lock JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 69 of 327

Brakes (a)

12.3 COMPONENT DESCRlPTlONS

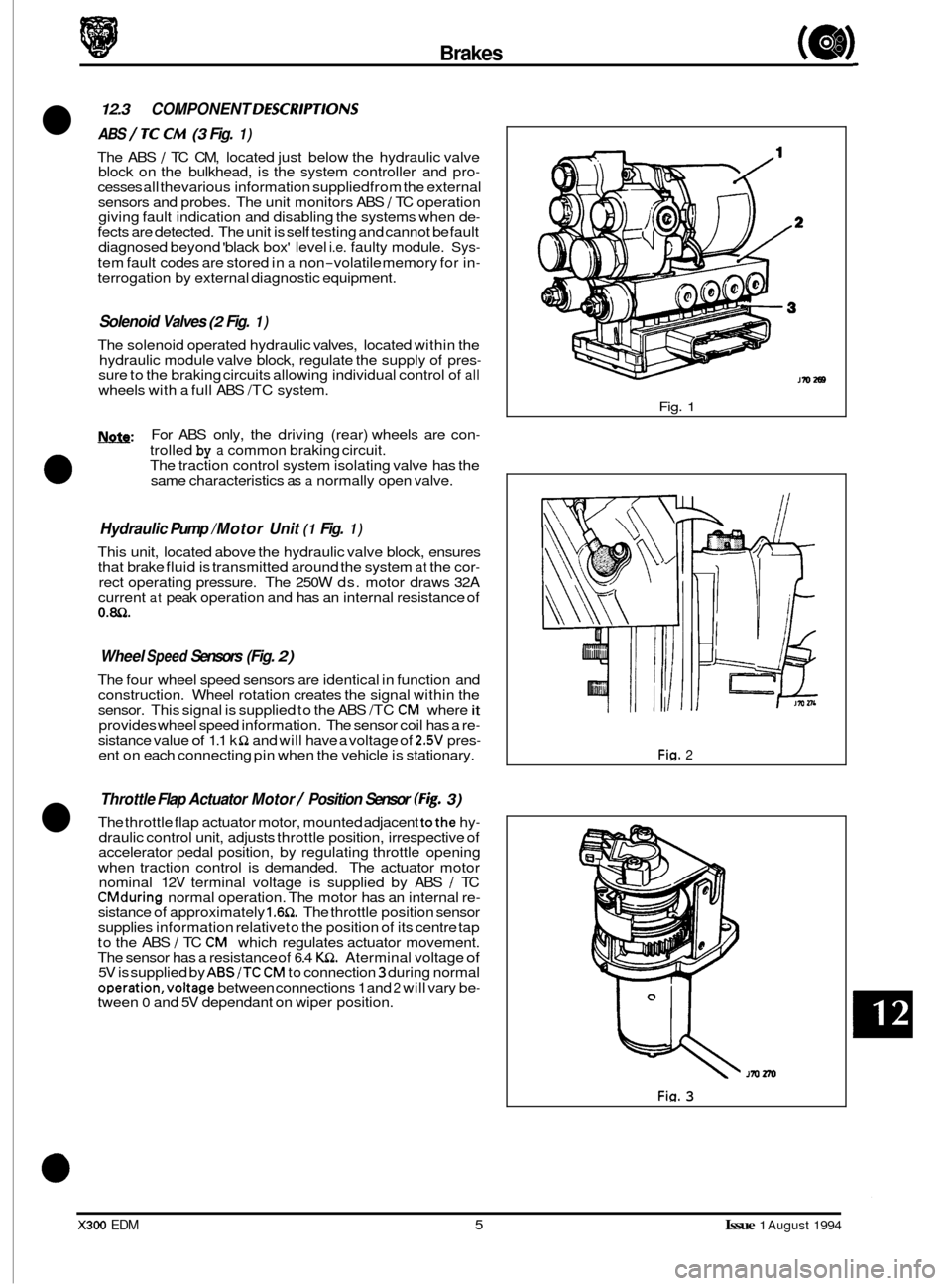

ABS / TC CM (3 Fig. 1)

The ABS / TC CM, located just below the hydraulic valve

block on the bulkhead, is the system controller and pro-

cesses all thevarious information supplied from the external

sensors and probes. The unit monitors ABS / TC operation

giving fault indication and disabling the systems when de- fects are detected. The unit is self testing and cannot be fault

diagnosed beyond 'black box' level i.e. faulty module. Sys-

tem fault codes are stored in a non-volatile memory for in- terrogation by external diagnostic equipment.

Solenoid Valves (2 Fig. 1)

The solenoid operated hydraulic valves, located within the

hydraulic module valve block, regulate the supply of pres- sure to the braking circuits allowing individual control of all wheels with a full ABS /TC system.

Nnfe: For ABS only, the driving (rear) wheels are con-

trolled by a common braking circuit.

The traction control system isolating valve has the

same characteristics as

a normally open valve. a

Hydraulic Pump /Motor Unit (1 Fig. 1)

This unit, located above the hydraulic valve block, ensures

that brake fluid is transmitted around the system at the cor- rect operating pressure. The 250W ds. motor draws 32A

current at peak operation and has an internal resistance of 0.m.

