temperature JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 248 of 3039

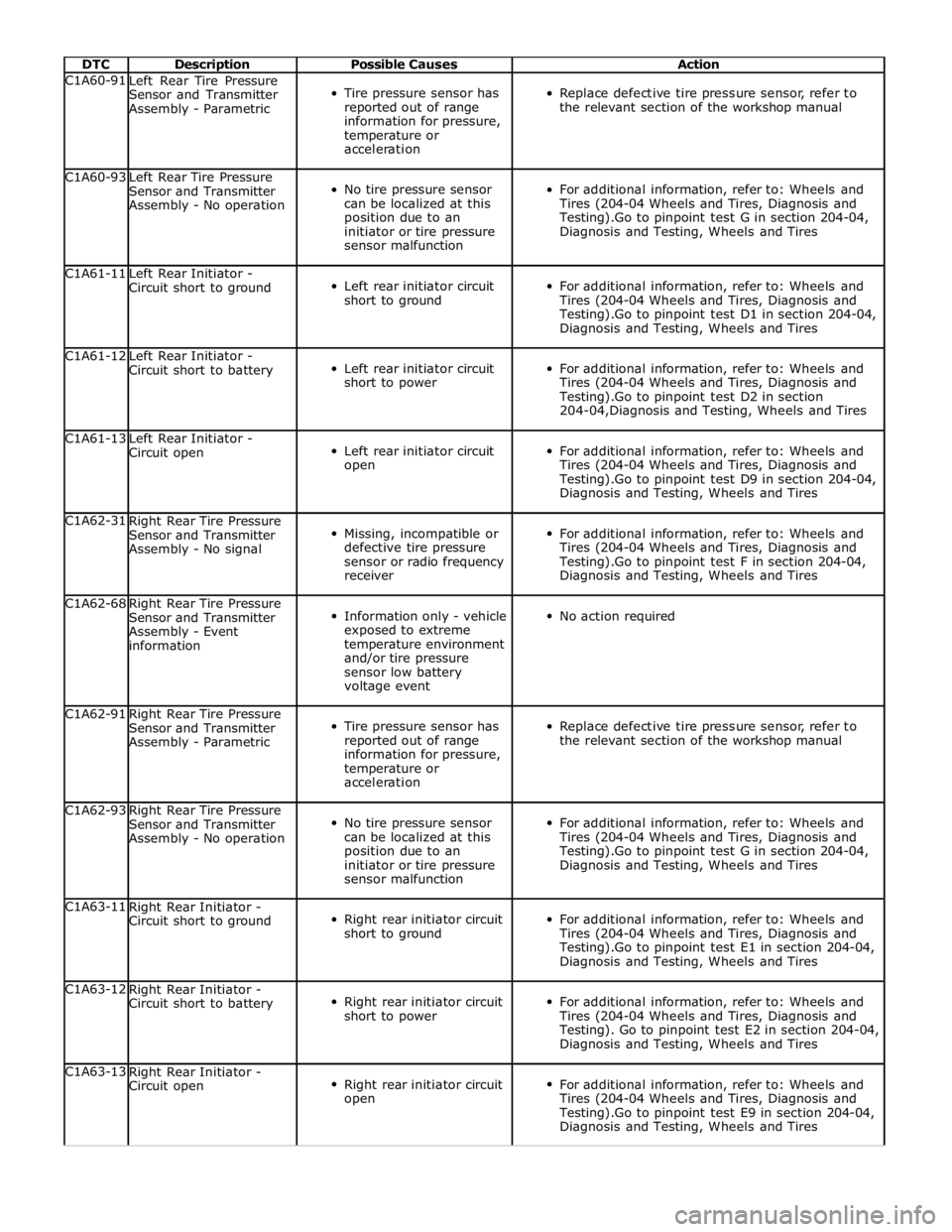

DTC Description Possible Causes Action C1A60-91

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A60-93

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A61-11

Left Rear Initiator -

Circuit short to ground

Left rear initiator circuit

short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A61-12

Left Rear Initiator -

Circuit short to battery

Left rear initiator circuit

short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D2 in section

204-04,Diagnosis and Testing, Wheels and Tires C1A61-13

Left Rear Initiator -

Circuit open

Left rear initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D9 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A62-31

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A62-68

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A62-91

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A62-93

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-11

Right Rear Initiator -

Circuit short to ground

Right rear initiator circuit

short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test E1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-12

Right Rear Initiator -

Circuit short to battery

Right rear initiator circuit

short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing). Go to pinpoint test E2 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-13

Right Rear Initiator -

Circuit open

Right rear initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test E9 in section 204-04,

