wheel JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 138 of 3039

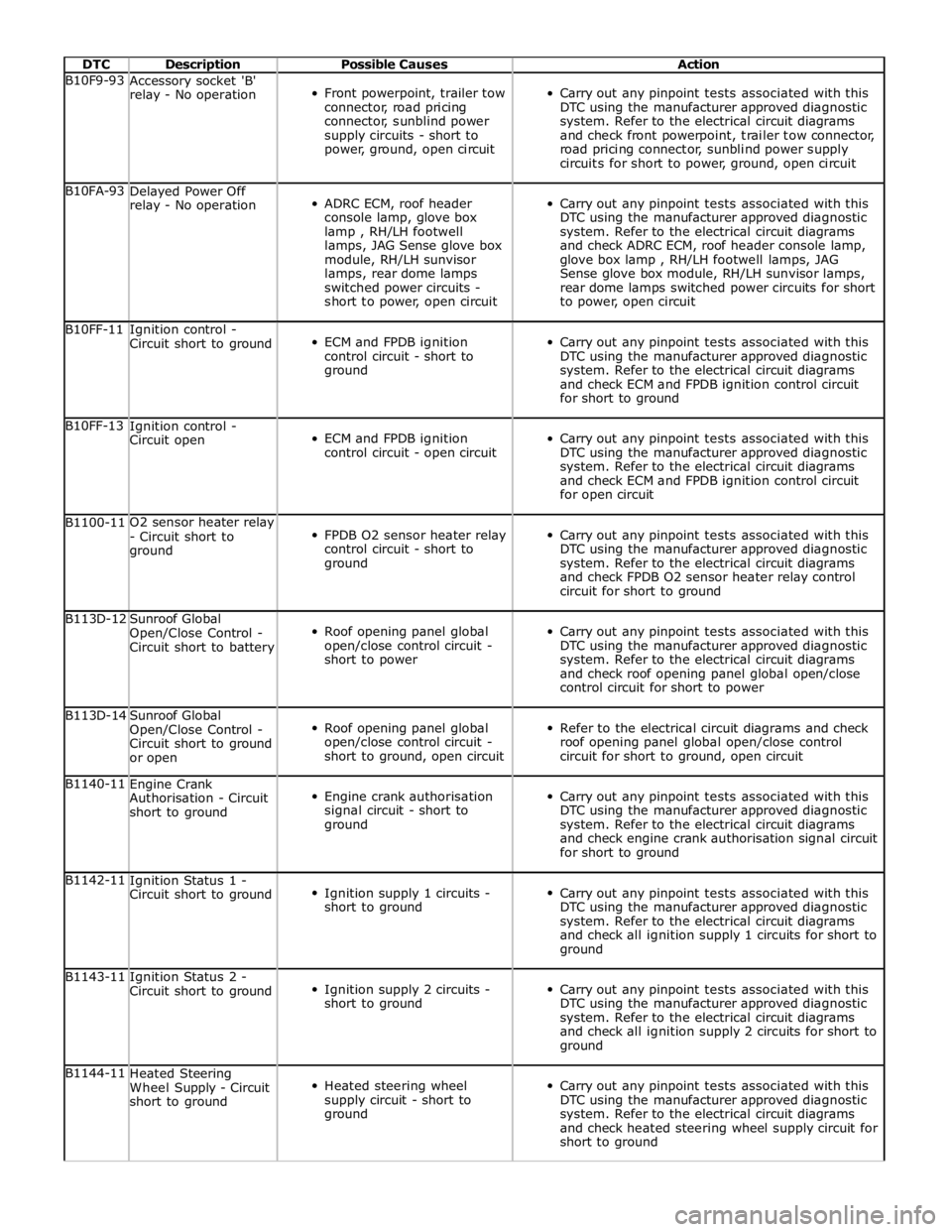

DTC Description Possible Causes Action B10F9-93

Accessory socket 'B'

relay - No operation

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to

power, ground, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check front powerpoint, trailer tow connector,

road pricing connector, sunblind power supply

circuits for short to power, ground, open circuit B10FA-93

Delayed Power Off

relay - No operation

ADRC ECM, roof header

console lamp, glove box

lamp , RH/LH footwell

lamps, JAG Sense glove box

module, RH/LH sunvisor

lamps, rear dome lamps

switched power circuits -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check ADRC ECM, roof header console lamp,

glove box lamp , RH/LH footwell lamps, JAG

Sense glove box module, RH/LH sunvisor lamps,

rear dome lamps switched power circuits for short

to power, open circuit B10FF-11

Ignition control -

Circuit short to ground

ECM and FPDB ignition

control circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check ECM and FPDB ignition control circuit

for short to ground B10FF-13

Ignition control -

Circuit open

ECM and FPDB ignition

control circuit - open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check ECM and FPDB ignition control circuit

for open circuit B1100-11 O2 sensor heater relay

- Circuit short to

ground

FPDB O2 sensor heater relay

control circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check FPDB O2 sensor heater relay control

circuit for short to ground B113D-12

Sunroof Global

Open/Close Control -

Circuit short to battery

Roof opening panel global

open/close control circuit -

short to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check roof opening panel global open/close

control circuit for short to power B113D-14

Sunroof Global

Open/Close Control -

Circuit short to ground

or open

Roof opening panel global

open/close control circuit -

short to ground, open circuit

Refer to the electrical circuit diagrams and check

roof opening panel global open/close control

circuit for short to ground, open circuit B1140-11

Engine Crank

Authorisation - Circuit

short to ground

Engine crank authorisation

signal circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check engine crank authorisation signal circuit

for short to ground B1142-11

Ignition Status 1 -

Circuit short to ground

Ignition supply 1 circuits -

short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check all ignition supply 1 circuits for short to

ground B1143-11

Ignition Status 2 -

Circuit short to ground

Ignition supply 2 circuits -

short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check all ignition supply 2 circuits for short to

ground B1144-11

Heated Steering

Wheel Supply - Circuit

short to ground

Heated steering wheel

supply circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check heated steering wheel supply circuit for

