wheel JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 246 of 3039

Published: 17-Apr-2014

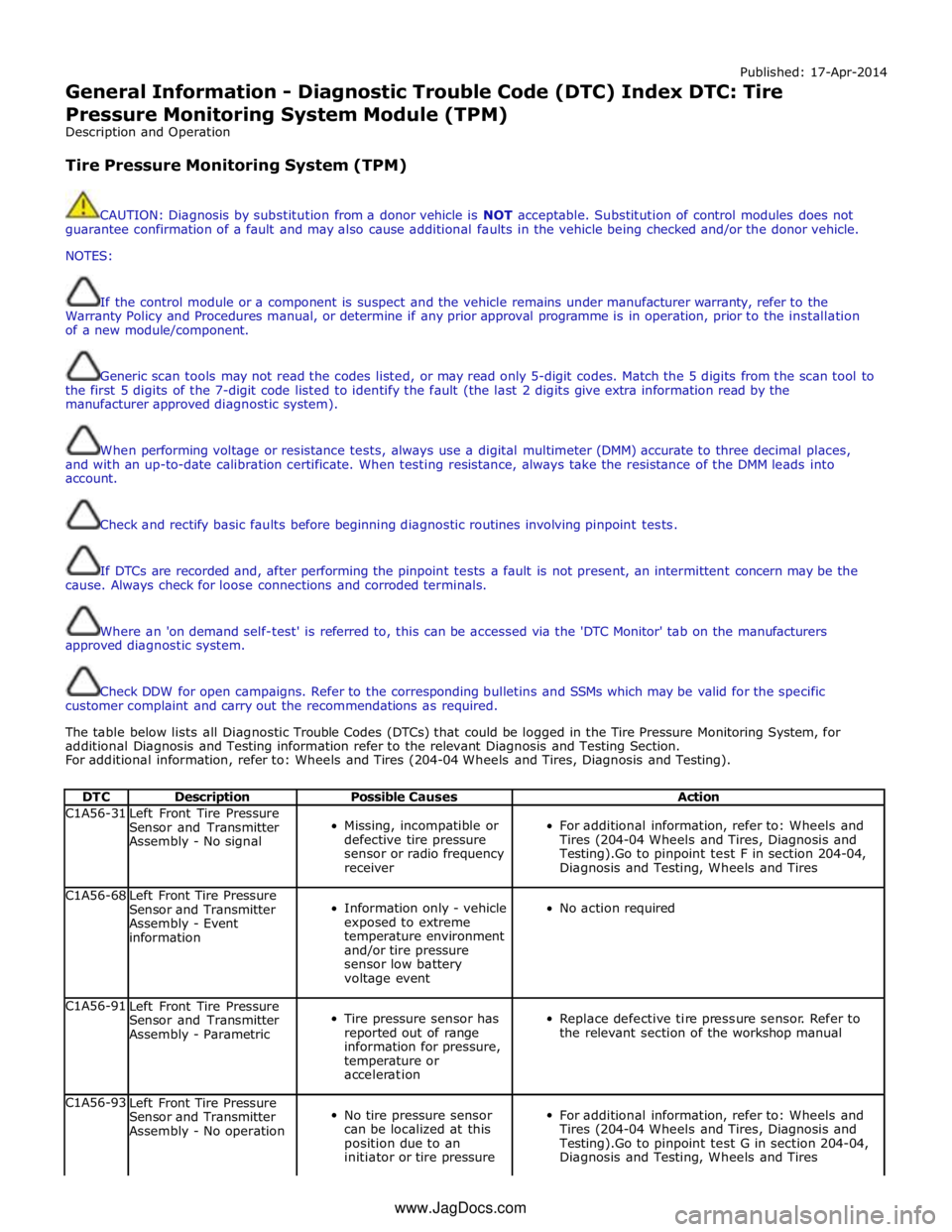

General Information - Diagnostic Trouble Code (DTC) Index DTC: Tire

Pressure Monitoring System Module (TPM)

Description and Operation

Tire Pressure Monitoring System (TPM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Tire Pressure Monitoring System, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Wheels and Tires (204-04 Wheels and Tires, Diagnosis and Testing).

