AUX JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1768 of 3039

Auxiliary Climate Control - Auxiliary Coolant Flow Pump

Removal and Installation

Removal Published: 11-May-2011

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Air Deflector (501-02, Removal and Installation).

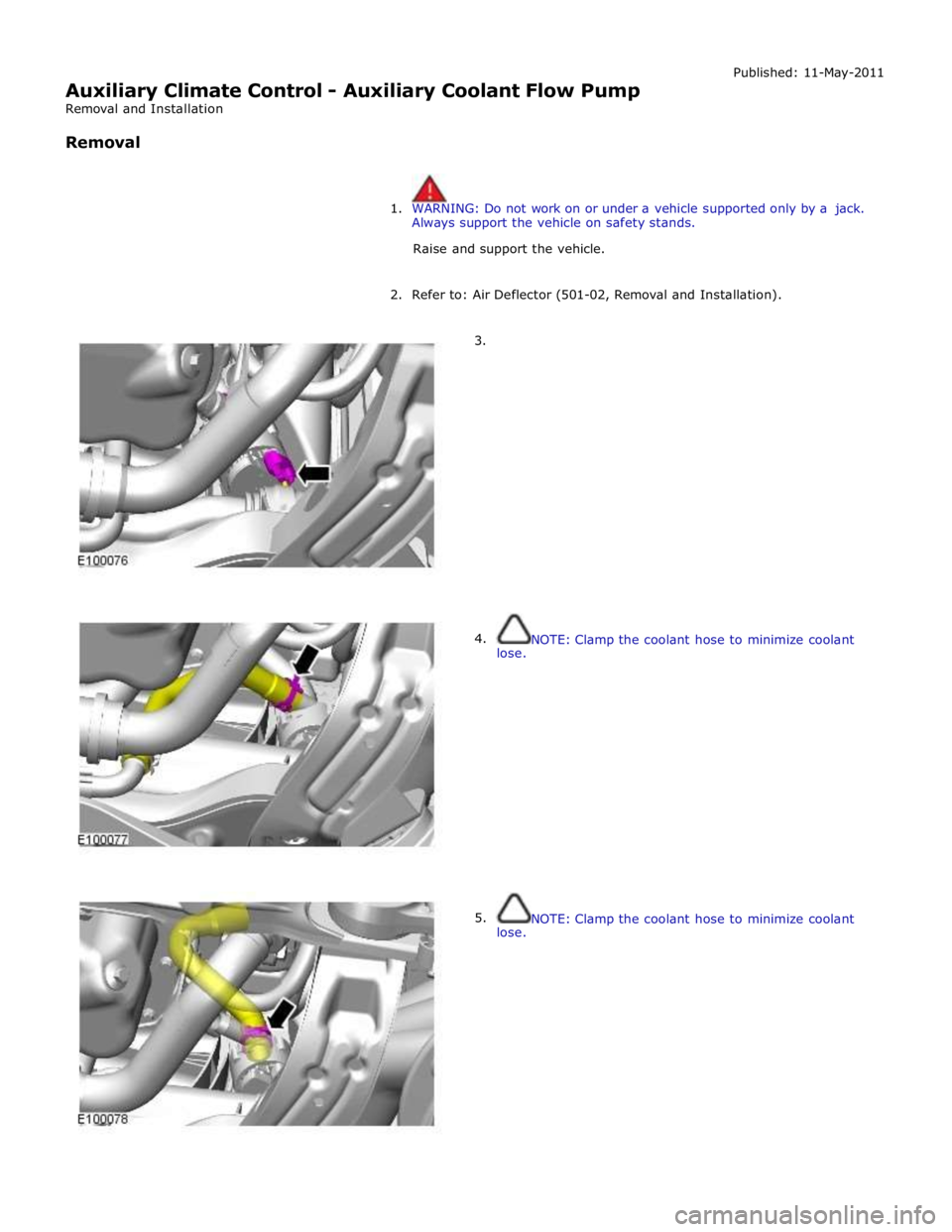

3.

