Dtc JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2132 of 3039

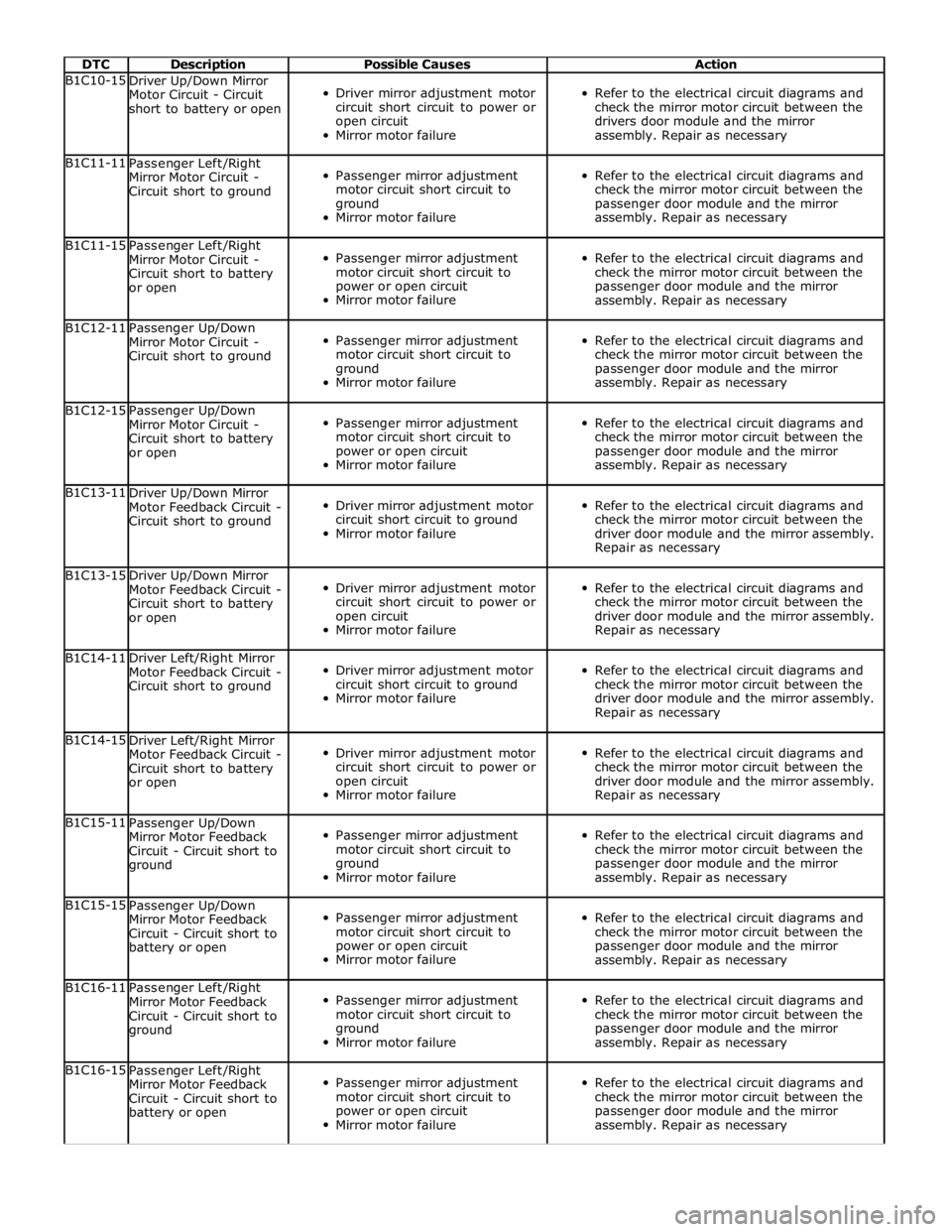

DTC Description Possible Causes Action B1C10-15

Driver Up/Down Mirror

Motor Circuit - Circuit

short to battery or open

Driver mirror adjustment motor

circuit short circuit to power or

open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

drivers door module and the mirror

assembly. Repair as necessary B1C11-11

Passenger Left/Right

Mirror Motor Circuit -

Circuit short to ground

Passenger mirror adjustment

motor circuit short circuit to

ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C11-15

Passenger Left/Right

Mirror Motor Circuit -

Circuit short to battery

or open

Passenger mirror adjustment

motor circuit short circuit to

power or open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C12-11

Passenger Up/Down

Mirror Motor Circuit -

Circuit short to ground

Passenger mirror adjustment

motor circuit short circuit to

ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C12-15

Passenger Up/Down

Mirror Motor Circuit -

Circuit short to battery

or open

Passenger mirror adjustment

motor circuit short circuit to

power or open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C13-11

Driver Up/Down Mirror

Motor Feedback Circuit -

Circuit short to ground

Driver mirror adjustment motor

circuit short circuit to ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

driver door module and the mirror assembly.

Repair as necessary B1C13-15

Driver Up/Down Mirror

Motor Feedback Circuit -

Circuit short to battery

or open

Driver mirror adjustment motor

circuit short circuit to power or

open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

driver door module and the mirror assembly.

Repair as necessary B1C14-11

Driver Left/Right Mirror

Motor Feedback Circuit -

Circuit short to ground

Driver mirror adjustment motor

circuit short circuit to ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

driver door module and the mirror assembly.

Repair as necessary B1C14-15

Driver Left/Right Mirror

Motor Feedback Circuit -

Circuit short to battery

or open

Driver mirror adjustment motor

circuit short circuit to power or

open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

driver door module and the mirror assembly.

