ESP inoperative JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1349 of 3039

Published: 03-Jun-2014

Evaporative Emissions - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Evaporative

Emissions

Diagnosis and Testing

Principles of Operation

For a detailed description of the Evaporative Emissions system, refer to the relevant Description and Operation section in the

workshop manual.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Fuel filler cap and seal

Fuel filler neck

Fuel pipes

Fuel tank

Evaporative emissions canister

Purge valve

Fuses

Wiring harnesses and connectors

Engine Control Module (ECM)

Purge valve

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Possible Causes Action Difficulty in filling

fuel tank

Restriction in the vapour line between the fuel tank and the

carbon canister outlet/atmospheric port

Check for

restrictions/damage Fuel smell

System leak

Purge valve inoperative

Check for leaks

Check the purge valve

operation DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

Page 1793 of 3039

. M–2

Benchmark noise against non-complaint

vehicle. . Trip (fuel) computer N–1

Check for consistent display (during test

drive) of valid 'Rolling Odometer' count in

Self-Diagnostic Mode/ETM test 24. Displays ---- , INV or 255 if message is not

received, or if received data is invalid. . N–2

Check that installed wheels and tires are

standard Jaguar fit. Confirm fitted wheel

size in IDS, 'ADD REMOVE ACCESSORY'

section. Non standard wheels and tires or incorrectly set

wheel size may lead to Odometer increment

inaccuracies. This will impact the distance

accumulators, which in turn affects the rolling

average, fuel economy and range values. Trip

distance accumulation will also be incorrect. . N–3

Consider noting odometer value and

resetting fuel computer system. Advise

customer to conduct brim-to-brim fuel

tank test. Use collected information to

determine if system accurate. . Column adjust O-1

Check with IDS for DTCs related to powered column system. . O-2

Check cluster battery supply voltage and

ground resistance. Check for loose

connections. . O-3

Check power column motors supply voltage. . O-4

Check power column switch for physical damage. . Passive Anti-Theft

System (PATS)

indicator P–1

Check for three second prove out when

vehicle start button is pressed. . . P–2

Check for loose connections/wiring continuity. . . P–3 Check ignition switch for physical damage. . Cluster illumination Q–1

Check for loose connections/wiring continuity. . . Q–2 Check dimmer switch operation. . Cluster backlight operation R–1

Is the backlight on other components inoperative. . . R–2 Check dimmer switch operation. . . R–3

Check for loose connections/wiring continuity. . Chime/tone operation S–1 Check vehicle configuration. . . S–2

Utilize lights ON, ignition OFF, door open warning to verify chime operation. . . S–3 Check appropriate sensing circuit. . Continuous chime/tone T–1 Check appropriate sensing circuit. . Unexpected chime operation U–1 Check vehicle configuration. . Message centre display illumination V–1

Is the backlight 'ON' and other components dim? . . V–2

Does the lighting level of other

components change when dimmer adjusted? . Message centre

display issue W–1

Perform Self-Diagnostic Mode test/ETM

tests 5 to 9, to prove out LCD display

function. . Message centre

missing lines X–1

Perform Self-Diagnostic Mode test/ETM

tests 5 to 9, to prove out LCD display

function. . Message centre

incorrect message Y–1 What is the message? . . Y–2

Check for open circuit/shorts in wiring to

related warning light trigger (module,

sensor, switch). . Cluster/connectivity Z–1 Check cluster battery and ignition wiring. . . Z–2 Check cluster grounds. . . Z–3 Disconnect/reconnect cluster. . . Z–4

Attempt to enter Self-Diagnostic

Mode/ETM to prove cluster response to inputs. . No crank AA–1

Check with IDS for presence of related

DTCs. . . AA–2

Is there a Passive Anti-Theft System (PATS) flash code? . . AA–3

Does the vehicle crank with the other passive key? .

Page 2015 of 3039

PINPOINT TEST A : IPOD® INOPERATIVE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK THE OPERATION OF THE IPOD® 1 Check if the iPOD® has crashed or frozen (it is unresponsive to any control commands) Has the iPOD® crashed or frozen?

Yes

Reset the iPOD® or refer to Apple service procedures

No

GO to A2. A2: CHECK THE IPOD® BATTERY 1 Check the charge state of the iPOD® battery Is the iPOD® battery flat?

Yes

Charge the iPOD® battery for at least 10 minutes either by connecting to the charger supplied with the

iPOD® or by connecting to the audio input control module. If iPOD® will not charge when connected to

