temperature JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 73 of 3039

Supplementary Restraint System (SRS) Precautions

WARNING: Do not install rear facing child seats in the front passenger seat.

The SRS contains components which are potentially hazardous to service personnel if not handled correctly. The following

guidelines and precautions are intended to alert personnel to potential sources of danger and emphasise the importance of

ensuring the integrity of the SRS components installed to the vehicle.

WARNING: The following precautions MUST be adhered to when working on the SRS system:

The correct procedures must always be used when working on SRS components.

Persons working on the SRS system must be fully trained and have been issued with the safety guidelines.

The airbag modules contain extremely flammable and hazardous compounds. Contact with water, acids or heavy

metals may produce harmful or explosive results. Do not dismantle, incinerate or bring into contact with electricity

before the unit has been deployed.

Always replace a seat belt assembly that has withstood the strain of a severe vehicle impact or if the webbing

shows signs of fraying.

Always disconnect the vehicle battery before carrying out any electric welding on a vehicle installed with an SRS

system.

CAUTION: Do not expose airbag modules or seat belt pre-tensioners to temperatures exceeding 85° C (185° F).

It should be noted that these precautions are not restricted to operations performed when servicing the SRS system. The same

care should be exercised when working on ancillary systems and components located in the vicinity of SRS components; these

include but are not limited to:

Steering wheel airbag, rotary coupler.

Passenger front airbag.

Head airbag modules - front and rear.

Seat belt pre-tensioners.

SRS harnesses, link leads and connectors.

Side (thorax) air bags.

Making the system safe

Before working on or in the vicinity of SRS components, make sure the system is rendered safe by performing the following

operations:

Remove the ignition key.

Disconnect battery, earth lead first.

Wait 2 minutes for the SRS power circuit to discharge before commencing work.

NOTE: The SRS uses energy reserve capacitors to keep the system active in the event of electrical supply failure under

crash conditions. It is necessary to allow the capacitors sufficient time to discharge (2 minutes) in order to avoid the risk of

accidental deployment.

Installation

In order to make sure system integrity, it is essential that the SRS system is regularly checked and maintained so that it is

ready for effective operation in the event of a collision. Carefully inspect SRS components before installation. Do not install a

part that shows signs of being dropped or improperly handled, such as dents, cracks or deformation.

WARNING: The integrity of the SRS systems is critical for safety reasons. Make sure the following precautions are always

adhered to:

Do not install accessories or other objects to trim panels which cover ITS airbags.

Never install used SRS components from another vehicle or attempt to repair an SRS component.

When repairing an SRS system, only use genuine new parts.

Never apply electrical power to an SRS component unless instructed to do so as part of an approved test

procedure.

Special fixings are necessary for installing an airbag module – do not use other fixings and make sure that all

fixings are tightened to the correct torque.

Always use new fixings when replacing an SRS component.

CAUTIONS:

Take care not to trap airbag modules when installing interior trim components.

Make sure SRS components are not contaminated by oil or grease.

NOTES:

Following seat belt pre-tensioner deployment, the seat belts can still be used as conventional seat belts but will need to

Page 93 of 3039

7

Measure the time using a suitable stopwatch 8

Wait for the specified period of time 9

The specified task requires the specified minimum temperature 10

The specified task requires the specified maximum temperature not to be exceeded 11

The specified task requires the specified temperature range 12

The specified task requires the specified temperature 13

Measure and check for the specified value using a dial indicator gauge 14

Measure and check for the specified MAX value using a dial indicator gauge 15

Measure and check for the specified MIN value using a dial indicator gauge

Page 102 of 3039

Live air bag modules must be placed in a suitable cage when removed from the vehicle. The air bag or trim cover must be

facing upwards.

Do not install a rearward facing child safety seat to the passenger seat with an activated passenger air bag.

CAUTIONS:

Pyrotechnic components must not be subjected to temperatures higher than 110°C.

Never install aftermarket accessories to the vehicle on or adjacent to the supplemental restraint system module.

Page 103 of 3039

General Information - Road/Roller Testing

Description and Operation Published: 11-May-2011

Road or roller testing may be carried out for various reasons and a procedure detailing pre-test checks, through engine starting

and stopping, pre-driving checks, on-test checks to final checks on completion of the test is given in this section.

Unless complete vehicle performance is being checked, the full road test procedure need not be carried out. Instead, those

items particularly relevant to the system/s being checked can be extracted.

Pre - Test Checks

WARNING: If the brake system hydraulic fluid level is low, pedal travel is excessive or a hydraulic leak is found, do not

attempt to road test the vehicle until the reason for the low fluid level, excessive pedal travel or hydraulic leak is found and

rectified.