DTC Description Possible Causes Action C1A56-31

Left Front Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A56-68

Left Front Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A56-91

Left Front Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor. Refer to

the relevant section of the workshop manual C1A56-93

Left Front Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires www.JagDocs.com

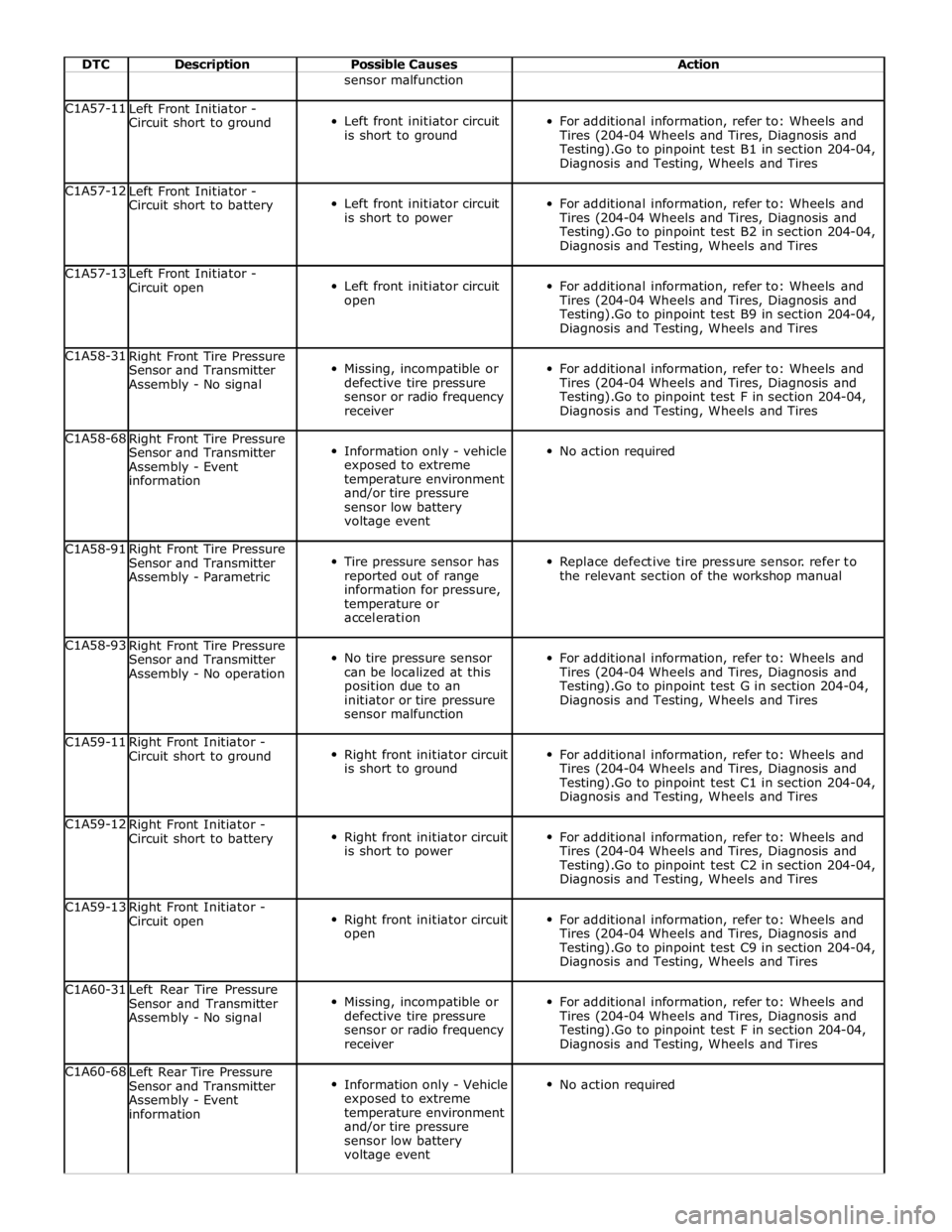

Page 247 of 3039

DTC Description Possible Causes Action sensor malfunction

C1A57-11

Left Front Initiator -

Circuit short to ground

Left front initiator circuit

is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test B1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A57-12

Left Front Initiator -

Circuit short to battery

Left front initiator circuit

is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test B2 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A57-13

Left Front Initiator -

Circuit open

Left front initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test B9 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A58-31

Right Front Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A58-68

Right Front Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A58-91

Right Front Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor. refer to

the relevant section of the workshop manual C1A58-93

Right Front Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A59-11

Right Front Initiator -

Circuit short to ground

Right front initiator circuit

is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test C1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A59-12

Right Front Initiator -

Circuit short to battery

Right front initiator circuit

is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test C2 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A59-13

Right Front Initiator -

Circuit open

Right front initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test C9 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A60-31

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A60-68

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - Vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required