Repair as necessary B1C15-11

Passenger Up/Down

Mirror Motor Feedback

Circuit - Circuit short to

ground

Passenger mirror adjustment

motor circuit short circuit to

ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C15-15

Passenger Up/Down

Mirror Motor Feedback

Circuit - Circuit short to

battery or open

Passenger mirror adjustment

motor circuit short circuit to

power or open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C16-11

Passenger Left/Right

Mirror Motor Feedback

Circuit - Circuit short to

ground

Passenger mirror adjustment

motor circuit short circuit to

ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C16-15

Passenger Left/Right

Mirror Motor Feedback

Circuit - Circuit short to

battery or open

Passenger mirror adjustment

motor circuit short circuit to

power or open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary

Page 2133 of 3039

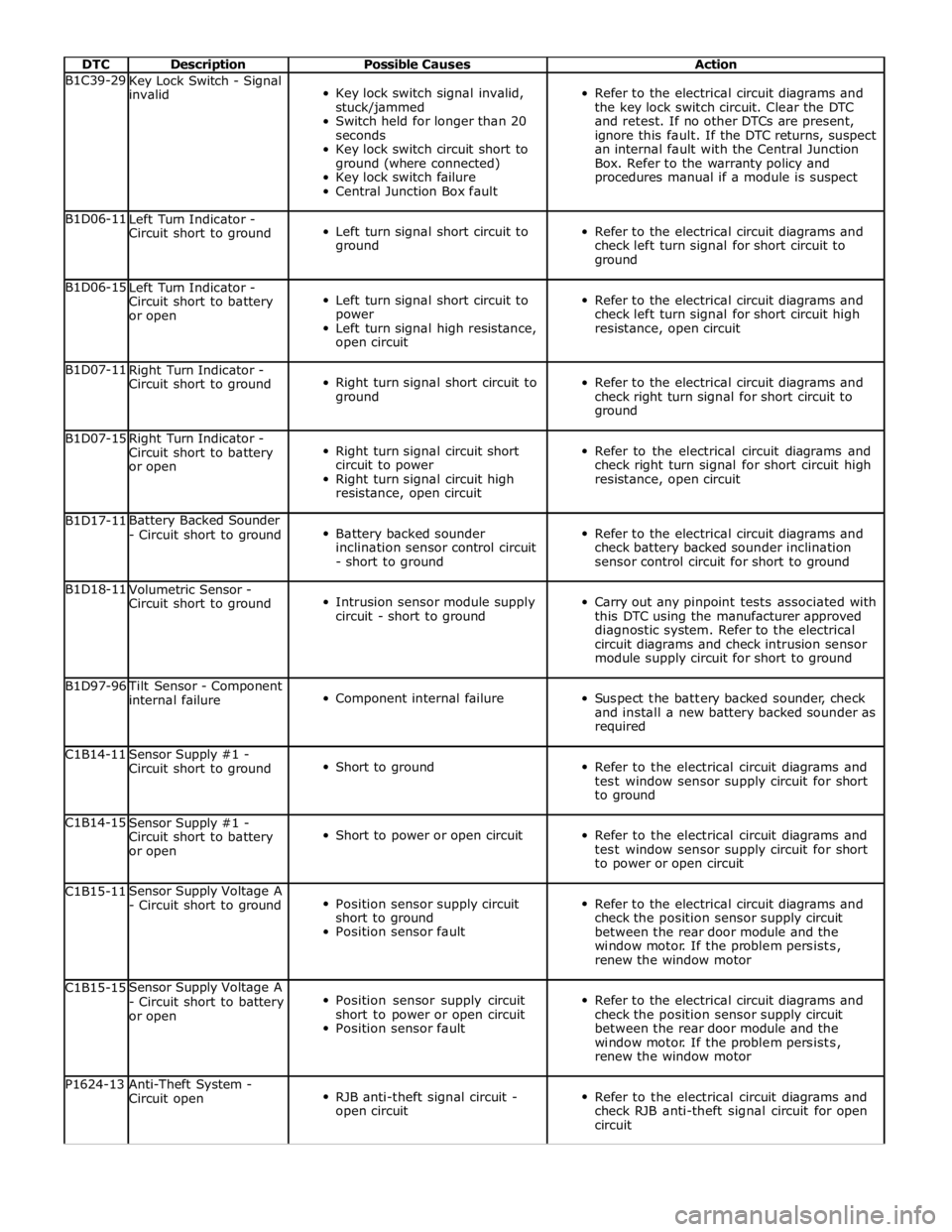

DTC Description Possible Causes Action B1C39-29

Key Lock Switch - Signal

invalid

Key lock switch signal invalid,

stuck/jammed

Switch held for longer than 20

seconds

Key lock switch circuit short to

ground (where connected)

Key lock switch failure

Central Junction Box fault

Refer to the electrical circuit diagrams and

the key lock switch circuit. Clear the DTC

and retest. If no other DTCs are present,

ignore this fault. If the DTC returns, suspect

an internal fault with the Central Junction

Box. Refer to the warranty policy and

procedures manual if a module is suspect B1D06-11

Left Turn Indicator -

Circuit short to ground

Left turn signal short circuit to

ground

Refer to the electrical circuit diagrams and

check left turn signal for short circuit to

ground B1D06-15

Left Turn Indicator -

Circuit short to battery

or open

Left turn signal short circuit to

power

Left turn signal high resistance,

open circuit

Refer to the electrical circuit diagrams and

check left turn signal for short circuit high

resistance, open circuit B1D07-11

Right Turn Indicator -

Circuit short to ground

Right turn signal short circuit to

ground

Refer to the electrical circuit diagrams and

check right turn signal for short circuit to

ground B1D07-15

Right Turn Indicator -

Circuit short to battery

or open

Right turn signal circuit short

circuit to power

Right turn signal circuit high

resistance, open circuit

Refer to the electrical circuit diagrams and

check right turn signal for short circuit high

resistance, open circuit B1D17-11 Battery Backed Sounder

- Circuit short to ground

Battery backed sounder

inclination sensor control circuit

- short to ground

Refer to the electrical circuit diagrams and

check battery backed sounder inclination

sensor control circuit for short to ground B1D18-11

Volumetric Sensor -

Circuit short to ground

Intrusion sensor module supply

circuit - short to ground

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and check intrusion sensor

module supply circuit for short to ground B1D97-96 Tilt Sensor - Component

internal failure

Component internal failure

Suspect the battery backed sounder, check

and install a new battery backed sounder as

required C1B14-11

Sensor Supply #1 -

Circuit short to ground

Short to ground

Refer to the electrical circuit diagrams and

test window sensor supply circuit for short

to ground C1B14-15

Sensor Supply #1 -

Circuit short to battery

or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test window sensor supply circuit for short

to power or open circuit C1B15-11 Sensor Supply Voltage A

- Circuit short to ground

Position sensor supply circuit

short to ground

Position sensor fault

Refer to the electrical circuit diagrams and

check the position sensor supply circuit

between the rear door module and the

window motor. If the problem persists,

renew the window motor C1B15-15 Sensor Supply Voltage A

- Circuit short to battery

or open

Position sensor supply circuit

short to power or open circuit

Position sensor fault

Refer to the electrical circuit diagrams and

check the position sensor supply circuit

between the rear door module and the

window motor. If the problem persists,

renew the window motor P1624-13

Anti-Theft System -

Circuit open

RJB anti-theft signal circuit -

open circuit

Refer to the electrical circuit diagrams and

check RJB anti-theft signal circuit for open

circuit

Page 2134 of 3039

DTC Description Possible Causes Action P254F-13

Engine Hood Switch

Circuit/Open - Circuit

open

Hood ajar switch signal circuit -

open circuit

Refer to the electrical circuit diagrams and

check hood ajar switch signal circuit for open

circuit U0010-00

Medium Speed CAN

Communication Bus - No

sub type information

Medium speed CAN

communication Bus

Carry out network integrity test using

manufacturer approved diagnostic system.