short to ground

Page 164 of 3039

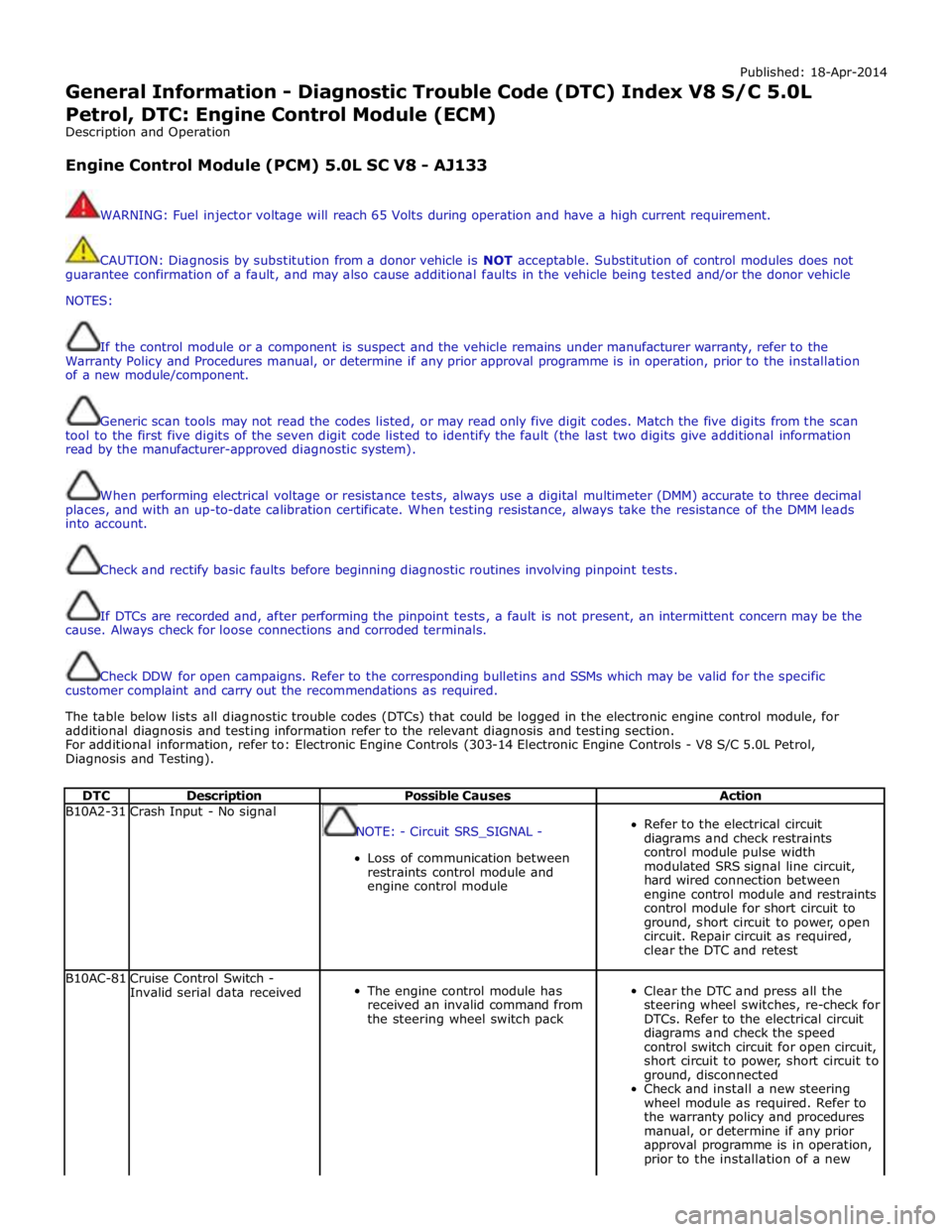

Published: 18-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index V8 S/C 5.0L

Petrol, DTC: Engine Control Module (ECM)

Description and Operation

Engine Control Module (PCM) 5.0L SC V8 - AJ133

WARNING: Fuel injector voltage will reach 65 Volts during operation and have a high current requirement.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the electronic engine control module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Electronic Engine Controls (303-14 Electronic Engine Controls - V8 S/C 5.0L Petrol,

Diagnosis and Testing).

DTC Description Possible Causes Action B10A2-31 Crash Input - No signal

NOTE: - Circuit SRS_SIGNAL -

Loss of communication between

restraints control module and

engine control module

Refer to the electrical circuit

diagrams and check restraints

control module pulse width

modulated SRS signal line circuit,

hard wired connection between

engine control module and restraints

control module for short circuit to

ground, short circuit to power, open

circuit. Repair circuit as required,

clear the DTC and retest B10AC-81

Cruise Control Switch -

Invalid serial data received

The engine control module has

received an invalid command from

the steering wheel switch pack

Clear the DTC and press all the

steering wheel switches, re-check for

DTCs. Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Check and install a new steering

wheel module as required. Refer to

the warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

Page 165 of 3039

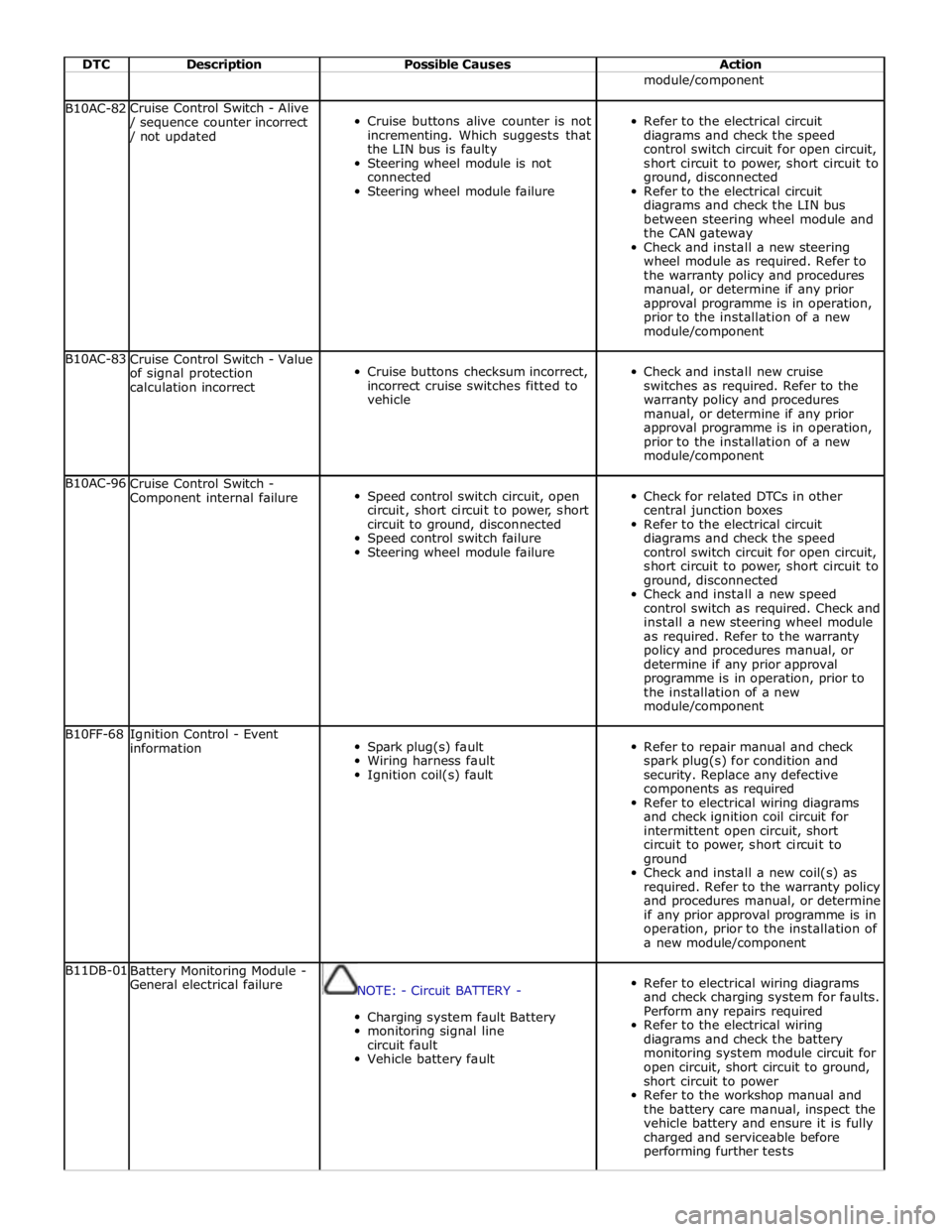

DTC Description Possible Causes Action module/component B10AC-82 Cruise Control Switch - Alive / sequence counter incorrect / not updated

