parking sensors JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 211 of 3039

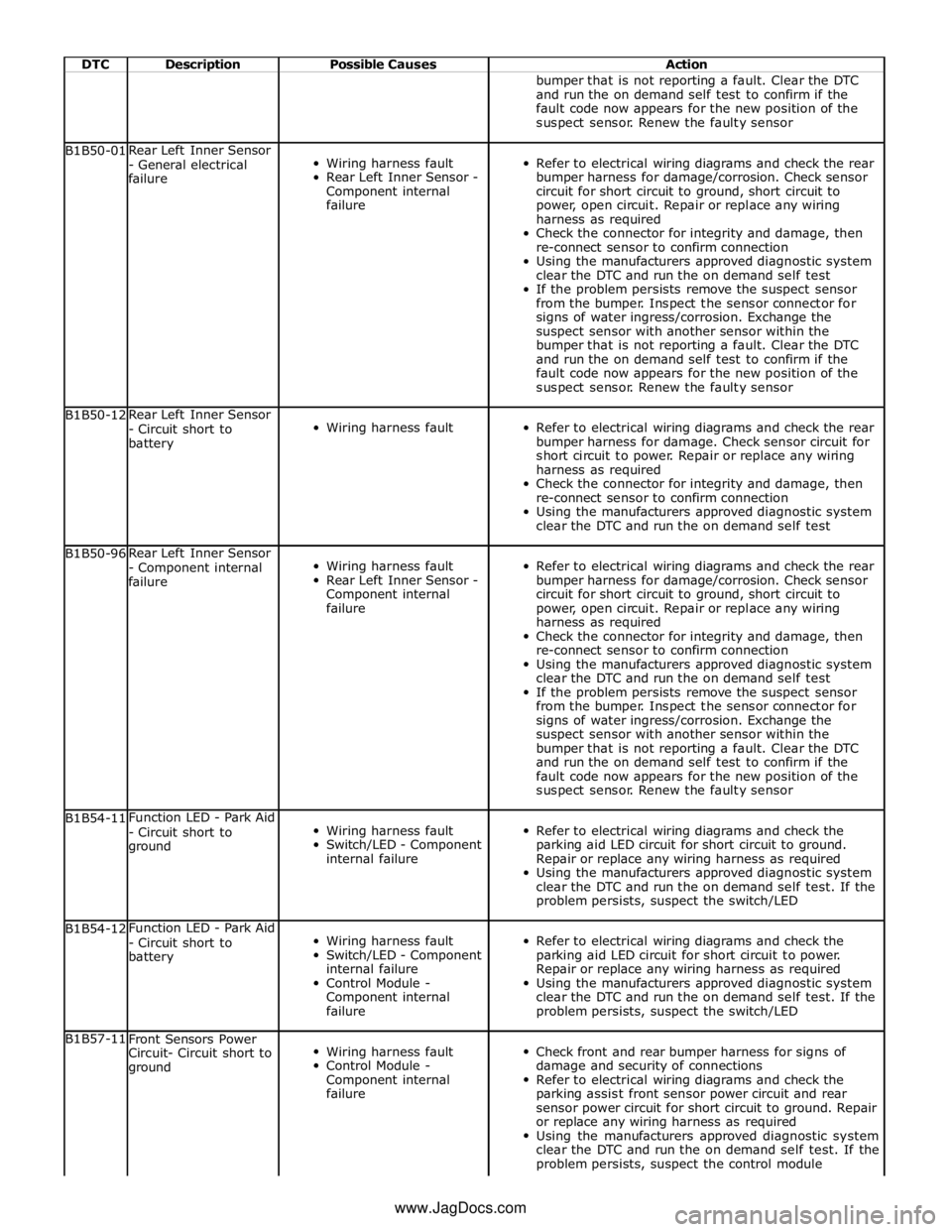

DTC Description Possible Causes Action bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B50-01 Rear Left Inner Sensor

- General electrical

failure

Wiring harness fault

Rear Left Inner Sensor -

Component internal

failure

Refer to electrical wiring diagrams and check the rear

bumper harness for damage/corrosion. Check sensor

circuit for short circuit to ground, short circuit to

power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B50-12 Rear Left Inner Sensor

- Circuit short to

battery

Wiring harness fault

Refer to electrical wiring diagrams and check the rear

bumper harness for damage. Check sensor circuit for

short circuit to power. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test B1B50-96 Rear Left Inner Sensor

- Component internal

failure

Wiring harness fault

Rear Left Inner Sensor -

Component internal

failure

Refer to electrical wiring diagrams and check the rear

bumper harness for damage/corrosion. Check sensor

circuit for short circuit to ground, short circuit to

power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B54-11 Function LED - Park Aid

- Circuit short to

ground

Wiring harness fault

Switch/LED - Component

internal failure

Refer to electrical wiring diagrams and check the

parking aid LED circuit for short circuit to ground.

Repair or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the switch/LED B1B54-12 Function LED - Park Aid

- Circuit short to

battery

Wiring harness fault

Switch/LED - Component

internal failure

Control Module -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking aid LED circuit for short circuit to power.

