tow bar JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1851 of 3039

Mechanical Electrical Parking aid control module

Parking aid sounder

Audio system

4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

5. If the cause is not visually evident, check for diagnostic trouble codes (DTCs) and refer to the DTC index

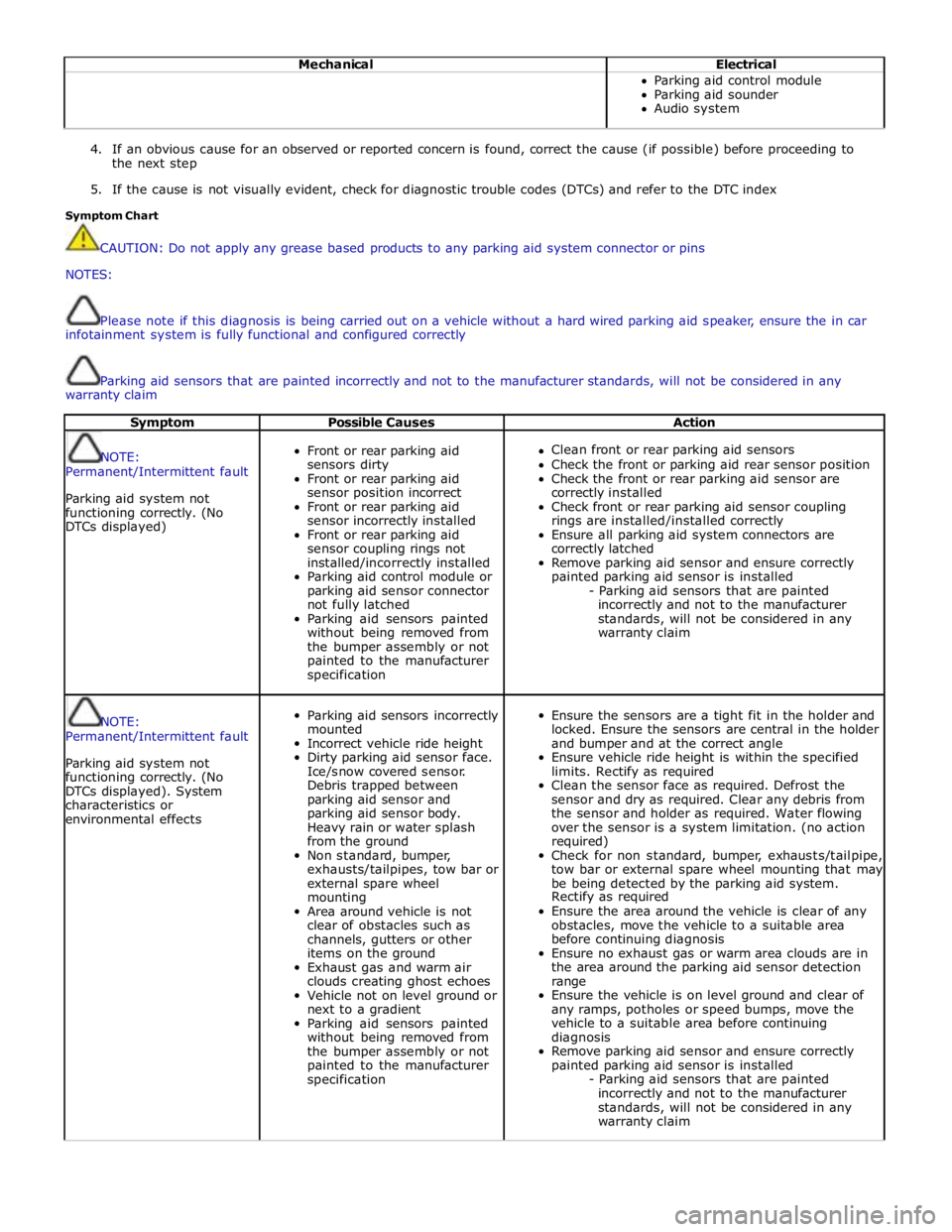

Symptom Chart

CAUTION: Do not apply any grease based products to any parking aid system connector or pins

NOTES:

Please note if this diagnosis is being carried out on a vehicle without a hard wired parking aid speaker, ensure the in car

infotainment system is fully functional and configured correctly

Parking aid sensors that are painted incorrectly and not to the manufacturer standards, will not be considered in any

warranty claim

Symptom Possible Causes Action

NOTE:

Permanent/Intermittent fault

Parking aid system not

functioning correctly. (No

DTCs displayed)

Front or rear parking aid

sensors dirty

Front or rear parking aid

sensor position incorrect

Front or rear parking aid

sensor incorrectly installed

Front or rear parking aid

sensor coupling rings not

installed/incorrectly installed

Parking aid control module or

parking aid sensor connector

not fully latched

Parking aid sensors painted

without being removed from

the bumper assembly or not

painted to the manufacturer

specification

Clean front or rear parking aid sensors

Check the front or parking aid rear sensor position

Check the front or rear parking aid sensor are

correctly installed

Check front or rear parking aid sensor coupling

rings are installed/installed correctly

Ensure all parking aid system connectors are

correctly latched

Remove parking aid sensor and ensure correctly

painted parking aid sensor is installed

- Parking aid sensors that are painted

incorrectly and not to the manufacturer

standards, will not be considered in any

warranty claim

NOTE:

Permanent/Intermittent fault

Parking aid system not

functioning correctly. (No

DTCs displayed). System

characteristics or

environmental effects

Parking aid sensors incorrectly

mounted

Incorrect vehicle ride height

Dirty parking aid sensor face.

Ice/snow covered sensor.

Debris trapped between

parking aid sensor and

parking aid sensor body.

Heavy rain or water splash

from the ground

Non standard, bumper,

exhausts/tailpipes, tow bar or

external spare wheel

mounting

Area around vehicle is not

clear of obstacles such as

channels, gutters or other

items on the ground

Exhaust gas and warm air

clouds creating ghost echoes

Vehicle not on level ground or

next to a gradient

Parking aid sensors painted

without being removed from

the bumper assembly or not

painted to the manufacturer

specification

Ensure the sensors are a tight fit in the holder and

locked. Ensure the sensors are central in the holder

and bumper and at the correct angle

Ensure vehicle ride height is within the specified

limits. Rectify as required

Clean the sensor face as required. Defrost the

sensor and dry as required. Clear any debris from

the sensor and holder as required. Water flowing

over the sensor is a system limitation. (no action

required)

Check for non standard, bumper, exhausts/tailpipe,

tow bar or external spare wheel mounting that may

be being detected by the parking aid system.

Rectify as required

Ensure the area around the vehicle is clear of any

obstacles, move the vehicle to a suitable area

before continuing diagnosis

Ensure no exhaust gas or warm area clouds are in

the area around the parking aid sensor detection

range

Ensure the vehicle is on level ground and clear of

any ramps, potholes or speed bumps, move the

vehicle to a suitable area before continuing

diagnosis

Remove parking aid sensor and ensure correctly

painted parking aid sensor is installed

- Parking aid sensors that are painted

incorrectly and not to the manufacturer

standards, will not be considered in any

warranty claim

Page 1854 of 3039

PINPOINT TEST B : PARKING AID SYSTEM NOT FUNCTIONING CORRECTLY WITH NO DTCS LOGGED TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Clean the parking aid sensor face. Check for any damage to the parking aid sensor face. Rectify as required. Snow, water or ice on sensor face. Parking aid sensor face has been repainted to the incorrect

thickness. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B2. B2: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Ensure the vehicle ride height is within manufacturer specified limits. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B3. B3: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Check for any non standard accessories are not fitted, such as tow bar, bike rack, body kit, modified exhaust, lighting or licence plate holder Parking aid system functioning correctly? Yes

No further action required

No

GO to B4. B4: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Limitations or characteristics of the parking aid system such as vehicle on a gradient, exhaust gas vapour, signal reflection Parking aid system functioning correctly? Yes

No further action required

No

For a detailed description of the parking aid system, refer to the relevant description and operation

section in the workshop manual.

REFER to: Parking Aid (413-13 Parking Aid, Description and Operation). DTC Index

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If the control module is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and

Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to the installation of a

new module.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals. Parking aid system functioning correctly

Yes

No further action required