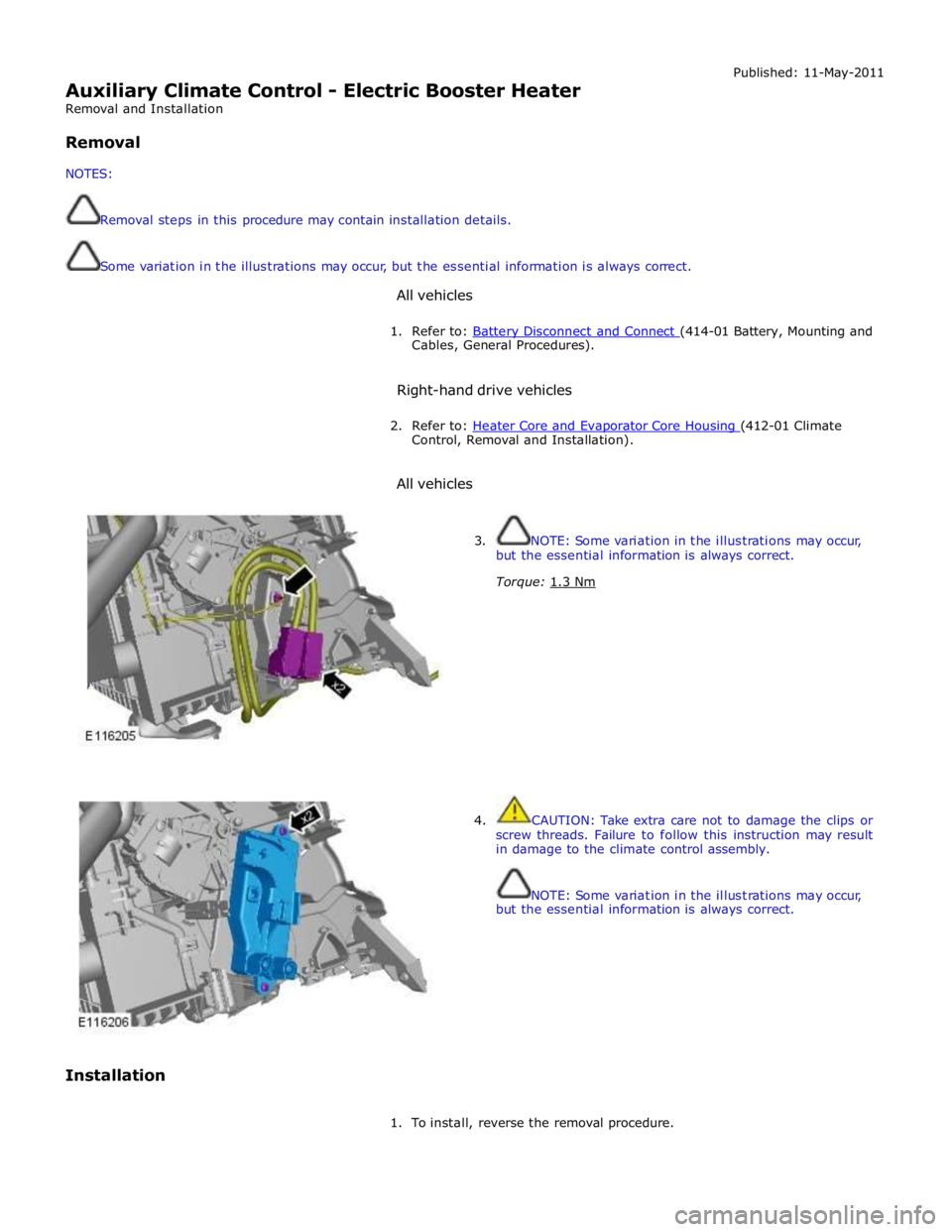

4.

lose.

5.

lose.

NOTE: Clamp the coolant hose to minimize coolant

NOTE: Clamp the coolant hose to minimize coolant

Page 1772 of 3039

Auxiliary Climate Control - Electric Booster Heater

Removal and Installation

Removal

NOTES:

Removal steps in this procedure may contain installation details.

Some variation in the illustrations may occur, but the essential information is always correct.

All vehicles Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Right-hand drive vehicles

2. Refer to: Heater Core and Evaporator Core Housing (412-01 Climate Control, Removal and Installation).

All vehicles

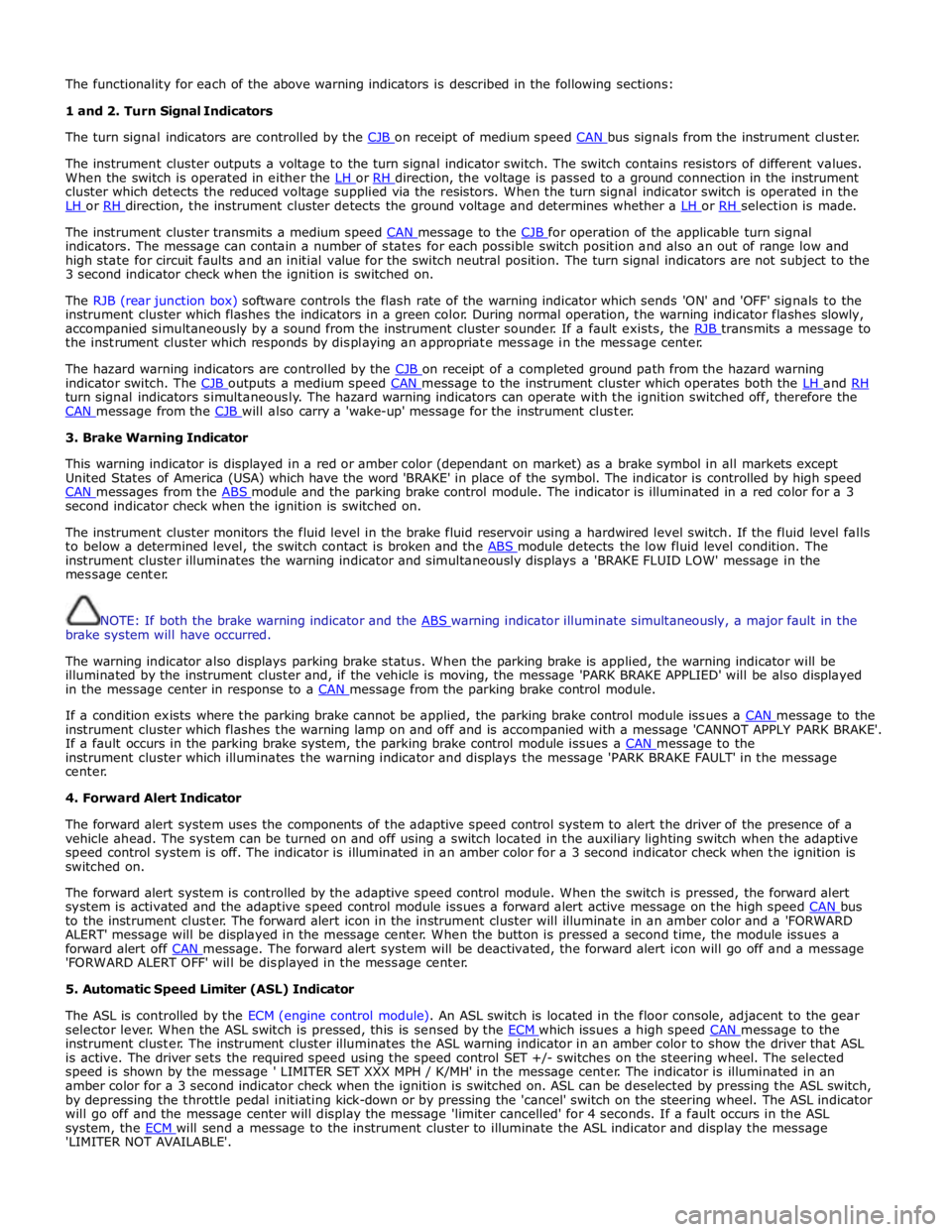

Installation

3. NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

Torque: 1.3 Nm

4. CAUTION: Take extra care not to damage the clips or

screw threads. Failure to follow this instruction may result

in damage to the climate control assembly.

NOTE: Some variation in the illustrations may occur,

but the essential information is always correct.

1. To install, reverse the removal procedure.

Page 1784 of 3039

7 Instrument cluster 8 Steering column motor 9 High speed CAN bus connection to other vehicle systems 10 Engine oil pressure switch 11 Steering column adjustment switch 12 Brake fluid level switch 13 LH (left-hand) steering column multifunction switch 14 Start control module 15 Clockspring 16 RH (right-hand) steering column multifunction switch 17 Engine coolant level sensor 18 Auxiliary lighting switch