Repair or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the switch/LED B1B57-11

Front Sensors Power

Circuit- Circuit short to

ground

Wiring harness fault

Control Module -

Component internal

failure

Check front and rear bumper harness for signs of

damage and security of connections

Refer to electrical wiring diagrams and check the

parking assist front sensor power circuit and rear

sensor power circuit for short circuit to ground. Repair

or replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module www.JagDocs.com

Page 212 of 3039

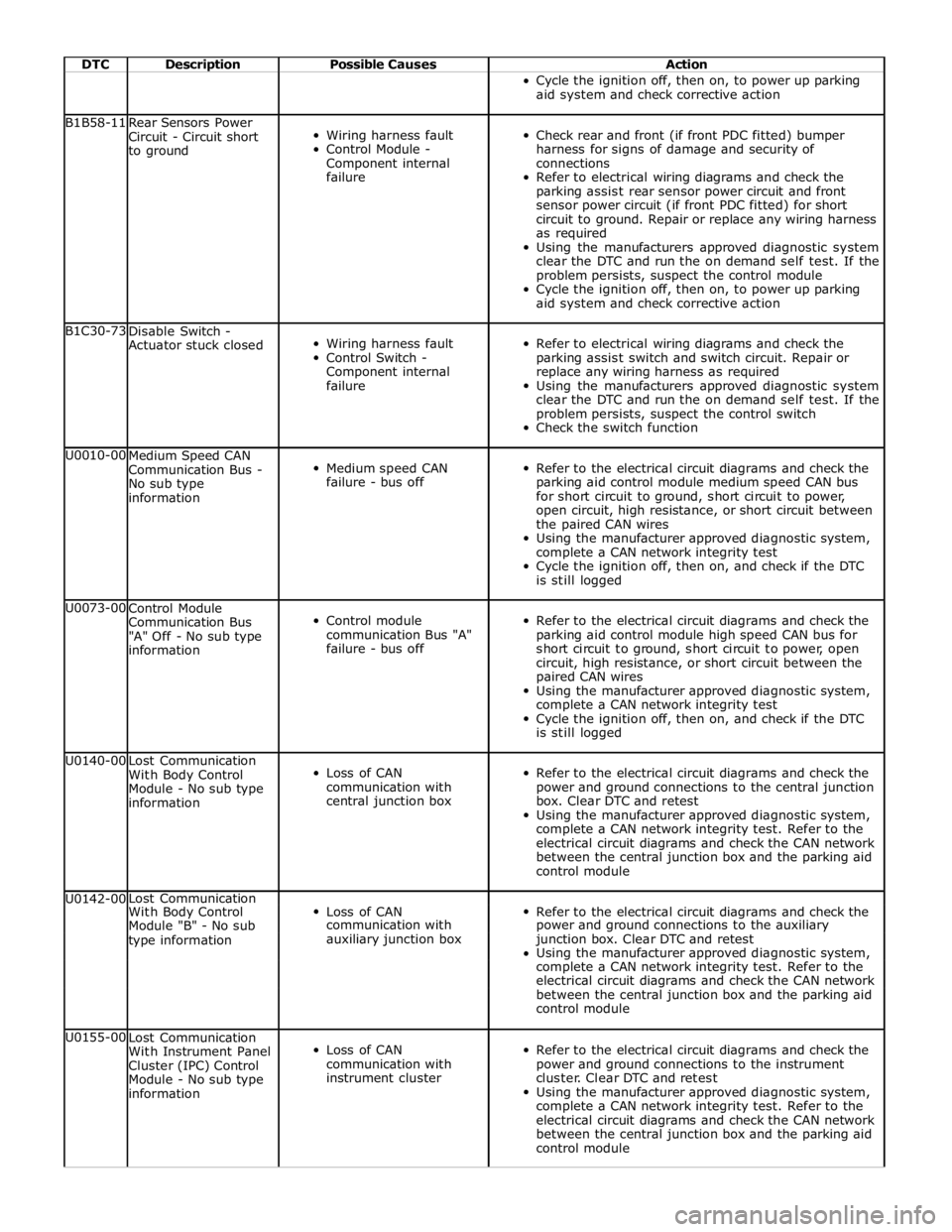

DTC Description Possible Causes Action Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1B58-11

Rear Sensors Power

Circuit - Circuit short

to ground

Wiring harness fault

Control Module -

Component internal

failure

Check rear and front (if front PDC fitted) bumper

harness for signs of damage and security of

connections

Refer to electrical wiring diagrams and check the

parking assist rear sensor power circuit and front

sensor power circuit (if front PDC fitted) for short

circuit to ground. Repair or replace any wiring harness

as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module

Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1C30-73

Disable Switch -

Actuator stuck closed

Wiring harness fault

Control Switch -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking assist switch and switch circuit. Repair or

replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control switch

Check the switch function U0010-00

Medium Speed CAN

Communication Bus -

No sub type

information

Medium speed CAN

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module medium speed CAN bus

for short circuit to ground, short circuit to power,

open circuit, high resistance, or short circuit between

the paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0073-00

Control Module

Communication Bus

"A" Off - No sub type

information

Control module

communication Bus "A"

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module high speed CAN bus for

short circuit to ground, short circuit to power, open

circuit, high resistance, or short circuit between the

paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Loss of CAN

communication with

central junction box

Refer to the electrical circuit diagrams and check the

power and ground connections to the central junction

box. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module U0142-00 Lost Communication

Loss of CAN

Refer to the electrical circuit diagrams and check the With Body Control Module "B" - No sub communication with power and ground connections to the auxiliary type information auxiliary junction box junction box. Clear DTC and retest Using the manufacturer approved diagnostic system, complete a CAN network integrity test. Refer to the electrical circuit diagrams and check the CAN network between the central junction box and the parking aid control module U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Loss of CAN

