change time JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1883 of 3039

first charges the battery to its full condition.

NOTE: If the vehicle is only driven for short periods the charging process could take a number of days to complete.

Once the battery is fully charged, the BMS control module will discharge the battery to approximately 75% of its full state of

charge, but never lower than 12.2 V. The time taken to complete this part of the routine is dependent on the electrical load on

the vehicle.

When the second part of the routine has been successfully completed, the BMS control module will return the battery to its

optimum level of charge. The optimum level of charge will be between 12.6 V and 15 V, depending on battery condition,

temperature and loading.

The BMS control module also monitors the primary battery condition with the engine switched off. If a low voltage condition is

detected the BMS control module can request the infotainment system is switched off to protect battery voltage.

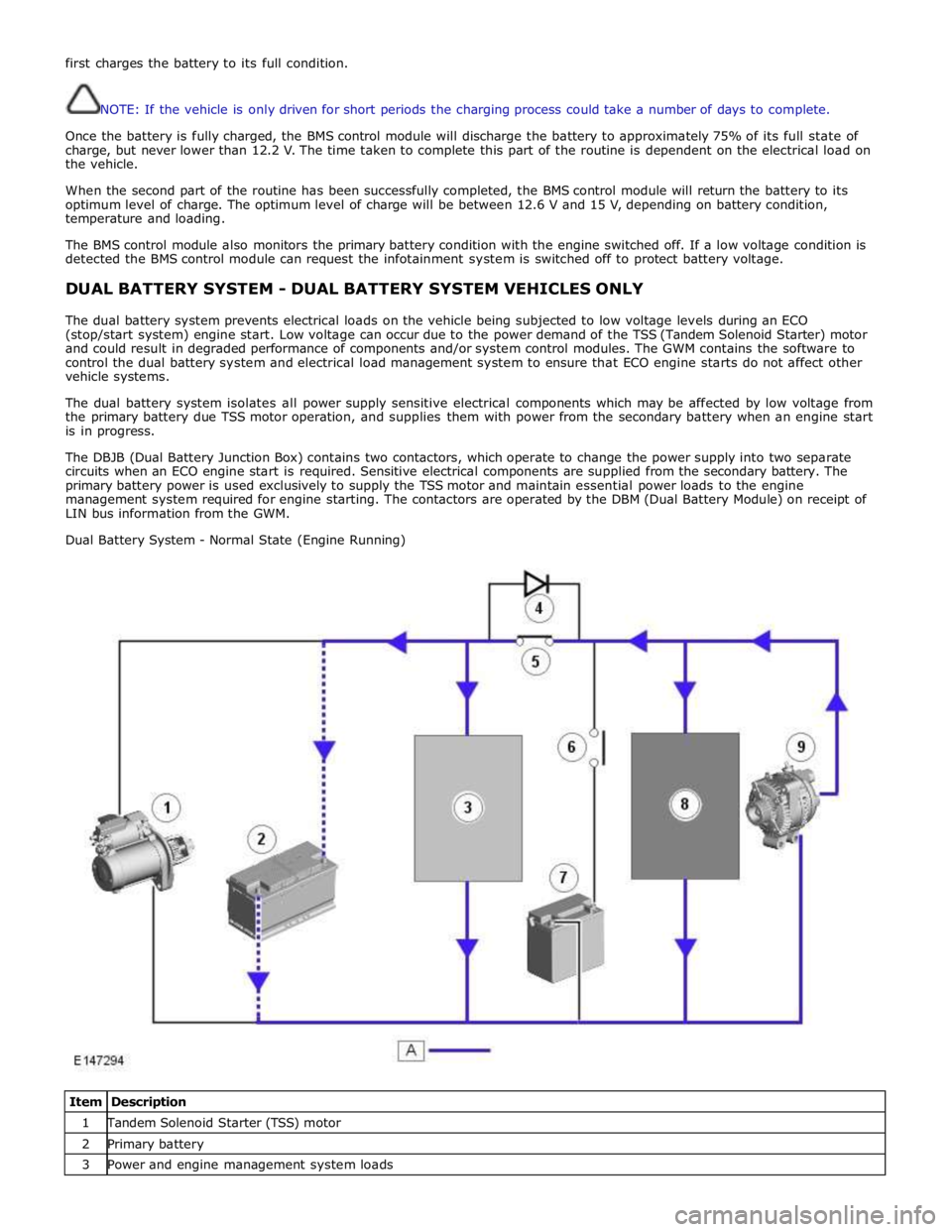

DUAL BATTERY SYSTEM - DUAL BATTERY SYSTEM VEHICLES ONLY

The dual battery system prevents electrical loads on the vehicle being subjected to low voltage levels during an ECO

(stop/start system) engine start. Low voltage can occur due to the power demand of the TSS (Tandem Solenoid Starter) motor

and could result in degraded performance of components and/or system control modules. The GWM contains the software to

control the dual battery system and electrical load management system to ensure that ECO engine starts do not affect other

vehicle systems.

The dual battery system isolates all power supply sensitive electrical components which may be affected by low voltage from

the primary battery due TSS motor operation, and supplies them with power from the secondary battery when an engine start

is in progress.

The DBJB (Dual Battery Junction Box) contains two contactors, which operate to change the power supply into two separate

circuits when an ECO engine start is required. Sensitive electrical components are supplied from the secondary battery. The

primary battery power is used exclusively to supply the TSS motor and maintain essential power loads to the engine

management system required for engine starting. The contactors are operated by the DBM (Dual Battery Module) on receipt of

LIN bus information from the GWM.

Dual Battery System - Normal State (Engine Running)

Item Description 1 Tandem Solenoid Starter (TSS) motor 2 Primary battery 3 Power and engine management system loads

Page 1886 of 3039

the secondary battery (if fitted) and passes through a grommet in the floorpan.

On new vehicles the primary battery positive terminal is fitted with a transit relay. The transit relay must removed using the

correct process detailed in the Pre Delivery Inspection (PDI) manual.

The battery negative terminal is fitted with a BMS control module. The control module is integral with the battery negative

cable and communicates with the GWM via a LIN bus connection. The battery condition information is passed to the GWM

which controls the generator output accordingly.

CAUTION: To avoid damage to the BMS control module, always use the body ground point in the engine compartment and

not the battery negative terminal when connecting a slave power supply.

Failure to use the recommended ground point will lead to the setting of a DTC. Incorrect information of battery condition will

be retained by the BMS control module due to the unmonitored current flow into the battery. The system will however,

recognize and compensate for the change in battery status after a period of time.

If a new battery is fitted, the BMS control module will require re-calibration using a Jaguar approved diagnostic system.

Replacement of the BMS control module requires no action as the control module will re-calibrate automatically.

SECONDARY BATTERY - DUAL BATTERY VEHICLES ONLY

The secondary battery is located in a tray on the next of the primary battery and is secured to the DBJB with a bracket. The

battery negative (-) terminal is connected via a cable to the vehicle body. The positive (+) terminal is connected by a cable to

the DBJB. The battery is vented via a tube which is connected with a T piece to the vent from the primary battery and passes

through a grommet in the floorpan.

