phone JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2073 of 3039

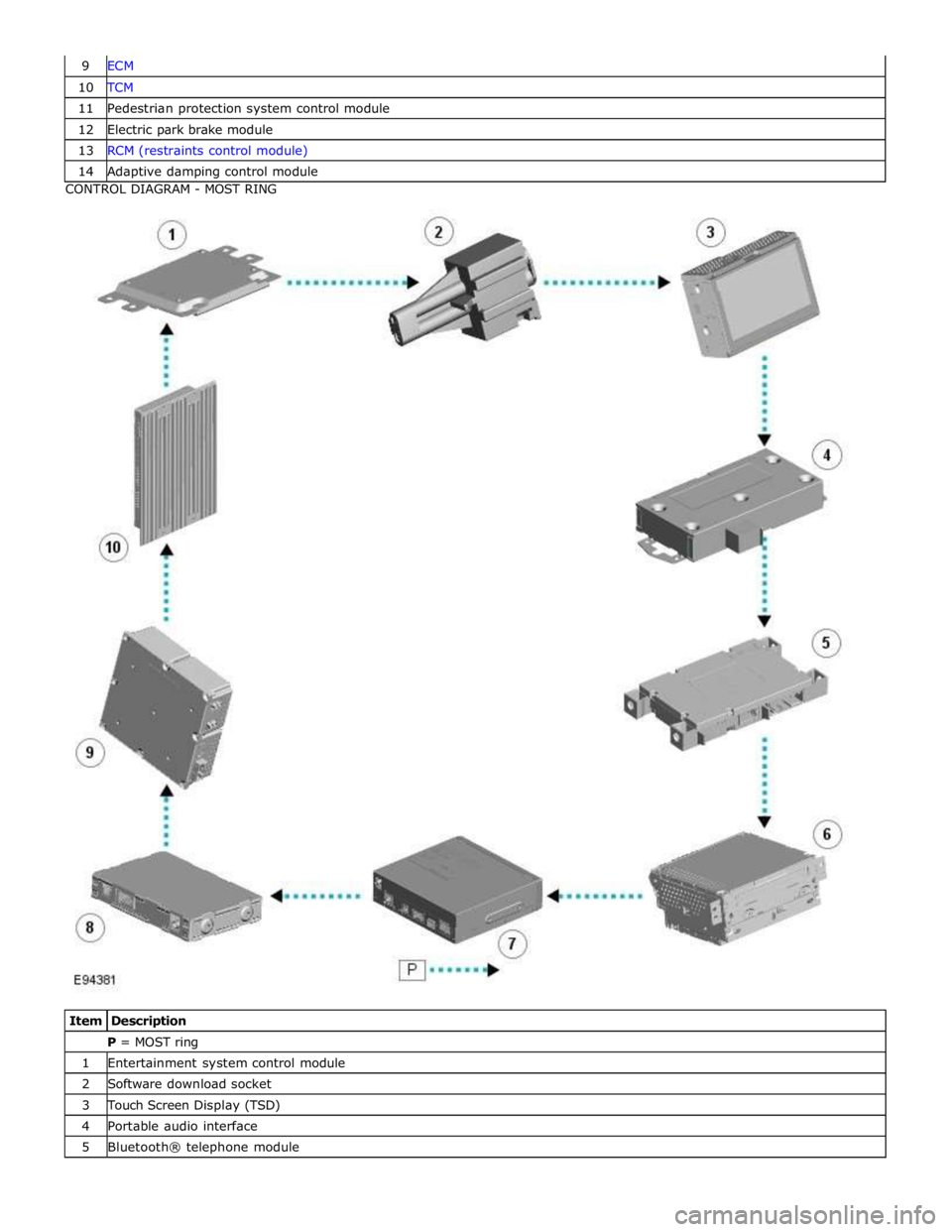

10 TCM 11 Pedestrian protection system control module 12 Electric park brake module 13 RCM (restraints control module) 14 Adaptive damping control module CONTROL DIAGRAM - MOST RING

Item Description P = MOST ring 1 Entertainment system control module 2 Software download socket 3 Touch Screen Display (TSD) 4 Portable audio interface 5 Bluetooth® telephone module

