headlamp JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2 of 3039

Table of ContentsContents1: General Information

100: Service Information

100-00: General Information

Description and OperationAbout This Manual

Application and Use of Specifications

Battery and Battery Charging Health and Safety Precautions

Brake System Health and Safety Precautions

Diesel Fuel System Health and Safety Precautions

General Service Information

Health and Safety Precautions

How To Use This Manual

Important Safety Instructions

Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions

Solvents, Sealants and Adhesives

Standard Workshop Practices

Symbols Glossary

Supplemental Restraint System (SRS) Health and Safety Precautions

Road/Roller Testing

Window Glass Health and Safety Precautions

Diagnostic Trouble Code (DTC) IndexDTC: Adaptive Damping Module (SUMB)

Diagnostic Trouble Code (DTC) IndexDTC: Anti-Lock Braking System (ABS)

Diagnostic Trouble Code (DTC) IndexDTC: Audio Amplifier Module (AAM)

Diagnostic Trouble Code (DTC) IndexDTC: Blind Spot Monitoring System Module (SODL/SODR)

Diagnostic Trouble Code (DTC) IndexDTC: Central Junction Box (CJB)

Diagnostic Trouble Code (DTC) IndexDTC: Climate Control Module (HVAC)

Diagnostic Trouble Code (DTC) IndexDTC: Digital Audio Broadcast Module (DABM)

Diagnostic Trouble Code (DTC) IndexDTC: Driver Door Module/Passenger Door Module (DDM/PDM)

Diagnostic Trouble Code (DTC) IndexDTC: Driver/Passenger Seat Module (DSM/PSM)

Diagnostic Trouble Code (DTC) IndexDTC: Electric Parking Brake (PBM)

Diagnostic Trouble Code (DTC) Index V8 S/C 5.0L Petrol, DTC: Engine Control Module (ECM)

Diagnostic Trouble Code (DTC) IndexDTC: Front Seat Climate Control Module (DCSM)

Diagnostic Trouble Code (DTC) IndexDTC: Headlamp Control Module (HCM)

Diagnostic Trouble Code (DTC) IndexDTC: Instrument Cluster (IPC)

Diagnostic Trouble Code (DTC) IndexDTC: Integrated Audio Module (IAM)

Diagnostic Trouble Code (DTC) IndexDTC: Integrated Control Panel (FCIMB)

Page 22 of 3039

Operation and

Component DescriptionCellular PhoneComponent

Location

Overview

System Operation

and Component DescriptionNavigation SystemComponent Location

Overview

System Operation and Component DescriptionVideo SystemComponent

Location

Overview

System Operation

and Component DescriptionDiagnosis and TestingInformation and Entertainment SystemRemoval and InstallationAudio Unit

Audio Unit Antenna Amplifier

Audio and Climate Control Assembly

Front Door Speaker

Information and Entertainment Display

Information and Entertainment Module

Instrument Panel Speaker

Rear Door Speaker

Steering Wheel Audio Controls

Subwoofer Amplifier

Subwoofer Speaker

Satellite Radio Tuner415-01B: Information and Entertainment System - DTC: Audio Input Control Module

Diagnosis and TestingAudio Input Control Module417: Lighting

417-01: Exterior LightingSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingHeadlampsGeneral ProceduresHeadlamp Adjustment (86.40.18)

Page 23 of 3039

Removal and InstallationApproach Lamp

Headlamp Assembly

Headlamp Leveling Front Sensor

Headlamp Leveling Rear Sensor

High Mounted Stoplamp

Rear Fog Lamp

Rear Lamp Assembly

Side Turn Signal Lamp417-02: Interior Lighting

Description and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingInterior Lighting417-04: Daytime Running Lamps (DRL)

Description and OperationOverview

System Operation and Component Description418: Electrical Distribution

418-00: Module Communications Network

Description and OperationOverview

System Operation and Component DescriptionDiagnosis and TestingCommunications NetworkRemoval and InstallationAuxiliary Junction Box (AJB)