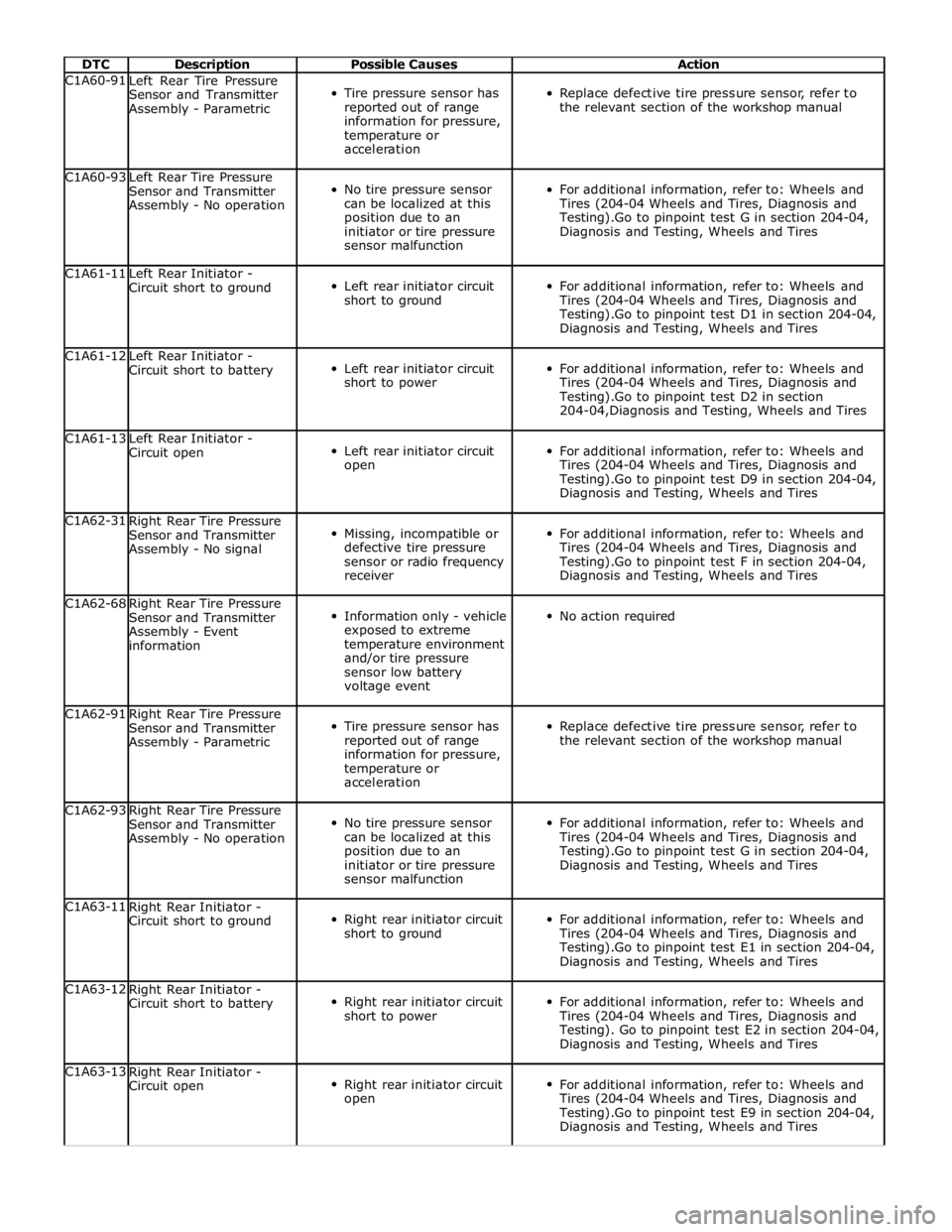

Page 248 of 3039

DTC Description Possible Causes Action C1A60-91

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A60-93

Left Rear Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A61-11

Left Rear Initiator -

Circuit short to ground

Left rear initiator circuit

short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A61-12

Left Rear Initiator -

Circuit short to battery

Left rear initiator circuit

short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D2 in section

204-04,Diagnosis and Testing, Wheels and Tires C1A61-13

Left Rear Initiator -

Circuit open

Left rear initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test D9 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A62-31

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A62-68

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A62-91

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A62-93

Right Rear Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

sensor malfunction

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-11

Right Rear Initiator -

Circuit short to ground

Right rear initiator circuit

short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test E1 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-12

Right Rear Initiator -

Circuit short to battery

Right rear initiator circuit

short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing). Go to pinpoint test E2 in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A63-13

