lock JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 92 of 327

Climate Control Systems

14.7.6 FaulfCode21

Solar Sensor

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A / CCM short circuit to ground.

The sensor provides a linear output response signal to

pin 35 (16-way connector) A/ CCM; the output ranges from 0 to 5 volts, the voltage will drop as light intensity increases.

A resistance check can be carried out on the sensor and should conform with the figures below:

With no light on the sensor, the resistance should read approximately 15

kL2.

With increasing light intensity, the resistance should decrease from 15 kQ.

Inspect the sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the sensor and harness appear correct, suspect the A/ CCM.

14.7.7 Fadf Code 22

Compressor lock Signal

(12 cy/. vehicles only)

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A/ CCM short circuit to ground.

The compressor lock sensor provides an

a.c. signal proportional to engine speed. As engine speed increases the a.c. signal voltage value will increase.

A voltage checkcan be carried out on the sensor and should read approximately 0.5V a.c. whilst the compressor is ON and OV whilst the compressor is OFF, measured between pin 26 (12-way connector) and pin 19 (22-way connector) A

/ C CM.

If the reading is OV whilst the compressor is ON, suspect the sensor or the sensor harness (open circuit or short circuit

to ground).

Check the resistance between pins 1 and 2 of the compressor lock sensor, value should be

190a & 20%.

If the resistance measured falls outside the limits, renew the compressor lock sensor.

Inspect the sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the sensor and harness appear correct, suspect the AI CCM.