Page 2077 of 3039

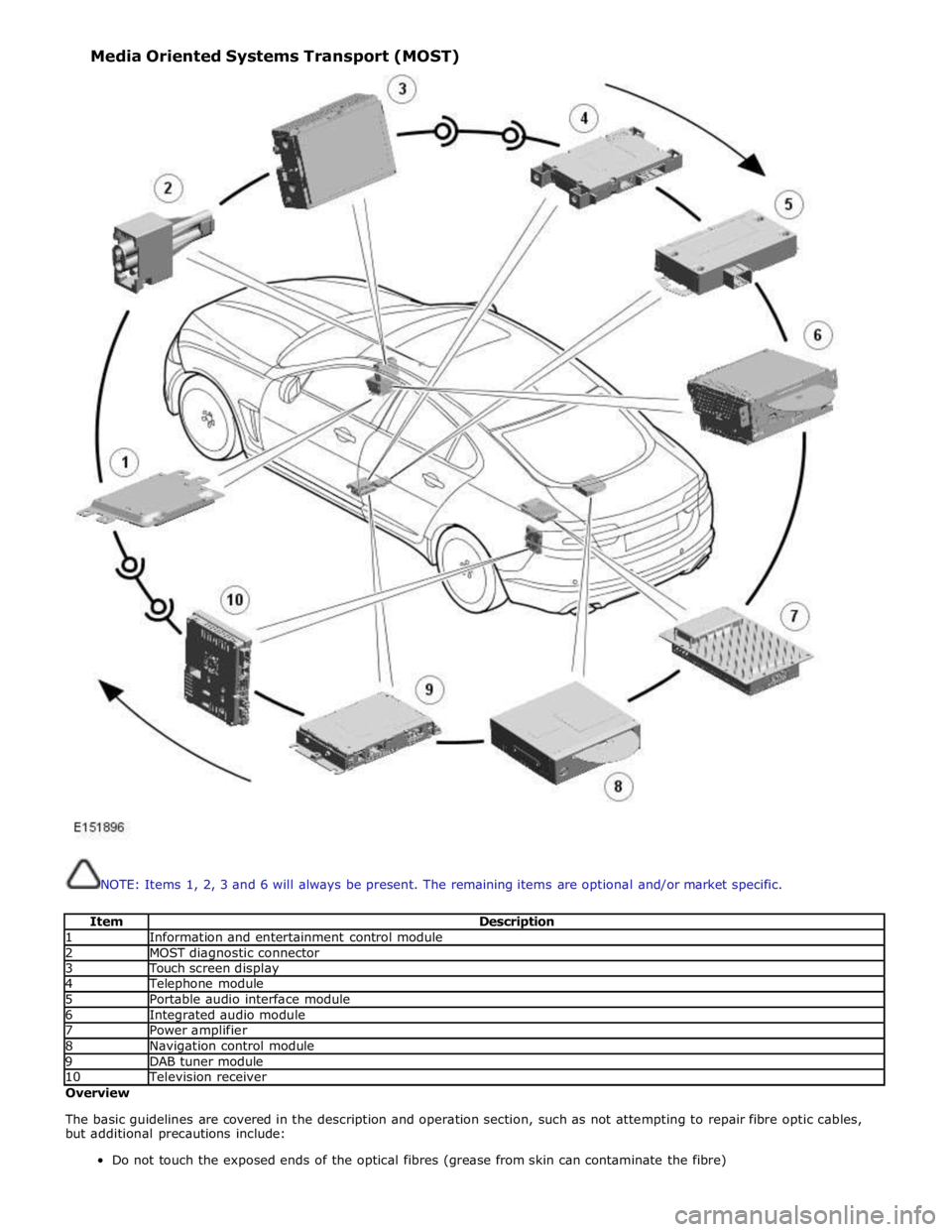

NOTE: Items 1, 2, 3 and 6 will always be present. The remaining items are optional and/or market specific.

Item Description 1 Information and entertainment control module 2 MOST diagnostic connector 3 Touch screen display 4 Telephone module 5 Portable audio interface module 6 Integrated audio module 7 Power amplifier 8 Navigation control module 9 DAB tuner module 10 Television receiver Overview

The basic guidelines are covered in the description and operation section, such as not attempting to repair fibre optic cables,

but additional precautions include:

Do not touch the exposed ends of the optical fibres (grease from skin can contaminate the fibre) Media Oriented Systems Transport (MOST)