The state of charge of the secondary battery is monitored by the Gateway Module (GWM).

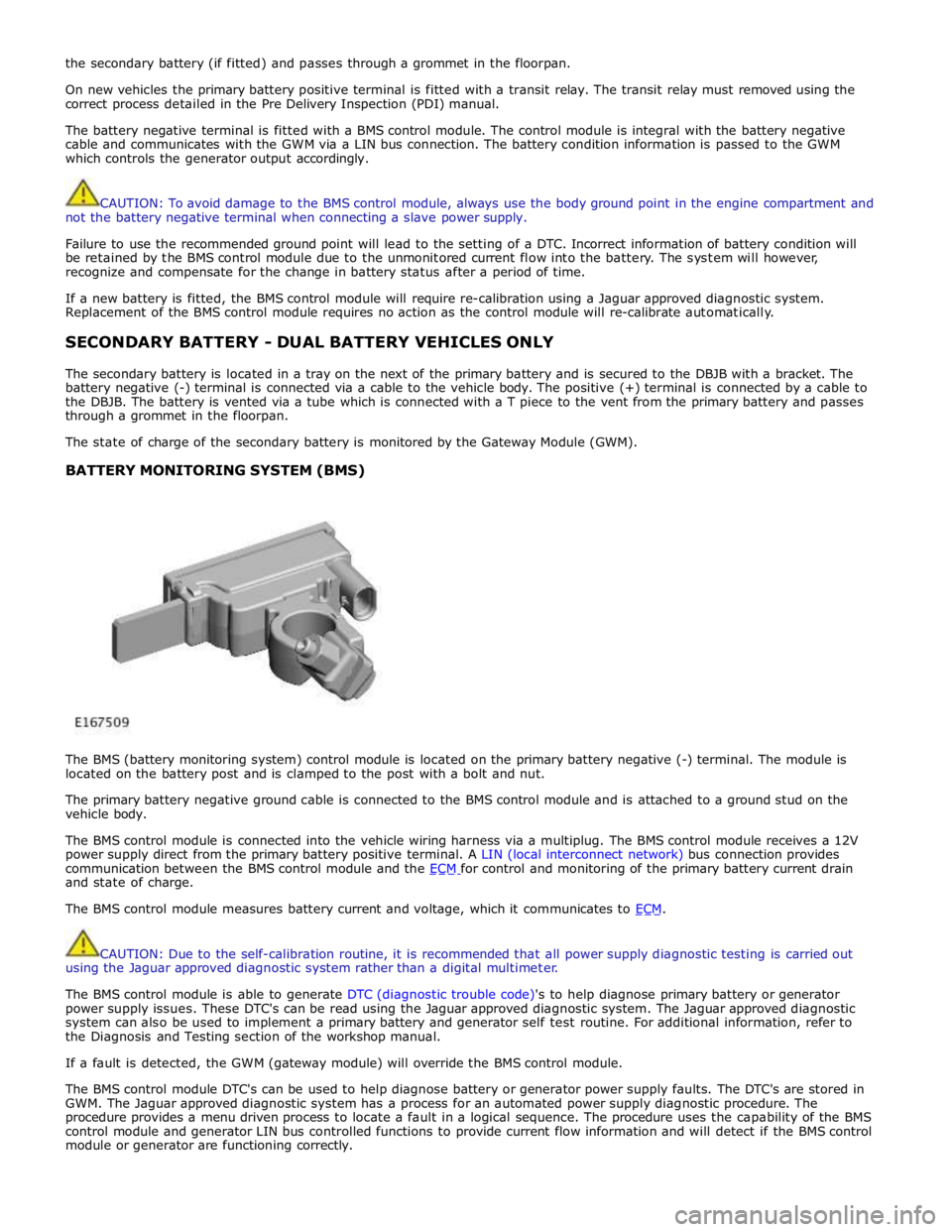

BATTERY MONITORING SYSTEM (BMS)

The BMS (battery monitoring system) control module is located on the primary battery negative (-) terminal. The module is

located on the battery post and is clamped to the post with a bolt and nut.

The primary battery negative ground cable is connected to the BMS control module and is attached to a ground stud on the

vehicle body.

The BMS control module is connected into the vehicle wiring harness via a multiplug. The BMS control module receives a 12V

power supply direct from the primary battery positive terminal. A LIN (local interconnect network) bus connection provides

communication between the BMS control module and the ECM for control and monitoring of the primary battery current drain and state of charge.

The BMS control module measures battery current and voltage, which it communicates to ECM.

CAUTION: Due to the self-calibration routine, it is recommended that all power supply diagnostic testing is carried out

using the Jaguar approved diagnostic system rather than a digital multimeter.

The BMS control module is able to generate DTC (diagnostic trouble code)'s to help diagnose primary battery or generator

power supply issues. These DTC's can be read using the Jaguar approved diagnostic system. The Jaguar approved diagnostic

system can also be used to implement a primary battery and generator self test routine. For additional information, refer to

the Diagnosis and Testing section of the workshop manual.

If a fault is detected, the GWM (gateway module) will override the BMS control module.

The BMS control module DTC's can be used to help diagnose battery or generator power supply faults. The DTC's are stored in

GWM. The Jaguar approved diagnostic system has a process for an automated power supply diagnostic procedure. The

procedure provides a menu driven process to locate a fault in a logical sequence. The procedure uses the capability of the BMS

control module and generator LIN bus controlled functions to provide current flow information and will detect if the BMS control

module or generator are functioning correctly.

