Dtc JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2 of 3039

Table of ContentsContents1: General Information

100: Service Information

100-00: General Information

Description and OperationAbout This Manual

Application and Use of Specifications

Battery and Battery Charging Health and Safety Precautions

Brake System Health and Safety Precautions

Diesel Fuel System Health and Safety Precautions

General Service Information

Health and Safety Precautions

How To Use This Manual

Important Safety Instructions

Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions

Solvents, Sealants and Adhesives

Standard Workshop Practices

Symbols Glossary

Supplemental Restraint System (SRS) Health and Safety Precautions

Road/Roller Testing

Window Glass Health and Safety Precautions

Diagnostic Trouble Code (DTC) IndexDTC: Adaptive Damping Module (SUMB)

Diagnostic Trouble Code (DTC) IndexDTC: Anti-Lock Braking System (ABS)

Diagnostic Trouble Code (DTC) IndexDTC: Audio Amplifier Module (AAM)

Diagnostic Trouble Code (DTC) IndexDTC: Blind Spot Monitoring System Module (SODL/SODR)

Diagnostic Trouble Code (DTC) IndexDTC: Central Junction Box (CJB)

Diagnostic Trouble Code (DTC) IndexDTC: Climate Control Module (HVAC)

Diagnostic Trouble Code (DTC) IndexDTC: Digital Audio Broadcast Module (DABM)

Diagnostic Trouble Code (DTC) IndexDTC: Driver Door Module/Passenger Door Module (DDM/PDM)

Diagnostic Trouble Code (DTC) IndexDTC: Driver/Passenger Seat Module (DSM/PSM)

Diagnostic Trouble Code (DTC) IndexDTC: Electric Parking Brake (PBM)

Diagnostic Trouble Code (DTC) Index V8 S/C 5.0L Petrol, DTC: Engine Control Module (ECM)

Diagnostic Trouble Code (DTC) IndexDTC: Front Seat Climate Control Module (DCSM)

Diagnostic Trouble Code (DTC) IndexDTC: Headlamp Control Module (HCM)

Diagnostic Trouble Code (DTC) IndexDTC: Instrument Cluster (IPC)

Diagnostic Trouble Code (DTC) IndexDTC: Integrated Audio Module (IAM)

Diagnostic Trouble Code (DTC) IndexDTC: Integrated Control Panel (FCIMB)

Page 3 of 3039

Diagnostic Trouble Code (DTC) IndexDTC: Occupant Classification System (OCS)

Diagnostic Trouble Code (DTC) IndexDTC: Parking Aid Module (PAM)

Diagnostic Trouble Code (DTC) IndexDTC: Pedestrian Protection System Control Module (PPSCM)

Diagnostic Trouble Code (DTC) IndexDTC: Rear Differential Control Module (RDCM)

Diagnostic Trouble Code (DTC) IndexDTC: Rear Junction Box (RJB)

Diagnostic Trouble Code (DTC) IndexDTC: Remote Keyless Entry Module (RFA)

Diagnostic Trouble Code (DTC) IndexDTC: Restraints Control Module (RCM)

Diagnostic Trouble Code (DTC) IndexDTC: Satellite Digital Audio Radio System Module (SARM)

Diagnostic Trouble Code (DTC) IndexDTC: Speed Control Module (CCM)

Diagnostic Trouble Code (DTC) IndexDTC: Steering Column Lock Module (VIM)

Diagnostic Trouble Code (DTC) IndexDTC: Television Module (TVM)

Diagnostic Trouble Code (DTC) IndexDTC: Tire Pressure Monitoring System Module (TPM)

Diagnostic Trouble Code (DTC) IndexDTC: Touch Screen Display (FCDIM)

Diagnostic Trouble Code (DTC) IndexVehicles With: 6HP28 6-Speed Automatic Transmission, DTC:

Transmission Control Module (TCM)

Diagnostic Trouble Code (DTC) IndexDTC: Transmission Shift Module (GSM)

Diagnostic Trouble Code (DTC) IndexDTC: Portable Audio Interface Control Module (PAICM)

Diagnostic Trouble Code (DTC) IndexDTC: Hybrid Digital Radio Control Module (HDRCM)

Diagnostic Trouble Code (DTC) IndexDTC: Infotainment Control Module (ICM)

Diagnostic Trouble Code (DTC) IndexDTC: Telephone Module (TEL)100-01: Identification Codes

Description and OperationIdentification Codes100-02: Jacking and Lifting

Description and OperationJacking

Lifting100-04: Noise, Vibration and Harshness

Description and OperationNoise, Vibration and Harshness (NVH)Diagnosis and TestingNoise, Vibration and Harshness (NVH)General ProceduresExhaust System Neutralizing2: Chassis

204: Suspension

204-00: Suspension System - General InformationSpecificationDiagnosis and TestingSuspension SystemGeneral ProceduresCamber and Caster Adjustment

Page 22 of 3039

Operation and

Component DescriptionCellular PhoneComponent

Location

Overview

System Operation

and Component DescriptionNavigation SystemComponent Location

Overview

System Operation and Component DescriptionVideo SystemComponent

Location

Overview

System Operation

and Component DescriptionDiagnosis and TestingInformation and Entertainment SystemRemoval and InstallationAudio Unit

Audio Unit Antenna Amplifier

Audio and Climate Control Assembly

Front Door Speaker

Information and Entertainment Display

Information and Entertainment Module

Instrument Panel Speaker

Rear Door Speaker

Steering Wheel Audio Controls

Subwoofer Amplifier

Subwoofer Speaker

Satellite Radio Tuner415-01B: Information and Entertainment System - DTC: Audio Input Control Module

Diagnosis and TestingAudio Input Control Module417: Lighting

417-01: Exterior LightingSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingHeadlampsGeneral ProceduresHeadlamp Adjustment (86.40.18)

