wiring diagram JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 211 of 3039

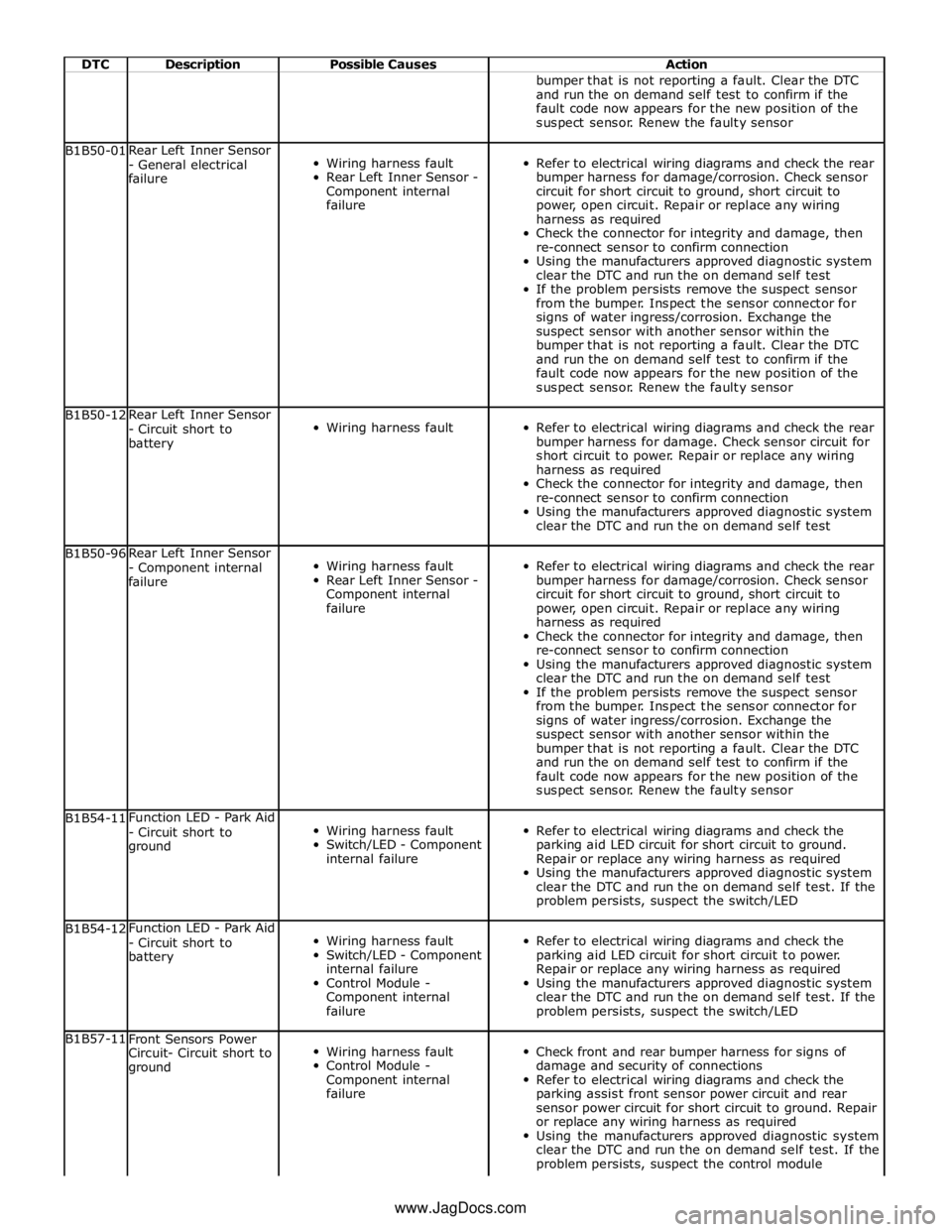

DTC Description Possible Causes Action bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B50-01 Rear Left Inner Sensor

- General electrical

failure

Wiring harness fault

Rear Left Inner Sensor -

Component internal

failure

Refer to electrical wiring diagrams and check the rear

bumper harness for damage/corrosion. Check sensor

circuit for short circuit to ground, short circuit to

power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B50-12 Rear Left Inner Sensor

- Circuit short to

battery

Wiring harness fault

Refer to electrical wiring diagrams and check the rear

bumper harness for damage. Check sensor circuit for

short circuit to power. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test B1B50-96 Rear Left Inner Sensor

- Component internal

failure

Wiring harness fault

Rear Left Inner Sensor -

Component internal

failure

Refer to electrical wiring diagrams and check the rear

bumper harness for damage/corrosion. Check sensor

circuit for short circuit to ground, short circuit to

power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B54-11 Function LED - Park Aid

- Circuit short to

ground

Wiring harness fault

Switch/LED - Component

internal failure

Refer to electrical wiring diagrams and check the

parking aid LED circuit for short circuit to ground.

Repair or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the switch/LED B1B54-12 Function LED - Park Aid

- Circuit short to

battery

Wiring harness fault

Switch/LED - Component

internal failure

Control Module -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking aid LED circuit for short circuit to power.

Repair or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the switch/LED B1B57-11

