set clock JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 26 of 73

AJ16 Engine Service Manual

SERVICE OPERATIONS

4.1 Camshaft, Renew

SRO 12.13.01

Remove camshaft cover, see Section 4.2.

Drain the cooling system, see Section 4.1 in the appropri

- ate Vehicle Service Manual.

1 Rotate the engine and set No. 1 cylinder at TDC using Ser- viceTool 18G 1433 (1 Fig. 1).

Push back the lock tabs (1 Fig.2) from the camshaft

sprocket securing bolts (2 Fig. 2). and slacken off the bolts.

Remove the upper chain tensioner valve clamp bolt

(3 Fig.

2), remove the clamp (4 Fig. 2) and remove the

valve (5 Fig. 2).

1 Using a 3 mm Allen key, wind backthe tensioner (6 Fig. 2) (turn clockwise) until the snail engages in the park posi- tion. Remove the tensioner housing securing bolt (7 Fig. 2) and withdraw the tensioner assembly (8, 9 Fig. 2).

1 Remove and discard the '0' ring (9 Fig. 2) and gasket (10 Fig. 2).

. Remove the camshaft sprocket securing bolts and tab

washers (1,2 Fig. 2) and remove the sprockets (11 Fig. 2) (ensure that neither the bolts nor the tab washer drop into

the timing case).

CAUTION: Do not rotate the engine while the camshaft is

disconnected.

. Remove the cylinder head bolt from No. 2 cap, left-hand

1 Remove No. 2 cap from the left-hand camshaft.

1 Fit spacer tool 18G 1435 (2 Fig. 3) to the head.

Fit and torque tighten the cylinder head bolt.

Repeat the procedure for Nos 3,4,5 and 6 caps, left-hand

camshaft (3 Fig. 3).

Remove the cylinder head bolt from

No. 7 cap, left-hand

camshaft.

Loosen in sequence the securing bolts from Nos 1 and 7 caps, until theleft-handcamshaft isfree. Liftthecamshaft

from the cylinder head and fit spacer tool 18G 1435 to No. 7 cylinder head bolt position (5 Fig. 3). Fit and torque

tighten the bolt.

Clean

all components and examine for wear and damage.

Renew all worn or damaged components.

Lubricate the new left

-hand camshaft.

Fit the camshaft at approximately TDC.

Lubricate Nos 1 and 7 caps.

Fit No. 1 cap but do not tighten the securing bolts. Remove No. 7 cap cylinder head bolt.

1 Remove the spacer tool. Fit No. 7 cap but do not tighten

the securing bolts.

1 Finally tighten Nos 1 and 7 cap securing bolts in sequence.

Remove No. 4 cap cylinder head bolt and remove the

spacer tool. Lubricate and fit No. 4 cap.

CAUTION: The cylinder head bolts MUST be renewed dur- ing assembly and torque tightened as de- scribed in Section 2.1, SPS Joint Control System.

camshaft

(1 Fig. 3).

1 Repeat

the procedure for the right-hand camshaft.