Cruise buttons alive counter is not

incrementing. Which suggests that

the LIN bus is faulty

Steering wheel module is not

connected

Steering wheel module failure

Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Refer to the electrical circuit

diagrams and check the LIN bus

between steering wheel module and

the CAN gateway

Check and install a new steering

wheel module as required. Refer to

the warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component B10AC-83

Cruise Control Switch - Value

of signal protection

calculation incorrect

Cruise buttons checksum incorrect,

incorrect cruise switches fitted to

vehicle

Check and install new cruise

switches as required. Refer to the

warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component B10AC-96

Cruise Control Switch -

Component internal failure

Speed control switch circuit, open

circuit, short circuit to power, short

circuit to ground, disconnected

Speed control switch failure

Steering wheel module failure

Check for related DTCs in other

central junction boxes

Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Check and install a new speed

control switch as required. Check and

install a new steering wheel module

as required. Refer to the warranty

policy and procedures manual, or

determine if any prior approval

programme is in operation, prior to

the installation of a new

module/component B10FF-68

Ignition Control - Event

information

Spark plug(s) fault

Wiring harness fault

Ignition coil(s) fault

Refer to repair manual and check

spark plug(s) for condition and

security. Replace any defective

components as required

Refer to electrical wiring diagrams

and check ignition coil circuit for

intermittent open circuit, short

circuit to power, short circuit to

ground

Check and install a new coil(s) as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component B11DB-01

Battery Monitoring Module -

General electrical failure

NOTE: - Circuit BATTERY -

Charging system fault Battery

monitoring signal line

circuit fault

Vehicle battery fault

Refer to electrical wiring diagrams

and check charging system for faults.

Perform any repairs required

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the workshop manual and

the battery care manual, inspect the

vehicle battery and ensure it is fully

charged and serviceable before

performing further tests

Page 166 of 3039

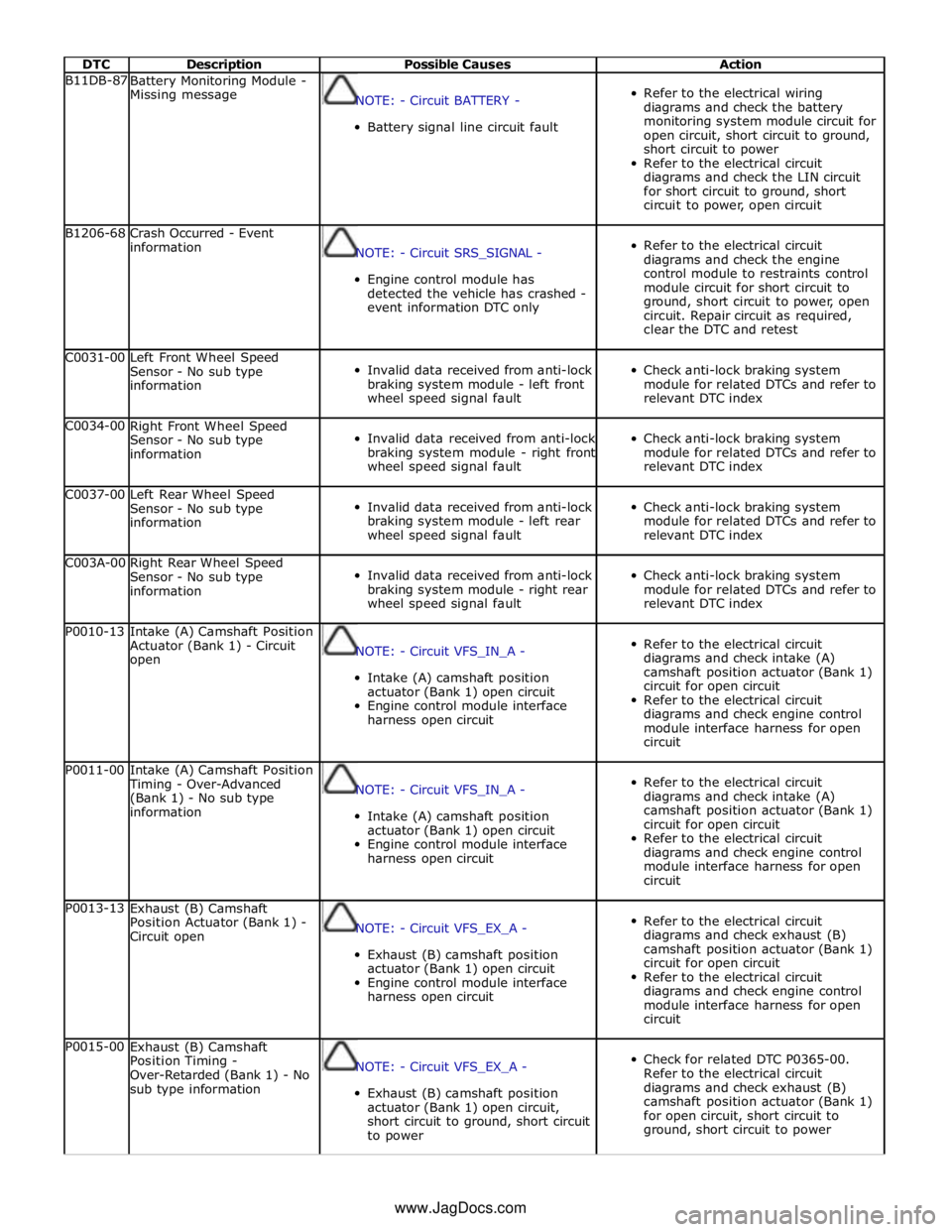

DTC Description Possible Causes Action B11DB-87

Battery Monitoring Module -

Missing message

NOTE: - Circuit BATTERY -

Battery signal line circuit fault

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the electrical circuit

diagrams and check the LIN circuit

for short circuit to ground, short

circuit to power, open circuit B1206-68

Crash Occurred - Event

information

NOTE: - Circuit SRS_SIGNAL -

Engine control module has

detected the vehicle has crashed -

event information DTC only

Refer to the electrical circuit

diagrams and check the engine

control module to restraints control

module circuit for short circuit to

ground, short circuit to power, open

circuit. Repair circuit as required,

clear the DTC and retest C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index P0010-13

Intake (A) Camshaft Position

Actuator (Bank 1) - Circuit

open

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0011-00

Intake (A) Camshaft Position

Timing - Over-Advanced

(Bank 1) - No sub type

information

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0013-13

Exhaust (B) Camshaft

Position Actuator (Bank 1) -

Circuit open

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0015-00

Exhaust (B) Camshaft

Position Timing -

Over-Retarded (Bank 1) - No

sub type information

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit,

short circuit to ground, short circuit

to power

Check for related DTC P0365-00.