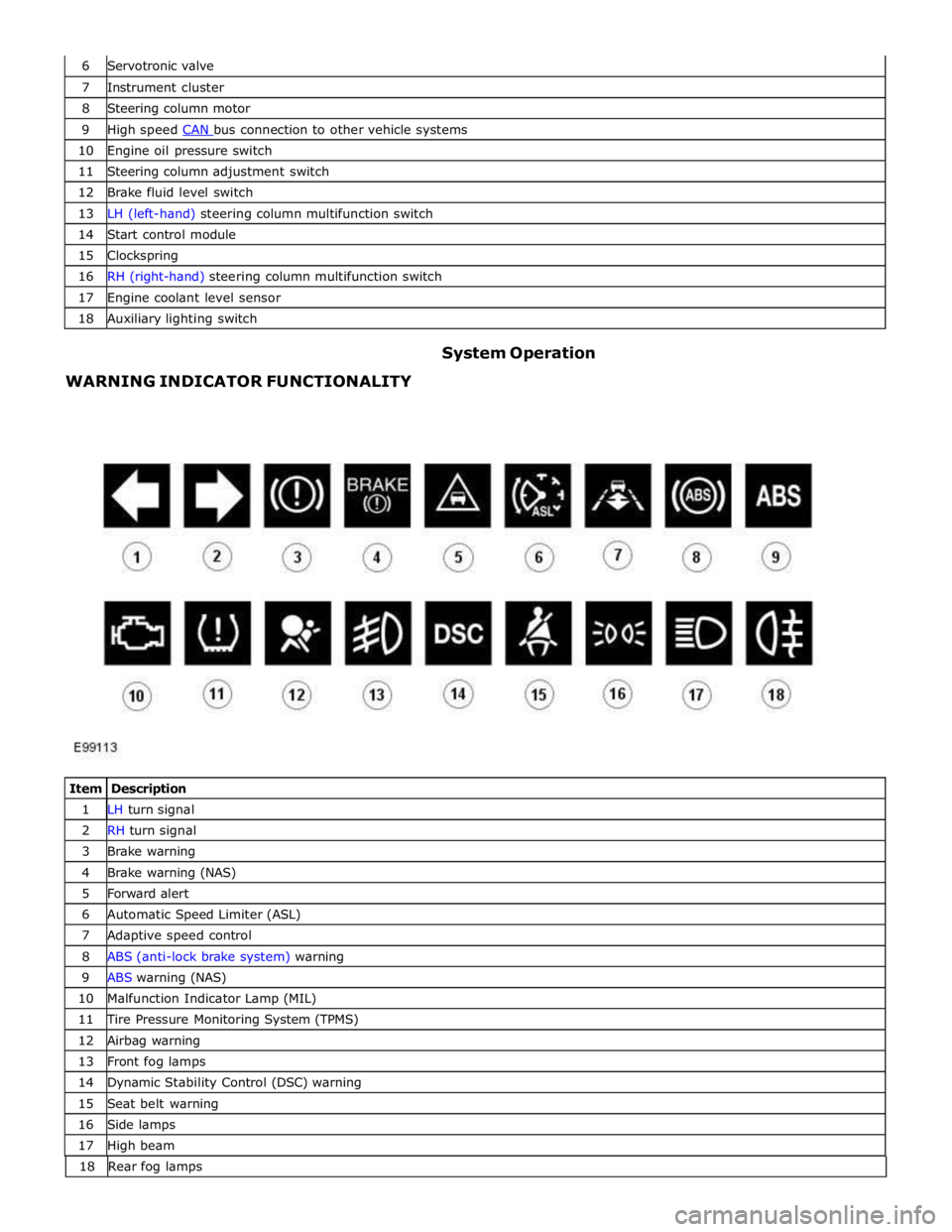

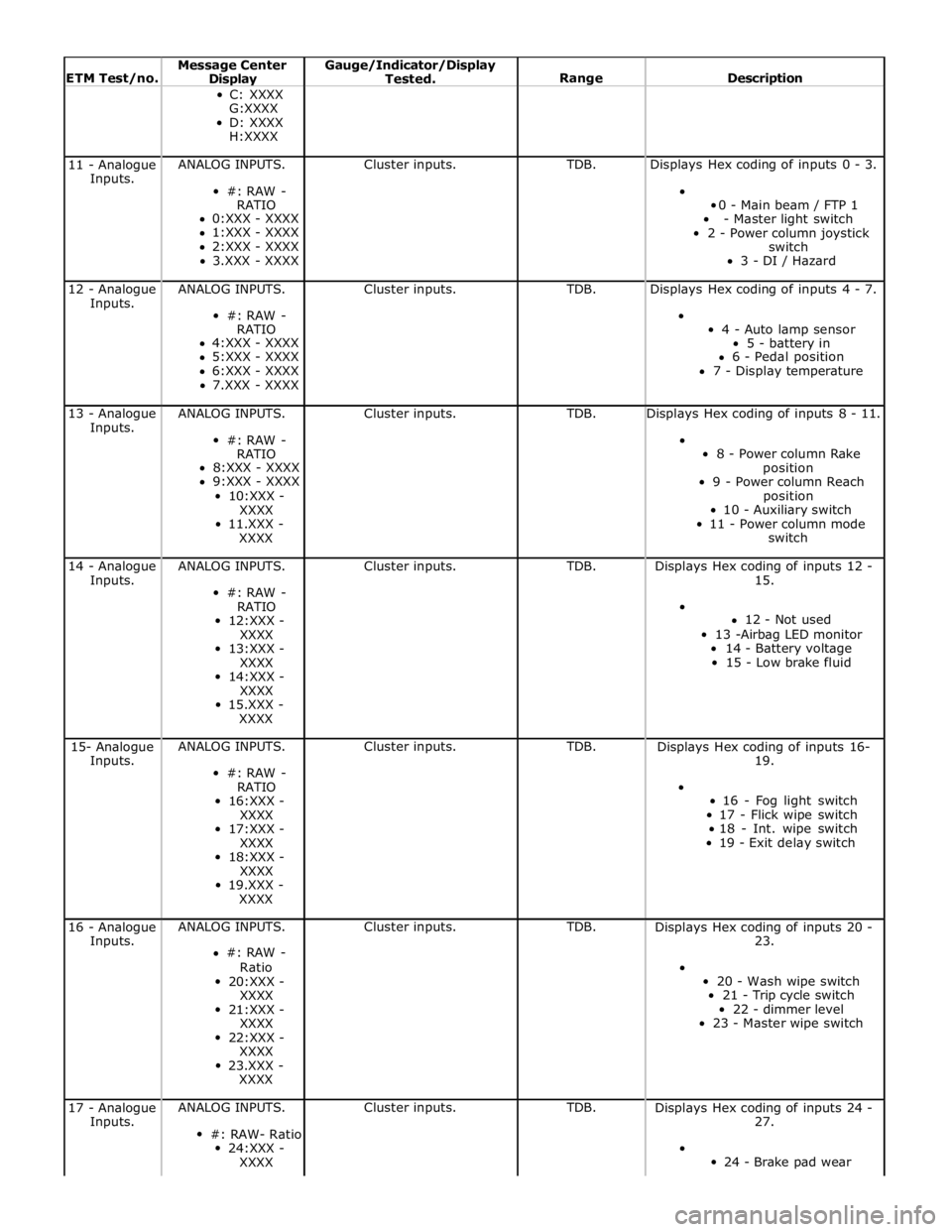

WARNING INDICATOR FUNCTIONALITY System Operation

Item Description 1 LH turn signal 2 RH turn signal 3 Brake warning 4 Brake warning (NAS) 5 Forward alert 6 Automatic Speed Limiter (ASL) 7 Adaptive speed control 8 ABS (anti-lock brake system) warning 9 ABS warning (NAS) 10 Malfunction Indicator Lamp (MIL) 11 Tire Pressure Monitoring System (TPMS) 12 Airbag warning 13 Front fog lamps 14 Dynamic Stability Control (DSC) warning 15 Seat belt warning 16 Side lamps 17 High beam 18 Rearfoglamps