1

Fia. 1

Fia. 2

Fig. 3

Issue 1 August 1994 7

Page 29 of 73

AJ16 Engine Service Manual

4.3

SRO 12.29.48

1 Remove camshaft cover, see Section 4.2.

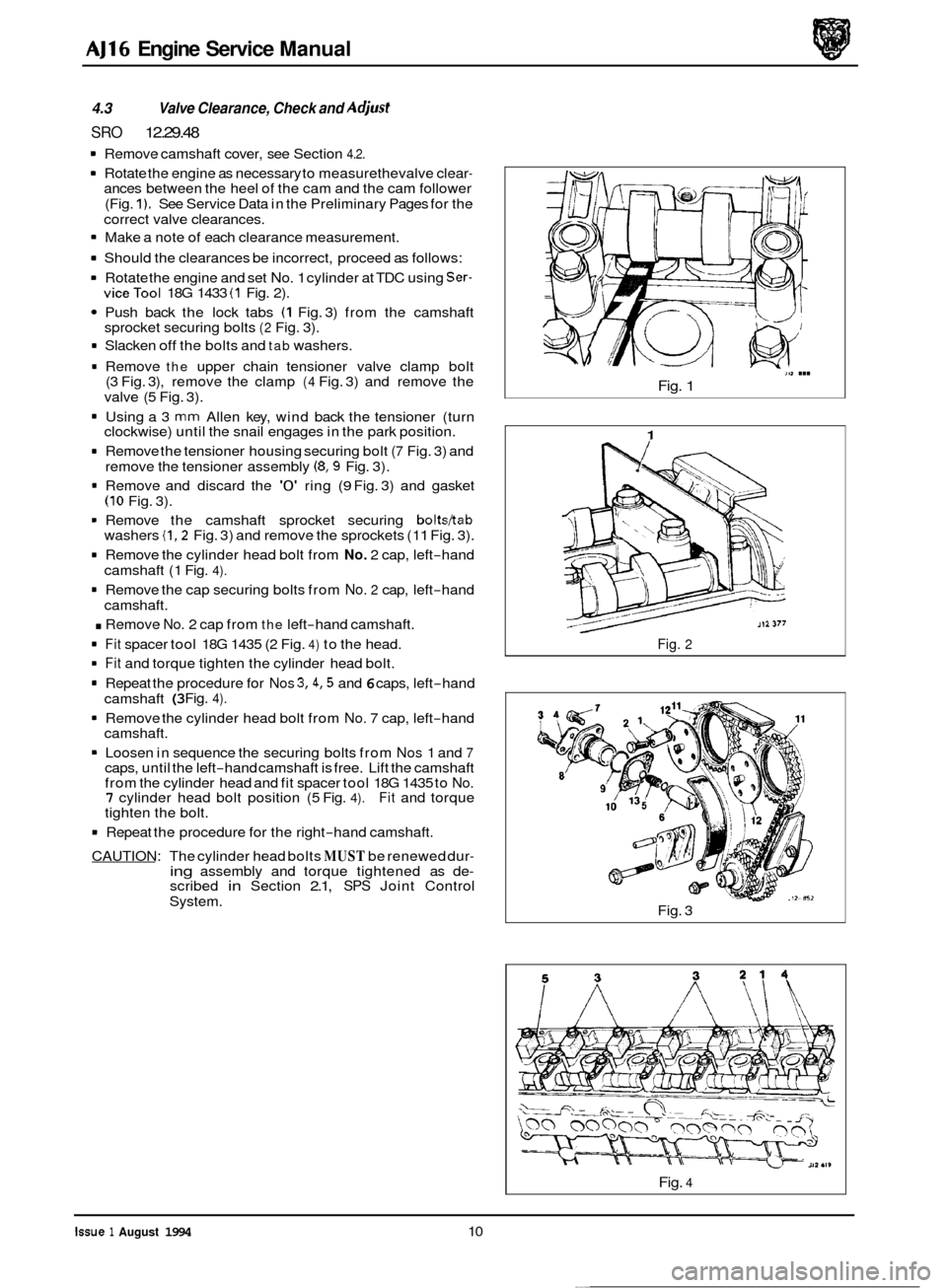

1 Rotate the engine as necessary to measurethevalve clear- ances between the heel of the cam and the cam follower

(Fig.

1). See Service Data in the Preliminary Pages for the

correct valve clearances.

1 Make a note of each clearance measurement.

1 Should the clearances be incorrect, proceed as follows:

1 Rotate the engine and set No. 1 cylinder at TDC using Ser- viceTool 18G 1433 (1 Fig. 2).

Push back the lock tabs (1 Fig. 3) from the camshaft

sprocket securing bolts (2 Fig. 3).

1 Slacken off the bolts and tab washers.

1 Remove the upper chain tensioner valve clamp bolt

(3 Fig. 3), remove the clamp (4 Fig. 3) and remove the

valve (5 Fig. 3).

1 Using a 3 mm Allen key, wind back the tensioner (turn

clockwise) until the snail engages in the park position.

1 Remove the tensioner housing securing bolt (7 Fig. 3) and

remove the tensioner assembly (8,9 Fig. 3).

1 Remove and discard the '0' ring (9 Fig. 3) and gasket (10 Fig. 3).

1 Remove the camshaft sprocket securing bolts/tab washers (1,2 Fig. 3) and remove the sprockets (1 1 Fig. 3).

1 Remove the cylinder head bolt from No. 2 cap, left-hand

camshaft (1 Fig. 4).

1 Remove the cap securing bolts from No. 2 cap, left-hand

cams haft.

. Remove No. 2 cap from the left-hand camshaft.

1 Fit spacer tool 18G 1435 (2 Fig. 4) to the head.

1 Fit and torque tighten the cylinder head bolt.

1 Repeat the procedure for Nos 3,4,5 and 6 caps, left-hand

camshaft

(3 Fig. 4).