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

for open circuit, short circuit to

ground, short circuit to power www.JagDocs.com

Page 184 of 3039

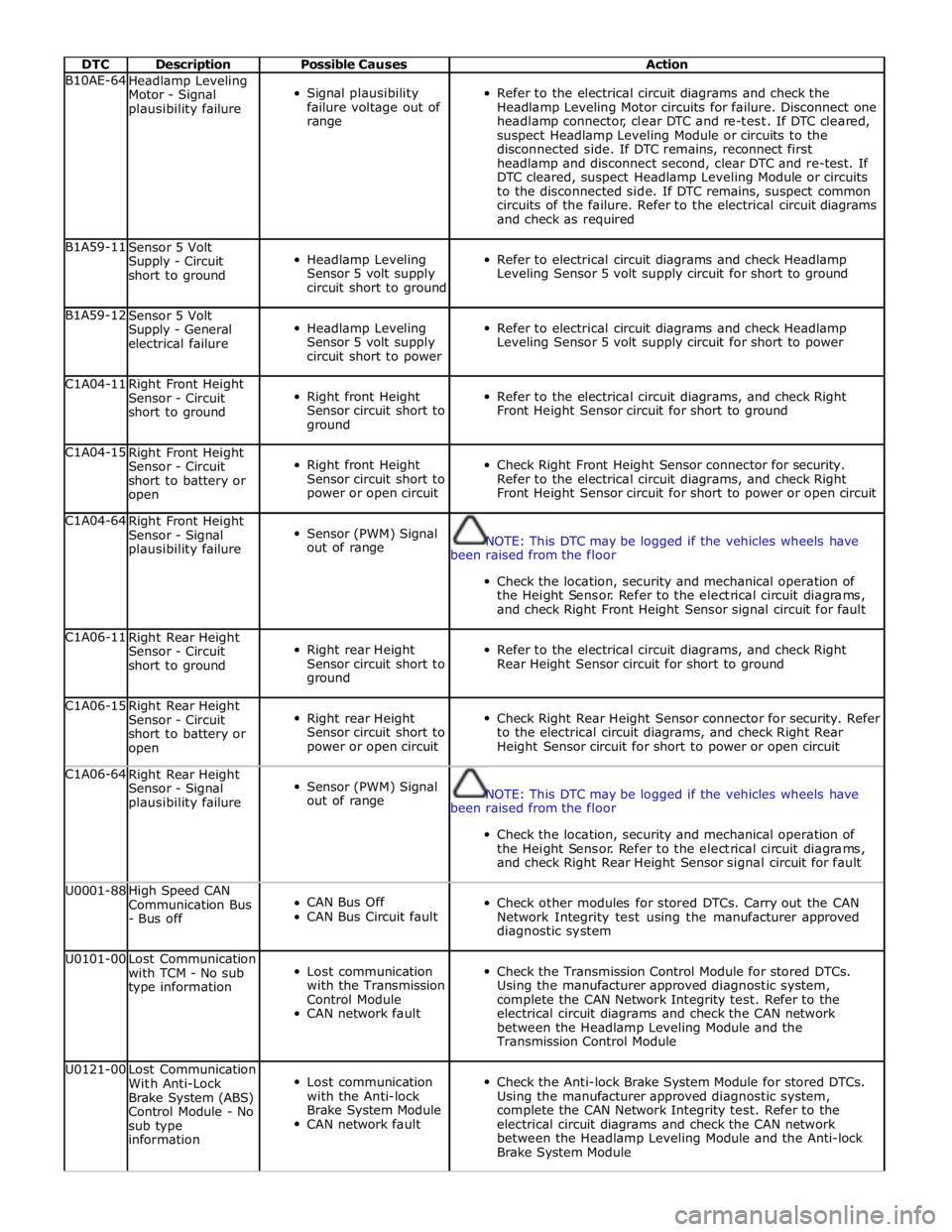

DTC Description Possible Causes Action B10AE-64

Headlamp Leveling

Motor - Signal

plausibility failure

Signal plausibility

failure voltage out of

range

Refer to the electrical circuit diagrams and check the

Headlamp Leveling Motor circuits for failure. Disconnect one

headlamp connector, clear DTC and re-test. If DTC cleared,

suspect Headlamp Leveling Module or circuits to the

disconnected side. If DTC remains, reconnect first

headlamp and disconnect second, clear DTC and re-test. If

DTC cleared, suspect Headlamp Leveling Module or circuits

to the disconnected side. If DTC remains, suspect common

circuits of the failure. Refer to the electrical circuit diagrams

and check as required B1A59-11

Sensor 5 Volt

Supply - Circuit

short to ground

Headlamp Leveling

Sensor 5 volt supply

circuit short to ground

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to ground B1A59-12

Sensor 5 Volt

Supply - General

electrical failure

Headlamp Leveling

Sensor 5 volt supply

circuit short to power

Refer to electrical circuit diagrams and check Headlamp

Leveling Sensor 5 volt supply circuit for short to power C1A04-11

Right Front Height

Sensor - Circuit

short to ground

Right front Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to ground C1A04-15

Right Front Height

Sensor - Circuit

short to battery or

open

Right front Height

Sensor circuit short to

power or open circuit

Check Right Front Height Sensor connector for security.

Refer to the electrical circuit diagrams, and check Right

Front Height Sensor circuit for short to power or open circuit C1A04-64

Right Front Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Front Height Sensor signal circuit for fault C1A06-11

Right Rear Height

Sensor - Circuit

short to ground

Right rear Height

Sensor circuit short to

ground

Refer to the electrical circuit diagrams, and check Right

Rear Height Sensor circuit for short to ground C1A06-15

Right Rear Height

Sensor - Circuit

short to battery or

open

Right rear Height

Sensor circuit short to

power or open circuit

Check Right Rear Height Sensor connector for security. Refer

to the electrical circuit diagrams, and check Right Rear

Height Sensor circuit for short to power or open circuit C1A06-64

Right Rear Height

Sensor - Signal

plausibility failure

Sensor (PWM) Signal

out of range

NOTE: This DTC may be logged if the vehicles wheels have

been raised from the floor

Check the location, security and mechanical operation of

the Height Sensor. Refer to the electrical circuit diagrams,

and check Right Rear Height Sensor signal circuit for fault U0001-88

High Speed CAN

Communication Bus

- Bus off

CAN Bus Off

CAN Bus Circuit fault

Check other modules for stored DTCs. Carry out the CAN

Network Integrity test using the manufacturer approved

diagnostic system U0101-00

Lost Communication

with TCM - No sub

type information

Lost communication

with the Transmission

Control Module

CAN network fault

Check the Transmission Control Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the

Transmission Control Module U0121-00

Lost Communication

With Anti-Lock

Brake System (ABS)

Control Module - No

sub type

information

Lost communication

with the Anti-lock

Brake System Module

CAN network fault

Check the Anti-lock Brake System Module for stored DTCs.

Using the manufacturer approved diagnostic system,

complete the CAN Network Integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the Headlamp Leveling Module and the Anti-lock

