Quiescent JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 21 of 3039

Quiescent Drain

Battery Report Form – In Service Batteries OnlyDiagnosis and TestingCharging System414-01: Battery, Mounting and CablesSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingBatteryGeneral ProceduresBattery Disconnect and ConnectRemoval and InstallationBattery414-02C: Generator and Regulator - V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionRemoval and InstallationGenerator - V8 S/C 5.0L Petrol415: Information and Entertainment Systems

415-00: Information and Entertainment System - General Information

Description and OperationNavigation System Map UpdatesDiagnosis and TestingInformation and Entertainment System

Cellular Phone

Navigation System415-01A: Information and Entertainment SystemSpecification

Description and OperationAudio SystemComponent Location

Overview

System Operation and Component DescriptionSpeakersComponent Location

Overview

Page 1866 of 3039

Published: 07-Aug-2014

Battery and Charging System - General Information - Battery Care

Requirements

Description and Operation

1. INTRODUCTION

This document defines the requirements for care and maintenance of batteries, and the standard of battery care at dealers and

retailers for new vehicles.

This applies to all types of 12 Volt Lead Acid Batteries used in Jaguar and Land Rover vehicles whether they are conventional

flooded technology or Absorbed Glass Mat (AGM – also known as Valve Regulated Lead Acid (VRLA)) technology and also

applies to both Primary, Secondary and Auxiliary Batteries. AGM batteries offer improved resistance to cycling as seen in stop

start applications.

In order to prevent damage to the battery and ensure a satisfactory service life, all processes detailed within this document

must be rigorously adhered to.

It is equally important therefore to note the following key points:

All new vehicles leave the factory with either a transit relay installed and/or have a transit mode programmed into the

vehicle control modules. The transit relay must be removed and the transit mode disabled (where applicable) using an

approved diagnostic system, NOT MORE THAN 72 HOURS before the customer takes delivery.

The battery can be discharged by the following mechanisms:

- Self Discharge: - A lead acid battery will very slowly discharge itself due to its own internal chemical processes

whether it is connected to a vehicle or not.

- Quiescent Discharge: - The vehicle electrical systems when connected to the battery will draw charge from the

battery.

12 Volt Lead Acid Batteries rely on internal chemical processes to create a voltage and deliver current. These processes and

the internal chemical structure of the battery can be damaged if the battery is allowed to discharge over a number of weeks /

months, or is left in a discharged state for a lengthy time period.

On vehicles with conventional ignition keys, these must not be left in the ignition lock barrel when the transit relay

has been removed, otherwise quiescent current will increase and the battery will discharge more rapidly.

For keyless vehicles, the Smart Key must be stored at least 5m (16 ft) away from the vehicle when the vehicle is

parked or stored.

AGM Batteries are fully sealed and cannot have the electrolyte level topped up.

NOTE: Dealers and retailers involved in the storage / handling of vehicles and replacement batteries have a responsibility

to ensure that only a fully charged battery may be processed through the distribution selling chain.

2. GENERAL RULES FOR BATTERY CARE

2.1 Dealer Demonstration Vehicles

Vehicles used as dealer demonstrator(s), in a showroom, must be connected to a JLR approved showroom conditioner capable

of delivering 50 Amps. This will prevent the battery from being damaged.

2.2 Software Reflash, SDD work or Ignition On related workshop activities

Due to the high electrical current demand and high depth of discharge that can occur during vehicle software re-flash activities,

SDD work or ignition on (power mode 6) related work in the workshop, vehicles that are undergoing such activities MUST have a

JLR approved power supply capable of delivering 50 Amps or more.

2.3 Extended Vehicle Rework

For any extended vehicle rework that results in consuming vehicle power, either the battery should be disconnected or a JLR

approved power supply connected.

2.4 Jump Starting New vehicles before they have been delivered to the customer

It is the dealer / retailers responsibility to make sure the battery is not allowed to discharge by following the

instructions and processes defined in this manual.

However, if circumstances dictate that a new vehicle must be jump started due to a discharged battery whilst the

vehicle is in the dealer / retailers care, the battery on this vehicle must be replaced with a new one prior to delivery

to the customer at the dealer / retailers liability.

The vehicle should also undergo investigation as to why the battery became discharged.

Do not connect the jump starting cable to the negative (-) terminal of the battery. Always connect to the recommended

earth point. As defined in the owners handbook or service documentation for that vehicle. 2.5 AGM Batteries

AGM batteries must not be charged above 14.8 Volts. Doing so will damage them.