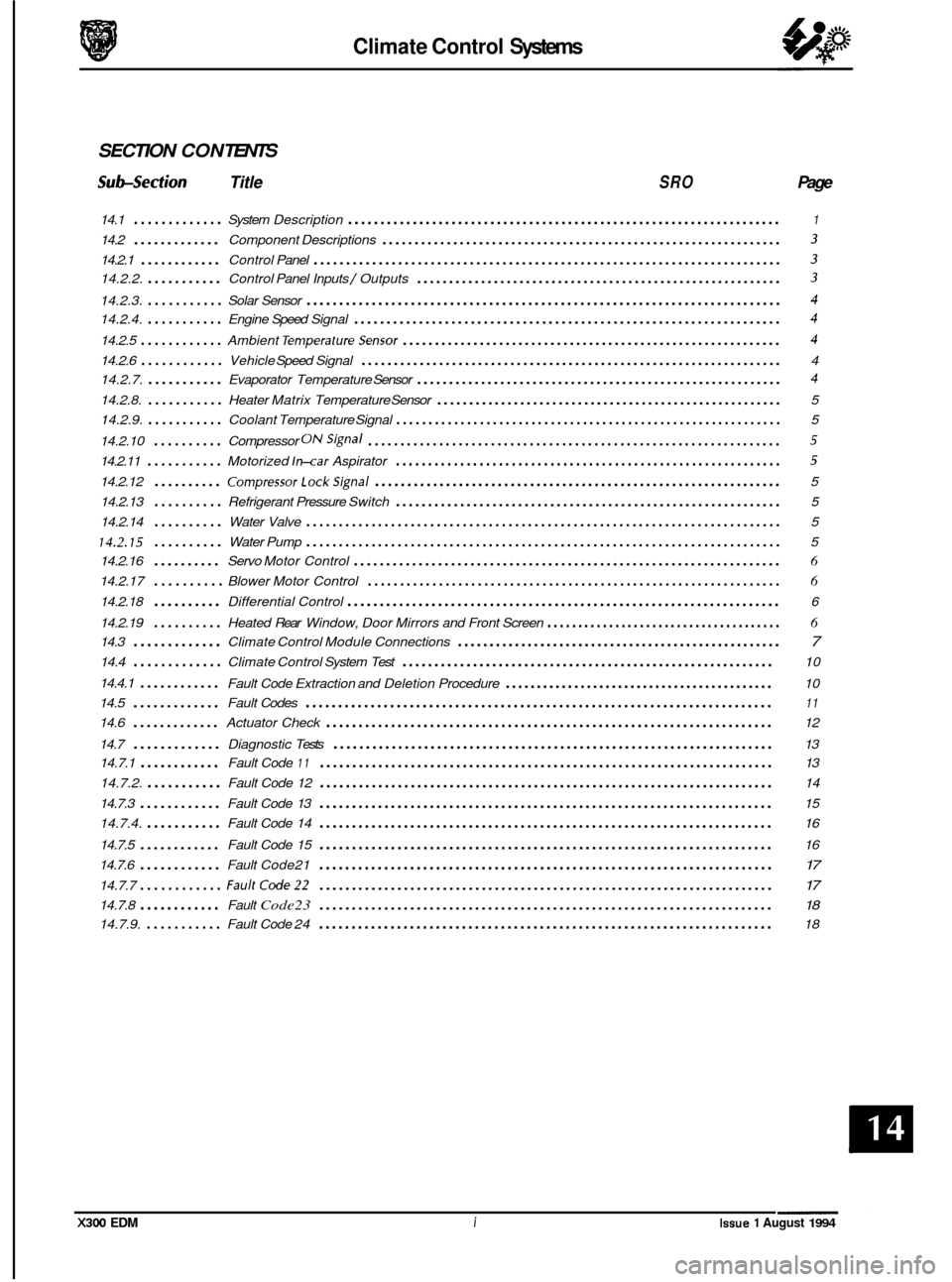

Wheel Speed Sensors (Fig. 2)

The four wheel speed sensors are identical in function and

construction. Wheel rotation creates the signal within the

sensor. This signal is supplied to the ABS /TC

CM where it provides wheel speed information. The sensor coil has a re- sistance value of 1.1 k Q and will have a voltage of 2.5V pres- ent on each connecting pin when the vehicle is stationary.

Throttle Flap Actuator Motor / Position Sensor (Fig. 3)

The throttle flap actuator motor, mounted adjacent tothe hy- draulic control unit, adjusts throttle position, irrespective of

accelerator pedal position, by regulating throttle opening

when traction control is demanded. The actuator motor

nominal 12V terminal voltage is supplied by ABS

/ TC CMduring normal operation. The motor has an internal re- sistance of approximately 1.6Q. The throttle position sensor

supplies information relative to the position of its centre tap

to the ABS

/ TC CM which regulates actuator movement.

The sensor has a resistance of 6.4 K!2. Aterminal voltage of 5V is supplied by ABS/TC CM to connection 3 during normal

operation,voltage between connections 1 and 2 will vary be- tween 0 and 5V dependant on wiper position.

Fig. 1

Fig. 2

Jrn 270

Fia. 3

X300 EDM 5 Issue 1 August 1994

Page 74 of 327

Climate Control Systems

SECTION CON TENTS

Subsection Title SRO Page

14.1 ............. System Description ................................................................... 1

14.2 ............. Component Descriptions .............................................................. 3

14.2.1 ............ Control Panel ........................................................................\

3

14.2.2. ........... Control Panel Inputs / Outputs ......................................................... 3

14.2.3. ........... Solar Sensor ........................................................................\

. 4

14.2.4. ........... Engine Speed Signal .................................................................. 4

14.2.5 ............ Ambient Temperaturesensor ........................................................... 4

14.2.6 ............ Vehicle Speed Signal ................................................................. 4

14.2.7.

........... Evaporator Temperature Sensor ......................................................... 4

14.2.8. ........... Heater Matrix Temperature Sensor ...................................................... 5

14.2.9.

........... Coolant Temperature Signal ............................................................ 5

14.2.10

.......... Compressor ONSignal ................................................................ 5

14.2.11 ........... Motorized ln-car Aspirator ............................................................ 5

14.2.12 .......... CompressorLockSignal ............................................................... 5

14.2.13

.......... Refrigerant Pressure Switch ............................................................ 5

14.2.14

.......... Water Valve ........................................................................\

. 5

14.2.15 .......... Water Pump ........................................................................\

. 5

14.2.16

.......... Servo Motor Control .................................................................. 6

14.2.17 .......... Blower Motor Control ................................................................ 6

14.2.18 .......... Differential Control ................................................................... 6

14.2.19

.......... Heated Rear Window, Door Mirrors and Front Screen ...................................... 6

14.3 ............. Climate Control Module Connections ................................................... 7

14.4 ............. Climate Control System Test .......................................................... 10

14.4.1

............ Fault Code Extraction and Deletion Procedure ........................................... 10

14.5

............. Fault Codes ........................................................................\

11

14.6 ............. Actuator Check ..................................................................... 12

14.7

............. Diagnostic Tests .................................................................... 13

14.7.1

............ Fault Code 11 ...................................................................... 13

14.7.2.

........... Fault Code 12 ...................................................................... 14

14.7.3

............ Fault Code 13 ...................................................................... 15

14.7.4.

........... Fault Code 14 ...................................................................... 16

14.7.5

............ Fault Code 15 ...................................................................... 16

14.7.6

............ Fault Code21 ...................................................................... 17

14.7.7 ............ FaultCode22 ...................................................................... 17

14.7.8 ............ Fault Code23 ...................................................................... 18

14.7.9. ........... Fault Code 24 ...................................................................... 18

X300 EDM i Issue 1 August 1994

Page 76 of 327

Climate Control Systems

.-)