Refer to electrical circuit diagrams and test

Medium speed CAN network for open, short

circuit and high resistance U0140-00

Lost Communication

With CJB - No sub type

information

Logged when subscribed CAN

message missing from CJB

Refer to the electrical circuit diagrams and

test power and ground supplies to Central

Junction Box. Check CAN network between

Driver Door Module and Central Junction

Box. Carry out network integrity test using

manufacturer approved diagnostic system U0208-00

Lost Communication

With Driver Seat Module

(DSM) - No sub type

information

Missing message

Refer to the electrical circuit diagrams and

test power and ground supplies to Driver

Seat Module. Check CAN network between

Driver Door Module and Driver Seat Module.

Carry out network integrity test using

manufacturer approved diagnostic system U0300-00

Internal Control Module

Software Incompatibility

- No sub type

information

Car configuration file mismatch

with vehicle specification

NOTE: After updating the car configuration

file, set the ignition to on and wait 30 seconds

before clearing the DTCs

Using the manufacturer approved diagnostic

system, check and up-date the car

configuration file as necessary U2002-24

Switch - Signal stuck

high

Signal stuck high

Clear DTC and re-test. If DTC remains,

install a new passenger side window switch U2004-24

Auxiliary Switch Pack -

Signal stuck high

Signal stuck high

Left or right rear door local

switch pressed for longer than

20 seconds

Switch circuit short to ground or

power

Refer to the electrical circuit diagrams and

check the left and right door switch circuits U2010-11

Switch Illumination -

Circuit short to ground

Switch illumination circuit short

to ground

Refer to electrical circuit diagrams and check

the switch illumination circuit U2012-08

Car Configuration

Parameter(s) - Bus

signal/message failures

Bus signal/message failures

Cycle the ignition status and re-test. If DTC

remains, re-configure the RJB using the

manufacturer approved diagnostic system U2013-24

Switch Pack - Signal

stuck high

Signal stuck high

Clear DTC and re-test. If DTC remains,

install a new driver side window switch pack U2014-44

Control Module

Hardware - Data

memory failure

Data Memory Failure

Install a new DDM/PDM, Refer to the

warranty policy and procedures manual if a

module is suspect U2100-00

Initial Configuration Not

Complete - No sub type

information

Driver/passenger door module is

not configured correctly

Re-configure the DDM/PDM using the

manufacturer approved diagnostic system U2101-00

Control Module

Configuration

Incompatible - No sub

type information

Car configuration file mismatch

with vehicle specification

Re-configure the module using the

manufacturer approved diagnostic system.

Check the configuration of the Car

Configuration File (CCF)

Page 2135 of 3039

DTC Description Possible Causes Action U3003-62

Battery Voltage - Signal

compare failure

Mis-match of battery voltage, of

2 volts or lower, between

DDM/PDM and RJB

Check vehicle battery and charging system.

Refer to the relevant section in the

workshop manual. Refer to the electrical

circuit diagrams and check the power and

ground supply circuits to both modules www.JagDocs.com

Page 2145 of 3039

Anti-Theft - Passive (Description and Operation), Anti-Theft - Passive (Description and Operation).

Inspection and Verification

Anti-theft - Passive

The best method to confirm the correct operation of the Passive Anti-Theft System (PATS) is to check the LED (located in the

center of the instrument panel). The LED should illuminate solid for 3 seconds, when the ignition status is set to ON, and then

extinguish. This validates all PATS functions (i.e. the key transponder matches a stored key code, the challenge/response

sequence between the respective modules was successful resulting in the EMS being enabled).