Front Sensors Power

Circuit- Circuit short to

ground

Wiring harness fault

Control Module -

Component internal

failure

Check front and rear bumper harness for signs of

damage and security of connections

Refer to electrical wiring diagrams and check the

parking assist front sensor power circuit and rear

sensor power circuit for short circuit to ground. Repair

or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module www.JagDocs.com

Page 212 of 3039

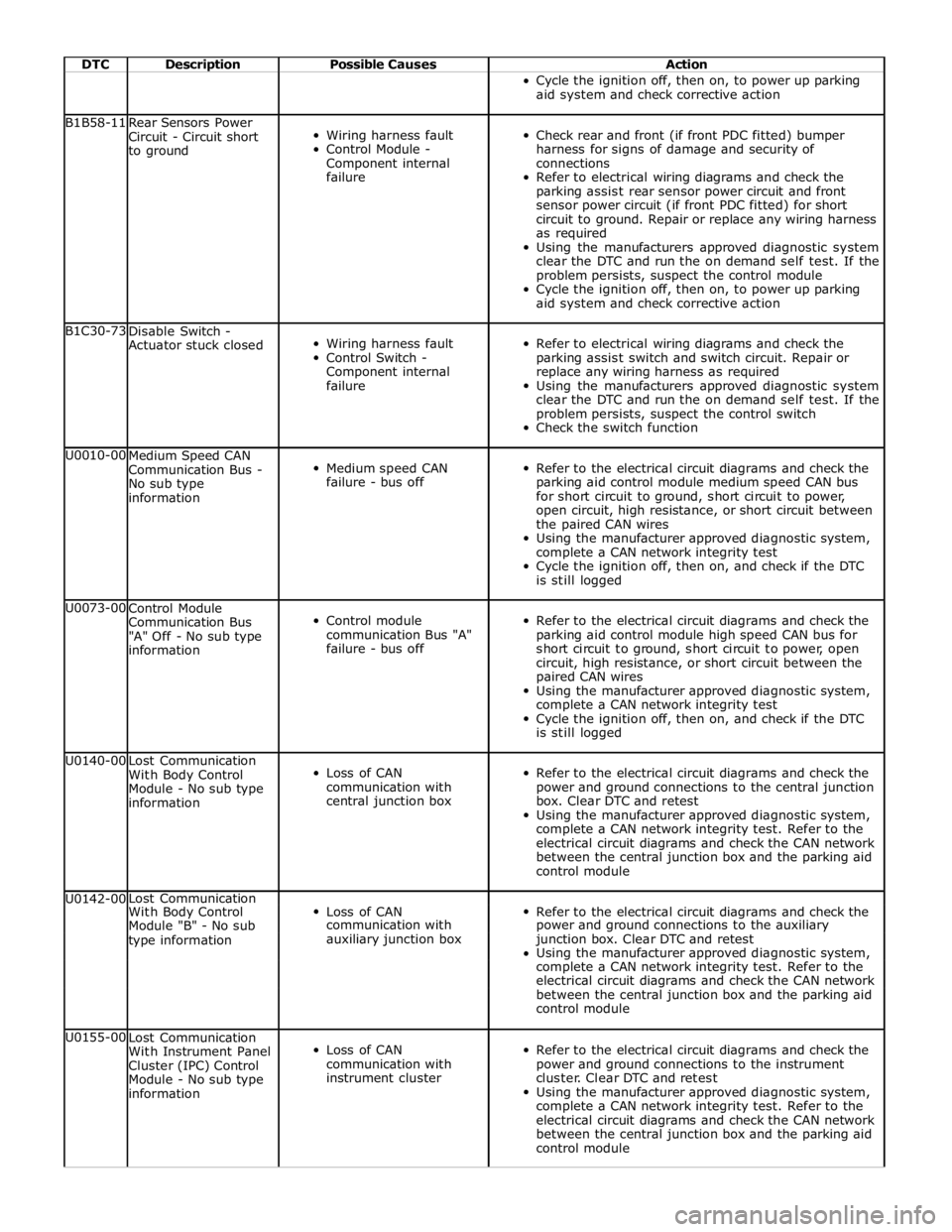

DTC Description Possible Causes Action Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1B58-11

Rear Sensors Power

Circuit - Circuit short

to ground

Wiring harness fault

Control Module -

Component internal

failure

Check rear and front (if front PDC fitted) bumper

harness for signs of damage and security of

connections

Refer to electrical wiring diagrams and check the

parking assist rear sensor power circuit and front

sensor power circuit (if front PDC fitted) for short

circuit to ground. Repair or replace any wiring harness

as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module

Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1C30-73

Disable Switch -

Actuator stuck closed

Wiring harness fault

Control Switch -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking assist switch and switch circuit. Repair or

replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control switch

Check the switch function U0010-00

Medium Speed CAN

Communication Bus -

No sub type

information

Medium speed CAN

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module medium speed CAN bus

for short circuit to ground, short circuit to power,

open circuit, high resistance, or short circuit between

the paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0073-00

Control Module

Communication Bus

"A" Off - No sub type

information

Control module

communication Bus "A"

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module high speed CAN bus for

short circuit to ground, short circuit to power, open

circuit, high resistance, or short circuit between the

paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Loss of CAN

communication with

central junction box

Refer to the electrical circuit diagrams and check the

power and ground connections to the central junction

box. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module U0142-00 Lost Communication

Loss of CAN

Refer to the electrical circuit diagrams and check the With Body Control Module "B" - No sub communication with power and ground connections to the auxiliary type information auxiliary junction box junction box. Clear DTC and retest Using the manufacturer approved diagnostic system, complete a CAN network integrity test. Refer to the electrical circuit diagrams and check the CAN network between the central junction box and the parking aid control module U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Loss of CAN

