battery capacity JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 67 of 3039

Do not empty fuel while working in a workshop or a pit

Ensure that working area is well ventilated

Ensure that any work on the fuel system is only carried out by experienced and well qualified maintenance personnel

Ensure that fume extraction equipment is used where appropriate

Fume extraction equipment must be in operation when solvents are used e.g. Trichloroethane, white spirit, sbp3,

methylene chloride, perchlorethylene. Do not smoke in the vicinity of volatile degreasing agents.

Whenever possible, use a ramp or pit whilst working beneath a vehicle, in preference to jacking. Position chocks at the wheels

as well as applying the parking brake. Never rely on a jack alone to support a vehicle. Use axle stands, or blocks carefully

placed at the jacking points, to provide a rigid location. Check that any lifting equipment used has adequate capacity and is

fully serviceable. Ensure that a suitable form of fire extinguisher is conveniently located. When using electrical tools and

equipment, inspect the power lead for damage and check that it is properly earthed. Disconnect the earth (grounded) terminal

of the vehicle battery. Do not disconnect any pipes of the air conditioning refrigeration system unless you are trained and

instructed to do so. A refrigerant is used which can cause blindness if allowed to come into contact with the eyes. Ensure that

adequate ventilation is provided when volatile degreasing agents are being used.

Adhere strictly to handling and safety instructions given on containers and labels. Keep oils and solvents away from naked

flames and other sources of ignition. Do not apply heat in an attempt to free seized nuts or fittings; as well as causing

damage to protective coatings, there is a risk of damage from stray heat to electronic equipment and brake lines. Do not leave

tools, equipment, spilt oil etc. around the work area. Wear protective overalls and use barrier cream when necessary.

Environmental Protection

In some countries it is illegal to pour used oil onto the ground, down sewers or drains, or into water courses. The burning of

used engine oil in small space heaters or boilers is not recommended unless emission control equipment is installed. Dispose

of used oil through authorized waste disposal contractors, to licensed waste disposal sites or to the waste oil reclamation

trade. If in doubt, contact the Local Authority for advice on disposal facilities.

Page 1344 of 3039

Published: 11-May-2011

Evaporative Emissions - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Evaporative Emissions - System Operation and Component Description

Description and Operation

System Operation DIAGNOSTIC MODULE - TANK LEAKAGE PUMP (NAS ONLY)

To check the fuel tank and the EVAP (evaporative emission) system for leaks, the ECM (engine control module) operates the

DMTL pump and monitors the current draw. Initially, the ECM establishes a reference current by pumping air through the reference orifice and back to atmosphere. Once the reference current is determined, the ECM closes the change-over valve, which seals the EVAP system. The EVAP canister purge valve remains de-energized and is therefore closed. The output from the air pump is diverted from the reference orifice and into the EVAP system.

When the change-over valve is closed, the load on the air pump falls to zero. Providing there are no leaks, the air pump will

begin to pressurize the EVAP system and the load and current draw in the pump increases. By monitoring the rate and level of the current increase, the ECM can determine if there is a leak in the EVAP system.

During normal vehicle operation, 15 seconds after the engine has started, the ECM energizes the heating element in the pump to prevent condensation formation and possible incorrect readings. The heater remains energized until either the engine and

ignition are off (if no DMTL test is running) or until after the DMTL test is completed.

Leaks are classified as:

Minor - equivalent to a hole diameter of 0.5 to 1.0 mm (0.02 to 0.04 in.).

Major - equivalent to a hole diameter of 1.0 mm (0.04 in.) or greater.

The ECM performs a check for major leaks each time the ignition is switched off, providing the following conditions are met: The vehicle speed is zero.

The engine speed is zero.

The atmospheric pressure is above 70 kPa (10.15 lbf/in2

), i.e. the altitude is less than approximately 3047 m (10000

feet).

The ambient temperature is between 0 and 40 °C (32 and 104 °F).

The EVAP canister vapor concentration factor is 5 or less (where 0 is no fuel vapor, 1 is stoichiometric fuel vapor and greater than 1 is rich fuel vapor).