Right Rear Initiator -

Circuit open

Right rear initiator circuit

open

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test E9 in section 204-04,

Diagnosis and Testing, Wheels and Tires

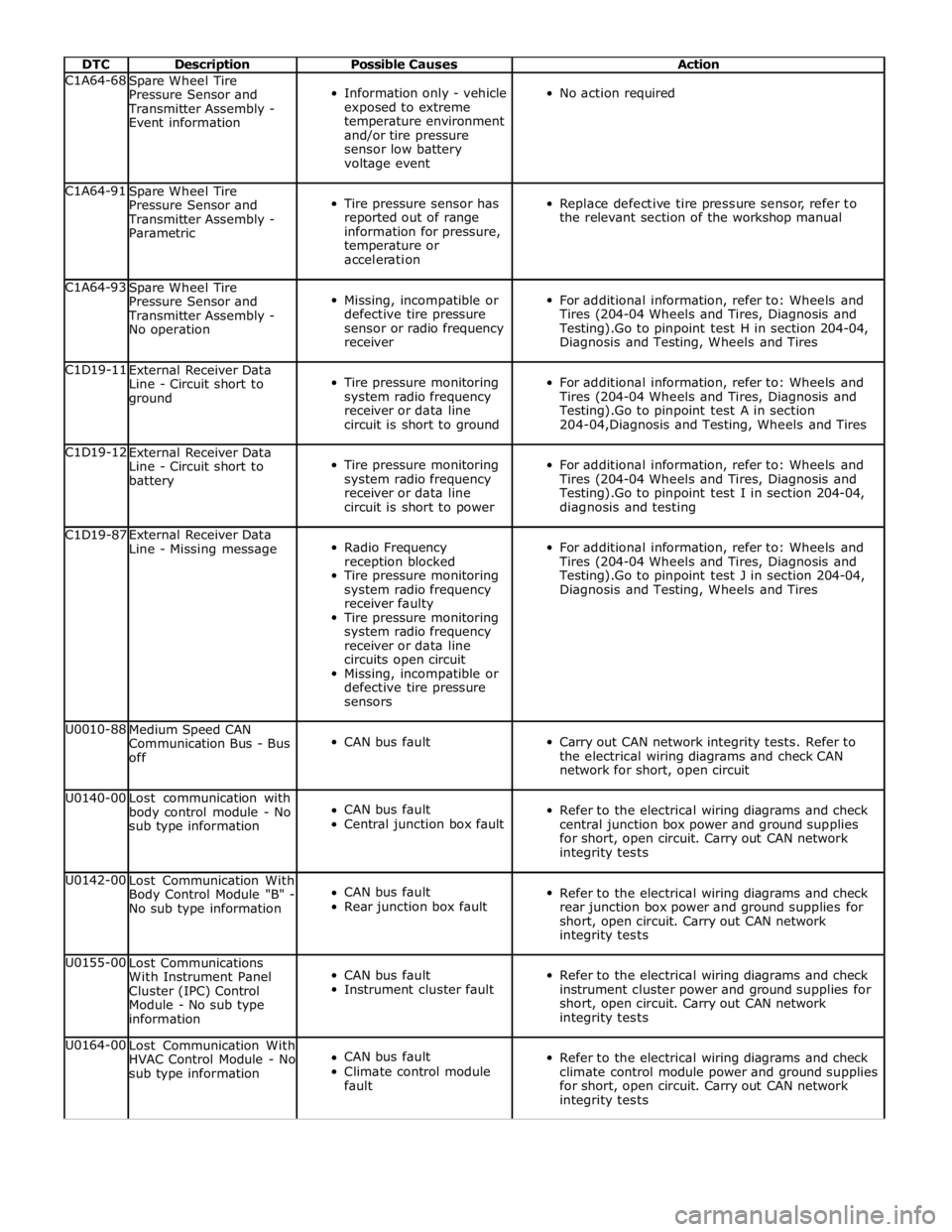

Page 249 of 3039

DTC Description Possible Causes Action C1A64-68

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Event information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A64-91

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A64-93

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

No operation

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test H in section 204-04,

Diagnosis and Testing, Wheels and Tires C1D19-11

External Receiver Data

Line - Circuit short to

ground

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test A in section

204-04,Diagnosis and Testing, Wheels and Tires C1D19-12

External Receiver Data

Line - Circuit short to

battery

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test I in section 204-04,

diagnosis and testing C1D19-87

External Receiver Data

Line - Missing message

Radio Frequency

reception blocked

Tire pressure monitoring

system radio frequency

receiver faulty

Tire pressure monitoring

system radio frequency

receiver or data line

circuits open circuit

Missing, incompatible or

defective tire pressure

sensors

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test J in section 204-04,

Diagnosis and Testing, Wheels and Tires U0010-88

Medium Speed CAN

Communication Bus - Bus

off

CAN bus fault

Carry out CAN network integrity tests. Refer to

the electrical wiring diagrams and check CAN

network for short, open circuit U0140-00

Lost communication with

body control module - No

sub type information

CAN bus fault

Central junction box fault

Refer to the electrical wiring diagrams and check

central junction box power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests U0142-00