Page 1785 of 3039

The functionality for each of the above warning indicators is described in the following sections:

1 and 2. Turn Signal Indicators

The turn signal indicators are controlled by the CJB on receipt of medium speed CAN bus signals from the instrument cluster.

The instrument cluster outputs a voltage to the turn signal indicator switch. The switch contains resistors of different values.

When the switch is operated in either the LH or RH direction, the voltage is passed to a ground connection in the instrument cluster which detects the reduced voltage supplied via the resistors. When the turn signal indicator switch is operated in the

LH or RH direction, the instrument cluster detects the ground voltage and determines whether a LH or RH selection is made.

The instrument cluster transmits a medium speed CAN message to the CJB for operation of the applicable turn signal indicators. The message can contain a number of states for each possible switch position and also an out of range low and

high state for circuit faults and an initial value for the switch neutral position. The turn signal indicators are not subject to the

3 second indicator check when the ignition is switched on.

The RJB (rear junction box) software controls the flash rate of the warning indicator which sends 'ON' and 'OFF' signals to the

instrument cluster which flashes the indicators in a green color. During normal operation, the warning indicator flashes slowly,

accompanied simultaneously by a sound from the instrument cluster sounder. If a fault exists, the RJB transmits a message to the instrument cluster which responds by displaying an appropriate message in the message center.

The hazard warning indicators are controlled by the CJB on receipt of a completed ground path from the hazard warning indicator switch. The CJB outputs a medium speed CAN message to the instrument cluster which operates both the LH and RH turn signal indicators simultaneously. The hazard warning indicators can operate with the ignition switched off, therefore the

CAN message from the CJB will also carry a 'wake-up' message for the instrument cluster. 3. Brake Warning Indicator

This warning indicator is displayed in a red or amber color (dependant on market) as a brake symbol in all markets except

United States of America (USA) which have the word 'BRAKE' in place of the symbol. The indicator is controlled by high speed

CAN messages from the ABS module and the parking brake control module. The indicator is illuminated in a red color for a 3 second indicator check when the ignition is switched on.

The instrument cluster monitors the fluid level in the brake fluid reservoir using a hardwired level switch. If the fluid level falls

to below a determined level, the switch contact is broken and the ABS module detects the low fluid level condition. The instrument cluster illuminates the warning indicator and simultaneously displays a 'BRAKE FLUID LOW' message in the

message center.

NOTE: If both the brake warning indicator and the ABS warning indicator illuminate simultaneously, a major fault in the brake system will have occurred.

The warning indicator also displays parking brake status. When the parking brake is applied, the warning indicator will be

illuminated by the instrument cluster and, if the vehicle is moving, the message 'PARK BRAKE APPLIED' will be also displayed

in the message center in response to a CAN message from the parking brake control module.

If a condition exists where the parking brake cannot be applied, the parking brake control module issues a CAN message to the instrument cluster which flashes the warning lamp on and off and is accompanied with a message 'CANNOT APPLY PARK BRAKE'.

If a fault occurs in the parking brake system, the parking brake control module issues a CAN message to the instrument cluster which illuminates the warning indicator and displays the message 'PARK BRAKE FAULT' in the message

center.

4. Forward Alert Indicator

The forward alert system uses the components of the adaptive speed control system to alert the driver of the presence of a

vehicle ahead. The system can be turned on and off using a switch located in the auxiliary lighting switch when the adaptive

speed control system is off. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is

switched on.

The forward alert system is controlled by the adaptive speed control module. When the switch is pressed, the forward alert

system is activated and the adaptive speed control module issues a forward alert active message on the high speed CAN bus to the instrument cluster. The forward alert icon in the instrument cluster will illuminate in an amber color and a 'FORWARD

ALERT' message will be displayed in the message center. When the button is pressed a second time, the module issues a

forward alert off CAN message. The forward alert system will be deactivated, the forward alert icon will go off and a message 'FORWARD ALERT OFF' will be displayed in the message center.

5. Automatic Speed Limiter (ASL) Indicator

The ASL is controlled by the ECM (engine control module). An ASL switch is located in the floor console, adjacent to the gear

selector lever. When the ASL switch is pressed, this is sensed by the ECM which issues a high speed CAN message to the instrument cluster. The instrument cluster illuminates the ASL warning indicator in an amber color to show the driver that ASL

is active. The driver sets the required speed using the speed control SET +/- switches on the steering wheel. The selected

speed is shown by the message ' LIMITER SET XXX MPH / K/MH' in the message center. The indicator is illuminated in an

amber color for a 3 second indicator check when the ignition is switched on. ASL can be deselected by pressing the ASL switch,

by depressing the throttle pedal initiating kick-down or by pressing the 'cancel' switch on the steering wheel. The ASL indicator

will go off and the message center will display the message 'limiter cancelled' for 4 seconds. If a fault occurs in the ASL

system, the ECM will send a message to the instrument cluster to illuminate the ASL indicator and display the message 'LIMITER NOT AVAILABLE'.

Page 1787 of 3039

the RCM and illuminated by the instrument cluster on receipt of high speed CAN bus messages. The safety belt warning indicator is not subject to the 3 second indicator check when the ignition is switched on.

The operation of the passenger seat buckle switch is as described below with the exception that the instrument cluster must

receive a hardwired signal from the belt minder control module to indicate that a passenger is occupying the seat.

The safety belt warning indicator is subject to a timer. The warning indicator is activated when the following conditions exist:

Ignition is switched on

One of the front seat belts is unbuckled

USA market only - 75 seconds has elapsed after ignition on mode is selected

Vehicle is not in reverse gear

Vehicle speed is more than 8 km/h (5 mph).