Page 53 of 3039

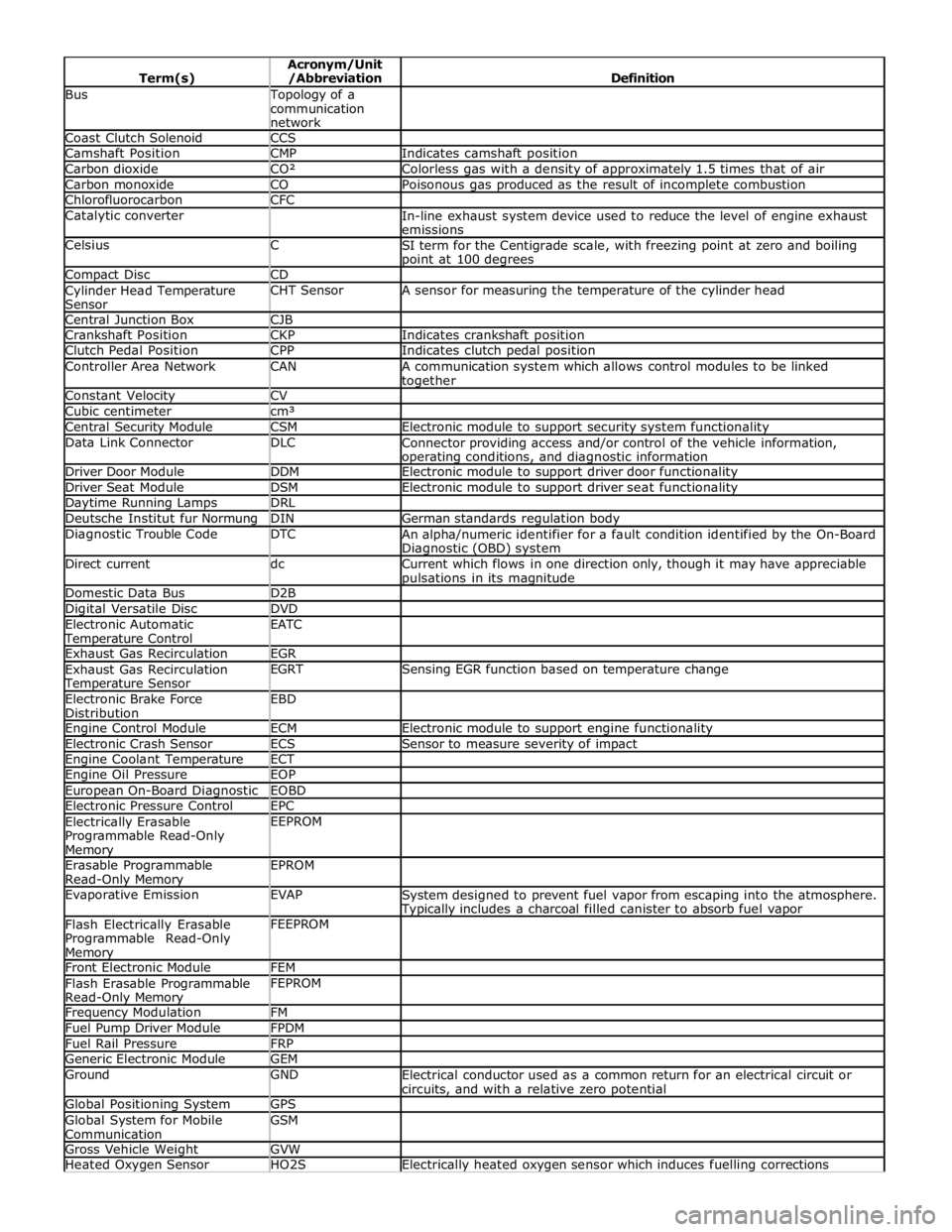

Bus Topology of a

communication

network Coast Clutch Solenoid CCS Camshaft Position CMP Indicates camshaft position Carbon dioxide CO² Colorless gas with a density of approximately 1.5 times that of air Carbon monoxide CO Poisonous gas produced as the result of incomplete combustion Chlorofluorocarbon CFC Catalytic converter

In-line exhaust system device used to reduce the level of engine exhaust

emissions Celsius C

SI term for the Centigrade scale, with freezing point at zero and boiling point at 100 degrees Compact Disc CD Cylinder Head Temperature

Sensor CHT Sensor A sensor for measuring the temperature of the cylinder head Central Junction Box CJB Crankshaft Position CKP Indicates crankshaft position Clutch Pedal Position CPP Indicates clutch pedal position Controller Area Network CAN

A communication system which allows control modules to be linked together Constant Velocity CV Cubic centimeter cm³ Central Security Module CSM Electronic module to support security system functionality Data Link Connector DLC

Connector providing access and/or control of the vehicle information, operating conditions, and diagnostic information Driver Door Module DDM Electronic module to support driver door functionality Driver Seat Module DSM Electronic module to support driver seat functionality Daytime Running Lamps DRL Deutsche Institut fur Normung DIN German standards regulation body Diagnostic Trouble Code DTC

An alpha/numeric identifier for a fault condition identified by the On-Board Diagnostic (OBD) system Direct current dc

Current which flows in one direction only, though it may have appreciable pulsations in its magnitude Domestic Data Bus D2B Digital Versatile Disc DVD Electronic Automatic Temperature Control EATC

Exhaust Gas Recirculation EGR Exhaust Gas Recirculation Temperature Sensor EGRT Sensing EGR function based on temperature change Electronic Brake Force

Distribution EBD

Engine Control Module ECM Electronic module to support engine functionality Electronic Crash Sensor ECS Sensor to measure severity of impact Engine Coolant Temperature ECT Engine Oil Pressure EOP European On-Board Diagnostic EOBD Electronic Pressure Control EPC Electrically Erasable

Programmable Read-Only Memory EEPROM

Erasable Programmable

Read-Only Memory EPROM

Evaporative Emission EVAP

System designed to prevent fuel vapor from escaping into the atmosphere. Typically includes a charcoal filled canister to absorb fuel vapor Flash Electrically Erasable