Central Junction Box (CJB)418-02: Wiring Harnesses

Description and OperationWiring HarnessGeneral ProceduresWiring Harness RepairRemoval and InstallationLuggage Compartment Lid Wiring Harness419: Electronic Feature Group

419-01A: Anti-Theft - Active

Description and OperationComponent Location

Overview

Page 28 of 3039

Instrument Panel Console

Instrument Panel Lower Trim Panel

Overhead Console501-14: Handles, Locks, Latches and Entry SystemsSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingLocks, Latches and Entry SystemsRemoval and InstallationDoor Lock Cylinder Cover

Exterior Front Door Handle

Exterior Luggage Compartment Lid Release Switch

Exterior Rear Door Handle

Front Door Latch

Front Door Lock Cylinder

Interior Front Door Handle

Luggage Compartment Lid Latch Actuator

Luggage Compartment Lid Lock Cylinder

Rear Door Latch501-16: Wipers and WashersSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingWipers and WashersRemoval and InstallationHeadlamp Washer Jet

Headlamp Washer Pump

Rain Sensor

Windshield Washer Reservoir

Windshield Wiper Motor

Windshield Wiper Pivot Arm

Windshield Washer Pump501-17: Roof Opening PanelSpecificationDescription and OperationComponent Location

Page 183 of 3039

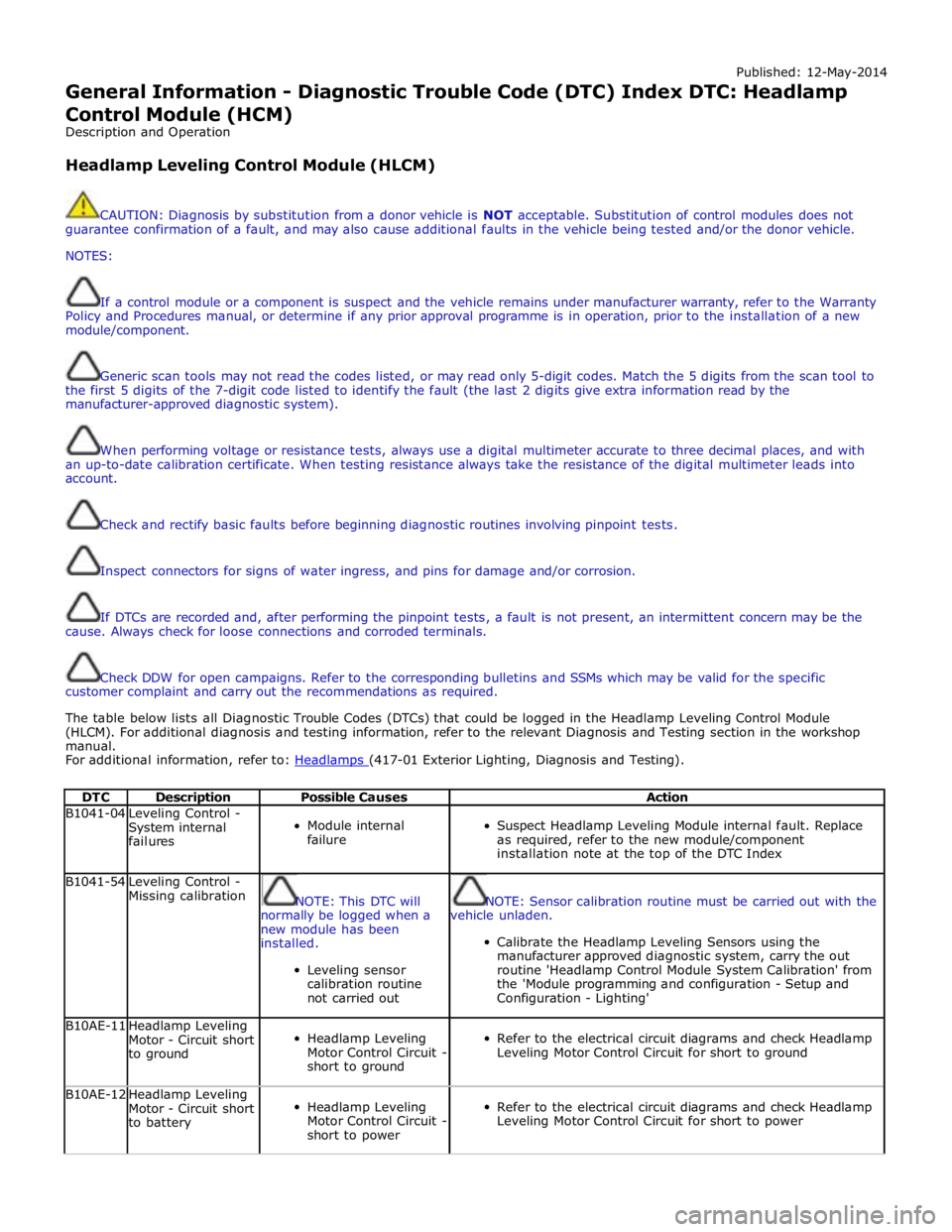

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Headlamp

Control Module (HCM)

Description and Operation

Headlamp Leveling Control Module (HLCM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Headlamp Leveling Control Module

(HLCM). For additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop

manual.

For additional information, refer to: Headlamps (417-01 Exterior Lighting, Diagnosis and Testing).

DTC Description Possible Causes Action B1041-04

Leveling Control -

System internal

failures

Module internal

failure

Suspect Headlamp Leveling Module internal fault. Replace

as required, refer to the new module/component

installation note at the top of the DTC Index B1041-54

Leveling Control -

Missing calibration

NOTE: This DTC will

normally be logged when a

new module has been

installed.

Leveling sensor

calibration routine

not carried out

NOTE: Sensor calibration routine must be carried out with the

vehicle unladen.