AGM Batteries must be tested with a capable battery tester as detailed in the Equipment section (Section 5) of this

Page 1871 of 3039

Published: 21-Dec-2012

Battery and Charging System - General Information - Quiescent Drain

Description and Operation

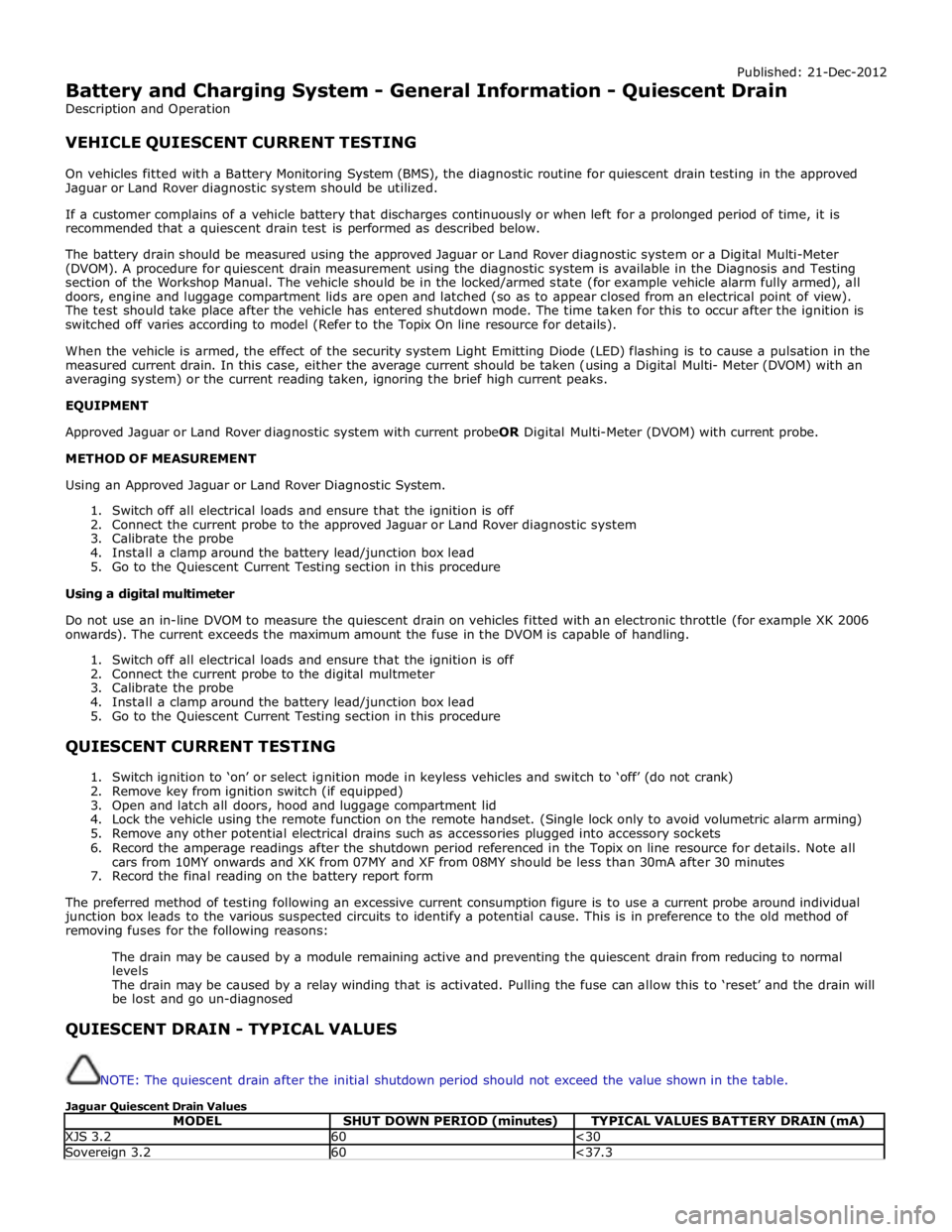

VEHICLE QUIESCENT CURRENT TESTING

On vehicles fitted with a Battery Monitoring System (BMS), the diagnostic routine for quiescent drain testing in the approved

Jaguar or Land Rover diagnostic system should be utilized.