communication with

instrument cluster

Refer to the electrical circuit diagrams and check the

power and ground connections to the instrument

cluster. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module

Page 443 of 3039

7 Initiators 8 TPMS module 9 Instrument cluster

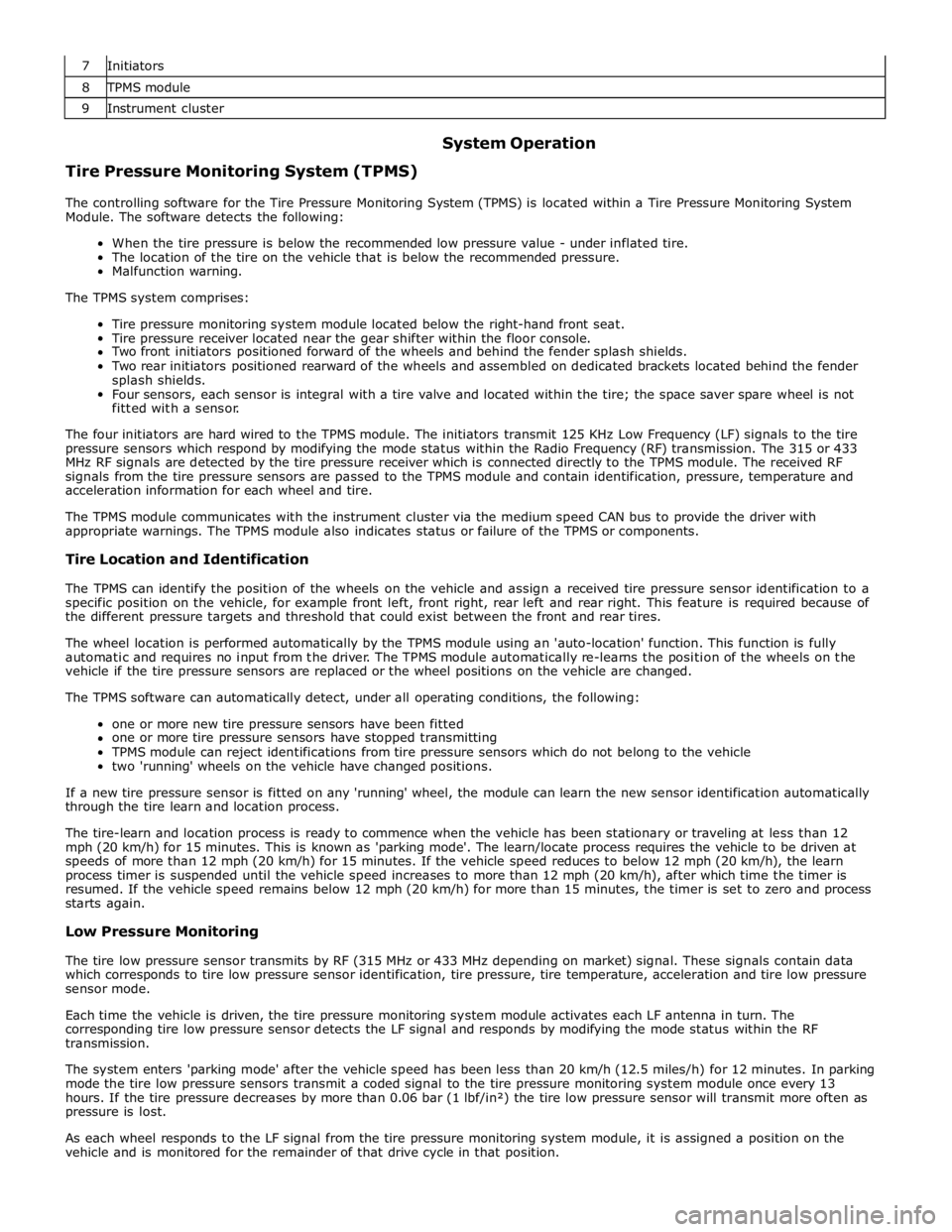

Tire Pressure Monitoring System (TPMS) System Operation

The controlling software for the Tire Pressure Monitoring System (TPMS) is located within a Tire Pressure Monitoring System

Module. The software detects the following:

When the tire pressure is below the recommended low pressure value - under inflated tire.

The location of the tire on the vehicle that is below the recommended pressure.

Malfunction warning.

The TPMS system comprises:

Tire pressure monitoring system module located below the right-hand front seat.

Tire pressure receiver located near the gear shifter within the floor console.

Two front initiators positioned forward of the wheels and behind the fender splash shields.

Two rear initiators positioned rearward of the wheels and assembled on dedicated brackets located behind the fender

splash shields.

Four sensors, each sensor is integral with a tire valve and located within the tire; the space saver spare wheel is not

fitted with a sensor.

The four initiators are hard wired to the TPMS module. The initiators transmit 125 KHz Low Frequency (LF) signals to the tire

pressure sensors which respond by modifying the mode status within the Radio Frequency (RF) transmission. The 315 or 433

MHz RF signals are detected by the tire pressure receiver which is connected directly to the TPMS module. The received RF

signals from the tire pressure sensors are passed to the TPMS module and contain identification, pressure, temperature and

acceleration information for each wheel and tire.

The TPMS module communicates with the instrument cluster via the medium speed CAN bus to provide the driver with

appropriate warnings. The TPMS module also indicates status or failure of the TPMS or components.

Tire Location and Identification

The TPMS can identify the position of the wheels on the vehicle and assign a received tire pressure sensor identification to a

specific position on the vehicle, for example front left, front right, rear left and rear right. This feature is required because of

the different pressure targets and threshold that could exist between the front and rear tires.

The wheel location is performed automatically by the TPMS module using an 'auto-location' function. This function is fully

automatic and requires no input from the driver. The TPMS module automatically re-learns the position of the wheels on the

vehicle if the tire pressure sensors are replaced or the wheel positions on the vehicle are changed.

The TPMS software can automatically detect, under all operating conditions, the following:

one or more new tire pressure sensors have been fitted

one or more tire pressure sensors have stopped transmitting

TPMS module can reject identifications from tire pressure sensors which do not belong to the vehicle

two 'running' wheels on the vehicle have changed positions.