Once the above parameters are met, the instrument cluster flashes the warning indicator at 2 Hz for 10 seconds accompanied

by a simultaneous chime. After 10 seconds the chime ceases and the warning indicator is permanently illuminated for 20

seconds. This sequence is repeated every 30 seconds until one of the following events occurs:

300 seconds has elapsed

The safety belt of the occupied front seats is fastened

The ignition is switched to off mode

The vehicle speed decreases to below 5 km/h (3 mph).

NOTE: On USA market vehicles, the warning indicator in not permanently illuminated.

The safety belt minder function cannot be disabled. The seat belt minder function can be disabled.

Refer to: Safety Belt System (501-20A Safety Belt System, Description and Operation). 14. Side Lamp Indicator

The instrument cluster controls the green colored side lamp indicator on receipt of a side lamp status message on the medium

speed CAN bus from the CJB and the auxiliary junction box. The lighting switch on the LH steering column multifunction switch is connected to the instrument cluster. Selections using this switch are detected by the cluster which requests the side or

headlamp operation via a message to the CJB and the RJB. The CJB and the RJB responds with a side lamp active message and the cluster illuminates the side lamp indicator. The side lamp indicator is not subject to the 3 second indicator check when

the ignition is switched on.

15. High Beam Indicator

The instrument cluster controls the blue colored high beam indicator on receipt of a high beam status message on the medium

speed CAN bus from the CJB. The lighting switch on the LH steering column multifunction switch is connected to the instrument cluster. High beam or flash selections using this switch are detected by the cluster which requests the light

operation via a CAN message to the CJB. The CJB responds with a high beam active message and the cluster illuminates the high beam indicator. The high beam indicator is not subject to the 3 second indicator check when the ignition is switched on.

16. Rear Fog Lamp Indicator

The amber colored rear fog lamp indicator is controlled by the auxiliary junction box and illuminated by the instrument cluster

on receipt of a rear fog lamp on message on the medium speed CAN bus from the RJB. The indicator is illuminated for as long as the rear fog lamps are active. The rear fog lamp indicator is not subject to the 3 second indicator check when the ignition is

switched on.

SPEEDOMETER

The speedometer is driven by high speed CAN signals transmitted by the ABS module. The wheel speeds are measured by sensors reading the rotational speed of the rear wheels from toothed targets on the hubs. An average of the two wheel speeds

are passed from the sensors to the ABS module in the form of pulsed signals. The ABS module converts these signals into a speed output on the high speed CAN to the instrument cluster. The same speed outputs from the wheel speed sensors are also used to calculate the distance the vehicle has travelled.

TACHOMETER

The tachometer is driven by an engine speed signal transmitted on the high speed CAN from the ECM. The signal is derived from the CKP (crankshaft position) sensor. The signal is received by the instrument cluster microprocessor and the output from

the microprocessor drives the tachometer.

FUEL GAGE

The fuel gage is controlled by CAN messages from the RJB. The RJB reads the values output by the fuel level sensors every 131 ms and transmits a fuel tank contents value, corrected for battery voltage, in a CAN message to the instrument cluster. A fuel pump symbol is displayed to the left of the linear gage. An arrow above the symbol shows the driver on which side of the

vehicle the fuel filler cap is located. Above the linear fuel gage, is a LCD (liquid crystal display) area which displays odometer

and trip readouts. When a trip computer function is selected, these are replaced by a trip computer display for the trip function

selected.

LIQUID CRYSTAL DISPLAY

In the area above and below the message center is a LCD display. The area below the message center displays a linear fuel www.JagDocs.com

Page 1795 of 3039

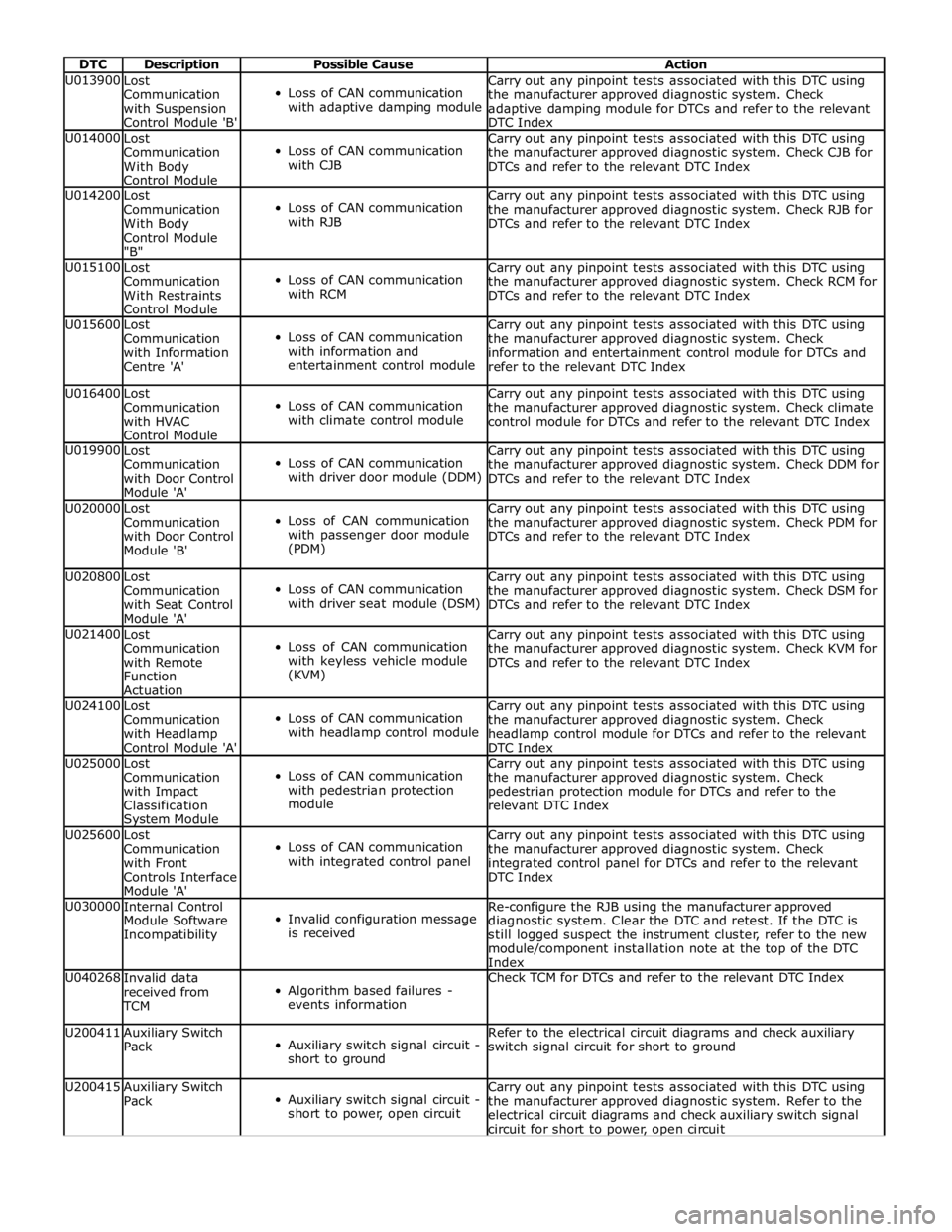

ETM Test/no. Message Center Display Gauge/Indicator/Display

Tested.