Lost Communication With

Body Control Module "B" -

No sub type information

CAN bus fault

Rear junction box fault

Refer to the electrical wiring diagrams and check

rear junction box power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

CAN bus fault

Instrument cluster fault

Refer to the electrical wiring diagrams and check

instrument cluster power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0164-00

Lost Communication With

HVAC Control Module - No

sub type information

CAN bus fault

Climate control module

fault

Refer to the electrical wiring diagrams and check

climate control module power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests

Page 260 of 3039

DTC Description Possible Causes Action suspect. P0783-77

3-4 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-07

4-5 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0784-77

4-5 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0798-1A

Pressure Control Solenoid

C Electrical - Circuit

Resistance Below Threshold

Pressure control solenoid

C Circuit resistance below

threshold

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-1E

Pressure Control Solenoid

C Electrical - Circuit Short

to Ground

Pressure control solenoid

C electrical circuit short

to ground

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0798-21

Pressure Control Solenoid

C Electrical - Signal

amplitude < minimum

Pressure Control Solenoid

C Electrical signal

amplitude < minimum

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0814-62 Transmission Range

Display Circuit - Signal

compare failure

Transmission Range

Display Circuit signal

compare failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0826-08

Up and Down Switch

circuit - Bus Signal

Message Failures

Invalid CAN signal from

Central Junction

Box/Instrument Cluster

Stuck Sprintronic switch

CAN bus circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check gear change switches for

correct operation. Refer to circuit diagrams and

check CAN bus for a circuit fault P0826-81

Up and Down Switch

Circuit - Invalid serial

data received

Invalid Can signal from

Central Junction Box /

Instrument Cluster

Stuck Sprintronic switch

CAN Bus Circuit fault

Check Central Junction Box and Instrument Cluster

for stored DTCs. Check Gear Change Switches for

correct operation. Refer to Circuit diagrams and

check CAN Bus for Circuit fault P0826-88

Up and Down Switch

Circuit - Bus off

Steering Wheel Module to

Central Junction Box /

Instrument Cluster LIN

Bus failure

Check Central Junction Box and Steering Wheel

Ice Switches for stored DTCs. Refer to Circuit

diagrams and check LIN Bus for Circuit fault P0829-07

5-6 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. www.JagDocs.com

Page 294 of 3039

Jacking and Lifting - Jacking

Description and Operation

Safety Precautions Published: 11-May-2011

WARNING: The jack provided with the vehicle is intended to be used in an emergency for changing a deflated tire. To

avoid damage to the vehicle, never use the jack to raise the vehicle for any other purpose. Refer to the Driver Handbook when

using the jack supplied with the vehicle. Failure to follow these instructions may result in personal injury.

The following safety precautions must be observed when raising the vehicle to carry out service operations:

Never rely on a jack alone to support a vehicle. Always use suitable vehicle stands to provide rigid support.

When working beneath a vehicle, whenever possible use a vehicle hoist instead of a jack and vehicle stands.

Make sure that the vehicle is standing on firm, level ground before using a jack.

Do not rely on the parking brake alone; chock the wheels and put the automatic transmission into Park if possible.

Check that any lifting equipment used has adequate capacity for the load being lifted and is in correct working order.