Page 1899 of 3039

Battery

test

code,

must

be

given if

a

battery,

starter

motor

or

generator

is

exchanged

under

warranty

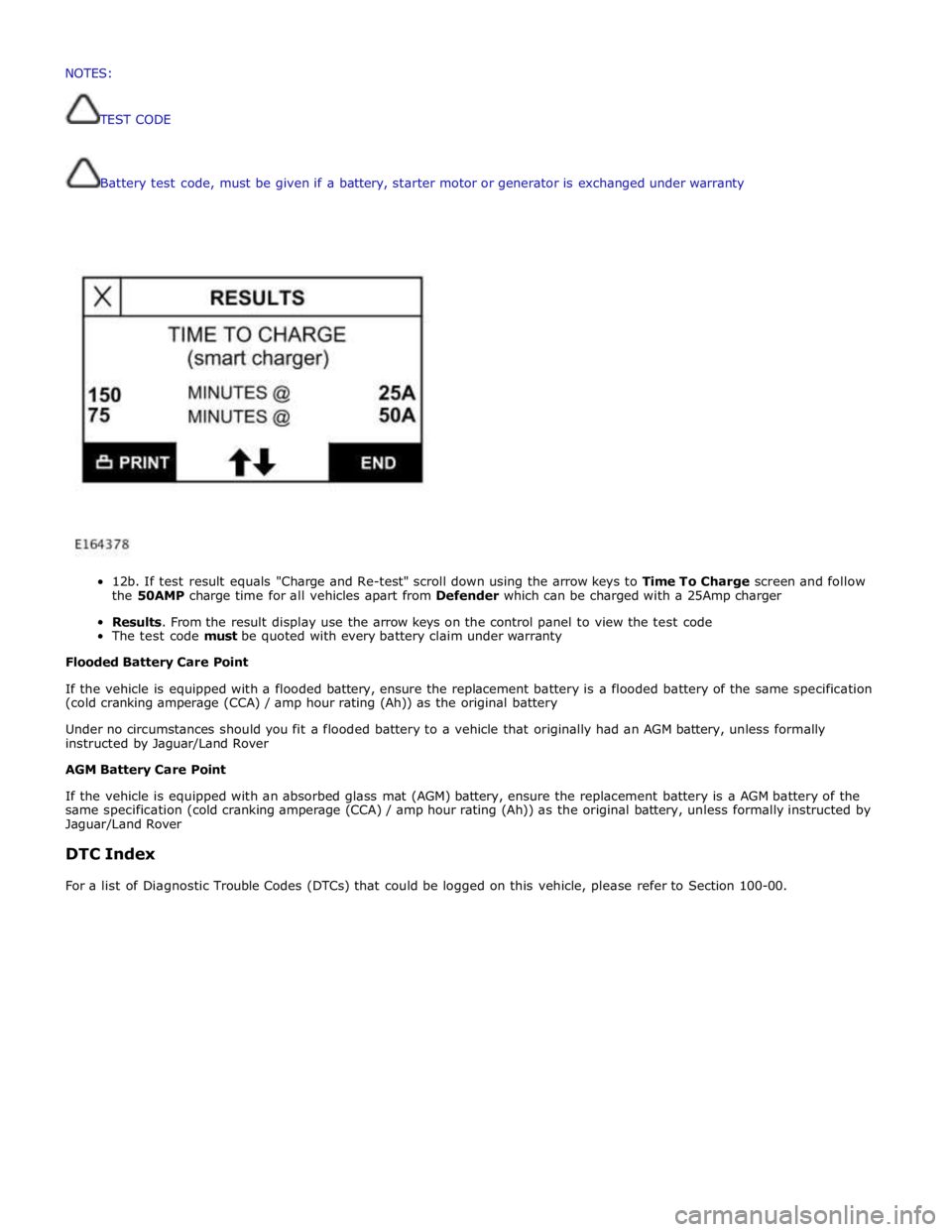

12b.

If

test

result

equals

"Charge

and

Re-test"

scroll

down

using

the

arrow

keys

to

Time To

Charge

screen and follow

the

50AMP

charge

time

for

all

vehicles

apart

from

Defender

which

can

be

charged

with a

25Amp

charger

Results.

From

the

result

display

use

the

arrow

keys

on

the

control

panel

to

view the

test

code

The

test

code

must

be

quoted

with every

battery

claim

under

warranty

Flooded

Battery

Care

Point

If

the

vehicle

is

equipped with

a

flooded

battery,

ensure

the

replacement

battery

is

a

flooded

battery

of

the

same

specification

(cold

cranking

amperage

(CCA)

/ amp

hour

rating

(Ah))

as

the

original

battery

Under

no

circumstances

should you

fit

a

flooded

battery

to a

vehicle

that

originally

had

an

AGM

battery,

unless

formally

instructed

by Jaguar/Land

Rover

AGM

Battery

Care

Point

If

the

vehicle

is

equipped with

an absorbed

glass

mat

(AGM)

battery,

ensure

the

replacement

battery

is

a

AGM

battery

of

the

same

specification

(cold

cranking

amperage

(CCA)

/

amp

hour

rating

(Ah))

as

the

original

battery,

unless

formally

instructed

by

Jaguar/Land

Rover

DTC

Index

For

a

list

of

Diagnostic

Trouble

Codes

(DTCs)

that

could

be

logged

on

this

vehicle,

please

refer

to

Section

100-00. NOTES:

TESTCODE

Page 1958 of 3039

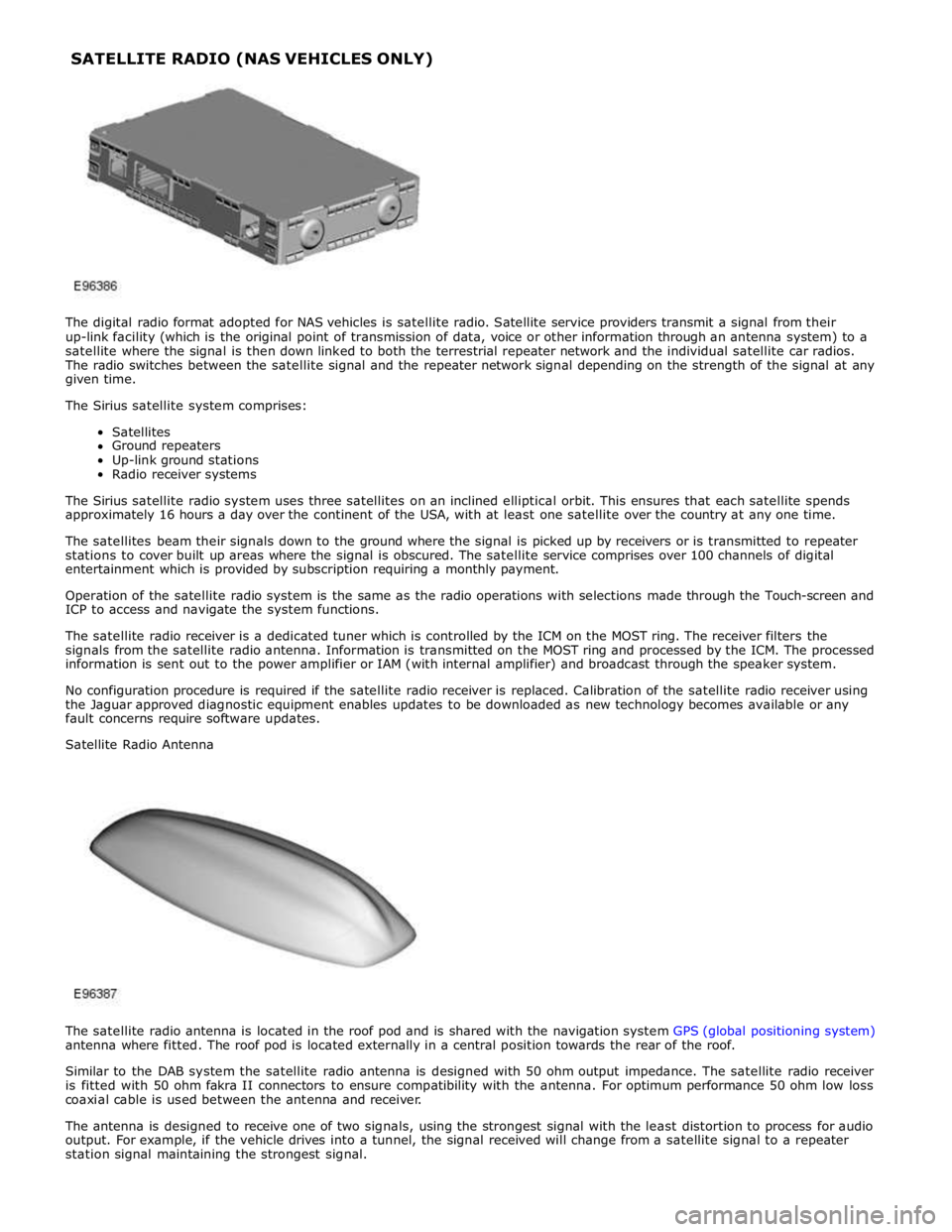

The digital radio format adopted for NAS vehicles is satellite radio. Satellite service providers transmit a signal from their

up-link facility (which is the original point of transmission of data, voice or other information through an antenna system) to a

satellite where the signal is then down linked to both the terrestrial repeater network and the individual satellite car radios.

