clutch JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1710 of 3039

control switch on the integrated control panel or the + and - soft buttons on the touch screen display (TSD). The ATC module also adjusts blower speed to compensate for the ram effect on inlet air produced by forward movement of the vehicle. As

vehicle speed and ram effect increases, blower motor speed is reduced, and vice versa.

Air Distribution Control

Two air distribution doors are used to direct air into the passenger compartment. The doors are operated by stepper motors,

which are controlled by the ATC module using LIN bus messages.

When the A/C system is in automatic mode, the ATC module automatically controls air distribution into the passenger compartment in line with its 'comfort' algorithm. Automatic control is overridden if any of the TSD air distribution soft buttons

are selected. Air distribution in the passenger compartment will remain as selected until the 'Auto' switch is pressed or a

different manual selection is made.

A/C Compressor Control

When A/C is selected the ATC module maintains the evaporator at an operating temperature that varies with the passenger compartment cooling requirements. If the requirement for cooled air decreases, the ATC module raises the evaporator operating temperature by reducing the flow of refrigerant provided by the A/C compressor. The ATC module closely controls the rate of temperature increase to avoid introducing moisture into the passenger compartment.

If the requirement for cooled air increases, the ATC module lowers the evaporator operating temperature by increasing the flow of refrigerant provided by the A/C compressor.

When A/C is off, the compressor current signal supplied by the ATC module holds the A/C compressor solenoid valve in the minimum flow position, effectively switching off the A/C function.

The ATC module incorporates limits for the operating pressure of the refrigerant system. If the system approaches the high pressure limit, the compressor current signal is progressively reduced until the system pressure decreases. If the system falls

below the low pressure limit, the compressor current signal is held at its lowest setting so that the A/C compressor is maintained at its minimum stroke. This avoids depletion of the lubricant from the A/C compressor.

A/C Compressor Torque

The ATC module transmits refrigerant pressure and A/C compressor current values to the ECM (engine control module) over the medium speed then high speed CAN bus, using the CJB as a gateway. The ECM uses these values to calculate the torque being used to drive the A/C compressor. The ECM compares the calculated value with its allowable value and if necessary forces the ATC module to inhibit the A/C compressor by transmitting the 'ACClutchInhibit' CAN message. This forces the ATC module to reduce the drive current to the A/C compressor solenoid valve, which reduces refrigerant flow. This in turn reduces the torque required to drive the A/C compressor.

By reducing the maximum A/C compressor torque, the ECM is able to reduce the load on the engine when it needs to maintain vehicle performance or cooling system integrity.

Cooling Fan Control

The ATC module determines the amount of condenser cooling required from the refrigerant pressure sensor, since there is a direct relationship between the temperature and pressure of the refrigerant. The cooling requirement is broadcast to the ECM on the medium speed CAN bus. The ECM then controls the temperature of the condenser using the cooling fan.

Programmed Defrost

The programmed defrost DEF switch is located on the integrated control panel. When the switch is pressed, the ATC module instigates the programmed defrost function. When selected, the ATC module configures the system as follows:

Automatic mode off.

A/C on. Selected temperature unchanged.

Air inlet set to fresh air.

Air distribution set to windshield.

Blower speed set to level 6.

Windshield heater (where fitted) and rear window heater on.

The programmed defrost function can be cancelled by one of the following:

Selecting any air distribution switch on the TSD.

Pressing the AUTO switch on the integrated control panel.

A second press of the DEF button.

Switching the ignition OFF.

The blower speed can be adjusted without terminating the programmed defrost function.

Rear Window Heater

Rear window heater operation is only enabled when the engine is running. The ATC module controls operation of the rear window heater using a relay in the RJB. When rear window heater operation is required, the ATC module broadcasts a message to the RJB on the medium speed CAN bus. On receipt of the message, the RJB energizes the relay by providing a ground path for the relay coil. This allows a battery feed to flow across the relay to power the rear window heater element.

