lock JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2723 of 3039

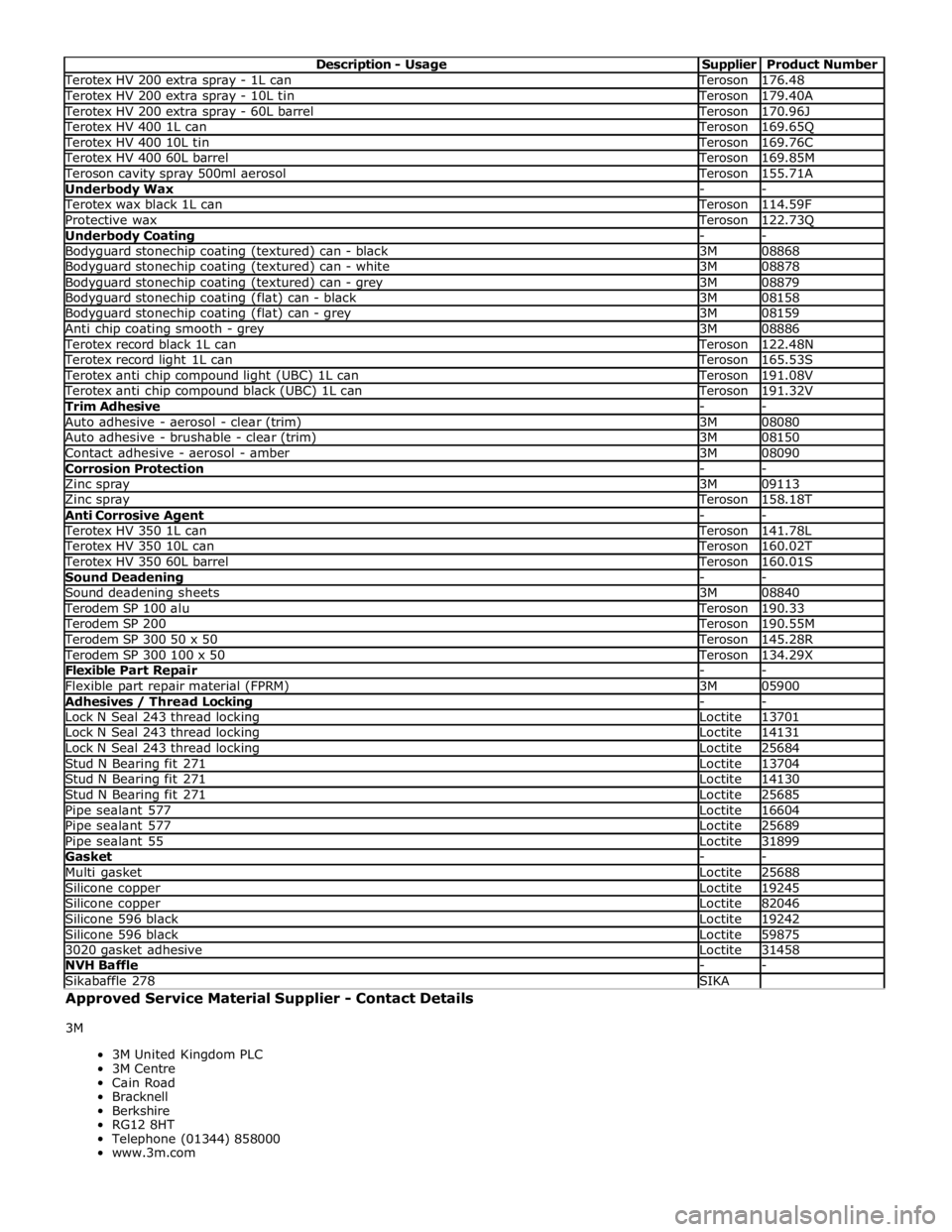

Terotex HV 200 extra spray - 1L can Teroson 176.48 Terotex HV 200 extra spray - 10L tin Teroson 179.40A Terotex HV 200 extra spray - 60L barrel Teroson 170.96J Terotex HV 400 1L can Teroson 169.65Q Terotex HV 400 10L tin Teroson 169.76C Terotex HV 400 60L barrel Teroson 169.85M Teroson cavity spray 500ml aerosol Teroson 155.71A Underbody Wax - - Terotex wax black 1L can Teroson 114.59F Protective wax Teroson 122.73Q Underbody Coating - - Bodyguard stonechip coating (textured) can - black 3M 08868 Bodyguard stonechip coating (textured) can - white 3M 08878 Bodyguard stonechip coating (textured) can - grey 3M 08879 Bodyguard stonechip coating (flat) can - black 3M 08158 Bodyguard stonechip coating (flat) can - grey 3M 08159 Anti chip coating smooth - grey 3M 08886 Terotex record black 1L can Teroson 122.48N Terotex record light 1L can Teroson 165.53S Terotex anti chip compound light (UBC) 1L can Teroson 191.08V Terotex anti chip compound black (UBC) 1L can Teroson 191.32V Trim Adhesive - - Auto adhesive - aerosol - clear (trim) 3M 08080 Auto adhesive - brushable - clear (trim) 3M 08150 Contact adhesive - aerosol - amber 3M 08090 Corrosion Protection - - Zinc spray 3M 09113 Zinc spray Teroson 158.18T Anti Corrosive Agent - - Terotex HV 350 1L can Teroson 141.78L Terotex HV 350 10L can Teroson 160.02T Terotex HV 350 60L barrel Teroson 160.01S Sound Deadening - - Sound deadening sheets 3M 08840 Terodem SP 100 alu Teroson 190.33 Terodem SP 200 Teroson 190.55M Terodem SP 300 50 x 50 Teroson 145.28R Terodem SP 300 100 x 50 Teroson 134.29X Flexible Part Repair - - Flexible part repair material (FPRM) 3M 05900 Adhesives / Thread Locking - - Lock N Seal 243 thread locking Loctite 13701 Lock N Seal 243 thread locking Loctite 14131 Lock N Seal 243 thread locking Loctite 25684 Stud N Bearing fit 271 Loctite 13704 Stud