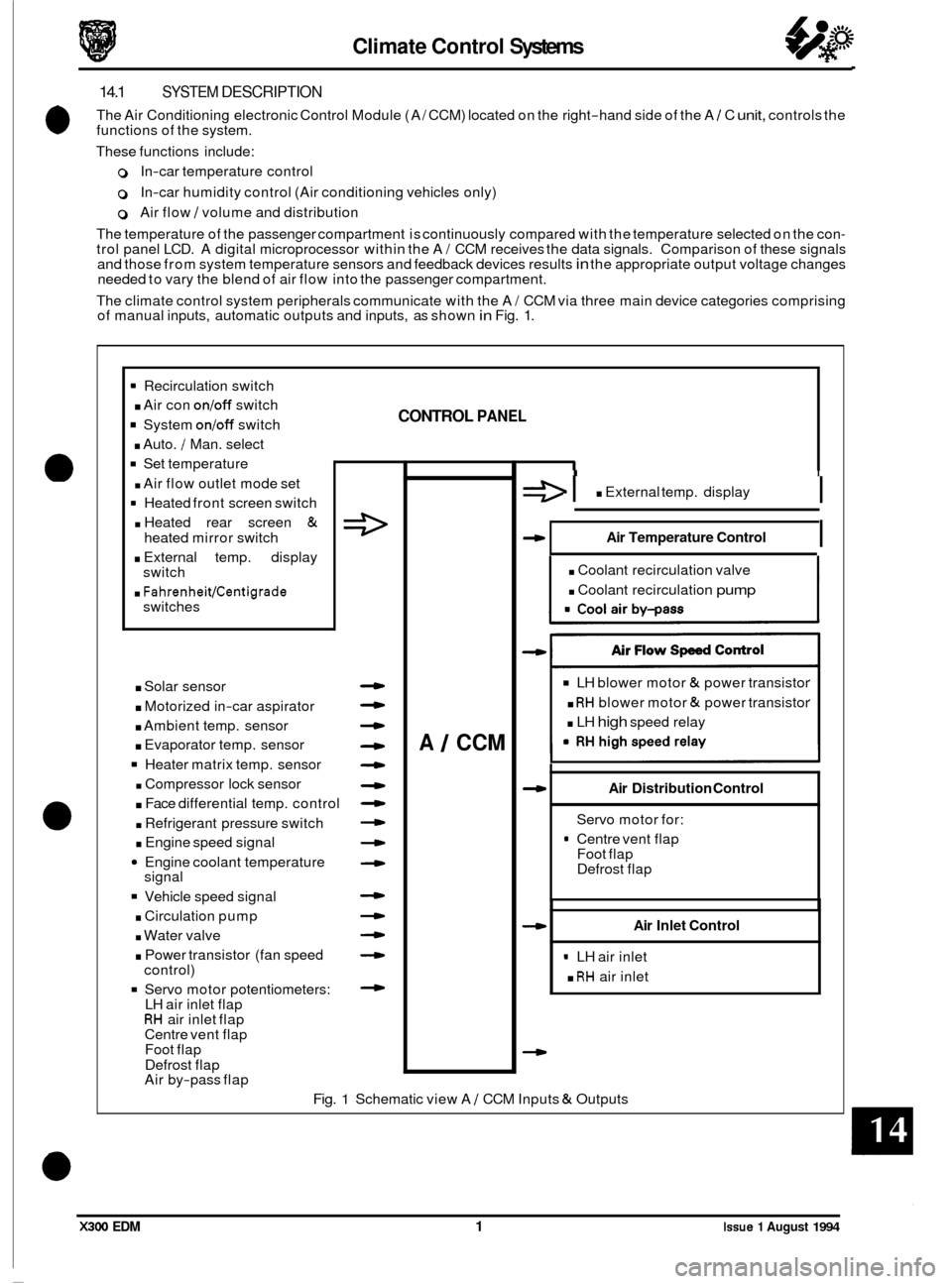

14.1 SYSTEM DESCRIPTION

The Air Conditioning electronic Control Module (A/ CCM) located on the right-hand side of the A / C unit, controls the 0 functions of the system.

These functions include:

0 In-car temperature control

0 In-car humidity control (Air conditioning vehicles only)

0 Air flow / volume and distribution

The temperature of the passenger compartment is continuously compared with the temperature selected on the con

- trol panel LCD. A digital microprocessor within the A/ CCM receives the data signals. Comparison of these signals

and those from system temperature sensors and feedback devices results in the appropriate output voltage changes

needed to vary the blend of air flow into the passenger compartment.

The climate control system peripherals communicate with the A/ CCM via three main device categories comprising

of manual inputs, automatic outputs and inputs, as shown

in Fig. 1.

Air Temperature Control I

9 Recirculation switch

. Air con on/off switch

System on/off switch

. Auto. / Man. select

Set temperature

. Air flow outlet mode set

Heated front screen switch

. Heated rear screen &

heated mirror switch

. External temp. display

switch

. FahrenheiVCentigrade switches

4

. Solar sensor

. Motorized in-car aspirator

. Ambient temp. sensor

. Evaporator temp. sensor

Heater matrix temp. sensor

. Compressor lock sensor

. Face differential temp. control

. Refrigerant pressure switch

. Engine speed signal

Engine coolant temperature

Vehicle speed signal

. Circulation pump

. Water valve

. Power transistor (fan speed

Servo motor potentiometers:

signal

control)

LH air inlet flap

RH air inlet flap

Centre vent flap

Foot flap

Defrost flap

Air by

-pass flap

Air Inlet Control

9 LH air inlet

. RH air inlet

CONTROL PANEL

1

A / CCM

I I

I . External temp. display I

. Coolant recirculation valve

. Coolant recirculation pump

LH blower motor & power transistor

. RH blower motor & power transistor

. LH high speed relay

Air Distribution Control

Servo motor for:

9 Centre vent flap

Foot flap

Defrost flap

Fig. 1 Schematic view A / CCM Inputs & Outputs

X300 EDM 1 Issue 1 August 1994

Page 78 of 327

Climate Control Systems

System Differences

m:

Heater only vehicles do not have the following fitted:

This section applies generally to both air conditioning and heater systems. System specific descriptions, pro-

cedures, tests etc. are indicated.

0 Solar sensor

0 Clutch request and acknowledge circuitry.

0 Refrigerant pressure switch.

0 Control panel - deletion of air conditioning button.

6 cyl. engined vehicles do not have either the electrical load inhibit or the compressor lock sensor.

Heated Front Screen

(HFS) is optional on both air conditioning and heater panel versions.