Page 296 of 3039

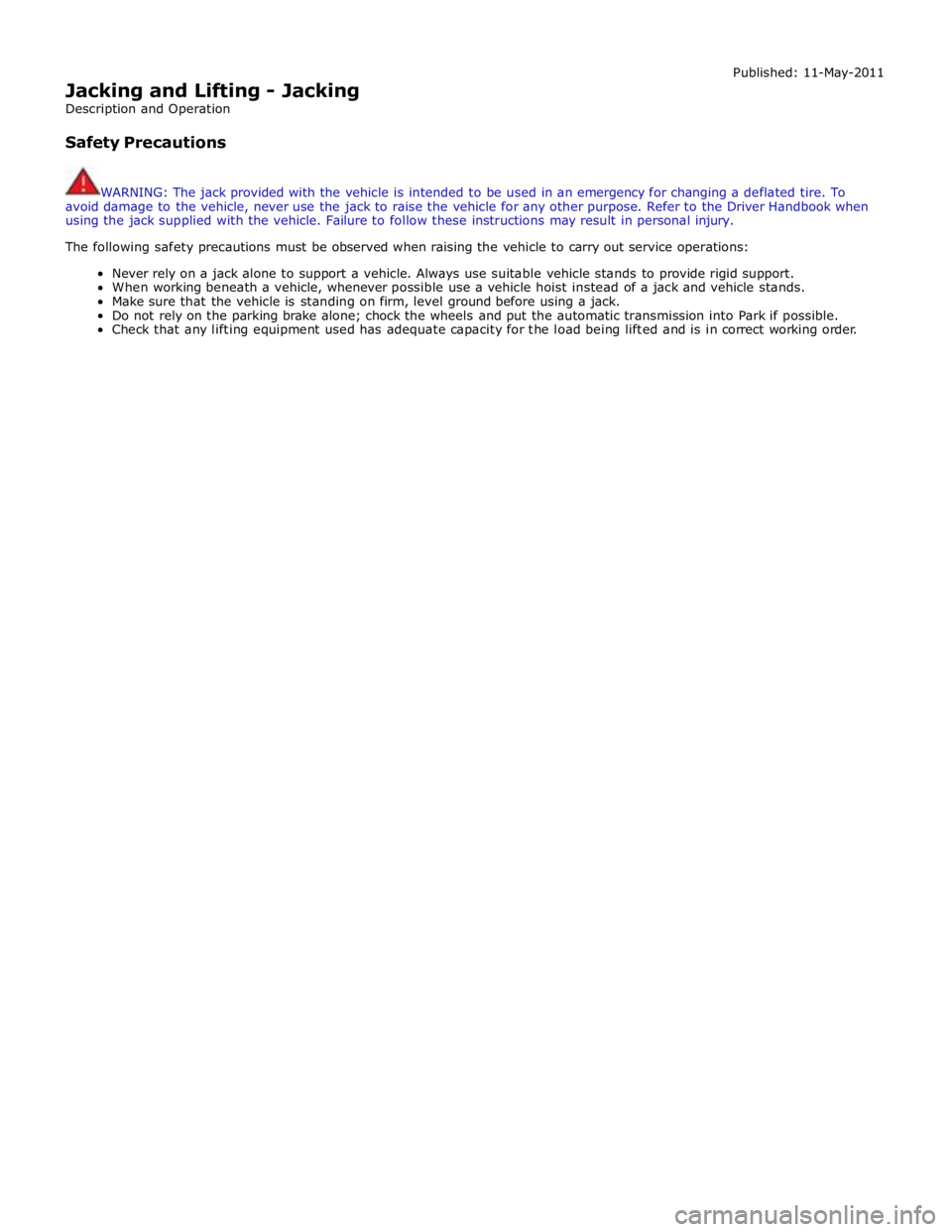

Vehicle Support Points

Vehicle Recovery

NOTE: Prior to vehicle recovery, make sure the vehicle keys are available and the security system is disarmed.

Vehicle recovery methods are:

By flat-bed transporter.

By rear suspended tow.

By rear suspended tow.

