Engine JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1889 of 3039

Battery, Mounting and Cables - Battery

Diagnosis and Testing

Principles of Operation Published: 10-Mar-2014

For a detailed description of the battery system and operation, refer to the relevant Description and Operation section of the

workshop manual. REFER to: Battery and Cables (414-01 Battery, Mounting and Cables, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Generator

Drive belt

Drive belt tensioner

Generator pulley

Check the security of the generator fixings

Generator

Battery

Battery connections

Starter motor

Harnesses and connectors

Fuses

Charge warning lamp function

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Possible Causes Action

Battery power to vehicle

interrupted

High resistance between battery terminals and

clamps

GO to Pinpoint Test

A. Midtronics EXP-1080 User Guide

Carry out the following: -

Surface Voltage Removal Process

A vehicle which has had its battery charged or been driven in a 24 hour period before the test, must have its surface charge

removed

Page 1890 of 3039

1. Turn on the ignition but do not start the vehicle

2. Switch on the headlamps on high beam for a minimum 3 minutes

3. Switch off the headlamps

4. Wait a minimum of 5 minutes before recording test results for any battery measurements

PINPOINT TEST A : VOLTAGE DROP TEST CONDITIONS DETAILS/RESULTS/ACTIONS A1: GROUND CIRCUIT

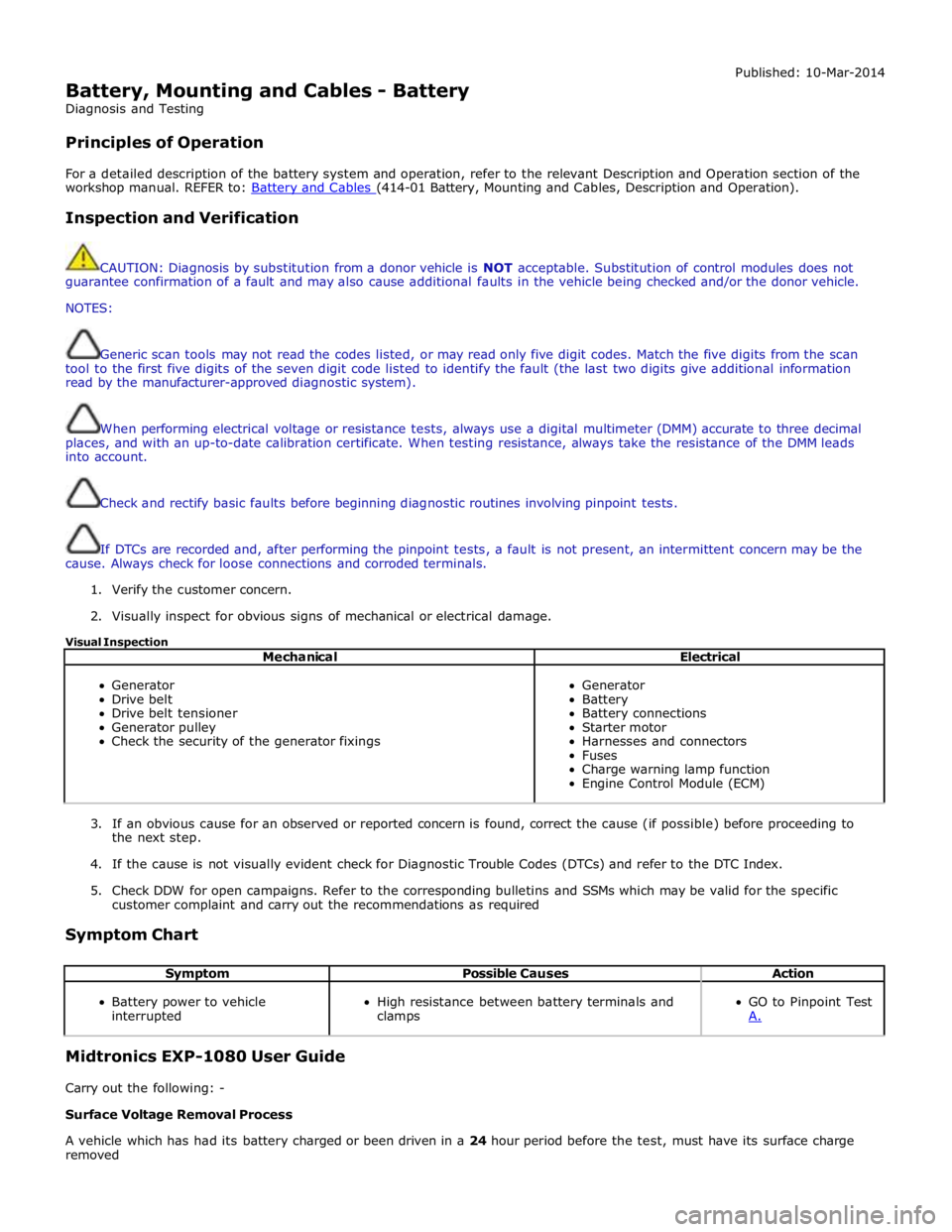

NOTE: This test checks for high resistance between the battery terminal and the battery clamp 1 Start the engine, turn on the following: (1) ) Air conditioning

(2) ) Blower fan on full speed

(3) Headlights on main beam

(4) Heated screen - rear

(5) Heated screen - front (if installed)

(6) Heated seats (if installed) 2 Connect the multimeter between the battery negative terminal and the battery clamp as shown in picture below (do not

disconnect the battery at this stage) 3 Set the multimeter to read DC voltage and record the reading Is reading equal to or below 0.1 volts? Yes