14.2 COMPONENT DESCRIPTIONS

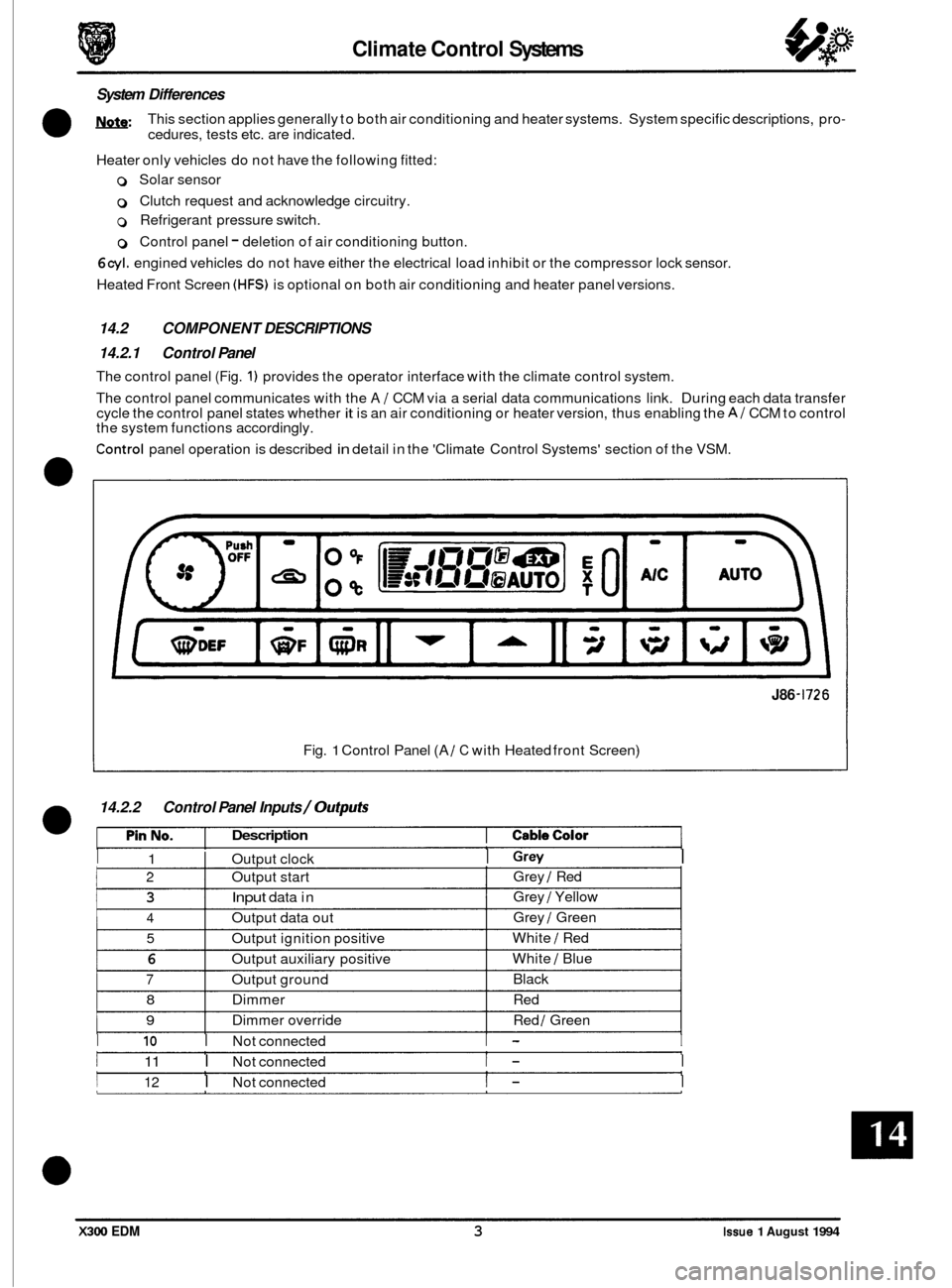

14.2.1 Control Panel

The control panel (Fig. 1) provides the operator interface with the climate control system.

The control panel communicates with the

A / CCM via a serial data communications link. During each data transfer

cycle the control panel states whether it is an air conditioning or heater version, thus enabling the A/ CCM to control

the system functions accordingly.

Tontrol panel operation is described in detail in the 'Climate Control Systems' section of the VSM.

-

Fig. 1 Control Panel (A / C with Heated front Screen)

J86 - I726

14.2.2 Control Panel Inputs /Outputs

Description I CableColor

I 1 I Output clock I Grey I

2 Output start Grey / Red

3 Input data

in Grey / Yellow

4 Output

data out Grey / Green

5 Output

ignition positive White / Red

6 Output auxiliary positive

White / Blue

7 Output

ground Black

8 Dimmer

Red

9 Dimmer override Red / Green

I 10 I Not connected I- I

I 11 I Not connected I- I

I 12 I Not connected l- I

X300 EDM 3 Issue 1 August 1994

Page 79 of 327

Climate Control Systems

14.2.3 Solar Sensor (Fig. 1)

The solar sensor is mounted on top of the facia, between the

facia defrost grilles.

The sensor isconstructed around

a photo-diode to measure

direct sunlight. The sensor provides an output response sig-

nal totheA1CCM;thisensuresthe in-cartemperaturestabil- ity whilst reducing outlet temperature to compensate for

solar load heating. The solar sensor is fitted to aircondition- ing vehicles only.

14.2.4 Engine Speed Signal

The A 1 CCM receives an engine speed signal from the En- gine Control Module (ECM).

This signal facilitates compressor lock sensing (12 cyl. ve- hicles only).

This signal also aids the A

1 CCM inhibition of the heated

screen relays. At engine speeds lower than 800 RPM the A I CCM assumes poor idle or engine not running and will not

permit the selection of the heated screens.

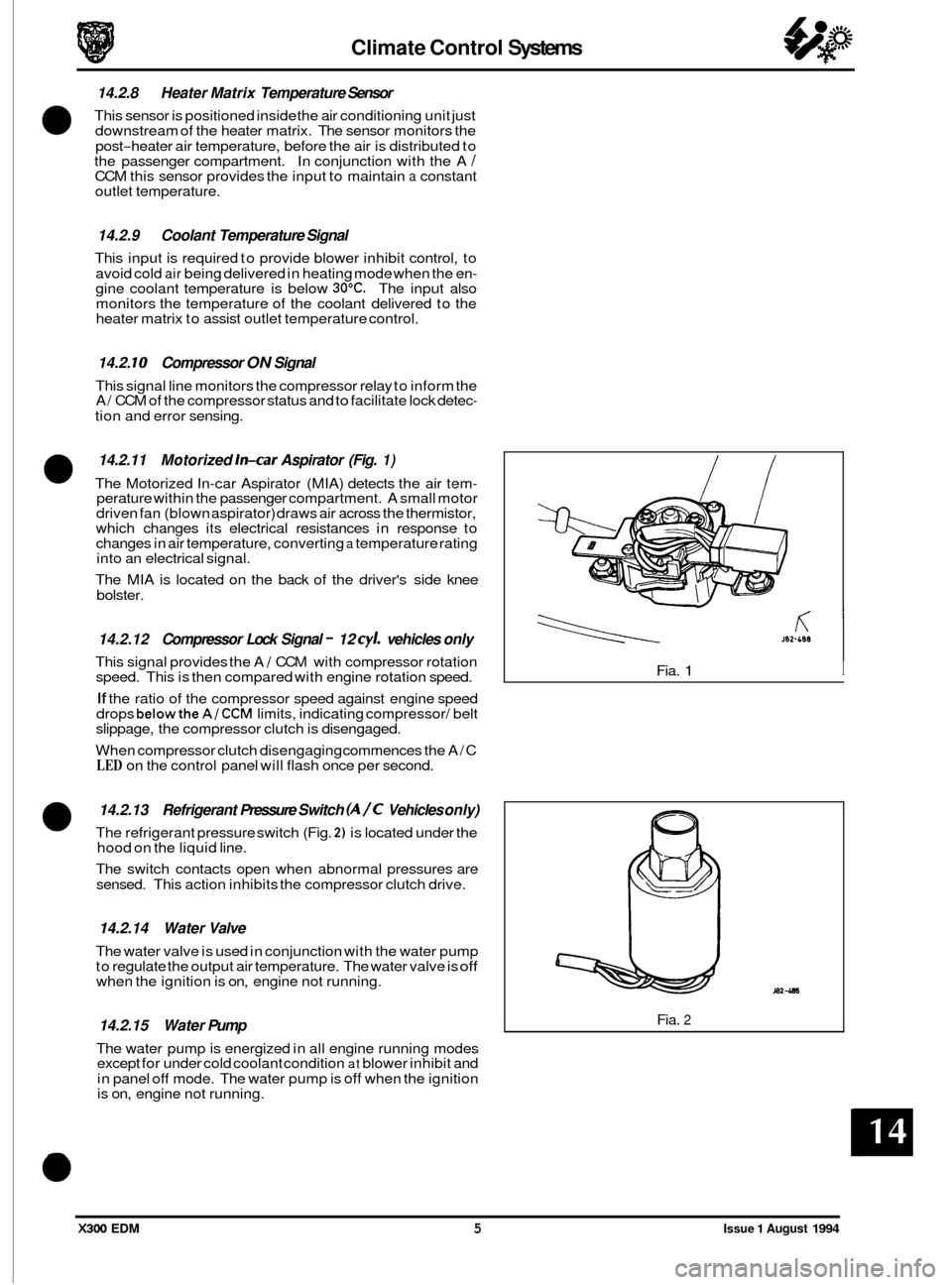

14.2.5 Ambient Temperature Sensor (Fig. 2)

The ambient temperature sensor is located within the LH

brake cooling duct.