1 Remove the cylinder head bolt from No. 7 cap, left-hand

camshaft.

1 Loosen in sequence the securing bolts from Nos 1 and 7 caps, until the left-hand camshaft is free. Lift the camshaft

from the cylinder head and fit spacer tool 18G 1435 to No. 7 cylinder head bolt position (5 Fig. 4). Fit and torque

tighten the bolt.

Valve Clearance, Check and Aa'just

1 Repeat the procedure for the right-hand camshaft.

CAUTION: The cylinder head bolts

MUST be renewed dur- ing assembly and torque tightened as de- scribed in Section 2.1, SPS Joint Control

System.

111 ...

Fig. 1

1

Fig. 2

Fig. 3

Fig. 4

Issue 1 August 1994 10 ~~

Page 33 of 73

AJ16 Engine Service Manual

= Refit the upper static damper assembly.

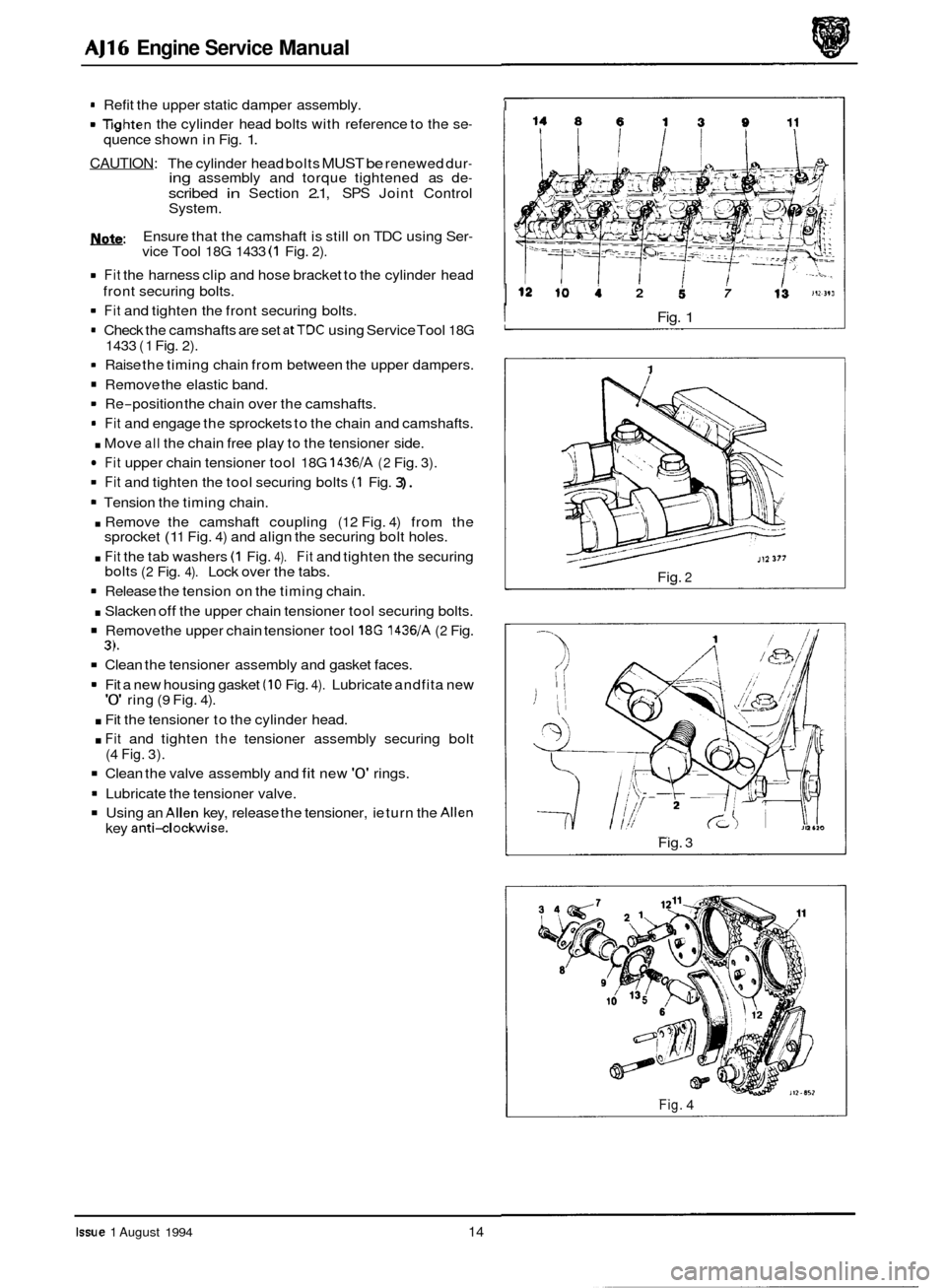

lighten the cylinder head bolts with reference to the se- quence shown in Fig. 1.