Diagnosis and Testing, Wheels and Tires

Page 249 of 3039

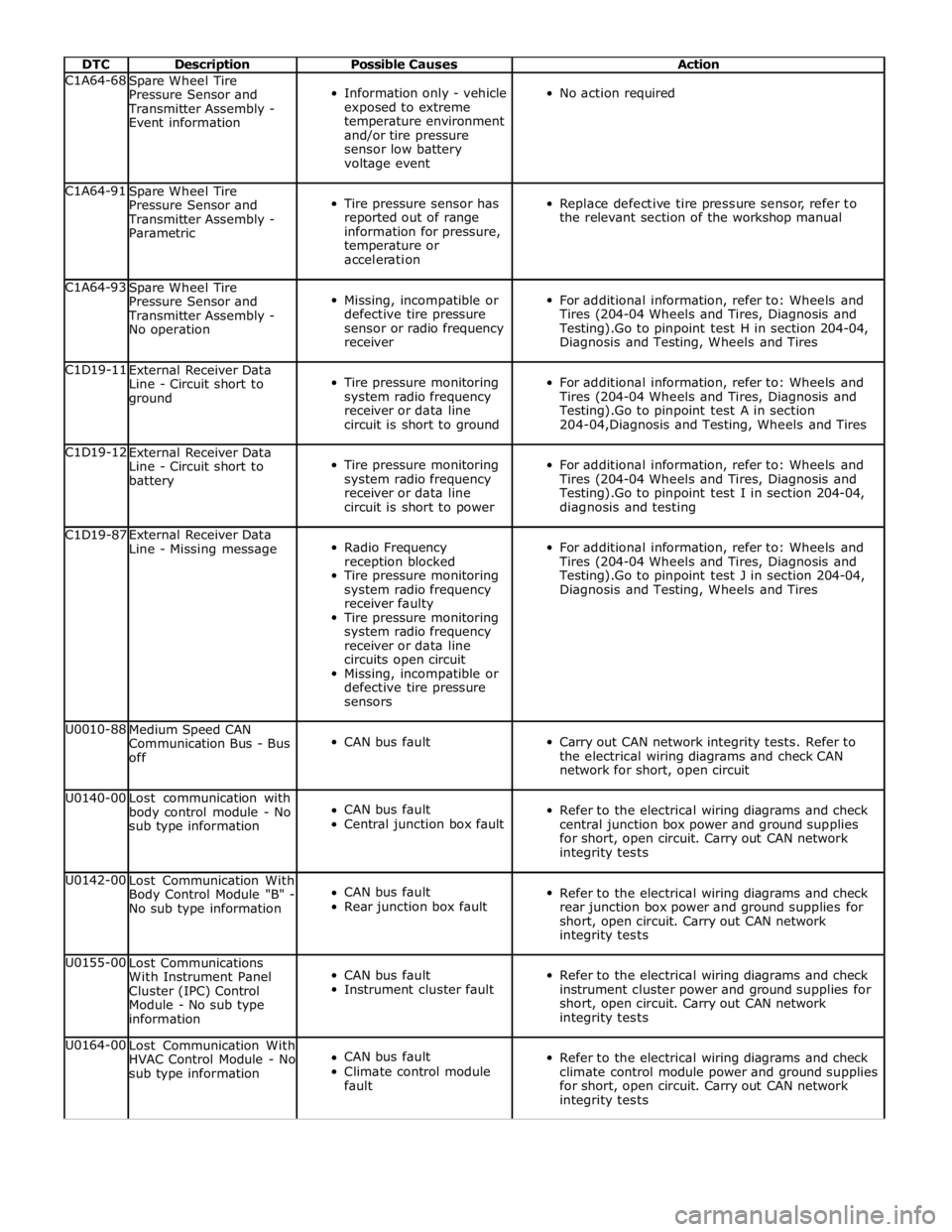

DTC Description Possible Causes Action C1A64-68

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Event information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A64-91

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A64-93

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

No operation

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test H in section 204-04,

Diagnosis and Testing, Wheels and Tires C1D19-11

External Receiver Data

Line - Circuit short to

ground

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test A in section

204-04,Diagnosis and Testing, Wheels and Tires C1D19-12

External Receiver Data

Line - Circuit short to

battery

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test I in section 204-04,

diagnosis and testing C1D19-87

External Receiver Data

Line - Missing message

Radio Frequency

reception blocked

Tire pressure monitoring

system radio frequency

receiver faulty

Tire pressure monitoring

system radio frequency

receiver or data line

circuits open circuit

Missing, incompatible or

defective tire pressure

sensors

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test J in section 204-04,

Diagnosis and Testing, Wheels and Tires U0010-88

Medium Speed CAN

Communication Bus - Bus

off

CAN bus fault

Carry out CAN network integrity tests. Refer to

the electrical wiring diagrams and check CAN

network for short, open circuit U0140-00

Lost communication with

body control module - No

sub type information

CAN bus fault

Central junction box fault

Refer to the electrical wiring diagrams and check

central junction box power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests U0142-00

Lost Communication With

Body Control Module "B" -

No sub type information

CAN bus fault

Rear junction box fault

Refer to the electrical wiring diagrams and check

rear junction box power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

CAN bus fault

Instrument cluster fault

Refer to the electrical wiring diagrams and check

instrument cluster power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0164-00

Lost Communication With

HVAC Control Module - No

sub type information

CAN bus fault

Climate control module

fault

Refer to the electrical wiring diagrams and check

climate control module power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests