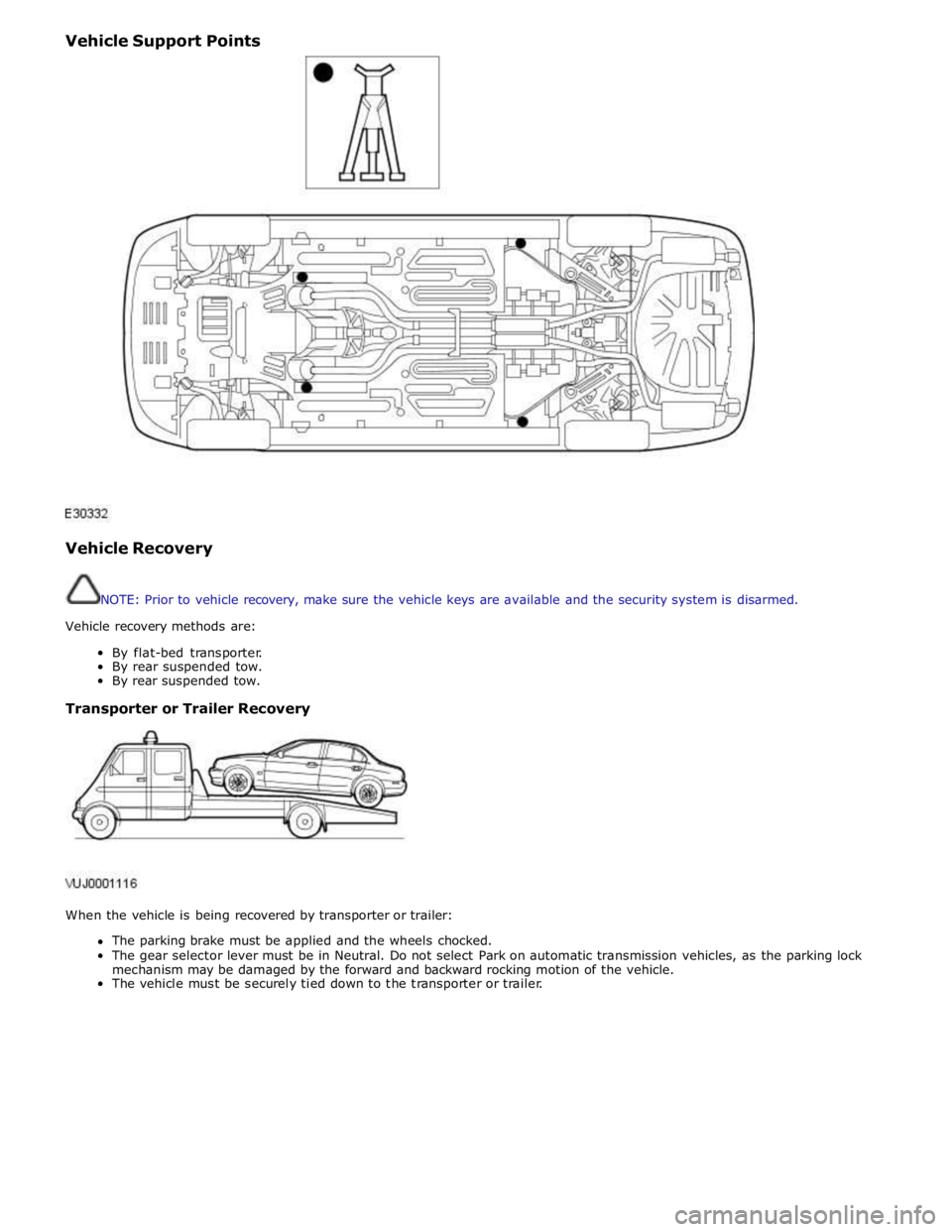

Transporter or Trailer Recovery

When the vehicle is being recovered by transporter or trailer:

The parking brake must be applied and the wheels chocked.

The gear selector lever must be in Neutral. Do not select Park on automatic transmission vehicles, as the parking lock

mechanism may be damaged by the forward and backward rocking motion of the vehicle.

The vehicle must be securely tied down to the transporter or trailer.

Page 297 of 3039

Rear Suspended Tow

When the vehicle is being recovered by rear suspended tow:

The ignition key must be removed from the ignition switch to lock the steering.

The rear wheels must be correctly positioned in the lifting cradle and securely tied down.

Emergency Towing

WARNING: If the engine is not running, the steering will become heavy and the force necessary to effectively apply the

brakes will be greatly increased.

CAUTION: A vehicle with a defective transmission must be towed by rear suspended tow.

When the vehicle is being towed on its own wheels:

Local regulations for the towing of vehicles must be followed. In some countries the registration number of the towing

vehicle and an 'On Tow' sign or warning triangle must be displayed at the rear of the towed vehicle.

The gear selector lever must be in Neutral.

The ignition switch must be in position II to release the steering lock and make the direction indicators, horn and stop

lamps operate.

A distance of 0,8 km (0.5 mile) must not be exceeded.

A speed of 48 km/h (30 mph) must not be exceeded.

The tow rope must be attached to the front towing eye. www.JagDocs.com

Page 299 of 3039

Published: 16-Sep-2013

Noise, Vibration and Harshness - Noise, Vibration and Harshness (NVH)

Diagnosis and Testing

Principle of Operation

For a detailed description of Noise, Vibration and Harshness issues, refer to the Description and Operation section of the

workshop manual.

REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Description and Operation).

Inspection and Verification

1. Verify the customer's concerns by operating the vehicle to duplicate the condition.

2. Visually inspect the vehicle to determine any obvious cause(s) of the concern(s).

3. If the inspection reveals obvious causes that can be readily identified, repair as necessary.

4. If the concern(s) remains after the inspection, determine the symptom(s) and refer to the Symptom Chart.

How To Use This Diagnostic Procedure Section

Noise, vibration and harshness (NVH) concerns have become more important as vehicles have become more sensitive to

these vibrations. This section is designed as an aid to identifying these situations

The section provides diagnostic procedures based on symptoms. If the condition occurs at high speed, for instance, the

most likely place to start is under High Speed Shake

The road test procedure will tell how to sort the conditions into categories and how to tell a vibration from a shake

A series of Road Test Quick Checks is provided to make sure that a cause is either pinpointed or eliminated

Name the condition, proceed to the appropriate section and locate the correct diagnosis. When the condition is

identified, the job is partly done

Follow the diagnostic procedure as outlined

Quick Checks are described within the step, while more involved tests and adjustments are outlined in General

Procedures

Always follow each step exactly and make notes to recall important findings later

Customer Interview

The road test and customer interview (if available) provide information that will help identify the concerns and will provide

direction to the correct starting point for diagnosis.