Page 1748 of 3039

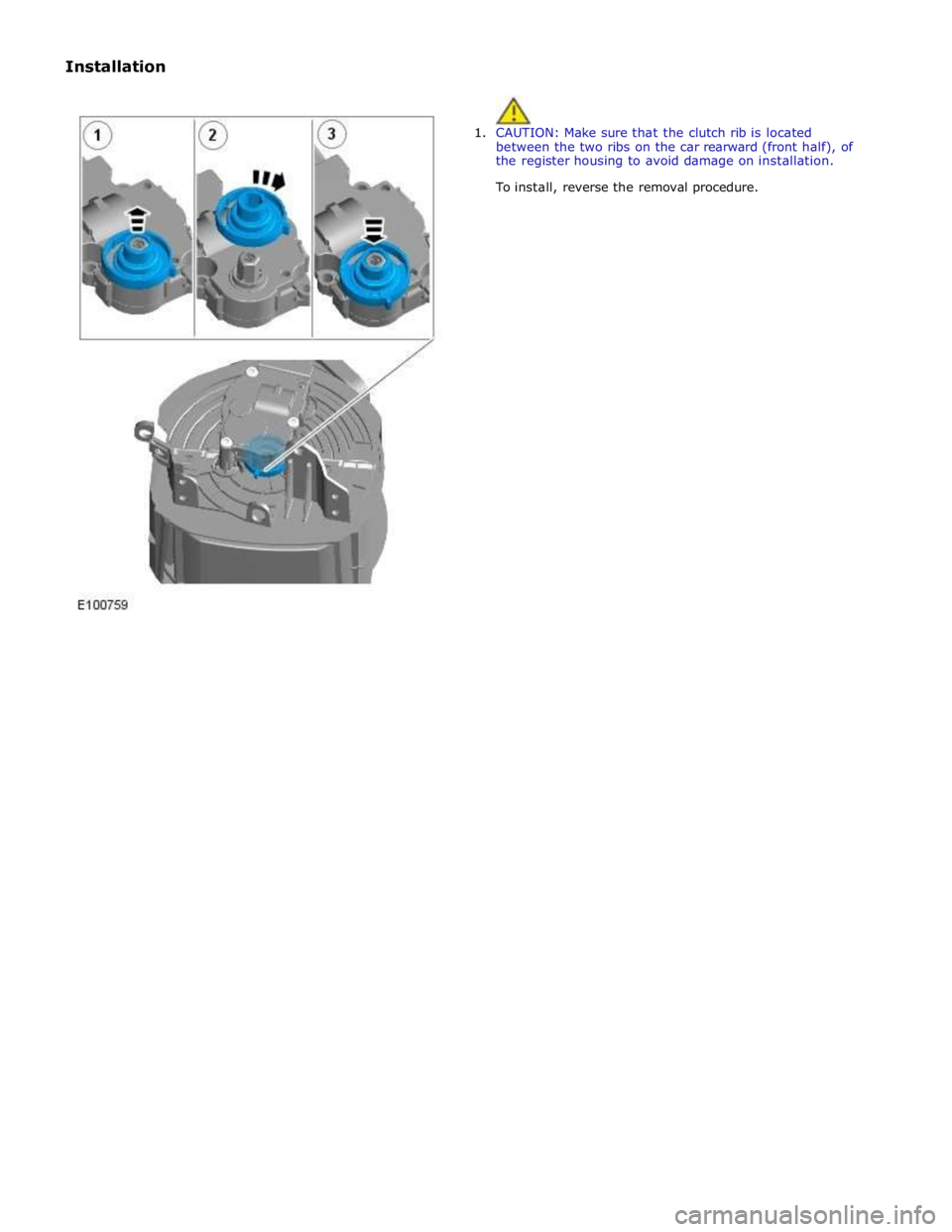

Installation

1. CAUTION: Make sure that the clutch rib is located

between the two ribs on the car rearward (front half), of

the register housing to avoid damage on installation.

To install, reverse the removal procedure.

Page 2179 of 3039

DTC Description Possible Cause Action B102B00 Passive Key

Response Error - general

failure Using the manufacturer approved diagnostic system, clear

all passive keys, re-learn all passive keys B10C100

Left Front Unlock Pull

Switch

No subtype information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B10C124

Left Front Unlock Pull

Switch

Signal stuck high - button

stuck in active position Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check for

stuck left front unlock switch. Refer to the electrical circuit

diagrams and check left front unlock switch circuit for short

to ground B10C200

Left Rear Unlock Pull

Switch

No subtype information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B10C224

Left Rear Unlock Pull

Switch

Signal stuck high - button

stuck in active position Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check for

stuck left rear unlock switch. Refer to the electrical circuit

diagrams and check left rear unlock switch circuit for short

to ground B10C300

Right Front Unlock

Pull Switch

No subtype information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B10C324

Right Front Unlock

Pull Switch

Signal stuck high - button

stuck in active position Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check for

stuck right front unlock switch. Refer to the electrical circuit

diagrams and check right front unlock switch circuit for

short to ground B10C400

Right Rear Unlock Pull

Switch

No subtype information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B10C424

