engine JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1360 of 3039

4 Diagnostic socket 5 To other system control modules 6 ECM 7 Electronic throttle 8 APP sensor 9 AAT sensor 10 ECT sensor (ECT 1) 11 LH upstream HO2S 12 LH downstream HO2S 13 MAPT (manifold absolute pressure and temperature) sensor 14 RH downstream HO2S 15 RH upstream HO2S

ECM ADAPTIONS System Operation

The ECM (engine control module) has the ability to adapt the input values it uses to control certain outputs. This capability

maintains engine refinement and ensures the engine emissions remain within the legislated limits. The components which

have adaptions associated with them are:

The APP (accelerator pedal position) sensor

The heated oxygen sensors

The MAFT (mass air flow and temperature) sensors

The CKP (crankshaft position) sensor

Electronic throttle.

OXYGEN AND MAFT SENSORS

There are several adaptive maps associated with the fueling strategy. Within the fueling strategy the ECM calculates short-term adaptions and long term adaptions. The ECM will monitor the deterioration of the heated oxygen sensors over a period of time. It will also monitor the current correction associated with the sensors.

The ECM will store a fault code in circumstances where an adaption is forced to exceed its operating parameters. At the same time, the ECM will record the engine speed, engine load and intake air temperature.

CRANKSHAFT POSITION SENSOR

The characteristics of the signal supplied by the CKP sensor are learned by the ECM. This enables the ECM to set an adaption and support the engine misfire detection function. Due to the small variation between different drive plates and different CKP sensors, the adaption must be reset if either component is renewed, or removed and refitted. It is also necessary to reset the

drive plate adaption if the ECM is renewed or replaced. The ECM supports four drive plate adaptions for the CKP sensor. Each adaption relates to a specific engine speed range. The engine speed ranges are detailed in the table below:

Adaption Engine Speed, rev/min 1 1800 - 3000 2 3001 - 3800 3 3801 - 4600 4 4601 - 5400 MISFIRE DETECTION

Legislation requires that the ECM must be able to detect the presence of an engine misfire. It must be able to detect misfires at two separate levels. The first level is a misfire that could lead to the legislated emissions limit being exceeded by a given

amount. The second level is a misfire that may cause catalytic converter damage.

The ECM monitors the number of misfire occurrences within two engine speed ranges. If the ECM detects more than a predetermined number of misfire occurrences within either of these two ranges, over two consecutive journeys, it will record a

fault code and details of the engine speed, engine load and engine coolant temperature. In addition, the ECM monitors the number of misfire occurrences that happen in a 'window' of 200 engine revolutions. The misfire occurrences are assigned a

weighting according to their likely impact on the catalytic converters. If the number of misfires exceeds a given value, the ECM stores catalytic converter damage fault codes, along with the engine speed, engine load and engine coolant temperature.

The signal from the CKP sensor indicates how fast the poles on the drive plate are passing the sensor tip. A sine wave is generated each time a pole passes the sensor tip. The ECM can detect variations in drive plate speed by monitoring the sine wave signal supplied by the crankshaft position sensor. By assessing this signal, the ECM can detect the presence of an engine misfire. At this time, the ECM will assess the amount of variation in the signal received from the CKP sensor and assign a roughness value to it. This roughness value can be viewed within the real time monitoring feature using Jaguar approved

diagnostic equipment. TheECM will evaluate the signal against a number of factors and will decide whether to record the occurrence or ignore it. The ECM can assign a roughness and misfire signal for each cylinder.

Page 1361 of 3039

DIAGNOSTICS

The ECM stores each fault as a DTC (diagnostic trouble code). The DTC and associated environmental and freeze frame data can be read using Jaguar approved diagnostic equipment, which can also read real time data from each sensor, the adaption

values currently being employed and the current fueling, ignition and idle speed settings.

ENGINE CONTROL MODULE Component Description

The ECM is installed in the front passenger side of the engine compartment, on a bracket attached to the engine bulkhead. The ECM has the capability of adapting its fuel and ignition control outputs in response to several sensor inputs. The ECM receives inputs from the following:

CKP sensor. CMP (camshaft position) sensors (4 off).

ECT (engine coolant temperature) sensor.

Knock sensors (4 off).

MAP (manifold absolute pressure) sensor.

MAFT sensors (2 off). MAPT (manifold absolute pressure and temperature) sensor.