X300 EDM 17 Issue 1 August 1994

Page 96 of 327

Climate Control Systems

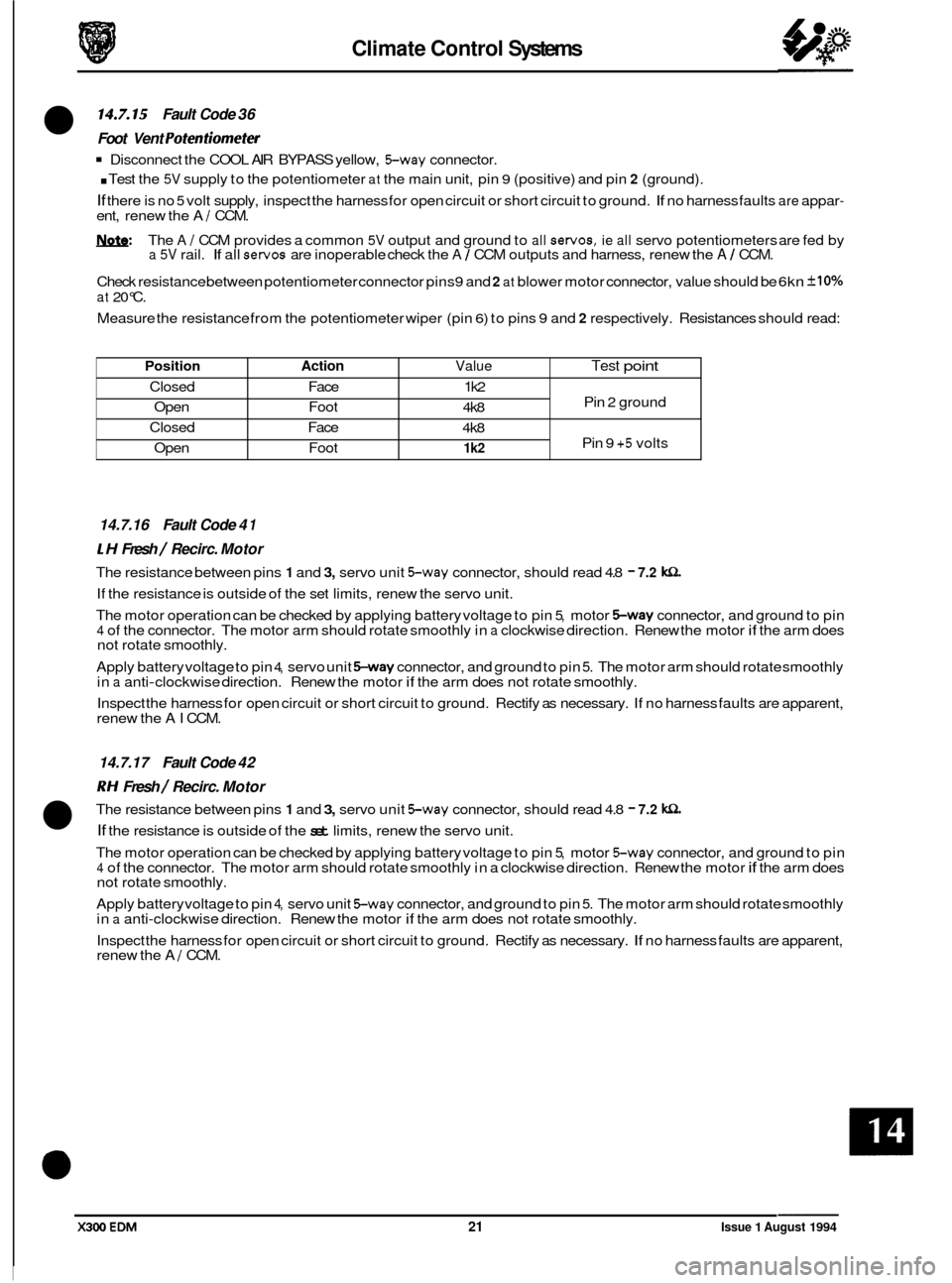

Position Action Value Test point

Closed Face 1 k2

Open Foot

4k8

Closed Face

4k8

Open Foot

1 k2

Pin 2 ground

Pin

9 +5 volts

14.7.15 Fault Code 36

Foot Vent

Potentiometer

Disconnect the COOL AIR BYPASS yellow, Sway connector.

. Test the 5V supply to the potentiometer at the main unit, pin 9 (positive) and pin 2 (ground).

If there is no 5 volt supply, inspect the harness for open circuit or short circuit to ground. If no harness faults are appar- ent, renew the A I CCM.

&&: The A I CCM provides a common 5V output and ground to all servos, ie all servo potentiometers are fed by a 5V rail. If all servos are inoperable check the A 1 CCM outputs and harness, renew the A 1 CCM.

Check resistance between potentiometer connector pins9 and

2 at blower motor connector, value should be 6kn +10%

at 20°C.

Measure the resistance from the potentiometer wiper (pin

6) to pins 9 and 2 respectively. Resistances should read:

14.7.16 Fault Code 4 1

1 H Fresh / Recirc. Motor

The resistance between pins 1 and 3, servo unit Sway connector, should read 4.8 - 7.2 kn.

If the resistance is outside of the set limits, renew the servo unit.

The motor operation can be checked by applying battery voltage to pin

5, motor %way connector, and ground to pin 4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, servo unit %ay connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

Inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the AI CCM.

14.7.17 Fault Code 42

RH Fresh / Recirc. Motor

The resistance between pins 1 and 3, servo unit Sway connector, should read 4.8 - 7.2 kn.

If the resistance is outside of the set limits, renew the servo unit.

The motor operation can be checked by applying battery voltage to pin

5, motor Sway connector, and ground to pin 4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, servo unit Sway connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

Inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the A I CCM.

21 Issue 1 August 1994

Page 97 of 327

Climate Control Systems

14.7.18 Fault Code 43

Cool Air Bypass Servomotor

The resistance between pins 1 and 3, motor Sway connector, should read 4.8 - 7.2 WZ.

If the resistance is outside of the set limits, renew the motor.

The motor operation can be checked by applying battery voltage to pin

5, motor Sway connector, and ground to pin

4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, motor Sway connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

Inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the AI CCM.

