positioned in the lifting cradle and securely tied down.

Emergency Towing

WARNING: If the engine is not running, the steering will become heavy and the force necessary to effectively apply the

brakes will be greatly increased.

CAUTION: A vehicle with a defective transmission must be towed by rear suspended tow.

When the vehicle is being towed on its own wheels:

Local regulations for the towing of vehicles must be followed. In some countries the registration number of the towing

vehicle and an 'On Tow' sign or warning triangle must be displayed at the rear of the towed vehicle.

The gear selector lever must be in Neutral.

The ignition switch must be in position II to release the steering lock and make the direction indicators, horn and stop

lamps operate.

A distance of 0,8 km (0.5 mile) must not be exceeded.

A speed of 48 km/h (30 mph) must not be exceeded.

The tow rope must be attached to the front towing eye. www.JagDocs.com