engine coolant JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1369 of 3039

Published: 16-Sep-2013

Electronic Engine Controls - V8 S/C 5.0L Petrol - Electronic Engine Controls

Diagnosis and Testing

Principle of Operation

For a detailed description of electronic engine controls, refer to the relevant Description and Operation section of the workshop

manual. REFER to: (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol)

Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation), Electronic Engine Controls (Description and Operation).

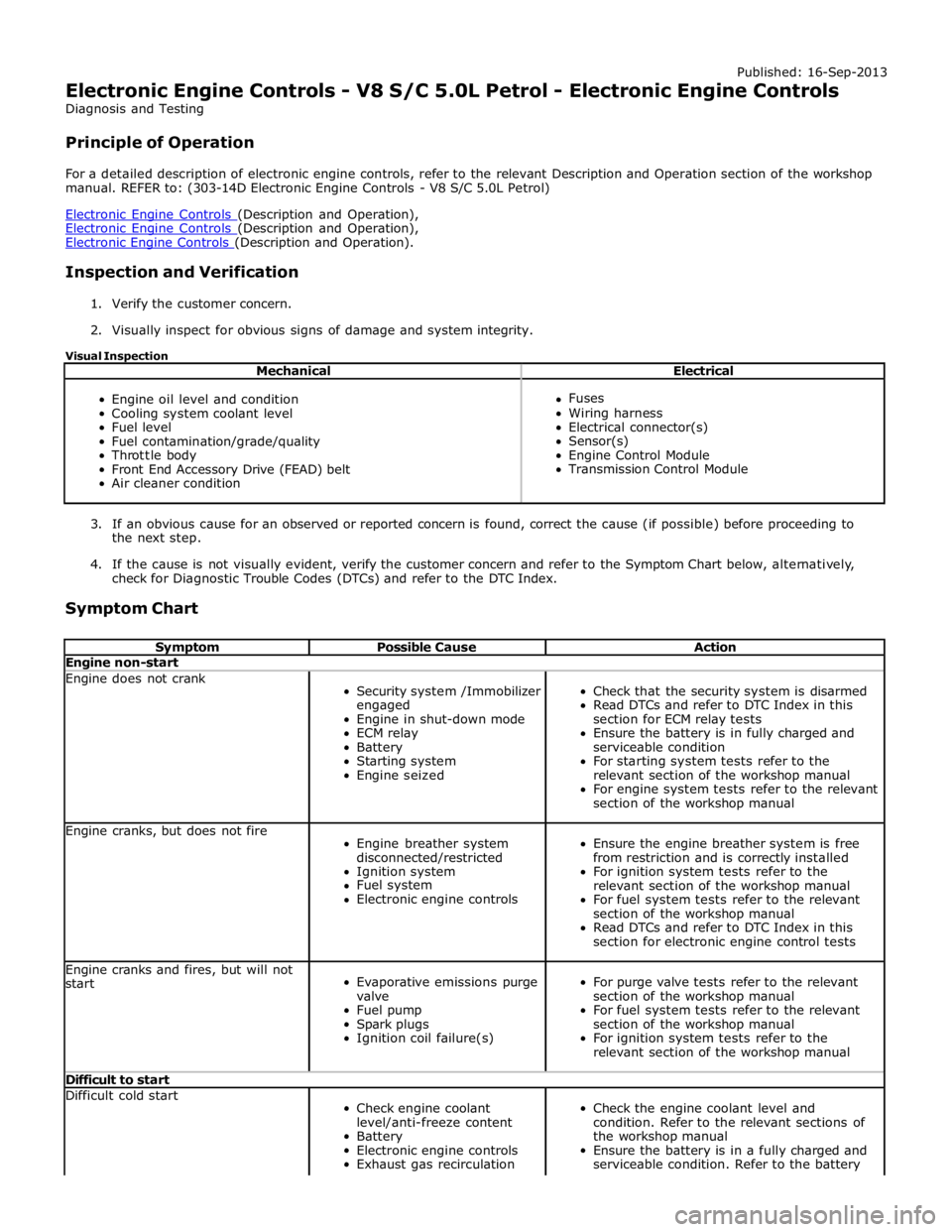

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Engine oil level and condition