If a new tire pressure sensor is fitted on any 'running' wheel, the module can learn the new sensor identification automatically

through the tire learn and location process.

The tire-learn and location process is ready to commence when the vehicle has been stationary or traveling at less than 12

mph (20 km/h) for 15 minutes. This is known as 'parking mode'. The learn/locate process requires the vehicle to be driven at

speeds of more than 12 mph (20 km/h) for 15 minutes. If the vehicle speed reduces to below 12 mph (20 km/h), the learn

process timer is suspended until the vehicle speed increases to more than 12 mph (20 km/h), after which time the timer is

resumed. If the vehicle speed remains below 12 mph (20 km/h) for more than 15 minutes, the timer is set to zero and process

starts again.

Low Pressure Monitoring

The tire low pressure sensor transmits by RF (315 MHz or 433 MHz depending on market) signal. These signals contain data

which corresponds to tire low pressure sensor identification, tire pressure, tire temperature, acceleration and tire low pressure

sensor mode.

Each time the vehicle is driven, the tire pressure monitoring system module activates each LF antenna in turn. The

corresponding tire low pressure sensor detects the LF signal and responds by modifying the mode status within the RF

transmission.

The system enters 'parking mode' after the vehicle speed has been less than 20 km/h (12.5 miles/h) for 12 minutes. In parking

mode the tire low pressure sensors transmit a coded signal to the tire pressure monitoring system module once every 13

hours. If the tire pressure decreases by more than 0.06 bar (1 lbf/in²) the tire low pressure sensor will transmit more often as

pressure is lost.

As each wheel responds to the LF signal from the tire pressure monitoring system module, it is assigned a position on the

vehicle and is monitored for the remainder of that drive cycle in that position.

Page 694 of 3039

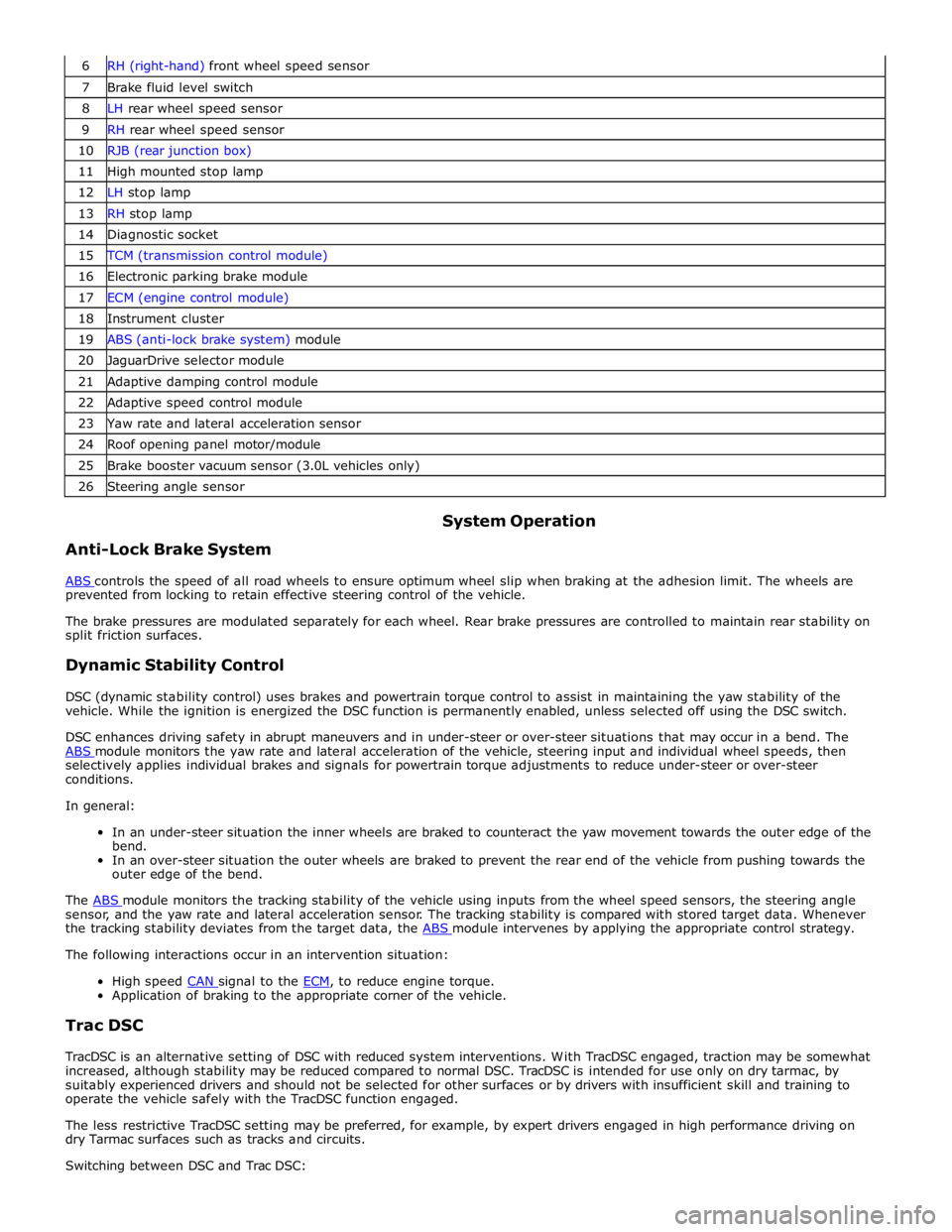

7 Brake fluid level switch 8 LH rear wheel speed sensor 9 RH rear wheel speed sensor 10 RJB (rear junction box) 11 High mounted stop lamp 12 LH stop lamp 13 RH stop lamp 14 Diagnostic socket 15 TCM (transmission control module) 16 Electronic parking brake module 17 ECM (engine control module) 18 Instrument cluster 19 ABS (anti-lock brake system) module 20 JaguarDrive selector module 21 Adaptive damping control module 22 Adaptive speed control module 23 Yaw rate and lateral acceleration sensor 24 Roof opening panel motor/module 25 Brake booster vacuum sensor (3.0L vehicles only) 26 Steering angle sensor

Anti-Lock Brake System System Operation

ABS controls the speed of all road wheels to ensure optimum wheel slip when braking at the adhesion limit. The wheels are prevented from locking to retain effective steering control of the vehicle.