14.7.19 Fault Code 44

Servomotor

- Defrost

The resistance between pins 1 and 3, motor Sway connector, should read 4.8 - 7.2 kQ.

If the resistance is outside of the set limits, renew the motor.

The motor operation can be checked by applying battery voltage to pin

5, motor Sway connector, and ground to pin 4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, motor Sway connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the A I CCM.

14.7.20 Fault Code 45

Servomotor

- Face

The resistance between pins 1 and 3, motor &way connector, should read 4.8 - 7.2 WZ.

If the resistance is outside of the set limits, renew the motor.

The motor operation can be checked by applying battery voltage to pin

5, motor Sway connector, and ground to pin 4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, motor 5-way connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

Inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the AI CCM.

14.7.21 Fault Code 46

Servomotor

- Foot

The resistance between pins 1 and 3, motor Sway connector, should read 4.8 - 7.2 WZ.

If the resistance is outside of the set limits, renew the motor.

The motor operation can be checked by applying battery voltage to pin

5, motor Sway connector, and ground to pin 4 of the connector. The motor arm should rotate smoothly in a clockwise direction. Renew the motor if the arm does

not rotate smoothly.

Apply battery voltage to pin

4, motor Sway connector, and ground to pin 5. The motor arm should rotate smoothly

in a anti-clockwise direction. Renew the motor if the arm does not rotate smoothly.

Inspect the harness for open circuit or short circuit to ground. Rectify as necessary.

If no harness faults are apparent,

renew the AI CCM.