communication with

instrument cluster

Refer to the electrical circuit diagrams and check the

power and ground connections to the instrument

cluster. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module

Page 215 of 3039

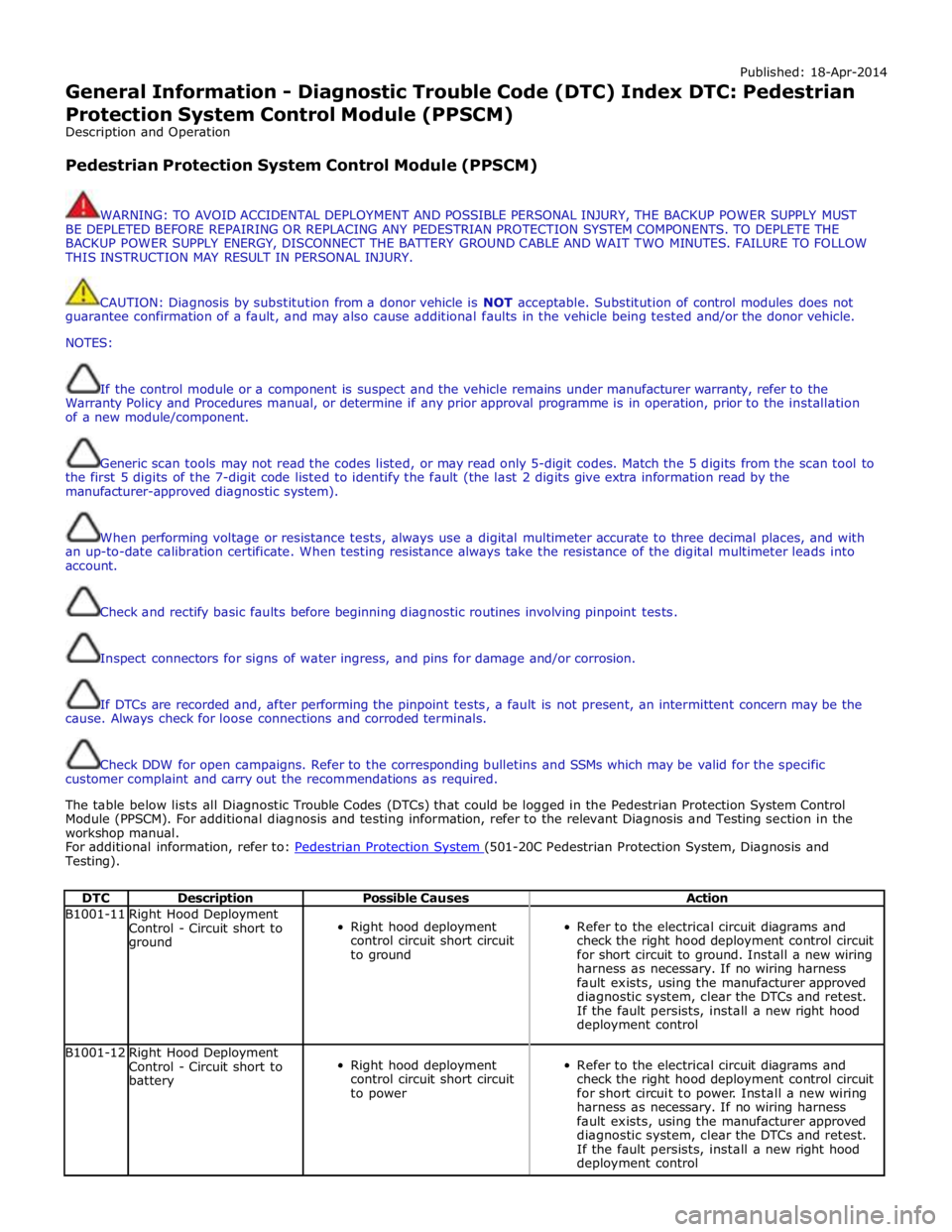

Published: 18-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Pedestrian

Protection System Control Module (PPSCM)

Description and Operation

Pedestrian Protection System Control Module (PPSCM)

WARNING: TO AVOID ACCIDENTAL DEPLOYMENT AND POSSIBLE PERSONAL INJURY, THE BACKUP POWER SUPPLY MUST

BE DEPLETED BEFORE REPAIRING OR REPLACING ANY PEDESTRIAN PROTECTION SYSTEM COMPONENTS. TO DEPLETE THE

BACKUP POWER SUPPLY ENERGY, DISCONNECT THE BATTERY GROUND CABLE AND WAIT TWO MINUTES. FAILURE TO FOLLOW

THIS INSTRUCTION MAY RESULT IN PERSONAL INJURY.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Pedestrian Protection System Control

Module (PPSCM). For additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the

workshop manual.

For additional information, refer to: Pedestrian Protection System (501-20C Pedestrian Protection System, Diagnosis and Testing).

DTC Description Possible Causes Action B1001-11

Right Hood Deployment

Control - Circuit short to

ground

Right hood deployment

control circuit short circuit

to ground

Refer to the electrical circuit diagrams and

check the right hood deployment control circuit

for short circuit to ground. Install a new wiring

harness as necessary. If no wiring harness

fault exists, using the manufacturer approved

diagnostic system, clear the DTCs and retest.

If the fault persists, install a new right hood

deployment control B1001-12

Right Hood Deployment

Control - Circuit short to

battery

Right hood deployment

control circuit short circuit

to power

Refer to the electrical circuit diagrams and

check the right hood deployment control circuit

for short circuit to power. Install a new wiring

harness as necessary. If no wiring harness

fault exists, using the manufacturer approved

diagnostic system, clear the DTCs and retest.

If the fault persists, install a new right hood

deployment control

Page 216 of 3039

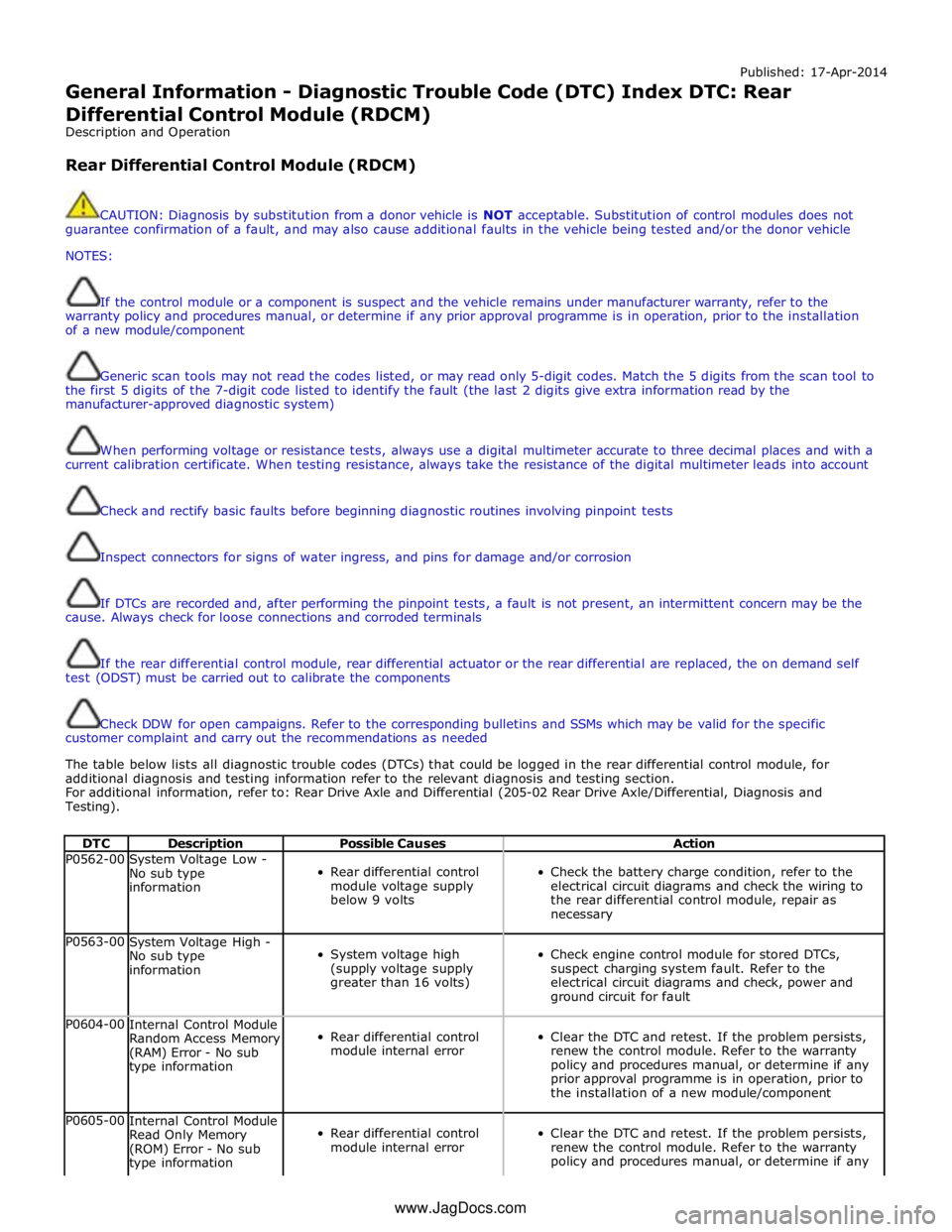

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Rear

Differential Control Module (RDCM)

Description and Operation

Rear Differential Control Module (RDCM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals

If the rear differential control module, rear differential actuator or the rear differential are replaced, the on demand self

test (ODST) must be carried out to calibrate the components

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as needed

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the rear differential control module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Rear Drive Axle and Differential (205-02 Rear Drive Axle/Differential, Diagnosis and

Testing).