GO to A2. No

Switch all electrical loads and engine off, return the vehicle to

an ignition off condition. Disconnect the battery negative

clamp, clean clamp and terminal then reconnect and repeat test

GO to A1. A2: POWER CIRCUIT

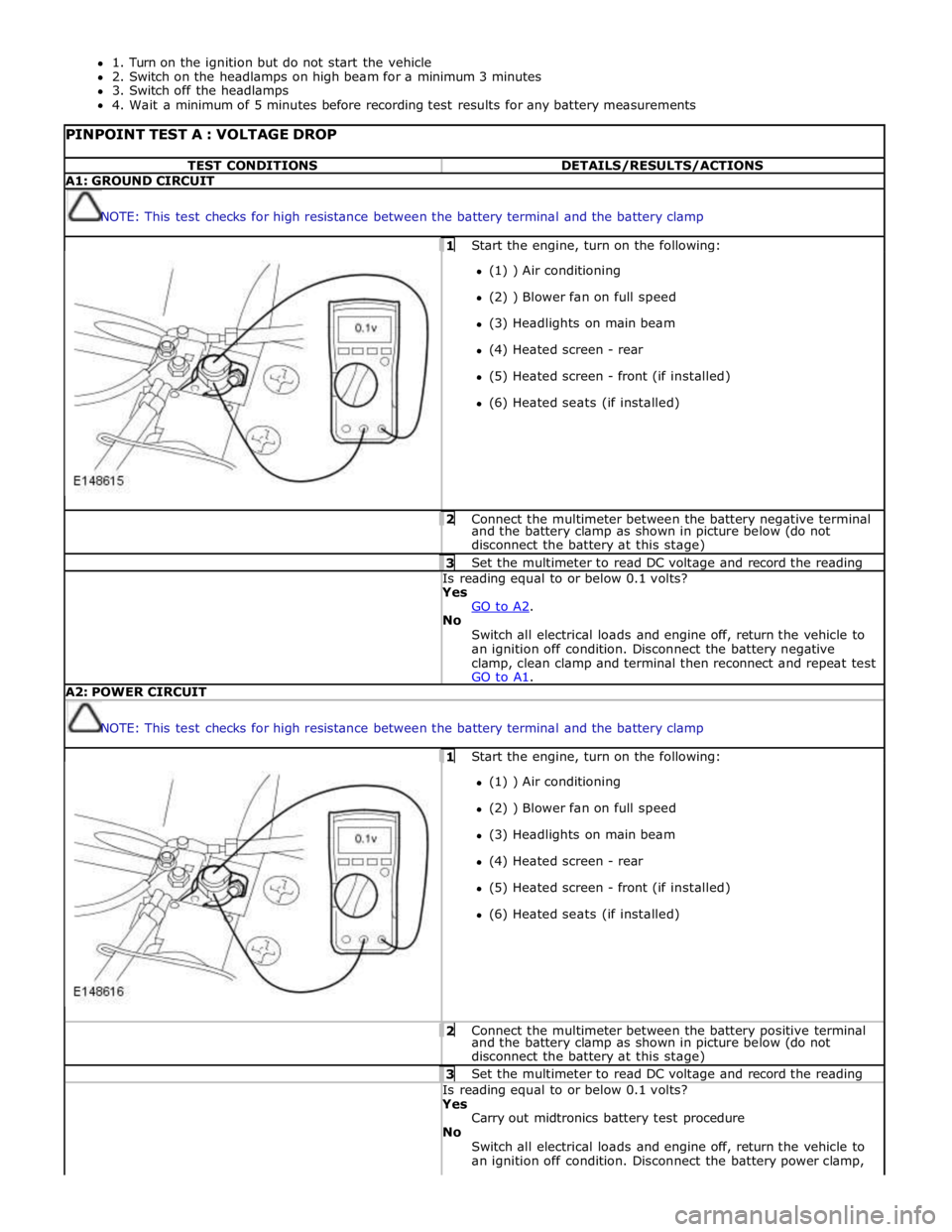

NOTE: This test checks for high resistance between the battery terminal and the battery clamp 1 Start the engine, turn on the following: (1) ) Air conditioning

(2) ) Blower fan on full speed

(3) Headlights on main beam

(4) Heated screen - rear

(5) Heated screen - front (if installed)

(6) Heated seats (if installed) 2 Connect the multimeter between the battery positive terminal and the battery clamp as shown in picture below (do not

disconnect the battery at this stage) 3 Set the multimeter to read DC voltage and record the reading Is reading equal to or below 0.1 volts? Yes