Cooling system coolant level

Fuel level

Fuel contamination/grade/quality

Throttle body

Front End Accessory Drive (FEAD) belt

Air cleaner condition

Fuses

Wiring harness

Electrical connector(s)

Sensor(s)

Engine Control Module

Transmission Control Module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the customer concern and refer to the Symptom Chart below, alternatively,

check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Cause Action Engine non-start Engine does not crank

Security system /Immobilizer

engaged

Engine in shut-down mode

ECM relay

Battery

Starting system

Engine seized

Check that the security system is disarmed

Read DTCs and refer to DTC Index in this

section for ECM relay tests

Ensure the battery is in fully charged and

serviceable condition

For starting system tests refer to the

relevant section of the workshop manual

For engine system tests refer to the relevant

section of the workshop manual Engine cranks, but does not fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine controls

Ensure the engine breather system is free

from restriction and is correctly installed

For ignition system tests refer to the

relevant section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

Read DTCs and refer to DTC Index in this

section for electronic engine control tests Engine cranks and fires, but will not

start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

Ignition coil failure(s)

For purge valve tests refer to the relevant

section of the workshop manual

For fuel system tests refer to the relevant

section of the workshop manual

For ignition system tests refer to the

relevant section of the workshop manual Difficult to start Difficult cold start

Check engine coolant

level/anti-freeze content

Battery

Electronic engine controls

Exhaust gas recirculation

Check the engine coolant level and

condition. Refer to the relevant sections of

the workshop manual

Ensure the battery is in a fully charged and

serviceable condition. Refer to the battery

Page 1387 of 3039

Published: 19-Aug-2013

Electronic Engine Controls - V8 S/C 5.0L Petrol - Engine Coolant Temperature

(ECT) Sensor

Removal and Installation

Removal

NOTES:

Some variation in the illustrations may occur, but the essential information is always correct.

Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Cooling System Partial Draining, Filling and Bleeding (303-03B Engine Cooling - V6 3.0L Petrol, General Procedures).

3. Refer to: Catalytic Converter RH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

4. Torque: 48 Nm

Page 1388 of 3039

Installation 5. WARNING: Fluid loss is unavoidable, use absorbent

cloth or a container to collect the fluid.

CAUTION: Engine coolant will damage the paint

finished surfaces. If spilt, immediately remove the coolant

and clean the area with water.

Lift the tang and rotate the engine coolant temperature

(ECT) sensor counter clockwise.