Calibrate the Headlamp Leveling Sensors using the

manufacturer approved diagnostic system, carry the out

routine 'Headlamp Control Module System Calibration' from

the 'Module programming and configuration - Setup and

Configuration - Lighting' B10AE-11

Headlamp Leveling

Motor - Circuit short

to ground

Headlamp Leveling

Motor Control Circuit -

short to ground

Refer to the electrical circuit diagrams and check Headlamp

Leveling Motor Control Circuit for short to ground B10AE-12

Headlamp Leveling

Motor - Circuit short

to battery

Headlamp Leveling

Motor Control Circuit -

short to power

Refer to the electrical circuit diagrams and check Headlamp

Leveling Motor Control Circuit for short to power

Page 184 of 3039

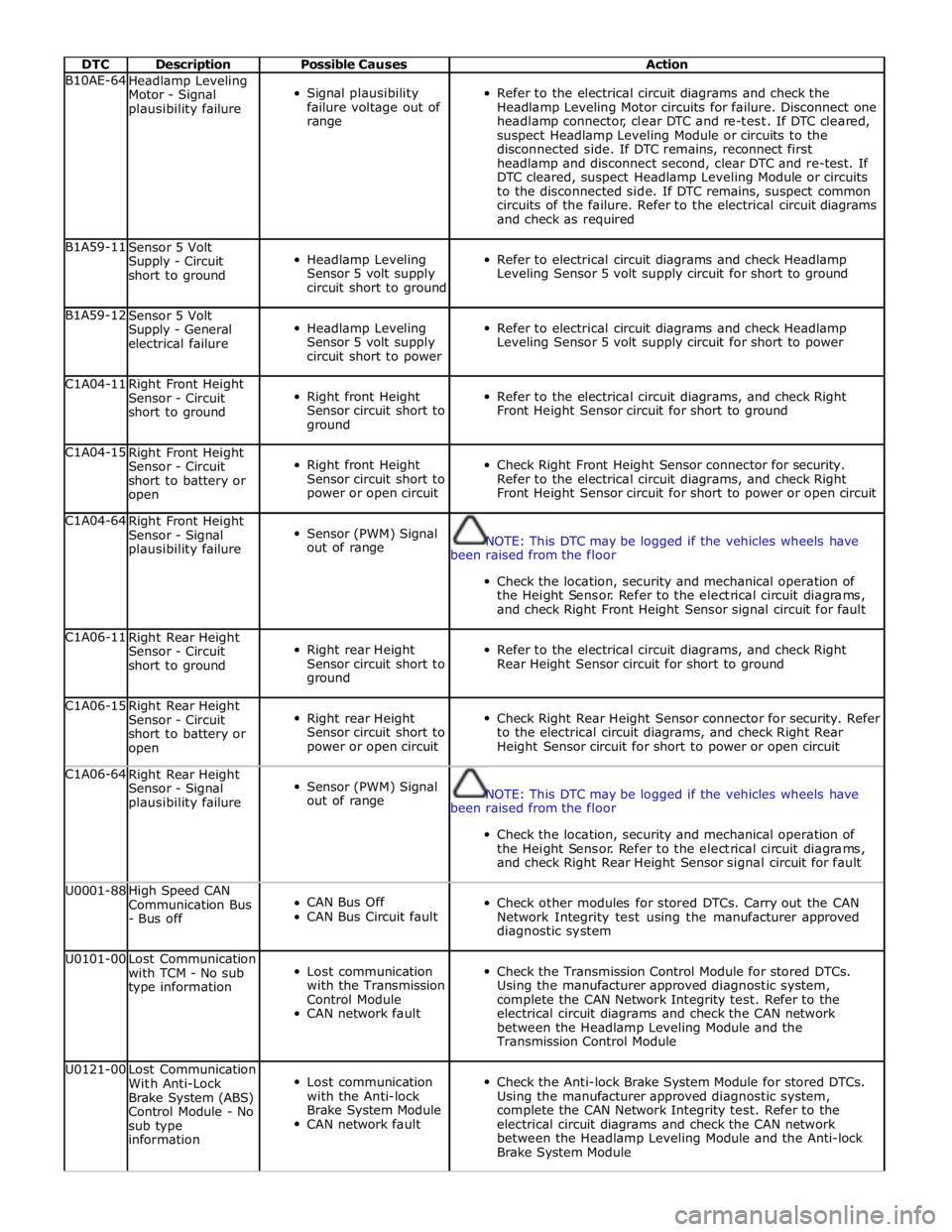

DTC Description Possible Causes Action B10AE-64

Headlamp Leveling

Motor - Signal

plausibility failure

Signal plausibility

failure voltage out of

range

Refer to the electrical circuit diagrams and check the

Headlamp Leveling Motor circuits for failure. Disconnect one

headlamp connector, clear DTC and re-test. If DTC cleared,

suspect Headlamp Leveling Module or circuits to the

disconnected side. If DTC remains, reconnect first

headlamp and disconnect second, clear DTC and re-test. If

DTC cleared, suspect Headlamp Leveling Module or circuits

to the disconnected side. If DTC remains, suspect common

circuits of the failure. Refer to the electrical circuit diagrams

and check as required B1A59-11

Sensor 5 Volt

Supply - Circuit

short to ground

Headlamp Leveling

Sensor 5 volt supply

circuit short to ground

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to ground B1A59-12

Sensor 5 Volt

Supply - General

electrical failure

Headlamp Leveling

Sensor 5 volt supply

circuit short to power

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to power C1A04-11

Right Front Height

Sensor - Circuit

short to ground

Right front Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to ground C1A04-15

Right Front Height

Sensor - Circuit

short to battery or

open

Right front Height

Sensor circuit short to

power or open circuit

Check Right Front Height Sensor connector for security.