Page 252 of 3039

DTC Description Possible Causes Action U3000-44

Control Module - Data

memory failure

EEPROM, External

RAM access failure

Suspect the TSD, check and install a new TSD as

required, refer to the new module/component

installation note at the top of the DTC Index U3000-48

Control Module -

Supervision software

failure

Supervision software

failure

Re-configure the TSD using the manufacturer approved

diagnostic system U3000-4B

Control Module - Over

temperature

Touch panel backlight

- high temperature

detected

Allow the system to cool, clear the DTC and

check/monitor system for re-occurrence. If DTC re-occurs

suspect the TSD. Check and install a new TSD as

required, refer to the new module/component

installation note at the top of the DTC Index U3000-55

Control Module - Not

configured

Incorrect Car

Configuration

Parameters received

Check/amend Car Configuration File using the

manufacturer approved diagnostic system U3000-87

Control Module -

Missing message

Car Configuration File

not received

Check RJB for related DTCs and refer to relevant DTC

Index. Check CAN and MOST networks, carry out the

CAN and MOST network tests using the manufacturer

approved diagnostic system U3000-98

Control Module -

Component or system

over temperature

TSD internal

temperature over

limit

Allow the system to cool, clear the DTC and

check/monitor system for re-occurrence. If DTC re-occurs

suspect the TSD. Check and install a new TSD as

required, refer to the new module/component

installation note at the top of the DTC Index U3003-16

Battery Voltage -

Circuit voltage below

threshold

Circuit voltage below

threshold

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U3003-17

Battery Voltage -

Circuit voltage above

threshold

Circuit voltage above

threshold

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system

Page 256 of 3039

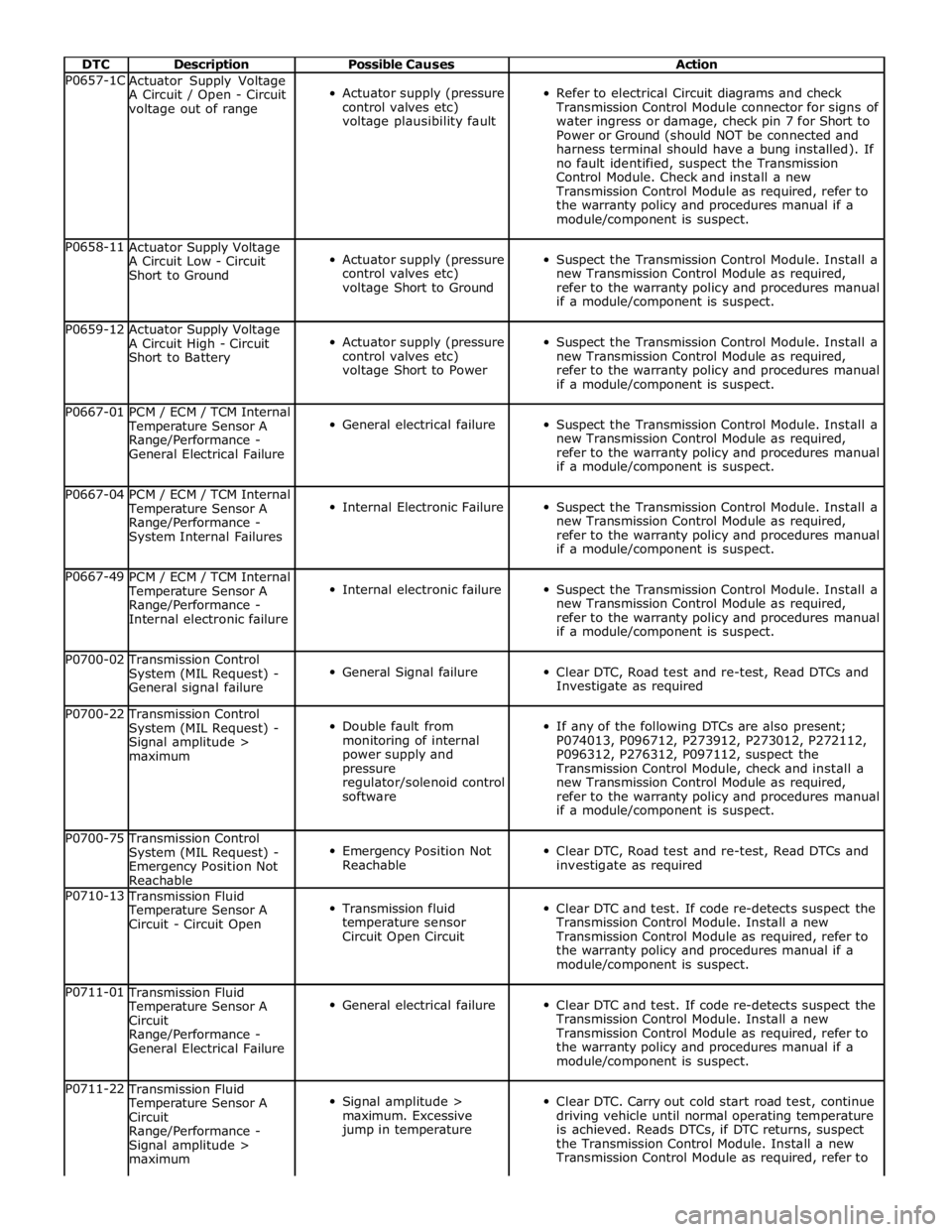

DTC Description Possible Causes Action P0657-1C

Actuator Supply Voltage

A Circuit / Open - Circuit

voltage out of range

Actuator supply (pressure

control valves etc)

voltage plausibility fault

Refer to electrical Circuit diagrams and check

Transmission Control Module connector for signs of

water ingress or damage, check pin 7 for Short to

Power or Ground (should NOT be connected and

harness terminal should have a bung installed). If

no fault identified, suspect the Transmission

Control Module. Check and install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0658-11

Actuator Supply Voltage

A Circuit Low - Circuit

Short to Ground

Actuator supply (pressure

control valves etc)

voltage Short to Ground

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0659-12

Actuator Supply Voltage

A Circuit High - Circuit

Short to Battery

Actuator supply (pressure

control valves etc)

voltage Short to Power

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0667-01

PCM / ECM / TCM Internal Temperature Sensor A

Range/Performance -

General Electrical Failure

General electrical failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0667-04

PCM / ECM / TCM Internal Temperature Sensor A

Range/Performance -

System Internal Failures

Internal Electronic Failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0667-49

PCM / ECM / TCM Internal Temperature Sensor A

Range/Performance -

Internal electronic failure

Internal electronic failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0700-02 Transmission Control

System (MIL Request) -

General signal failure

General Signal failure

Clear DTC, Road test and re-test, Read DTCs and

Investigate as required P0700-22 Transmission Control

System (MIL Request) -

Signal amplitude >

maximum

Double fault from

monitoring of internal

power supply and

pressure

regulator/solenoid control

software

If any of the following DTCs are also present;

P074013, P096712, P273912, P273012, P272112,

P096312, P276312, P097112, suspect the

Transmission Control Module, check and install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0700-75 Transmission Control

System (MIL Request) -

Emergency Position Not

Reachable

Emergency Position Not

Reachable

Clear DTC, Road test and re-test, Read DTCs and

investigate as required P0710-13 Transmission Fluid Temperature Sensor A

Circuit - Circuit Open

Transmission fluid

temperature sensor

Circuit Open Circuit

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0711-01 Transmission Fluid Temperature Sensor A

Circuit

Range/Performance -

General Electrical Failure

General electrical failure

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0711-22 Transmission Fluid Temperature Sensor A

Circuit

Range/Performance -

Signal amplitude >

maximum

Signal amplitude >

maximum. Excessive

jump in temperature

Clear DTC. Carry out cold start road test, continue

driving vehicle until normal operating temperature

is achieved. Reads DTCs, if DTC returns, suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