1. To install, reverse the removal procedure.

Page 1487 of 3039

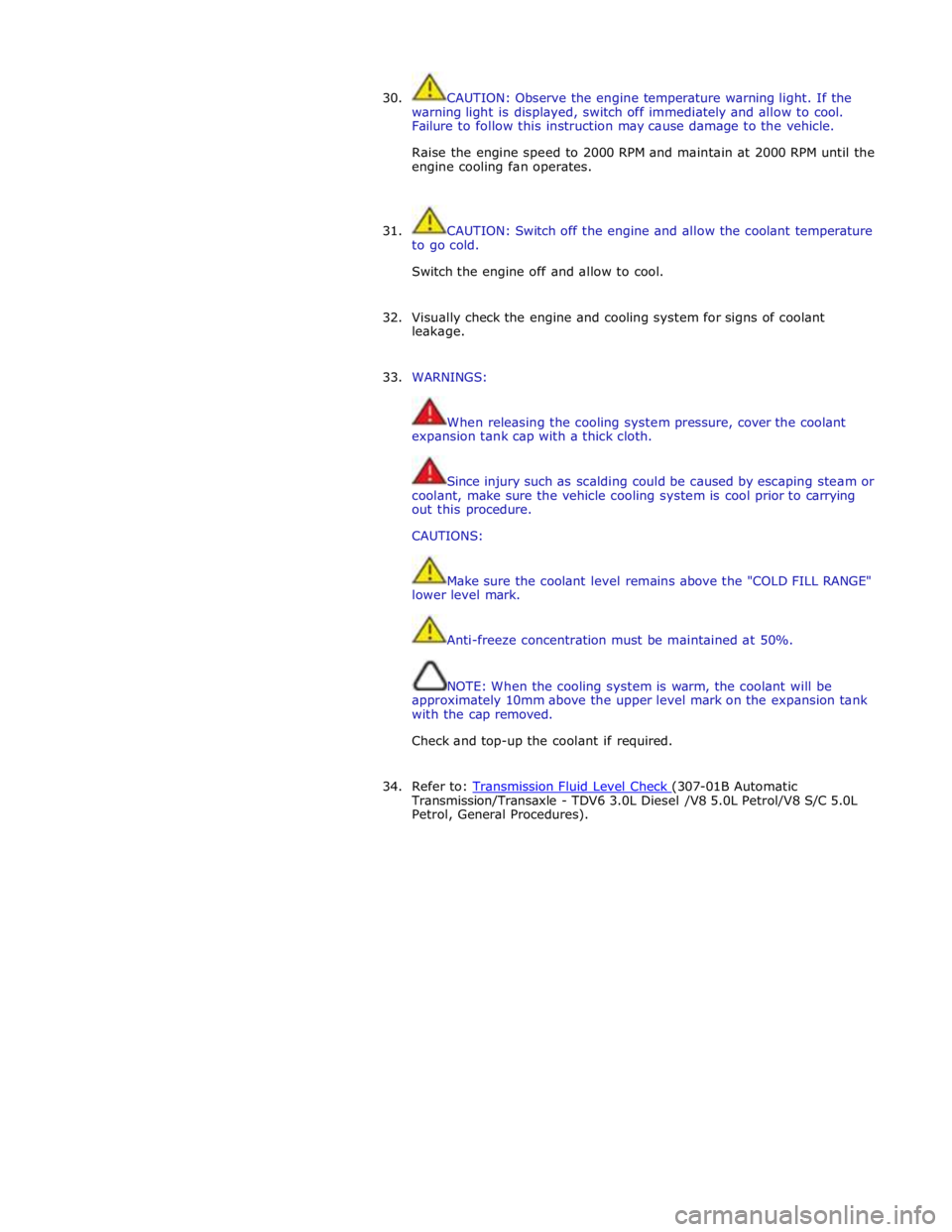

30. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Raise the engine speed to 2000 RPM and maintain at 2000 RPM until the

engine cooling fan operates.

31. CAUTION: Switch off the engine and allow the coolant temperature

to go cold.

Switch the engine off and allow to cool.

32. Visually check the engine and cooling system for signs of coolant

leakage.

33. WARNINGS:

When releasing the cooling system pressure, cover the coolant

expansion tank cap with a thick cloth.

Since injury such as scalding could be caused by escaping steam or

coolant, make sure the vehicle cooling system is cool prior to carrying

out this procedure.

CAUTIONS:

Make sure the coolant level remains above the "COLD FILL RANGE"

lower level mark.

Anti-freeze concentration must be maintained at 50%.

NOTE: When the cooling system is warm, the coolant will be

approximately 10mm above the upper level mark on the expansion tank

with the cap removed.

Check and top-up the coolant if required.