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to power or open circuit C1A04-64

Right Front Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Front Height Sensor signal circuit for fault C1A06-11

Right Rear Height

Sensor - Circuit

short to ground

Right rear Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Rear Height Sensor circuit for short to ground C1A06-15

Right Rear Height

Sensor - Circuit

short to battery or

open

Right rear Height

Sensor circuit short to

power or open circuit

Check Right Rear Height Sensor connector for security. Refer

to the electrical circuit diagrams, and check Right Rear

Height Sensor circuit for short to power or open circuit C1A06-64

Right Rear Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Rear Height Sensor signal circuit for fault U0001-88

High Speed CAN

Communication Bus

- Bus off

CAN Bus Off

CAN Bus Circuit fault

Check other modules for stored DTCs. Carry out the CAN

Network Integrity test using the manufacturer approved

diagnostic system U0101-00

Lost Communication

with TCM - No sub

type information

Lost communication

with the Transmission

Control Module

CAN network fault

Check the Transmission Control Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0121-00

Lost Communication

With Anti-Lock

Brake System (ABS)

Control Module - No

sub type

information

Lost communication

with the Anti-lock

Brake System Module

CAN network fault

Check the Anti-lock Brake System Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the Anti-lock

Brake System Module

Page 185 of 3039

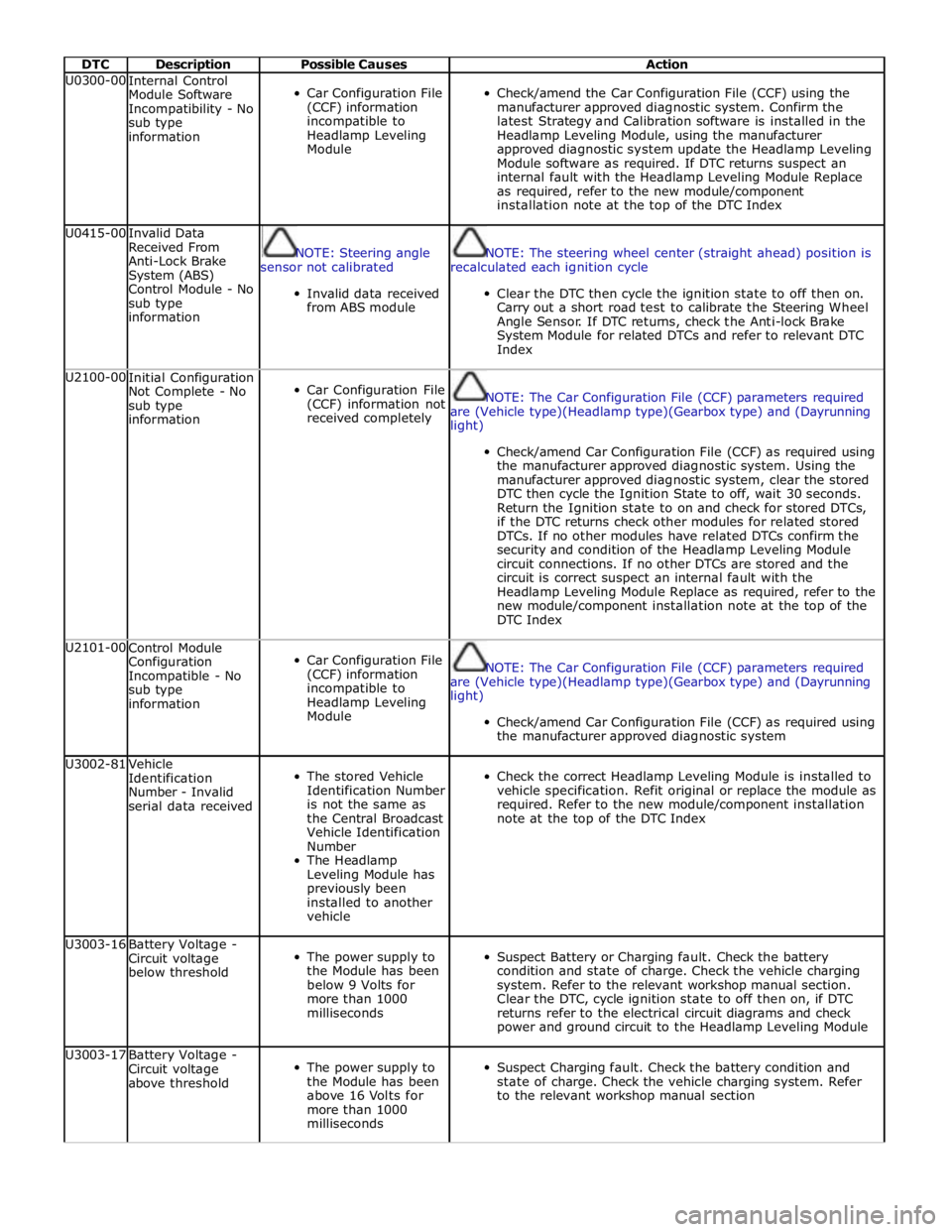

DTC Description Possible Causes Action U0300-00

Internal Control

Module Software

Incompatibility - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

Check/amend the Car Configuration File (CCF) using the

manufacturer approved diagnostic system. Confirm the

latest Strategy and Calibration software is installed in the

Headlamp Leveling Module, using the manufacturer

approved diagnostic system update the Headlamp Leveling

Module software as required. If DTC returns suspect an

internal fault with the Headlamp Leveling Module Replace

as required, refer to the new module/component