0

0

0

Issue 1 August 1994 22 X300 EDM

Page 102 of 327

Electrical IT

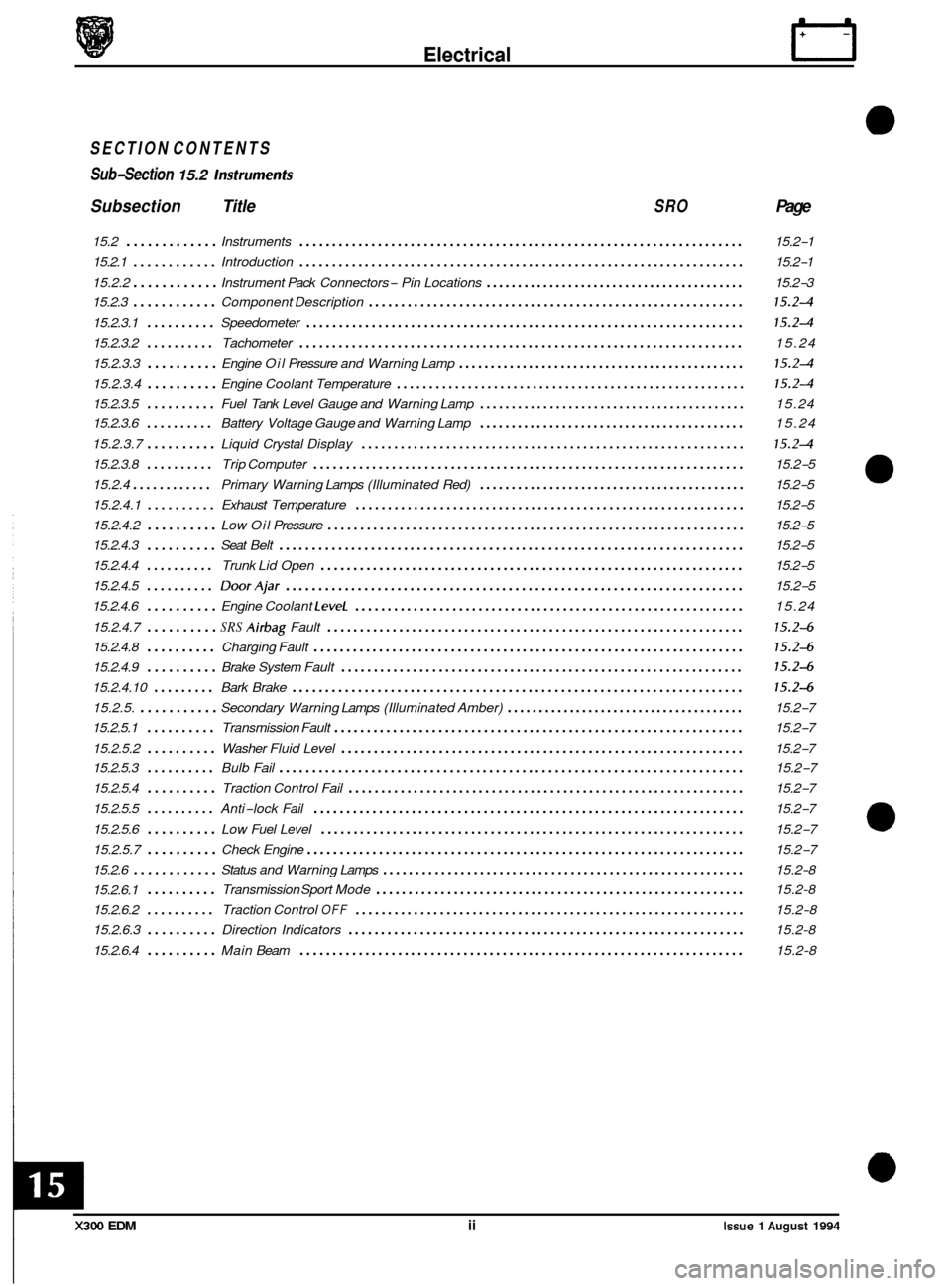

SECTION CONTENTS

Sub

-Section 15.2 lnsfrumenfs

Subsection Title SRO Page

15.2 ............. Instruments .................................................................... 15.2-1

15.2.1

............ Introduction .................................................................... 15.2-1

15.2.2

............ Instrument Pack Connectors - Pin Locations ......................................... 15.2-3

15.2.3

............ Component Description .......................................................... 15.24

15.2.3.1 .......... Speedometer ................................................................... 15.24

15.2.3.2 .......... Tachometer .................................................................... 15.24

15.2.3.3

.......... Engine Oil Pressure and Warning Lamp ............................................. 15.24

15.2.3.4 .......... Engine Coolant Temperature ...................................................... 15.24

15.2.3.5 .......... Fuel Tank Level Gauge and Warning Lamp .......................................... 15.24

15.2.3.6

.......... Battery Voltage Gauge and Warning Lamp .......................................... 15.24

15.2.3.7

.......... Liquid Crystal Display ........................................................... 15.24

15.2.3.8 .......... Trip Computer .................................................................. 15.2-5

15.2.4

............ Primary Warning Lamps (Illuminated Red) .......................................... 15.2-5

15.2.4.1

.......... Exhaust Temperature ............................................................ 15.2-5

15.2.4.2

.......... Low Oil Pressure ................................................................ 15.2-5

15.2.4.3

.......... Seat Belt ....................................................................... \

15.2-5

15.2.4.4

.......... Trunk Lid Open ................................................................. 15.2-5

15.2.4.5

.......... DoorAjar ...................................................................... 15.2-5

15.2.4.6

.......... Engine Coolant LeveL ............................................................ 15.24

15.2.4.7

.......... SRS Airbag Fault ................................................................ 15.24

15.2.4.8 .......... Charging Fault .................................................................. 15.24

15.2.4.9 .......... Brake System Fault .............................................................. 15.24

15.2.4.10 ......... Bark Brake ..................................................................... 15.24

15.2.5. ........... Secondary Warning Lamps (Illuminated Amber) ...................................... 15.2-7

15.2.5.1

.......... Transmission Fault ............................................................... 15.2-7

15.2.5.2

.......... Washer Fluid Level .............................................................. 15.2-7

15.2.5.3

.......... Bulb Fail ....................................................................... \