Right Rear Unlock Pull

Switch

Signal stuck high - button

stuck in active position Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check for

stuck right rear unlock switch. Refer to the electrical circuit

diagrams and check right front unlock switch circuit for

short to ground B10C524 Trunk Unlock Pull

Switch

Signal stuck high - button

stuck in active position Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check for

stuck luggage compartment lid unlock switch. Refer to the

electrical circuit diagrams and check luggage compartment

lid unlock switch circuit for short to ground B10C61F

Exterior Trunk

Antenna

Circuit intermittent -

general electrical error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check exterior luggage

compartment antenna circuits for short to ground, power, open circuit B10C71F

Interior Trunk

Antenna

Circuit intermittent -

general electrical error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check interior luggage

compartment antenna circuits for short to ground, power, open circuit B10C81F

Interior Center

Antenna

Circuit intermittent -

general electrical error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check interior center antenna

circuits for short to ground, power, open circuit B10C91F Interior Front Antenna

Circuit intermittent -

general electrical error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check interior front antenna

circuits for short to ground, power, open circuit B10CA1F

Left Rear Door Handle

Antenna

Circuit intermittent -

general electrical error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check left rear door handle

antenna circuits for short to ground, power, open circuit B10CB1F

Right Rear Door

Handle Antenna

Circuit intermittent -

general electrical error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check right rear door handle

antenna circuits for short to ground, power, open circuit B10CC24

Left Front Latch

Clutch Switch

Signal stuck high - button

stuck in active position Check for stuck left front door latch clutch switch. Refer to

the electrical circuit diagrams and check left front door

latch clutch switch circuit for short to ground B10CD24

Left Rear Latch Clutch

Switch

Signal stuck high - button

stuck in active position Check for stuck left rear door latch clutch switch. Refer to