Range

Description C: XXXX

G:XXXX

D: XXXX

H:XXXX 11 - Analogue

Inputs. ANALOG INPUTS.

#: RAW -

RATIO

0:XXX - XXXX

1:XXX - XXXX

2:XXX - XXXX

3.XXX - XXXX Cluster inputs. TDB. Displays Hex coding of inputs 0 - 3.

0 - Main beam / FTP 1

- Master light switch

2 - Power column joystick

switch

3 - DI / Hazard 12 - Analogue

Inputs. ANALOG INPUTS.

#: RAW -

RATIO

4:XXX - XXXX

5:XXX - XXXX

6:XXX - XXXX

7.XXX - XXXX Cluster inputs. TDB. Displays Hex coding of inputs 4 - 7.

4 - Auto lamp sensor

5 - battery in

6 - Pedal position

7 - Display temperature 13 - Analogue

Inputs. ANALOG INPUTS.

#: RAW -

RATIO

8:XXX - XXXX

9:XXX - XXXX

10:XXX -

XXXX

11.XXX -

XXXX Cluster inputs. TDB. Displays Hex coding of inputs 8 - 11.

8 - Power column Rake

position

9 - Power column Reach

position

10 - Auxiliary switch

11 - Power column mode

switch 14 - Analogue

Inputs. ANALOG INPUTS.

#: RAW -

RATIO

12:XXX -

XXXX

13:XXX -

XXXX

14:XXX -

XXXX

15.XXX -

XXXX Cluster inputs. TDB.

Displays Hex coding of inputs 12 -

15.

12 - Not used

13 -Airbag LED monitor

14 - Battery voltage

15 - Low brake fluid 15- Analogue

Inputs. ANALOG INPUTS.

#: RAW -

RATIO

16:XXX -

XXXX

17:XXX -

XXXX

18:XXX -

XXXX

19.XXX -

XXXX Cluster inputs. TDB.

Displays Hex coding of inputs 16-

19.

16 - Fog light switch

17 - Flick wipe switch

18 - Int. wipe switch

19 - Exit delay switch 16 - Analogue

Inputs. ANALOG INPUTS.

#: RAW -

Ratio

20:XXX -

XXXX

21:XXX -

XXXX

22:XXX -

XXXX

23.XXX -

XXXX Cluster inputs. TDB.

Displays Hex coding of inputs 20 -

23.

20 - Wash wipe switch

21 - Trip cycle switch

22 - dimmer level

23 - Master wipe switch 17 - Analogue

Inputs. ANALOG INPUTS.

#: RAW- Ratio

24:XXX -

XXXX Cluster inputs. TDB.

Displays Hex coding of inputs 24 -

27.

24 - Brake pad wear

Page 1805 of 3039

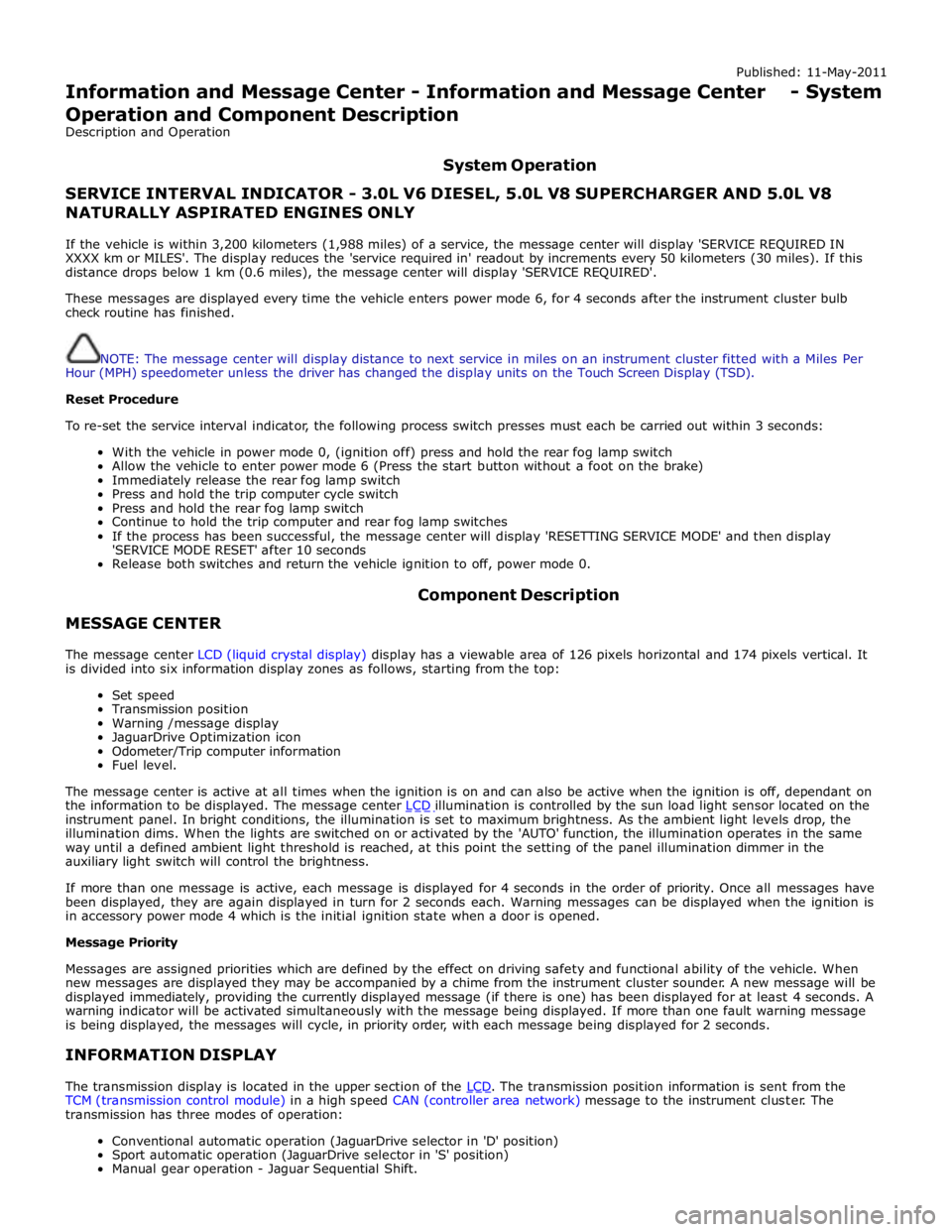

DTC Description Possible Cause Action U013900

Lost

Communication

with Suspension

Control Module 'B'