The fuel tank level is valid and between 15 and 85% of nominal capacity.

The engine running time during the previous cycle was more than 10 minutes.

The battery voltage is between 10 and 15 volts.

The last engine off time was more than 180 minutes.

No errors are detected with the EVAP components, the ambient air temperature and the fuel level.

NOTE: A leak test can be performed using a Jaguar recognized diagnostic tool. This overrides the above conditions and is

useful for checking correct system and component operation.

The ECM performs a check for minor leaks after every 2nd major leak check.

When the leak check is complete, the ECM stops the DMTL pump and opens (de-energizes) the change-over valve.

If the fuel filler cap is opened or refueling is detected during the leak check, by a sudden drop in the current draw or a rise in

the fuel level, the ECM aborts the leak check.

If a leak is detected during the check, the ECM stores an appropriate fault code in its memory. If a leak is detected on two consecutive checks, the ECM illuminates the MIL (malfunction indicator lamp) in the instrument cluster on the next drive cycle. The duration of a leak check can be between 60 and 900 seconds depending on the results and fuel tank level.

EVAP CANISTER PURGE VALVE

The ECM waits until the engine is running above 55 °C (131 °F) coolant temperature with closed loop fuel operational before the purging process is activated. Under these conditions the engine should be running smoothly with no warm up enrichment.

The EVAP canister purge valve duty (and flow) is initially ramped slowly because the vapor concentration is unknown (a sudden increase in purge could cause unstable engine running or cause it to stall due to an extremely "rich" air/fuel mixture). The

concentration is then determined from the amount of adjustment that the closed loop fueling is required to make to achieve

the target AFR (air fuel ratio). Once the concentration has been determined, the purge flow can be increased rapidly and the

injected fuel can be pro-actively adjusted to compensate for the known purge vapor and the target AIR control is maintained.

When the purging process is active, fresh air is drawn into the EVAP canister via the DMTL filter and pump on NAS vehicles, or via the vent port on the EVAP canister of non NAS vehicles.

Page 1882 of 3039

11 Secondary battery 12 Dual Battery Junction Box (DBJB) 13 Rear Junction Box (RJB) 14 Megafuse 15 Battery Junction box (BJB) 16 Primary battery

System Operation BATTERY MONITORING SYSTEM - TD4 2.2L DIESEL VEHICLES ONLY

Periodically the battery monitoring system module will instigate a self-calibration routine. To self calibrate, the battery

monitoring system first charges the battery to its full condition.

NOTE: If the vehicle is only driven for short periods the charging process could take a number of days to complete.

Once the battery is fully charged, the battery monitoring system will discharge the battery to approximately 75% of its full

state of charge, but never lower than 12.2 V. The time taken to complete this part of the routine is dependent on the electrical

load on the vehicle.

When the second part of the routine has been successfully completed, the battery monitoring system will return the battery to

its optimum level of charge. The optimum level of charge will be between 12.6 V and 15 V, depending on battery condition,

temperature and loading.

The battery monitoring system module also monitors the battery condition with the engine switched off. If a low voltage

condition is detected the module can request the infotainment system is switched off to protect battery voltage. Once the

infotainment system has been switched off, the vehicle must be run for at least 5 minutes to charge the battery before the

infotainment system can be operated with the engine switched off.

BATTERY MONITORING SYSTEM - SINGLE AND DUAL BATTERY SYSTEM VEHICLES

When the ignition is off (power mode 0), the BMS control module records the primary battery state of charge and begins to

monitor the battery condition from this point.

If the battery state of charge falls by 7%, the BMS control module will monitor the primary battery for 5 minutes. If after the 5

minute monitoring period, the primary battery charge has continued to fall due to the quiescent drain current being too high,

the BMS control module will determine that some control modules are still 'awake'. The BMS control module sends a shutdown

message on the LIN (local interconnect network) bus to the GWM (Gateway Module). The GWM sends a CAN (controller area

network) bus message on both the medium and high speed networks to all control modules, requesting them to shutdown.