DTC Description Possible Causes Action P0562-00

System Voltage Low -

No sub type

information

Rear differential control

module voltage supply

below 9 volts

Check the battery charge condition, refer to the

electrical circuit diagrams and check the wiring to

the rear differential control module, repair as

necessary P0563-00

System Voltage High -

No sub type

information

System voltage high

(supply voltage supply

greater than 16 volts)

Check engine control module for stored DTCs,

suspect charging system fault. Refer to the

electrical circuit diagrams and check, power and

ground circuit for fault P0604-00

Internal Control Module

Random Access Memory

(RAM) Error - No sub

type information

Rear differential control

module internal error

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any

prior approval programme is in operation, prior to

the installation of a new module/component P0605-00

Internal Control Module

Read Only Memory

(ROM) Error - No sub

type information

Rear differential control

module internal error

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any www.JagDocs.com

Page 219 of 3039

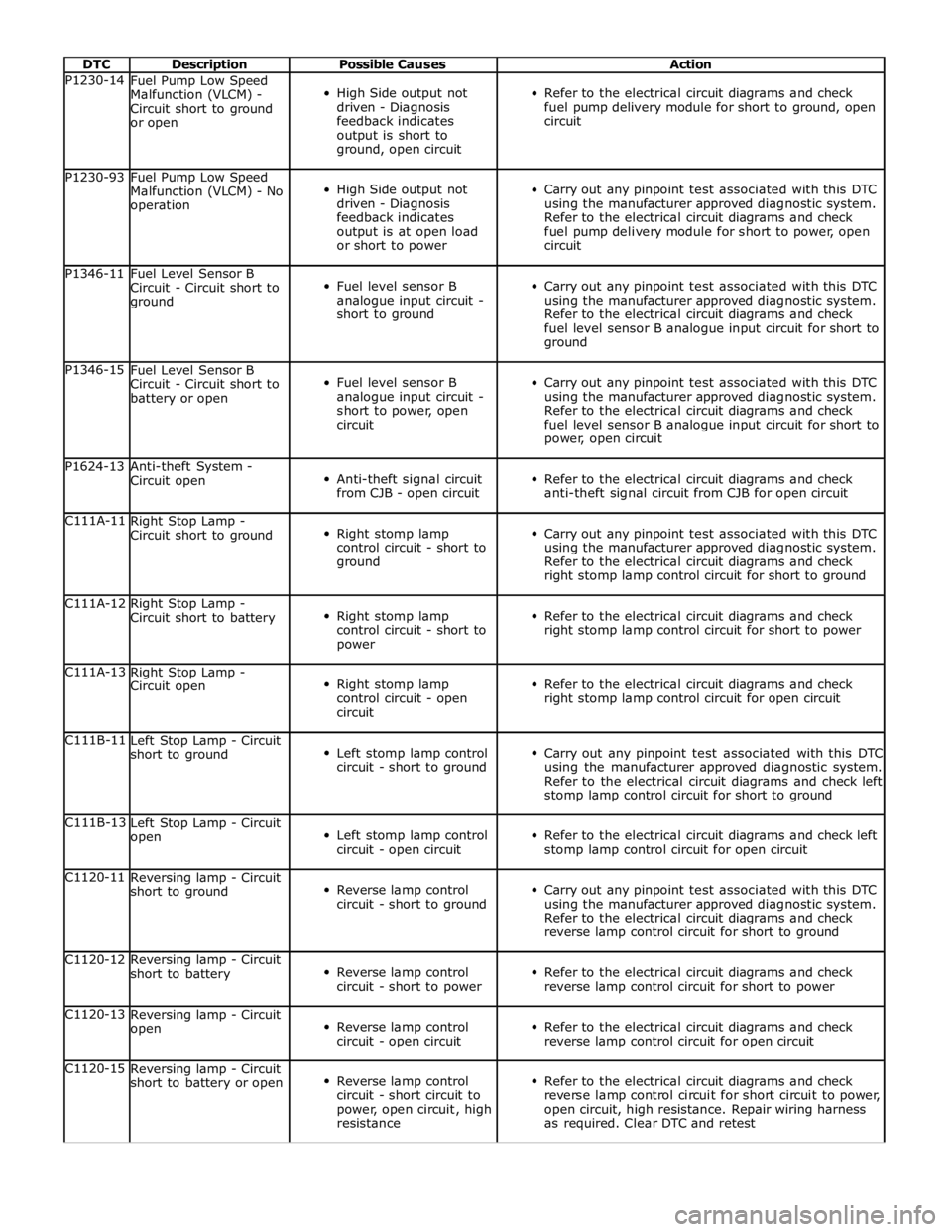

DTC Description Possible Causes Action P1230-14

Fuel Pump Low Speed

Malfunction (VLCM) -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to ground, open

circuit P1230-93

Fuel Pump Low Speed

Malfunction (VLCM) - No

operation

High Side output not

driven - Diagnosis

feedback indicates

output is at open load

or short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to power, open

circuit P1346-11

Fuel Level Sensor B

Circuit - Circuit short to

ground

Fuel level sensor B

analogue input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor B analogue input circuit for short to

ground P1346-15

Fuel Level Sensor B

Circuit - Circuit short to

battery or open

Fuel level sensor B

analogue input circuit -

short to power, open

circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor B analogue input circuit for short to

power, open circuit P1624-13

Anti-theft System -

Circuit open

Anti-theft signal circuit

from CJB - open circuit

Refer to the electrical circuit diagrams and check

anti-theft signal circuit from CJB for open circuit C111A-11

Right Stop Lamp -

Circuit short to ground

Right stomp lamp

control circuit - short to

ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for short to ground C111A-12

Right Stop Lamp -

Circuit short to battery

Right stomp lamp

control circuit - short to

power

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for short to power C111A-13

Right Stop Lamp -

Circuit open

Right stomp lamp

control circuit - open

circuit

Refer to the electrical circuit diagrams and check

right stomp lamp control circuit for open circuit C111B-11

Left Stop Lamp - Circuit

short to ground

Left stomp lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check left

stomp lamp control circuit for short to ground C111B-13

Left Stop Lamp - Circuit

open

Left stomp lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check left

stomp lamp control circuit for open circuit C1120-11

Reversing lamp - Circuit

short to ground

Reverse lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short to ground C1120-12

Reversing lamp - Circuit

short to battery

Reverse lamp control

circuit - short to power

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short to power C1120-13

Reversing lamp - Circuit

open

Reverse lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for open circuit C1120-15