The radio switches between the satellite signal and the repeater network signal depending on the strength of the signal at any

given time.

The Sirius satellite system comprises:

Satellites

Ground repeaters

Up-link ground stations

Radio receiver systems

The Sirius satellite radio system uses three satellites on an inclined elliptical orbit. This ensures that each satellite spends

approximately 16 hours a day over the continent of the USA, with at least one satellite over the country at any one time.

The satellites beam their signals down to the ground where the signal is picked up by receivers or is transmitted to repeater

stations to cover built up areas where the signal is obscured. The satellite service comprises over 100 channels of digital

entertainment which is provided by subscription requiring a monthly payment.

Operation of the satellite radio system is the same as the radio operations with selections made through the Touch-screen and

ICP to access and navigate the system functions.

The satellite radio receiver is a dedicated tuner which is controlled by the ICM on the MOST ring. The receiver filters the

signals from the satellite radio antenna. Information is transmitted on the MOST ring and processed by the ICM. The processed

information is sent out to the power amplifier or IAM (with internal amplifier) and broadcast through the speaker system.

No configuration procedure is required if the satellite radio receiver is replaced. Calibration of the satellite radio receiver using

the Jaguar approved diagnostic equipment enables updates to be downloaded as new technology becomes available or any

fault concerns require software updates.

Satellite Radio Antenna

The satellite radio antenna is located in the roof pod and is shared with the navigation system GPS (global positioning system)

antenna where fitted. The roof pod is located externally in a central position towards the rear of the roof.

Similar to the DAB system the satellite radio antenna is designed with 50 ohm output impedance. The satellite radio receiver

is fitted with 50 ohm fakra II connectors to ensure compatibility with the antenna. For optimum performance 50 ohm low loss

coaxial cable is used between the antenna and receiver.

The antenna is designed to receive one of two signals, using the strongest signal with the least distortion to process for audio

output. For example, if the vehicle drives into a tunnel, the signal received will change from a satellite signal to a repeater

station signal maintaining the strongest signal. SATELLITE RADIO (NAS VEHICLES ONLY)

Page 1977 of 3039

In addition to the standard navigation system there are two market dependant systems that supply extra information to the

navigation system and the driver. These are:

TMC (traffic message channel) (Europe only)

VICS (vehicle information and communication system) (Japan only)

The TMC (traffic message channel) is a function of the FM (frequency modulation)RDS (radio data system). The system

broadcasts real-time traffic and weather information. Data messages are received and decoded by the TMC (traffic message

channel) integral receiver and processed by the navigation computer. TMC (traffic message channel) messages can be filtered

by the navigation computer so that only those relevant to the current journey are displayed, allowing the navigation system to

offer dynamic route guidance - alerting the driver of a problem on the planned route and calculating an alternative route to

avoid the incident. All TMC (traffic message channel) events on the map can be viewed not just the ones on the calculated

route.

TMC (traffic message channel) traffic information systems conform to a global standard that has been adopted by traffic data

gatherers, information service providers, broadcasters and vehicle/receiver manufacturers.

All TMC (traffic message channel) receivers use the same list of event codes, while the location database (on the map disc)

contains both a country-specific set of location codes for the strategic European road network.

TMC (traffic message channel) traffic data is currently broadcast in many European countries.

The VICS (vehicle information and communication system) is broadcast in the Japanese market.

The VICS (vehicle information and communication system) supplies information to enable the navigation computer to re-route

the navigation guidance or to inform the vehicle driver of traffic conditions in the vehicles vicinity. Information is provided to

the system through 3 routes:

RF (radio frequency) transmission

Infra-red transmission

FM multiplex transmissions

The RF (radio frequency) transmissions are generally transmitted from road side beacons mainly on expressways. The

information transmitted is as follows:

Traffic congestion

Travel time to next intersection

Traffic conditions in surrounding areas and expressway turn offs

Traffic accidents

Speed limits

Lane regulations

Tire change

Parking availability at expressway service areas and parking areas

Infra-Red transmissions are transmitted from road side beacons on major trunk roads. The information transmitted is:

Traffic congestion and travel time

Traffic accidents

Breakdowns

Road works restrictions

Parking availability

FM transmissions are broadcast as part of the FM multiplex broadcasting system from NHK FM stations. Information transmitted is:

Traffic congestion and travel time for wide areas

Traffic accidents, road works, speed limits and lane restrictions for a wide area

Parking availability information

The traffic data is split from the normal FM transmissions by the diversity antenna module.

Selection of 'Navigation' on the Touch-screen home menu and subsequent sub-menu selection sends a control request signal to

the navigation computer on the MOST (media orientated systems transport) ring. The requested control information is

processed by the navigation computer.

If voice guidance is operational the voice signal information is relayed from the navigation computer on the MOST (media

orientated systems transport) ring to either the IAM (integrated audio unit) or Power Amplifier, dependant on equipment level,

for output on the speaker system. The navigation audio output is through the front speakers whilst the background audio, for

example radio or CD (compact disc), is played at a reduced volume on the rear speakers.

The GPS signal is available to the navigation system at all times when the vehicle ignition is switched on.

Navigation user voice commands are made using the JaguarVoice system. The ICM (information control module) processes the

analogue signal from the JaguarVoice switch into a digital signal. The digital signal is passed from the ICM (information control

module) onto the MOST (media orientated systems transport) system to the JaguarVoice control unit which is integral with the

navigation computer.

The navigation computer sends an instruction via the MOST (media orientated systems transport) ring to the IAM (integrated

audio module) to turn on the microphone facility.