Identify the Condition

NVH problems usually occur in a number of areas:

tires

engine accessories

suspension

driveline

air leakage (wind noise)

squeaks and rattles

heating ventilation and air conditioning (HVAC)

electrical (e.g. motor noise)

transmission

engine

It is important, therefore, that an NVH concern be isolated into its specific area(s) as soon as possible. The easiest and

quickest way to do this is to carry out the Road Test as outlined.

Noise Diagnostic Procedure

Non-Axle Noise

The five most important sources of non-axle noise are exhaust, tires, roof racks, trim and mouldings, and transmission.

Therefore, make sure that none of the following conditions are the cause of the noise before proceeding with a driveline tear

down and diagnosis.

Under certain conditions, the pitch of the exhaust may sound very much like gear noise. At other times, it can be

mistaken for a wheel bearing rumble

Tires, especially snow tires, can have a high pitched tread whine or roar, similar to gear noise. Radial tires, to some

degree, have this characteristic. Also, any non-standard tire with an unusual tread construction may emit a roar or

whine type noise

Trim and mouldings can also cause whistling or a whining noise

Clunk may be a metallic noise heard when the automatic transmission is engaged in reverse or drive, or it may occur

when the throttle is applied or released. It is caused by backlash somewhere in the driveline

Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a damaged wheel bearing

Page 300 of 3039

Noise Conditions

Gear noise is typically a howling or whining due to gear damage or incorrect bearing preload. It can occur at various

speeds and driving conditions, or it can be continuous

Chuckle is a particular rattling noise that sounds like a stick against the spokes of a spinning bicycle wheel. It occurs

while decelerating from approximately 64 km/h (40 miles/h) and can usually be heard all the way to a stop. The

frequency varies with vehicle speed

Knock is very similar to chuckle, though it may be louder and occurs on acceleration or deceleration. The tear down will

disclose what has to be corrected

Check and rule out tires, exhaust and trim items before disassembling the transmission to diagnose and correct gear noise.

The noises described under Road Test usually have specific causes that can be diagnosed by observation as the unit is

disassembled. The initial clues are the type of noise heard on the road test and the driving conditions.

Vibration Conditions

wear. NOTE: New Constant Velocity (CV) joints should not be installed unless disassembly and inspection revealed unusual

Clicking, popping or grinding noises may be caused by the following:

Cut or damaged CV joint boots resulting in inadequate or contaminated lubricant in the outboard or inboard CV joint

bearing housings

Loose CV joint boot clamps

Another component contacting the rear drive half shaft

Worn, damaged or incorrectly installed wheel bearing, suspension or brake component

Vibration at highway speeds may be caused by the following:

Out-of-balance front or rear wheels

Out-of-round tires

Driveline imbalance

Driveline run-out (alignment)

NOTE: Rear drive half shafts are not balanced and are not likely to contribute to rotational vibration disturbance.

Shudder or vibration during acceleration (including from rest) may be caused by the following:

Driveline alignment

Excessively worn or damaged outboard or inboard CV joint bearing housing

Excessively high CV joint operating angles caused by incorrect ride height. Check ride height, verify correct spring rate

and check items under Inoperative Conditions

Excessively worn driveshaft components

Leakage Conditions

1. Inspect the CV joint boots for evidence of cracks, tears or splits.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the rear drive half shaft, outboard and

inboard CV joint boot locations, which is an indication of CV joint boot or CV joint boot clamp damage.

3. Inspect the inboard CV joint bearing housing seal for leakage.

Inoperative Conditions

If a CV joint or rear drive half shaft pull-out occurs, check the following:

suspension components for correct location, damage or wear

bushings for wear

subframe for damage

bent or worn components

- Stabilizer bar link

- Left-hand rear suspension lower arm and bushing

- Right-hand rear suspension lower arm and bushing

- Rear wheel hub and rear drive half shaft

Road Test

A gear-driven unit will produce a certain amount of noise. Some noise is acceptable and may be audible at certain speeds or

under various driving conditions as on a newly paved blacktop road. The slight noise is in no way detrimental and must be

considered normal.

The road test and customer interview (if available) provide information needed to identify the condition and give direction to

the correct starting point for diagnosis.

1. Make notes throughout the diagnosis routine. Make sure to write down even the smallest piece of information, because