Reversing lamp - Circuit

short to battery or open

Reverse lamp control

circuit - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check

reverse lamp control circuit for short circuit to power,

open circuit, high resistance. Repair wiring harness

as required. Clear DTC and retest

Page 222 of 3039

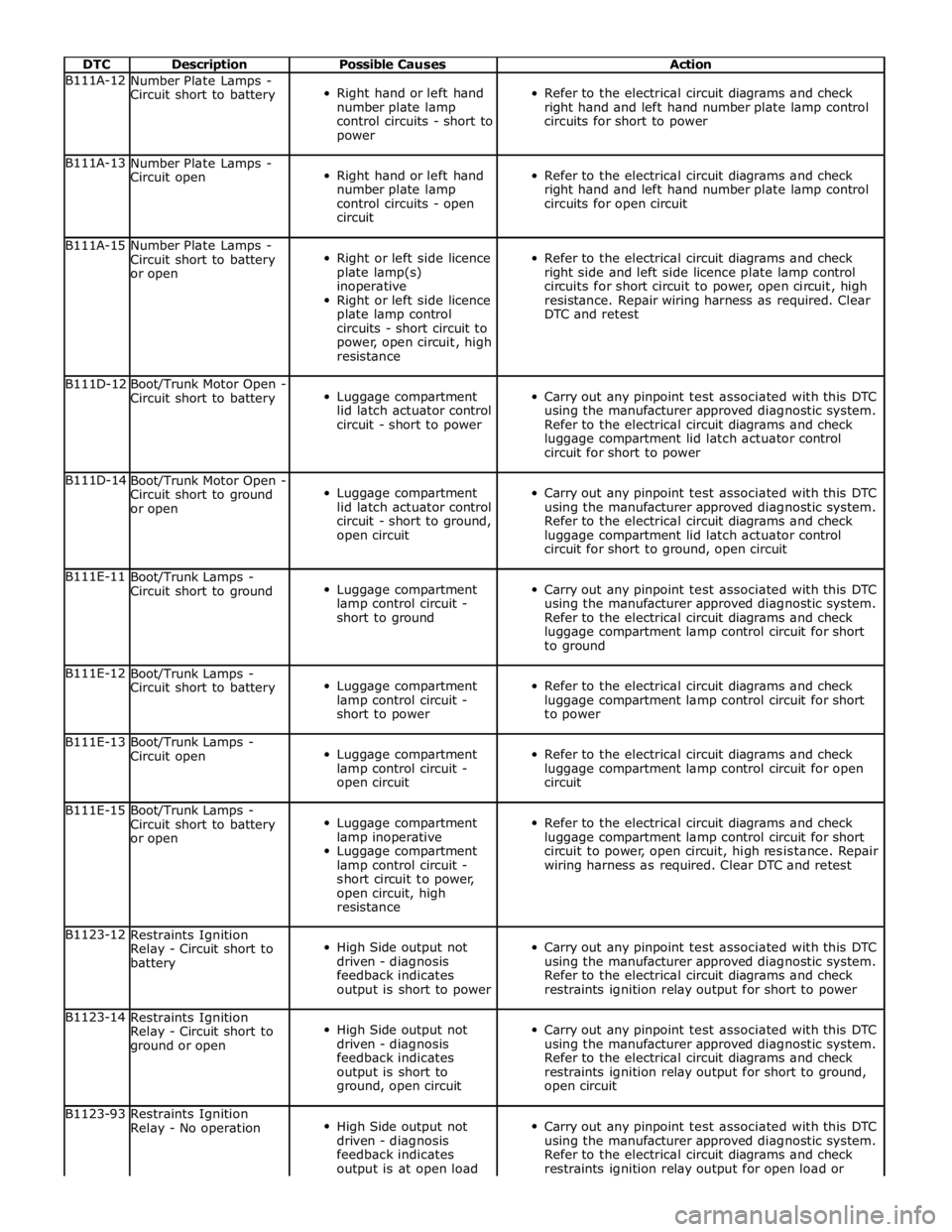

DTC Description Possible Causes Action B111A-12

Number Plate Lamps -

Circuit short to battery

Right hand or left hand

number plate lamp

control circuits - short to

power

Refer to the electrical circuit diagrams and check

right hand and left hand number plate lamp control

circuits for short to power B111A-13

Number Plate Lamps -

Circuit open

Right hand or left hand

number plate lamp

control circuits - open

circuit

Refer to the electrical circuit diagrams and check

right hand and left hand number plate lamp control

circuits for open circuit B111A-15

Number Plate Lamps -

Circuit short to battery

or open

Right or left side licence

plate lamp(s)