15.2-7

15.2.5.4

.......... Traction Control Fail ............................................................. 15.2-7

15.2.5.5

.......... Anti-lock Fail .................................................................. 15.2-7

15.2.5.6

.......... Low Fuel Level ................................................................. 15.2-7

15.2.5.7

.......... Check Engine ................................................................... 15.2-7

15.2.6.1

.......... Transmission Sport Mode ......................................................... 15.2-8

15.2.6.2

.......... Traction Control OFF ............................................................ 15.2-8

15.2.6.3

.......... Direction Indicators ............................................................. 15.2-8

15.2.6.4

.......... Main Beam .................................................................... 15.2-8

15.2.6

............ Status

and Warning Lamps ........................................................ 15.2-8

m

a

0

e

0

X300 EDM ii Issue 1 August 1994

Page 103 of 327

Electrical IT

SECTION CON TENTS

Subsection 15.2 Instruments (continued)

Sub-Section Title SRO Page

15.2.7 ............ Fault Diagnosis ................................................................. 15.2-9

15.2.7.1

.......... Active High /Low Inputs ......................................................... 15.2-9

15.2.8.

........... Instrument Pack Pin-point Tests .................................................. 15.2-1 0

15.2.8.1 .......... Oil Pressure, Battery Condition, Coolant Temperature and Fuel Gauges ................. 15.2-1 0

75.2.8.2

.......... Speedometer .................................................................. 15.2-10

15.2.8.4

.......... Liquid Crystal Display .......................................................... 15.2-17

15.2.8.6

.......... Door Open Warning Lamp ...................................................... 15.2-12

15.2.8.7

.......... Exhaust Temperature Warning Lamp .............................................. 15.2-1 3

15.2.8.8 .......... Luggage Compartment Warning Lamp ............................................. 15.2-14

15.2.8.9

.......... Seat Belt Warning Indicator ...................................................... 15.2-1 5

15.2.8.3

.......... Tachometer ................................................................... 15.2-11

15.2.8.5

.......... Trip Computer ................................................................. 15.2-11

15.2.8.70

......... Park Brake Indicator ............................................................ 15.2-16

15.2.8.71

......... Main Beam Indicator ........................................................... 15.2-17

75.2.8.12

......... Direction Indicator Tell Tales ..................................................... 15.2-18

15.2.8.14

......... Washer Fluid Level Indicator ..................................................... 15.2-20

15.2.8.16

......... Brake Fluid Level Indicator ...................................................... 15.2-22

75.2.8.17

......... General Bulb Failure Indicator ................................................... 15.2-23

15.2.8.18

.........

75.2.8.19 .........

15.2.8.20 ......... Traction Control OFF Tell-tale .................................................... 15.2-24

0

75.2.8.13 ......... Generator IND Voltage Indicator ................................................. 15.2-19

7 5.2.8.15 ......... Engine Coolant Level indicator ................................................... 15.2-2 1

Transmission Sport mode Indicator ................................................ 75.2-24

Traction Control Failure Warning Lamp

............................................ 15.2-24

15.2.8.21

......... Anti-lock Failure Warning Lamp .................................................. 15.2-24

15.2.8.22

......... Check Engine Warning Lamp .................................................... 75.2-24

Issue 1 August 1994 iii X300 EDM

Page 114 of 327

rl E I ect r ica I

CONTINUOUS AIR BAG MIL LAMP ILLUMINATION

Inoperative Lamp Circuit or No Ignition to the Diagnostic

Module

Normal Operation

The air bag MIL Lamp is designed to illuminate for approximately six seconds when the ignition is switched 'on'; this

time has been allocated to prove the MIL Lamp operation. If, after this proving period, the DM detects faults within

the system the MIL Lamp will illuminate and 'AIR BAG' will be displayed to the driver. If the MIL Lamp remains ON constantly, for over 8 seconds after ignition switch on, a fault is present within the indicator circuit.