Throttle position sensor.

Heated oxygen sensors (4 off).

APP sensor. Ambient air temperature sensor.

FRP (fuel rail pressure) sensor. For additional information, refer to 303-04G Fuel Charging and Controls.

Engine cooling fan. For additional information, refer to 303-03D Engine Cooling.

Stoplamp switch. For additional information, refer to 206-09 Anti-Lock Control - Stability Assist.

Speed control cancel/suspend switch. For additional information, refer to 310-03D Speed Control.

Oil level and temperature sensor. For additional information, refer to 303-01F Engine.

Fuel LP (low pressure) sensor. For additional information, refer to 310-01D Fuel Tank and Lines.

Fuel pump driver module. For additional information, refer to 310-01D Fuel Tank and Lines.

The ECM provides outputs to the following: Electronic throttle.

Main relay.

Heater elements of the heated oxygen sensors (4 off).

Fuel injectors (8 off). For additional information, refer to 303-04G Fuel Charging and Controls. www.JagDocs.com

Page 1362 of 3039

speed.

The CKP sensor is installed in the rear left side of the sump body, in line with the engine drive plate. The sensor is secured with a single screw and sealed with an O-ring. A two pin electrical connector provides the interface with the engine harness.

The head of the CKP sensor faces a reluctor ring pressed into the outer circumference of the engine drive plate. The reluctor ring has a 60 minus 2 tooth pattern. There are 58 teeth at 6° intervals, with two teeth removed to provide a reference point

with a centerline that is 21° BTDC (before top dead center) on cylinder 1 of bank A.

If the CKP sensor fails, the ECM:

Uses signals from the CMP sensors to determine the angular position of the crankshaft and the engine speed Adopts a limp home mode where engine speed is limited to a maximum of 3000 rev/min.

With a failed CKP sensor, engine starts will require a long crank time while the ECM determines the angular position of the crankshaft.

CAMSHAFT POSITION SENSORS

The CMP sensors are MRE (magneto resistive element) sensors that allow the ECM to determine the angular position of the camshafts. MRE sensors produce a digital output which allows the ECM to detect speeds down to zero. The four CMP sensors are installed in the front upper timing covers, one for each camshaft.

Each CMP sensor is secured with a single screw and sealed with an O-ring. On each CMP sensor, a three pin electrical connector provides the interface with the engine harness.

The head of each CMP sensor faces a sensor wheel attached to the front of the related VCT unit.

Page 1363 of 3039

Defaults to base mapping for the ignition timing, with no cylinder correction

Disables the VCT system.

ENGINE COOLANT TEMPERATURE SENSORS

The ECT sensors are NTC (negative temperature coefficient) thermistors that allow the ECM to monitor the engine coolant temperature.

There are two identical ECT sensors installed, which are identified as ECT 1 and ECT 2. Each sensor is secured with a twist-lock and latch mechanism, and is sealed with an O-ring. A two pin electrical connector provides the interface between the sensor

and the engine harness.

ECT 1

ECT 1 is installed in the heater manifold, at the rear of the RH (right-hand) cylinder head. The input from this sensor is used in

calibration tables and by other systems.

ECT 2

ECT 2 is installed in the lower hose connector which attaches to the bottom of the thermostat. The input from this sensor is

used for OBD (on-board diagnostic) 2 diagnostics and, in conjunction with the input from ECT 1, to confirm that the thermostat

is functional.

KNOCK SENSORS

The knock sensors are piezo-ceramic sensors that allow the ECM to employ active knock control and prevent engine damage from pre-ignition or detonation.

Two knock sensors are installed on the inboard side of each cylinder head, one mid-way between cylinders 1 and 2, and one

mid-way between cylinders 3 and 4. Each knock sensor is secured with a single screw. On each knock sensor, a two pin

electrical connector provides the interface with the engine harness.

The ECM compares the signals from the knock sensors with mapped values stored in memory to determine when detonation occurs on individual cylinders. When detonation is detected, the ECM retards the ignition timing on that cylinder for a number of engine cycles, then gradually returns it to the original setting.

The ECM cancels closed loop control of the ignition system if the signal received from a knock sensor becomes implausible. In these circumstances the ECM defaults to base mapping for the ignition timing. This ensures the engine will not become damaged if low quality fuel is used. The MIL (malfunction indicator lamp) will not illuminate, although the driver may notice

that the engine 'pinks' in some driving conditions and displays a drop in performance and smoothness.