N Bearing fit 271 Loctite 14130 Stud N Bearing fit 271 Loctite 25685 Pipe sealant 577 Loctite 16604 Pipe sealant 577 Loctite 25689 Pipe sealant 55 Loctite 31899 Gasket - - Multi gasket Loctite 25688 Silicone copper Loctite 19245 Silicone copper Loctite 82046 Silicone 596 black Loctite 19242 Silicone 596 black Loctite 59875 3020 gasket adhesive Loctite 31458 NVH Baffle - - Sikabaffle 278 SIKA Approved Service Material Supplier - Contact Details

3M

3M United Kingdom PLC

3M Centre

Cain Road

Bracknell

Berkshire

RG12 8HT

Telephone (01344) 858000

www.3m.com

Page 2726 of 3039

metal surfaces are bolted together always interpose a suitable interface material such as weldable zinc rich primer, extruded

strip, or zinc tape.

Steam Cleaning

Due to the high pressure/temperature generated by steam cleaning equipment, there is a risk that certain adhesives and

corrosion prevention material may become softened or liquified.

Take care not to allow the steam jet to dwell on one area, and keep the nozzle at least 300mm from the panel surface.

CAUTION: Do not remove wax or lacquer from underbody areas during repairs.

Inspection During Maintenance Servicing

It is a requirement of the corrosion warranty that the vehicle is inspected for corrosion by a Jaguar Authorised Repairer during a

routine service, to ensure that the factory-applied protection remains effective.

Rectify any bodywork damage or evidence of corrosion found during inspection as soon as is practicable, both to minimise the

extent of the damage and to ensure the long term effectiveness of the factory-applied corrosion prevention treatment.

Underbody Protection Repairs

Whenever body repairs have been carried out, ensure that full sealing and corrosion protection treatments are reinstated. This

applies both to the damaged areas and also to areas where protection has been indirectly impaired, as a result either of

accident damage or repair operations.