Page 2109 of 3039

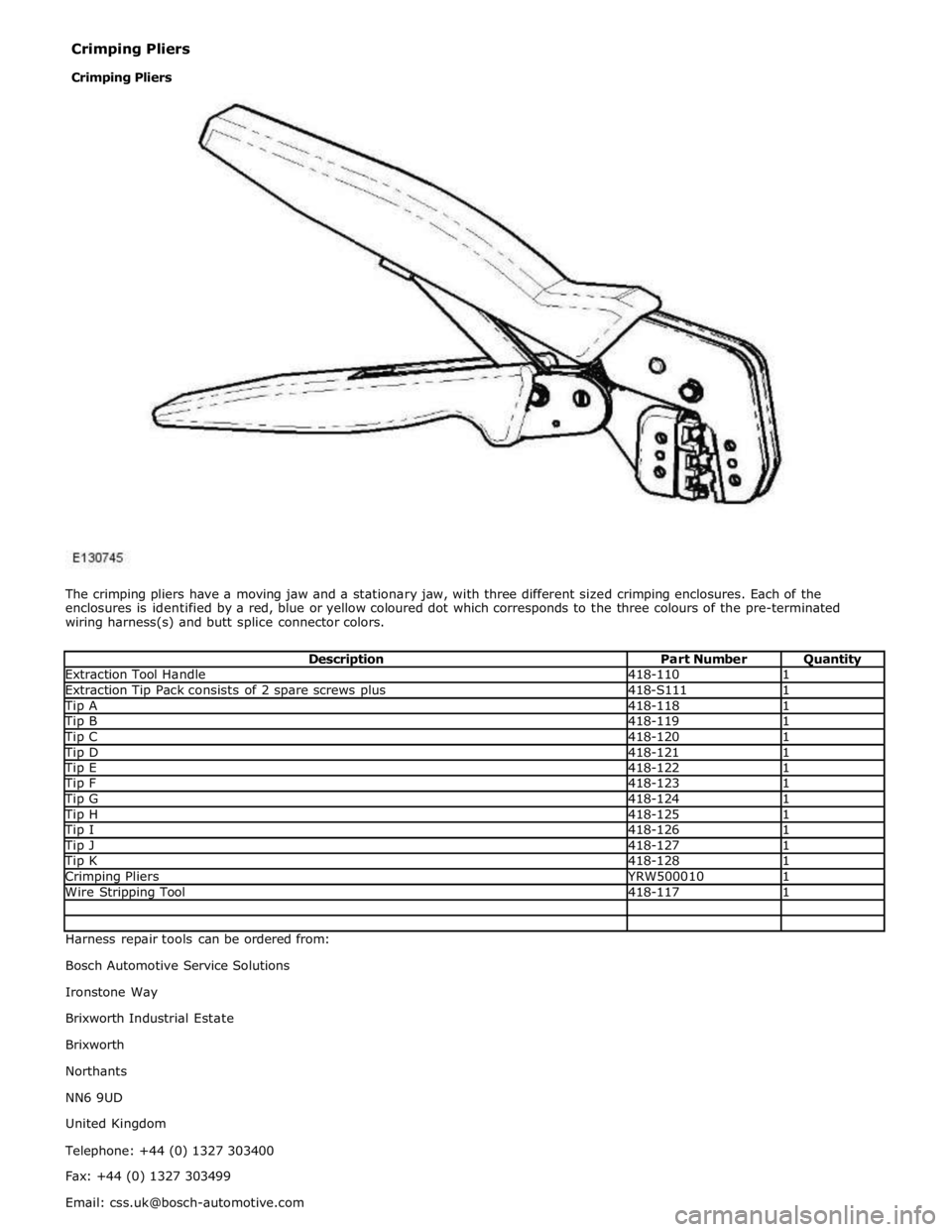

Extraction Tool Handle 418-110 1 Extraction Tip Pack consists of 2 spare screws plus 418-S111 1 Tip A 418-118 1 Tip B 418-119 1 Tip C 418-120 1 Tip D 418-121 1 Tip E 418-122 1 Tip F 418-123 1 Tip G 418-124 1 Tip H 418-125 1 Tip I 418-126 1 Tip J 418-127 1 Tip K 418-128 1 Crimping Pliers YRW500010 1 Wire Stripping Tool 418-117 1 Harness repair tools can be ordered from:

Bosch Automotive Service Solutions

Ironstone Way

Brixworth Industrial Estate

Brixworth

Northants

NN6 9UD

United Kingdom

Telephone: +44 (0) 1327 303400

Fax: +44 (0) 1327 303499

Email: [email protected] Crimping Pliers

Crimping Pliers

Page 2168 of 3039

7 Television (TV) tuner 8 Portable audio interface 9 Blue tooth phone module 10 Software download socket

Page 2172 of 3039

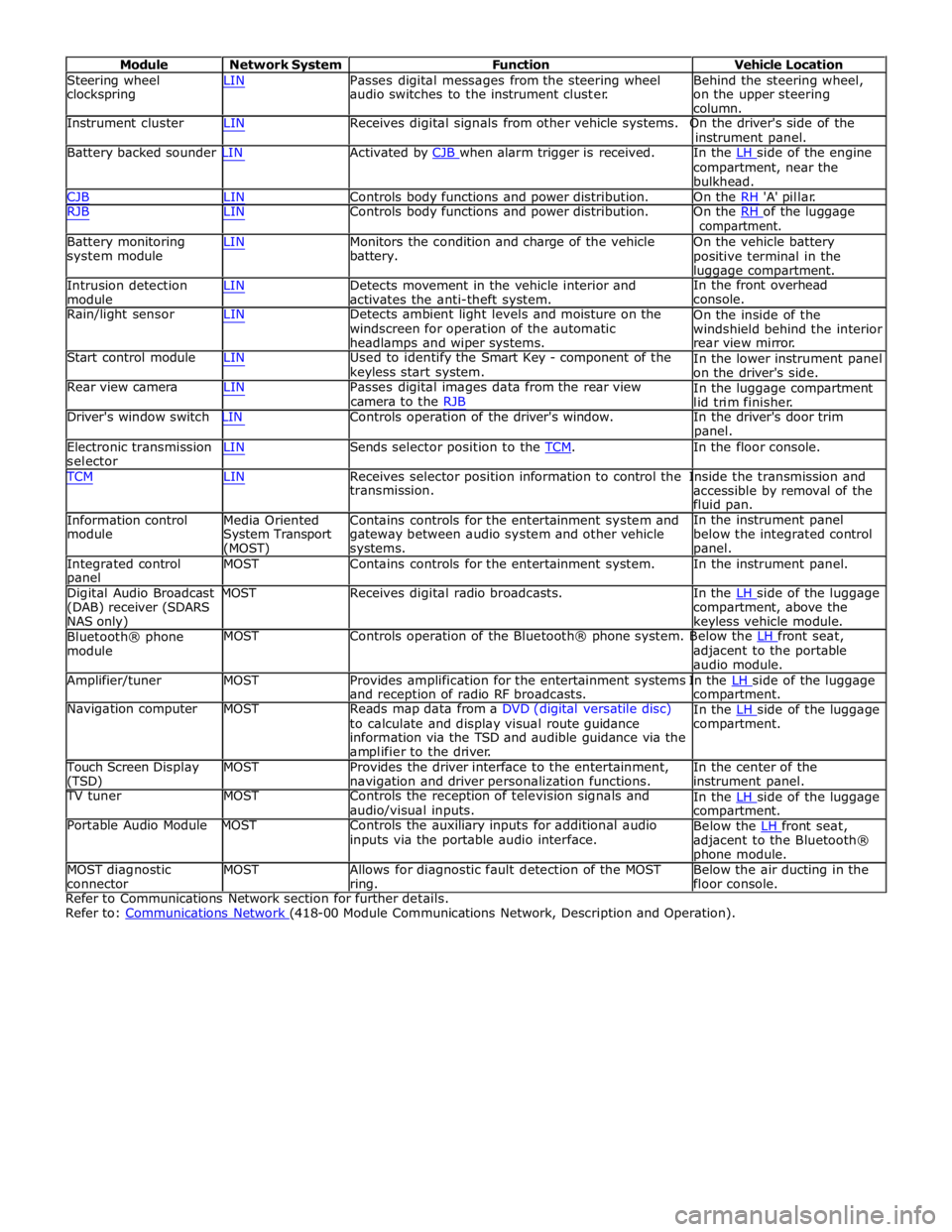

Module Network System Function Vehicle Location

Steering wheel

clockspring LIN Passes digital messages from the steering wheel

audio switches to the instrument cluster. Behind the steering wheel,

on the upper steering

column.

Instrument cluster LIN Receives digital signals from other vehicle systems. On the driver's side of the

instrument panel.

Battery backed sounder LIN Activated by CJB when alarm trigger is received. In the LH side of the engine compartment, near the

bulkhead.

CJB LIN Controls body functions and power distribution. On the RH 'A' pillar.

RJB LIN Controls body functions and power distribution. On the RH of the luggage compartment.

Battery monitoring

system module

Intrusion detection

module LIN Monitors the condition and charge of the vehicle

battery.

LIN Detects movement in the vehicle interior and

activates the anti-theft system. On the vehicle battery

positive terminal in the

luggage compartment.

In the front overhead

console.

Rain/light sensor LIN Detects ambient light levels and moisture on the

windscreen for operation of the automatic

headlamps and wiper systems.

Start control module LIN Used to identify the Smart Key - component of the

keyless start system.

Rear view camera LIN Passes digital images data from the rear view

camera to the RJB On the inside of the

windshield behind the interior

rear view mirror.

In the lower instrument panel

on the driver's side.

In the luggage compartment

lid trim finisher.

Driver's window switch LIN Controls operation of the driver's window. In the driver's door trim

panel.

Electronic transmission

selector LIN Sends selector position to the TCM. In the floor console. TCM LIN Receives selector position information to control the Inside the transmission and

Information control

module

Media Oriented

System Transport

(MOST) transmission.

Contains controls for the entertainment system and

gateway between audio system and other vehicle

systems. accessible by removal of the

fluid pan.

In the instrument panel

below the integrated control

panel.

Integrated control

panel MOST Contains controls for the entertainment system. In the instrument panel.

Digital Audio Broadcast MOST Receives digital radio broadcasts. In the LH side of the luggage (DAB) receiver (SDARS

NAS only)

Bluetooth® phone

module compartment, above the

keyless vehicle module.

MOST Controls operation of the Bluetooth® phone system. Below the LH front seat, adjacent to the portable

audio module.

Amplifier/tuner MOST Provides amplification for the entertainment systems In the LH side of the luggage and reception of radio RF broadcasts.

Navigation computer MOST Reads map data from a DVD (digital versatile disc)

to calculate and display visual route guidance

information via the TSD and audible guidance via the

amplifier to the driver. compartment.

In the LH side of the luggage compartment.

Touch Screen Display

(TSD) MOST Provides the driver interface to the entertainment,

navigation and driver personalization functions. In the center of the

instrument panel.

TV tuner MOST Controls the reception of television signals and

audio/visual inputs.

Portable Audio Module MOST Controls the auxiliary inputs for additional audio

inputs via the portable audio interface. In the LH side of the luggage compartment.

Below the LH front seat, adjacent to the Bluetooth®

phone module.