inoperative

Right or left side licence

plate lamp control

circuits - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check

right side and left side licence plate lamp control

circuits for short circuit to power, open circuit, high

resistance. Repair wiring harness as required. Clear

DTC and retest B111D-12

Boot/Trunk Motor Open -

Circuit short to battery

Luggage compartment

lid latch actuator control

circuit - short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

luggage compartment lid latch actuator control

circuit for short to power B111D-14

Boot/Trunk Motor Open -

Circuit short to ground

or open

Luggage compartment

lid latch actuator control

circuit - short to ground,

open circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

luggage compartment lid latch actuator control

circuit for short to ground, open circuit B111E-11

Boot/Trunk Lamps -

Circuit short to ground

Luggage compartment

lamp control circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for short

to ground B111E-12

Boot/Trunk Lamps -

Circuit short to battery

Luggage compartment

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for short

to power B111E-13

Boot/Trunk Lamps -

Circuit open

Luggage compartment

lamp control circuit -

open circuit

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for open

circuit B111E-15

Boot/Trunk Lamps -

Circuit short to battery

or open

Luggage compartment

lamp inoperative

Luggage compartment

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for short

circuit to power, open circuit, high resistance. Repair

wiring harness as required. Clear DTC and retest B1123-12

Restraints Ignition

Relay - Circuit short to

battery

High Side output not

driven - diagnosis

feedback indicates

output is short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

restraints ignition relay output for short to power B1123-14

Restraints Ignition

Relay - Circuit short to

ground or open

High Side output not

driven - diagnosis

feedback indicates

output is short to

ground, open circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

restraints ignition relay output for short to ground,

open circuit B1123-93

Restraints Ignition

Relay - No operation

High Side output not

driven - diagnosis

feedback indicates

output is at open load

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

restraints ignition relay output for open load or

Page 224 of 3039

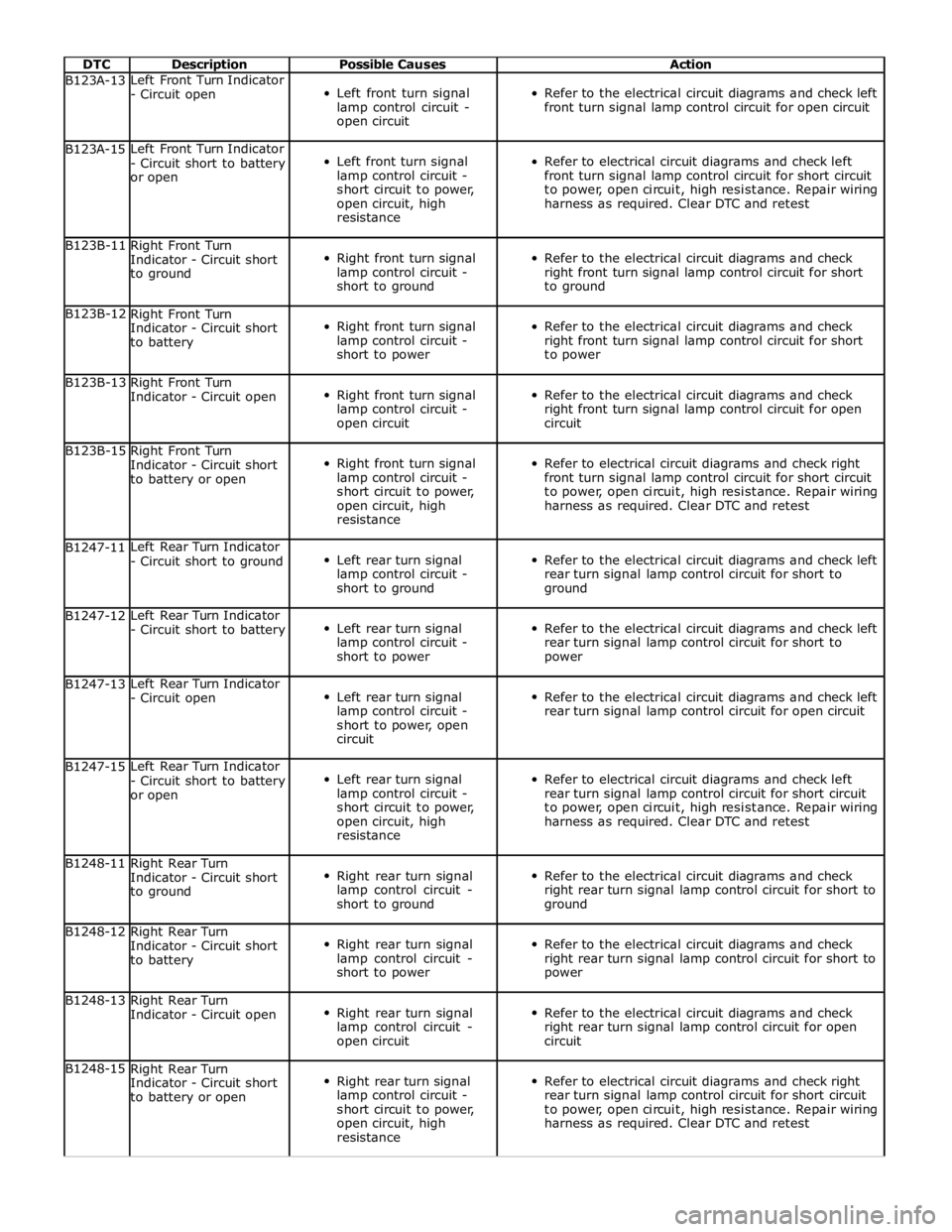

DTC Description Possible Causes Action B123A-13 Left Front Turn Indicator

- Circuit open

Left front turn signal

lamp control circuit -

open circuit

Refer to the electrical circuit diagrams and check left

front turn signal lamp control circuit for open circuit B123A-15 Left Front Turn Indicator

- Circuit short to battery

or open

Left front turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check left

front turn signal lamp control circuit for short circuit

to power, open circuit, high resistance. Repair wiring

harness as required. Clear DTC and retest B123B-11

Right Front Turn

Indicator - Circuit short

to ground

Right front turn signal

lamp control circuit -

short to ground

Refer to the electrical circuit diagrams and check

right front turn signal lamp control circuit for short

to ground B123B-12

Right Front Turn

Indicator - Circuit short

to battery

Right front turn signal

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check

right front turn signal lamp control circuit for short

to power B123B-13

Right Front Turn

Indicator - Circuit open

Right front turn signal

lamp control circuit -

open circuit

Refer to the electrical circuit diagrams and check

right front turn signal lamp control circuit for open

circuit B123B-15

Right Front Turn

Indicator - Circuit short

to battery or open

Right front turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check right

front turn signal lamp control circuit for short circuit

to power, open circuit, high resistance. Repair wiring

harness as required. Clear DTC and retest B1247-11 Left Rear Turn Indicator

- Circuit short to ground

Left rear turn signal

lamp control circuit -

short to ground

Refer to the electrical circuit diagrams and check left

rear turn signal lamp control circuit for short to

ground B1247-12 Left Rear Turn Indicator

- Circuit short to battery

Left rear turn signal

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check left

rear turn signal lamp control circuit for short to

power B1247-13 Left Rear Turn Indicator

- Circuit open

Left rear turn signal

lamp control circuit -

short to power, open

circuit

Refer to the electrical circuit diagrams and check left

rear turn signal lamp control circuit for open circuit B1247-15 Left Rear Turn Indicator