Page 1364 of 3039

MANIFOLD ABSOLUTE PRESSURE SENSOR

The MAP sensor allows the ECM to calculate the load on the engine, which is used in the calculation of fuel injection time.

The MAP sensor is installed in the air inlet of the SC (supercharger). The sensor is secured with a single screw and sealed with an O-ring. A three pin electrical connector provides the interface with the engine harness.

If the MAP sensor fails, the ECM adopts a default value of 1 bar (14.5 lbf/in.2

). With a failed MAP sensor, the engine will suffer from poor starting, rough running and poor driveability.

MASS AIR FLOW AND TEMPERATURE SENSORS

The MAFT sensors allow the ECM to measure the mass and the temperature of the air flow into the engine. The mass air flow is measured with a hot film element in the sensor. The temperature of the air flow is measured with a NTC thermistor in the sensor. The mass air flow is used to determine the fuel quantity to be injected in order to maintain the stoichiometric air/fuel

mixture required for correct operation of the engine and the catalytic converters.

There are two MAFT sensors installed, one in each air cleaner outlet duct. Each MAFT sensor is secured with two screws and sealed with an O-ring. On each MAFT sensor, a five pin electrical connector provides the interface with the engine harness.

If the hot film element signal fails the ECM invokes a software backup strategy to calculate the mass air flow from other inputs. Closed loop fuel control, closed loop idle speed control and evaporative emissions control are discontinued. The engine

will suffer from poor starting, poor throttle response and, if the failure occurs while driving, the engine speed may dip before

recovering.

If the NTC thermistor signal fails the ECM adopts a default value of 25 °C (77 °F) for the intake air temperature.

Page 1365 of 3039

MANIFOLD ABSOLUTE PRESSURE AND TEMPERATURE SENSOR

The MAPT sensor allows the ECM to calculate the air charge density immediately before it enters the cylinders. This is used to adjust the ignition timing relative to the boost pressure, and to monitor the performance of the charge air coolers.

The MAPT sensor is installed in the rear of the LH intake manifold. The sensor is secured with a single screw and sealed with an O-ring. A four pin electrical connector provides the interface with the engine harness.

THROTTLE POSITION SENSORS

The TP (throttle position) sensors allow the ECM to determine the position and angular rate of change of the throttle blade. There are two TP sensors located in the electronic throttle. See below for details of the electronic throttle. If aTP sensor fails, the ECM:

Adopts a limp home mode where engine speed is limited to a maximum of approximately 2000 rev/min

Discontinues evaporative emissions control

Discontinues closed loop control of engine idle speed.

With a failed TP sensor, the engine will suffer from poor running and throttle response.