installation note at the top of the DTC Index U0415-00

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module - No

sub type

information

NOTE: Steering angle

sensor not calibrated

Invalid data received

from ABS module

NOTE: The steering wheel center (straight ahead) position is

recalculated each ignition cycle

Clear the DTC then cycle the ignition state to off then on.

Carry out a short road test to calibrate the Steering Wheel

Angle Sensor. If DTC returns, check the Anti-lock Brake

System Module for related DTCs and refer to relevant DTC

Index U2100-00

Initial Configuration

Not Complete - No

sub type

information

Car Configuration File

(CCF) information not

received completely

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system. Using the

manufacturer approved diagnostic system, clear the stored

DTC then cycle the Ignition State to off, wait 30 seconds.

Return the Ignition state to on and check for stored DTCs,

if the DTC returns check other modules for related stored

DTCs. If no other modules have related DTCs confirm the

security and condition of the Headlamp Leveling Module

circuit connections. If no other DTCs are stored and the

circuit is correct suspect an internal fault with the

Headlamp Leveling Module Replace as required, refer to the

new module/component installation note at the top of the

DTC Index U2101-00

Control Module

Configuration

Incompatible - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data received

The stored Vehicle

Identification Number

is not the same as

the Central Broadcast

Vehicle Identification

Number

The Headlamp

Leveling Module has

previously been

installed to another

vehicle

Check the correct Headlamp Leveling Module is installed to

vehicle specification. Refit original or replace the module as

required. Refer to the new module/component installation

note at the top of the DTC Index U3003-16

Battery Voltage -

Circuit voltage

below threshold

The power supply to

the Module has been

below 9 Volts for

more than 1000

milliseconds

Suspect Battery or Charging fault. Check the battery

condition and state of charge. Check the vehicle charging

system. Refer to the relevant workshop manual section.