Page 257 of 3039

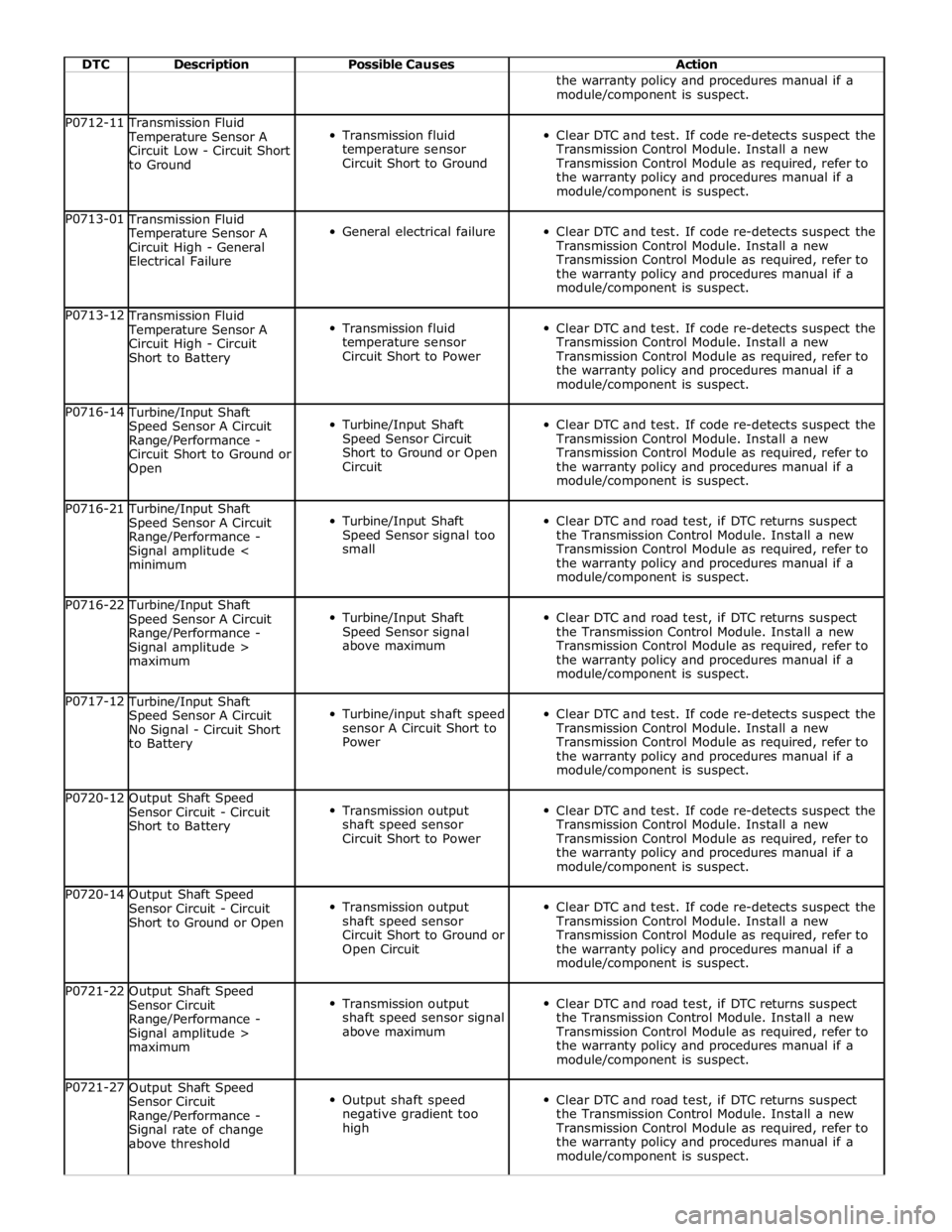

DTC Description Possible Causes Action the warranty policy and procedures manual if a

module/component is suspect. P0712-11 Transmission Fluid Temperature Sensor A

Circuit Low - Circuit Short

to Ground

Transmission fluid

temperature sensor

Circuit Short to Ground

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0713-01 Transmission Fluid Temperature Sensor A

Circuit High - General

Electrical Failure

General electrical failure

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0713-12 Transmission Fluid Temperature Sensor A

Circuit High - Circuit

Short to Battery

Transmission fluid

temperature sensor

Circuit Short to Power

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0716-14 Turbine/Input Shaft

Speed Sensor A Circuit

Range/Performance -

Circuit Short to Ground or

Open

Turbine/Input Shaft

Speed Sensor Circuit

Short to Ground or Open

Circuit

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0716-21 Turbine/Input Shaft

Speed Sensor A Circuit

Range/Performance -

Signal amplitude <

minimum

Turbine/Input Shaft

Speed Sensor signal too

small

Clear DTC and road test, if DTC returns suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0716-22 Turbine/Input Shaft

Speed Sensor A Circuit

Range/Performance -

Signal amplitude >

maximum

Turbine/Input Shaft

Speed Sensor signal

above maximum

Clear DTC and road test, if DTC returns suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0717-12 Turbine/Input Shaft

Speed Sensor A Circuit

No Signal - Circuit Short

to Battery

Turbine/input shaft speed

sensor A Circuit Short to

Power

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0720-12

Output Shaft Speed

Sensor Circuit - Circuit

Short to Battery

Transmission output

shaft speed sensor

Circuit Short to Power

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0720-14

Output Shaft Speed

Sensor Circuit - Circuit

Short to Ground or Open

Transmission output

shaft speed sensor

Circuit Short to Ground or

Open Circuit

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0721-22

Output Shaft Speed

Sensor Circuit

Range/Performance -

Signal amplitude >

maximum

Transmission output

shaft speed sensor signal

above maximum

Clear DTC and road test, if DTC returns suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0721-27

Output Shaft Speed

Sensor Circuit

Range/Performance -

Signal rate of change

above threshold

Output shaft speed

negative gradient too

high

Clear DTC and road test, if DTC returns suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect.