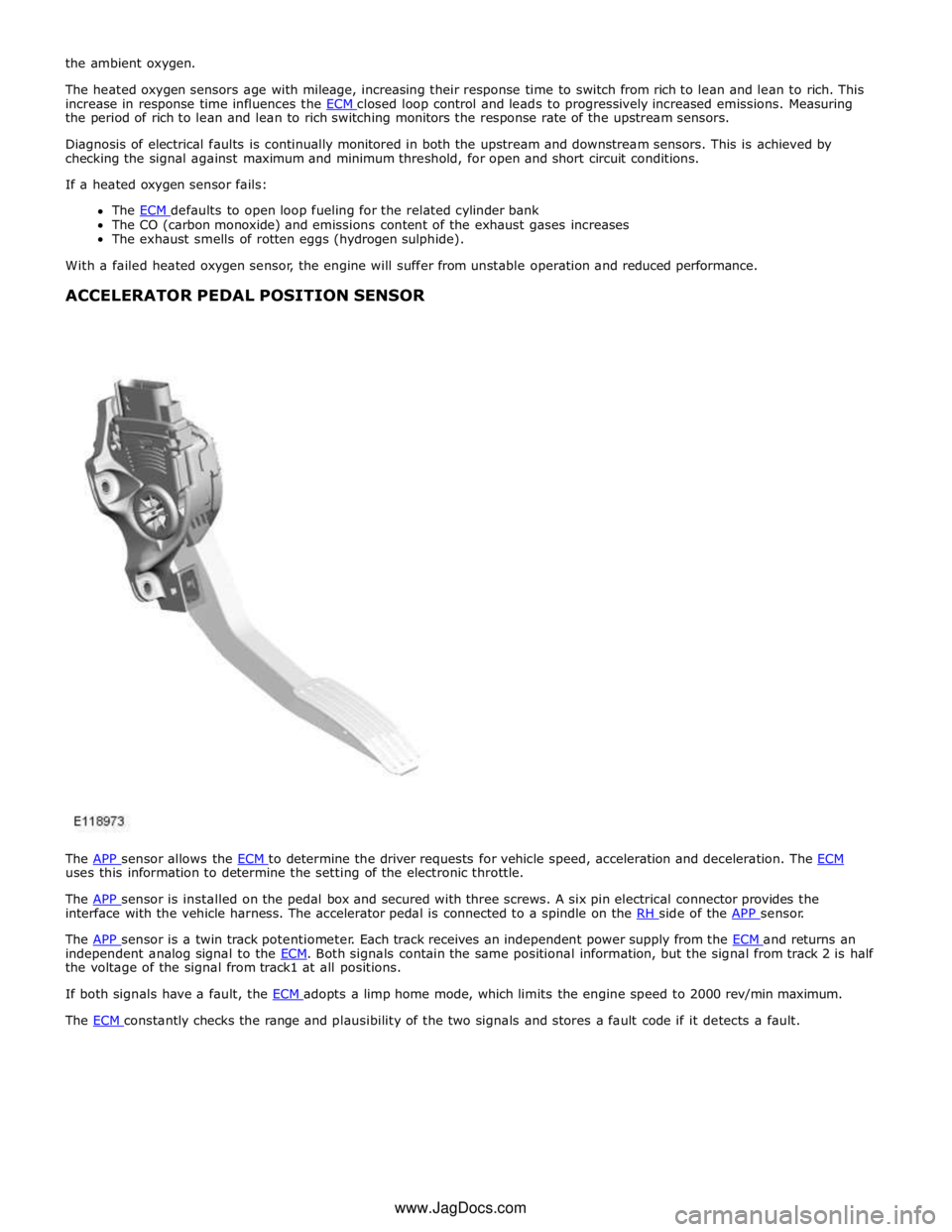

HEATED OXYGEN SENSORS

Item Description A Upstream heated oxygen sensor B Downstream heated oxygen sensor The heated oxygen sensors allow the ECM to measure the oxygen content of the exhaust gases, for closed loop control of the fuel:air mixture and for catalytic converter monitoring.

An upstream heated oxygen sensor is installed in the outlet of each exhaust manifold, which enables independent control of

the fuel:air mixture for each cylinder bank. A downstream heated oxygen sensor is installed in each catalytic converter, which

enables the performance of the catalytic converters to be monitored.

Oxygen sensors need to operate at high temperatures in order to function correctly. To achieve the high temperatures required,

the sensors are fitted with heater elements that are controlled by a PWM (pulse width modulation) signal from the ECM. The heater elements are operated immediately after each engine start and during low load conditions when the temperature of the

exhaust gases is insufficient to maintain the required sensor temperature. The PWM duty cycle is carefully controlled to prevent thermal shock to cold sensors. A non-functioning heater delays the sensor’s readiness for closed loop control and

increases emissions.

The upstream heated oxygen sensors produce a constant voltage, with a variable current that is proportional to the lambda

ratio. The downstream heated oxygen sensors produce an output voltage dependant on the ratio of the exhaust gas oxygen to

Page 1366 of 3039

the period of rich to lean and lean to rich switching monitors the response rate of the upstream sensors.

Diagnosis of electrical faults is continually monitored in both the upstream and downstream sensors. This is achieved by

checking the signal against maximum and minimum threshold, for open and short circuit conditions.

If a heated oxygen sensor fails:

The ECM defaults to open loop fueling for the related cylinder bank The CO (carbon monoxide) and emissions content of the exhaust gases increases

The exhaust smells of rotten eggs (hydrogen sulphide).

With a failed heated oxygen sensor, the engine will suffer from unstable operation and reduced performance.

ACCELERATOR PEDAL POSITION SENSOR

The APP sensor allows the ECM to determine the driver requests for vehicle speed, acceleration and deceleration. The ECM uses this information to determine the setting of the electronic throttle.