It is suggested that pre-test checks, and functional tests of those systems/circuits which affect the safe and legal operations

of the vehicle, such as brakes, lights and steering, should always be carried out before the road or roller test.

Engine oil level

Engine coolant level

Tires, for correct pressure, compatible types and tread patterns, and wear within limits

There is sufficient fuel in the tank to complete the test

All around the engine, transmission and under the vehicle for oil, coolant, hydraulic and fuel leaks. Make a note of any

apparent leaks and wipe off the surrounding areas to make it easier to identify the extent of the leak on completion of

the test

Starting the Engine

CAUTION: On initial drive away from cold and within the first 1.5 km (1 mile), do not depress accelerator pedal beyond

half travel until the vehicle has attained a minimum speed of 25 km/h (15 miles/h). Never operate at high engine speed or

with the accelerator pedal at full travel whilst the engine is cold.

With the ignition switched off, check:

The parking brake is applied

The transmission selector lever is in Park

All instrument gauges (except fuel gauge) read zero

With the ignition switched on, check:

Ignition controlled warning lamps come on

Engine coolant temperature gauge registers a reading compatible with the engine coolant temperature

Fuel gauge registers a reading appropriate to the fuel level in the tank

The operation of the parking brake and brake fluid level warning lamps

On Road or Roller Test Check:

CAUTION: If road testing, check the brake operation while still travelling at low speed before continuing with the test. If

the brakes pull to one side, or appear to be otherwise faulty, do not continue with the road test until the fault has been found

and rectified.

Initial gear engagement is smooth

Parking brake control operates smoothly and the parking brake releases quickly and completely

Transmission takes up the drive smoothly, without judder

The engine power output is satisfactory, full power is achieved, acceleration is smooth and pedal operation not stiff or

heavy, and engine speed returns to idle correctly

There is no excessive or abnormally colored smoke from the engine under normal driving, heavy load or overrun

conditions

Steering operation, including power steering, is smooth, accurate, not excessively heavy or with excessive free play or

vibration. Does not pull to one side and self centres smoothly after cornering

Speedometer, oil pressure warning lamp, coolant temperature gauge and tachometer register the correct readings or

operate correctly

Switches and controls operate smoothly and positively, warning lamps operate correctly and the direction indicator

control self cancels when the steering is returned to the straight ahead position

Heating and ventilation systems work correctly and effectively

Brake operation and efficiency

Brake Testing

WARNING: When brake testing, avoid breathing the smoke or fumes from hot brakes, this may contain asbestos dust

which is hazardous to health, see Health and Safety Precautions.