Carry out midtronics battery test procedure

No

Switch all electrical loads and engine off, return the vehicle to

an ignition off condition. Disconnect the battery power clamp,

Page 1903 of 3039

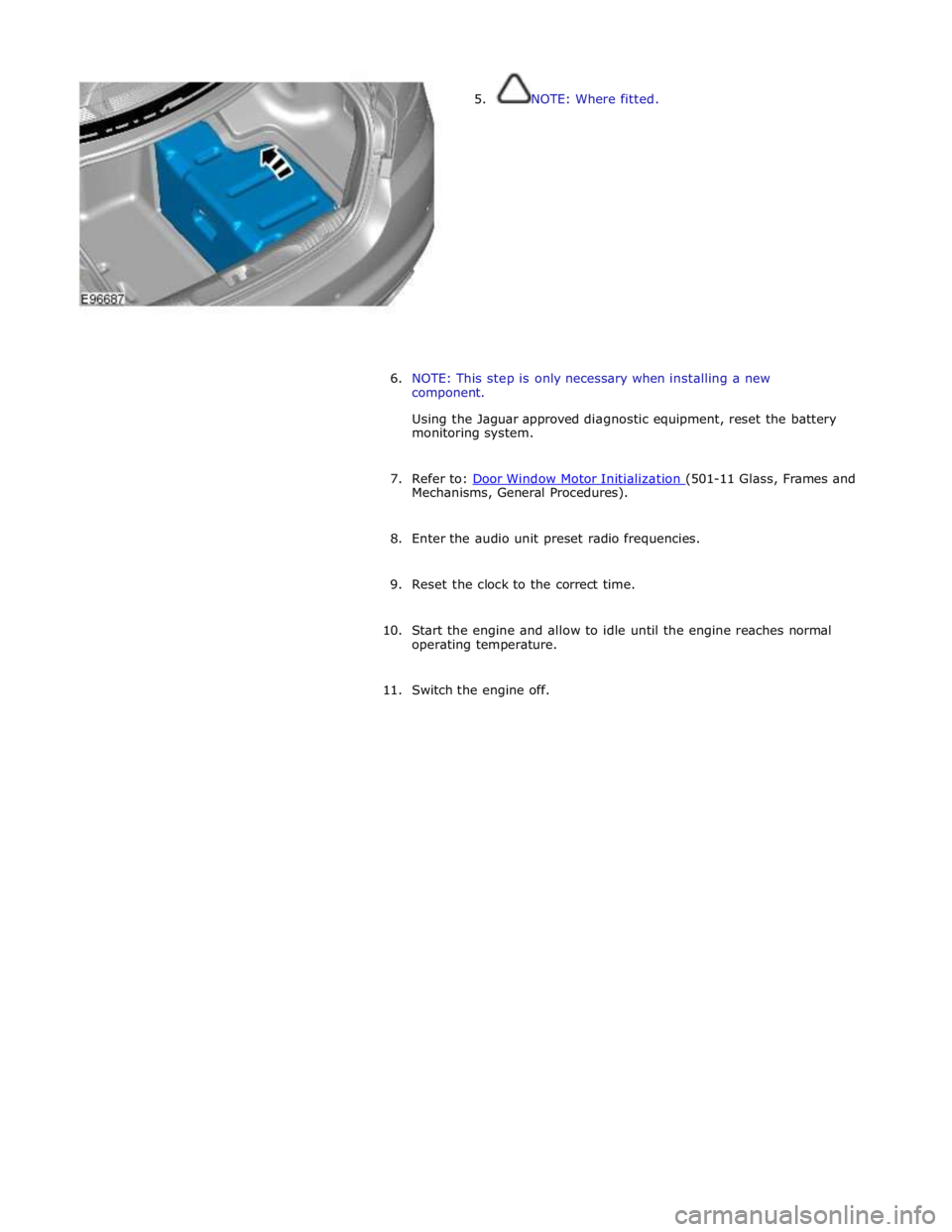

5. NOTE: Where fitted.

6. NOTE: This step is only necessary when installing a new

component.

Using the Jaguar approved diagnostic equipment, reset the battery

monitoring system.

7. Refer to: Door Window Motor Initialization (501-11 Glass, Frames and Mechanisms, General Procedures).

8. Enter the audio unit preset radio frequencies.

9. Reset the clock to the correct time.

10. Start the engine and allow to idle until the engine reaches normal

operating temperature.