The sensor detects exterior airtemperature and provides the

A

I CCM with a signal to allow compensation for ambient

conditions.

The A

1 CCM is then capable of informing the control panel of the ambient air temperature in both Centigrade and

Fahrenheit, and updates the information every four

seconds.

The sensor is damped and

so does not detect temperature

fluctuations as quickly as other temperature sensors. This

facility prevents temporary temperature fluctuations affec

- ting overall temperature control.

14.2.6 Vehicle Speed Signal

The A 1 CCM receives a road speed signal from the instru- ment pack, derived from the ABS 1 TC CM.

This signal is required to control the blower fan speed to mi

- nimise the effects of ram air, i.e. blower fan speed changes

in proportion to vehicle road speed.

The signal also determines the frequency

at which the ambi- ent air temperature is updated. The road speed compensa-

tion for blower control is inhibited when the selected

temperature is 'LO (maximum cooling) and 'HI' (maximum

heating) and defrost mode.

14.2.7 Evaporator Temperature Sensor

Located next to the evaporator fins, the sensor detects the air temperature leaving the evaporator, and sends this sig- nal to the A 1 CCM.

When the temperature approaches

OOC, the A 1 CCM disen-

gages the compressor to prevent freezing conditions. When

thetemperature rises above3OC.theAlCCM re-engagesthe

compressor.

J82-L06 Fig. 1

Fig. 2

0

0

Issue 1 August 1994 4 X300 EDM

Page 80 of 327

Climate Control Systems

14.2.8 Heater Matrix Temperature Sensor

This sensor is positioned inside the air conditioning unit just

downstream of the heater matrix. The sensor monitors the

post

-heater air temperature, before the air is distributed to

the passenger compartment. In conjunction with the A / CCM this sensor provides the input to maintain a constant

outlet temperature.

14.2.9 Coolant Temperature Signal

This input is required to provide blower inhibit control, to

avoid cold

air being delivered in heating mode when the en- gine coolant temperature is below 3OOC. The input also

monitors the temperature of the coolant delivered to the

heater matrix to assist outlet temperature control.

14.2. IO Compressor ON Signal

This signal line monitors the compressor relay to inform the

A/ CCM of the compressor status and to facilitate lock detec-

tion and error sensing.

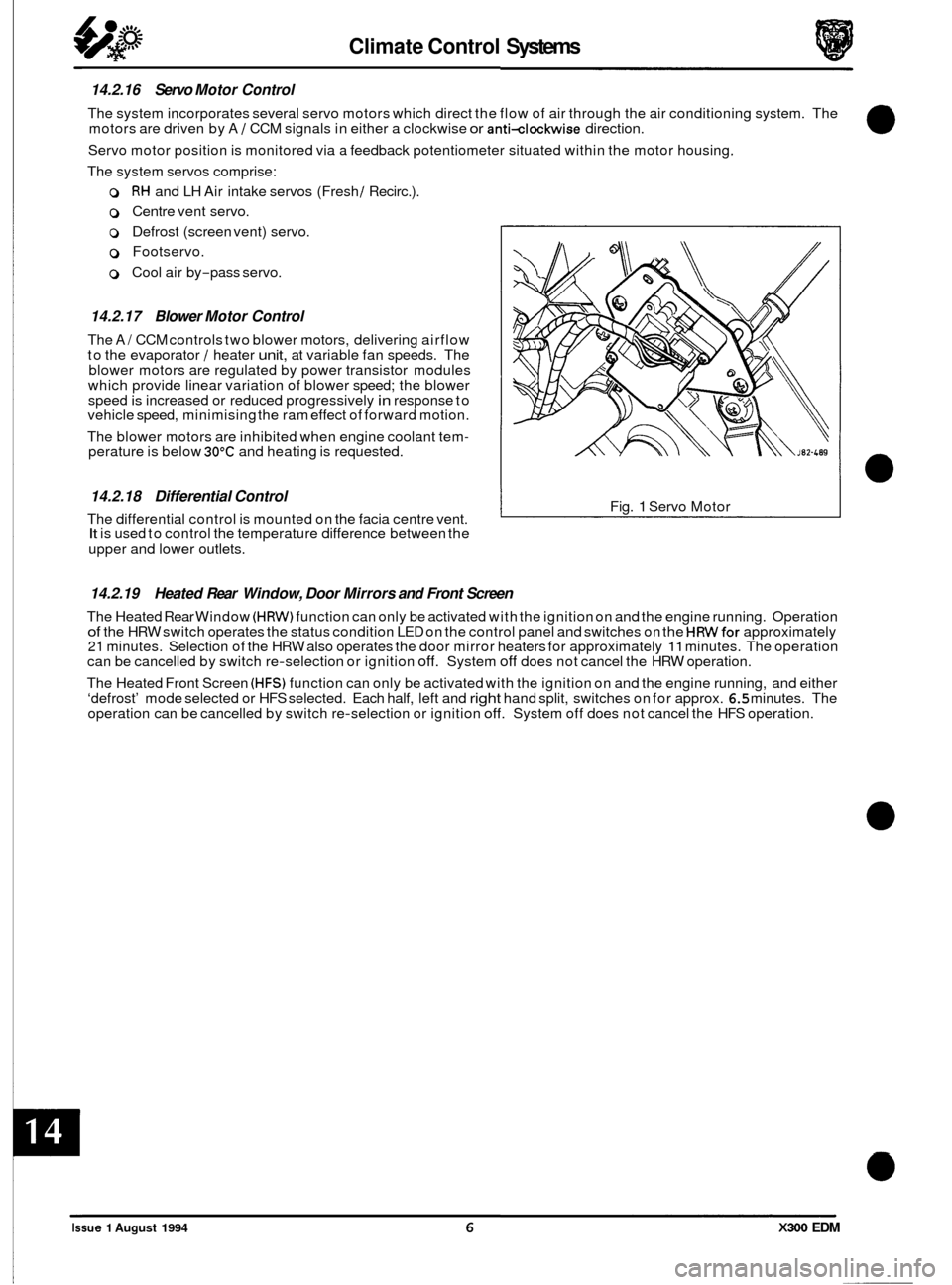

14.2.11 Motorized In-car Aspirator (Fig. 1)

The Motorized In-car Aspirator (MIA) detects the air tem- perature within the passenger compartment. A small motor

driven fan (blown aspirator) draws air across the thermistor,

which changes its electrical resistances in response to

changes in air temperature, converting

a temperature rating

into an electrical signal.

The MIA is located on the back of the driver's side knee

bolster.

14.2.12 Compressor Lock Signal - 12 cy/. vehicles only

This signal provides the A / CCM with compressor rotation

speed. This is then compared with engine rotation speed.