MOST diagnostic

connector MOST Allows for diagnostic fault detection of the MOST

ring. Below the air ducting in the

floor console.

Refer to Communications Network section for further details.

Refer to: Communications Network (418-00 Module Communications Network, Description and Operation).

Page 2595 of 3039

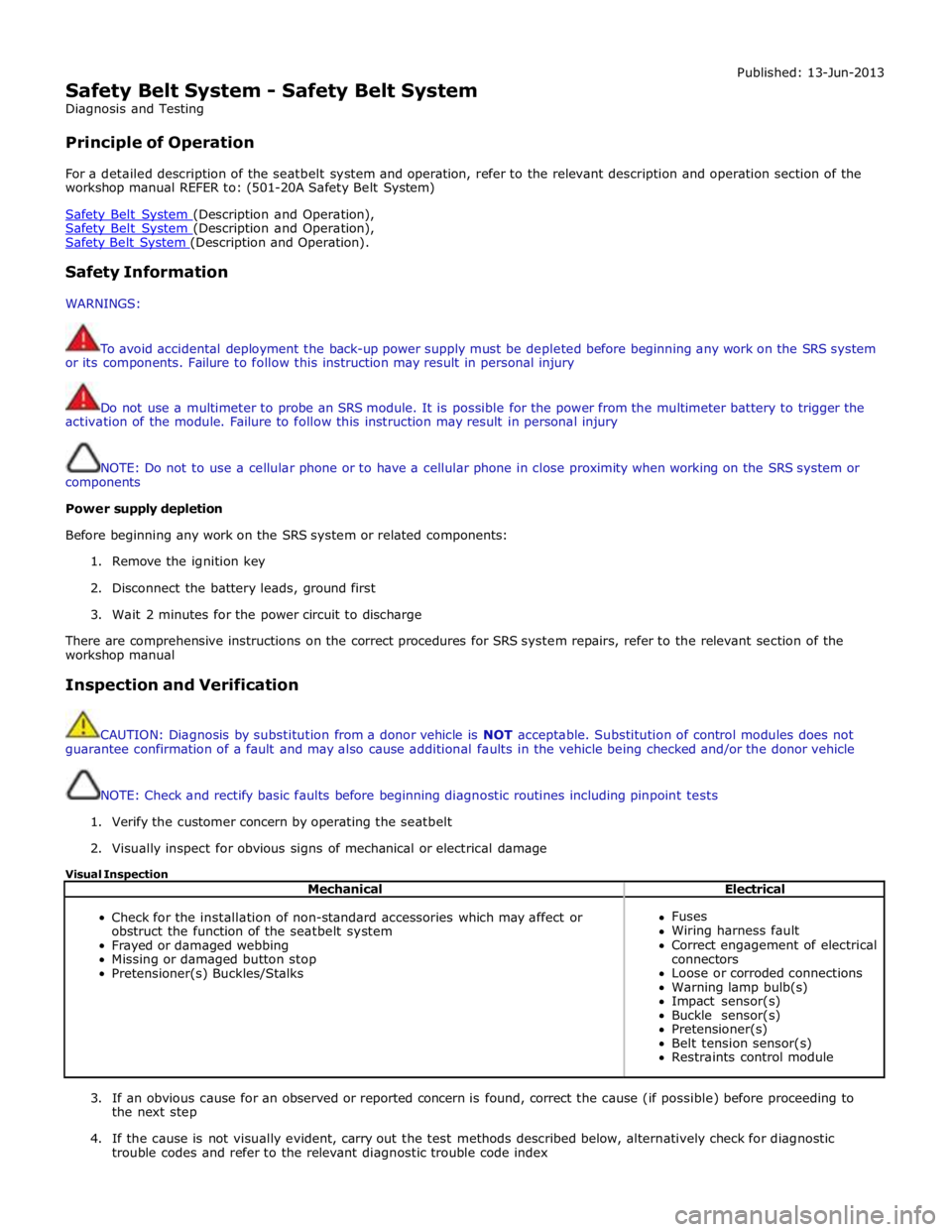

Safety Belt System - Safety Belt System

Diagnosis and Testing

Principle of Operation Published: 13-Jun-2013

For a detailed description of the seatbelt system and operation, refer to the relevant description and operation section of the

workshop manual REFER to: (501-20A Safety Belt System)

Safety Belt System (Description and Operation), Safety Belt System (Description and Operation), Safety Belt System (Description and Operation).