The brake pressures are modulated separately for each wheel. Rear brake pressures are controlled to maintain rear stability on

split friction surfaces.

Dynamic Stability Control

DSC (dynamic stability control) uses brakes and powertrain torque control to assist in maintaining the yaw stability of the

vehicle. While the ignition is energized the DSC function is permanently enabled, unless selected off using the DSC switch.

DSC enhances driving safety in abrupt maneuvers and in under-steer or over-steer situations that may occur in a bend. The

ABS module monitors the yaw rate and lateral acceleration of the vehicle, steering input and individual wheel speeds, then selectively applies individual brakes and signals for powertrain torque adjustments to reduce under-steer or over-steer

conditions.

In general:

In an under-steer situation the inner wheels are braked to counteract the yaw movement towards the outer edge of the

bend.

In an over-steer situation the outer wheels are braked to prevent the rear end of the vehicle from pushing towards the

outer edge of the bend.

The ABS module monitors the tracking stability of the vehicle using inputs from the wheel speed sensors, the steering angle sensor, and the yaw rate and lateral acceleration sensor. The tracking stability is compared with stored target data. Whenever

the tracking stability deviates from the target data, the ABS module intervenes by applying the appropriate control strategy. The following interactions occur in an intervention situation:

High speed CAN signal to the ECM, to reduce engine torque. Application of braking to the appropriate corner of the vehicle.

Trac DSC

TracDSC is an alternative setting of DSC with reduced system interventions. With TracDSC engaged, traction may be somewhat

increased, although stability may be reduced compared to normal DSC. TracDSC is intended for use only on dry tarmac, by

suitably experienced drivers and should not be selected for other surfaces or by drivers with insufficient skill and training to

operate the vehicle safely with the TracDSC function engaged.

The less restrictive TracDSC setting may be preferred, for example, by expert drivers engaged in high performance driving on

dry Tarmac surfaces such as tracks and circuits.

Switching between DSC and Trac DSC:

Page 1434 of 3039

solenoid valve in the valve housing directs hydraulic pressure to the lock cylinder, which moves the piston within the cylinder

and releases the park lock pawl at the rear of the transmission by means of a connecting rod. The solenoid on the lock cylinder

is energized and locks the cylinder piston in the unlocked position. Additional locking of the piston is achieved with ball

catches within the lock cylinder.

When park is selected, the solenoid on the lock cylinder is de-energized, the ball catches are released and the piston is free to

move in the lock cylinder. The solenoid in the valve housing is also de-energized. The spring loaded parking disc pulls the

cylinder piston in the park direction which allows the park disc to move on its mounting. This movement is transferred via the

connecting rod to parking pawl, which is engaged in the park lock gear.

If an electrical failure occurs, the park lock can be manually released by means of an emergency park release lever located in

the floor console. The lever is connected to the parking disc by a cable and allows the park lock to be released manually. For

additional information, refer to 307-05B Automatic Transmission/Transaxle External Controls.

TRANSMISSION CONTROL MODULE

The TCM is an integral part of the Mechatronic valve block which is located at the bottom of the transmission, within the fluid pan. The TCM is the main controlling component of the transmission.

The TCM processes signals from the transmission speed and temperature sensors, ECM and other vehicle systems. From the received signal inputs and pre-programmed data, the module calculates the correct gear, torque converter clutch setting and

optimum pressure settings for gear shift and lock-up clutch control.