If the ratio of the compressor speed against engine speed

drops belowthe A/CCM limits, indicating compressor/ belt

slippage, the compressor clutch is disengaged.

When compressor clutch disengaging commences the A/C

LED on the control panel will flash once per second.

14.2.13 Refrigerant Pressure Switch (A/C Vehicles only)

The refrigerant pressure switch (Fig. 2) is located under the

hood on the liquid line.

The switch contacts open when abnormal pressures are

sensed. This action inhibits the compressor clutch drive.

14.2.14 Water Valve

The water valve is used in conjunction with the water pump

to regulate the output air temperature. The water valve is off when the ignition is on, engine not running.

14.2.15 Water Pump

The water pump is energized in all engine running modes

except for under cold coolant condition at blower inhibit and

in panel

off mode. The water pump is off when the ignition

is on, engine not running.

If

J82-488

KI Fia. 1 I

Fia. 2

X300 EDM 5 Issue 1 August 1994

Page 81 of 327

Climate Control Systems

14.2.16 Servo Motor Control

The system incorporates several servo motors which direct the flow of air through the air conditioning system. The

motors are driven by A / CCM signals in either a clockwise or anti-clockwise direction.

Servo motor position is monitored via

a feedback potentiometer situated within the motor housing.

The system servos comprise:

o RH and LH Air intake servos (Fresh / Recirc.).

0 Centre vent servo.

o Defrost (screen vent) servo.

0 Footservo.

0 Cool air by-pass servo.

14.2.17 Blower Motor Control

The A/ CCM controls two blower motors, delivering airflow

to the evaporator / heater unit, at variable fan speeds. The

blower motors are regulated by power transistor modules

which provide linear variation of blower speed; the blower

speed

is increased or reduced progressively in response to

vehicle speed, minimising the ram effect of forward motion.

The blower motors are inhibited when engine coolant tem

- perature is below 30°C and heating is requested.

14.2.18 Differential Control

The differential control is mounted on the facia centre vent. It is used to control the temperature difference between the

upper and lower outlets. Fig.

1 Servo

Motor

14.2.19 Heated Rear Window, Door Mirrors and Front Screen

The Heated Rear Window (HRW) function can only be activated with the ignition on and the engine running. Operation of the HRW switch operates the status condition LED on the control panel and switches on the HRWfor approximately 21 minutes. Selection of the HRW also operates the door mirror heaters for approximately 11 minutes. The operation

can be cancelled by switch re-selection or ignition off. System off does not cancel the HRW operation.

The Heated Front Screen

(HFS) function can only be activated with the ignition on and the engine running, and either

‘defrost’ mode selected or HFS selected. Each half, left and right hand split, switches on for approx. 6.5 minutes. The

operation can be cancelled by switch re-selection or ignition off. System off does not cancel the HFS operation.

0

0

Issue 1 August 1994 6 X300 EDM

Page 83 of 327

Climate Control Systems

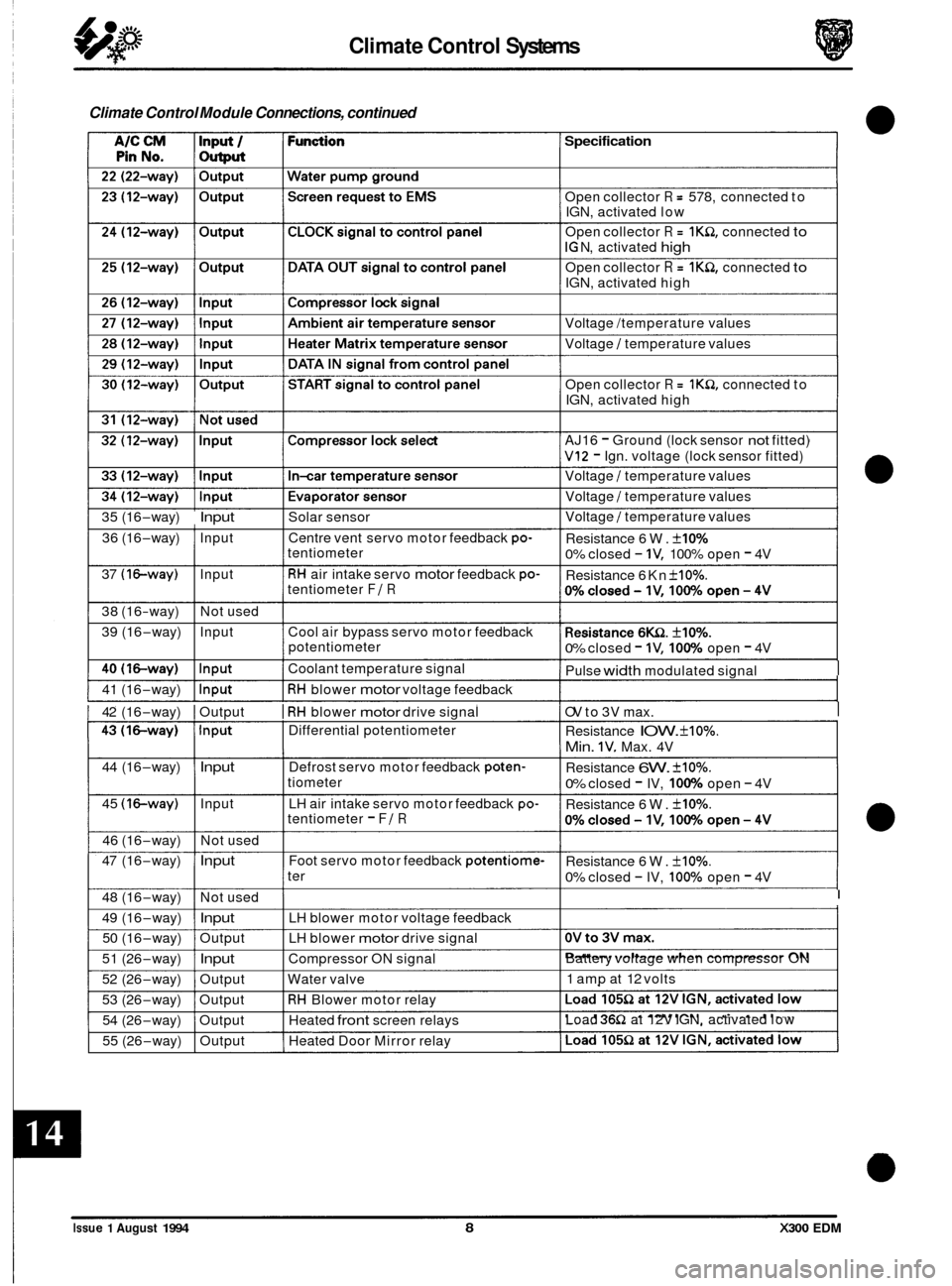

Climate Control Module Connections, continued

35 (16-way) Input Solar sensor

36 (16

-way) Input Centre vent servo motor feedback po- tentiometer

37

(16-way) Input RH air intake servo motor feedback po- tentiometer F / R

38 (16-way) Not used

39 (16

-way) Input Cool air bypass servo motor feedback

potentiometer

I 40(16-way) llnput I Coolant temperature signal

1 41 (16-way) llnput I RH blower motor voltage feedback

I 42 (16-way) I Output I RH blower motor drive signal

I 43(16-way) I Input

I Differential potentiometer

44 (16

-way) Input Defrost servo motor feedback poten-

tiometer

45

(%-way) Input LH air intake servo motor feedback po- tentiometer - F / R

46 (16-way) Not used

47 (16

-way) Input Foot servo motor feedback potentiome-

ter

48 (16

-way) Not used

49 (16

-way) Input LH blower motor voltage feedback

50 (16

-way) Output LH blower motor drive signal

51 (26

-way) Input Compressor ON signal

52 (26

-way) Output Water valve

53 (26

-way) Output RH Blower motor relay

54 (26

-way) Output Heated front screen relays

55 (26

-way) Output Heated Door Mirror relay

Specification

Open collector R = 578, connected to

IGN, activated low

Open collector

R = IKn, connected to

IG N, activated high

Open collector R = IKQ, connected to

IGN, activated high

Voltage /temperature values

Voltage

/ temperature values

Open collector

R = IKQ, connected to

IGN, activated high

AJ16

- Ground (lock sensor not fitted)