The microphone is hardwired to the IAM (integrated audio module). The spoken voice command signals are relayed from the

IAM (integrated audio module) via the MOST (media orientated systems transport) ring to the navigation computer for

Page 2013 of 3039

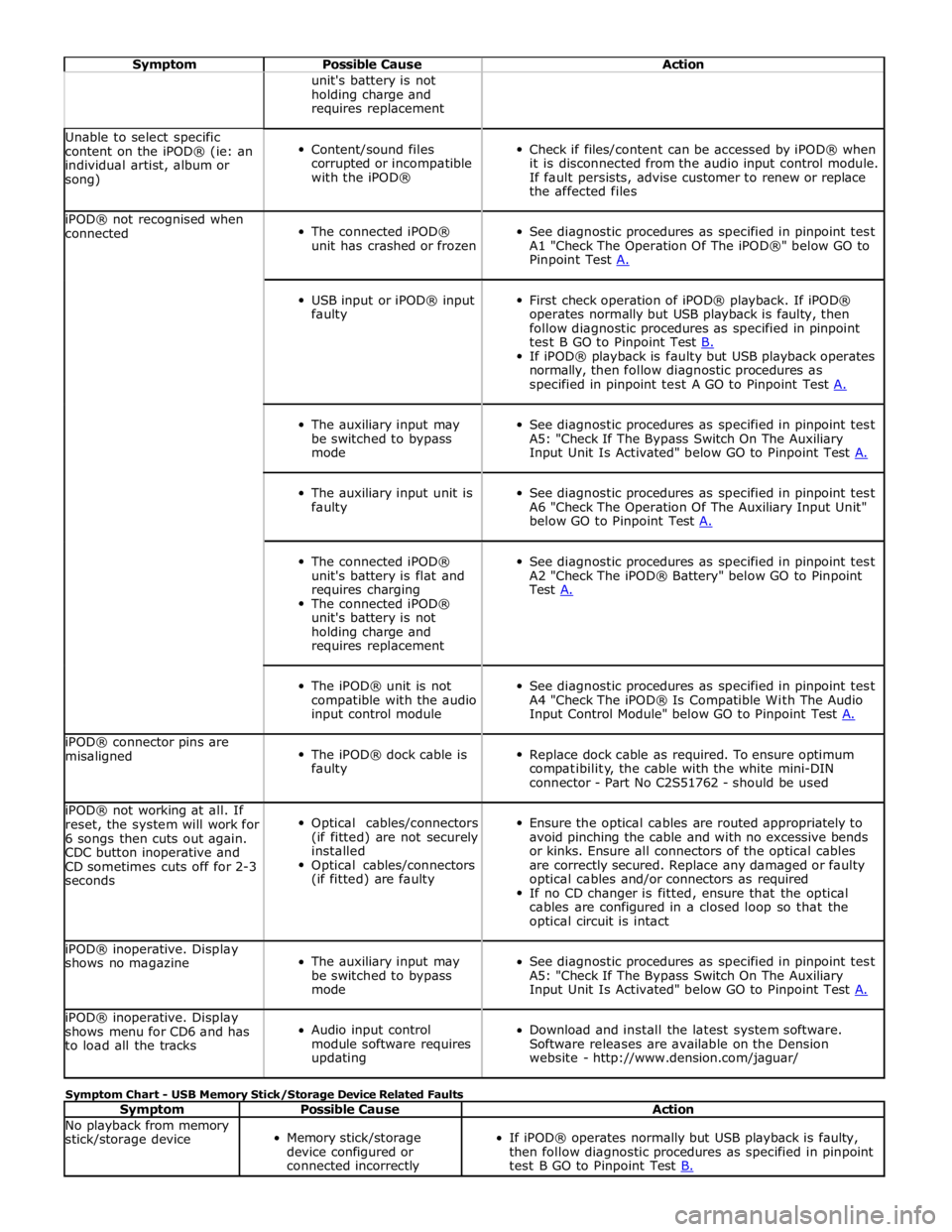

Symptom Possible Cause Action unit's battery is not

holding charge and

requires replacement Unable to select specific

content on the iPOD® (ie: an

individual artist, album or

song)

Content/sound files

corrupted or incompatible

with the iPOD®

Check if files/content can be accessed by iPOD® when

it is disconnected from the audio input control module.

If fault persists, advise customer to renew or replace

the affected files iPOD® not recognised when

connected

The connected iPOD®

unit has crashed or frozen

See diagnostic procedures as specified in pinpoint test

A1 "Check The Operation Of The iPOD®" below GO to

Pinpoint Test A.

USB input or iPOD® input

faulty

First check operation of iPOD® playback. If iPOD®

operates normally but USB playback is faulty, then

follow diagnostic procedures as specified in pinpoint

test B GO to Pinpoint Test B. If iPOD® playback is faulty but USB playback operates

normally, then follow diagnostic procedures as

specified in pinpoint test A GO to Pinpoint Test A.

The auxiliary input may

be switched to bypass

mode

See diagnostic procedures as specified in pinpoint test

A5: "Check If The Bypass Switch On The Auxiliary

Input Unit Is Activated" below GO to Pinpoint Test A.

The auxiliary input unit is

faulty

See diagnostic procedures as specified in pinpoint test

A6 "Check The Operation Of The Auxiliary Input Unit"

below GO to Pinpoint Test A.

The connected iPOD®

unit's battery is flat and

requires charging

The connected iPOD®

unit's battery is not

holding charge and

requires replacement

See diagnostic procedures as specified in pinpoint test

A2 "Check The iPOD® Battery" below GO to Pinpoint

Test A.

The iPOD® unit is not

compatible with the audio

input control module

See diagnostic procedures as specified in pinpoint test

A4 "Check The iPOD® Is Compatible With The Audio

Input Control Module" below GO to Pinpoint Test A. iPOD® connector pins are

misaligned

The iPOD® dock cable is

faulty

Replace dock cable as required. To ensure optimum

compatibility, the cable with the white mini-DIN

connector - Part No C2S51762 - should be used iPOD® not working at all. If

reset, the system will work for

6 songs then cuts out again.

CDC button inoperative and

CD sometimes cuts off for 2-3

seconds

Optical cables/connectors

(if fitted) are not securely

installed

Optical cables/connectors

(if fitted) are faulty

Ensure the optical cables are routed appropriately to

avoid pinching the cable and with no excessive bends

or kinks. Ensure all connectors of the optical cables

are correctly secured. Replace any damaged or faulty

optical cables and/or connectors as required

If no CD changer is fitted, ensure that the optical

cables are configured in a closed loop so that the

optical circuit is intact iPOD® inoperative. Display

shows no magazine

The auxiliary input may

be switched to bypass

mode

See diagnostic procedures as specified in pinpoint test

A5: "Check If The Bypass Switch On The Auxiliary

Input Unit Is Activated" below GO to Pinpoint Test A. iPOD® inoperative. Display

shows menu for CD6 and has

to load all the tracks

Audio input control

module software requires

updating

Download and install the latest system software.

Software releases are available on the Dension

website - http://www.dension.com/jaguar/ Symptom Chart - USB Memory Stick/Storage Device Related Faults

Symptom Possible Cause Action No playback from memory

stick/storage device

Memory stick/storage

device configured or

connected incorrectly

If iPOD® operates normally but USB playback is faulty,

then follow diagnostic procedures as specified in pinpoint

test B GO to Pinpoint Test B.

Page 2027 of 3039

by Field Effect Transistors (FET's). The FET's can detect overloads and short circuits and respond to heat generated by

increased current flow caused by a short circuit.