Page 104 of 3039

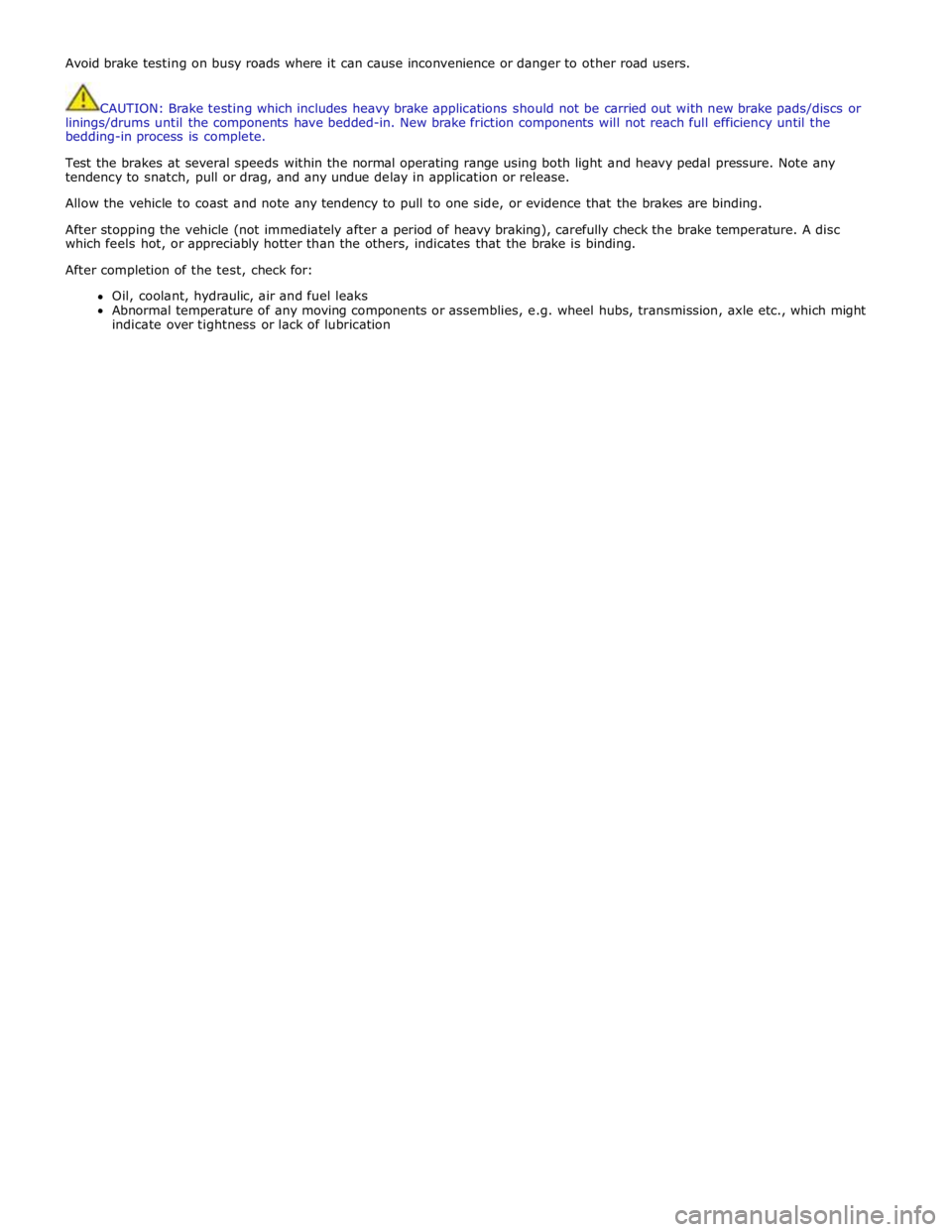

Avoid brake testing on busy roads where it can cause inconvenience or danger to other road users.

CAUTION: Brake testing which includes heavy brake applications should not be carried out with new brake pads/discs or

linings/drums until the components have bedded-in. New brake friction components will not reach full efficiency until the

bedding-in process is complete.

Test the brakes at several speeds within the normal operating range using both light and heavy pedal pressure. Note any

tendency to snatch, pull or drag, and any undue delay in application or release.

Allow the vehicle to coast and note any tendency to pull to one side, or evidence that the brakes are binding.

After stopping the vehicle (not immediately after a period of heavy braking), carefully check the brake temperature. A disc

which feels hot, or appreciably hotter than the others, indicates that the brake is binding.

After completion of the test, check for:

Oil, coolant, hydraulic, air and fuel leaks

Abnormal temperature of any moving components or assemblies, e.g. wheel hubs, transmission, axle etc., which might

indicate over tightness or lack of lubrication

Page 105 of 3039

Published: 11-May-2011

General Information - Window Glass Health and Safety Precautions

Description and Operation

WARNINGS:

Cured polyurethane (PU) adhesive can degrade if subjected to high temperatures. Isocyanide compounds can be released

when grinding or welding in close proximity to cured PU adhesive.

SKIN CONTACT: Prolonged exposure to polyurethane (PU) adhesive may cause skin irritation. If PU adhesive comes into

contact with the skin, remove any contaminated clothing. Immediately wash the skin with soap and water. Seek medical

attention for any persistent skin irritation or abnormality.

EYE CONTACT: Polyurethane (PU) adhesive may cause severe irritation or damage. If PU adhesive comes into contact with

the eyes, immediately flush eyes with plenty of running water for at least 15 minutes. Seek immediate medical attention.

SWALLOWED: If polyurethane (PU) adhesive is swallowed, flush the mouth thoroughly. Do not induce vomiting. Provide

rest, warmth and fresh air. Seek immediate medical attention.

INHALED: Persons having a respiratory allergy may have an allergic reaction when handling polyurethane (PU) adhesive.

INHALED: Polyurethane (PU) adhesive can cause asthma like symptoms. Isocyanate vapor from primer or PU adhesive can

cause allergies in the respiratory tract.

INHALED: If polyurethane (PU) adhesive fumes are inhaled, move victim to fresh air. Provide oxygen if necessary. If

breathing stops, provide artificial respiration. Keep a victim warm and at rest. Seek immediate medical attention.

CAUTIONS:

Make sure that the direct glazing for bonded glass cutting blades are changed where the cutting depth changes to avoid

damage to the body and trim panels.