Safety Information

WARNINGS:

To avoid accidental deployment the back-up power supply must be depleted before beginning any work on the SRS system

or its components. Failure to follow this instruction may result in personal injury

Do not use a multimeter to probe an SRS module. It is possible for the power from the multimeter battery to trigger the

activation of the module. Failure to follow this instruction may result in personal injury

NOTE: Do not to use a cellular phone or to have a cellular phone in close proximity when working on the SRS system or

components

Power supply depletion

Before beginning any work on the SRS system or related components:

1. Remove the ignition key

2. Disconnect the battery leads, ground first

3. Wait 2 minutes for the power circuit to discharge

There are comprehensive instructions on the correct procedures for SRS system repairs, refer to the relevant section of the

workshop manual

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle

NOTE: Check and rectify basic faults before beginning diagnostic routines including pinpoint tests

1. Verify the customer concern by operating the seatbelt

2. Visually inspect for obvious signs of mechanical or electrical damage

Visual Inspection

Mechanical Electrical

Check for the installation of non-standard accessories which may affect or

obstruct the function of the seatbelt system

Frayed or damaged webbing

Missing or damaged button stop

Pretensioner(s) Buckles/Stalks

Fuses

Wiring harness fault

Correct engagement of electrical

connectors

Loose or corroded connections

Warning lamp bulb(s)

Impact sensor(s)

Buckle sensor(s)

Pretensioner(s)

Belt tension sensor(s)

Restraints control module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, carry out the test methods described below, alternatively check for diagnostic

trouble codes and refer to the relevant diagnostic trouble code index

Page 2687 of 3039

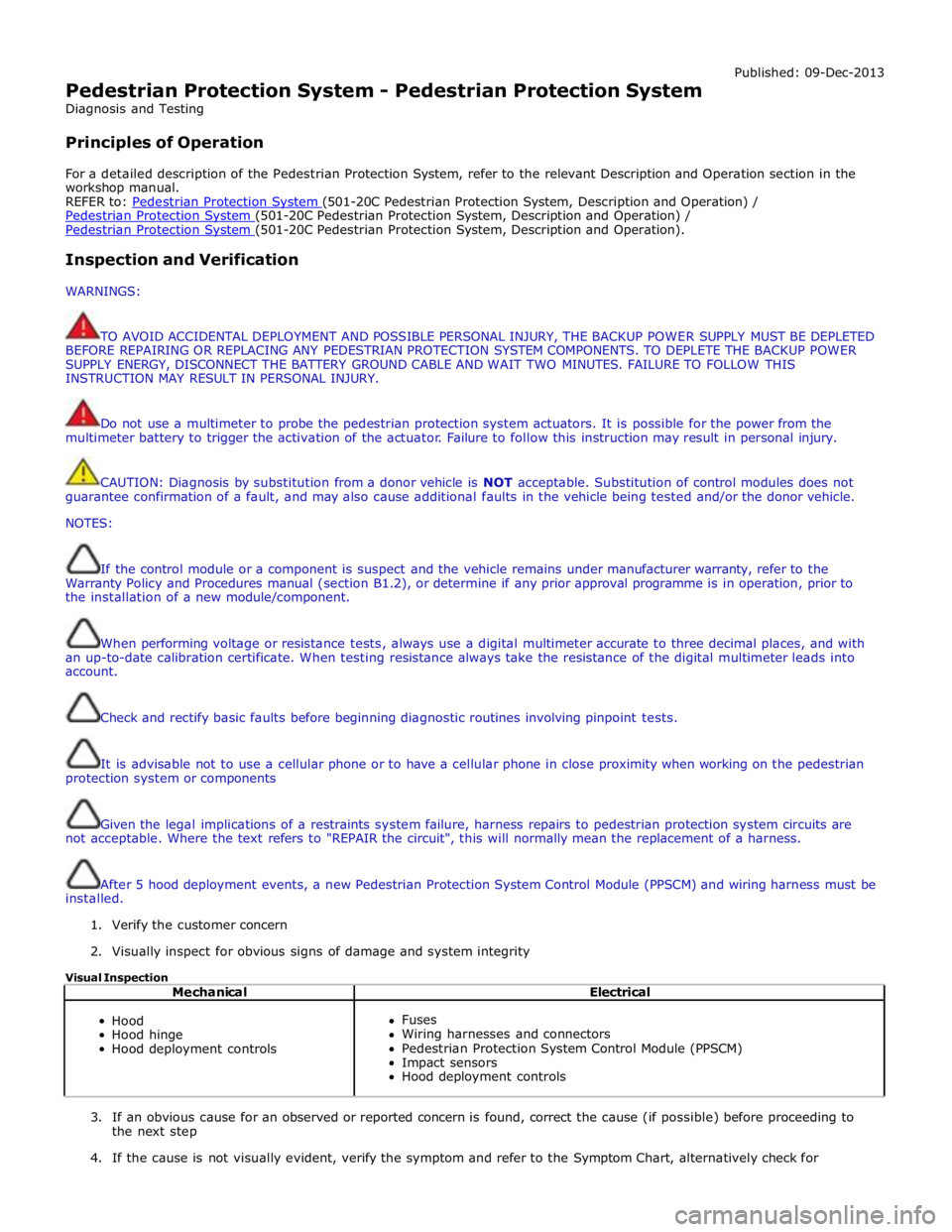

Pedestrian Protection System - Pedestrian Protection System

Diagnosis and Testing

Principles of Operation Published: 09-Dec-2013

For a detailed description of the Pedestrian Protection System, refer to the relevant Description and Operation section in the

workshop manual.

REFER to: Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation) / Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation) / Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation).