Loss of CAN communication

with adaptive damping module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

adaptive damping module for DTCs and refer to the relevant

DTC Index U014000

Lost

Communication

With Body

Control Module

Loss of CAN communication

with CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

DTCs and refer to the relevant DTC Index U014200

Lost

Communication

With Body

Control Module

"B"

Loss of CAN communication

with RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

DTCs and refer to the relevant DTC Index U015100

Lost

Communication

With Restraints

Control Module

Loss of CAN communication

with RCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RCM for

DTCs and refer to the relevant DTC Index U015600

Lost

Communication

with Information

Centre 'A'

Loss of CAN communication

with information and

entertainment control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment control module for DTCs and

refer to the relevant DTC Index U016400

Lost

Communication

with HVAC

Control Module

Loss of CAN communication

with climate control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check climate

control module for DTCs and refer to the relevant DTC Index U019900

Lost

Communication

with Door Control

Module 'A'

Loss of CAN communication

with driver door module (DDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DDM for

DTCs and refer to the relevant DTC Index U020000

Lost

Communication

with Door Control

Module 'B'

Loss of CAN communication

with passenger door module

(PDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check PDM for

DTCs and refer to the relevant DTC Index U020800

Lost

Communication

with Seat Control

Module 'A'

Loss of CAN communication

with driver seat module (DSM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DSM for

DTCs and refer to the relevant DTC Index U021400

Lost

Communication

with Remote

Function

Actuation

Loss of CAN communication

with keyless vehicle module

(KVM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check KVM for

DTCs and refer to the relevant DTC Index U024100

Lost

Communication

with Headlamp

Control Module 'A'

Loss of CAN communication

with headlamp control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

headlamp control module for DTCs and refer to the relevant

DTC Index U025000

Lost

Communication

with Impact

Classification System Module

Loss of CAN communication

with pedestrian protection

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

pedestrian protection module for DTCs and refer to the

relevant DTC Index U025600

Lost

Communication

with Front

Controls Interface

Module 'A'

Loss of CAN communication

with integrated control panel Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

integrated control panel for DTCs and refer to the relevant

DTC Index U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message

is received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC is

still logged suspect the instrument cluster, refer to the new

module/component installation note at the top of the DTC

Index U040268

Invalid data

received from

TCM

Algorithm based failures -

events information Check TCM for DTCs and refer to the relevant DTC Index U200411

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to ground Refer to the electrical circuit diagrams and check auxiliary

switch signal circuit for short to ground U200415

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check auxiliary switch signal

circuit for short to power, open circuit

Page 1821 of 3039

Published: 11-May-2011

Information and Message Center - Information and Message Center - System

Operation and Component Description

Description and Operation

System Operation

SERVICE INTERVAL INDICATOR - 3.0L V6 DIESEL, 5.0L V8 SUPERCHARGER AND 5.0L V8 NATURALLY ASPIRATED ENGINES ONLY

If the vehicle is within 3,200 kilometers (1,988 miles) of a service, the message center will display 'SERVICE REQUIRED IN

XXXX km or MILES'. The display reduces the 'service required in' readout by increments every 50 kilometers (30 miles). If this

distance drops below 1 km (0.6 miles), the message center will display 'SERVICE REQUIRED'.

These messages are displayed every time the vehicle enters power mode 6, for 4 seconds after the instrument cluster bulb

check routine has finished.

NOTE: The message center will display distance to next service in miles on an instrument cluster fitted with a Miles Per

Hour (MPH) speedometer unless the driver has changed the display units on the Touch Screen Display (TSD).

Reset Procedure

To re-set the service interval indicator, the following process switch presses must each be carried out within 3 seconds:

With the vehicle in power mode 0, (ignition off) press and hold the rear fog lamp switch

Allow the vehicle to enter power mode 6 (Press the start button without a foot on the brake)

Immediately release the rear fog lamp switch

Press and hold the trip computer cycle switch

Press and hold the rear fog lamp switch

Continue to hold the trip computer and rear fog lamp switches

If the process has been successful, the message center will display 'RESETTING SERVICE MODE' and then display

'SERVICE MODE RESET' after 10 seconds

Release both switches and return the vehicle ignition to off, power mode 0.

MESSAGE CENTER Component Description

The message center LCD (liquid crystal display) display has a viewable area of 126 pixels horizontal and 174 pixels vertical. It

is divided into six information display zones as follows, starting from the top:

Set speed

Transmission position

Warning /message display

JaguarDrive Optimization icon

Odometer/Trip computer information

Fuel level.

The message center is active at all times when the ignition is on and can also be active when the ignition is off, dependant on

the information to be displayed. The message center LCD illumination is controlled by the sun load light sensor located on the instrument panel. In bright conditions, the illumination is set to maximum brightness. As the ambient light levels drop, the

illumination dims. When the lights are switched on or activated by the 'AUTO' function, the illumination operates in the same

way until a defined ambient light threshold is reached, at this point the setting of the panel illumination dimmer in the

auxiliary light switch will control the brightness.

If more than one message is active, each message is displayed for 4 seconds in the order of priority. Once all messages have

been displayed, they are again displayed in turn for 2 seconds each. Warning messages can be displayed when the ignition is

in accessory power mode 4 which is the initial ignition state when a door is opened.

Message Priority

Messages are assigned priorities which are defined by the effect on driving safety and functional ability of the vehicle. When

new messages are displayed they may be accompanied by a chime from the instrument cluster sounder. A new message will be

displayed immediately, providing the currently displayed message (if there is one) has been displayed for at least 4 seconds. A

warning indicator will be activated simultaneously with the message being displayed. If more than one fault warning message

is being displayed, the messages will cycle, in priority order, with each message being displayed for 2 seconds.

INFORMATION DISPLAY

The transmission display is located in the upper section of the LCD. The transmission position information is sent from the TCM (transmission control module) in a high speed CAN (controller area network) message to the instrument cluster. The

transmission has three modes of operation:

Conventional automatic operation (JaguarDrive selector in 'D' position)

Sport automatic operation (JaguarDrive selector in 'S' position)

Manual gear operation - Jaguar Sequential Shift.

Page 1866 of 3039

Published: 07-Aug-2014

Battery and Charging System - General Information - Battery Care

Requirements

Description and Operation

1. INTRODUCTION

This document defines the requirements for care and maintenance of batteries, and the standard of battery care at dealers and

retailers for new vehicles.