During the curing period of the PU adhesive, the door windows must be left open to avoid a build up of pressure when the

doors are opened and closed.

www.JagDocs.com

Page 129 of 3039

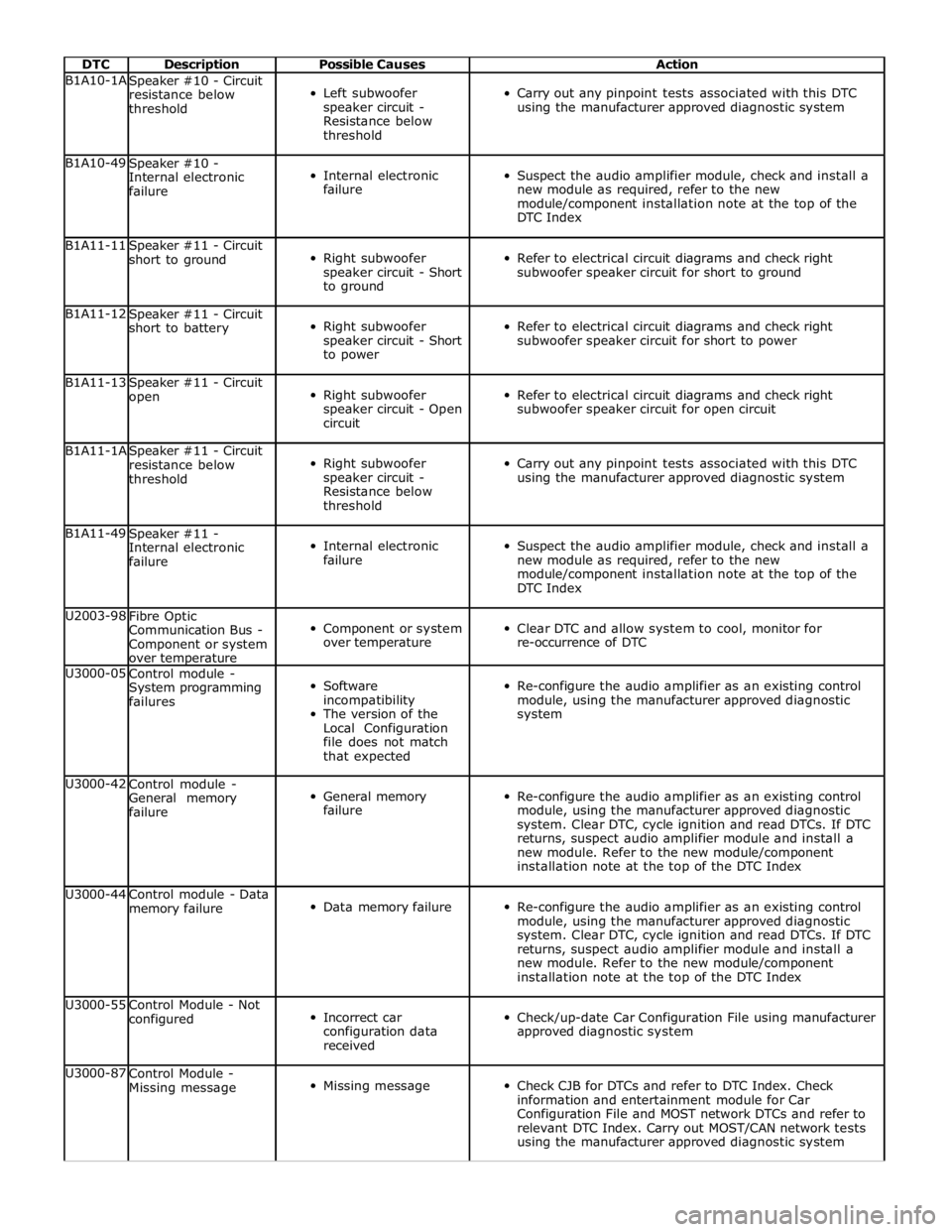

DTC Description Possible Causes Action B1A10-1A

Speaker #10 - Circuit

resistance below

threshold

Left subwoofer

speaker circuit -

Resistance below

threshold

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system B1A10-49

Speaker #10 -

Internal electronic

failure

Internal electronic

failure

Suspect the audio amplifier module, check and install a

new module as required, refer to the new

module/component installation note at the top of the

DTC Index B1A11-11

Speaker #11 - Circuit

short to ground

Right subwoofer

speaker circuit - Short

to ground

Refer to electrical circuit diagrams and check right

subwoofer speaker circuit for short to ground B1A11-12

Speaker #11 - Circuit

short to battery

Right subwoofer

speaker circuit - Short

to power

Refer to electrical circuit diagrams and check right

subwoofer speaker circuit for short to power B1A11-13

Speaker #11 - Circuit

open

Right subwoofer

speaker circuit - Open

circuit

Refer to electrical circuit diagrams and check right

subwoofer speaker circuit for open circuit B1A11-1A

Speaker #11 - Circuit