34. Refer to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, General Procedures).

Page 1503 of 3039

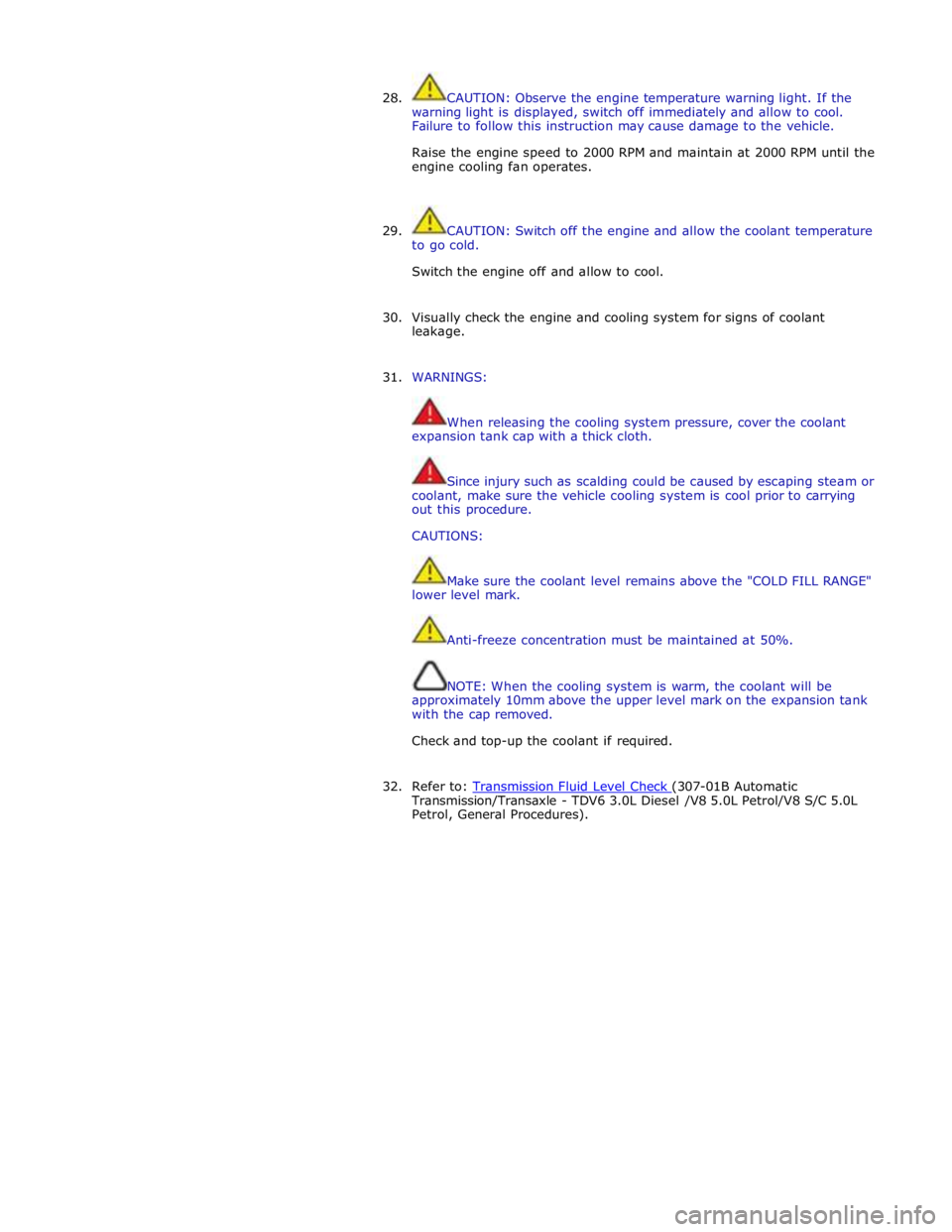

28. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Raise the engine speed to 2000 RPM and maintain at 2000 RPM until the

engine cooling fan operates.

29. CAUTION: Switch off the engine and allow the coolant temperature

to go cold.

Switch the engine off and allow to cool.

30. Visually check the engine and cooling system for signs of coolant

leakage.