Programmable Read-Only Memory FEEPROM

Front Electronic Module FEM Flash Erasable Programmable

Read-Only Memory FEPROM

Frequency Modulation FM Fuel Pump Driver Module FPDM Fuel Rail Pressure FRP Generic Electronic Module GEM Ground GND

Electrical conductor used as a common return for an electrical circuit or

circuits, and with a relative zero potential Global Positioning System GPS Global System for Mobile

Communication GSM

Gross Vehicle Weight GVW Heated Oxygen Sensor HO2S Electrically heated oxygen sensor which induces fuelling corrections

Page 106 of 3039

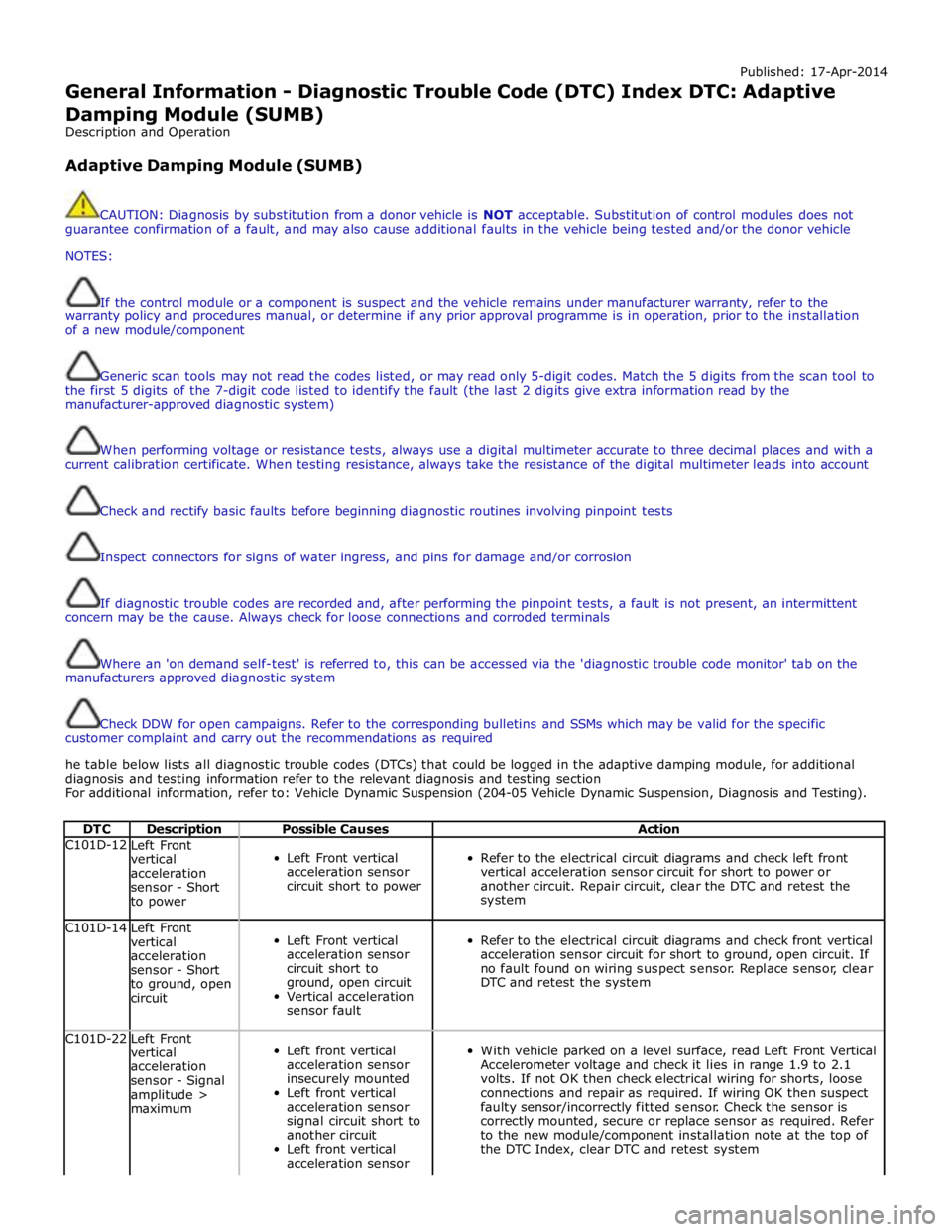

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Adaptive

Damping Module (SUMB)

Description and Operation

Adaptive Damping Module (SUMB)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

he table below lists all diagnostic trouble codes (DTCs) that could be logged in the adaptive damping module, for additional

diagnosis and testing information refer to the relevant diagnosis and testing section

For additional information, refer to: Vehicle Dynamic Suspension (204-05 Vehicle Dynamic Suspension, Diagnosis and Testing).