If a customer complains of a vehicle battery that discharges continuously or when left for a prolonged period of time, it is

recommended that a quiescent drain test is performed as described below.

The battery drain should be measured using the approved Jaguar or Land Rover diagnostic system or a Digital Multi-Meter

(DVOM). A procedure for quiescent drain measurement using the diagnostic system is available in the Diagnosis and Testing

section of the Workshop Manual. The vehicle should be in the locked/armed state (for example vehicle alarm fully armed), all

doors, engine and luggage compartment lids are open and latched (so as to appear closed from an electrical point of view).

The test should take place after the vehicle has entered shutdown mode. The time taken for this to occur after the ignition is

switched off varies according to model (Refer to the Topix On line resource for details).

When the vehicle is armed, the effect of the security system Light Emitting Diode (LED) flashing is to cause a pulsation in the

measured current drain. In this case, either the average current should be taken (using a Digital Multi- Meter (DVOM) with an

averaging system) or the current reading taken, ignoring the brief high current peaks.

EQUIPMENT

Approved Jaguar or Land Rover diagnostic system with current probeOR Digital Multi-Meter (DVOM) with current probe.

METHOD OF MEASUREMENT

Using an Approved Jaguar or Land Rover Diagnostic System.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the approved Jaguar or Land Rover diagnostic system

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

Using a digital multimeter

Do not use an in-line DVOM to measure the quiescent drain on vehicles fitted with an electronic throttle (for example XK 2006

onwards). The current exceeds the maximum amount the fuse in the DVOM is capable of handling.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the digital multmeter

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

QUIESCENT CURRENT TESTING

1. Switch ignition to ‘on’ or select ignition mode in keyless vehicles and switch to ‘off’ (do not crank)

2. Remove key from ignition switch (if equipped)

3. Open and latch all doors, hood and luggage compartment lid

4. Lock the vehicle using the remote function on the remote handset. (Single lock only to avoid volumetric alarm arming)

5. Remove any other potential electrical drains such as accessories plugged into accessory sockets

6. Record the amperage readings after the shutdown period referenced in the Topix on line resource for details. Note all

cars from 10MY onwards and XK from 07MY and XF from 08MY should be less than 30mA after 30 minutes

7. Record the final reading on the battery report form

The preferred method of testing following an excessive current consumption figure is to use a current probe around individual

junction box leads to the various suspected circuits to identify a potential cause. This is in preference to the old method of

removing fuses for the following reasons:

The drain may be caused by a module remaining active and preventing the quiescent drain from reducing to normal

levels

The drain may be caused by a relay winding that is activated. Pulling the fuse can allow this to ‘reset’ and the drain will

be lost and go un-diagnosed

QUIESCENT DRAIN - TYPICAL VALUES

NOTE: The quiescent drain after the initial shutdown period should not exceed the value shown in the table.

Jaguar Quiescent Drain Values

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJS 3.2 60 <30 Sovereign 3.2 60 <37.3