CAUTION: The cylinder head bolts MUST be renewed dur- ing assembly and torque tightened as de-

scribed in Section 2.1, SPS Joint Control

System.

Ensure that the camshaft is still on TDC using Ser

-

vice Tool 18G 1433 (1 Fig. 2).

Fit the harness clip and hose bracket to the cylinder head

front securing bolts.

Fit and tighten the front securing bolts.

1433 (1 Fig. 2).

b:

= Check the camshafts are set atTDC using Service Tool 18G

= Raise the timing chain from between the upper dampers.

Remove the elastic band.

= Fit and engage the sprockets to the chain and camshafts.

. Move all the chain free play to the tensioner side.

Fit upper chain tensioner tool 18G 1436/A (2 Fig. 3).

Fit and tighten the tool securing bolts (1 Fig. 3).

Tension the timing chain.

sprocket

(1 1 Fig. 4) and align the securing bolt holes.

bolts

(2 Fig. 4). Lock over the tabs.

Release the tension on the timing chain.

Re

-position the

chain over the camshafts.

. Remove the camshaft coupling (12 Fig. 4) from the

. Fit the tab washers (1 Fig. 4). Fit and tighten the securing

. Slacken off the upper chain tensioner tool securing bolts.

Remove the upper chain tensioner tool 18G 14361A (2 Fig.

Clean the tensioner assembly and gasket faces.

3).

Fit a new housing gasket (10 Fig. 4). Lubricate andfita new '0' ring (9 Fig. 4).

. Fit the tensioner to the cylinder head.

. Fit and tighten the tensioner assembly securing bolt

Clean the valve assembly and fit new '0' rings.

Using an Allen key, release the tensioner, ie turn the Allen

(4 Fig. 3).

Lubricate the tensioner valve.

key

anti-clockwise.