- Circuit short to battery

or open

Left rear turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check left

rear turn signal lamp control circuit for short circuit

to power, open circuit, high resistance. Repair wiring

harness as required. Clear DTC and retest B1248-11

Right Rear Turn

Indicator - Circuit short

to ground

Right rear turn signal

lamp control circuit -

short to ground

Refer to the electrical circuit diagrams and check

right rear turn signal lamp control circuit for short to

ground B1248-12

Right Rear Turn

Indicator - Circuit short

to battery

Right rear turn signal

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check

right rear turn signal lamp control circuit for short to

power B1248-13

Right Rear Turn

Indicator - Circuit open

Right rear turn signal

lamp control circuit -

open circuit

Refer to the electrical circuit diagrams and check

right rear turn signal lamp control circuit for open

circuit B1248-15

Right Rear Turn

Indicator - Circuit short

to battery or open

Right rear turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check right

rear turn signal lamp control circuit for short circuit

to power, open circuit, high resistance. Repair wiring

harness as required. Clear DTC and retest

Page 227 of 3039

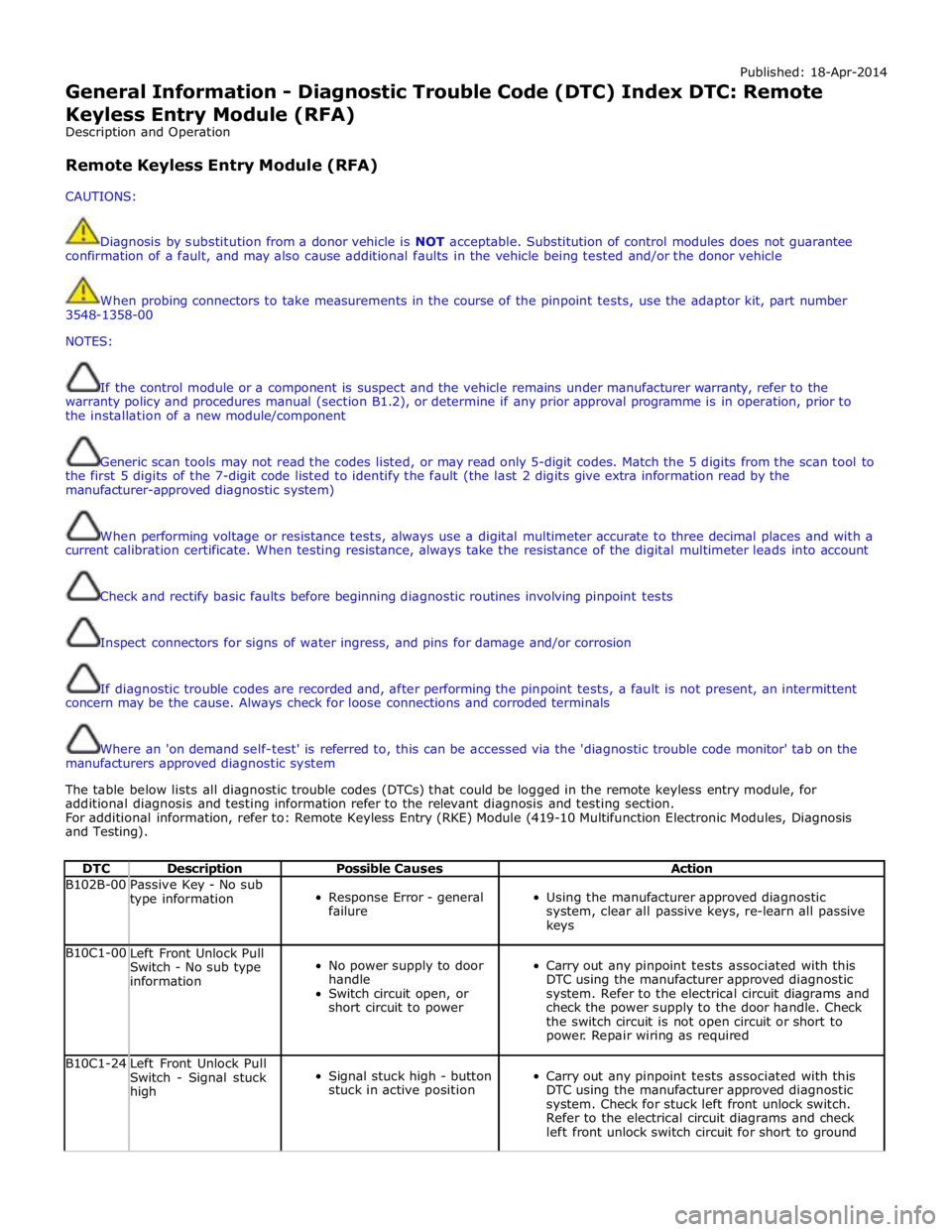

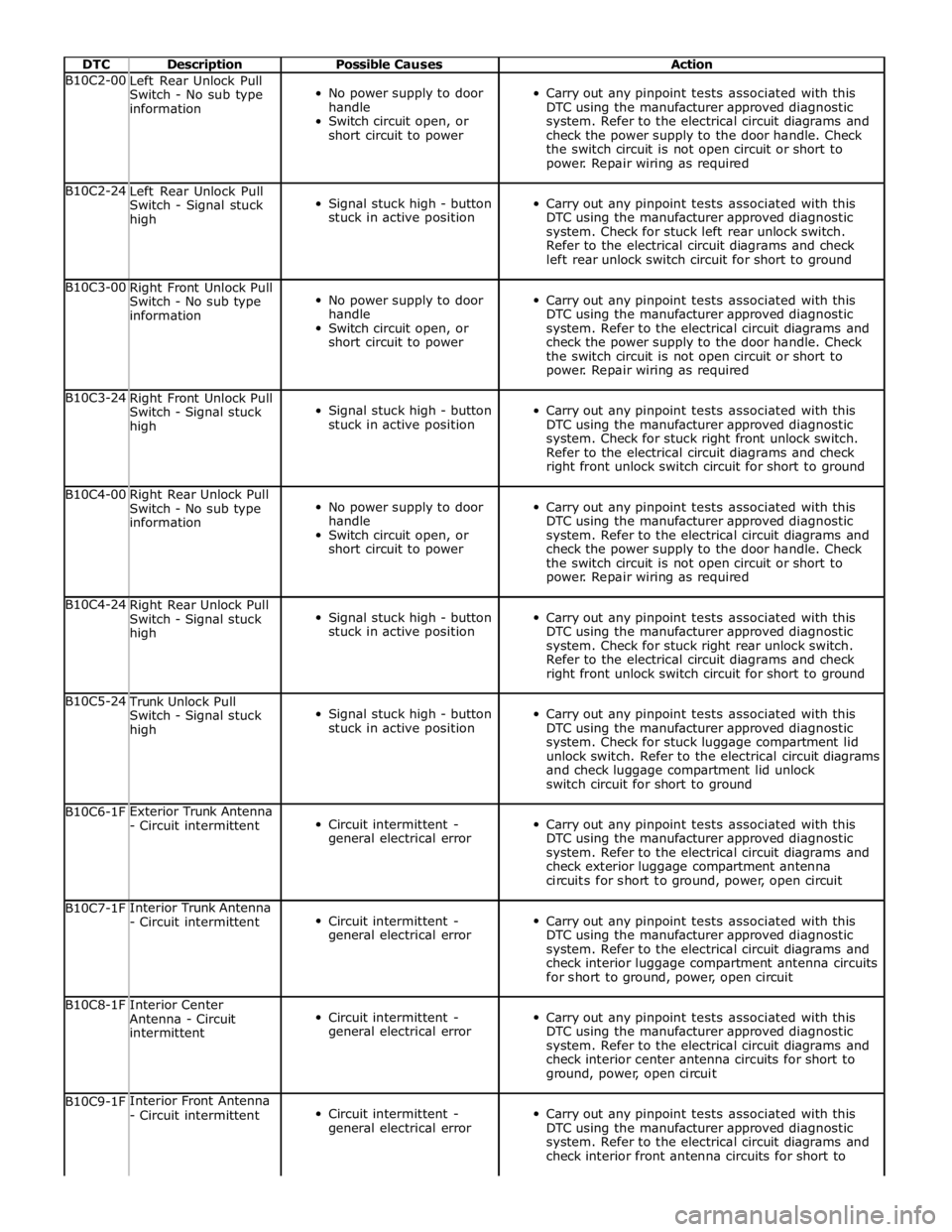

Published: 18-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Remote

Keyless Entry Module (RFA)

Description and Operation

Remote Keyless Entry Module (RFA)

CAUTIONS:

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee

confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part number

3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the remote keyless entry module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Remote Keyless Entry (RKE) Module (419-10 Multifunction Electronic Modules, Diagnosis

and Testing).