Poor connection, or disconnection, of the indicator harness will cause

a short between pins 4 and 5, connecting the

circuit to ground and giving constant illumination of the MIL Lamp.

Faulty operation

ofthe DM internal logic may fail to turn off the indicator control circuit and cause constant illumination

of the MIL Lamp.

Fault Diagnosis

1. DM connectors

8 Disarm the SRS system.

8 Inspect the DM connectors.

2. MIL Lamp short circuit.

8 Disconnect the DM.

8 Remove the plastic locking wedge from the grey DM connector.

Switch on the ignition.

8 If the MIL Lamp is not illuminated, go to step 3.

If the MIL Lamp is illuminated; short circuit to ground between pin 45 instrument pack to pin 4 DM (Y / W). Rectify

8 Arm and verify the SRS system.

the short circuit.

3. Shorting

bar

Is the connector shorting bar operating correctly ?

Yes -

8 Renew the DM.

Reconnect, arm and verify the SRS system.

8 Renew the plastic locking wedge.

. Reconnect, arm and verify the SRS system.

NO -

15.1 -8 X300 EDM Issue 1 August 1994

Page 120 of 327

Electrical I3

FAULTCODE 14

Front Impact Sensor Circuit Shorted to Ground

Normal Operation

The DM monitors voltage level at pins 2 and 6. If this voltage falls to 5 volts, or less, the MIL Lamp will illuminate and

fault code 14 will be present, indicating a short circuit to ground on either of the two front impact sensorcircuits. During

the presence of fault code 14 the DM internal thermal fuse will blow, disabling the air bag deployment circuit. If voltage

to pins

2 and 6 is restored after the fuse has blown,fault code 51, open internal fuse will be present. Fault code 14 will

be present only as long as the short to ground remains.

Possible Causes

Short to ground in any of the following circuits:

0 Front impact sensor wiring.

0 Disconnection, or poor connection of harness.

0 Front impact sensors internal ground.

Fault Diagnosis

1. Sub-circuit identification

. Disarm SRS system.

. Remove plastic locking wedge from the grey DM connector.

. Measure resistance between connector pin 3 and all of the following pins; 2,6, 17 and 18.

9 Does any resistance reading indicate short circuit ?

Yes - Renew faulty sensor.

No - Examine sensor wiring harness, locate and rectify faults as necessary.

Proceed to fault code 51 on successful diagnosis.

rm

0

0

0

0

X300 EDM Issue 1 August 1994 15.1 - 14

Page 130 of 327

rl Electrical

FAULT CODE 32

Driver-side Air Bag Circuit High Resistance or Open

Normal Operation

The DM monitors the resistance between pins 10 and 11. The value of this resistance is the sum of the two cable reel

cassettes, the air bag and is normally between

1.5~2 and 2Q. If the resistance measured exceeds 4Q the MIL Lamp will illuminate and fault code 32 will be present, indicating high resistance or open circuit on the air bag circuit.

Possible Causes

0 Poor connections or corrosion at clockspring / main harness connections.

0 Open circuit or high resistance of cable reel cassettes.

0 Open circuit or high resistance in driver-side air bag.

0 Faulty driver-side air bag wiring.

Fault Diagnosis

1. Circuit - check

. Disarm SRS system and disconnect DM.

Disconnect DM and remove plastic locking wedge from black DM harness connector.

. Measure resistance across harness connections to passenger air bag, wires KN and RF!

. Is resistance value less than 2Q ?

Yes -

. Ensure locking wedge has been removed correctly from black connector.

. Examine harness for broken, dirty or incorrectly seated connections.

. Rectify faults as necessary.

No - Proceed to step 2.

2. Resistance -check

. Is resistance measured in step 1 greater than 352 7

Yes - Proceed to step 4.

No - Proceed to step 3.

3. Fault code verification

. Reconnect DM and check if code 32 is still present.

Yes

- Renew DM.

No - Examine harness or broken, dirty or incorrectly seated connections. Rectify faults as necessary.