Page 1824 of 3039

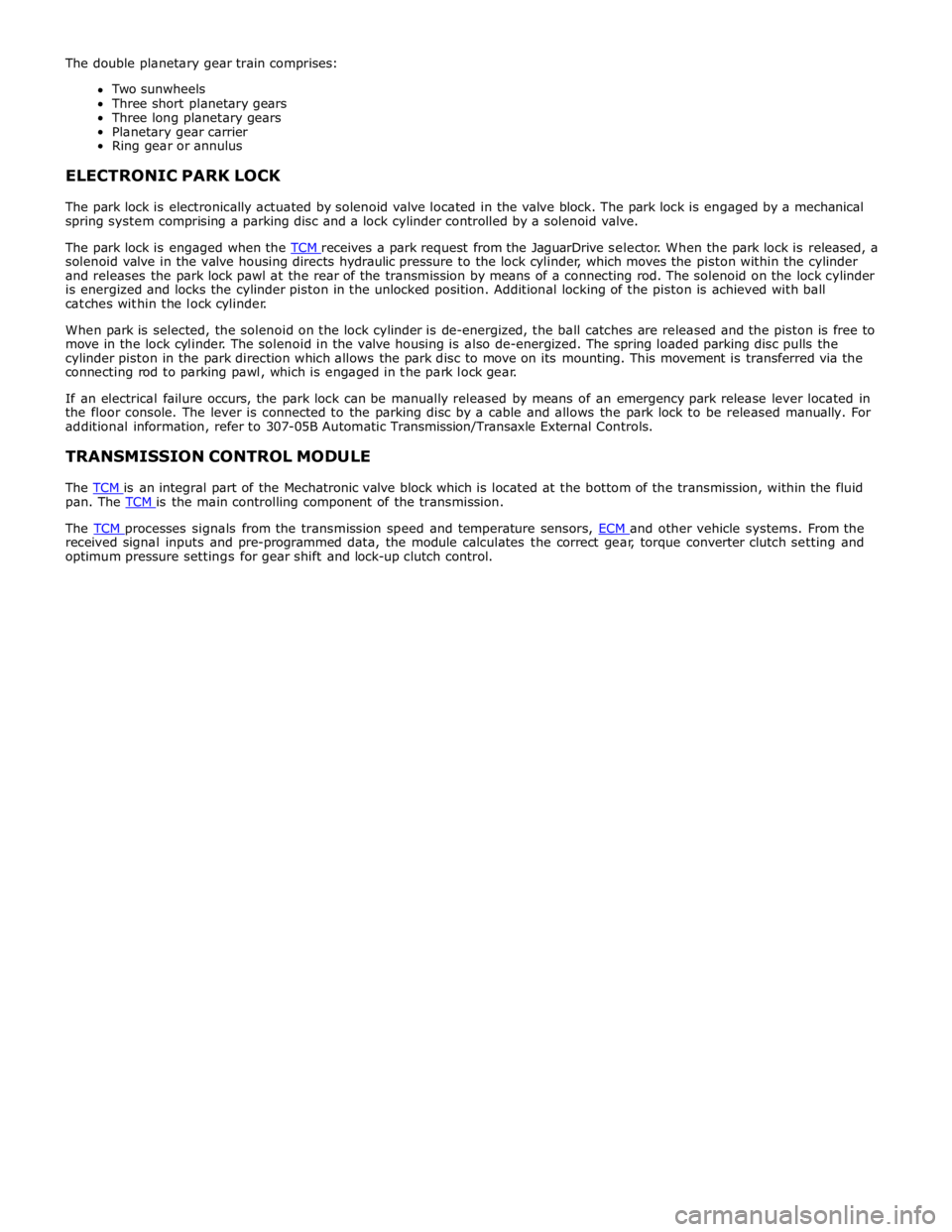

Message Other Warnings Reason Action APPLY FOOT AND

PARK BRAKE Amber warning triangle

illuminated in LCD. The battery has been disconnected or

power supply interrupted to the parking

brake module. Apply foot brake and parking brake to

reset the parking brake module. CANNOT APPLY

PARK BRAKE

Brake warning

indicator flashing.

Red warning triangle

illuminated in LCD. NOTE: In certain

markets the brake

warning indicator

does not flash. A fault is present in the parking brake

system and the parking brake cannot be

applied. A fault has occurred in the parking

brake system. Interrogate the parking

brake module for faults and diagnose

using an approved Jaguar Diagnostic

System. CHECK TYRE

PRESSURE

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location. A tire pressure has decreased to below

the warning threshold. Check tires for punctures and re-inflate

to correct pressures. TYRE NOT

MONITORED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location.

One or more tire pressure

sensors have developed a fault.

A temporary spare wheel or a

wheel without a sensor has been

fitted at the displayed position.

An unapproved accessory may be

interfering with the TPMS.

Check for local RF interference.

A wheel has been fitted without

a TPMS sensor fitted (space

saver spare wheel).

TPMS sensor has developed a

fault or the battery voltage is

low.

A fault has occurred in the

TPMS. Interrogate the TPMS

module for faults and diagnose

using an approved Jaguar

Diagnostic System. CHECK ALL TYRE

PRESSURES

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. Vehicle graphic

displaying tire

location. One or more tire pressures have

decreased to below the warning

threshold.

Check tires for punctures and

re-inflate to correct pressures.

Message may be displayed

when TPMS is learning position

of a new sensor. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD.

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS

system and the tire pressures

cannot be monitored. A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System. TYRE PRESSURE

LOW FOR SPEED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. TPMS has detected current tire

pressures are too low for sustained high

speed driving Check tire pressures and inflate to the

correct pressures if necessary. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System.