Page 261 of 3039

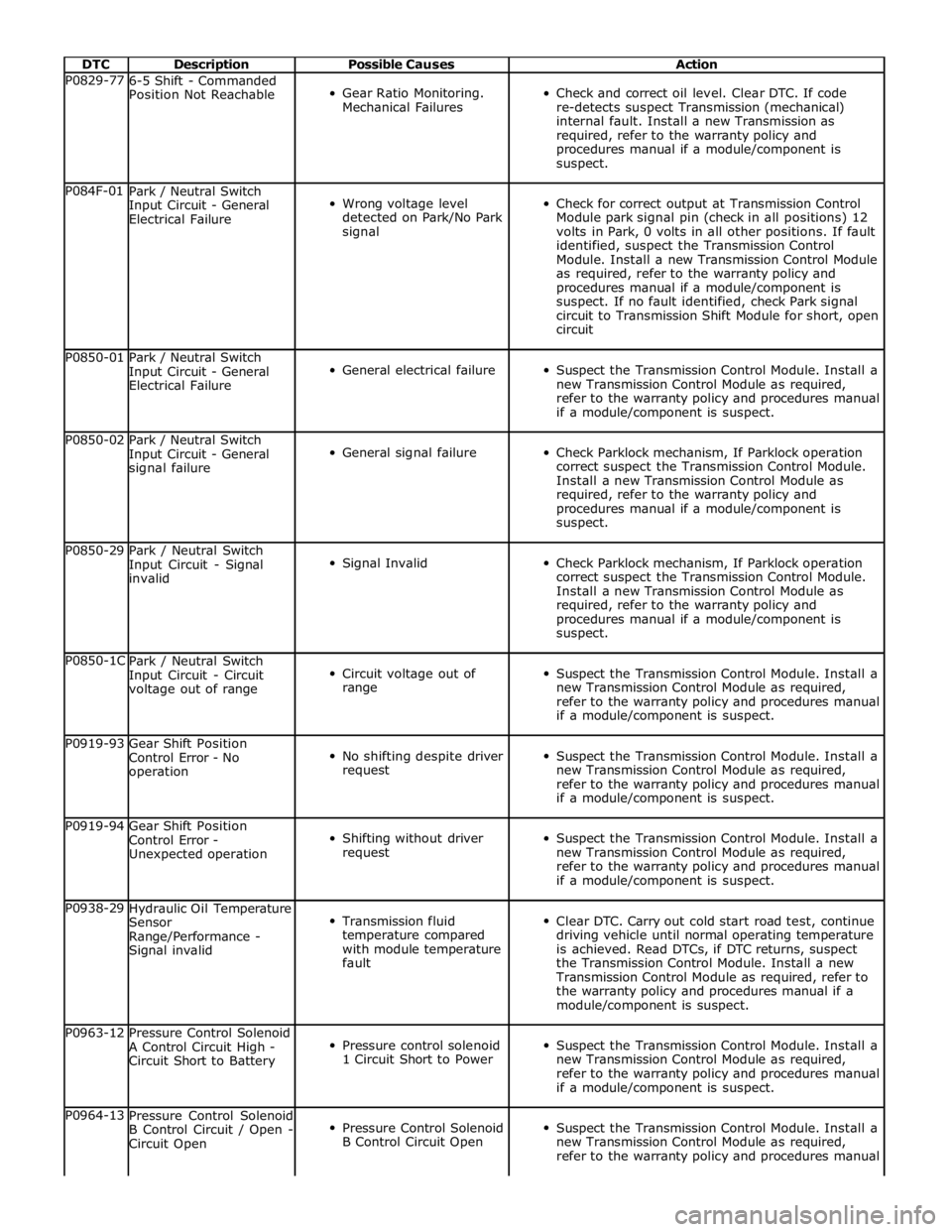

DTC Description Possible Causes Action P0829-77

6-5 Shift - Commanded

Position Not Reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P084F-01

Park / Neutral Switch

Input Circuit - General

Electrical Failure

Wrong voltage level

detected on Park/No Park

signal

Check for correct output at Transmission Control

Module park signal pin (check in all positions) 12

volts in Park, 0 volts in all other positions. If fault

identified, suspect the Transmission Control

Module. Install a new Transmission Control Module

as required, refer to the warranty policy and

procedures manual if a module/component is

suspect. If no fault identified, check Park signal

circuit to Transmission Shift Module for short, open

circuit P0850-01

Park / Neutral Switch

Input Circuit - General

Electrical Failure

General electrical failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0850-02

Park / Neutral Switch

Input Circuit - General

signal failure

General signal failure

Check Parklock mechanism, If Parklock operation

correct suspect the Transmission Control Module.

Install a new Transmission Control Module as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0850-29

Park / Neutral Switch

Input Circuit - Signal

invalid

Signal Invalid

Check Parklock mechanism, If Parklock operation

correct suspect the Transmission Control Module.

Install a new Transmission Control Module as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0850-1C

Park / Neutral Switch

Input Circuit - Circuit

voltage out of range

Circuit voltage out of

range

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0919-93

Gear Shift Position

Control Error - No

operation

No shifting despite driver

request

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0919-94

Gear Shift Position

Control Error -

Unexpected operation

Shifting without driver

request

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0938-29

Hydraulic Oil Temperature

Sensor

Range/Performance -

Signal invalid

Transmission fluid

temperature compared

with module temperature

fault

Clear DTC. Carry out cold start road test, continue

driving vehicle until normal operating temperature

is achieved. Read DTCs, if DTC returns, suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0963-12