On a normal conventionally protected circuit this would cause a fuse to blow. The FET's respond to the heat increase and

disconnect the power supply to the affected circuit. When the fault is rectified or the FET has cooled, the FET will reset and

operate the circuit normally. If the fault persists the FET will cycle, disconnecting and reconnecting the power supply.

The CJB and the RJB store fault codes which can be retrieved using a Jaguar approved diagnostic system. The fault code will identify that there is a fault on a particular output circuit which will assist with fault diagnosis and detection.

Alarm Indications

The exterior lighting system is used for alarm arm and disarm requests to show alarm system status.

When the driver locks and arms the vehicle, a visual indication of a successful lock and arm request is displayed to the driver

by a single flash of the hazard flashers. If the vehicle is superlocked, then the hazard flashers will flash a second time (200 ms

off and 200 ms on) to confirm the superlock request.

If the alarm is activated, the hazard flashers are operated for 10, 30 second cycles of 200 ms on and 200 ms off, with a 10

second delay between each cycle.

NOTE: On North American Specification (NAS) vehicles, the delay between the cycle when the alarm is activated is 60

seconds.

Lights on Warning

When the ignition is in the off power mode 0 or accessory power mode 4 and the lighting control switch is in the side lamp or

headlamp position, a warning chime will sound if the driver's door is opened. This indicates to the driver that the exterior

lights have been left switched on.

The chime is generated from the instrument cluster sounder on receipt of a lights on signal, a driver's door open signal and an

ignition off power mode 0 or accessory power mode 4 signal via a medium speed CAN bus signal from the CJB. Headlamp Timer

The RJB controls the headlamp timer function which allows the headlamps to remain on for a period of time after leaving the vehicle. This is a driver convenience feature which illuminates the driveway after leaving the vehicle.

To operate the timer function the lighting control switch must be in one of the three headlamp timer positions when the

ignition status is changed from ignition on power mode 6 to the off power mode 0. The timer function will then be initiated and

the low beam headlamps will be illuminated for the selected timer period.

NOTE: If the lighting switch is in the AUTO position, the headlamp timer will not function when the ignition is changed to

off power mode 0.

When the lighting control switch is in the autolamp exit delay position, the lighting control switch reference voltage flows

through 4 of the resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on the

medium speed CAN bus to the RJB that autolamps has been selected.

Depending on the selected exit delay position, the reference voltage to the autolamp exit delay switch is routed through 3, 2

or 1 resistors which is detected by the instrument cluster. The cluster outputs a message on the medium speed CAN bus to the RJB that autolamp exit delay period has been selected at 30, 60 or 120 seconds respectively. Crash Signal Activation

When a crash signal is transmitted from the RCM (restraints control module), the RJB activates the hazard flashers. The hazard flashers continue to operate until the ignition is in the off power mode 0 or accessory power mode 6. Once this ignition state

has occurred, the RCM will cease to transmit the crash signal.

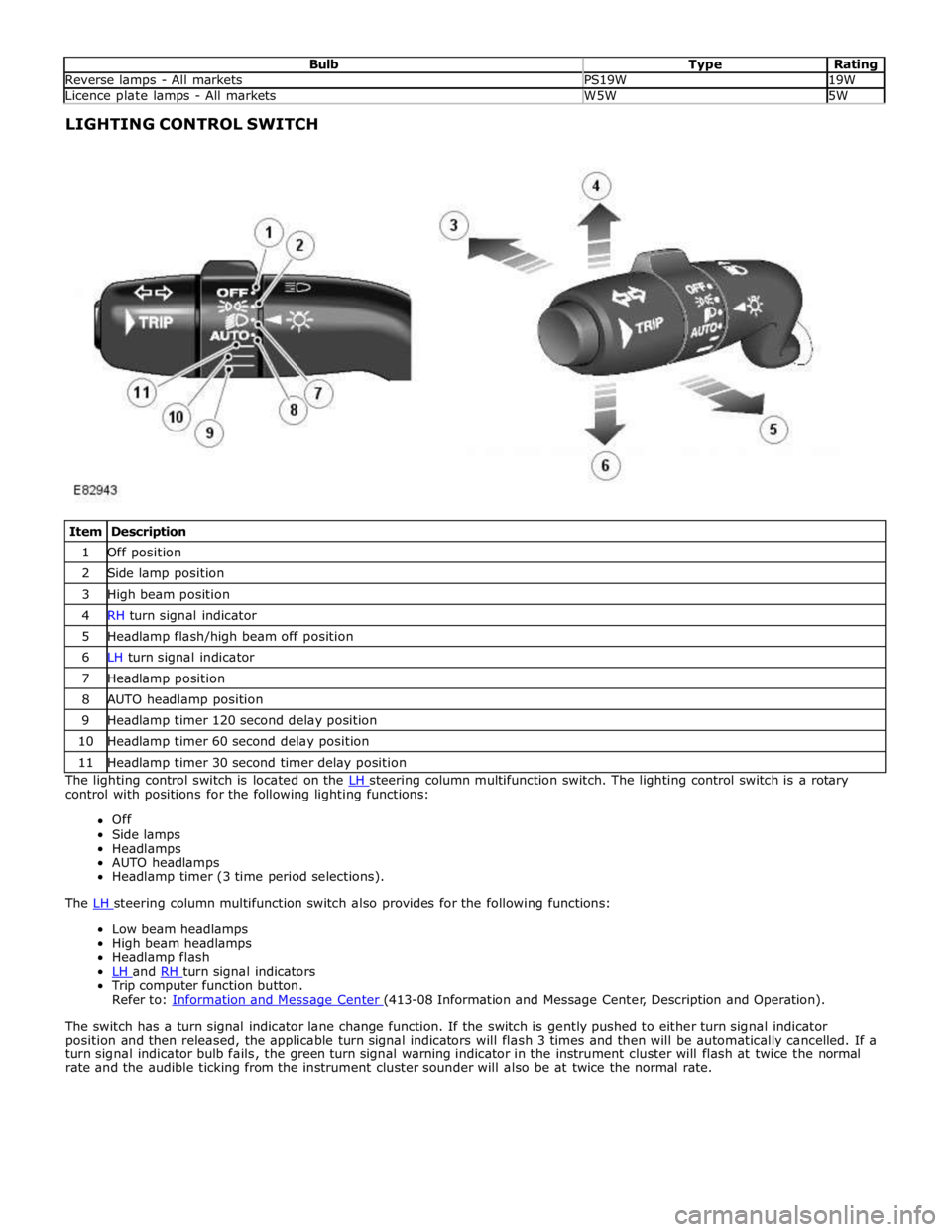

LIGHTING CONTROL SWITCH

The instrument cluster outputs 2 reference voltages to the rotary lighting control switch; one feed being supplied to the light

selection function of the switch and the second feed being supplied to the auto headlamp exit delay function. The switch

position is determined by instrument cluster by the change in returned signal voltage which is routed through up to 4 resistors

in series depending on the selection made.