Page 1840 of 3039

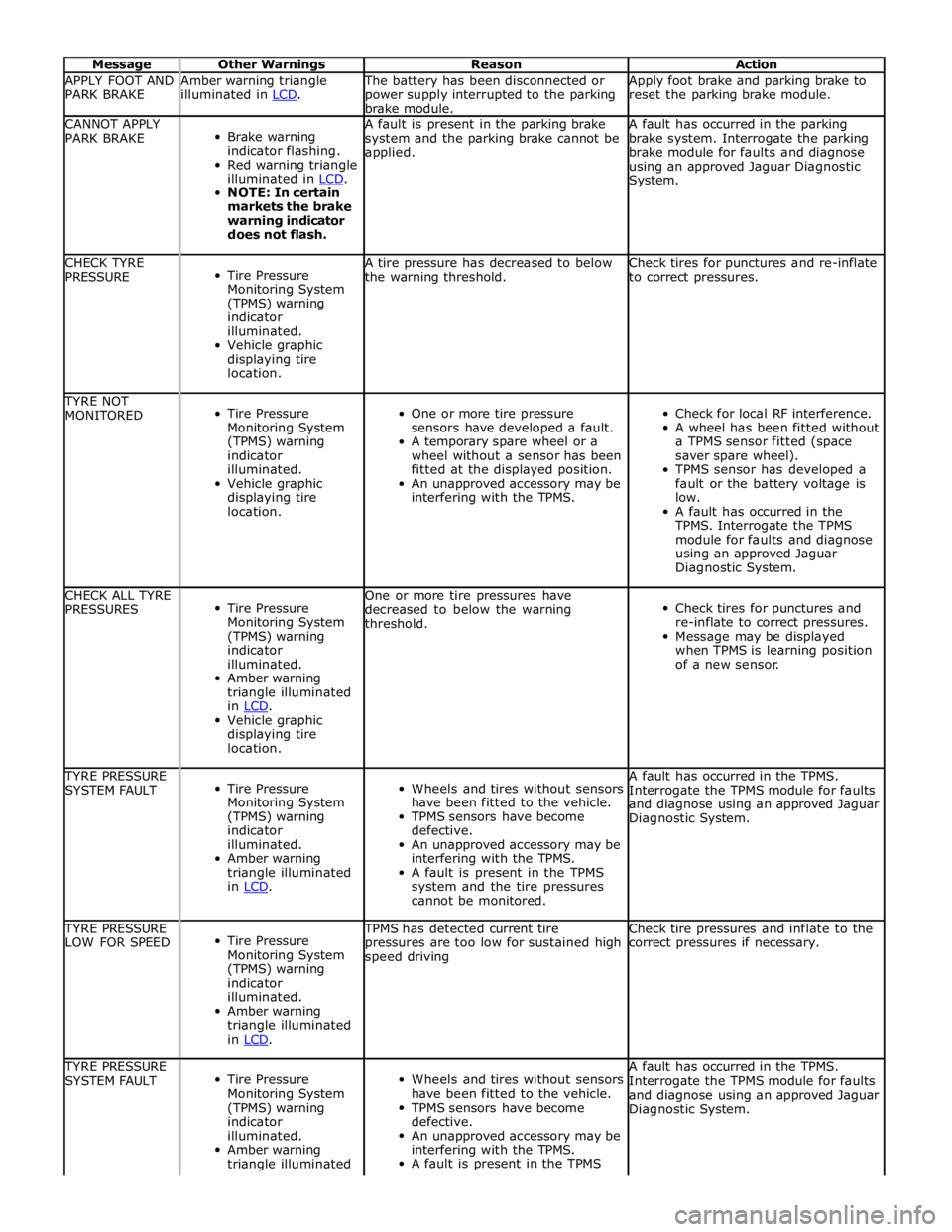

Parking Aid - Parking Aid - Component Location

Description and Operation

COMPONENT LOCATION - PARKING AID Published: 11-May-2011

Item Description 1 Front parking aid sensors (4 off) 2 Parking aid switch 3 Rear parking aid sensors (4 off) 4 Parking aid module

Page 1842 of 3039

Parking Aid - Parking Aid - Overview

Description and Operation

OVERVIEW Published: 11-May-2011

The parking aid system provides an audible warning to the driver when any obstacles are in the path of the vehicle during a

forward (if front sensors are fitted) or reversing manoeuver. The purpose of the system is to assist the driver when parking or

manoeuvring in a restricted space. It is not designed as a crash avoidance system or a replacement for visual interpretation by

the driver.

All vehicles are fitted with rear parking aid sensors. Higher specification vehicles may also be fitted with front parking aid

sensors.

A roof console mounted parking aid switch allows the driver to deactivate the parking aid system if operation is not required.

NOTE: The switch is only fitted to vehicles with front parking aid sensors.

A parking aid camera is a standard fitment on some models and optional on others. The parking aid camera supplements the

information provided by the parking aid system by providing the driver with a visual display of the area directly behind the

vehicle.