Ignition fails to operate

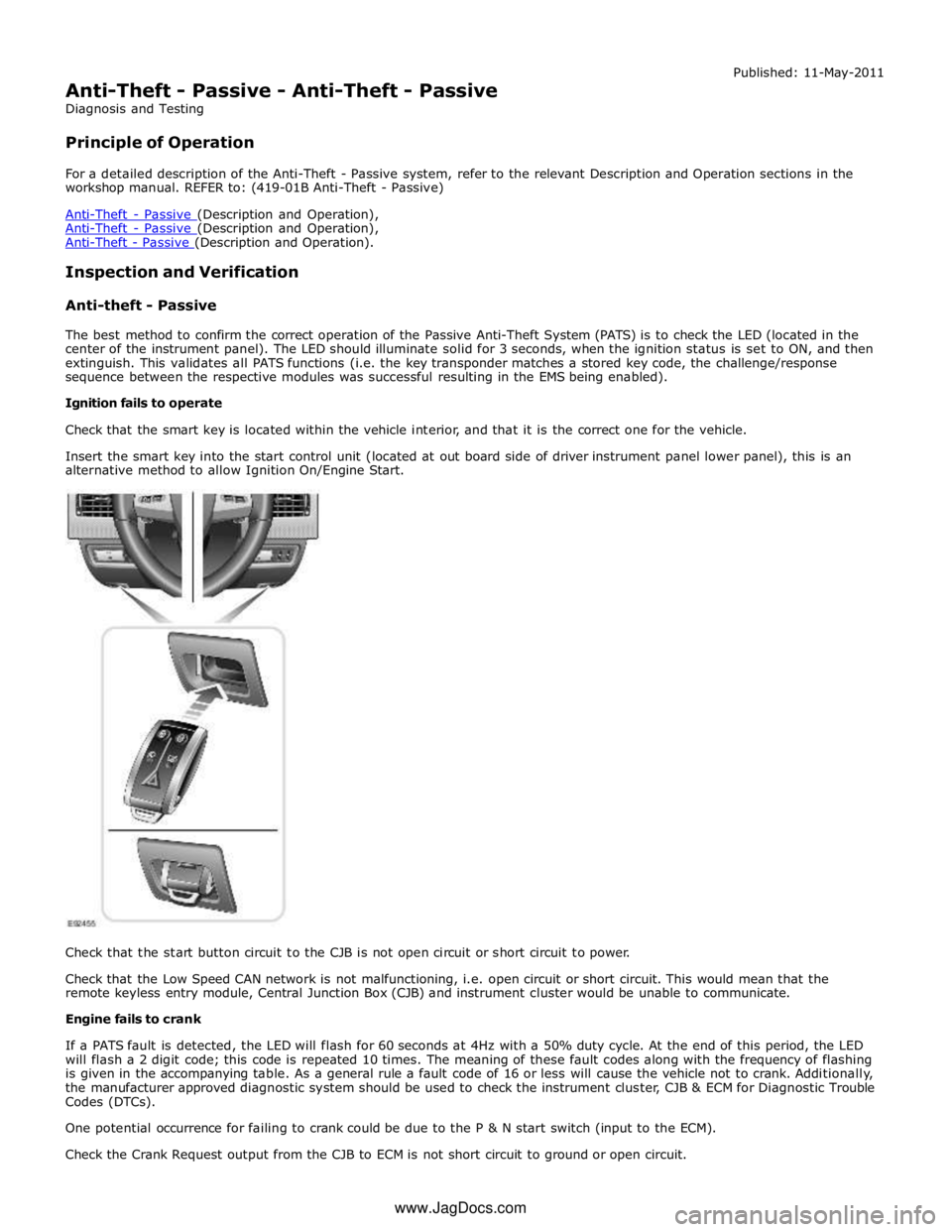

Check that the smart key is located within the vehicle interior, and that it is the correct one for the vehicle.

Insert the smart key into the start control unit (located at out board side of driver instrument panel lower panel), this is an

alternative method to allow Ignition On/Engine Start.

Check that the start button circuit to the CJB is not open circuit or short circuit to power.

Check that the Low Speed CAN network is not malfunctioning, i.e. open circuit or short circuit. This would mean that the

remote keyless entry module, Central Junction Box (CJB) and instrument cluster would be unable to communicate.

Engine fails to crank

If a PATS fault is detected, the LED will flash for 60 seconds at 4Hz with a 50% duty cycle. At the end of this period, the LED

will flash a 2 digit code; this code is repeated 10 times. The meaning of these fault codes along with the frequency of flashing

is given in the accompanying table. As a general rule a fault code of 16 or less will cause the vehicle not to crank. Additionally,

the manufacturer approved diagnostic system should be used to check the instrument cluster, CJB & ECM for Diagnostic Trouble

Codes (DTCs).

One potential occurrence for failing to crank could be due to the P & N start switch (input to the ECM).

Check the Crank Request output from the CJB to ECM is not short circuit to ground or open circuit. www.JagDocs.com

Page 2146 of 3039

Check the Starter Relay circuit.

NOTE: On petrol engine variants, due to Smart Start, both sides of Relay Coil are switched directly from ECM (If

conditions correct). On diesel engine variants the low side only is switched directly from the ECM.

Check that the Steering Column Lock correctly operates and the steering wheel can turn freely.

Check that the High Speed CAN network is not malfunctioning, i.e. the CAN circuit is open or short circuit. This would mean

that the instrument cluster and ECM would be unable to communicate resulting in no Challenge being performed to enable the

ECM. This would be supported by LED Flash Code 24, see PATS Fault Code Table.

Also check the CAN network between the ABS module and the CJB. The CJB uses the CAN_BrakePressureTMC signal to

determine if the brake pedal has been pressed in order to allow an engine crank. The CJB uses a value of 0x05, if the CJB sees

a value less than this, it will not enable the Crank Request Output.

Engine cranks but will not start

If the Engine is cranking it means that the ECM has passed the authorisation required with the Instrument Cluster. If this

authorisation failed, the ECM would not engage the starter relay. This could be confirmed by verifying the PATS LED prove out

(illuminated solid for 3 seconds) or by reading DTCs from the instrument cluster and ECM.

In this case, the fuel pump circuit should be verified. The Fuel Pump Delivery Module (FPDM), which is supplied via the RJB

(authentication required with the instrument cluster) and controlled by the ECM, supplies the fuel pump.

In all cases of suspected non-start issues, the most logical failure modes should be eliminated first. i.e.