DTC Description Possible Causes Action C101D-12

Left Front

vertical

acceleration

sensor - Short

to power

Left Front vertical

acceleration sensor

circuit short to power

Refer to the electrical circuit diagrams and check left front

vertical acceleration sensor circuit for short to power or

another circuit. Repair circuit, clear the DTC and retest the

system C101D-14

Left Front

vertical

acceleration

sensor - Short

to ground, open

circuit

Left Front vertical

acceleration sensor

circuit short to

ground, open circuit

Vertical acceleration

sensor fault

Refer to the electrical circuit diagrams and check front vertical

acceleration sensor circuit for short to ground, open circuit. If

no fault found on wiring suspect sensor. Replace sensor, clear

DTC and retest the system C101D-22

Left Front

vertical

acceleration

sensor - Signal

amplitude >

maximum

Left front vertical

acceleration sensor

insecurely mounted

Left front vertical

acceleration sensor

signal circuit short to

another circuit

Left front vertical

acceleration sensor

With vehicle parked on a level surface, read Left Front Vertical

Accelerometer voltage and check it lies in range 1.9 to 2.1

volts. If not OK then check electrical wiring for shorts, loose

connections and repair as required. If wiring OK then suspect

faulty sensor/incorrectly fitted sensor. Check the sensor is

correctly mounted, secure or replace sensor as required. Refer

to the new module/component installation note at the top of

the DTC Index, clear DTC and retest system

Page 107 of 3039

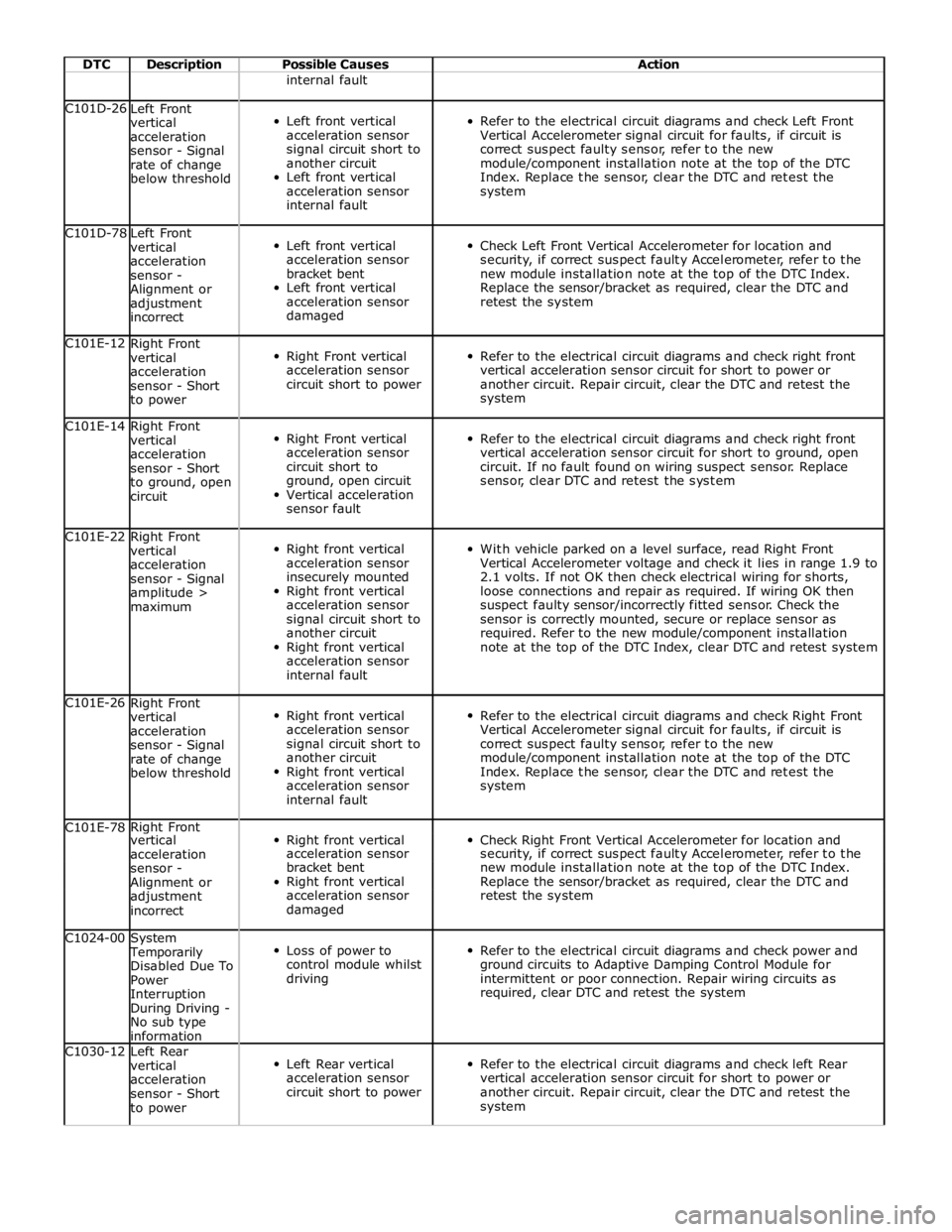

DTC Description Possible Causes Action internal fault

C101D-26

Left Front

vertical

acceleration

sensor - Signal

rate of change

below threshold

Left front vertical

acceleration sensor

signal circuit short to

another circuit

Left front vertical

acceleration sensor

internal fault

Refer to the electrical circuit diagrams and check Left Front

Vertical Accelerometer signal circuit for faults, if circuit is

correct suspect faulty sensor, refer to the new

module/component installation note at the top of the DTC

Index. Replace the sensor, clear the DTC and retest the

system C101D-78

Left Front

vertical

acceleration

sensor -

Alignment or

adjustment

incorrect

Left front vertical

acceleration sensor

bracket bent

Left front vertical

acceleration sensor

damaged

Check Left Front Vertical Accelerometer for location and

security, if correct suspect faulty Accelerometer, refer to the

new module installation note at the top of the DTC Index.