The BMS control module will monitor the primary battery state of charge for a further 5 minutes and determine if the primary

battery state of charge is still dropping. If a quiescent drain current continues, the primary battery state of charge will

continue to drop. If the state of charge falls to 12% of the initial monitoring value, the BMS control module determines that

one or more control modules are still awake and a failure to respond to the shutdown request may indicate an error state

within the control module(s).

BMS Low Battery Warning and Energy Management Messages

The BMS continuously monitors the condition of the primary vehicle battery. If excessive battery discharge occurs, the system

will begin to shut down non-essential electrical systems in order to protect the battery.

If the BMS calculates that battery condition is not within set parameters, there are 3 messages that can be displayed, 2 on the

touch screen and 1 on the message center. These inform the user that the battery is either at a low level of charge or the

engine-off power consumption limit has been exceeded.

Low Battery - Please switch engine on or system will shutdown in 3 minutes: is displayed as a Warning on the

touch screen if the engine is not running. This indicates that the battery has fallen below a predefined threshold. As

soon as the battery is charged back above this threshold then the message will be removed.

Low Battery - Please start your engine is displayed on the message center if the engine is not running. This indicates

that the battery has fallen below a predefined threshold. As soon as the battery is charged back above this threshold

then the message will be removed or it can be manually removed by pressing 'OK'.

System will shut down in 3 minutes: is displayed as an Energy management on the touch screen if the engine is not

running, and system features are causing excessive battery discharge. After 3 minutes the BMS will begin shutting

down vehicle systems. Normal system operation will resume when the engine is started.

This is based on a percentage of battery capacity available for the customer to use with the engine off. The percentage can

change based upon several factors.

Once triggered, the resetting of this message will not occur until the vehicle is driven for 10 minutes with the engine running

(to allow the battery to recoup any lost charge). However, if the engine is run for less than 10 minutes, the message will only

be displayed after an additional 5 minutes with the ignition on but engine off.

BMS Control Module Self Calibration

Periodically the BMS control module will instigate a self-calibration routine. To self calibrate, the battery monitoring system www.JagDocs.com