11. Switch the engine off.

Page 1907 of 3039

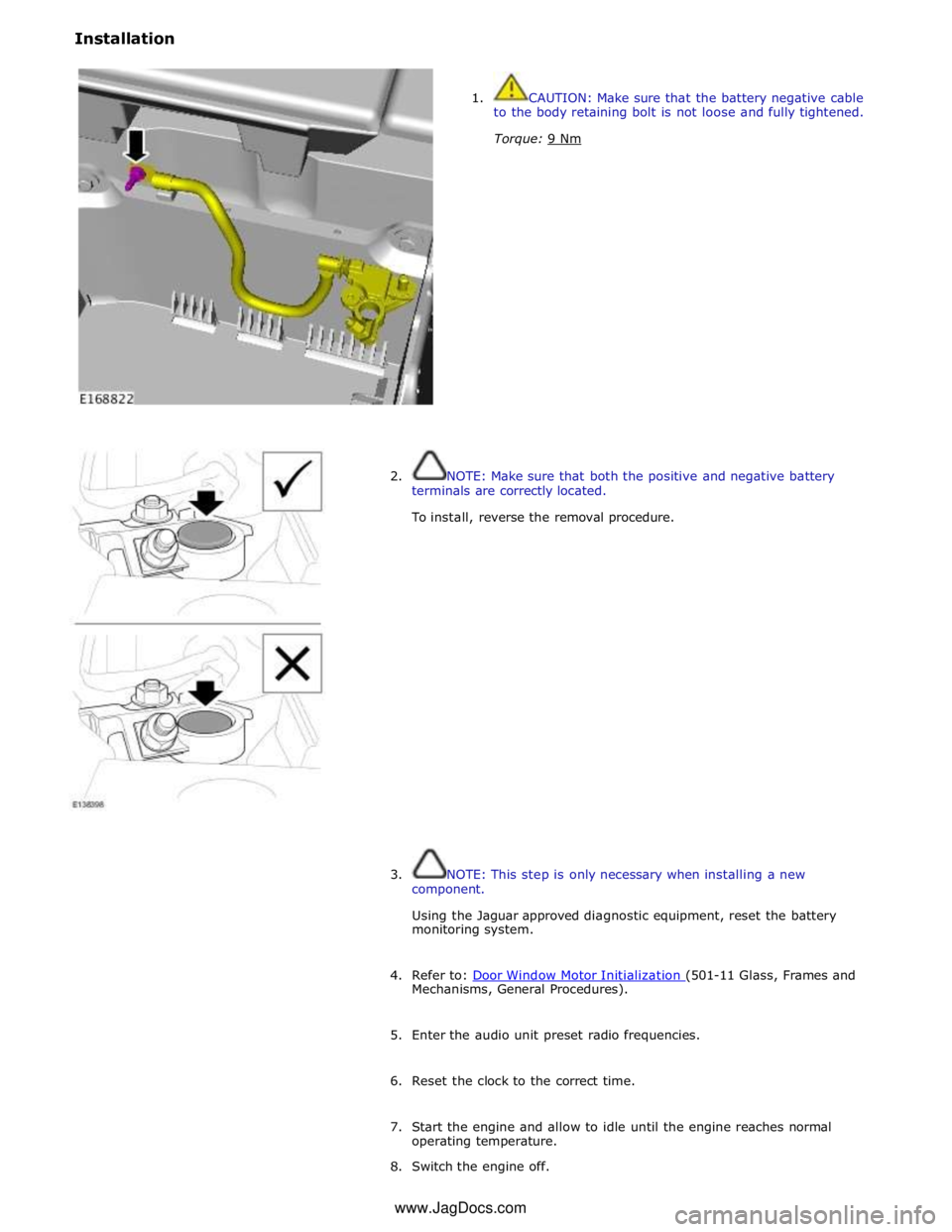

Installation

1. CAUTION: Make sure that the battery negative cable

to the body retaining bolt is not loose and fully tightened.

Torque: 9 Nm

2. NOTE: Make sure that both the positive and negative battery

terminals are correctly located.

To install, reverse the removal procedure.

3. NOTE: This step is only necessary when installing a new

component.

Using the Jaguar approved diagnostic equipment, reset the battery

monitoring system.

4. Refer to: Door Window Motor Initialization (501-11 Glass, Frames and Mechanisms, General Procedures).

5. Enter the audio unit preset radio frequencies.

6. Reset the clock to the correct time.

7. Start the engine and allow to idle until the engine reaches normal

operating temperature.

8. Switch the engine off. www.JagDocs.com

Page 1910 of 3039

Published: 11-May-2011

Generator and Regulator - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Generator - Overview

Description and Operation

OVERVIEW

On 5.0L V8 vehicles (naturally aspirated and supercharger), the charging system consists of a 150 Amp output generator and

regulator assembly. The generator and regulator assembly generates electrical power for the vehicle electrical system and

maintains the battery in a charged state.

When the engine is running the generator produces an alternating current, which is converted to a direct current internally. The

output from the generator is controlled by the voltage regulator (located inside the generator) and then supplied to the battery

through the main battery positive cable. The generator is mounted on the front right side of the engine and driven at

approximately 3 times engine speed by the accessory drive belt.