VI2 - Ign. voltage (lock sensor fitted)

Voltage

/ temperature values

Voltage

/ temperature values

Voltage

/ temperature values

Resistance 6W.

&IO%

0% closed - IV, 100% open - 4V

Resistance 6Kn

+IO%.

0% closed - IV, IOW0 open - 4V

Pulse

width modulated signal I

OV to 3V max. I

Resistance IOW. &IO%.

Min. IV, Max. 4V

Resistance

6W. +IO%.

0% closed - IV, IOW0 open - 4V

Resistance 6W.

+IO%.

Resistance 6W. &IO%.

0% closed - IV, 10096 open - 4V

I

Battery voltage when compressor ON

1 amp at 12 volts

Load

36Q at 12V IGN, activated low

0

0

0

0

Issue 1 August 1994 8 X300 EDM

Page 85 of 327

Climate Control Systems

Actlon

Simultaneously hold FACE and FAN and switch the ignition

ON

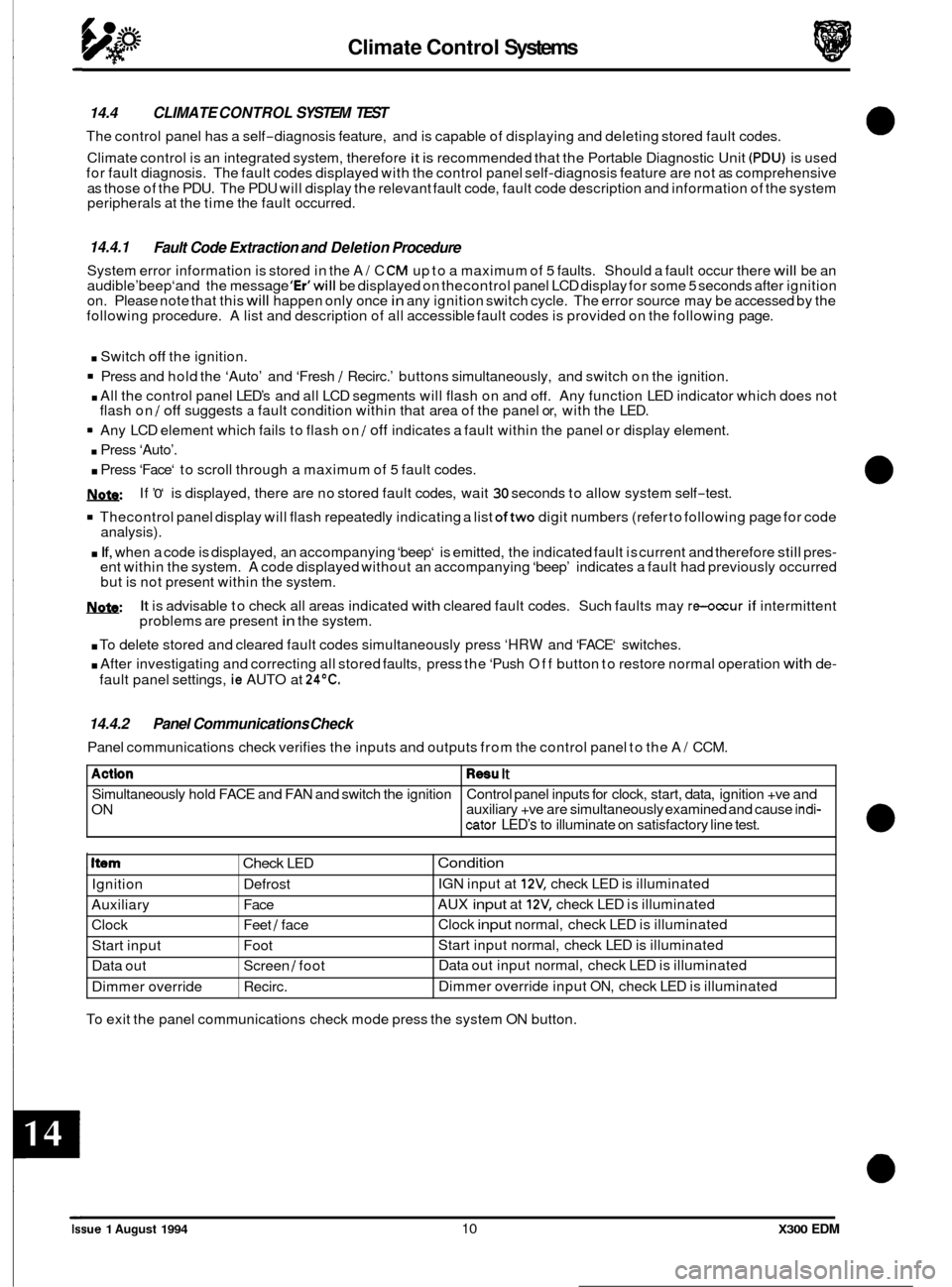

14.4 CLIMATE CONTROL SYSTEM TEST

The control panel has a self-diagnosis feature, and is capable of displaying and deleting stored fault codes.

Climate control is an integrated system, therefore

it is recommended that the Portable Diagnostic Unit (PDU) is used

for fault diagnosis. The fault codes displayed with the control panel self-diagnosis feature are not as comprehensive

as those of the PDU. The PDU will display the relevant fault code, fault code description and information of the system

peripherals at the time the fault occurred.

Resu It

Control panel inputs for clock, start, data, ignition +ve and

auxiliary +ve are simultaneously examined and cause indi-

cator LED’s to illuminate on satisfactory line test.

14.4.1

System error information is stored in the A/ C CM up to a maximum of 5 faults. Should a fault occur there will be an

audible’beep‘and the message ‘Er’will be displayed on thecontrol panel LCD display for some 5 seconds after ignition

on. Please note that this will happen only once in any ignition switch cycle. The error source may be accessed by the

following procedure. A list and description of all accessible fault codes is provided on the following page.

Fault Code Extraction and Deletion Procedure

I Item Check LED

Ignition Defrost

Auxiliary Face

Clock Feet

/ face

Start input Foot

Data out Screen

/ foot

Dimmer override Recirc.

. Switch off the ignition.