I

104 2 5 7 I l2

I Fig. 1

1

Fig. 2

Fig. 3

Fig. 4

Issue 1 August 1994 14

Page 54 of 73

AJ16 Engine Service Manual

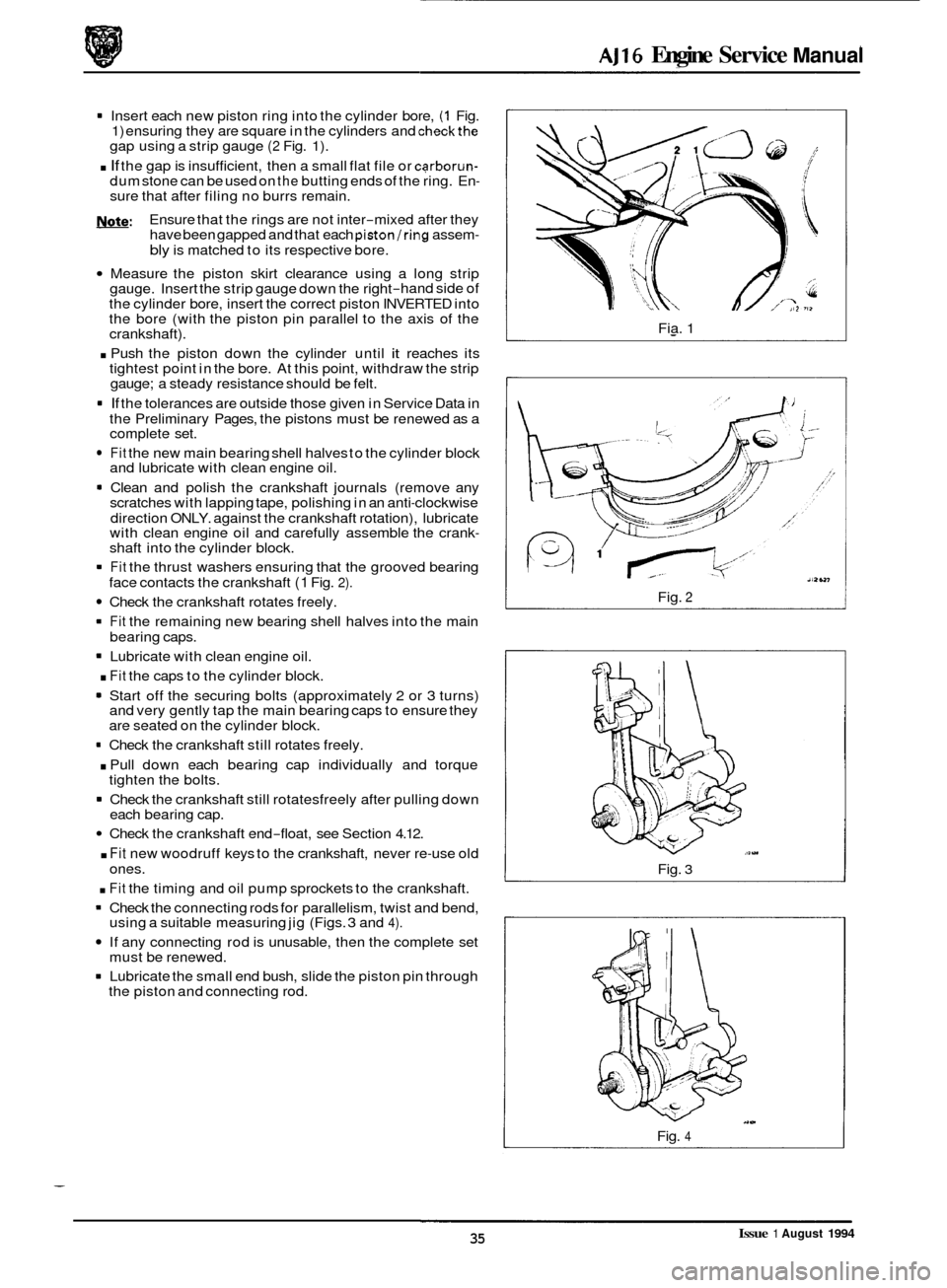

0 1 Insert each new piston ring into the cylinder bore, (1 Fig. 1) ensuring they are square in the cylinders and checkthe gap using a strip gauge (2 Fig. 1).

. If the gap is insufficient, then a small flat file or carborun- dum stone can be used on the butting ends of the ring. En- sure that after filing no burrs remain.

Ensure that the rings are not inter

-mixed after they

have been gapped and that each piston/ring assem- bly is matched to its respective bore.

Measure the piston skirt clearance using a long strip

gauge. Insert the strip gauge down the right-hand side of

the cylinder bore, insert the correct piston INVERTED into

the bore (with the piston pin parallel to the axis of the

crankshaft).

. Push the piston down the cylinder until it reaches its

tightest point in the bore. At this point, withdraw the strip

gauge; a steady resistance should be felt.

1 If the tolerances are outside those given in Service Data in

the Preliminary Pages, the pistons must be renewed as a

complete set.

Note:

0

Fit the new main bearing shell halves to the cylinder block

and lubricate with clean engine oil.

1 Clean and polish the crankshaft journals (remove any

scratches with lapping tape, polishing in an anti-clockwise

direction ONLY. against the crankshaft rotation), lubricate

with clean engine oil and carefully assemble the crank

- shaft into the cylinder block.

1 Fit the thrust washers ensuring that the grooved bearing

Check the crankshaft rotates freely.

1 Fit the remaining new bearing shell halves into the main

1 Lubricate with clean engine oil.

. Fit the caps to the cylinder block.

1 Start off the securing bolts (approximately 2 or 3 turns)

and very gently tap the main bearing caps to ensure they

are seated on the cylinder block.

face contacts

the crankshaft

(1 Fig. 2).

bearing caps.

= Check the crankshaft still rotates freely.

. Pull down each bearing cap individually and torque

1 Check the crankshaft still rotatesfreely after pulling down

tighten

the bolts.

each bearing cap.

Check the crankshaft end-float, see Section 4.12.

. Fit new woodruff keys to the crankshaft, never re-use old

. Fit the timing and oil pump sprockets to the crankshaft.

1 Check the connecting rods for parallelism, twist and bend,

If any connecting rod is unusable, then the complete set

1 Lubricate the small end bush, slide the piston pin through

ones.

using

a suitable measuring jig (Figs.

3 and 4).

must be renewed.

the piston and connecting rod. Fia.

1

Fig. 2

Fig. 3

Fig. 4

Issue 1 August 1994 35