Page 1898 of 3039

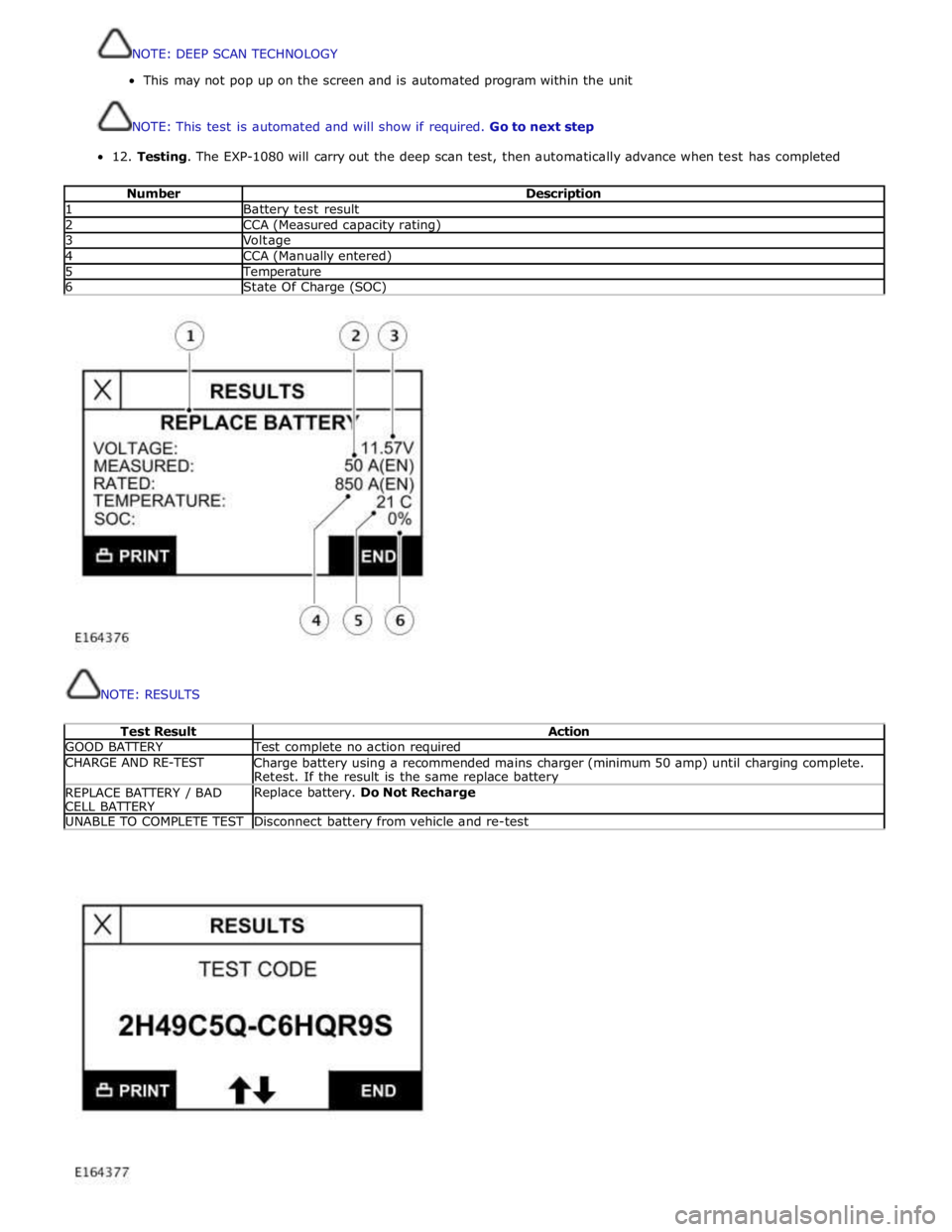

12.

Testing.

The

EXP-1080

will

carry

out

the

deep

scan

test,

then

automatically

advance

when test

has

completed

Number

Description 1

Battery

test

result 2

CCA

(Measured

capacity

rating) 3

Voltage 4

CCA

(Manually

entered) 5

Temperature 6

State

Of

Charge

(SOC)

NOTE:

RESULTS

Test

Result

Action GOOD

BATTERY

Test

complete

no

action required CHARGE

AND RE-TEST

Charge

battery

using a

recommended

mains

charger

(minimum 50 amp)

until

charging

complete.

Retest.

If

the

result

is

the

same replace battery REPLACE

BATTERY

/ BAD

CELL

BATTERY

Replace

battery.