Brake System Module

Page 185 of 3039

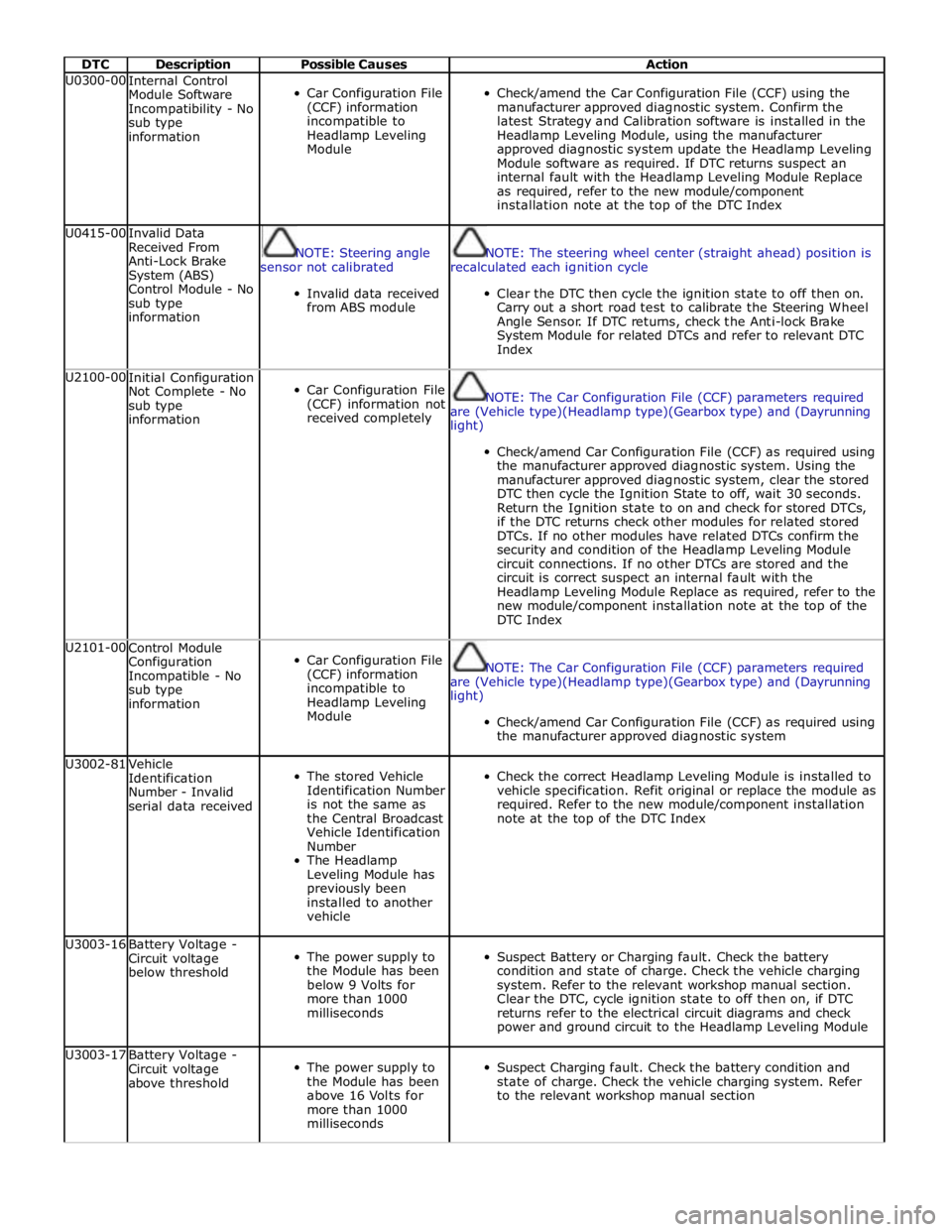

DTC Description Possible Causes Action U0300-00

Internal Control

Module Software

Incompatibility - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

Check/amend the Car Configuration File (CCF) using the

manufacturer approved diagnostic system. Confirm the

latest Strategy and Calibration software is installed in the

Headlamp Leveling Module, using the manufacturer

approved diagnostic system update the Headlamp Leveling

Module software as required. If DTC returns suspect an

internal fault with the Headlamp Leveling Module Replace

as required, refer to the new module/component

installation note at the top of the DTC Index U0415-00

Invalid Data

Received From

Anti-Lock Brake

System (ABS)

Control Module - No

sub type

information

NOTE: Steering angle

sensor not calibrated

Invalid data received

from ABS module

NOTE: The steering wheel center (straight ahead) position is

recalculated each ignition cycle

Clear the DTC then cycle the ignition state to off then on.

Carry out a short road test to calibrate the Steering Wheel

Angle Sensor. If DTC returns, check the Anti-lock Brake

System Module for related DTCs and refer to relevant DTC

Index U2100-00

Initial Configuration

Not Complete - No

sub type

information

Car Configuration File

(CCF) information not

received completely

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system. Using the

manufacturer approved diagnostic system, clear the stored

DTC then cycle the Ignition State to off, wait 30 seconds.

Return the Ignition state to on and check for stored DTCs,

if the DTC returns check other modules for related stored

DTCs. If no other modules have related DTCs confirm the

security and condition of the Headlamp Leveling Module

circuit connections. If no other DTCs are stored and the

circuit is correct suspect an internal fault with the

Headlamp Leveling Module Replace as required, refer to the

new module/component installation note at the top of the

DTC Index U2101-00

Control Module

Configuration

Incompatible - No

sub type

information

Car Configuration File

(CCF) information

incompatible to

Headlamp Leveling

Module

NOTE: The Car Configuration File (CCF) parameters required

are (Vehicle type)(Headlamp type)(Gearbox type) and (Dayrunning

light)

Check/amend Car Configuration File (CCF) as required using

the manufacturer approved diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data received

The stored Vehicle

Identification Number

is not the same as

the Central Broadcast

Vehicle Identification

Number

The Headlamp

Leveling Module has

previously been

installed to another

vehicle

Check the correct Headlamp Leveling Module is installed to

vehicle specification. Refit original or replace the module as

required. Refer to the new module/component installation

note at the top of the DTC Index U3003-16

Battery Voltage -

Circuit voltage

below threshold

The power supply to

the Module has been

below 9 Volts for

more than 1000

milliseconds

Suspect Battery or Charging fault. Check the battery

condition and state of charge. Check the vehicle charging

system. Refer to the relevant workshop manual section.