Pressure Control Solenoid

A Control Circuit High -

Circuit Short to Battery

Pressure control solenoid

1 Circuit Short to Power

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0964-13

Pressure Control Solenoid

B Control Circuit / Open -

Circuit Open

Pressure Control Solenoid

B Control Circuit Open

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

Page 274 of 3039

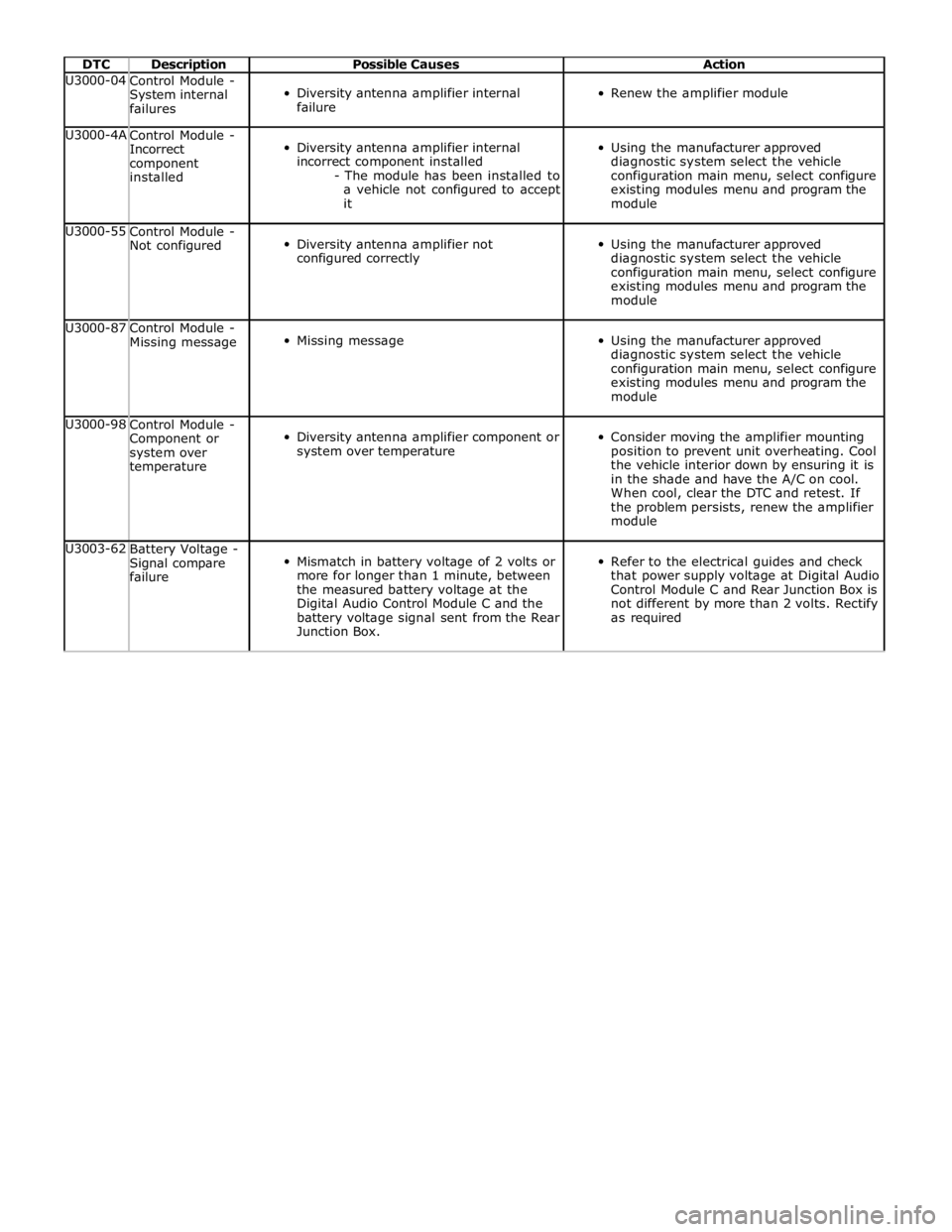

DTC Description Possible Causes Action U3000-04

Control Module -

System internal

failures

Diversity antenna amplifier internal

failure

Renew the amplifier module U3000-4A

Control Module -

Incorrect

component

installed

Diversity antenna amplifier internal

incorrect component installed

- The module has been installed to

a vehicle not configured to accept

it

Using the manufacturer approved

diagnostic system select the vehicle

configuration main menu, select configure

existing modules menu and program the

module U3000-55

Control Module -

Not configured

Diversity antenna amplifier not

configured correctly

Using the manufacturer approved

diagnostic system select the vehicle

configuration main menu, select configure

existing modules menu and program the

module U3000-87

Control Module -

Missing message

Missing message

Using the manufacturer approved

diagnostic system select the vehicle

configuration main menu, select configure

existing modules menu and program the

module U3000-98

Control Module -

Component or

system over

temperature

Diversity antenna amplifier component or

system over temperature

Consider moving the amplifier mounting

position to prevent unit overheating. Cool

the vehicle interior down by ensuring it is

in the shade and have the A/C on cool.

When cool, clear the DTC and retest. If

the problem persists, renew the amplifier

module U3003-62

Battery Voltage -

Signal compare

failure

Mismatch in battery voltage of 2 volts or

more for longer than 1 minute, between

the measured battery voltage at the

Digital Audio Control Module C and the

battery voltage signal sent from the Rear

Junction Box.

Refer to the electrical guides and check

that power supply voltage at Digital Audio

Control Module C and Rear Junction Box is

not different by more than 2 volts. Rectify

as required

Page 280 of 3039

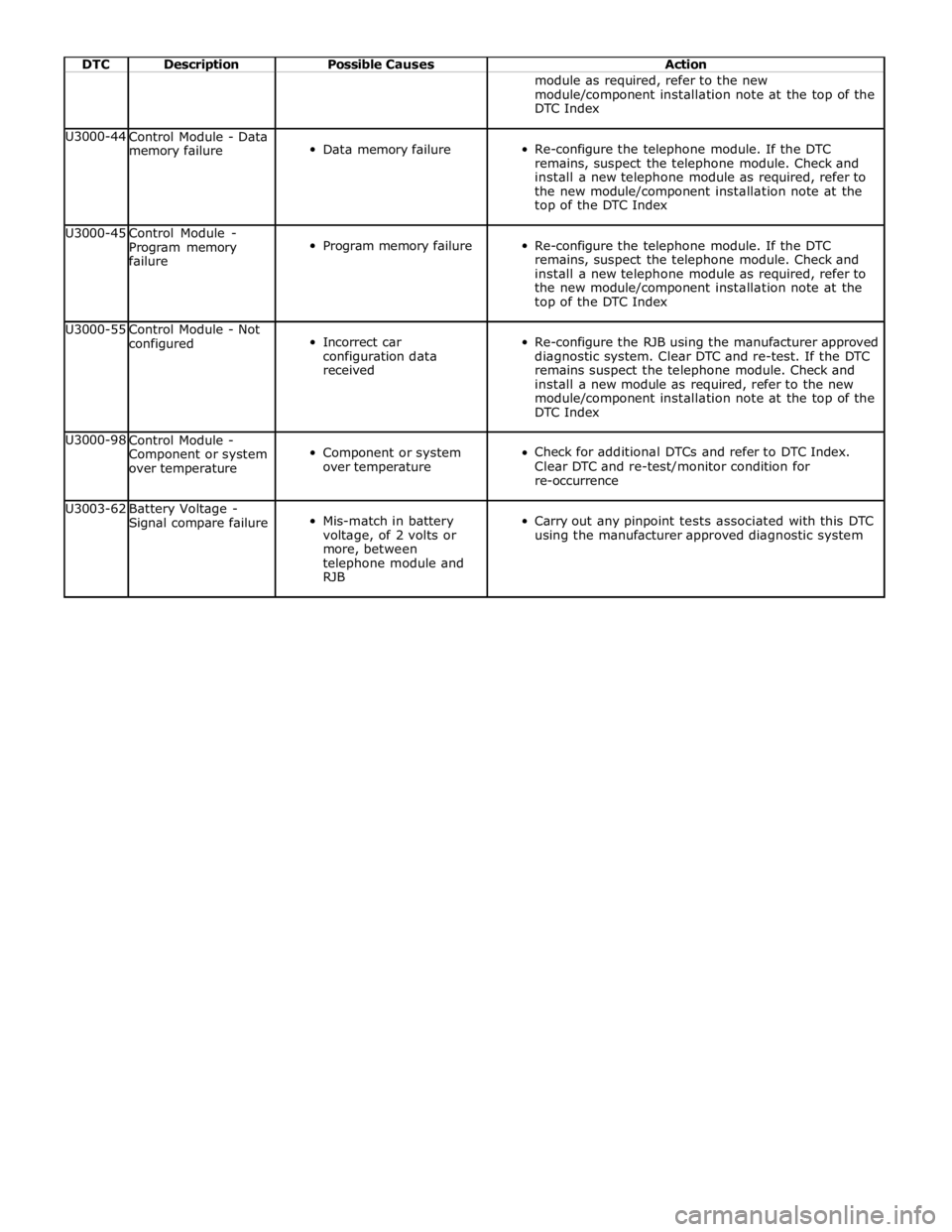

DTC Description Possible Causes Action module as required, refer to the new

module/component installation note at the top of the

DTC Index U3000-44

Control Module - Data

memory failure

Data memory failure

Re-configure the telephone module. If the DTC

remains, suspect the telephone module. Check and

install a new telephone module as required, refer to

the new module/component installation note at the

top of the DTC Index U3000-45

Control Module -

Program memory

failure

Program memory failure

Re-configure the telephone module. If the DTC

remains, suspect the telephone module. Check and

install a new telephone module as required, refer to

the new module/component installation note at the

top of the DTC Index U3000-55

Control Module - Not

configured

Incorrect car

configuration data

received

Re-configure the RJB using the manufacturer approved

diagnostic system. Clear DTC and re-test. If the DTC

remains suspect the telephone module. Check and

install a new module as required, refer to the new

module/component installation note at the top of the

DTC Index U3000-98

Control Module -

Component or system

over temperature

Component or system

over temperature

Check for additional DTCs and refer to DTC Index.