Inspection and Verification

WARNINGS:

TO AVOID ACCIDENTAL DEPLOYMENT AND POSSIBLE PERSONAL INJURY, THE BACKUP POWER SUPPLY MUST BE DEPLETED

BEFORE REPAIRING OR REPLACING ANY PEDESTRIAN PROTECTION SYSTEM COMPONENTS. TO DEPLETE THE BACKUP POWER

SUPPLY ENERGY, DISCONNECT THE BATTERY GROUND CABLE AND WAIT TWO MINUTES. FAILURE TO FOLLOW THIS

INSTRUCTION MAY RESULT IN PERSONAL INJURY.

Do not use a multimeter to probe the pedestrian protection system actuators. It is possible for the power from the

multimeter battery to trigger the activation of the actuator. Failure to follow this instruction may result in personal injury.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

It is advisable not to use a cellular phone or to have a cellular phone in close proximity when working on the pedestrian

protection system or components

Given the legal implications of a restraints system failure, harness repairs to pedestrian protection system circuits are

not acceptable. Where the text refers to "REPAIR the circuit", this will normally mean the replacement of a harness.

After 5 hood deployment events, a new Pedestrian Protection System Control Module (PPSCM) and wiring harness must be

installed.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Hood

Hood hinge

Hood deployment controls

Fuses

Wiring harnesses and connectors

Pedestrian Protection System Control Module (PPSCM)