Page 1911 of 3039

Published: 11-May-2011

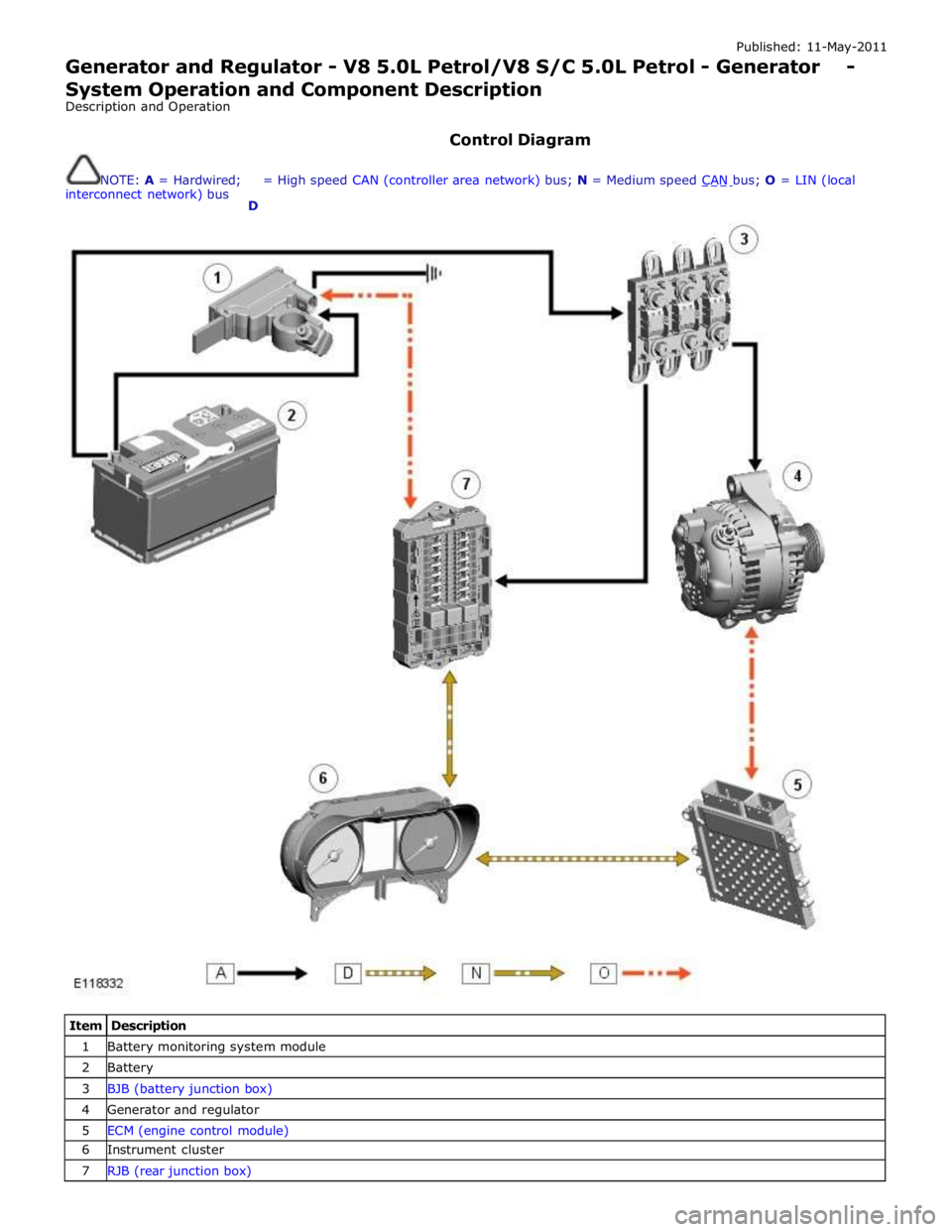

Generator and Regulator - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Generator - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired;

interconnect network) bus

D = High speed CAN (controller area network) bus; N = Medium speed CAN bus; O = LIN (local

Item Description 1 Battery monitoring system module 2 Battery 3 BJB (battery junction box) 4 Generator and regulator 5 ECM (engine control module) 6 Instrument cluster 7 RJB (rear junction box)

Page 1930 of 3039

The navigation will restart upon completion of the map update.

NOTE: Remove USB stick immediately

Turn off the engine.

Exit, lock the vehicle and leave for at 15 minutes before using the navigation system.

Japanese Navigation

The Japanese satellite navigation system uses a separate navigation computer module.

The HDD in the ACM/IAM is not used for navigation downloads in this market.