the electrical circuit diagrams and check left rear door latch

clutch switch circuit for short to ground

Page 2180 of 3039

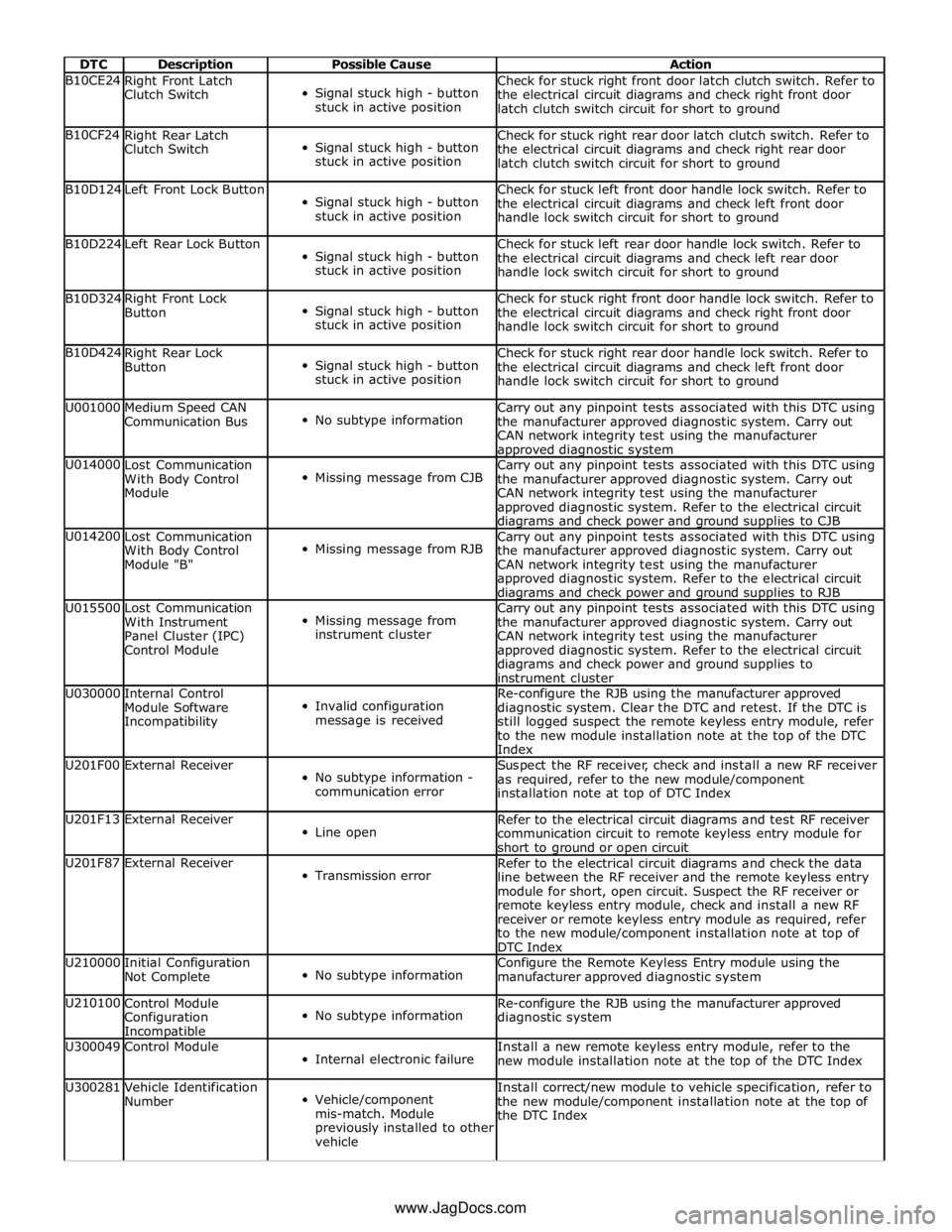

DTC Description Possible Cause Action B10CE24

Right Front Latch

Clutch Switch

Signal stuck high - button

stuck in active position Check for stuck right front door latch clutch switch. Refer to

the electrical circuit diagrams and check right front door

latch clutch switch circuit for short to ground B10CF24

Right Rear Latch

Clutch Switch

Signal stuck high - button

stuck in active position Check for stuck right rear door latch clutch switch. Refer to

the electrical circuit diagrams and check right rear door

latch clutch switch circuit for short to ground B10D124 Left Front Lock Button

Signal stuck high - button

stuck in active position Check for stuck left front door handle lock switch. Refer to

the electrical circuit diagrams and check left front door

handle lock switch circuit for short to ground B10D224 Left Rear Lock Button

Signal stuck high - button

stuck in active position Check for stuck left rear door handle lock switch. Refer to

the electrical circuit diagrams and check left rear door

handle lock switch circuit for short to ground B10D324

Right Front Lock

Button

Signal stuck high - button

stuck in active position Check for stuck right front door handle lock switch. Refer to

the electrical circuit diagrams and check right front door

handle lock switch circuit for short to ground B10D424

Right Rear Lock

Button

Signal stuck high - button

stuck in active position Check for stuck right rear door handle lock switch. Refer to

the electrical circuit diagrams and check left front door

handle lock switch circuit for short to ground U001000

Medium Speed CAN

Communication Bus

No subtype information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out

CAN network integrity test using the manufacturer approved diagnostic system U014000

Lost Communication

With Body Control

Module

Missing message from CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out

CAN network integrity test using the manufacturer

approved diagnostic system. Refer to the electrical circuit diagrams and check power and ground supplies to CJB U014200

Lost Communication

With Body Control

Module "B"

Missing message from RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out

CAN network integrity test using the manufacturer

approved diagnostic system. Refer to the electrical circuit diagrams and check power and ground supplies to RJB U015500

Lost Communication

With Instrument

Panel Cluster (IPC)

Control Module

Missing message from

instrument cluster Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out

CAN network integrity test using the manufacturer

approved diagnostic system. Refer to the electrical circuit

diagrams and check power and ground supplies to

instrument cluster U030000

Internal Control

Module Software

Incompatibility

Invalid configuration

message is received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC is

still logged suspect the remote keyless entry module, refer

to the new module installation note at the top of the DTC

Index U201F00 External Receiver

No subtype information -

communication error Suspect the RF receiver, check and install a new RF receiver

as required, refer to the new module/component

installation note at top of DTC Index U201F13 External Receiver

Line open Refer to the electrical circuit diagrams and test RF receiver

communication circuit to remote keyless entry module for

short to ground or open circuit U201F87 External Receiver

Transmission error Refer to the electrical circuit diagrams and check the data

line between the RF receiver and the remote keyless entry

module for short, open circuit. Suspect the RF receiver or

remote keyless entry module, check and install a new RF

receiver or remote keyless entry module as required, refer

to the new module/component installation note at top of

DTC Index U210000

Initial Configuration

Not Complete

No subtype information Configure the Remote Keyless Entry module using the

manufacturer approved diagnostic system U210100

Control Module

Configuration Incompatible

No subtype information Re-configure the RJB using the manufacturer approved

diagnostic system U300049 Control Module

Internal electronic failure Install a new remote keyless entry module, refer to the

new module installation note at the top of the DTC Index U300281

Vehicle Identification

Number

Vehicle/component

mis-match. Module

previously installed to other

vehicle Install correct/new module to vehicle specification, refer to

the new module/component installation note at the top of

the DTC Index www.JagDocs.com