resistance below

threshold

Right subwoofer

speaker circuit -

Resistance below

threshold

Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system B1A11-49

Speaker #11 -

Internal electronic

failure

Internal electronic

failure

Suspect the audio amplifier module, check and install a

new module as required, refer to the new

module/component installation note at the top of the

DTC Index U2003-98

Fibre Optic

Communication Bus -

Component or system

over temperature

Component or system

over temperature

Clear DTC and allow system to cool, monitor for

re-occurrence of DTC U3000-05

Control module -

System programming

failures

Software

incompatibility

The version of the

Local Configuration

file does not match

that expected

Re-configure the audio amplifier as an existing control

module, using the manufacturer approved diagnostic

system U3000-42

Control module -

General memory

failure

General memory

failure

Re-configure the audio amplifier as an existing control

module, using the manufacturer approved diagnostic

system. Clear DTC, cycle ignition and read DTCs. If DTC

returns, suspect audio amplifier module and install a

new module. Refer to the new module/component

installation note at the top of the DTC Index U3000-44

Control module - Data

memory failure

Data memory failure

Re-configure the audio amplifier as an existing control

module, using the manufacturer approved diagnostic

system. Clear DTC, cycle ignition and read DTCs. If DTC

returns, suspect audio amplifier module and install a

new module. Refer to the new module/component

installation note at the top of the DTC Index U3000-55

Control Module - Not

configured

Incorrect car

configuration data

received

Check/up-date Car Configuration File using manufacturer

approved diagnostic system U3000-87

Control Module -

Missing message

Missing message

Check CJB for DTCs and refer to DTC Index. Check

information and entertainment module for Car

Configuration File and MOST network DTCs and refer to

relevant DTC Index. Carry out MOST/CAN network tests

using the manufacturer approved diagnostic system

Page 141 of 3039

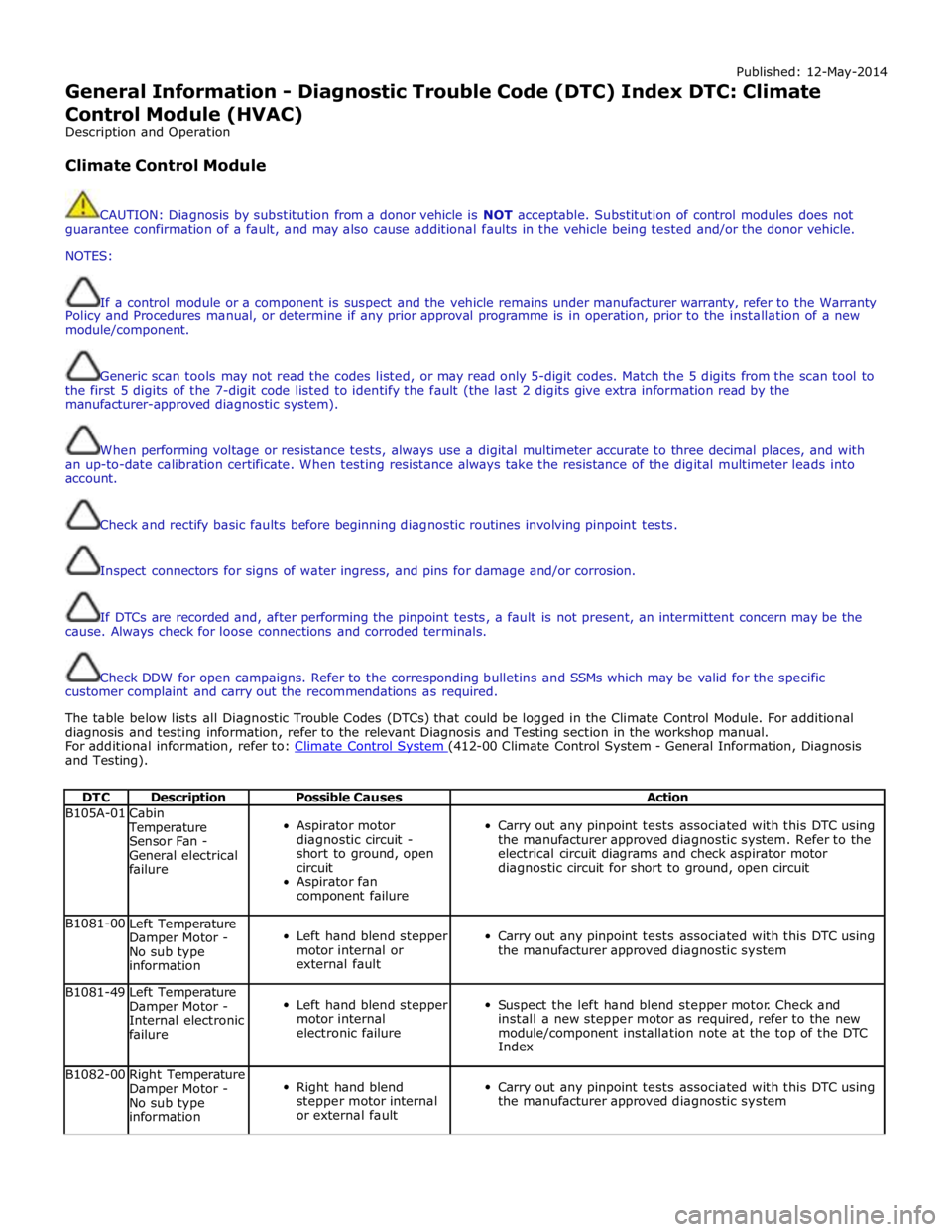

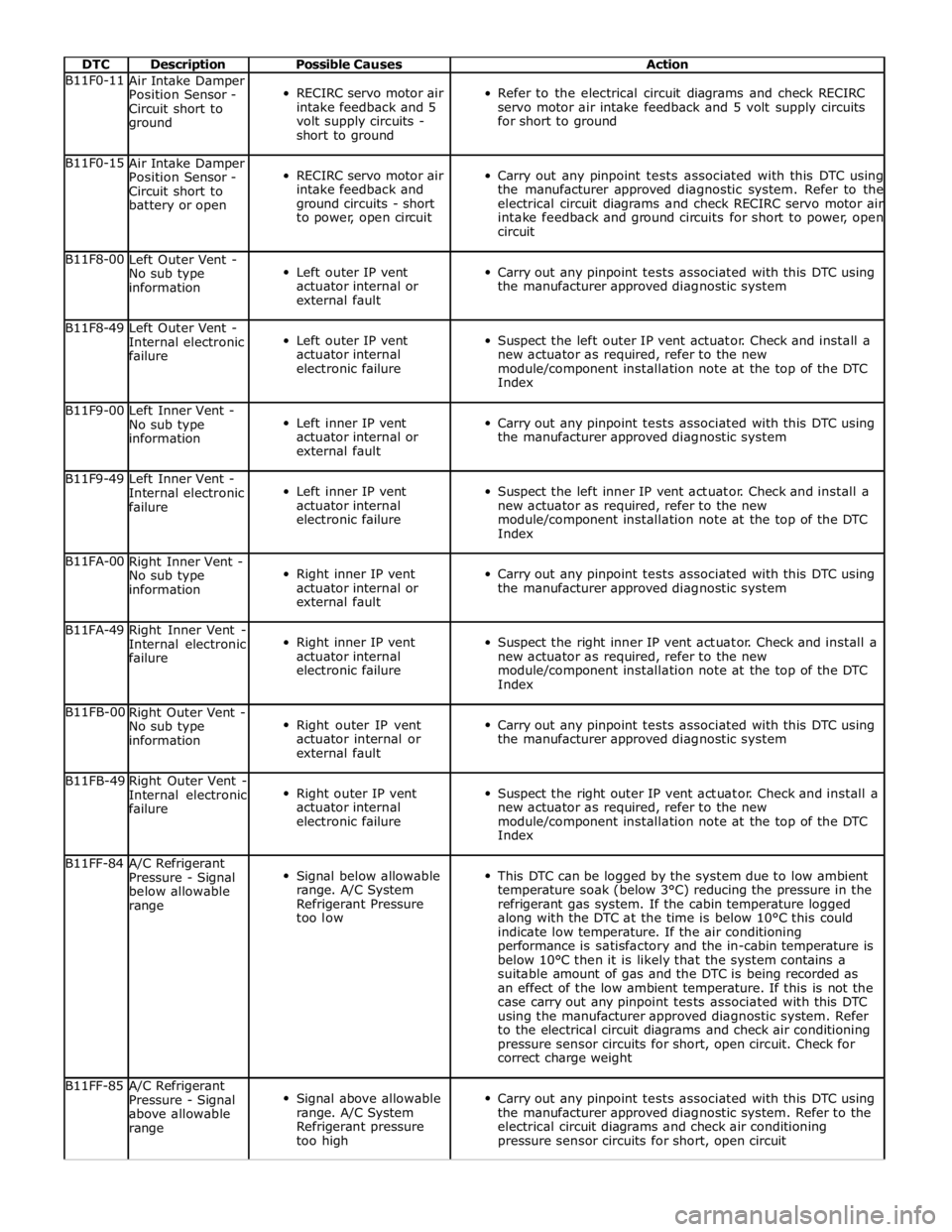

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Climate

Control Module (HVAC)

Description and Operation

Climate Control Module

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Climate Control Module. For additional

diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Climate Control System (412-00 Climate Control System - General Information, Diagnosis and Testing).