Replace the sensor/bracket as required, clear the DTC and

retest the system C101E-12

Right Front

vertical

acceleration

sensor - Short

to power

Right Front vertical

acceleration sensor

circuit short to power

Refer to the electrical circuit diagrams and check right front

vertical acceleration sensor circuit for short to power or

another circuit. Repair circuit, clear the DTC and retest the

system C101E-14

Right Front

vertical

acceleration

sensor - Short

to ground, open

circuit

Right Front vertical

acceleration sensor

circuit short to

ground, open circuit

Vertical acceleration

sensor fault

Refer to the electrical circuit diagrams and check right front

vertical acceleration sensor circuit for short to ground, open

circuit. If no fault found on wiring suspect sensor. Replace

sensor, clear DTC and retest the system C101E-22

Right Front

vertical

acceleration

sensor - Signal

amplitude >

maximum

Right front vertical

acceleration sensor

insecurely mounted

Right front vertical

acceleration sensor

signal circuit short to

another circuit

Right front vertical

acceleration sensor

internal fault

With vehicle parked on a level surface, read Right Front

Vertical Accelerometer voltage and check it lies in range 1.9 to

2.1 volts. If not OK then check electrical wiring for shorts,

loose connections and repair as required. If wiring OK then

suspect faulty sensor/incorrectly fitted sensor. Check the

sensor is correctly mounted, secure or replace sensor as

required. Refer to the new module/component installation

note at the top of the DTC Index, clear DTC and retest system C101E-26

Right Front

vertical

acceleration

sensor - Signal

rate of change

below threshold

Right front vertical

acceleration sensor

signal circuit short to

another circuit

Right front vertical

acceleration sensor

internal fault

Refer to the electrical circuit diagrams and check Right Front

Vertical Accelerometer signal circuit for faults, if circuit is

correct suspect faulty sensor, refer to the new

module/component installation note at the top of the DTC

Index. Replace the sensor, clear the DTC and retest the

system C101E-78 Right Front

Right front vertical

Check Right Front Vertical Accelerometer for location and vertical acceleration acceleration sensor security, if correct suspect faulty Accelerometer, refer to the sensor - bracket bent new module installation note at the top of the DTC Index. Alignment or Right front vertical Replace the sensor/bracket as required, clear the DTC and adjustment acceleration sensor retest the system incorrect damaged C1024-00