31. WARNINGS:

When releasing the cooling system pressure, cover the coolant

expansion tank cap with a thick cloth.

Since injury such as scalding could be caused by escaping steam or

coolant, make sure the vehicle cooling system is cool prior to carrying

out this procedure.

CAUTIONS:

Make sure the coolant level remains above the "COLD FILL RANGE"

lower level mark.

Anti-freeze concentration must be maintained at 50%.

NOTE: When the cooling system is warm, the coolant will be

approximately 10mm above the upper level mark on the expansion tank

with the cap removed.

Check and top-up the coolant if required.

32. Refer to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, General Procedures).

Page 1518 of 3039

1 Latch-plate 2 Feed hose and pipe (from transmission) 3 Transmission fluid cooler 4 Engine coolant hose connections 5 Return hose and pipe (to transmission)

Page 1519 of 3039

Published: 11-May-2011

Transmission/Transaxle Cooling - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Cooling - Overview

Description and Operation

OVERVIEW

Transmission cooling is provided by a transmission fluid cooler, which transfers heat from the transmission to the engine

cooling system. The transmission fluid cooler is attached to a mounting bracket on the front subframe, in the front left corner

of the engine compartment.

Two hose and pipe assemblies connect the transmission fluid cooler to the automatic transmission. Two engine coolant hose

connections are incorporated into the top of the transmission fluid cooler for the supply and return of coolant from the engine

cooling system. For additional information, refer to 303-03D Engine Cooling.