Page 1873 of 3039

Published: 02-Apr-2014

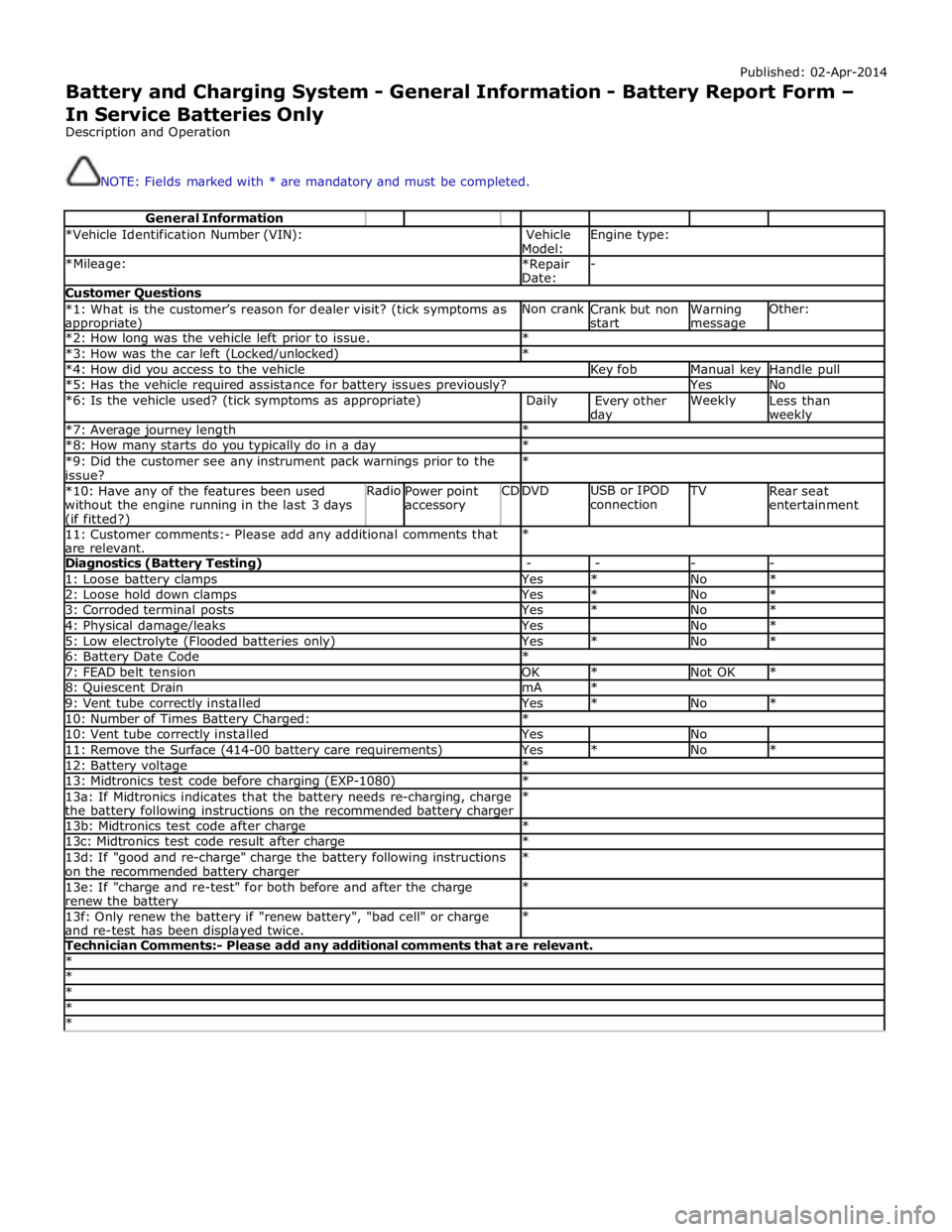

Battery and Charging System - General Information - Battery Report Form – In Service Batteries Only

Description and Operation

NOTE: Fields marked with * are mandatory and must be completed.

General Information *Vehicle Identification Number (VIN):

Vehicle

Model: Engine type: *Mileage:

*Repair

Date: - Customer Questions *1: What is the customer’s reason for dealer visit? (tick symptoms as appropriate) Non crank

Crank but non

start Warning message Other: *2: How long was the vehicle left prior to issue. * *3: How was the car left (Locked/unlocked) * *4: How did you access to the vehicle Key fob Manual key Handle pull *5: Has the vehicle required assistance for battery issues previously? Yes No *6: Is the vehicle used? (tick symptoms as appropriate) Daily

Every other day Weekly

Less than weekly *7: Average journey length * *8: How many starts do you typically do in a day * *9: Did the customer see any instrument pack warnings prior to the

issue? * *10: Have any of the features been used

without the engine running in the last 3 days (if fitted?) Radio

Power point

accessory CD DVD USB or IPOD

connection TV

Rear seat

entertainment 11: Customer comments:- Please add any additional comments that

are relevant. * Diagnostics (Battery Testing) - - - - 1: Loose battery clamps Yes * No * 2: Loose hold down clamps Yes * No * 3: Corroded terminal posts Yes * No * 4: Physical damage/leaks Yes No * 5: Low electrolyte (Flooded batteries only) Yes * No * 6: Battery Date Code * 7: FEAD belt tension OK * Not OK * 8: Quiescent Drain mA * 9: Vent tube correctly installed Yes * No * 10: Number of Times Battery Charged: * 10: Vent tube correctly installed Yes No 11: Remove the Surface (414-00 battery care requirements) Yes * No * 12: Battery voltage * 13: Midtronics test code before charging (EXP-1080) * 13a: If Midtronics indicates that the battery needs re-charging, charge

the battery following instructions on the recommended battery charger * 13b: Midtronics test code after charge * 13c: Midtronics test code result after charge * 13d: If "good and re-charge" charge the battery following instructions

on the recommended battery charger * 13e: If "charge and re-test" for both before and after the charge

renew the battery * 13f: Only renew the battery if "renew battery", "bad cell" or charge

and re-test has been displayed twice. * Technician Comments:- Please add any additional comments that are relevant. * * * * *