The APP sensor is installed on the pedal box and secured with three screws. A six pin electrical connector provides the interface with the vehicle harness. The accelerator pedal is connected to a spindle on the RH side of the APP sensor.

The APP sensor is a twin track potentiometer. Each track receives an independent power supply from the ECM and returns an independent analog signal to the ECM. Both signals contain the same positional information, but the signal from track 2 is half the voltage of the signal from track1 at all positions.

If both signals have a fault, the ECM adopts a limp home mode, which limits the engine speed to 2000 rev/min maximum. The ECM constantly checks the range and plausibility of the two signals and stores a fault code if it detects a fault. www.JagDocs.com

Page 1367 of 3039

around the vehicle. The ECM uses the AAT input for a number of functions, including engine cooling fan control. The ECM also transmits the ambient temperature on the high speed CAN bus for use by other control modules.

The AAT sensor is installed in the LH (left-hand) exterior mirror, with the bulb of the sensor positioned over a hole in the

bottom of the mirror casing.

The ECM supplies the sensor with a 5 V reference voltage and a ground, and translates the return signal voltage into a temperature.

If there is a fault with the AAT sensor, the ECM calculates the AAT from the temperature inputs of the MAFT sensors. If the AAT sensor and the temperature inputs of the MAFT sensors are all faulty, the ECM adopts a default ambient temperature of 20 °C (68 °F).

ELECTRONIC THROTTLE

The ECM uses the electronic throttle to regulate engine torque.

The electronic throttle is installed between the T piece duct, of the intake air distribution and filtering system, and the inlet of

the SC. For additional information, refer to 303-12F Intake Air Distribution and Filtering.

The throttle plate is operated by an electric DC (direct current) motor integrated into the throttle body. The ECM uses a PWM signal to control the DC motor. The ECM compares the APP sensor inputs against an electronic map to determine the required position of the throttle plate. The ECM and electronic throttle are also required to: Monitor requests for cruise control operation

Automatically operate the electronic throttle for accurate cruise control

Perform all dynamic stability control engine interventions

Monitor and carry out maximum engine speed and road speed cut outs

Provide different engine maps for the ride and handling optimization system.

A software strategy within the ECM calibrates the position of the throttle plate at the beginning of each ignition cycle. When the ignition is turned on, the ECM performs a self test and calibration routine by fully closing the throttle plate and then opening it again. This tests the default position springs and allows the ECM to learn the position of the closed hard stop. Subsequently the ECM keeps the throttle plate a minimum of 0.5 degree from the closed hard stop. AMBIENT AIR TEMPERATURE SENSOR

Page 1368 of 3039

(engine junction box).

When the ignition is turned on, battery voltage is applied to the ignition sense input. The ECM then starts its power up routines and energizes the main relay.

When the ignition is turned off, the ECM maintains its powered up state while it conducts the power down routines (up to 20 minutes in extreme cases, when cooling fans are required) and on completion will turn off the main relay.

Page 1369 of 3039

Published: 16-Sep-2013

Electronic Engine Controls - V8 S/C 5.0L Petrol - Electronic Engine Controls

Diagnosis and Testing

Principle of Operation

For a detailed description of electronic engine controls, refer to the relevant Description and Operation section of the workshop

manual. REFER to: (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol)

Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Engine oil level and condition

Cooling system coolant level

Fuel level

Fuel contamination/grade/quality

Throttle body

Front End Accessory Drive (FEAD) belt

Air cleaner condition

Fuses

Wiring harness

Electrical connector(s)

Sensor(s)

Engine Control Module

Transmission Control Module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the customer concern and refer to the Symptom Chart below, alternatively,