OFF - When the lighting control switch is in the off position, the reference voltage flows through 1 of the resistors. The

returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that no lighting selection is made. The reference voltage to the auto headlamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that auto headlamp or exit delay has not been selected.

SIDE LAMPS - When the lighting control switch is in the side lamp position, the reference voltage flows through 2 of the

resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed

CAN bus to the CJB to activate the side lamps. The reference voltage to the autolamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that auto headlamp or exit delay has not been selected.

HEADLAMPS - When the lighting control switch is in the headlamp position, the reference voltage flows through 3 of the

Page 2028 of 3039

resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed

CAN bus to the CJB to activate the headlamps. The reference voltage to the auto headlamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that auto headlamp or exit delay has not been selected.

AUTOLAMPS - When the lighting control switch is in the auto headlamp position, the reference voltage flows through 4 of the

resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed

CAN bus to the CJB to activate the autolamp function. The reference voltage to the autolamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that auto headlamp has been selected.

AUXILIARY LIGHTING SWITCH

Headlamp Leveling Rotary Thumbwheel (Halogen headlamps only)

A power supply is passed to the headlamp leveling thumbwheel from the ignition relay in the EJB. Depending on the position of the thumbwheel, the voltage passes through 1, 2 or 3 resistors connected in series. The voltage through the resistors is

passed to the headlamp leveling motor controller in each headlamp. The received voltage is determined as a request for the

appropriate level position and the controller powers the headlamp level motors to the applicable position for each headlamp.

Rear Fog Lamp Switch

The instrument cluster supplies a reference voltage and return to the rear fog lamp switch. The fog lamp switch is a

non-latching, momentary switch.

When the fog lamp switch is off the reference voltage is passed through a 1Kohm resistor. The voltage through the resistor is

returned to the instrument cluster that determines that no request for fog lamp operation has been made.

When the driver presses the fog lamp switch, the reference voltage is passed through a 330 ohm resistor. The change is return

voltage is sensed by the instrument cluster which determines fog lamp operation has been requested. The instrument cluster

transmits a medium speed CAN bus signal to the RJB providing the lighting control switch is in the correct position. The RJB reacts to the message and provides a power supply to the 3 LED (light emitting diode)'s in each rear fog lamp. A fog lamp

warning lamp in the instrument cluster will also be illuminated when the fog lamps are operating.

The RJB will only activate the rear fog lamps if the headlamps are selected on or are active with auto headlamp activation. When the headlamps are turned off the fog lamps are also turned off. When the headlamps are next switched on, the fog

lamps will not be activated until the driver requests fog lamp operation.

NOTE: The fog lamps do operate when DRL (daytime running lamps) are active.

HEADLAMP LEVELING

Manual Headlamp Leveling - Halogen headlamps only

A power supply is passed to the headlamp leveling motor in each headlamp from the ignition relay in the EJB. When a signal voltage is received from the headlamp leveling rotary thumbwheel, the headlamp leveling motor controller in each headlamp

uses the power supply to operate the motors and move the headlamp to the requested position.

Static Dynamic Headlamp Leveling - Xenon headlamps only

The headlamp leveling module receives a power supply from the ignition relay in the EJB. The same power supply is also supplied to the headlamp leveling motor in each headlamp assembly. The front and rear height sensors are connected to the

headlamp leveling module and receive a power and ground from the module. Each sensor has a signal line to the headlamp

leveling module to return height information to the module. The module uses the height signals from the sensors to calculate

the vehicle attitude and supplies a signal to each motor to power the headlamp to the required position.

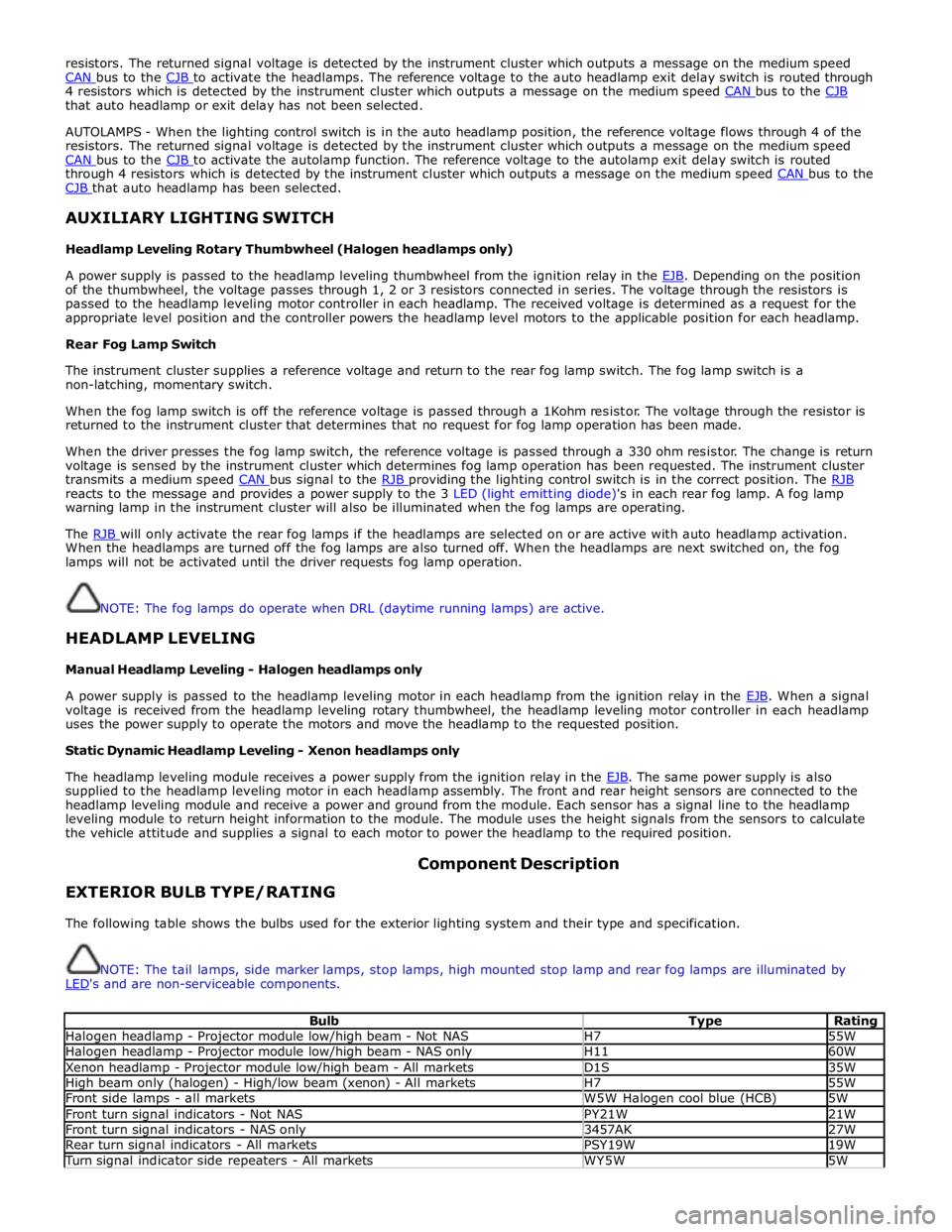

EXTERIOR BULB TYPE/RATING Component Description

The following table shows the bulbs used for the exterior lighting system and their type and specification.