Clear DTC and re-test/monitor condition for

re-occurrence U3003-62

Battery Voltage -

Signal compare failure

Mis-match in battery

voltage, of 2 volts or

more, between

telephone module and

RJB

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system

Page 439 of 3039

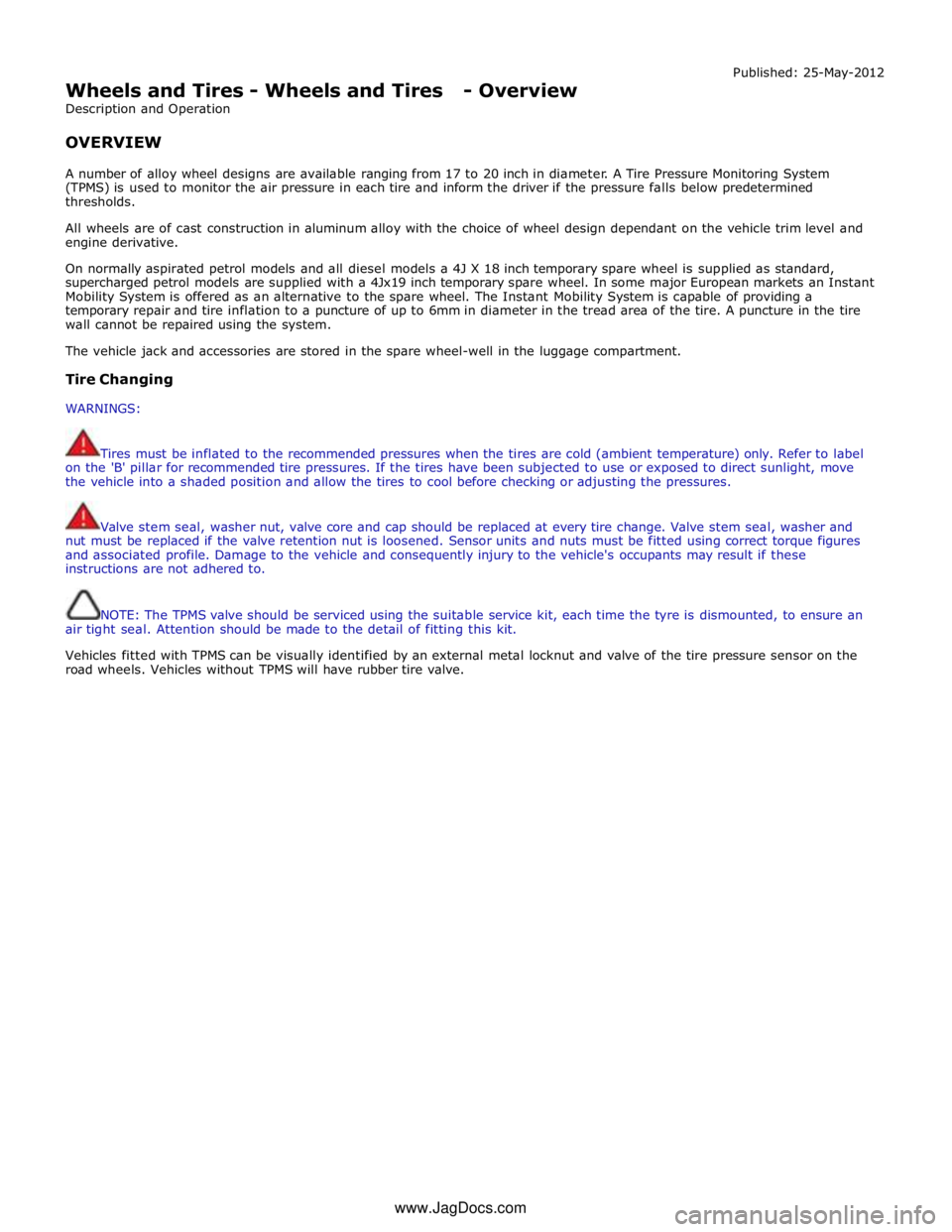

Wheels and Tires - Wheels and Tires - Overview

Description and Operation

OVERVIEW Published: 25-May-2012

A number of alloy wheel designs are available ranging from 17 to 20 inch in diameter. A Tire Pressure Monitoring System

(TPMS) is used to monitor the air pressure in each tire and inform the driver if the pressure falls below predetermined

thresholds.

All wheels are of cast construction in aluminum alloy with the choice of wheel design dependant on the vehicle trim level and

engine derivative.

On normally aspirated petrol models and all diesel models a 4J X 18 inch temporary spare wheel is supplied as standard,

supercharged petrol models are supplied with a 4Jx19 inch temporary spare wheel. In some major European markets an Instant

Mobility System is offered as an alternative to the spare wheel. The Instant Mobility System is capable of providing a

temporary repair and tire inflation to a puncture of up to 6mm in diameter in the tread area of the tire. A puncture in the tire

wall cannot be repaired using the system.

The vehicle jack and accessories are stored in the spare wheel-well in the luggage compartment.

Tire Changing

WARNINGS:

Tires must be inflated to the recommended pressures when the tires are cold (ambient temperature) only. Refer to label

on the 'B' pillar for recommended tire pressures. If the tires have been subjected to use or exposed to direct sunlight, move

the vehicle into a shaded position and allow the tires to cool before checking or adjusting the pressures.

Valve stem seal, washer nut, valve core and cap should be replaced at every tire change. Valve stem seal, washer and

nut must be replaced if the valve retention nut is loosened. Sensor units and nuts must be fitted using correct torque figures

and associated profile. Damage to the vehicle and consequently injury to the vehicle's occupants may result if these

instructions are not adhered to.

NOTE: The TPMS valve should be serviced using the suitable service kit, each time the tyre is dismounted, to ensure an

air tight seal. Attention should be made to the detail of fitting this kit.

Vehicles fitted with TPMS can be visually identified by an external metal locknut and valve of the tire pressure sensor on the

road wheels. Vehicles without TPMS will have rubber tire valve.