4. Resistance -check

. Disconnect cable reel cassette at base of steering column.

Install air bag simulator (ensure 2Q resistance of simulator before connection) in place of cable reel cassette.

Measure resistance across harness connections to air bag, wires KIN and RI?

Is resistance equal to between 1.m and 2.2Q 7

Yes - Renew cable reel cassette.

No - Examine harness wiring for open circuit, rectify faults as necessary.

5. On completion.

. Arm and verify the SRS system.

0

0

0

0

Issue 1 August 1994 15.1 - 24 X300 EDM

Page 132 of 327

Electrical rl

FAULT CODE 33

Passenger-side Air BAg Circuit High Resistance or Open

Normal Operation

The DM monitors the resistance between pins 8 and 9. The value of this resistance is normally between 0.99 and 1.29. If the resistance measured exceeds 49 the MIL Lamp will illuminate and fault code 33 will be present, indicating high resistance or open circuit on the air bag circuit.

Possible Causes

0 Faulty passenger-side air bag wiring.

0 Open circuit or high resistance in passenger-side air bag.

Fault Diagnosis

1. Circuit - check

. Disarm SRS system and disconnect DM.

. Disconnect DM and remove plastic locking wedge from black DM harness connector.

Measure resistance across harness connections to passenger air bag, wires RP and KP:

. Is resistance value greater than 2.29 ?

Yes - Examine harness wiring and connections for open circuit, rectify as necessary.

No - Proceed to step 2.

2. Code verification

. Reconnect DM.

. Switch on the ignition and wait 30 seconds.

Yes

- Renew DM.

No - Proceed to step 3.

Is code 33 still present ?

3. Code 33 -check

. Switch off the ignition.

. Arm the SRS system.

. Is code 33 still present 7

Yes - Renew passenger-side air bag.

No - Examine harness wiring and connectors for intermittent open circuit.

4. On completion.

. Re-arm and verify the SRS system.

rm

0

0

0

0

Issue 1 August 1994 15.1 - 26 X300 EDM

Page 134 of 327

rl E I ect r ica I

FAULT CODE 34

Driver-side Air Bag Circuit Low Resistance or Shorted

Normal Operation

The DM monitors the resistance between pins 10 and 11. The value of this resistance is the sum of the two cable reel

cassettes and the air bag and is normally between 1.552 and 2Q. If the resistance measured is less than 0.752 the MIL Lamp will illuminate and fault code 34 will be present, indicating low resistance or short circuit on the air bag circuit.

Possible Causes

0 Poor connection of cable reel cassettes.

0 Worn cable reel cassette connectors.

0 Short circuit in cable reel cassette.

0 Poor connection of air bag harness.

0 Short circuit across air bag terminals.

Fault Diagnosis

1. Resistance - check

. Disarm the SRS system and disconnect the driver-side air bag.

rn Disconnect DM and remove plastic locking wedge from black harness connector.

. Measure resistance across harness connections to driver-side air bag, wires RP and KN.

. Does resistance value indicate open circuit.

Yes

- Proceed to step 2.

No - Proceed to step 3.

2. Diagnostic Module -check

Install air bag simulator in place of cable reel cassette at steering column base.

. Re-connect DM.

. Switch on the ignition and wait 30 seconds.

rn Is code 34 still present ?

Yes - Renew DM.

No - Examine shorting bar on driver-side air bag connector for correct operation, rectify if necessary. Renew air bag

module if shorting bar is functioning correctly.

3. Harness -check

. Measure resistance across harness connections to driver-side air bag, wires RP and KN.

. Does resistance value indicate open circuit 7

Yes -

. Examine shorting bar on cable reel cassette connector for correct operation, rectify if necessary.

. Renew cable reel cassette if shorting bar is functioning correctly.

NO -

Inspect harness wiring, cable reel cassettes and terminals for short circuit. Rectify as necessary.

4. On completion

. Arm and verify the SRS system.