Map updates are supplied in DVD format. The DVD is loaded into the navigation module. Map data is read directly from the

DVD.

SD Card Navigation Updates (Asia Navigation)

The Asia market navigation system is an aftermarket unit.

Map updates are supplied in an SD card format. The SD card is loaded into the navigation module. Map data is read directly

from the SD card.

NOTE: The following countries use SD card navigation updates.

Country ANGOLA ARGENTINA AZERBAIJAN BAHAMAS BARBADOS BENIN BOTSWANA BRAZIL BRUNEI BURUNDI CAYMAN ISLANDS CHILE CHINA COLOMBIA EGYPT FIJI GHANA HONG KONG INDIA INDONESIA ISRAEL JAMAICA KENYA LEBANON LESOTHO MALAWI MALI MAURITIUS MONGOLIA MOROCCO MOZAMBIQUE NAMIBIA NIGER www.JagDocs.com

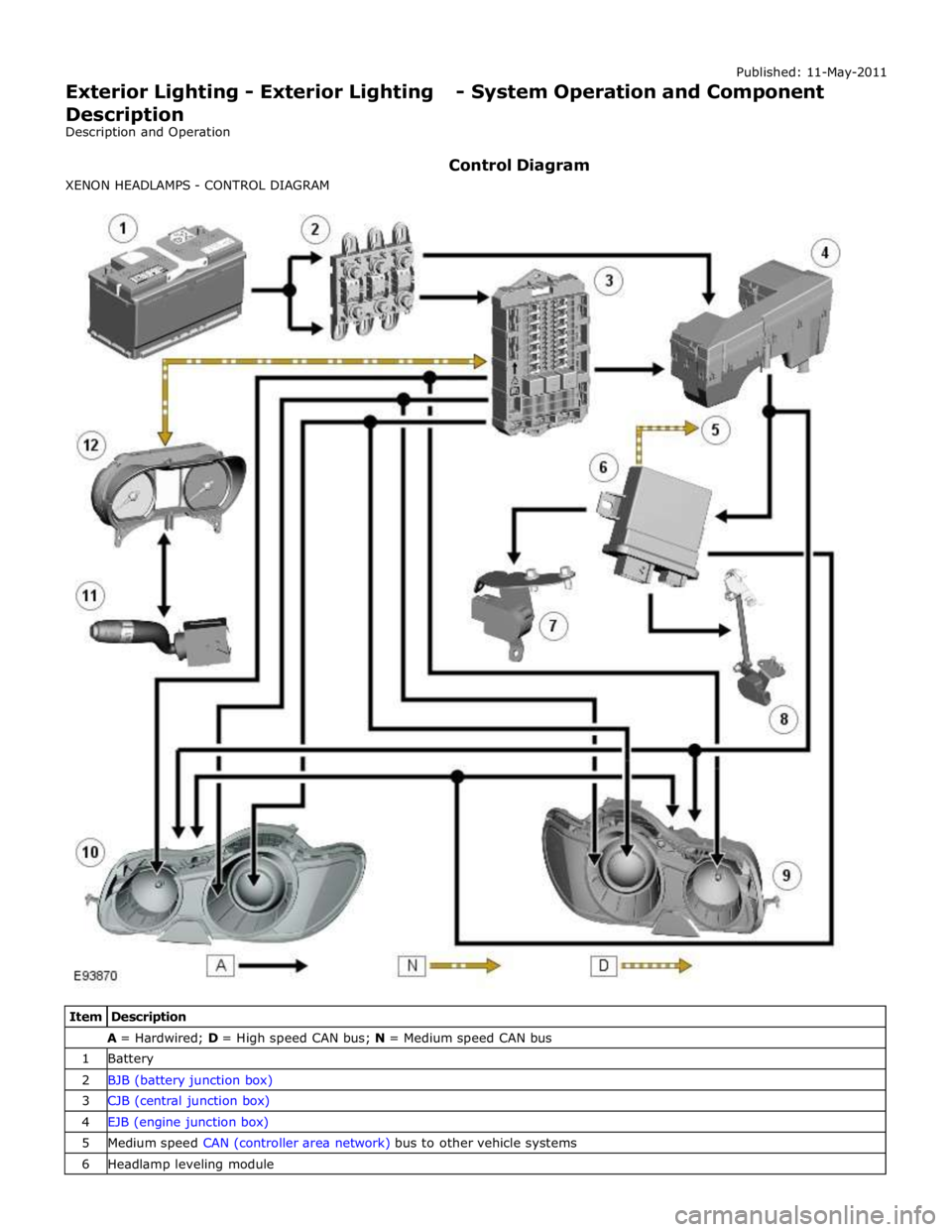

Page 2023 of 3039

A = Hardwired; D = High speed CAN bus; N = Medium speed CAN bus 1 Battery 2 BJB (battery junction box) 3 CJB (central junction box) 4 EJB (engine junction box) 5 Medium speed CAN (controller area network) bus to other vehicle systems 6 Headlamp leveling module

Page 2066 of 3039

Published: 11-May-2011

Daytime Running Lamps (DRL) - Daytime Running Lamps (DRL) - System

Operation and Component Description

Description and Operation

CENTRAL JUNCTION BOX (CJB) System Operation

The CJB (central junction box) controls the operation of the DRL (daytime running lamps). The DRL are activated once the CJB detects an ignition on power mode 6 signal.

The CJB also monitors the lighting control switch and the auto lamps feature and overrides the DRL if required.

DAYTIME RUNNING LAMPS - CANADA Component Description

The DRL for this market use full intensity low beam headlamps. The side marker lamps, tail lamps and license plate lamps will be on, but instrument cluster illumination will be off. DRL are active when the following parameters are met:

PARK is not selected on the electronic transmission selector

Electronic Parking Brake (EPB) is off

Power mode 6 (ignition on) detected by the CJB The CJB receives an engine running signal The lighting control switch is in the off or side lamps position.

NOTES:

If the lighting control switch is moved to the headlamp position, DRL are deactivated and normal side lamp and headlamp functionality is operational.