Page 1596 of 3039

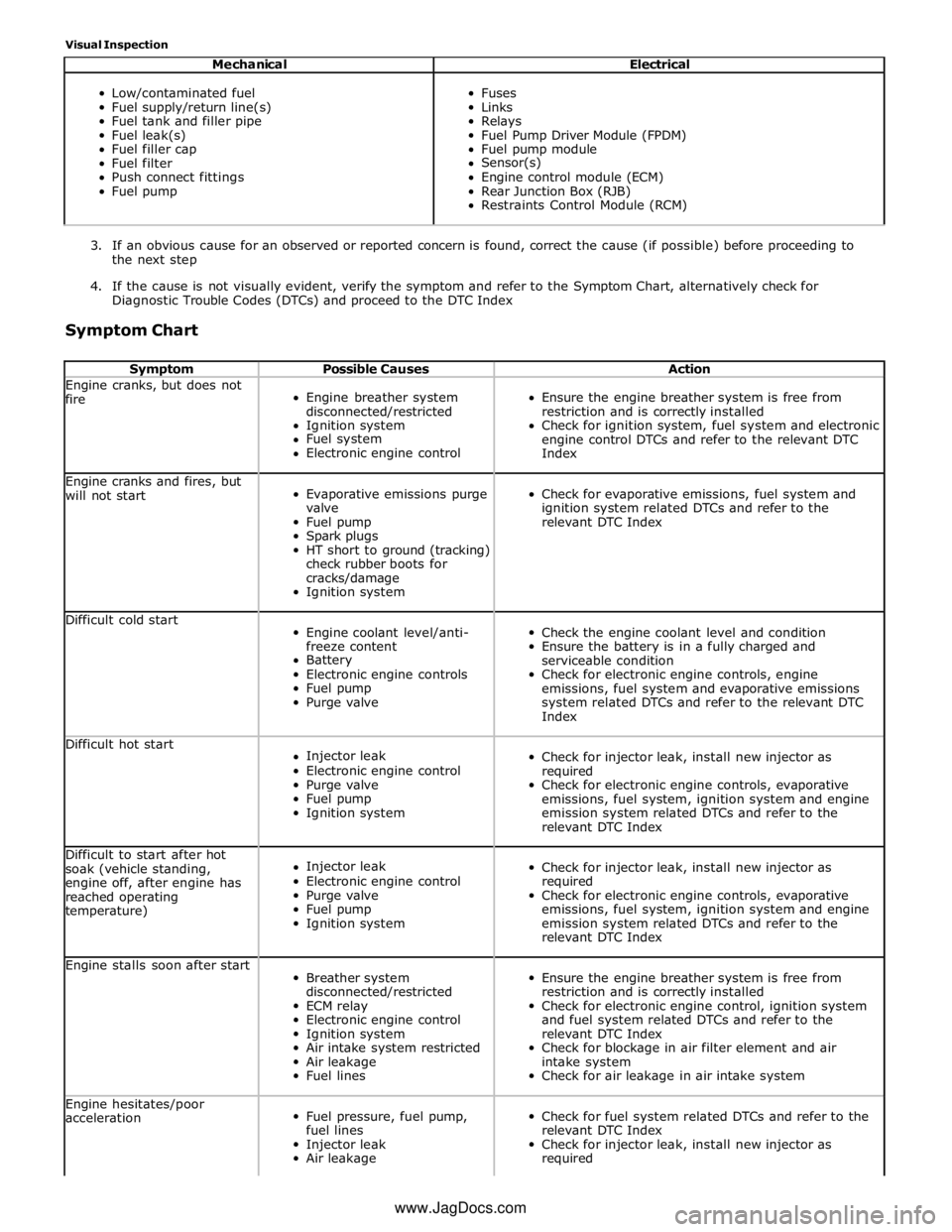

Visual Inspection

Mechanical Electrical

Low/contaminated fuel

Fuel supply/return line(s)

Fuel tank and filler pipe

Fuel leak(s)

Fuel filler cap

Fuel filter

Push connect fittings

Fuel pump

Fuses

Links

Relays

Fuel Pump Driver Module (FPDM)

Fuel pump module

Sensor(s)

Engine control module (ECM)

Rear Junction Box (RJB)

Restraints Control Module (RCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and proceed to the DTC Index

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control

Ensure the engine breather system is free from

restriction and is correctly installed

Check for ignition system, fuel system and electronic

engine control DTCs and refer to the relevant DTC

Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system

Check for evaporative emissions, fuel system and

ignition system related DTCs and refer to the

relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Fuel pump

Purge valve

Check the engine coolant level and condition

Ensure the battery is in a fully charged and

serviceable condition

Check for electronic engine controls, engine

emissions, fuel system and evaporative emissions

system related DTCs and refer to the relevant DTC

Index Difficult hot start

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Difficult to start after hot

soak (vehicle standing,

engine off, after engine has

reached operating

temperature)

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Engine stalls soon after start

Breather system

disconnected/restricted

ECM relay

Electronic engine control

Ignition system

Air intake system restricted

Air leakage

Fuel lines

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine control, ignition system

and fuel system related DTCs and refer to the

relevant DTC Index

Check for blockage in air filter element and air

intake system

Check for air leakage in air intake system Engine hesitates/poor

acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Check for fuel system related DTCs and refer to the

relevant DTC Index

Check for injector leak, install new injector as

required www.JagDocs.com

Page 1693 of 3039

Touch screen display (TSD) 6 Integrated control panel 7 Information control module 8 ATC (automatic temperature control) module 9 Face/Feet distribution stepper motor 10 RH (right-hand) temperature blend stepper motor 11 LH (left-hand) temperature blend stepper motor 12 Windshield (defrost) distribution stepper motor 13 Blower control module 14 RJB (rear junction box) 15 Blower

System Operation

Operation of the heating and ventilation system is controlled by the ATC module. Refer to: Control Components (412-01 Climate Control, Description and Operation).

The system can be operated in automatic or manual mode, with temperature settings selected using the switches on the

integrated control panel.

When the engine is running, coolant is constantly circulated through the heater core by the engine coolant pump and the

auxiliary coolant pump. Where fitted, the auxiliary coolant pump is energized by the CJB on receipt of medium speed CAN bus signals from the ATC module. The CJB broadcasts auxiliary coolant pump status over the medium speed CAN bus for use by other vehicle systems.