www.JagDocs.com

Page 443 of 3039

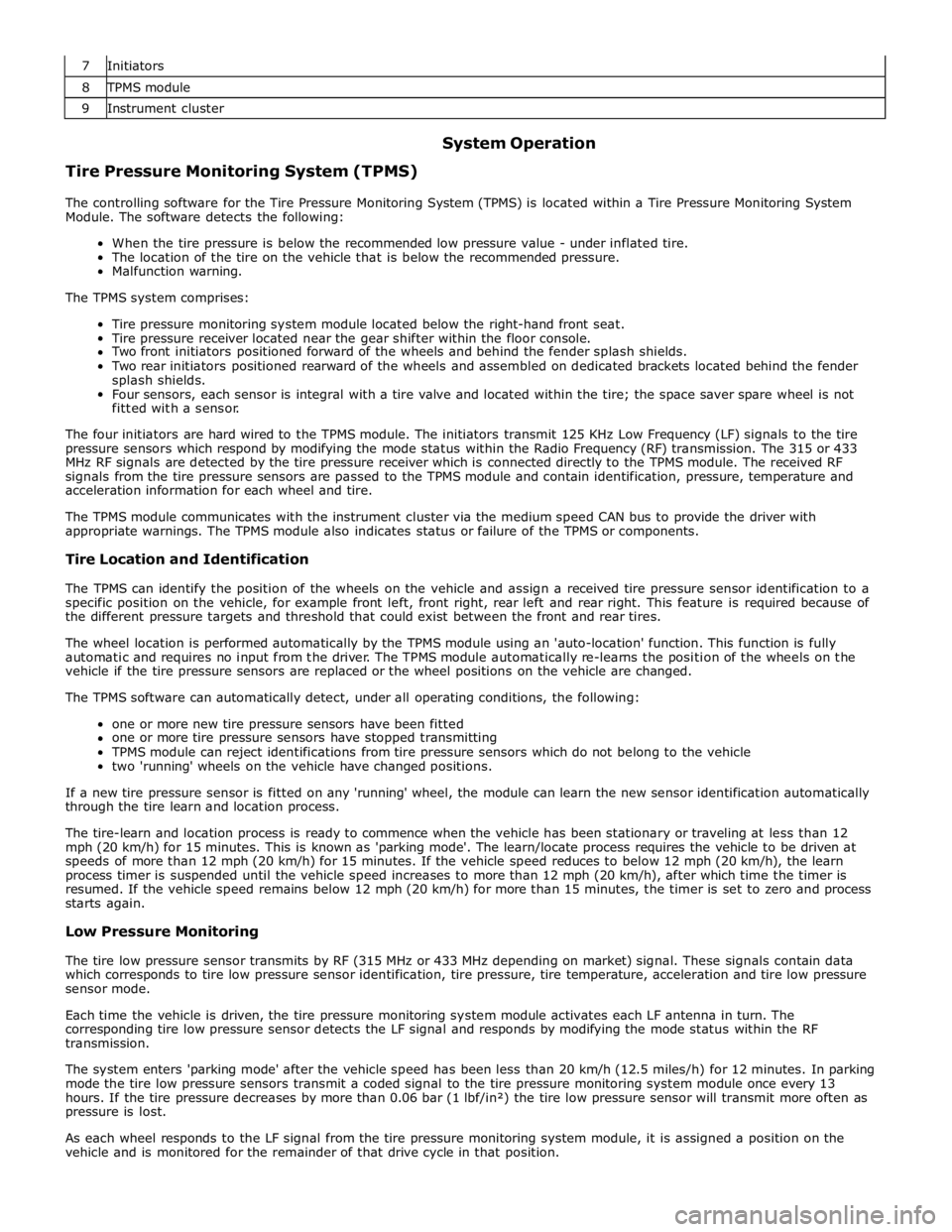

7 Initiators 8 TPMS module 9 Instrument cluster

Tire Pressure Monitoring System (TPMS) System Operation

The controlling software for the Tire Pressure Monitoring System (TPMS) is located within a Tire Pressure Monitoring System

Module. The software detects the following:

When the tire pressure is below the recommended low pressure value - under inflated tire.

The location of the tire on the vehicle that is below the recommended pressure.

Malfunction warning.

The TPMS system comprises:

Tire pressure monitoring system module located below the right-hand front seat.

Tire pressure receiver located near the gear shifter within the floor console.

Two front initiators positioned forward of the wheels and behind the fender splash shields.

Two rear initiators positioned rearward of the wheels and assembled on dedicated brackets located behind the fender

splash shields.

Four sensors, each sensor is integral with a tire valve and located within the tire; the space saver spare wheel is not

fitted with a sensor.

The four initiators are hard wired to the TPMS module. The initiators transmit 125 KHz Low Frequency (LF) signals to the tire

pressure sensors which respond by modifying the mode status within the Radio Frequency (RF) transmission. The 315 or 433

MHz RF signals are detected by the tire pressure receiver which is connected directly to the TPMS module. The received RF

signals from the tire pressure sensors are passed to the TPMS module and contain identification, pressure, temperature and

acceleration information for each wheel and tire.

The TPMS module communicates with the instrument cluster via the medium speed CAN bus to provide the driver with

appropriate warnings. The TPMS module also indicates status or failure of the TPMS or components.

Tire Location and Identification

The TPMS can identify the position of the wheels on the vehicle and assign a received tire pressure sensor identification to a

specific position on the vehicle, for example front left, front right, rear left and rear right. This feature is required because of

the different pressure targets and threshold that could exist between the front and rear tires.

The wheel location is performed automatically by the TPMS module using an 'auto-location' function. This function is fully

automatic and requires no input from the driver. The TPMS module automatically re-learns the position of the wheels on the

vehicle if the tire pressure sensors are replaced or the wheel positions on the vehicle are changed.

The TPMS software can automatically detect, under all operating conditions, the following:

one or more new tire pressure sensors have been fitted

one or more tire pressure sensors have stopped transmitting

TPMS module can reject identifications from tire pressure sensors which do not belong to the vehicle

two 'running' wheels on the vehicle have changed positions.

If a new tire pressure sensor is fitted on any 'running' wheel, the module can learn the new sensor identification automatically

through the tire learn and location process.

The tire-learn and location process is ready to commence when the vehicle has been stationary or traveling at less than 12

mph (20 km/h) for 15 minutes. This is known as 'parking mode'. The learn/locate process requires the vehicle to be driven at

speeds of more than 12 mph (20 km/h) for 15 minutes. If the vehicle speed reduces to below 12 mph (20 km/h), the learn

process timer is suspended until the vehicle speed increases to more than 12 mph (20 km/h), after which time the timer is

resumed. If the vehicle speed remains below 12 mph (20 km/h) for more than 15 minutes, the timer is set to zero and process

starts again.

Low Pressure Monitoring

The tire low pressure sensor transmits by RF (315 MHz or 433 MHz depending on market) signal. These signals contain data

which corresponds to tire low pressure sensor identification, tire pressure, tire temperature, acceleration and tire low pressure

sensor mode.

Each time the vehicle is driven, the tire pressure monitoring system module activates each LF antenna in turn. The

corresponding tire low pressure sensor detects the LF signal and responds by modifying the mode status within the RF

transmission.

The system enters 'parking mode' after the vehicle speed has been less than 20 km/h (12.5 miles/h) for 12 minutes. In parking

mode the tire low pressure sensors transmit a coded signal to the tire pressure monitoring system module once every 13

hours. If the tire pressure decreases by more than 0.06 bar (1 lbf/in²) the tire low pressure sensor will transmit more often as

pressure is lost.

As each wheel responds to the LF signal from the tire pressure monitoring system module, it is assigned a position on the

vehicle and is monitored for the remainder of that drive cycle in that position.