DTC Description Possible Causes Action B105A-01

Cabin Temperature

Sensor Fan -

General electrical

failure

Aspirator motor

diagnostic circuit -

short to ground, open

circuit

Aspirator fan

component failure

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check aspirator motor

diagnostic circuit for short to ground, open circuit B1081-00

Left Temperature

Damper Motor -

No sub type

information

Left hand blend stepper

motor internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B1081-49

Left Temperature

Damper Motor -

Internal electronic

failure

Left hand blend stepper

motor internal

electronic failure

Suspect the left hand blend stepper motor. Check and

install a new stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1082-00

Right Temperature

Damper Motor -

No sub type

information

Right hand blend

stepper motor internal

or external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system

Page 142 of 3039

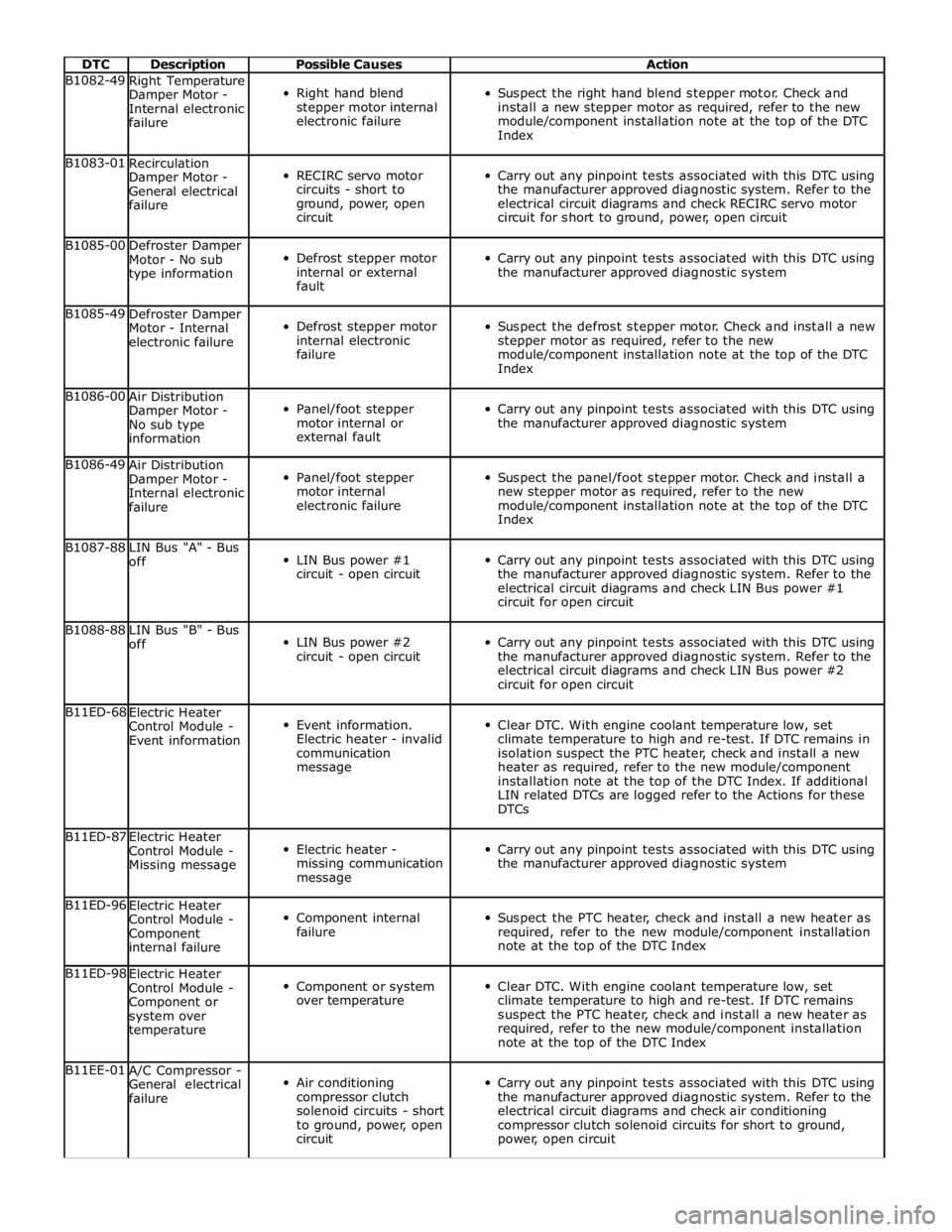

DTC Description Possible Causes Action B1082-49

Right Temperature

Damper Motor -

Internal electronic

failure

Right hand blend

stepper motor internal

electronic failure

Suspect the right hand blend stepper motor. Check and

install a new stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1083-01

Recirculation

Damper Motor -

General electrical

failure

RECIRC servo motor

circuits - short to

ground, power, open

circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check RECIRC servo motor