NOTE: The tail lamps, side marker lamps, stop lamps, high mounted stop lamp and rear fog lamps are illuminated by

LED's and are non-serviceable components.

Bulb Type Rating Halogen headlamp - Projector module low/high beam - Not NAS H7 55W Halogen headlamp - Projector module low/high beam - NAS only H11 60W Xenon headlamp - Projector module low/high beam - All markets D1S 35W High beam only (halogen) - High/low beam (xenon) - All markets H7 55W Front side lamps - all markets W5W Halogen cool blue (HCB) 5W Front turn signal indicators - Not NAS PY21W 21W Front turn signal indicators - NAS only 3457AK 27W Rear turn signal indicators - All markets PSY19W 19W Turn signal indicator side repeaters - All markets WY5W 5W

Page 2029 of 3039

Bulb Type Rating Reverse lamps - All markets PS19W 19W Licence plate lamps - All markets W5W 5W LIGHTING CONTROL SWITCH

Item Description 1 Off position 2 Side lamp position 3 High beam position 4 RH turn signal indicator 5 Headlamp flash/high beam off position 6 LH turn signal indicator 7 Headlamp position 8 AUTO headlamp position 9 Headlamp timer 120 second delay position 10 Headlamp timer 60 second delay position 11 Headlamp timer 30 second timer delay position The lighting control switch is located on the LH steering column multifunction switch. The lighting control switch is a rotary control with positions for the following lighting functions:

Off

Side lamps

Headlamps

AUTO headlamps

Headlamp timer (3 time period selections).

The LH steering column multifunction switch also provides for the following functions: Low beam headlamps

High beam headlamps

Headlamp flash

LH and RH turn signal indicators Trip computer function button.

Refer to: Information and Message Center (413-08 Information and Message Center, Description and Operation).

The switch has a turn signal indicator lane change function. If the switch is gently pushed to either turn signal indicator

position and then released, the applicable turn signal indicators will flash 3 times and then will be automatically cancelled. If a

turn signal indicator bulb fails, the green turn signal warning indicator in the instrument cluster will flash at twice the normal

rate and the audible ticking from the instrument cluster sounder will also be at twice the normal rate.

Page 2032 of 3039

15 Xenon igniter unit and bulb 16 Xenon igniter electrical connector 17 Cornering/static bending lamp bulb (if fitted) 18 Side lamp bulb 19 High beam headlamp bulb 20 Cover - Side lamp, cornering/static bending lamp (if fitted) and high beam headlamp bulbs 21 Electrical connector Bi-Xenon Headlamp

The bi-xenon headlamp uses a projector lens, similar to the halogen headlamp. The projector module comprises an ellipsoidal

lens and a reflector. The projector reflector collects the light produced by the halogen bulb and projects the light into a focal

plane containing a shield. The contour of the shield is projected onto the road by the lens. A complex surface reflector is used

for the halogen fill in high beam lamp. This type of reflector is divided into separate parabolic segments, with each segment

having a different focal length. The low and high beam bulbs are quartz halogen H7, with a rating of 55W. The bulbs are

retained in the headlamp unit with conventional wire retaining clips.

A tourist lever mechanism is located on the right hand side of the projector module. This mechanism moves a flap to blank off

a portion of the beam spread to enable the vehicle to be driven in opposite drive hand markets without applying blanking

decals to the headlamp lens. The beam is changed by removing the access cover at the rear of the lamp assembly and moving

a small lever located near the bulb holder, at the side of the projector.

NOTE: The tourist lever is not fitted to NAS vehicles.

WARNING: The Xenon system generates up to 30000 volts and contact with this voltage could lead to fatality. Make sure

that the headlamps are switched off before working on the system.

The following safety precautions must be adhered to when working on the xenon low beam headlamp system:

DO NOT attempt any procedures on the xenon headlamps when the lights are switched on.

Handling of the D1S xenon bulb must be performed using suitable protective equipment; for example gloves and

goggles. The glass part of the bulb must not be touched.

Xenon bulbs must be disposed of as hazardous waste.

Only operate the bulb in a mounted condition in the projector module installed in the headlamp.

The xenon headlamp is known as 'bi-xenon' because it operates as both a low and high beam headlamp unit. The xenon lamp,

or High Intensity Discharge (HID) lamp as they are sometimes referred to, comprises an ellipsoidal lens with a solenoid

controlled shutter to change the beam output from low to high beam.

NOTE: If the lighting control switch is in the 'off' position, both the xenon lamp and the halogen high beam lamp will

operate when the high beam 'flash' function is operated.

The xenon headlamp system is controlled by the CJB using a control module for each headlamp and an igniter. The control modules and the igniters provide the regulated power supply required to illuminate the bulbs through their start-up phases of

operation.

The xenon headlamp is a self contained unit located within the headlamp assembly. The unit comprises a reflector, an adaptor

ring, the lens, a shutter controller and the xenon bulb, which together forms an assembly known as the projector module. The

reflector is curved and provides the mounting point for the xenon bulb. The bulb locates in a keyway to ensure the correct

alignment in the reflector and is secured by a plastic mounting ring. The bulb is an integral component of the igniter and is

electrically connected by a connector located in the igniter unit.

The shutter controller is a solenoid which operates the shutter mechanism via a lever. The shutter is used to change the beam

projection from low beam to high beam and vice versa.

The xenon bulbs illuminate when an arc of electrical current is established between 2 electrodes within the bulb. The xenon

gas sealed in the bulb reacts to the electrical excitation and the heat generated by the current flow to produce the

characteristic blue/white light.

To operate at full efficiency, the xenon bulb goes through 3 full stages of operation before full output for continuous operation

is achieved. The 3 phases are; start-up phase, warm-up phase and continuous phase.

In the start-up phase, the bulb requires an initial high voltage starting pulse of up to 30000 volts to establish the arc. This is

produced by the igniter. The warm-up phase begins once the arc is established. The xenon control module regulates the supply

to the bulb to 2.6A which gives a lamp output of 75W. During this phase, the xenon gas begins to illuminate brightly and the

environment within the bulb stabilizes, ensuring a continual current flow between the electrodes. When the warm-up phase is

complete, the xenon control module changes to continuous phase. The supply voltage to the bulb is reduced and the operating

power required for continual operation is reduced to 35W. The process from start-up to continuous phase is completed in a very

short time.

The xenon control modules (one per headlamp) receive an operating voltage from the CJB when the headlamps are switched on. The modules regulate the power supply required through the phases of start-up.

The igniters (one per headlamp) generate the initial high voltage required to establish the arc. The igniters have integral coils

which generate high voltage pulses required for start-up. Once the xenon bulbs are operating, the igniters provide a closed

circuit for the regulated power supply from the control modules.