www.JagDocs.com

Page 1845 of 3039

3 RJB 4 Entertainment system control module 5 Touch Screen Display (TSD) 6 Parking aid camera

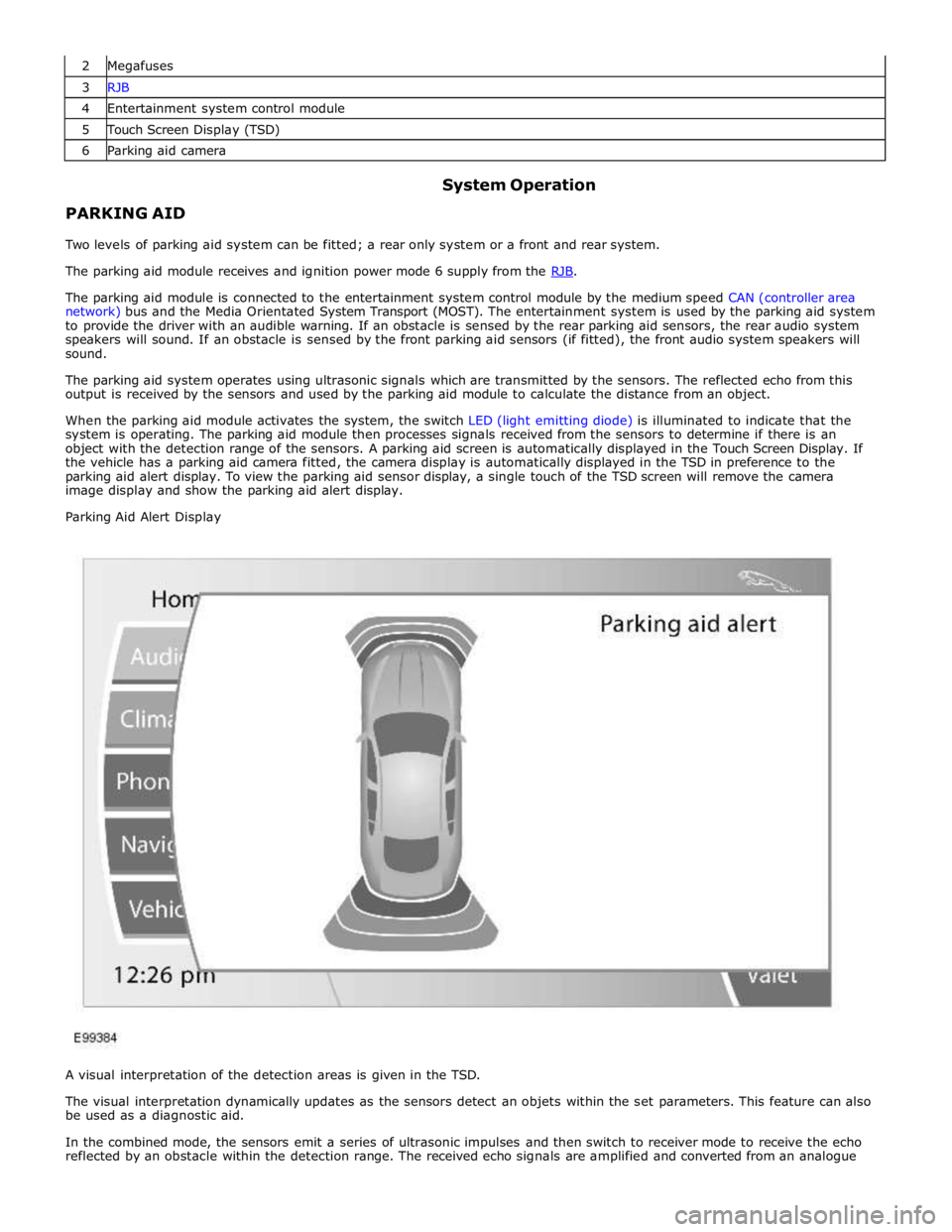

PARKING AID System Operation

Two levels of parking aid system can be fitted; a rear only system or a front and rear system.

The parking aid module receives and ignition power mode 6 supply from the RJB. The parking aid module is connected to the entertainment system control module by the medium speed CAN (controller area

network) bus and the Media Orientated System Transport (MOST). The entertainment system is used by the parking aid system

to provide the driver with an audible warning. If an obstacle is sensed by the rear parking aid sensors, the rear audio system

speakers will sound. If an obstacle is sensed by the front parking aid sensors (if fitted), the front audio system speakers will

sound.

The parking aid system operates using ultrasonic signals which are transmitted by the sensors. The reflected echo from this

output is received by the sensors and used by the parking aid module to calculate the distance from an object.

When the parking aid module activates the system, the switch LED (light emitting diode) is illuminated to indicate that the

system is operating. The parking aid module then processes signals received from the sensors to determine if there is an

object with the detection range of the sensors. A parking aid screen is automatically displayed in the Touch Screen Display. If

the vehicle has a parking aid camera fitted, the camera display is automatically displayed in the TSD in preference to the

parking aid alert display. To view the parking aid sensor display, a single touch of the TSD screen will remove the camera

image display and show the parking aid alert display.

Parking Aid Alert Display

A visual interpretation of the detection areas is given in the TSD.

The visual interpretation dynamically updates as the sensors detect an objets within the set parameters. This feature can also

be used as a diagnostic aid.

In the combined mode, the sensors emit a series of ultrasonic impulses and then switch to receiver mode to receive the echo

reflected by an obstacle within the detection range. The received echo signals are amplified and converted from an analogue

Page 1846 of 3039

signal to a digital signal by the sensor. The digital signal is passed to the parking aid module and compared with

pre-programmed data stored in an EEPROM (electrically erasable programmable read only memory) within the module. The

module receives this data via the signal line from the sensor and calculates the distance from the object using the elapsed

time between the transmitted and received impulse. The duration of the impulse duration is determined by the module, with

the sensor controlling the frequency of the impulse output.

In receiver mode, the sensor receives impulses that were emitted by adjacent sensors. The module uses this information to

precisely determine the position and distance of the object.

If no objects are detected there are no further warning tones. If an object is detected, repeated audible tones are emitted

from either the front or rear audio speakers as appropriate. The time delay between the tones decreases as the distance

between the object and the vehicle decreases, until at approximately 300 mm (12 inches), the audible tone becomes

continuous.

After the initial detection of an object, if there is no decrease in the distance between an object and the central sensors, the

time delay between the audible warnings remains constant. If an object is detected by one of the corner sensors only, the

audible warnings stop after approximately 5 seconds if there is no change in the distance between an object and the corner

sensor.

When approaching several objects within detection range, the control module recognises the distance from the vehicle to the

nearest object.

The PDC module will prioritise the objects detected, the nearest object detected will take priority and the corresponding audio

outputs will be emitted. For example if 2 objects are detected (one front one rear) the nearest detected object will take

priority and relevant audible tone will be heard.

If two objects are detected at equal distance (one front one rear) the audible tones will alternate between the front and rear

speakers.

If reverse (R) is the first gear selected after the ignition is switched on, both the front (if fitted) and rear parking aid sensors

will become operational. If a forward drive gear is subsequently selected, the front and rear parking aid sensors will remain

operational until vehicle speed increases above 16 km/h (10 mph), park (P) is selected or the PDC control switch is pressed.

If drive (D) is the first gear selected after the ignition is switched on the parking aid system will have to be activated by

pressing the PDC control switch.

NOTE: The PDC system can not be activated whilst the vehicle is in park (P).

The volume output of the parking aid audible tones can be adjusted by selecting the 'Vehicle Settings' menu and selecting

'Parking' from the menu on the TSD. The volume can be adjusted using the + or - selections on the TSD.

The system can detect when a trailer is connected to the vehicle by a message output on the medium speed CAN bus from the trailer module. When the parking aid module detects that a trailer is connected to the vehicle, the rear sensors are disabled to

prevent constant warnings due to the close proximity of the trailer.

NOTE: The ignition needs to be cycled once the trailer has been disconnected to activate the rear parking aid system.