The blower is supplied with power by the blower relay on the RJB and connected to ground via the blower control module. The blower control module regulates the voltage across the blower motor to control blower speed. The voltage set by the blower

control module is controlled by a PWM (pulse width modulation) signal from the ATC module. The ATC module uses a feedback signal from the blower control module to monitor blower speed.

Refer to: Control Components (412-01 Climate Control, Description and Operation).

Heater Assembly Component Description

The heater assembly controls the temperature and flow of air supplied to the air distribution ducts. The heater assembly is

mounted on the vehicle centerline, between the instrument panel and the engine bulkhead.

The heater assembly consists of a casing that contains an A/C (air conditioning) evaporator, a heater core, two air distribution

control doors and two temperature blend control doors. On 2.7L diesel vehicles, the heater assembly also contains an electric

booster heater.

Refer to: Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation).

Mounted on the heater casing are four stepper motors. Each of the stepper motors is connected to either an air distribution

control door or a temperature blend control door.

The A/C evaporator is part of the A/C system. Refer to: Air Conditioning (412-01 Climate Control, Description and Operation).

The heater core provides the heat source to warm the air supplied to the passenger compartment. The heater core is an

aluminum two pass, fin and tube heat exchanger, and is installed across the width of the heater housing. Two aluminum tubes

attached to the heater core extend through the engine bulkhead and connect to the engine cooling system. For additional

information, refer to:

Engine Cooling (303-03A, Description and Operation),

Engine Cooling (303-03B Engine Cooling - V6 3.0L Petrol, Description and Operation), Engine Cooling (303-03C, Description and Operation).

Air Inlet Duct

The air inlet duct connects the fresh air inlet in the engine bulkhead to the heater assembly. The air inlet duct is installed

behind the instrument panel on the passenger side.

The air inlet duct consists of a casing that contains a pollen filter, an air inlet door, a blower and a blower control module. A

recirculation air inlet is incorporated into the casing. A servo motor is mounted on the casing and connected to the air inlet

door, to allow selection between fresh and recirculated air.

Refer to: Control Components (412-01 Climate Control, Description and Operation). The pollen filter is part of the air distribution and filtering system.

Refer to: Air Distribution and Filtering (412-01 Climate Control, Description and Operation).

The blower regulates the volume of air flowing through the air inlet duct to the heater assembly. The blower consists of an

open hub, centrifugal fan and an electric motor.

The blower control module regulates the power supply to the blower motor. The blower control module is installed in the air

Page 1767 of 3039

7 ECT (engine coolant temperature) sensor 8 Ambient temperature sensor 9 Electric booster heater 10 Face/Feet distribution stepper motor 11 RH (right-hand) temperature blend stepper motor 12 LH (left-hand) temperature blend stepper motor 13 Windshield (defrost) distribution stepper motor 14 ATC (automatic temperature control) module 15 150 A megafuse

General System Operation

Operation of the electric booster heater is controlled by the ATC module, which communicates with the micro-controller in the booster heater using the LIN bus. The temperature requested by the ATC module is based on:

The ambient air temperature.

The engine coolant temperature.

The temperatures selected on the integrated control panel.

The blower must be running for the electric booster heater to operate.

If electrical load management is in force, electric booster heater performance is reduced. For additional information, refer to:

Electronic Engine Controls (303-14A, Description and Operation),

Electronic Engine Controls (303-14B Electronic Engine Controls - V6 3.0L Petrol, Description and Operation), Electronic Engine Controls (303-14C, Description and Operation).

Electric Booster Heater Component Description

The electric booster heater is installed in the heater assembly, on the downstream side of the heater core. It consists of

ceramic coated thermistor elements, rated at 1.25 kW, and a micro-controller. Electrical power for the booster heater is

supplied by the BJB via a 150 A megafuse installed under the RH front seat.