Remove corrosion protection from the damaged areas before straightening or panel beating. This applies in particular to panels

coated with wax, PVC underbody sealer, sound deadening pads etc.

CAUTION: Do not use oxy-acetylene to remove corrosion prevention material. Large volumes of fumes and gases are

liberated by these materials when they burn.

The most common method of removal is by means of a hot air blower with an integral scraper. High temperatures can be

generated with this equipment which may cause fumes. Take care during its use.

Structural Adhesive

CAUTION: When separating a joint with metal to metal adhesive, it is important to avoid distortion. Heat gradually until

the bond weakens sufficiently to permit panel separation - do not apply excessive heat.

NOTE: When spot welding through metal to metal adhesive, take particular care to adjust the equipment setting to

ensure a suitable weld.

Metal to metal adhesive is applied to critical joint areas during factory assembly. The material used is a high temperature,

heat cured, nitrile phenolic which serves to bond two metal surfaces and also to seal the joint against ingress of dust,

moisture and fumes. This material is not suitable for service use and, during repair, should be substituted by an approved

structural adhesive. For panel specific information and to identify the areas of structural adhesive application in repair, refer to

the relevant sheet metal removal and installation procedure.

Expanding Foam Acoustic Seals

Expanding foam acoustic seals are used in various closed-sections of the body to improve vehicle refinement. The seals are

installed during the vehicle body manufacture and expand during the paint process up to ten times original size, thus locking

them into position. They are located such that they prevent noise accentuation along a section and reflect air borne noise

away from the cabin.

The seals have spilt functionality depending on location. The seals located at the base of the body pillars have a primary

function of preventing water ingress when wading. Their secondary function is to prevent noise and dust ingress.

The seal around the fuel filler has a primary function of preventing both fuel and water ingress. With a secondary function of

preventing noise and dust ingress.

The remaining seals primary function is to prevent noise accentuation along a section and reflect air borne noise away from the

cabin.

Another advantage of the seals is that they marginally increase the overall stiffness of the body and its structural performance

in case of a crash.

The seals are manufactured from an expandible polymer.

Replacing Expanding Foam Acoustic Seals

As paint oven temperatures used in a repair workshop are significantly lower than those that are used during manufacture of

the vehicle, (the temperatures are not sufficient to expand the foam), a different process is required to replicate the foam in

repair.

Page 2735 of 3039

Side windows

In the case of side windows, the same problems can arise as for a windscreen. The same corrective actions must therefore be

used.

Door seal

Diagnosis:

- Water ingress in the lower part of the interior door trim or in the rocker panel area.

Cause:

- The water shield fitted behind the interior door trim exists to drain off water that has entered the door via the

drainage holes, either downwards or outwards. If the water shield seal is damaged or has been fitted incorrectly,

then water can get into the passenger compartment.

- In addition to this, the drainage holes can become clogged with leaves, dirt or excess cavity protection agents.

Water gathers in the door and ingresses into the passenger compartment.

- Check water shield for damage or correct fitting.

- If the water shield needs to be re-bonded, then approved seam sealer should be used.

- Before the water shield is installed, the drainage holes must be checked for unhindered flow.

Door seals

Diagnosis:

- Ingress of water into the rocker panel area

Cause:

- Insufficient clamping load between seal and door.

Corrective action:

NOTE: When adjusting the clamping load, the profile alignment of the relevant components must always be taken

into consideration.

NOTE: Do not realign the flange too far in the direction of the door, as this can reduce the bearing surface of the

seal to the door.

- Check clamping load:

- The easiest way to check the clamping load of a seal to the respective bearing surface is by means of a paper

strip test. This consists of trapping strips of paper at various points between the door and the seal, and fully

closing the door. If it is possible to pull out the paper with no great resistance, then the clamping load is too

low.

- Adjust the clamping load:

- The clamping load is normally adjusted using the striker. When doing so, the edge alignment from the door to

the side panel, or from the front door to the rear door must be taken into account.

- Another setting method is to realign the panel flange for the seal mounting. The clamping load is increased by

moving the flange towards the door.