Do

Not

Recharge UNABLE

TO

COMPLETE

TEST

Disconnect

battery

from

vehicle

and re-test

NOTE:DEEPSCANTECHNOLOGY

Thismaynotpop uponthescreen and isautomatedprogramwithin theunit

NOTE:Thistestisautomatedandwillshow ifrequired.Gotonextstep

Page 2014 of 3039

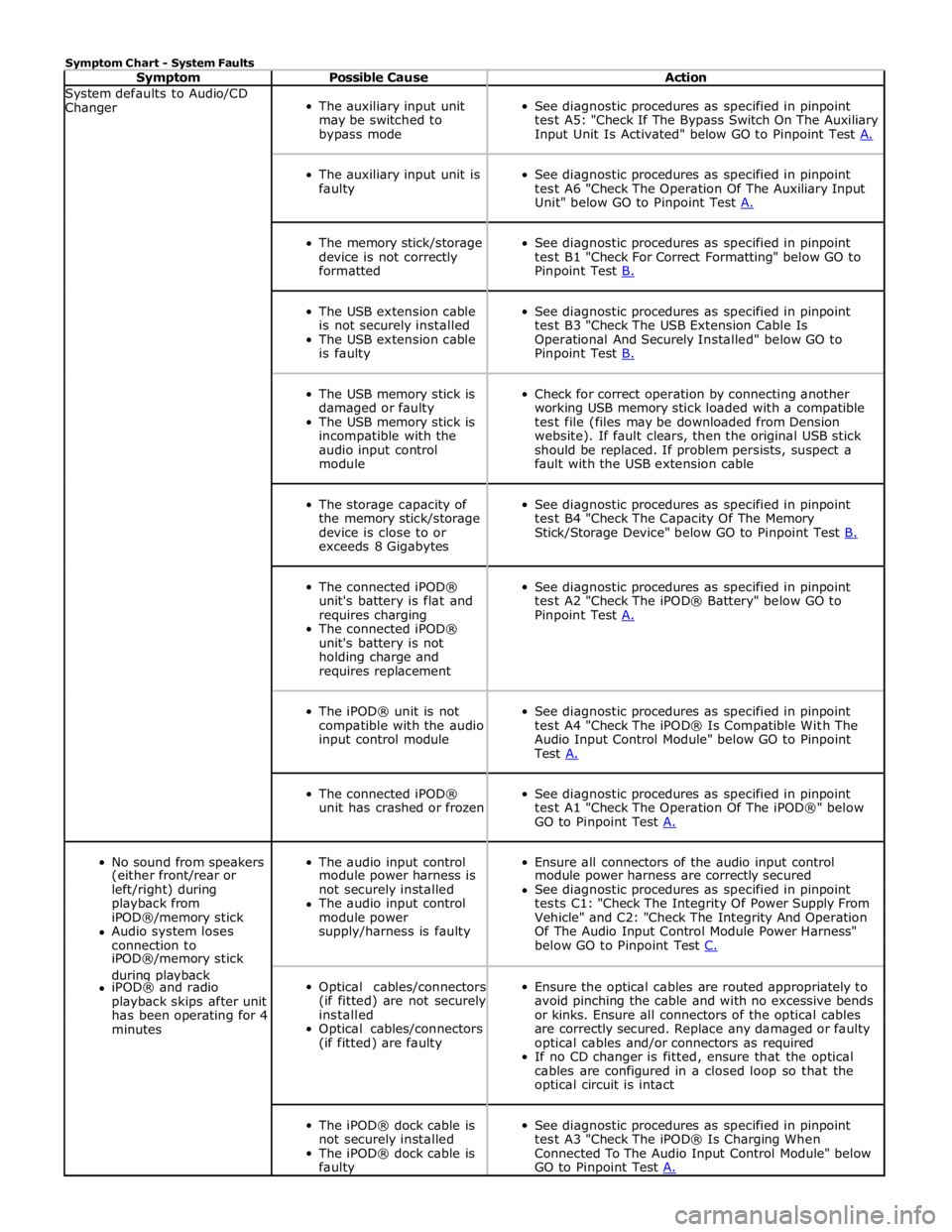

Symptom Chart - System Faults

Symptom Possible Cause Action System defaults to Audio/CD

Changer

The auxiliary input unit

may be switched to

bypass mode

See diagnostic procedures as specified in pinpoint

test A5: "Check If The Bypass Switch On The Auxiliary

Input Unit Is Activated" below GO to Pinpoint Test A.

The auxiliary input unit is

faulty

See diagnostic procedures as specified in pinpoint

test A6 "Check The Operation Of The Auxiliary Input

Unit" below GO to Pinpoint Test A.

The memory stick/storage

device is not correctly

formatted

See diagnostic procedures as specified in pinpoint

test B1 "Check For Correct Formatting" below GO to

Pinpoint Test B.

The USB extension cable

is not securely installed

The USB extension cable

is faulty

See diagnostic procedures as specified in pinpoint

test B3 "Check The USB Extension Cable Is

Operational And Securely Installed" below GO to

Pinpoint Test B.

The USB memory stick is

damaged or faulty

The USB memory stick is

incompatible with the

audio input control

module

Check for correct operation by connecting another

working USB memory stick loaded with a compatible

test file (files may be downloaded from Dension

website). If fault clears, then the original USB stick

should be replaced. If problem persists, suspect a

fault with the USB extension cable

The storage capacity of

the memory stick/storage

device is close to or

exceeds 8 Gigabytes

See diagnostic procedures as specified in pinpoint

test B4 "Check The Capacity Of The Memory

Stick/Storage Device" below GO to Pinpoint Test B.