Clear the DTC, cycle ignition state to off then on, if DTC

returns refer to the electrical circuit diagrams and check

power and ground circuit to the Headlamp Leveling Module U3003-17

Battery Voltage -

Circuit voltage

above threshold

The power supply to

the Module has been

above 16 Volts for

more than 1000

milliseconds

Suspect Charging fault. Check the battery condition and

state of charge. Check the vehicle charging system. Refer

to the relevant workshop manual section

Page 190 of 3039

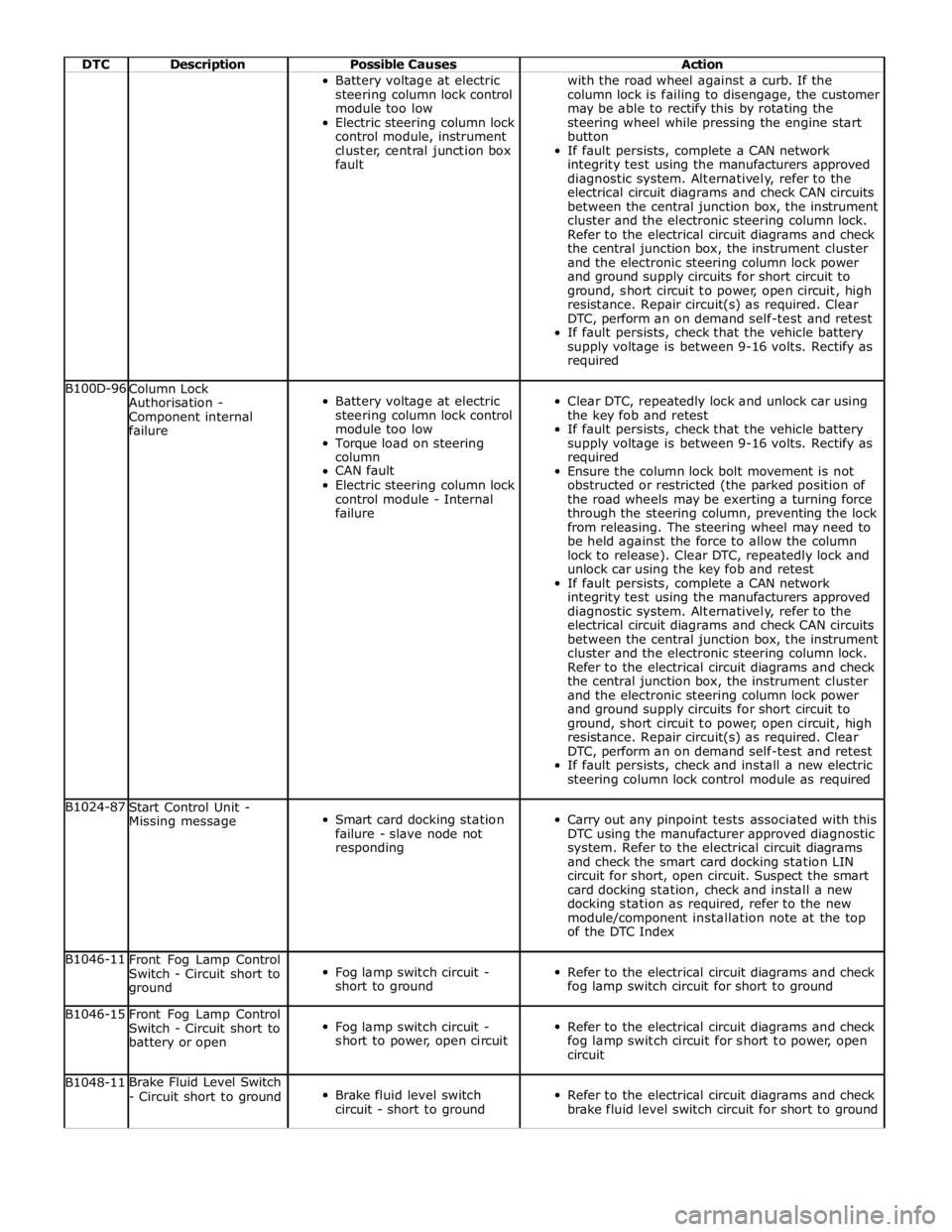

DTC Description Possible Causes Action Battery voltage at electric

steering column lock control

module too low

Electric steering column lock

control module, instrument

cluster, central junction box

fault with the road wheel against a curb. If the

column lock is failing to disengage, the customer

may be able to rectify this by rotating the

steering wheel while pressing the engine start

button

If fault persists, complete a CAN network

integrity test using the manufacturers approved

diagnostic system. Alternatively, refer to the

electrical circuit diagrams and check CAN circuits

between the central junction box, the instrument

cluster and the electronic steering column lock.

Refer to the electrical circuit diagrams and check

the central junction box, the instrument cluster

and the electronic steering column lock power

and ground supply circuits for short circuit to

ground, short circuit to power, open circuit, high

resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery

supply voltage is between 9-16 volts. Rectify as

required B100D-96

Column Lock

Authorisation -

Component internal

failure

Battery voltage at electric

steering column lock control

module too low

Torque load on steering

column

CAN fault

Electric steering column lock

control module - Internal

failure

Clear DTC, repeatedly lock and unlock car using

the key fob and retest

If fault persists, check that the vehicle battery

supply voltage is between 9-16 volts. Rectify as

required

Ensure the column lock bolt movement is not

obstructed or restricted (the parked position of

the road wheels may be exerting a turning force

through the steering column, preventing the lock

from releasing. The steering wheel may need to

be held against the force to allow the column

lock to release). Clear DTC, repeatedly lock and

unlock car using the key fob and retest

If fault persists, complete a CAN network

integrity test using the manufacturers approved

diagnostic system. Alternatively, refer to the

electrical circuit diagrams and check CAN circuits

between the central junction box, the instrument

cluster and the electronic steering column lock.

Refer to the electrical circuit diagrams and check

the central junction box, the instrument cluster

and the electronic steering column lock power

and ground supply circuits for short circuit to

ground, short circuit to power, open circuit, high

resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check and install a new electric

steering column lock control module as required B1024-87

Start Control Unit -

Missing message

Smart card docking station

failure - slave node not

responding

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check the smart card docking station LIN

circuit for short, open circuit. Suspect the smart

card docking station, check and install a new

docking station as required, refer to the new

module/component installation note at the top

of the DTC Index B1046-11

Front Fog Lamp Control

Switch - Circuit short to

ground

Fog lamp switch circuit -

short to ground

Refer to the electrical circuit diagrams and check

fog lamp switch circuit for short to ground B1046-15

Front Fog Lamp Control

Switch - Circuit short to

battery or open

Fog lamp switch circuit -

short to power, open circuit

Refer to the electrical circuit diagrams and check

fog lamp switch circuit for short to power, open

circuit B1048-11 Brake Fluid Level Switch

- Circuit short to ground

Brake fluid level switch

circuit - short to ground

Refer to the electrical circuit diagrams and check

brake fluid level switch circuit for short to ground

Page 191 of 3039

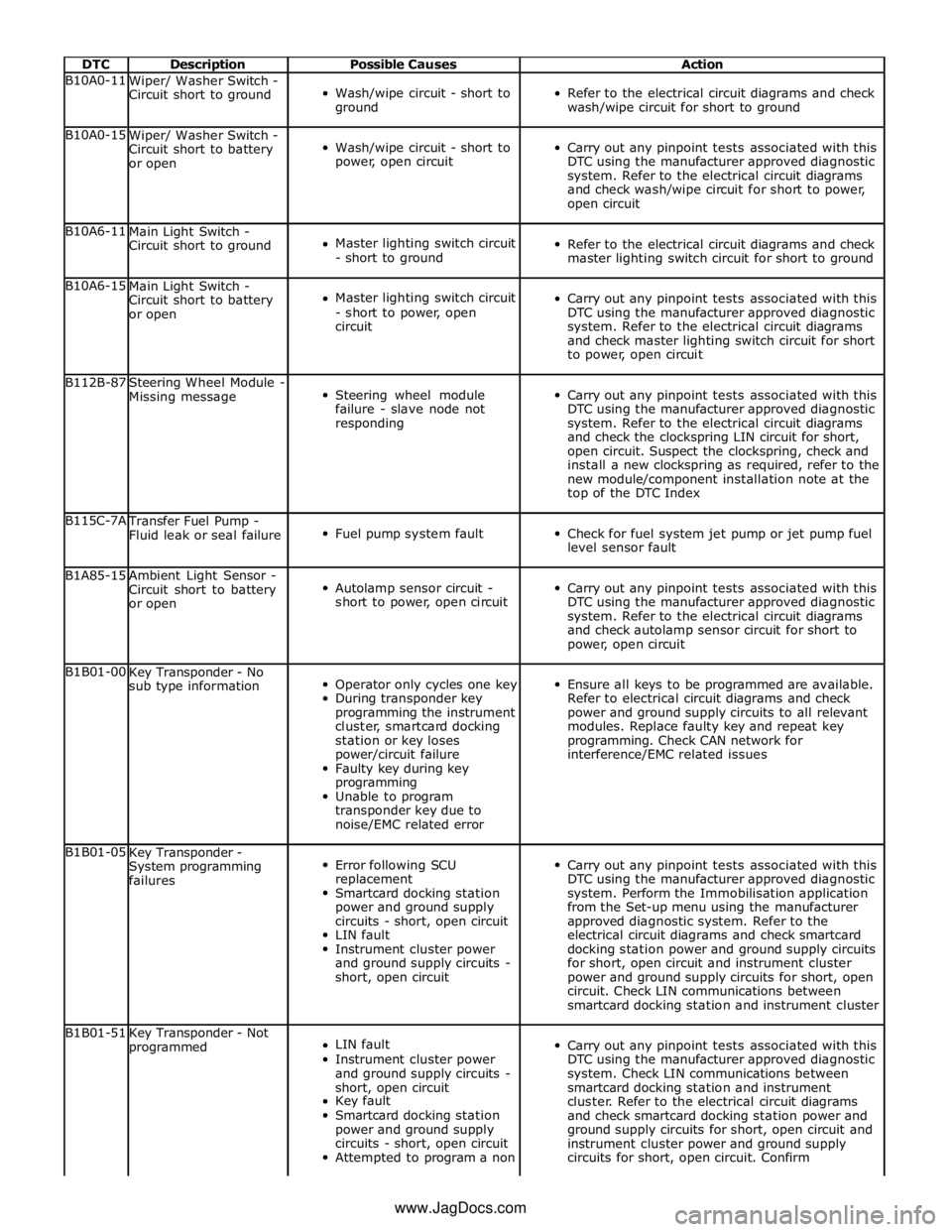

DTC Description Possible Causes Action B10A0-11

Wiper/ Washer Switch -

Circuit short to ground

Wash/wipe circuit - short to

ground

Refer to the electrical circuit diagrams and check

wash/wipe circuit for short to ground B10A0-15

Wiper/ Washer Switch -

Circuit short to battery

or open

Wash/wipe circuit - short to

power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check wash/wipe circuit for short to power,