When DRL are active, the headlamp flash function using the left hand steering column multifunction switch will operate normally.

The high beam headlamp function using the left hand steering column stalk switch will be deactivated. When the transmission

is in PARK, DRL are turned off. This is to reduce battery discharge during long periods of engine idling in cold climate conditions. When the electronic transmission selector is moved from the PARK position, normal DRL functionality is restored.

DAYTIME RUNNING LAMPS - DENMARK, HOLLAND, NORWAY, SWEDEN, FINLAND AND POLAND

NOTE: DRL for Poland is on vehicles from 2008MY.

DRL for these markets use full intensity low beam headlamps. Side lamps and license plate lamps will be on, but instrument cluster illumination will be off. DRL are active when the following parameters are met:

Power mode 6 (ignition on) detected by the CJB The CJB receives an engine running signal The lighting control switch is in the off position.

NOTE: When DRL are active, the headlamp flash function using the left hand steering column multifunction switch will operate normally. The high beam headlamp function using the left hand steering column stalk switch will be deactivated.

If the lighting control switch is moved to the side lamp or headlamp positions, DRL are deactivated and normal side lamp and headlamp functionality is operational.

AUTOMATIC HEADLAMPS

On vehicles fitted with the automatic headlamps feature, DRL are overridden if the lighting control switch is in the 'Auto' position and the CJB receives a signal from the rain/light sensor to activate the exterior lights.

When the CJB receives a signal to de-activate the automatic headlamps feature the DRL function is restored providing the parameters for DRL activation are met.

Page 2069 of 3039

5 RJB (rear junction box) 6 Battery monitoring system module 7 Rear view camera 8 TCM (transmission control module) 9 Generator 10 Driver's door switch pack 11 Rear door control module 12 Driver's door control module 13 ECM (engine control module) 14 Electronic transmission selector 15 Driver's seat module 16 Driver's seat switch pack 17 Rear door control module 18 Front passenger door control module 19 Clockspring 20 Audio and telephone steering wheel switches 21 Instrument cluster 22 Start control module