System Temporarily

Disabled Due To

Power

Interruption

During Driving -

No sub type

information

Loss of power to

control module whilst

driving

Refer to the electrical circuit diagrams and check power and

ground circuits to Adaptive Damping Control Module for

intermittent or poor connection. Repair wiring circuits as

required, clear DTC and retest the system C1030-12

Left Rear

vertical

acceleration

sensor - Short

to power

Left Rear vertical

acceleration sensor

circuit short to power

Refer to the electrical circuit diagrams and check left Rear

vertical acceleration sensor circuit for short to power or

another circuit. Repair circuit, clear the DTC and retest the

system

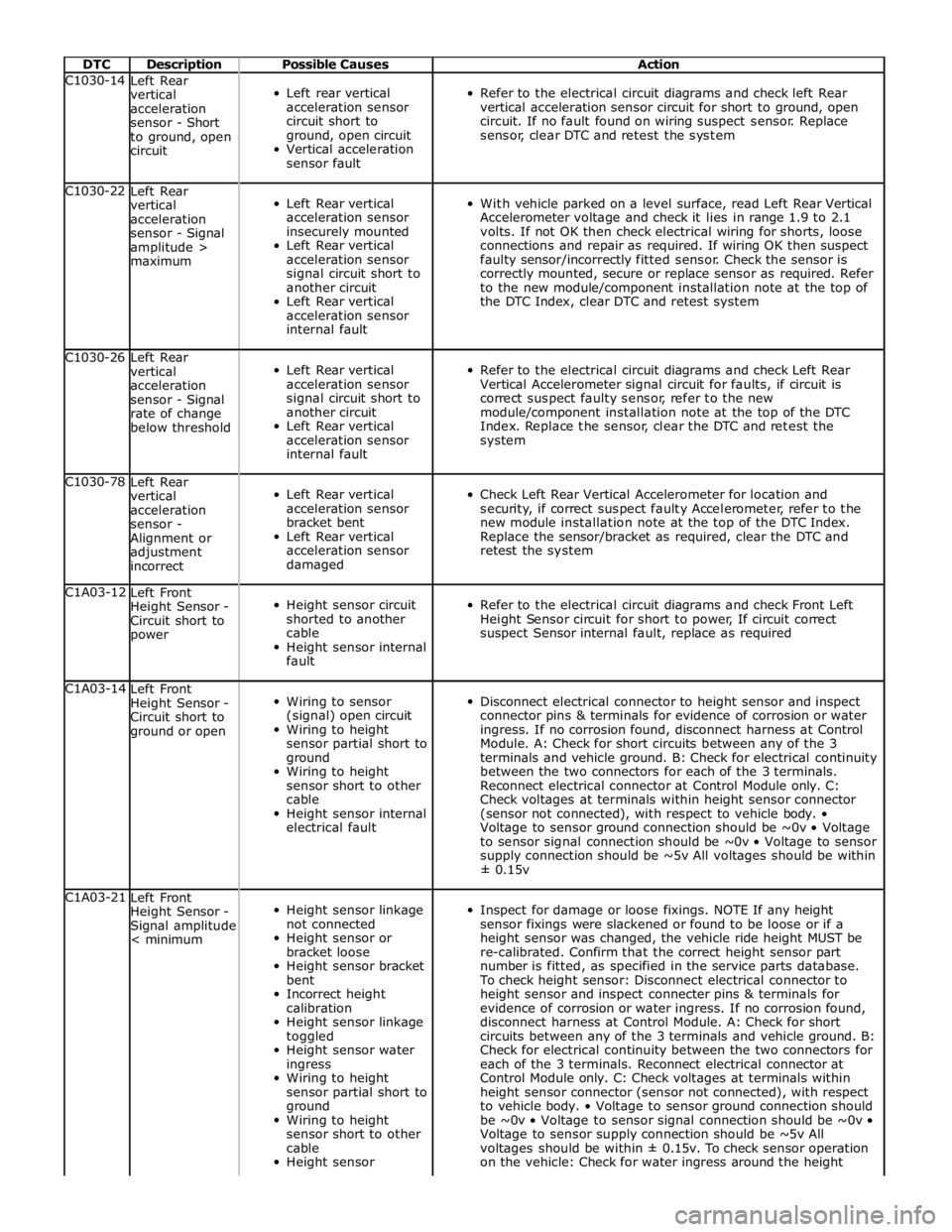

Page 108 of 3039

DTC Description Possible Causes Action C1030-14

Left Rear

vertical

acceleration

sensor - Short

to ground, open

circuit

Left rear vertical

acceleration sensor

circuit short to

ground, open circuit

Vertical acceleration

sensor fault

Refer to the electrical circuit diagrams and check left Rear

vertical acceleration sensor circuit for short to ground, open

circuit. If no fault found on wiring suspect sensor. Replace

sensor, clear DTC and retest the system C1030-22

Left Rear

vertical

acceleration

sensor - Signal

amplitude >

maximum

Left Rear vertical

acceleration sensor

insecurely mounted

Left Rear vertical

acceleration sensor

signal circuit short to

another circuit

Left Rear vertical

acceleration sensor

internal fault

With vehicle parked on a level surface, read Left Rear Vertical

Accelerometer voltage and check it lies in range 1.9 to 2.1

volts. If not OK then check electrical wiring for shorts, loose

connections and repair as required. If wiring OK then suspect

faulty sensor/incorrectly fitted sensor. Check the sensor is

correctly mounted, secure or replace sensor as required. Refer

to the new module/component installation note at the top of

the DTC Index, clear DTC and retest system C1030-26

Left Rear

vertical

acceleration

sensor - Signal

rate of change

below threshold

Left Rear vertical

acceleration sensor

signal circuit short to

another circuit

Left Rear vertical

acceleration sensor

internal fault

Refer to the electrical circuit diagrams and check Left Rear

Vertical Accelerometer signal circuit for faults, if circuit is

correct suspect faulty sensor, refer to the new

module/component installation note at the top of the DTC

Index. Replace the sensor, clear the DTC and retest the

system C1030-78

Left Rear

vertical

acceleration

sensor -

Alignment or

adjustment

incorrect

Left Rear vertical

acceleration sensor

bracket bent

Left Rear vertical

acceleration sensor

damaged

Check Left Rear Vertical Accelerometer for location and

security, if correct suspect faulty Accelerometer, refer to the

new module installation note at the top of the DTC Index.

Replace the sensor/bracket as required, clear the DTC and

retest the system C1A03-12

Left Front

Height Sensor -

Circuit short to

power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Front Left

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A03-14

Left Front

Height Sensor -

Circuit short to

ground or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

± 0.15v C1A03-21

Left Front

Height Sensor -

Signal amplitude

< minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

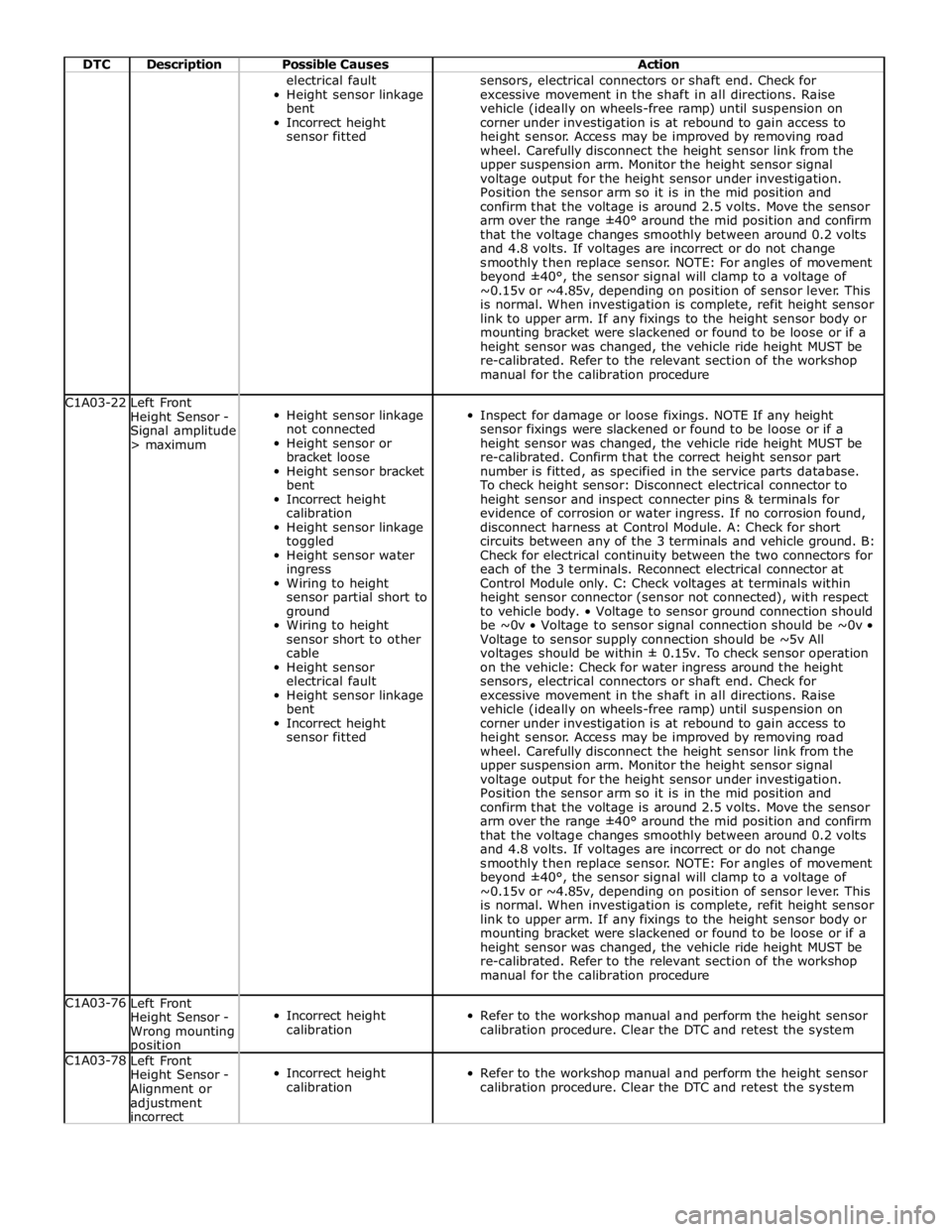

Page 109 of 3039

DTC Description Possible Causes Action electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A03-22