This applies to all types of 12 Volt Lead Acid Batteries used in Jaguar and Land Rover vehicles whether they are conventional

flooded technology or Absorbed Glass Mat (AGM – also known as Valve Regulated Lead Acid (VRLA)) technology and also

applies to both Primary, Secondary and Auxiliary Batteries. AGM batteries offer improved resistance to cycling as seen in stop

start applications.

In order to prevent damage to the battery and ensure a satisfactory service life, all processes detailed within this document

must be rigorously adhered to.

It is equally important therefore to note the following key points:

All new vehicles leave the factory with either a transit relay installed and/or have a transit mode programmed into the

vehicle control modules. The transit relay must be removed and the transit mode disabled (where applicable) using an

approved diagnostic system, NOT MORE THAN 72 HOURS before the customer takes delivery.

The battery can be discharged by the following mechanisms:

- Self Discharge: - A lead acid battery will very slowly discharge itself due to its own internal chemical processes

whether it is connected to a vehicle or not.

- Quiescent Discharge: - The vehicle electrical systems when connected to the battery will draw charge from the

battery.

12 Volt Lead Acid Batteries rely on internal chemical processes to create a voltage and deliver current. These processes and

the internal chemical structure of the battery can be damaged if the battery is allowed to discharge over a number of weeks /

months, or is left in a discharged state for a lengthy time period.

On vehicles with conventional ignition keys, these must not be left in the ignition lock barrel when the transit relay

has been removed, otherwise quiescent current will increase and the battery will discharge more rapidly.

For keyless vehicles, the Smart Key must be stored at least 5m (16 ft) away from the vehicle when the vehicle is

parked or stored.

AGM Batteries are fully sealed and cannot have the electrolyte level topped up.

NOTE: Dealers and retailers involved in the storage / handling of vehicles and replacement batteries have a responsibility

to ensure that only a fully charged battery may be processed through the distribution selling chain.

2. GENERAL RULES FOR BATTERY CARE

2.1 Dealer Demonstration Vehicles

Vehicles used as dealer demonstrator(s), in a showroom, must be connected to a JLR approved showroom conditioner capable

of delivering 50 Amps. This will prevent the battery from being damaged.

2.2 Software Reflash, SDD work or Ignition On related workshop activities

Due to the high electrical current demand and high depth of discharge that can occur during vehicle software re-flash activities,

SDD work or ignition on (power mode 6) related work in the workshop, vehicles that are undergoing such activities MUST have a

JLR approved power supply capable of delivering 50 Amps or more.

2.3 Extended Vehicle Rework

For any extended vehicle rework that results in consuming vehicle power, either the battery should be disconnected or a JLR

approved power supply connected.

2.4 Jump Starting New vehicles before they have been delivered to the customer

It is the dealer / retailers responsibility to make sure the battery is not allowed to discharge by following the

instructions and processes defined in this manual.

However, if circumstances dictate that a new vehicle must be jump started due to a discharged battery whilst the

vehicle is in the dealer / retailers care, the battery on this vehicle must be replaced with a new one prior to delivery

to the customer at the dealer / retailers liability.

The vehicle should also undergo investigation as to why the battery became discharged.

Do not connect the jump starting cable to the negative (-) terminal of the battery. Always connect to the recommended

earth point. As defined in the owners handbook or service documentation for that vehicle. 2.5 AGM Batteries

AGM batteries must not be charged above 14.8 Volts. Doing so will damage them.

AGM Batteries must be tested with a capable battery tester as detailed in the Equipment section (Section 5) of this

Page 1945 of 3039

player is only compatible with standard CD's. All other versions of CD player are compatible with standard CDs and CDs with MP3 or WMA (windows media audio) files.

A portable audio module allows for the connection of a range of portable audio devices to the car’s audio system. The portable

audio module is controlled through the IAM (integrated audio module) and Touch-screen with play back through the car’s

speaker system. The introduction of this system allows the user to import their personal portable media player to interface

with the car, including iPod and other MP3 players, or USB mass storage devices such as memory sticks. MP3 players can also

be controlled through the Touch-screen if they are configured as mass storage devices. Details of how to do this will be

contained in the manufacturers instructions.

The chosen audio device can be plugged into the car using an interface panel located in the floor console between the front

seats. The interface includes a 3.5mm auxiliary jack-plug socket, a 12-volt power supply, a dedicated iPod connector with

charging function, plus a USB2 connector which allows connectivity for a wide variety of USB devices. The USB port also

provides a charging function although it does not support a USB hub. The maximum charging current supplied is 500ma. The

user can connect an iPod and USB device at the same time, changing the source via the Touch-screen. The non selected source

will still charge.

The Jaguar Sound System is the basic audio system which comprises of an IAM (integrated audio module) with no external

amplifier and 8 speakers.

The Jaguar 320W Premium Sound System has the addition of an AUD 8 power amplifier and a 9 speaker system.

The Bowers & Wilkins 440w Surround Sound System additions include an AUD 12 power amplifier, a Dolby Pro-Logic 2 7.1

Surround Sound System, and 14 speakers.

DAB (digital audio broadcasting) is available for most European markets and gives access to digital radio channels for better

sound quality and enhanced functionality depending on local service availability. The DAB (digital audio broadcasting) module

is located in the luggage compartment. The system receives reception signals from the following sources to ensure optimum

signal strength.

DAB band L antenna located in the roof pod antenna module

DAB band III antenna located in the heated rear window.

For NAS vehicles the digital format adopted is satellite radio which specifically links to the Sirius network. The system operates

in the S-band frequency range, and as a result of the use of satellite transmission, has the ability to provide CD quality audio broadcasts over very large areas (typically continents). The satellite radio receiver is located in the luggage compartment. The

system receives reception signals from the satellite radio antenna located in the roof pod module.

Primary user control of the audio system is via the ICP (integrated control panel) and the Touch-screen which are located in the

center of the instrument panel. Control signals from the ICP (integrated control panel) are relayed on the medium speed CAN

(controller area network) bus to the ICM (information control module). The ICM (information control module) relays the control

signals to the rest of the audio system on the MOST (media oriented systems transport) ring. The ICM (information control

module) is the timing master for the MOST (media oriented systems transport) ring and also hosts a gateway function between

the medium speed CAN bus and the MOST (media oriented systems transport) ring. Audio output signals on the Jaguar 320W Premium Sound System and Bowers & Wilkins 440W Surround Sound System are sent on the MOST (media oriented systems

transport) ring from the IAM (integrated audio module) to the power amplifier for speaker output. www.JagDocs.com