the audio input control module and with the ignition on thenGO to A3. No

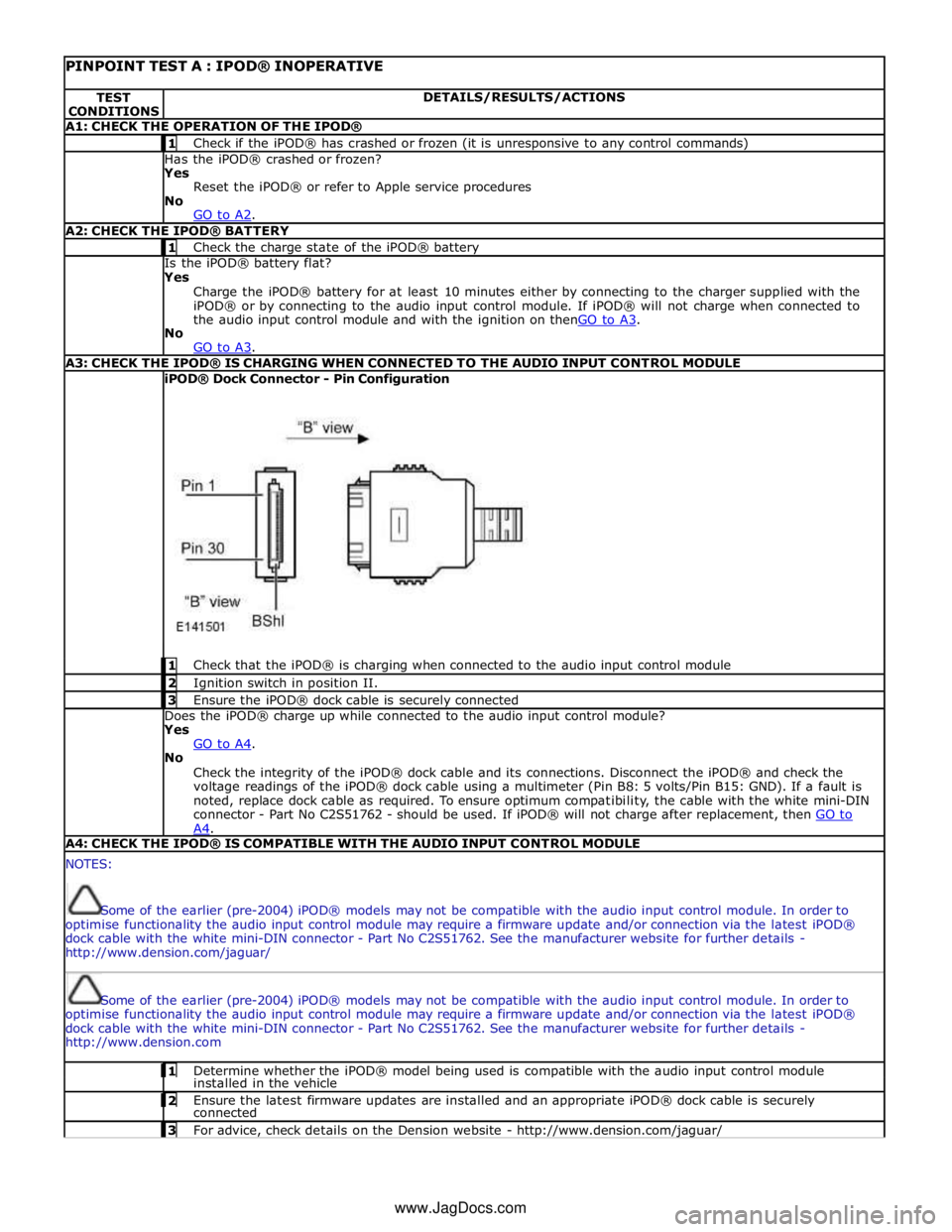

GO to A3. A3: CHECK THE IPOD® IS CHARGING WHEN CONNECTED TO THE AUDIO INPUT CONTROL MODULE iPOD® Dock Connector - Pin Configuration

1 Check that the iPOD® is charging when connected to the audio input control module 2 Ignition switch in position II. 3 Ensure the iPOD® dock cable is securely connected Does the iPOD® charge up while connected to the audio input control module?

Yes

GO to A4. No

Check the integrity of the iPOD® dock cable and its connections. Disconnect the iPOD® and check the

voltage readings of the iPOD® dock cable using a multimeter (Pin B8: 5 volts/Pin B15: GND). If a fault is

noted, replace dock cable as required. To ensure optimum compatibility, the cable with the white mini-DIN

connector - Part No C2S51762 - should be used. If iPOD® will not charge after replacement, then GO to A4. A4: CHECK THE IPOD® IS COMPATIBLE WITH THE AUDIO INPUT CONTROL MODULE NOTES:

Some of the earlier (pre-2004) iPOD® models may not be compatible with the audio input control module. In order to

optimise functionality the audio input control module may require a firmware update and/or connection via the latest iPOD®

dock cable with the white mini-DIN connector - Part No C2S51762. See the manufacturer website for further details -

http://www.dension.com/jaguar/

Some of the earlier (pre-2004) iPOD® models may not be compatible with the audio input control module. In order to

optimise functionality the audio input control module may require a firmware update and/or connection via the latest iPOD®

dock cable with the white mini-DIN connector - Part No C2S51762. See the manufacturer website for further details -

http://www.dension.com 1 Determine whether the iPOD® model being used is compatible with the audio input control module installed in the vehicle 2 Ensure the latest firmware updates are installed and an appropriate iPOD® dock cable is securely connected 3 For advice, check details on the Dension website - http://www.dension.com/jaguar/ www.JagDocs.com