Left Front

Height Sensor -

Signal amplitude

> maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A03-76

Left Front

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A03-78

Left Front

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system

Page 110 of 3039

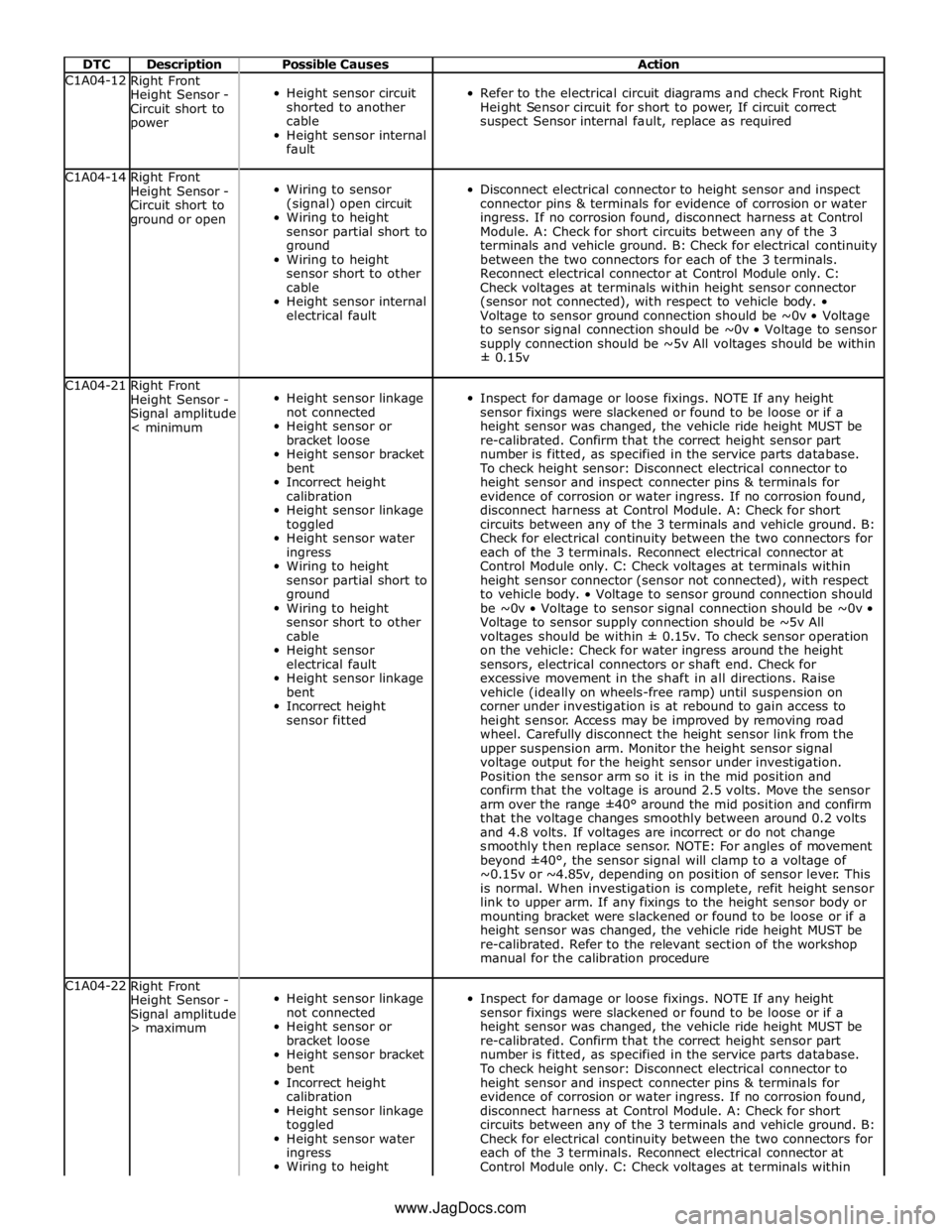

DTC Description Possible Causes Action C1A04-12

Right Front

Height Sensor -

Circuit short to

power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Front Right

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A04-14

Right Front

Height Sensor -

Circuit short to

ground or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

± 0.15v C1A04-21

Right Front

Height Sensor -

Signal amplitude

< minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A04-22

Right Front

Height Sensor -

Signal amplitude

> maximum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within www.JagDocs.com