Impact sensors

Hood deployment controls

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Page 2723 of 3039

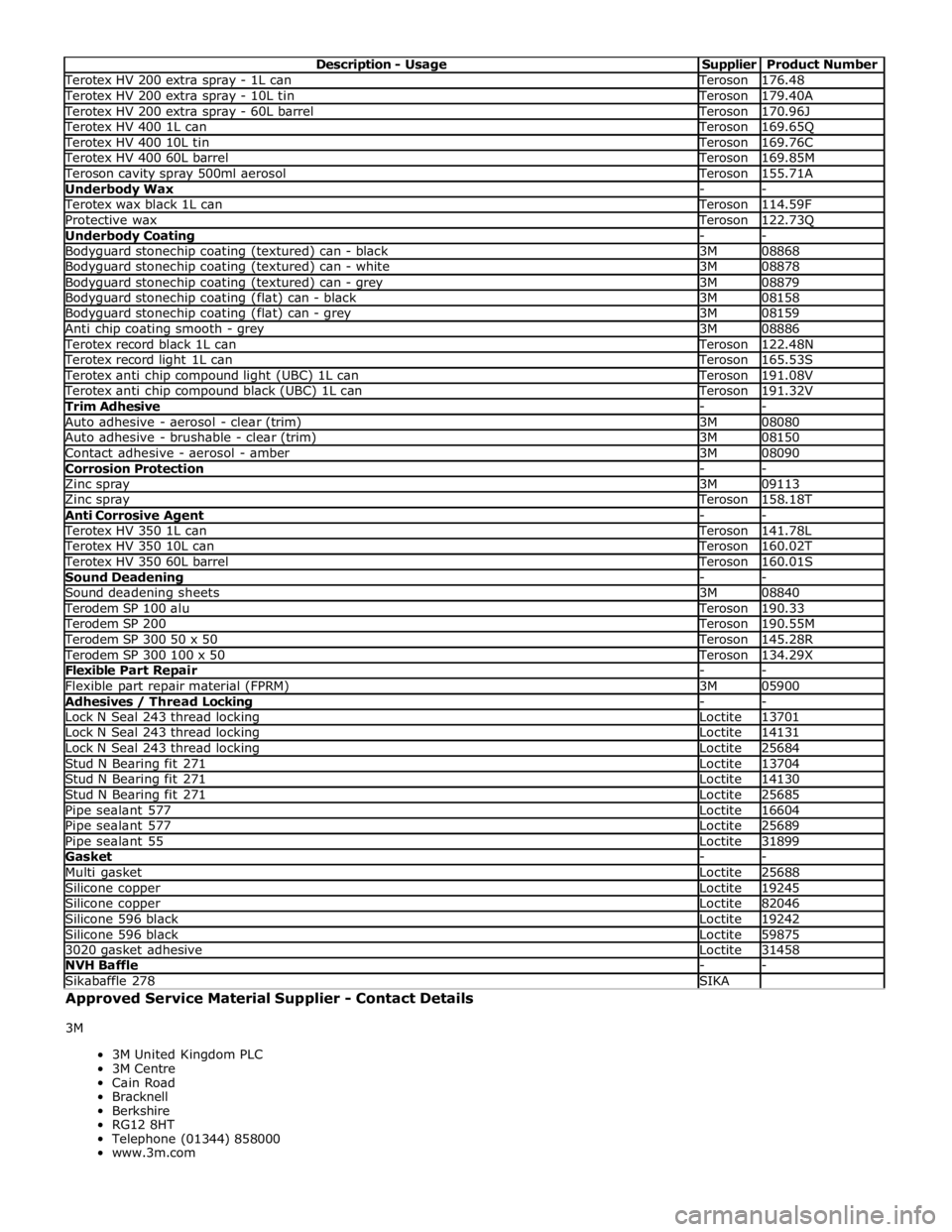

Terotex HV 200 extra spray - 1L can Teroson 176.48 Terotex HV 200 extra spray - 10L tin Teroson 179.40A Terotex HV 200 extra spray - 60L barrel Teroson 170.96J Terotex HV 400 1L can Teroson 169.65Q Terotex HV 400 10L tin Teroson 169.76C Terotex HV 400 60L barrel Teroson 169.85M Teroson cavity spray 500ml aerosol Teroson 155.71A Underbody Wax - - Terotex wax black 1L can Teroson 114.59F Protective wax Teroson 122.73Q Underbody Coating - - Bodyguard stonechip coating (textured) can - black 3M 08868 Bodyguard stonechip coating (textured) can - white 3M 08878 Bodyguard stonechip coating (textured) can - grey 3M 08879 Bodyguard stonechip coating (flat) can - black 3M 08158 Bodyguard stonechip coating (flat) can - grey 3M 08159 Anti chip coating smooth - grey 3M 08886 Terotex record black 1L can Teroson 122.48N Terotex record light 1L can Teroson 165.53S Terotex anti chip compound light (UBC) 1L can Teroson 191.08V Terotex anti chip compound black (UBC) 1L can Teroson 191.32V Trim Adhesive - - Auto adhesive - aerosol - clear (trim) 3M 08080 Auto adhesive - brushable - clear (trim) 3M 08150 Contact adhesive - aerosol - amber 3M 08090 Corrosion Protection - - Zinc spray 3M 09113 Zinc spray Teroson 158.18T Anti Corrosive Agent - - Terotex HV 350 1L can Teroson 141.78L Terotex HV 350 10L can Teroson 160.02T Terotex HV 350 60L barrel Teroson 160.01S Sound Deadening - - Sound deadening sheets 3M 08840 Terodem SP 100 alu Teroson 190.33 Terodem SP 200 Teroson 190.55M Terodem SP 300 50 x 50 Teroson 145.28R Terodem SP 300 100 x 50 Teroson 134.29X Flexible Part Repair - - Flexible part repair material (FPRM) 3M 05900 Adhesives / Thread Locking - - Lock N Seal 243 thread locking Loctite 13701 Lock N Seal 243 thread locking Loctite 14131 Lock N Seal 243 thread locking Loctite 25684 Stud N Bearing fit 271 Loctite 13704 Stud N Bearing fit 271 Loctite 14130 Stud N Bearing fit 271 Loctite 25685 Pipe sealant 577 Loctite 16604 Pipe sealant 577 Loctite 25689 Pipe sealant 55 Loctite 31899 Gasket - - Multi gasket Loctite 25688 Silicone copper Loctite 19245 Silicone copper Loctite 82046 Silicone 596 black Loctite 19242 Silicone 596 black Loctite 59875 3020 gasket adhesive Loctite 31458 NVH Baffle - - Sikabaffle 278 SIKA Approved Service Material Supplier - Contact Details

3M

3M United Kingdom PLC

3M Centre

Cain Road

Bracknell

Berkshire

RG12 8HT

Telephone (01344) 858000

www.3m.com

Page 2724 of 3039

Cooper Pegler

Burgess Hill

Sussex

RH 15 9LA

Telephone (014446) 42526

Sika Ltd

Watchmead

Welwyn Garden City

Hertfordshire

AL7 1BQ

Telephone (01707) 394444

www.sika.co.uk

SATA Spray Equipment

Minden Industrial equipment

16 Greyfriars Road

Moreton Hall

Bury St Edmunds

Suffolk

IP32 7DX

Telephone (01284) 760791

www.sata.com

Henkel Loctite Adhesives Limited

Technologies House

Wood Lane End

Hemel Hempstead

Hertfordshire

HP2 4RQ

Telephone (01442) 278000

www.loctite.co.uk

Teroson

Henkel Ltd

Apollo Court

2 Bishops Square Business Park

Hatfield

Hertfordshire

AL10 9EY

Telephone (01707) 635000

www.henkel.co.uk

Underbody sealer

Under floor areas and the front part of the spare wheel well are treated with a plastisol PVC underbody sealer. This material is

not suitable for re-treatment. When repairing areas of underbody sealer, strip the factory-applied underbody sealer back to a

suitable break point. Ensure that a clean metal surface is exposed and that the edge of the existing adheres soundly to the

panel.

Apply new underbody sealer between primer and surface paint operations. Apply seam sealer as necessary before application

of underbody sealer. Ensure that blanking plugs and grommets in the floor pan (except those used for wax injection) are fitted

before underbody sealer application. Refit any heat-fusible plugs which have been disturbed in repair with the aid of a hot air

blower, or replace with rubber grommets

CAUTION: Ensure that suspension units, wheels, tires, power unit, drive shafts, exhaust and brakes, (including all

mounting points), are shielded prior to application of fresh underbody sealer. www.JagDocs.com