- Check the bearing surface:

- Apply chalk evenly to the surface of the seal. Evenly coat the bearing surface of the door with Vaseline.

- Close the door fully, the lock must engage. Open the door. The imprint of the chalk (bearing surface) can be

identified in the film of Vaseline.

- The bearing surface should be at least 5mm across at all points.

Other causes:

- The door seal must completely seal the door where it meets the bodywork.

- Water can ingress directly or indirectly into the interior of the vehicle if the seal is damaged at any point.

Corrective action:

- A damaged or worn door seal must always be renewed in full.

- When renewing the seal, the following must be taken into account:

- Always fit the seal first in the area of the narrow radii (corner points).

- Next, secure the seal to the flange evenly by tapping lightly with a rubber hammer. The installed seal must not

be kinked at any point.

NOTE: The prescribed length of a seal must not be shortened.

Other cause:

- The door seal is attached to the welded flange all the way round. If this welded flange is uneven or damaged at

any point (usually in areas with small radii) then this point could be subject to leaks.

- A stretched seal carrier can also cause a leak.

- In both cases, water gets into the vehicle interior under the seal carrier.

Corrective action:

- Align the deformed welded flange using a hammer and anvil block, prevent and, if necessary, repair any paint

damage.

Sliding roof/tilting roof

Diagnosis:

- Ingress of water at sliding roof aperture

Cause:

- The sliding roof/tilting roof is installed in a water trap. The water drains off via the water trap, water drain holes

and drain hoses. The drain hoses lead downwards on both sides via the A-pillar and B-pillar.

- The drain holes or drain hoses can become clogged with leaves, dirt, underbody protection and so on.

Corrective action:

Page 2736 of 3039

NOTE: In the case of a sliding or tilting roof, the external rubber seal and the lock actuator or latch mechanism

must be checked first of all.

- Check the water trap for leaks.

- Check the drain hoses for leaks and for correct connection to the water trap.

- Check the drainage system for unhindered flow, and blow out with compressed air if necessary.

- Check the external seal and the correct adjustment of the sliding roof.

Liftgate

Diagnosis:

- Ingress of water into rear headlining area and luggage area.

Cause:

- The leak problems of the tailgate and liftgate correspond to those of the doors.

- In addition to this, the area to be sealed is much bigger. The routing holes for cables and hoses must also be

sealed.

- The rubber grommets for the routing holes must be checked for damage and correct seating (fully unhooked).

- The mounting points of the liftgate hinges may leak.

Corrective action:

- Check the rubber grommets and renew if necessary.

- Check the hinge mounting points, and re-seal with sealing compound if necessary.

Forced air extraction

Diagnosis:

- Ingress of water into side luggage compartment area

Cause:

- The forced air extraction for the vehicle interior is located in the quarter panel lower extension.

- The rubber flap of the forced air extraction must be able to move freely.

Corrective action:

- Remove the forced air extraction.

- Check the seal area between the bodywork and housing, as well as the rubber flap.

- Renew seal if necessary.

Rear window

Diagnosis:

- Ingress of water into the luggage compartment area

Cause:

- Rear window leaking.

- Check for leak in the same way as for leaking windscreen.

Page 2881 of 3039

(100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the front door window regulator and motor.

For additional information, refer to: Front Door Window Regulator and Motor (501-11 Glass, Frames and Mechanisms, Removal and Installation).

5. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

6. Remove the exterior mirror.

For additional information, refer to: Exterior Mirror (501-09 Rear View Mirrors, Removal and Installation).

7. Remove the front door latch.

For additional information, refer to: Front Door Latch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

8. Remove the front door outer window frame mouldings.

9. Remove the front door weatherstrips.

Page 2887 of 3039

(100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the rear door window regulator and motor.

For additional information, refer to: Rear Door Window Regulator and Motor (501-11 Glass, Frames and Mechanisms, Removal and Installation).

5. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

6. Remove the rear door latch.

For additional information, refer to: Rear Door Latch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

7. Remove the rear door outer window frame mouldings.

8. Remove the rear door weatherstrips.

9. Remove the rear door wiring harness.