Press and hold the ‘Auto’ and ‘Fresh / Recirc.’ buttons simultaneously, and switch on the ignition.

. All the control panel LED’s and all LCD segments will flash on and off. Any function LED indicator which does not

flash on / off suggests a fault condition within that area of the panel or, with the LED.

Any LCD element which fails to flash on

/ off indicates a fault within the panel or display element.

. Press ‘Auto’.

. Press ‘Face‘ to scroll through a maximum of 5 fault codes.

W

Thecontrol panel display will flash repeatedly indicating a list oftwo digit numbers (refer to following page for code

analysis).

. If, when a code is displayed, an accompanying ‘beep‘ is emitted, the indicated fault is current and therefore still pres- ent within the system. A code displayed without an accompanying ‘beep’ indicates a fault had previously occurred

but is not present within the system.

It is advisable to check all areas indicated with cleared fault codes. Such faults may re-occur if intermittent

problems are present in the system.

If

’0‘ is

displayed, there are no stored fault codes, wait 30 seconds to allow system self-test.

W:

. To delete stored and cleared fault codes simultaneously press ‘HRW and ‘FACE‘ switches.

. After investigating and correcting all stored faults, press the ‘Push Off button to restore normal operation with de-

fault panel settings, ie AUTO at 24OC.

Condition

IGN input at 12V, check LED is illuminated

AUX

input at 12V, check LED is illuminated

Clock

input normal, check LED is illuminated

Start input normal, check LED is illuminated

Data out input normal, check LED is illuminated

Dimmer override input

ON, check LED is illuminated

14.4.2 Panel Communications Check

Panel communications check verifies the inputs and outputs from the control panel to the A/ CCM.

To exit the panel communications check mode press the system ON button.

Issue 1 August 1994 10 X300 EDM

Page 86 of 327

Climate Control Systems

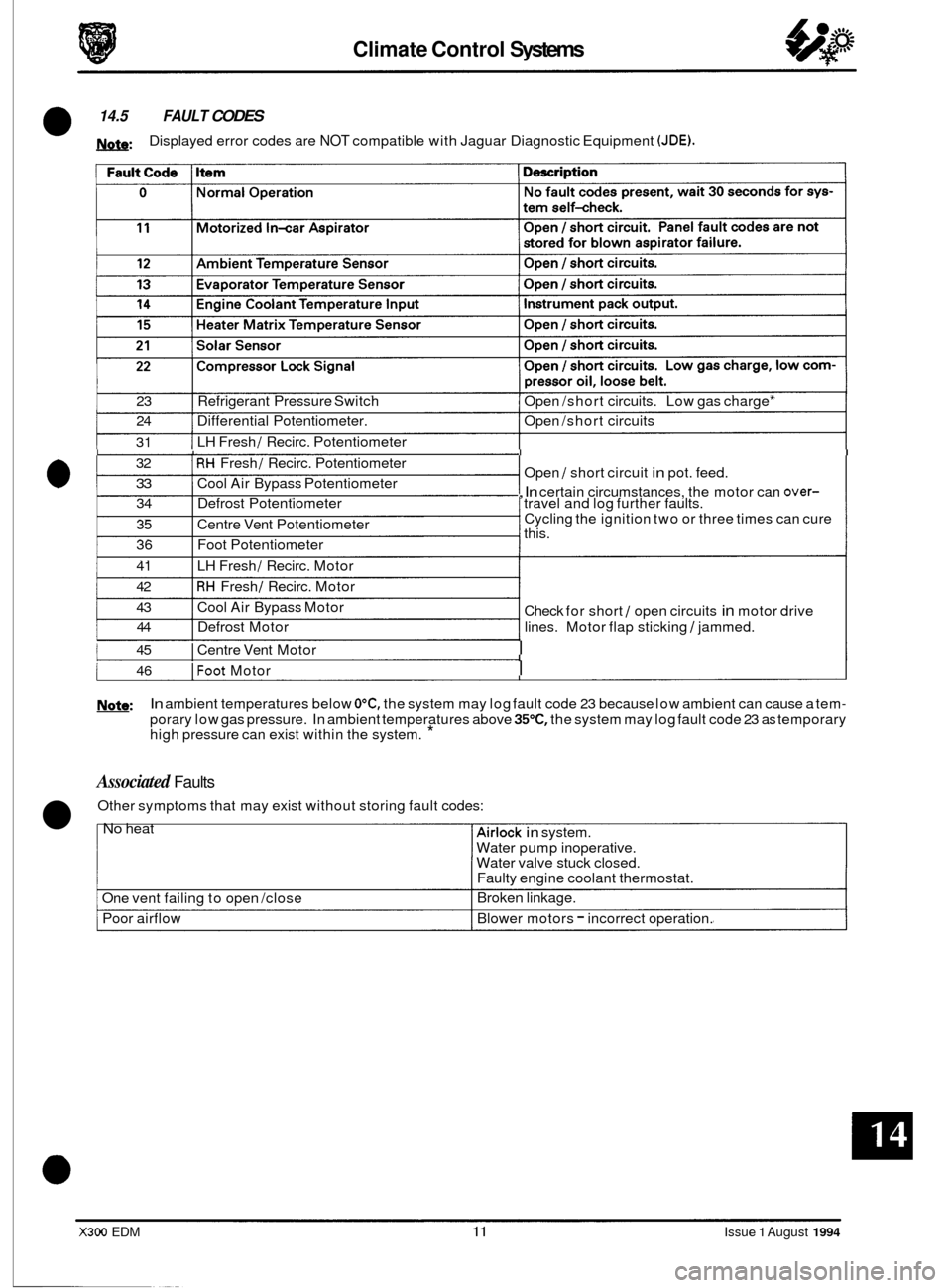

0 14.5 FAULT CODES

J&&: Displayed error codes are NOT compatible with Jaguar Diagnostic Equipment (JDE).

23 Refrigerant Pressure Switch Open /short circuits. Low gas charge*

24 Differential Potentiometer. Open /short circuits

31 LH Fresh

/ Recirc.

Potentiometer I I I I RH Fresh / Recirc. Potentiometer

Open / short circuit in pot. feed.

32

, In certain

circumstances, the motor can over- 0 33 Cool Air Bypass Potentiometer

34 Defrost Potentiometer travel and log further faults.

35

36 Foot Potentiometer Cycling

the ignition two or three times can cure

this.

Centre

Vent Potentiometer

41

42

I LH Fresh / Recirc. Motor

I RH Fresh / Recirc. Motor

43 Cool Air Bypass Motor

44 Defrost Motor lines. Motor flap sticking

/ jammed.

Check

for short

/ open circuits in motor drive

1 45 I Centre Vent Motor I

1 46 IFoot Motor I

W: In ambient temperatures below OOC, the system may log fault code 23 because low ambient can cause a tem-

porary low gas pressure. In ambient temperatures above 35"C, the system may log fault code 23 as temporary

high pressure can exist within the system. *

Associated Faults

Other symptoms that may exist without storing fault codes:

Airlock in system.

Water pump inoperative.

Water valve stuck closed.

Faulty engine coolant thermostat.

Broken linkage.

Blower motors

- incorrect operation.

No heat

One vent failing to open /close

Poor airflow

X300 EDM 11 Issue 1 August 1994