The connected iPOD®

unit's battery is flat and

requires charging

The connected iPOD®

unit's battery is not

holding charge and

requires replacement

See diagnostic procedures as specified in pinpoint

test A2 "Check The iPOD® Battery" below GO to

Pinpoint Test A.

The iPOD® unit is not

compatible with the audio

input control module

See diagnostic procedures as specified in pinpoint

test A4 "Check The iPOD® Is Compatible With The

Audio Input Control Module" below GO to Pinpoint

Test A.

The connected iPOD®

unit has crashed or frozen

See diagnostic procedures as specified in pinpoint

test A1 "Check The Operation Of The iPOD®" below

GO to Pinpoint Test A.

No sound from speakers

The audio input control

Ensure all connectors of the audio input control (either front/rear or module power harness is module power harness are correctly secured left/right) during not securely installed See diagnostic procedures as specified in pinpoint playback from The audio input control tests C1: "Check The Integrity Of Power Supply From iPOD®/memory stick module power Vehicle" and C2: "Check The Integrity And Operation Audio system loses supply/harness is faulty Of The Audio Input Control Module Power Harness" connection to below GO to Pinpoint Test C. iPOD®/memory stick during playback

Optical cables/connectors

(if fitted) are not securely

installed

Optical cables/connectors

(if fitted) are faulty

Ensure the optical cables are routed appropriately to

avoid pinching the cable and with no excessive bends

or kinks. Ensure all connectors of the optical cables

are correctly secured. Replace any damaged or faulty

optical cables and/or connectors as required

If no CD changer is fitted, ensure that the optical

cables are configured in a closed loop so that the

optical circuit is intact iPOD® and radio playback skips after unit has been operating for 4 minutes

The iPOD® dock cable is

not securely installed

The iPOD® dock cable is

faulty

See diagnostic procedures as specified in pinpoint

test A3 "Check The iPOD® Is Charging When

Connected To The Audio Input Control Module" below

GO to Pinpoint Test A.

Page 2017 of 3039

Is the USB extension cable securely pushed into the USB connection port on the audio input control module

Yes

Replace the USB extension cable

No

Secure connections and retest B4: CHECK THE CAPACITY OF THE MEMORY STICK/STORAGE DEVICE

NOTE: The higher the capacity of the memory stick is the longer it takes to register with the audio input control module

and power up. The maximum permitted capacity is 8 Gigabytes 1 Check the storage capacity of the memory stick/storage device does not exceed 8 Gigabytes Is the storage capacity of the memory stick/storage device 8 Gigabytes or less?

Yes

High capacity devices may require longer to register and should be allowed up to two minutes to power up

following connection to the USB port. If memory stick fails to power up after two minutes, suspect a