open circuit B10A6-11

Main Light Switch -

Circuit short to ground

Master lighting switch circuit

- short to ground

Refer to the electrical circuit diagrams and check

master lighting switch circuit for short to ground B10A6-15

Main Light Switch -

Circuit short to battery

or open

Master lighting switch circuit

- short to power, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check master lighting switch circuit for short

to power, open circuit B112B-87

Steering Wheel Module -

Missing message

Steering wheel module

failure - slave node not

responding

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check the clockspring LIN circuit for short,

open circuit. Suspect the clockspring, check and

install a new clockspring as required, refer to the

new module/component installation note at the

top of the DTC Index B115C-7A Transfer Fuel Pump -

Fluid leak or seal failure

Fuel pump system fault

Check for fuel system jet pump or jet pump fuel

level sensor fault B1A85-15

Ambient Light Sensor -

Circuit short to battery

or open

Autolamp sensor circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check autolamp sensor circuit for short to

power, open circuit B1B01-00

Key Transponder - No

sub type information

Operator only cycles one key

During transponder key

programming the instrument

cluster, smartcard docking

station or key loses

power/circuit failure

Faulty key during key

programming

Unable to program

transponder key due to

noise/EMC related error

Ensure all keys to be programmed are available.

Refer to electrical circuit diagrams and check

power and ground supply circuits to all relevant

modules. Replace faulty key and repeat key

programming. Check CAN network for

interference/EMC related issues B1B01-05

Key Transponder -

System programming

failures

Error following SCU

replacement

Smartcard docking station

power and ground supply

circuits - short, open circuit

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Perform the Immobilisation application

from the Set-up menu using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check smartcard

docking station power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check LIN communications between

smartcard docking station and instrument cluster B1B01-51

Key Transponder - Not

programmed

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Key fault

Smartcard docking station

power and ground supply

circuits - short, open circuit

Attempted to program a non

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check LIN communications between

smartcard docking station and instrument

cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Confirm www.JagDocs.com

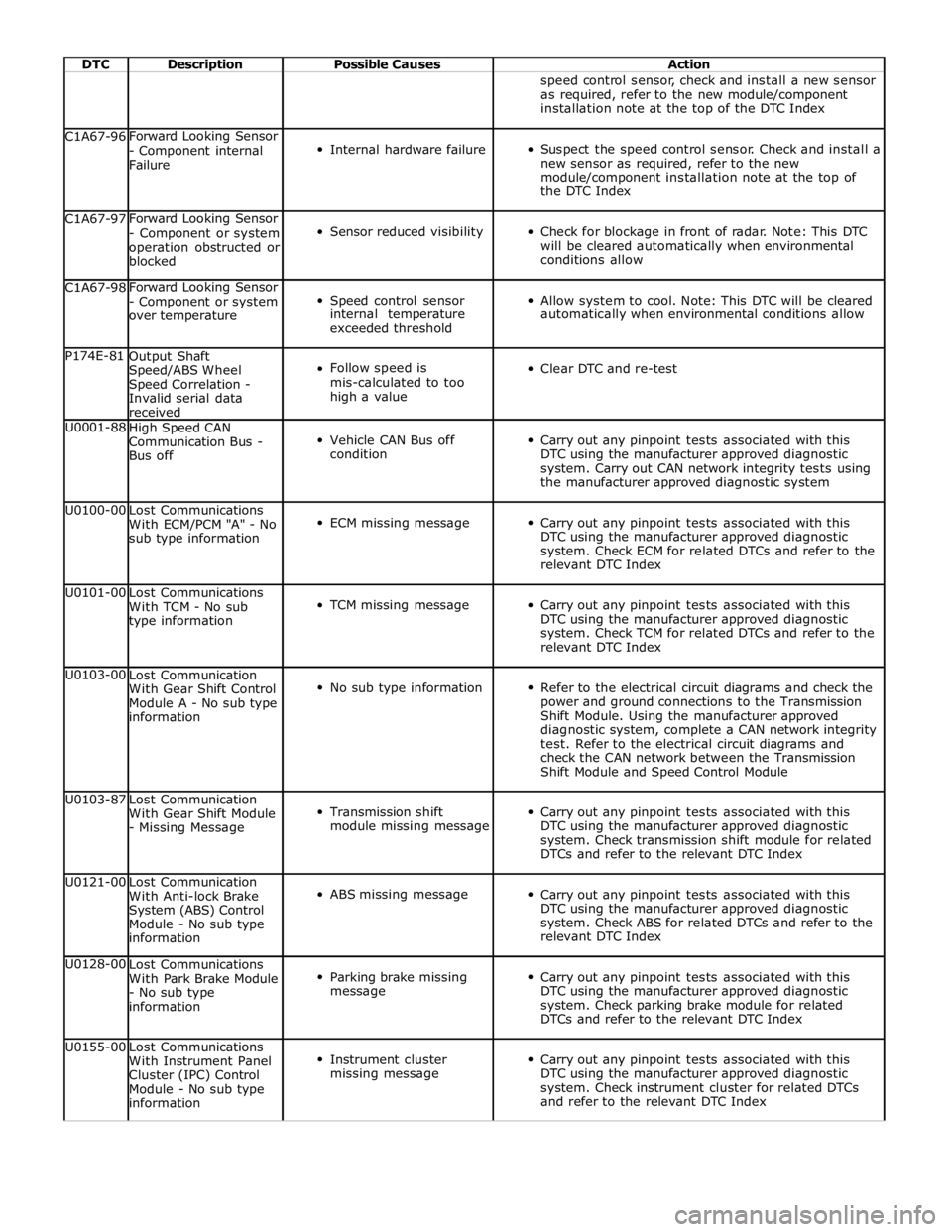

Page 239 of 3039

DTC Description Possible Causes Action speed control sensor, check and install a new sensor

as required, refer to the new module/component

installation note at the top of the DTC Index C1A67-96 Forward Looking Sensor

- Component internal

Failure

Internal hardware failure

Suspect the speed control sensor. Check and install a

new sensor as required, refer to the new

module/component installation note at the top of

the DTC Index C1A67-97 Forward Looking Sensor

- Component or system

operation obstructed or

blocked

Sensor reduced visibility

Check for blockage in front of radar. Note: This DTC

will be cleared automatically when environmental

conditions allow C1A67-98 Forward Looking Sensor

- Component or system

over temperature

Speed control sensor

internal temperature

exceeded threshold

Allow system to cool. Note: This DTC will be cleared

automatically when environmental conditions allow P174E-81

Output Shaft

Speed/ABS Wheel

Speed Correlation -

Invalid serial data

received

Follow speed is

mis-calculated to too

high a value

Clear DTC and re-test U0001-88

High Speed CAN

Communication Bus -

Bus off

Vehicle CAN Bus off

condition

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity tests using

the manufacturer approved diagnostic system U0100-00

Lost Communications

With ECM/PCM "A" - No

sub type information

ECM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ECM for related DTCs and refer to the