DTC Description Possible Causes Action B102B-00

Passive Key - No sub

type information

Response Error - general

failure

Using the manufacturer approved diagnostic

system, clear all passive keys, re-learn all passive

keys B10C1-00

Left Front Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C1-24

Left Front Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck left front unlock switch.

Refer to the electrical circuit diagrams and check

left front unlock switch circuit for short to ground

Page 228 of 3039

DTC Description Possible Causes Action B10C2-00

Left Rear Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C2-24

Left Rear Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck left rear unlock switch.

Refer to the electrical circuit diagrams and check

left rear unlock switch circuit for short to ground B10C3-00

Right Front Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C3-24

Right Front Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck right front unlock switch.

Refer to the electrical circuit diagrams and check

right front unlock switch circuit for short to ground B10C4-00

Right Rear Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C4-24

Right Rear Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck right rear unlock switch.

Refer to the electrical circuit diagrams and check

right front unlock switch circuit for short to ground B10C5-24 Trunk Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck luggage compartment lid

unlock switch. Refer to the electrical circuit diagrams

and check luggage compartment lid unlock

switch circuit for short to ground B10C6-1F Exterior Trunk Antenna

- Circuit intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check exterior luggage compartment antenna

circuits for short to ground, power, open circuit B10C7-1F Interior Trunk Antenna

- Circuit intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check interior luggage compartment antenna circuits

for short to ground, power, open circuit B10C8-1F

Interior Center

Antenna - Circuit

intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check interior center antenna circuits for short to

ground, power, open circuit B10C9-1F Interior Front Antenna

- Circuit intermittent

Circuit intermittent -

general electrical error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check interior front antenna circuits for short to

Page 236 of 3039

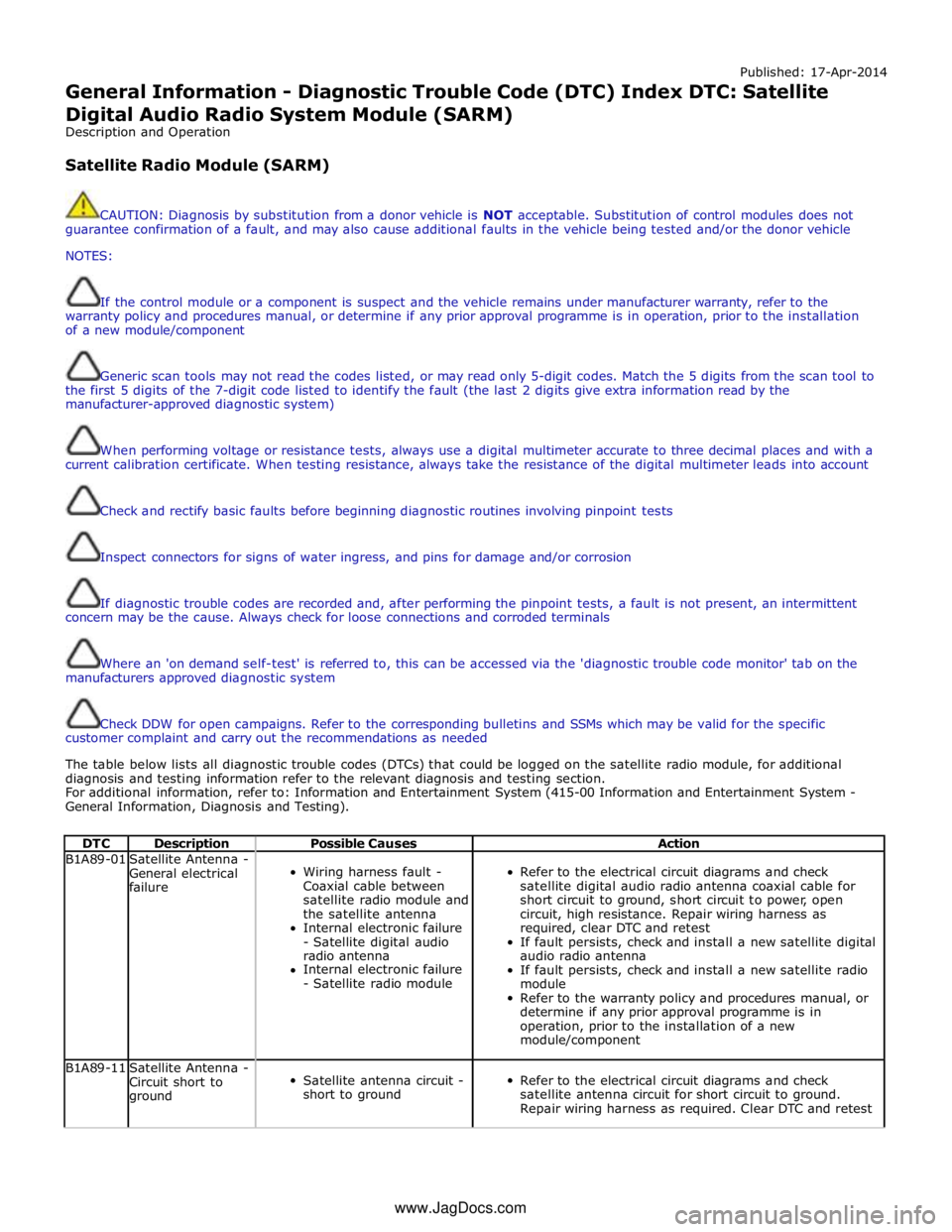

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Satellite

Digital Audio Radio System Module (SARM)

Description and Operation

Satellite Radio Module (SARM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as needed

The table below lists all diagnostic trouble codes (DTCs) that could be logged on the satellite radio module, for additional

diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Information and Entertainment System (415-00 Information and Entertainment System -

General Information, Diagnosis and Testing).

DTC Description Possible Causes Action B1A89-01

Satellite Antenna -

General electrical

failure

Wiring harness fault -

Coaxial cable between

satellite radio module and

the satellite antenna

Internal electronic failure

- Satellite digital audio

radio antenna

Internal electronic failure

- Satellite radio module

Refer to the electrical circuit diagrams and check

satellite digital audio radio antenna coaxial cable for

short circuit to ground, short circuit to power, open

circuit, high resistance. Repair wiring harness as

required, clear DTC and retest

If fault persists, check and install a new satellite digital

audio radio antenna

If fault persists, check and install a new satellite radio

module

Refer to the warranty policy and procedures manual, or

determine if any prior approval programme is in

operation, prior to the installation of a new

module/component B1A89-11

Satellite Antenna -

Circuit short to

ground

Satellite antenna circuit -

short to ground

Refer to the electrical circuit diagrams and check

satellite antenna circuit for short circuit to ground.

Repair wiring harness as required. Clear DTC and retest www.JagDocs.com