1. Check all relevant supplies and grounds to the relevant modules listed herein.

2. Note any unusual behaviour from other systems/functionality.

3. Note any functions that are not operating as expected.

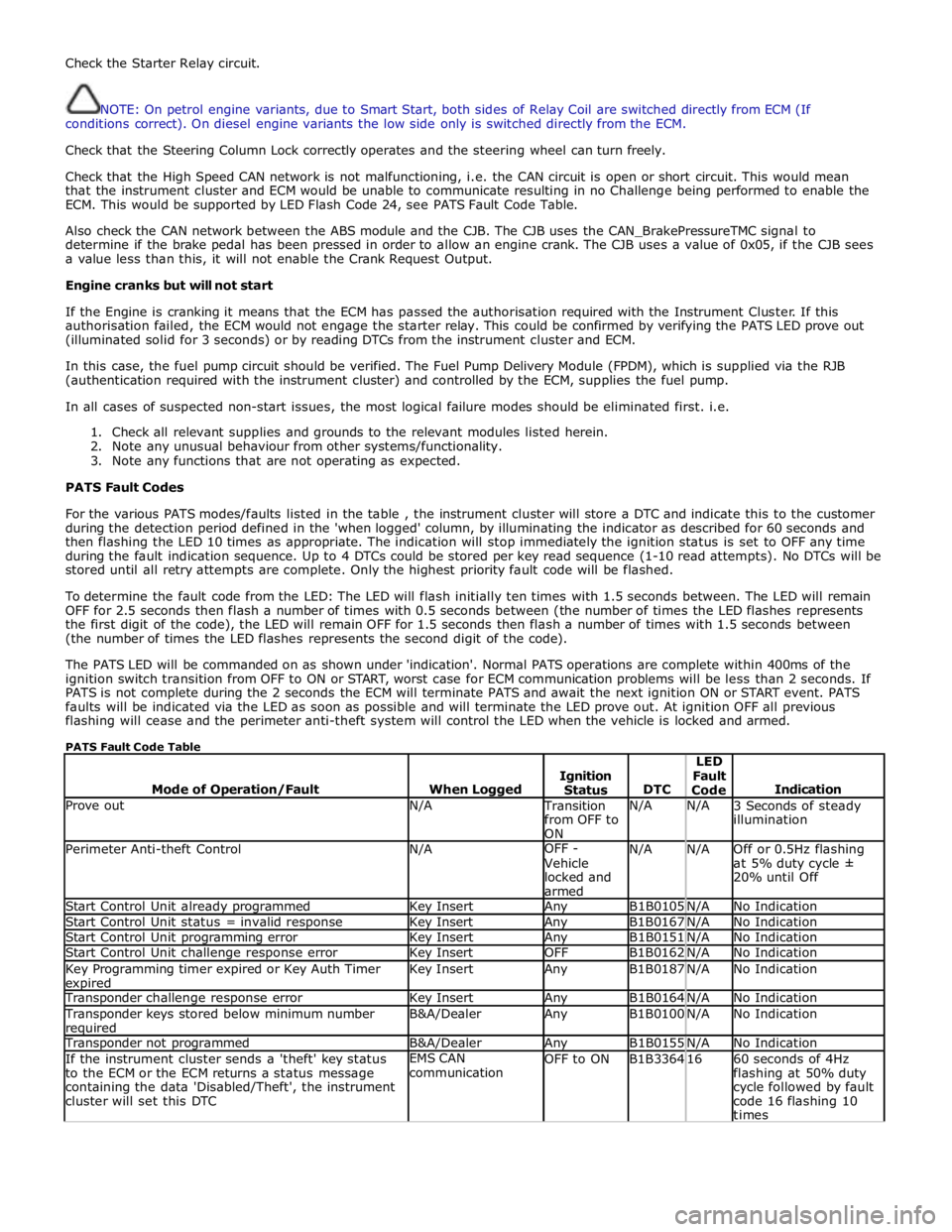

PATS Fault Codes

For the various PATS modes/faults listed in the table , the instrument cluster will store a DTC and indicate this to the customer

during the detection period defined in the 'when logged' column, by illuminating the indicator as described for 60 seconds and

then flashing the LED 10 times as appropriate. The indication will stop immediately the ignition status is set to OFF any time

during the fault indication sequence. Up to 4 DTCs could be stored per key read sequence (1-10 read attempts). No DTCs will be

stored until all retry attempts are complete. Only the highest priority fault code will be flashed.

To determine the fault code from the LED: The LED will flash initially ten times with 1.5 seconds between. The LED will remain

OFF for 2.5 seconds then flash a number of times with 0.5 seconds between (the number of times the LED flashes represents

the first digit of the code), the LED will remain OFF for 1.5 seconds then flash a number of times with 1.5 seconds between

(the number of times the LED flashes represents the second digit of the code).

The PATS LED will be commanded on as shown under 'indication'. Normal PATS operations are complete within 400ms of the

ignition switch transition from OFF to ON or START, worst case for ECM communication problems will be less than 2 seconds. If

PATS is not complete during the 2 seconds the ECM will terminate PATS and await the next ignition ON or START event. PATS

faults will be indicated via the LED as soon as possible and will terminate the LED prove out. At ignition OFF all previous

flashing will cease and the perimeter anti-theft system will control the LED when the vehicle is locked and armed.

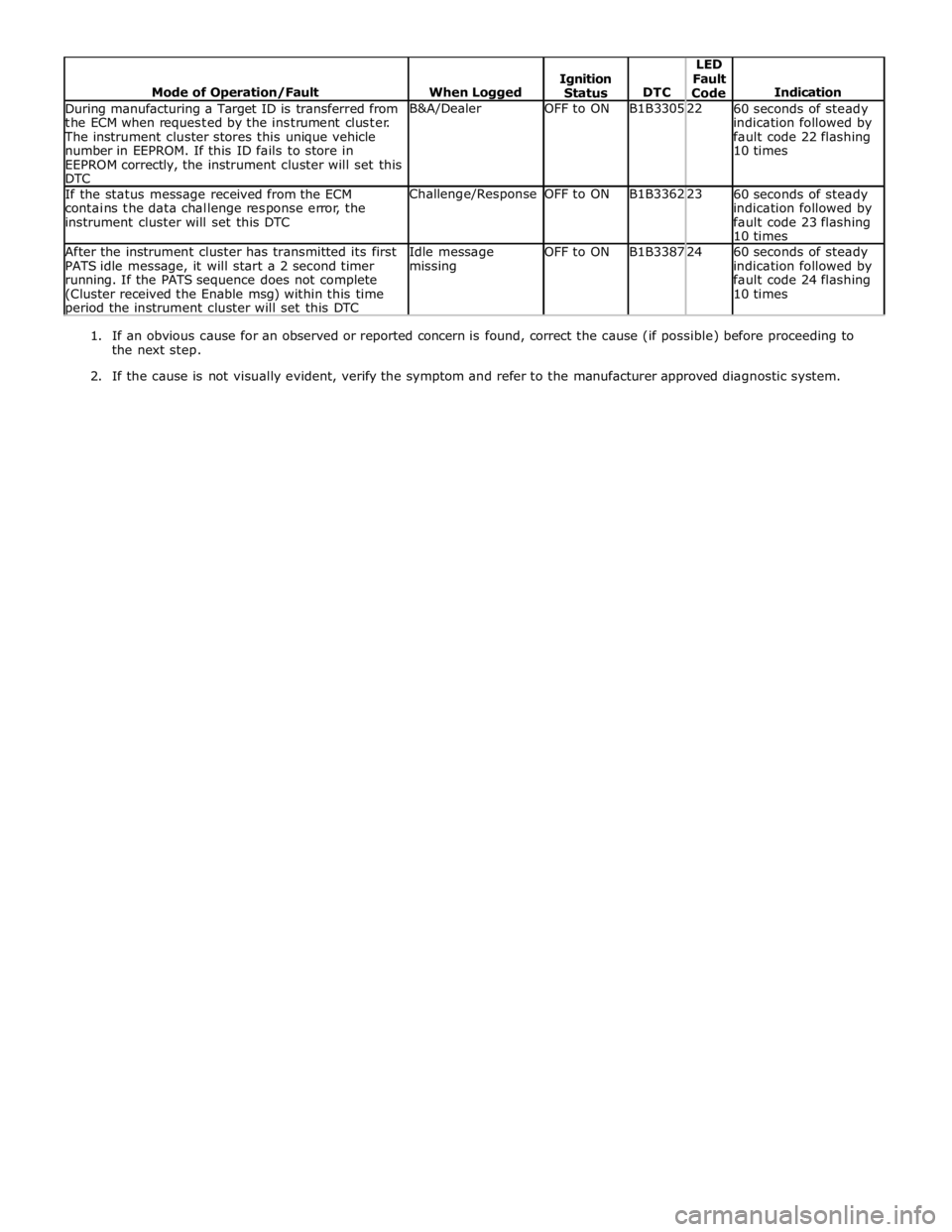

PATS Fault Code Table

Mode of Operation/Fault

When Logged

Ignition

Status

DTC LED

Fault

Code

Indication Prove out N/A Transition

from OFF to

ON N/A N/A

3 Seconds of steady

illumination Perimeter Anti-theft Control N/A OFF -

Vehicle

locked and

armed N/A N/A

Off or 0.5Hz flashing

at 5% duty cycle ±

20% until Off Start Control Unit already programmed Key Insert Any B1B0105 N/A No Indication Start Control Unit status = invalid response Key Insert Any B1B0167 N/A No Indication Start Control Unit programming error Key Insert Any B1B0151 N/A No Indication Start Control Unit challenge response error Key Insert OFF B1B0162 N/A No Indication Key Programming timer expired or Key Auth Timer expired Key Insert Any B1B0187 N/A No Indication Transponder challenge response error Key Insert Any B1B0164 N/A No Indication Transponder keys stored below minimum number required B&A/Dealer Any B1B0100 N/A No Indication Transponder not programmed B&A/Dealer Any B1B0155 N/A No Indication If the instrument cluster sends a 'theft' key status