faulty memory stick GO to B2. or USB extension cable GO to B3. No

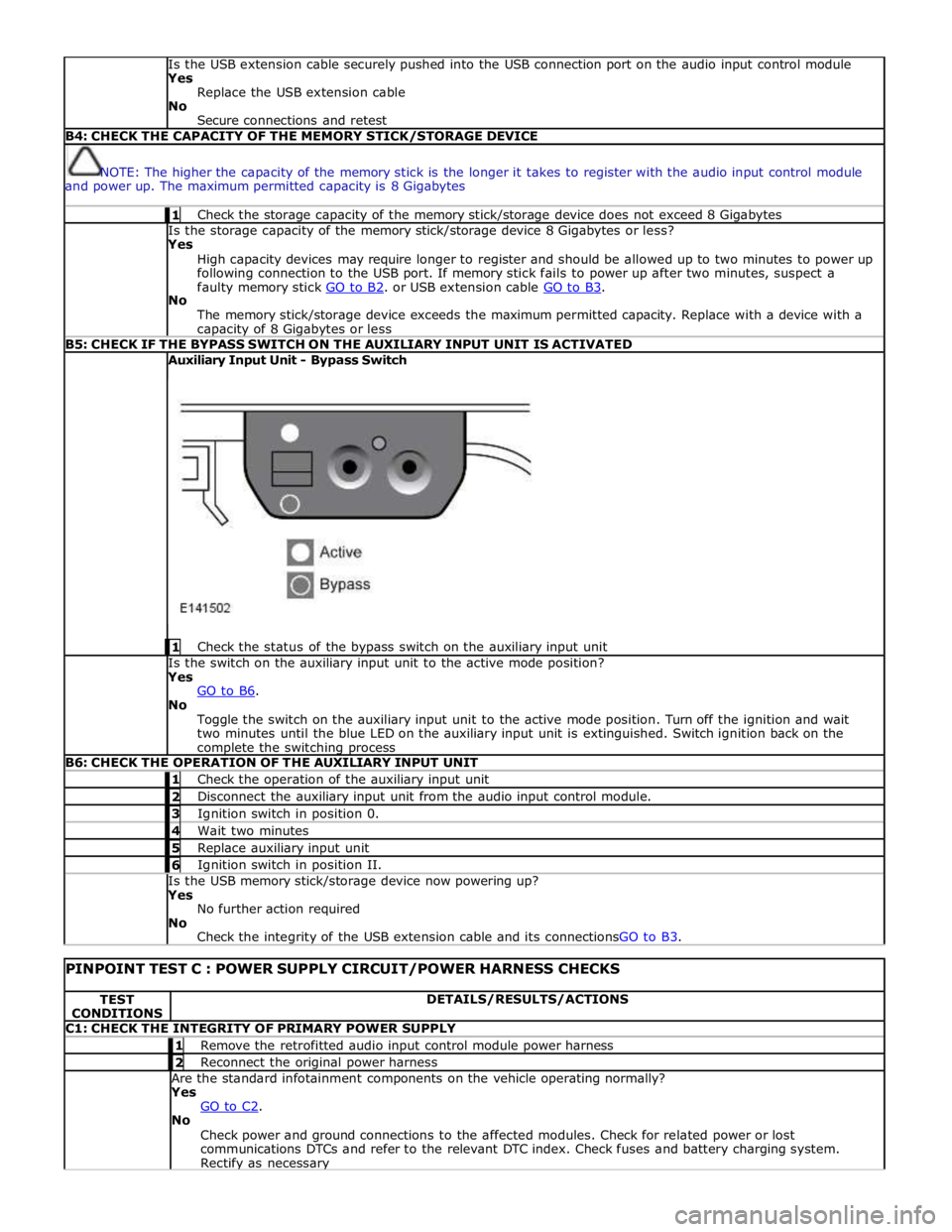

The memory stick/storage device exceeds the maximum permitted capacity. Replace with a device with a capacity of 8 Gigabytes or less B5: CHECK IF THE BYPASS SWITCH ON THE AUXILIARY INPUT UNIT IS ACTIVATED Auxiliary Input Unit - Bypass Switch

1 Check the status of the bypass switch on the auxiliary input unit Is the switch on the auxiliary input unit to the active mode position?

Yes

GO to B6. No

Toggle the switch on the auxiliary input unit to the active mode position. Turn off the ignition and wait

two minutes until the blue LED on the auxiliary input unit is extinguished. Switch ignition back on the complete the switching process B6: CHECK THE OPERATION OF THE AUXILIARY INPUT UNIT 1 Check the operation of the auxiliary input unit 2 Disconnect the auxiliary input unit from the audio input control module. 3 Ignition switch in position 0. 4 Wait two minutes 5 Replace auxiliary input unit 6 Ignition switch in position II. Is the USB memory stick/storage device now powering up?

Yes

No further action required

No

Check the integrity of the USB extension cable and its connectionsGO to B3.

PINPOINT TEST C : POWER SUPPLY CIRCUIT/POWER HARNESS CHECKS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK THE INTEGRITY OF PRIMARY POWER SUPPLY 1 Remove the retrofitted audio input control module power harness 2 Reconnect the original power harness Are the standard infotainment components on the vehicle operating normally?

Yes

GO to C2. No

Check power and ground connections to the affected modules. Check for related power or lost

communications DTCs and refer to the relevant DTC index. Check fuses and battery charging system. Rectify as necessary