relevant DTC Index U0101-00

Lost Communications

With TCM - No sub

type information

TCM missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check TCM for related DTCs and refer to the

relevant DTC Index U0103-00

Lost Communication

With Gear Shift Control

Module A - No sub type

information

No sub type information

Refer to the electrical circuit diagrams and check the

power and ground connections to the Transmission

Shift Module. Using the manufacturer approved

diagnostic system, complete a CAN network integrity

test. Refer to the electrical circuit diagrams and

check the CAN network between the Transmission

Shift Module and Speed Control Module U0103-87

Lost Communication

With Gear Shift Module

- Missing Message

Transmission shift

module missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check transmission shift module for related

DTCs and refer to the relevant DTC Index U0121-00

Lost Communication

With Anti-lock Brake

System (ABS) Control

Module - No sub type

information

ABS missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check ABS for related DTCs and refer to the

relevant DTC Index U0128-00

Lost Communications

With Park Brake Module

- No sub type

information

Parking brake missing

message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check parking brake module for related

DTCs and refer to the relevant DTC Index U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Instrument cluster

missing message

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check instrument cluster for related DTCs

and refer to the relevant DTC Index

Page 243 of 3039

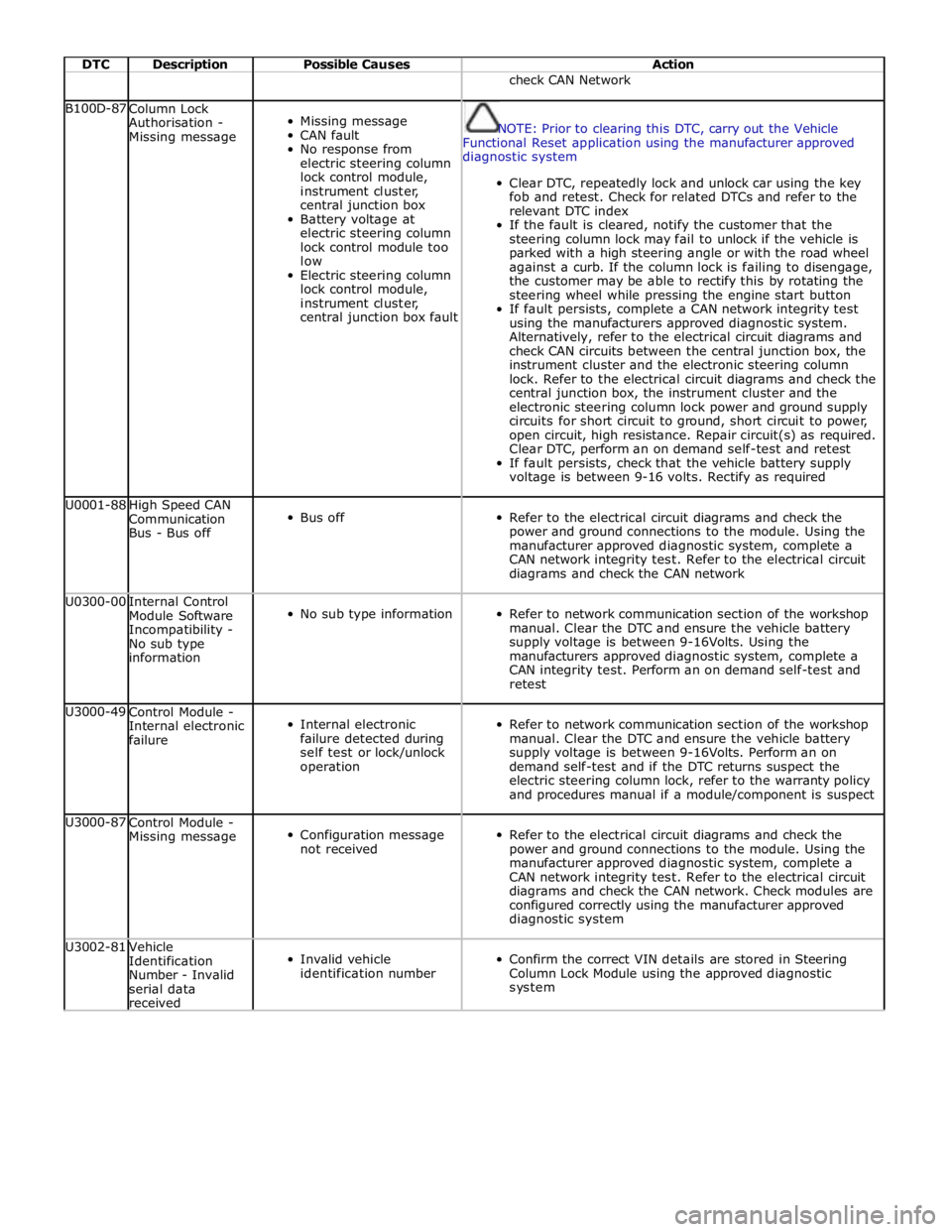

DTC Description Possible Causes Action check CAN Network B100D-87

Column Lock

Authorisation -

Missing message

Missing message

CAN fault

No response from

electric steering column

lock control module,

instrument cluster,

central junction box

Battery voltage at

electric steering column

lock control module too

low

Electric steering column

lock control module,

instrument cluster,

central junction box fault

NOTE: Prior to clearing this DTC, carry out the Vehicle

Functional Reset application using the manufacturer approved

diagnostic system

Clear DTC, repeatedly lock and unlock car using the key

fob and retest. Check for related DTCs and refer to the

relevant DTC index

If the fault is cleared, notify the customer that the

steering column lock may fail to unlock if the vehicle is

parked with a high steering angle or with the road wheel

against a curb. If the column lock is failing to disengage,

the customer may be able to rectify this by rotating the

steering wheel while pressing the engine start button

If fault persists, complete a CAN network integrity test

using the manufacturers approved diagnostic system.

Alternatively, refer to the electrical circuit diagrams and

check CAN circuits between the central junction box, the

instrument cluster and the electronic steering column

lock. Refer to the electrical circuit diagrams and check the

central junction box, the instrument cluster and the

electronic steering column lock power and ground supply

circuits for short circuit to ground, short circuit to power,

open circuit, high resistance. Repair circuit(s) as required.

Clear DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required U0001-88

High Speed CAN

Communication

Bus - Bus off

Bus off

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network U0300-00

Internal Control

Module Software

Incompatibility -

No sub type

information

No sub type information

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Using the

manufacturers approved diagnostic system, complete a

CAN integrity test. Perform an on demand self-test and

retest U3000-49

Control Module -

Internal electronic

failure

Internal electronic

failure detected during

self test or lock/unlock

operation

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Perform an on

demand self-test and if the DTC returns suspect the

electric steering column lock, refer to the warranty policy

and procedures manual if a module/component is suspect U3000-87

Control Module -

Missing message

Configuration message

not received

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network. Check modules are

configured correctly using the manufacturer approved

diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data

received

Invalid vehicle

identification number

Confirm the correct VIN details are stored in Steering

Column Lock Module using the approved diagnostic

system