to the ECM or the ECM returns a status message

containing the data 'Disabled/Theft', the instrument

cluster will set this DTC EMS CAN

communication OFF to ON B1B3364 16

60 seconds of 4Hz

flashing at 50% duty

cycle followed by fault

code 16 flashing 10

times

Page 2147 of 3039

During manufacturing a Target ID is transferred from

the ECM when requested by the instrument cluster. The instrument cluster stores this unique vehicle

number in EEPROM. If this ID fails to store in

EEPROM correctly, the instrument cluster will set this

DTC B&A/Dealer OFF to ON B1B3305 22

60 seconds of steady

indication followed by

fault code 22 flashing

10 times If the status message received from the ECM

contains the data challenge response error, the

instrument cluster will set this DTC Challenge/Response OFF to ON B1B3362 23

60 seconds of steady

indication followed by

fault code 23 flashing

10 times After the instrument cluster has transmitted its first

PATS idle message, it will start a 2 second timer

running. If the PATS sequence does not complete

(Cluster received the Enable msg) within this time period the instrument cluster will set this DTC Idle message

missing OFF to ON B1B3387 24

60 seconds of steady

indication followed by

fault code 24 flashing

10 times

1. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

2. If the cause is not visually evident, verify the symptom and refer to the manufacturer approved diagnostic system.

Page 2149 of 3039

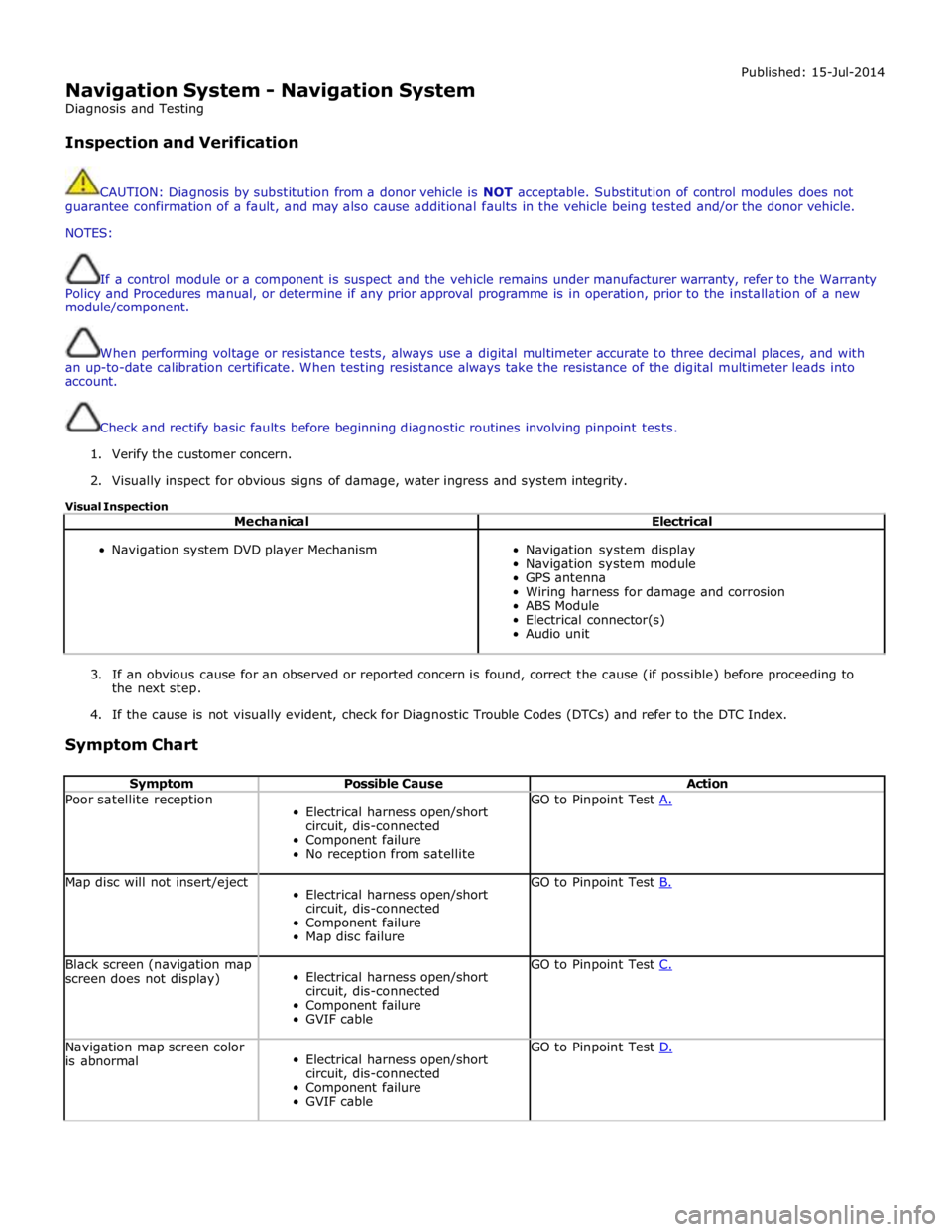

Navigation System - Navigation System

Diagnosis and Testing

Inspection and Verification Published: 15-Jul-2014

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage, water ingress and system integrity.