Page 1882 of 3039

11 Secondary battery 12 Dual Battery Junction Box (DBJB) 13 Rear Junction Box (RJB) 14 Megafuse 15 Battery Junction box (BJB) 16 Primary battery

System Operation BATTERY MONITORING SYSTEM - TD4 2.2L DIESEL VEHICLES ONLY

Periodically the battery monitoring system module will instigate a self-calibration routine. To self calibrate, the battery

monitoring system first charges the battery to its full condition.

NOTE: If the vehicle is only driven for short periods the charging process could take a number of days to complete.

Once the battery is fully charged, the battery monitoring system will discharge the battery to approximately 75% of its full

state of charge, but never lower than 12.2 V. The time taken to complete this part of the routine is dependent on the electrical

load on the vehicle.

When the second part of the routine has been successfully completed, the battery monitoring system will return the battery to

its optimum level of charge. The optimum level of charge will be between 12.6 V and 15 V, depending on battery condition,

temperature and loading.

The battery monitoring system module also monitors the battery condition with the engine switched off. If a low voltage

condition is detected the module can request the infotainment system is switched off to protect battery voltage. Once the

infotainment system has been switched off, the vehicle must be run for at least 5 minutes to charge the battery before the

infotainment system can be operated with the engine switched off.

BATTERY MONITORING SYSTEM - SINGLE AND DUAL BATTERY SYSTEM VEHICLES

When the ignition is off (power mode 0), the BMS control module records the primary battery state of charge and begins to

monitor the battery condition from this point.

If the battery state of charge falls by 7%, the BMS control module will monitor the primary battery for 5 minutes. If after the 5

minute monitoring period, the primary battery charge has continued to fall due to the quiescent drain current being too high,

the BMS control module will determine that some control modules are still 'awake'. The BMS control module sends a shutdown

message on the LIN (local interconnect network) bus to the GWM (Gateway Module). The GWM sends a CAN (controller area

network) bus message on both the medium and high speed networks to all control modules, requesting them to shutdown.

The BMS control module will monitor the primary battery state of charge for a further 5 minutes and determine if the primary

battery state of charge is still dropping. If a quiescent drain current continues, the primary battery state of charge will

continue to drop. If the state of charge falls to 12% of the initial monitoring value, the BMS control module determines that

one or more control modules are still awake and a failure to respond to the shutdown request may indicate an error state

within the control module(s).

BMS Low Battery Warning and Energy Management Messages

The BMS continuously monitors the condition of the primary vehicle battery. If excessive battery discharge occurs, the system

will begin to shut down non-essential electrical systems in order to protect the battery.

If the BMS calculates that battery condition is not within set parameters, there are 3 messages that can be displayed, 2 on the

touch screen and 1 on the message center. These inform the user that the battery is either at a low level of charge or the

engine-off power consumption limit has been exceeded.

Low Battery - Please switch engine on or system will shutdown in 3 minutes: is displayed as a Warning on the

touch screen if the engine is not running. This indicates that the battery has fallen below a predefined threshold. As

soon as the battery is charged back above this threshold then the message will be removed.

Low Battery - Please start your engine is displayed on the message center if the engine is not running. This indicates

that the battery has fallen below a predefined threshold. As soon as the battery is charged back above this threshold

then the message will be removed or it can be manually removed by pressing 'OK'.

System will shut down in 3 minutes: is displayed as an Energy management on the touch screen if the engine is not

running, and system features are causing excessive battery discharge. After 3 minutes the BMS will begin shutting

down vehicle systems. Normal system operation will resume when the engine is started.

This is based on a percentage of battery capacity available for the customer to use with the engine off. The percentage can

change based upon several factors.

Once triggered, the resetting of this message will not occur until the vehicle is driven for 10 minutes with the engine running

(to allow the battery to recoup any lost charge). However, if the engine is run for less than 10 minutes, the message will only

be displayed after an additional 5 minutes with the ignition on but engine off.

BMS Control Module Self Calibration

Periodically the BMS control module will instigate a self-calibration routine. To self calibrate, the battery monitoring system www.JagDocs.com