check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

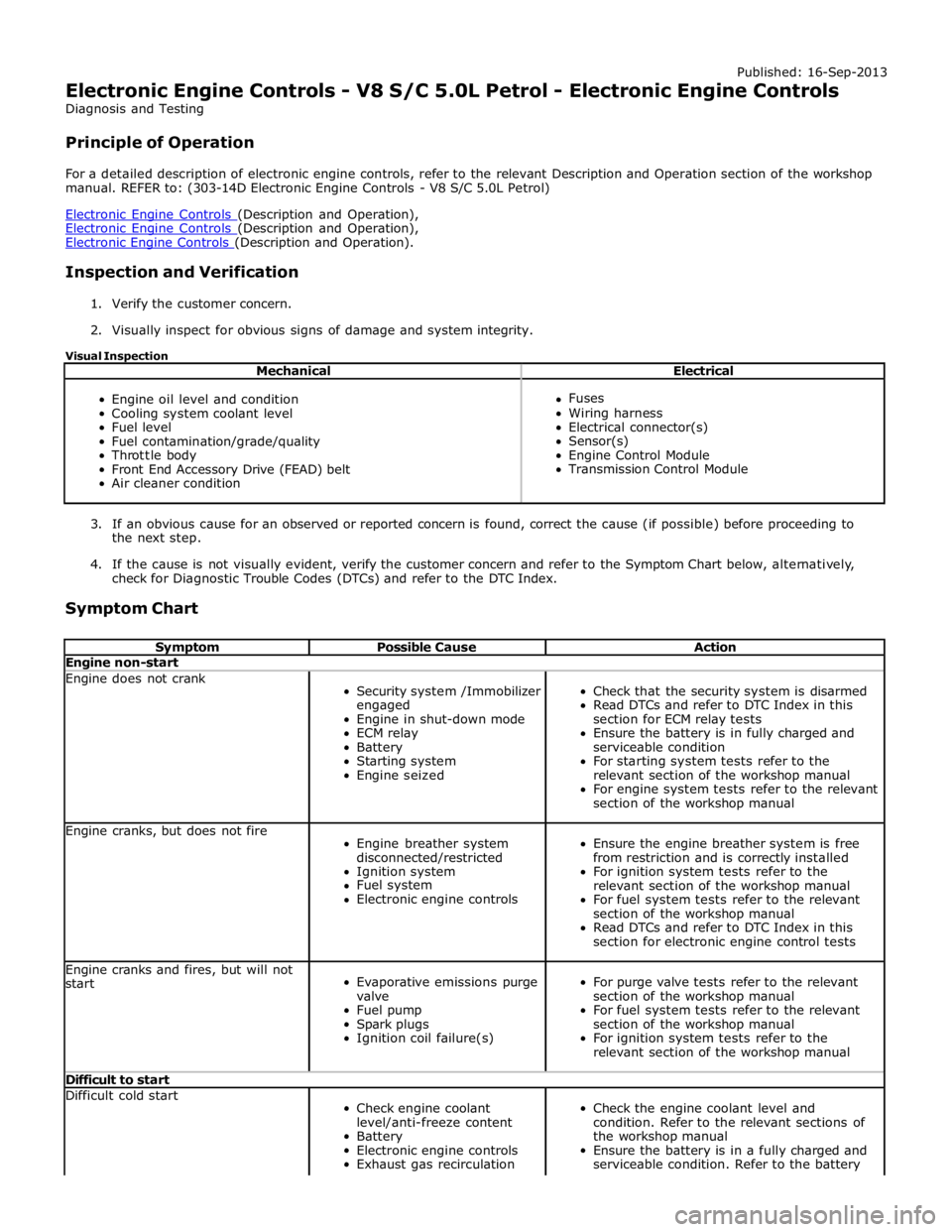

Symptom Chart

Symptom Possible Cause Action Engine non-start Engine does not crank

Security system /Immobilizer

engaged

Engine in shut-down mode

ECM relay

Battery

Starting system

Engine seized

Check that the security system is disarmed

Read DTCs and refer to DTC Index in this

section for ECM relay tests

Ensure the battery is in fully charged and

serviceable condition

For starting system tests refer to the

relevant section of the workshop manual

For engine system tests refer to the relevant

section of the workshop manual Engine cranks, but does not fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine controls

Ensure the engine breather system is free

from restriction and is correctly installed

For ignition system tests refer to the

relevant section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

Read DTCs and refer to DTC Index in this

section for electronic engine control tests Engine cranks and fires, but will not

start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

Ignition coil failure(s)

For purge valve tests refer to the relevant

section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

For ignition system tests refer to the

relevant section of the workshop manual Difficult to start Difficult cold start

Check engine coolant

level/anti-freeze content

Battery

Electronic engine controls

Exhaust gas recirculation

Check the engine coolant level and

condition. Refer to the relevant sections of

the workshop manual

Ensure the battery is in a fully charged and

serviceable condition. Refer to the battery