Clear the DTC, cycle ignition state to off then on, if DTC

returns refer to the electrical circuit diagrams and check

power and ground circuit to the Headlamp Leveling Module U3003-17

Battery Voltage -

Circuit voltage

above threshold

The power supply to

the Module has been

above 16 Volts for

more than 1000

milliseconds

Suspect Charging fault. Check the battery condition and

state of charge. Check the vehicle charging system. Refer

to the relevant workshop manual section

Page 186 of 3039

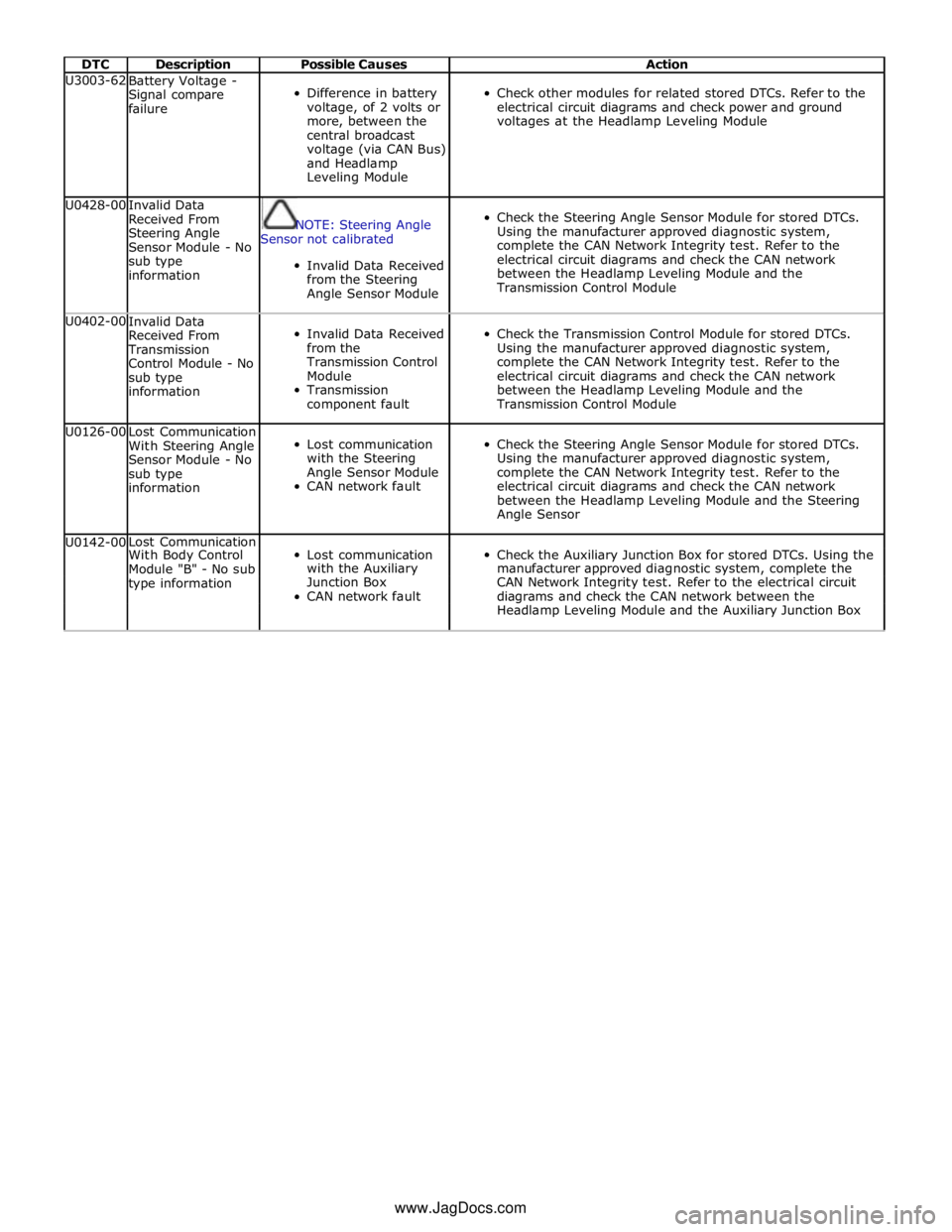

DTC Description Possible Causes Action U3003-62

Battery Voltage -

Signal compare

failure

Difference in battery

voltage, of 2 volts or

more, between the

central broadcast

voltage (via CAN Bus)

and Headlamp

Leveling Module

Check other modules for related stored DTCs. Refer to the

electrical circuit diagrams and check power and ground

voltages at the Headlamp Leveling Module U0428-00

Invalid Data

Received From

Steering Angle

Sensor Module - No

sub type

information

NOTE: Steering Angle

Sensor not calibrated

Invalid Data Received

from the Steering

Angle Sensor Module

Check the Steering Angle Sensor Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0402-00

Invalid Data

Received From

Transmission

Control Module - No

sub type

information

Invalid Data Received

from the

Transmission Control

Module

Transmission

component fault

Check the Transmission Control Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0126-00