Page 111 of 3039

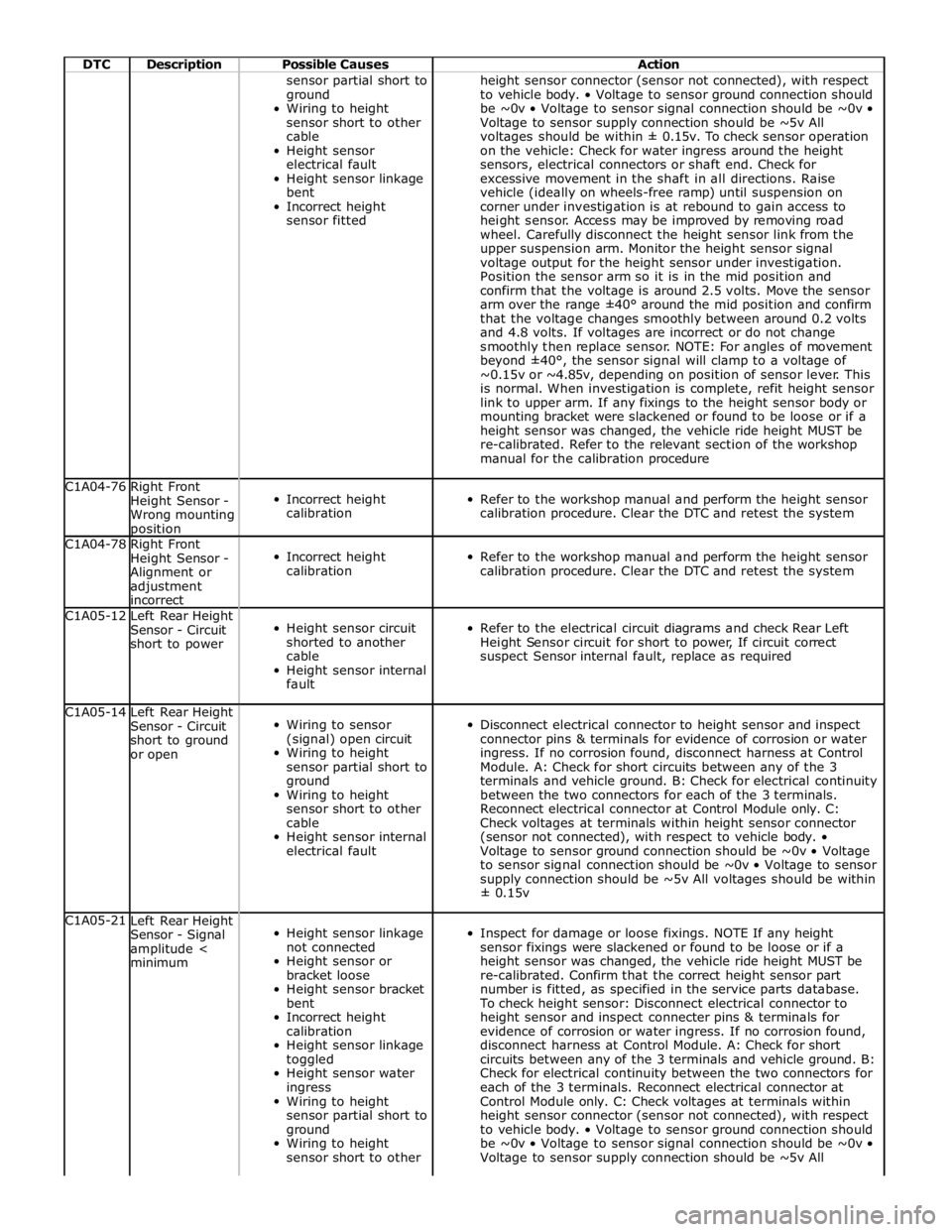

DTC Description Possible Causes Action sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor

electrical fault

Height sensor linkage

bent

Incorrect height

sensor fitted height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All

voltages should be within ± 0.15v. To check sensor operation

on the vehicle: Check for water ingress around the height

sensors, electrical connectors or shaft end. Check for

excessive movement in the shaft in all directions. Raise

vehicle (ideally on wheels-free ramp) until suspension on

corner under investigation is at rebound to gain access to

height sensor. Access may be improved by removing road

wheel. Carefully disconnect the height sensor link from the

upper suspension arm. Monitor the height sensor signal

voltage output for the height sensor under investigation.

Position the sensor arm so it is in the mid position and

confirm that the voltage is around 2.5 volts. Move the sensor

arm over the range ±40° around the mid position and confirm

that the voltage changes smoothly between around 0.2 volts

and 4.8 volts. If voltages are incorrect or do not change

smoothly then replace sensor. NOTE: For angles of movement

beyond ±40°, the sensor signal will clamp to a voltage of

~0.15v or ~4.85v, depending on position of sensor lever. This

is normal. When investigation is complete, refit height sensor

link to upper arm. If any fixings to the height sensor body or

mounting bracket were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Refer to the relevant section of the workshop

manual for the calibration procedure C1A04-76

Right Front

Height Sensor -

Wrong mounting position

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A04-78

Right Front

Height Sensor -

Alignment or

adjustment

incorrect

Incorrect height

calibration

Refer to the workshop manual and perform the height sensor

calibration procedure. Clear the DTC and retest the system C1A05-12

Left Rear Height

Sensor - Circuit

short to power

Height sensor circuit

shorted to another

cable

Height sensor internal

fault

Refer to the electrical circuit diagrams and check Rear Left

Height Sensor circuit for short to power, If circuit correct

suspect Sensor internal fault, replace as required C1A05-14

Left Rear Height

Sensor - Circuit

short to ground

or open

Wiring to sensor

(signal) open circuit

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

cable

Height sensor internal

electrical fault

Disconnect electrical connector to height sensor and inspect

connector pins & terminals for evidence of corrosion or water

ingress. If no corrosion found, disconnect harness at Control

Module. A: Check for short circuits between any of the 3

terminals and vehicle ground. B: Check for electrical continuity

between the two connectors for each of the 3 terminals.

Reconnect electrical connector at Control Module only. C:

Check voltages at terminals within height sensor connector

(sensor not connected), with respect to vehicle body. •

Voltage to sensor ground connection should be ~0v • Voltage

to sensor signal connection should be ~0v • Voltage to sensor

supply connection should be ~5v All voltages should be within

± 0.15v C1A05-21

Left Rear Height

Sensor - Signal

amplitude <

minimum

Height sensor linkage

not connected

Height sensor or

bracket loose

Height sensor bracket

bent

Incorrect height

calibration

Height sensor linkage

toggled

Height sensor water

ingress

Wiring to height

sensor partial short to

ground

Wiring to height

sensor short to other

Inspect for damage or loose fixings. NOTE If any height

sensor fixings were slackened or found to be loose or if a

height sensor was changed, the vehicle ride height MUST be

re-calibrated. Confirm that the correct height sensor part

number is fitted, as specified in the service parts database.

To check height sensor: Disconnect electrical connector to

height sensor and inspect connecter pins & terminals for

evidence of corrosion or water ingress. If no corrosion found,

disconnect harness at Control Module. A: Check for short

circuits between any of the 3 terminals and vehicle ground. B:

Check for electrical continuity between the two connectors for

each of the 3 terminals. Reconnect electrical connector at

Control Module only. C: Check voltages at terminals within

height sensor connector (sensor not connected), with respect

to vehicle body. • Voltage to sensor ground connection should

be ~0v • Voltage to sensor signal connection should be ~0v •

Voltage to sensor supply connection should be ~5v All