Visual Inspection

Mechanical Electrical

Navigation system DVD player Mechanism

Navigation system display

Navigation system module

GPS antenna

Wiring harness for damage and corrosion

ABS Module

Electrical connector(s)

Audio unit

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Cause Action Poor satellite reception

Electrical harness open/short

circuit, dis-connected

Component failure

No reception from satellite GO to Pinpoint Test A. Map disc will not insert/eject

Electrical harness open/short

circuit, dis-connected

Component failure

Map disc failure GO to Pinpoint Test B. Black screen (navigation map

screen does not display)

Electrical harness open/short

circuit, dis-connected

Component failure

GVIF cable GO to Pinpoint Test C. Navigation map screen color

is abnormal

Electrical harness open/short

circuit, dis-connected

Component failure

GVIF cable GO to Pinpoint Test D.

Page 2150 of 3039

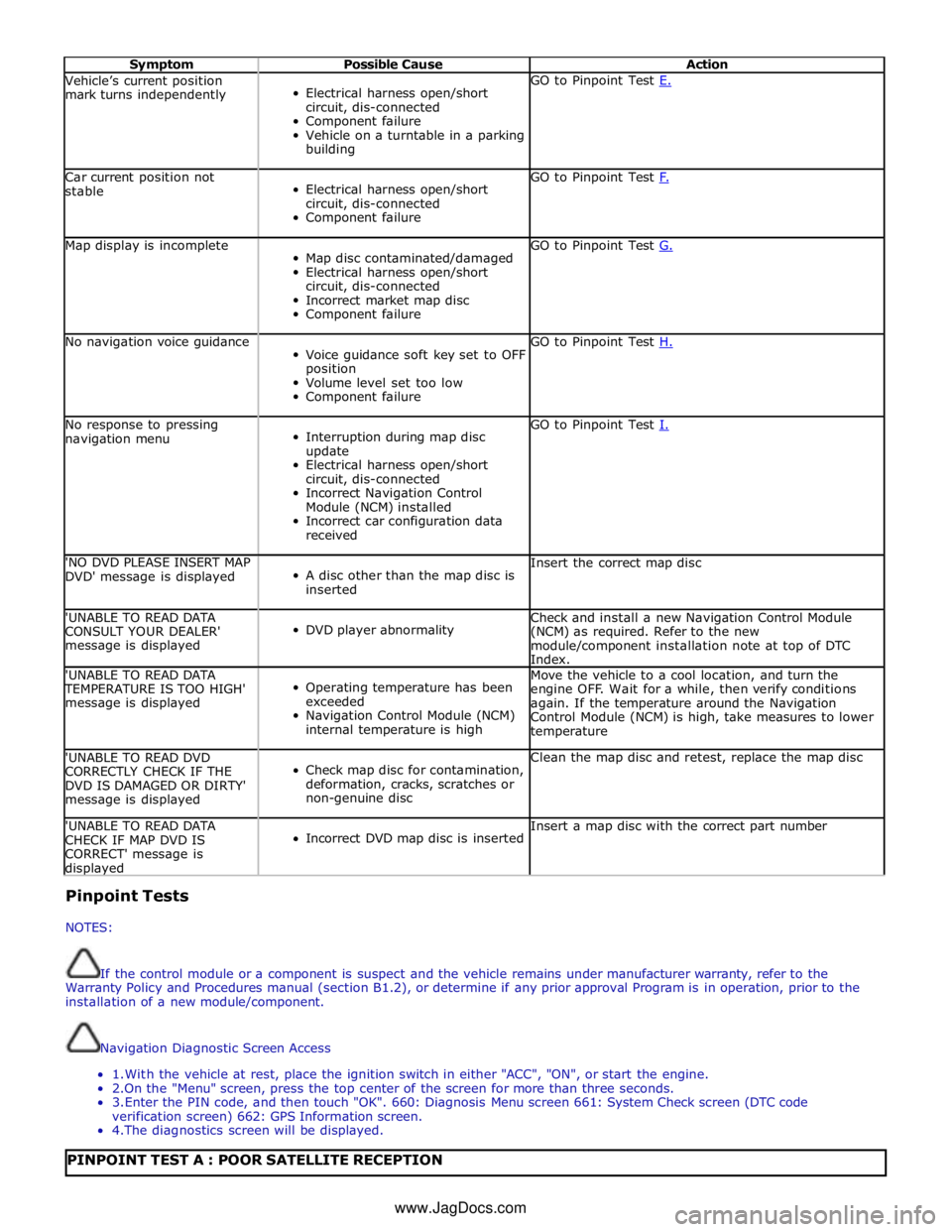

Symptom Possible Cause Action Vehicle’s current position

mark turns independently

Electrical harness open/short

circuit, dis-connected

Component failure

Vehicle on a turntable in a parking

building GO to Pinpoint Test E. Car current position not

stable

Electrical harness open/short

circuit, dis-connected

Component failure GO to Pinpoint Test F. Map display is incomplete

Map disc contaminated/damaged

Electrical harness open/short

circuit, dis-connected

Incorrect market map disc

Component failure GO to Pinpoint Test G. No navigation voice guidance

Voice guidance soft key set to OFF

position

Volume level set too low

Component failure GO to Pinpoint Test H. No response to pressing

navigation menu

Interruption during map disc

update

Electrical harness open/short

circuit, dis-connected

Incorrect Navigation Control

Module (NCM) installed

Incorrect car configuration data

received GO to Pinpoint Test I. 'NO DVD PLEASE INSERT MAP

DVD' message is displayed

A disc other than the map disc is

inserted Insert the correct map disc 'UNABLE TO READ DATA

CONSULT YOUR DEALER'

message is displayed

DVD player abnormality Check and install a new Navigation Control Module

(NCM) as required. Refer to the new

module/component installation note at top of DTC

Index. 'UNABLE TO READ DATA TEMPERATURE IS TOO HIGH'

message is displayed

Operating temperature has been

exceeded

Navigation Control Module (NCM)

internal temperature is high Move the vehicle to a cool location, and turn the

engine OFF. Wait for a while, then verify conditions

again. If the temperature around the Navigation

Control Module (NCM) is high, take measures to lower

temperature 'UNABLE TO READ DVD

CORRECTLY CHECK IF THE

DVD IS DAMAGED OR DIRTY'

message is displayed

Check map disc for contamination,

deformation, cracks, scratches or

non-genuine disc Clean the map disc and retest, replace the map disc 'UNABLE TO READ DATA

CHECK IF MAP DVD IS

CORRECT' message is displayed

Incorrect DVD map disc is inserted Insert a map disc with the correct part number Pinpoint Tests

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval Program is in operation, prior to the

installation of a new module/component.

Navigation Diagnostic Screen Access

1. With the vehicle at rest, place the ignition switch in either "ACC", "ON", or start the engine.

2.On the "Menu" screen, press the top center of the screen for more than three seconds.