Lost Communication

With Steering Angle

Sensor Module - No

sub type

information

Lost communication

with the Steering

Angle Sensor Module

CAN network fault

Check the Steering Angle Sensor Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the Steering

Angle Sensor U0142-00 Lost Communication

Lost communication

Check the Auxiliary Junction Box for stored DTCs. Using the With Body Control Module "B" - No sub with the Auxiliary manufacturer approved diagnostic system, complete the type information Junction Box CAN Network Integrity test. Refer to the electrical circuit CAN network fault diagrams and check the CAN network between the Headlamp Leveling Module and the Auxiliary Junction Box www.JagDocs.com

Page 486 of 3039

2 Main piston 3 Tube 4 Bypass valve (closed) 5 Piston and rod assembly ACCELEROMETERS

Three accelerometers are used in the adaptive dynamics system. The accelerometers are located as follows:

One each on the rear edge of the radiator support panel.

One in the luggage compartment, in the rear LH corner adjacent to the rear lamp assembly.

The accelerometers measure acceleration in the vertical plane and output a corresponding analogue signal to the adaptive

damping module. The algorithms in the adaptive damping module calculate the heave, pitch and roll motions of the vehicle,

which are used by the module to control road induced body modes.

Each accelerometer is connected to the adaptive damping module via three wires, which supply ground, 5 V supply and signal

return.

The sensing element comprises a single parallel plate capacitor, one plate of which moves relative to the other dependant on

the force (acceleration) applied. This causes the capacitance to change as a function of applied acceleration. This capacitance

is compared with a fixed reference capacitor in a bridge circuit and the signal is processed by means of a dedicated integrated

circuit to generate an output voltage that varies as a function of applied acceleration. The sensors output a signal voltage of

approximately 1 V/g ± 0.05 V/g.

SUSPENSION HEIGHT SENSORS

Four suspension height sensors are used in the adaptive dynamics system, two for the front suspension and two for the rear

suspension. A front suspension height sensor is attached to each side of the front subframes and connected by a sensor arm

and sensor link to the related lower lateral arm of the front suspension. A rear suspension height sensor is attached to each

side of the rear subframe and connected by a sensor arm and sensor link to the related upper control arm of the rear

suspension. On each suspension height sensor, the sensor arm and sensor link convert linear movement of the suspension into

rotary movement of the sensor shaft.

The sensors are also used for the static dynamic headlamp leveling system on vehicles fitted with xenon headlamps.

The suspension height sensors measure suspension displacement at each corner of the vehicle and output a corresponding

analogue signal to the adaptive damping module. The algorithms in the adaptive damping module calculate the position,

velocity and frequency content of the signals and use the results for wheel control.

Each suspension height sensor is connected to the adaptive damping module via three wires, which supply ground, 5 V supply

Page 797 of 3039

Published: 11-May-2011

Steering Column Switches - Steering Column Switches - Overview

Description and Operation

OVERVIEW

The steering column multifunction switch is situated on the steering column and consists of the wiper switch, the turn signal

indicator/lighting switch and the trip computer switch.

The RH (right-hand) multifunction switch controls the following windshield wiper functions:

Flick wipe

Intermittent wipe

Slow speed wipe

High speed wipe

Wash/Wipe

Headlamp powerwash

Rain sensing / variable wipe selection.

The LH (left-hand) multifunction switch controls the following functions:

Turn signal indicators

Side lamps

Headlamps

Auto lamps

High/low beam

Headlamp flash

Headlamp timer

Trip computer.

The steering column adjustment switch is located in the steering column lower shroud on the LH side. The switch is a 4 position 'joystick' which controls reach and rake adjustment.

The trip button allows the driver to cycle though an option menu and also reset trip cycle mileage calculations. The trip

computer information is displayed in the instrument cluster message centre.

Steering wheel mounted switches on the LH side of the driver's airbag, control the audio and telephone functions. Switches on the RH side of the driver's airbag, control the speed control functions. The steering wheel has an internal heating element. This is controlled by the driver via the Touch Screen Display (TSD). www.JagDocs.com