circuit for short to ground, power, open circuit B1085-00

Defroster Damper

Motor - No sub

type information

Defrost stepper motor

internal or external

fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B1085-49

Defroster Damper

Motor - Internal

electronic failure

Defrost stepper motor

internal electronic

failure

Suspect the defrost stepper motor. Check and install a new

stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1086-00

Air Distribution

Damper Motor -

No sub type

information

Panel/foot stepper

motor internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B1086-49

Air Distribution

Damper Motor -

Internal electronic

failure

Panel/foot stepper

motor internal

electronic failure

Suspect the panel/foot stepper motor. Check and install a

new stepper motor as required, refer to the new

module/component installation note at the top of the DTC

Index B1087-88

LIN Bus "A" - Bus

off

LIN Bus power #1

circuit - open circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check LIN Bus power #1

circuit for open circuit B1088-88

LIN Bus "B" - Bus

off

LIN Bus power #2

circuit - open circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check LIN Bus power #2

circuit for open circuit B11ED-68

Electric Heater

Control Module -

Event information

Event information.

Electric heater - invalid

communication

message

Clear DTC. With engine coolant temperature low, set

climate temperature to high and re-test. If DTC remains in

isolation suspect the PTC heater, check and install a new

heater as required, refer to the new module/component

installation note at the top of the DTC Index. If additional

LIN related DTCs are logged refer to the Actions for these

DTCs B11ED-87

Electric Heater

Control Module -

Missing message

Electric heater -

missing communication

message

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11ED-96

Electric Heater

Control Module -

Component

internal failure

Component internal

failure

Suspect the PTC heater, check and install a new heater as

required, refer to the new module/component installation

note at the top of the DTC Index B11ED-98

Electric Heater

Control Module -

Component or

system over

temperature

Component or system

over temperature

Clear DTC. With engine coolant temperature low, set

climate temperature to high and re-test. If DTC remains

suspect the PTC heater, check and install a new heater as

required, refer to the new module/component installation

note at the top of the DTC Index B11EE-01

A/C Compressor -

General electrical

failure

Air conditioning

compressor clutch

solenoid circuits - short

to ground, power, open

circuit

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check air conditioning

compressor clutch solenoid circuits for short to ground,

power, open circuit

Page 143 of 3039

DTC Description Possible Causes Action B11F0-11

Air Intake Damper

Position Sensor -

Circuit short to

ground

RECIRC servo motor air

intake feedback and 5

volt supply circuits -

short to ground

Refer to the electrical circuit diagrams and check RECIRC

servo motor air intake feedback and 5 volt supply circuits

for short to ground B11F0-15

Air Intake Damper

Position Sensor -

Circuit short to

battery or open

RECIRC servo motor air

intake feedback and

ground circuits - short

to power, open circuit

Carry out any pinpoint tests associated with this DTC using the manufacturer approved diagnostic system. Refer to the electrical circuit diagrams and check RECIRC servo motor air intake feedback and ground circuits for short to power, open circuit B11F8-00

Left Outer Vent -

No sub type

information

Left outer IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11F8-49

Left Outer Vent -

Internal electronic

failure

Left outer IP vent

actuator internal

electronic failure

Suspect the left outer IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11F9-00

Left Inner Vent -

No sub type

information

Left inner IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11F9-49

Left Inner Vent -

Internal electronic

failure

Left inner IP vent

actuator internal

electronic failure

Suspect the left inner IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11FA-00

Right Inner Vent -

No sub type

information

Right inner IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11FA-49

Right Inner Vent -

Internal electronic

failure

Right inner IP vent

actuator internal

electronic failure

Suspect the right inner IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11FB-00

Right Outer Vent -

No sub type

information

Right outer IP vent

actuator internal or

external fault

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system B11FB-49

Right Outer Vent -

Internal electronic

failure

Right outer IP vent

actuator internal

electronic failure

Suspect the right outer IP vent actuator. Check and install a

new actuator as required, refer to the new

module/component installation note at the top of the DTC

Index B11FF-84

A/C Refrigerant

Pressure - Signal

below allowable

range

Signal below allowable

range. A/C System

Refrigerant Pressure

too low

This DTC can be logged by the system due to low ambient

temperature soak (below 3°C) reducing the pressure in the

refrigerant gas system. If the cabin temperature logged

along with the DTC at the time is below 10°C this could

indicate low temperature. If the air conditioning

performance is satisfactory and the in-cabin temperature is

below 10°C then it is likely that the system contains a

suitable amount of gas and the DTC is being recorded as

an effect of the low ambient temperature. If this is not the

case carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check air conditioning

pressure sensor circuits for short, open circuit. Check for

correct charge weight B11FF-85

A/C Refrigerant

Pressure - Signal

above allowable

range

Signal above allowable

range. A/C System

Refrigerant pressure

too high

Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check air conditioning

pressure sensor circuits for short, open circuit