3. Enter the PIN code, and then touch "OK". 660: Diagnosis Menu screen 661: System Check screen (DTC code

verification screen) 662: GPS Information screen.

4. The diagnostics screen will be displayed.

PINPOINT TEST A : POOR SATELLITE RECEPTION www.JagDocs.com

Page 2151 of 3039

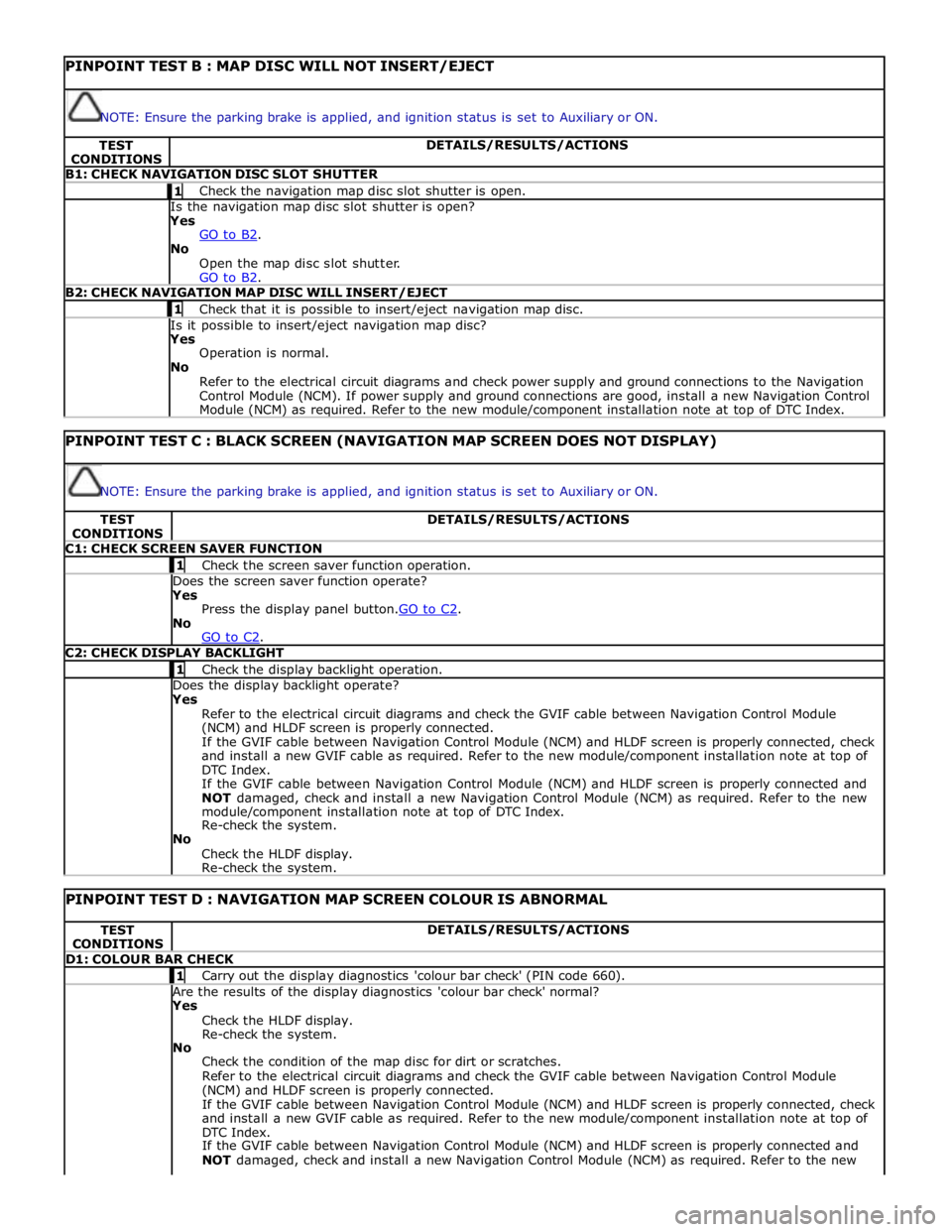

PINPOINT TEST B : MAP DISC WILL NOT INSERT/EJECT

NOTE: Ensure the parking brake is applied, and ignition status is set to Auxiliary or ON. TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK NAVIGATION DISC SLOT SHUTTER 1 Check the navigation map disc slot shutter is open. Is the navigation map disc slot shutter is open? Yes

GO to B2. No

Open the map disc slot shutter.

GO to B2. B2: CHECK NAVIGATION MAP DISC WILL INSERT/EJECT 1 Check that it is possible to insert/eject navigation map disc. Is it possible to insert/eject navigation map disc? Yes

Operation is normal.

No

Refer to the electrical circuit diagrams and check power supply and ground connections to the Navigation

Control Module (NCM). If power supply and ground connections are good, install a new Navigation Control

Module (NCM) as required. Refer to the new module/component installation note at top of DTC Index.

PINPOINT TEST C : BLACK SCREEN (NAVIGATION MAP SCREEN DOES NOT DISPLAY)

NOTE: Ensure the parking brake is applied, and ignition status is set to Auxiliary or ON. TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK SCREEN SAVER FUNCTION 1 Check the screen saver function operation. Does the screen saver function operate? Yes

Press the display panel button.GO to C2. No

GO to C2. C2: CHECK DISPLAY BACKLIGHT 1 Check the display backlight operation. Does the display backlight operate? Yes

Refer to the electrical circuit diagrams and check the GVIF cable between Navigation Control Module

(NCM) and HLDF screen is properly connected.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected, check

and install a new GVIF cable as required. Refer to the new module/component installation note at top of

DTC Index.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected and

NOT damaged, check and install a new Navigation Control Module (NCM) as required. Refer to the new

module/component installation note at top of DTC Index.

Re-check the system.

No

Check the HLDF display.

Re-check the system.

PINPOINT TEST D : NAVIGATION MAP SCREEN COLOUR IS ABNORMAL TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: COLOUR BAR CHECK 1 Carry out the display diagnostics 'colour bar check' (PIN code 660). Are the results of the display diagnostics 'colour bar check' normal? Yes

Check the HLDF display.

Re-check the system.

No

Check the condition of the map disc for dirt or scratches.

Refer to the electrical circuit diagrams and check the GVIF cable between Navigation Control Module

(NCM) and HLDF screen is properly connected.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected, check

and install a new GVIF cable as required. Refer to the new module/component installation note at top of

DTC Index.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected and

NOT damaged, check and install a new Navigation Control Module (NCM) as required. Refer to the new