torque JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 41 of 327

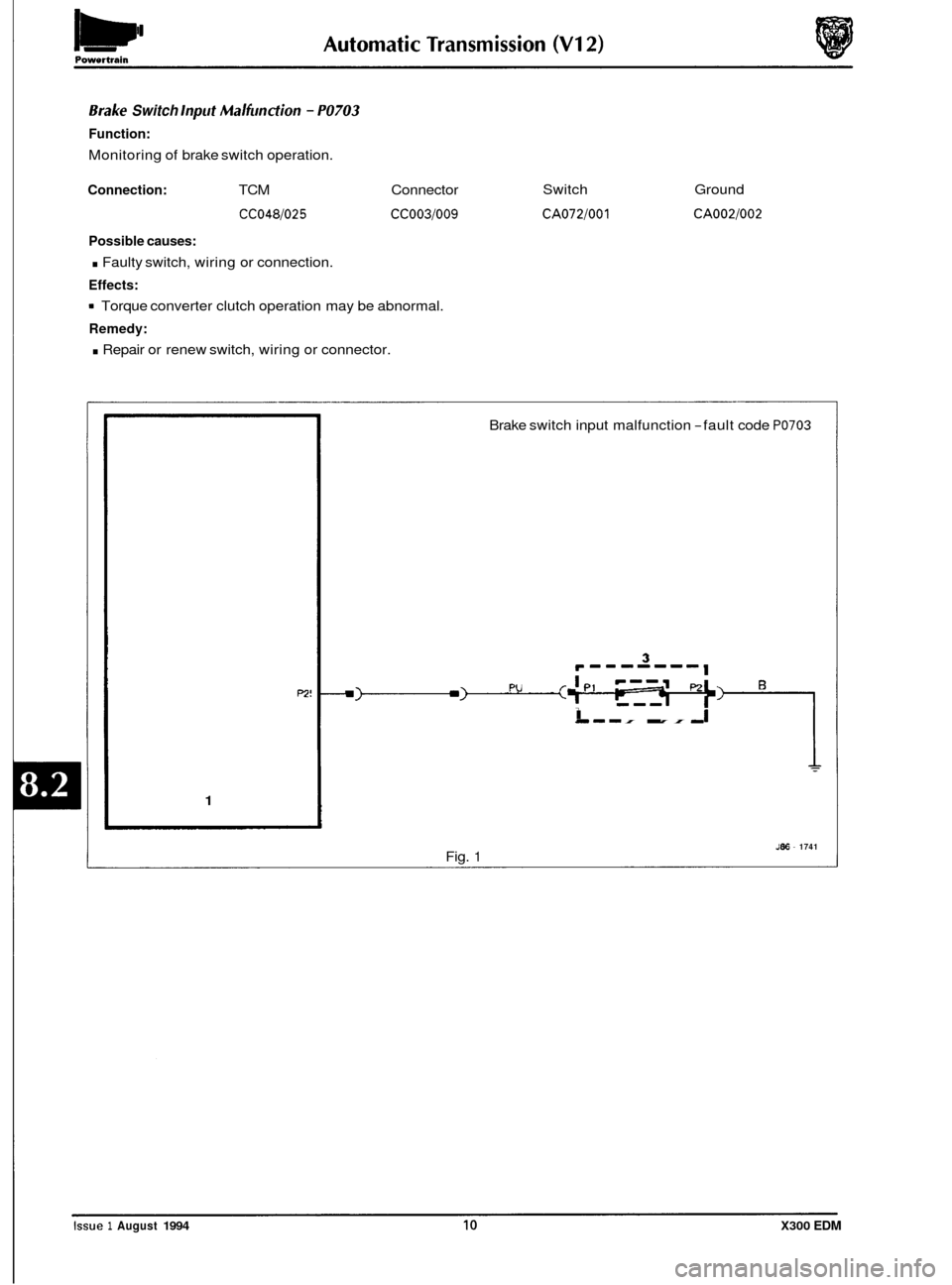

Srake Switch lnpiit Malfiincfion - PO703

Function:

Monitoring of brake switch operation.

Connection: TCM Connector

CC048/025 CC003/009

Possible causes:

. Faulty switch, wiring or connection.

Effects:

Torque converter clutch operation may be abnormal.

Remedy:

. Repair or renew switch, wiring or connector. Switch

CA072/001

Ground

CA002/002

P2!

1

Brake

switch input malfunction -fault code PO703

I -I I I I I I ,I

J86 - 1741 Fig. 1

Issue 1 August 1994 10 X300 EDM

Page 44 of 327

Automatic Transmission (V12) Powertrain

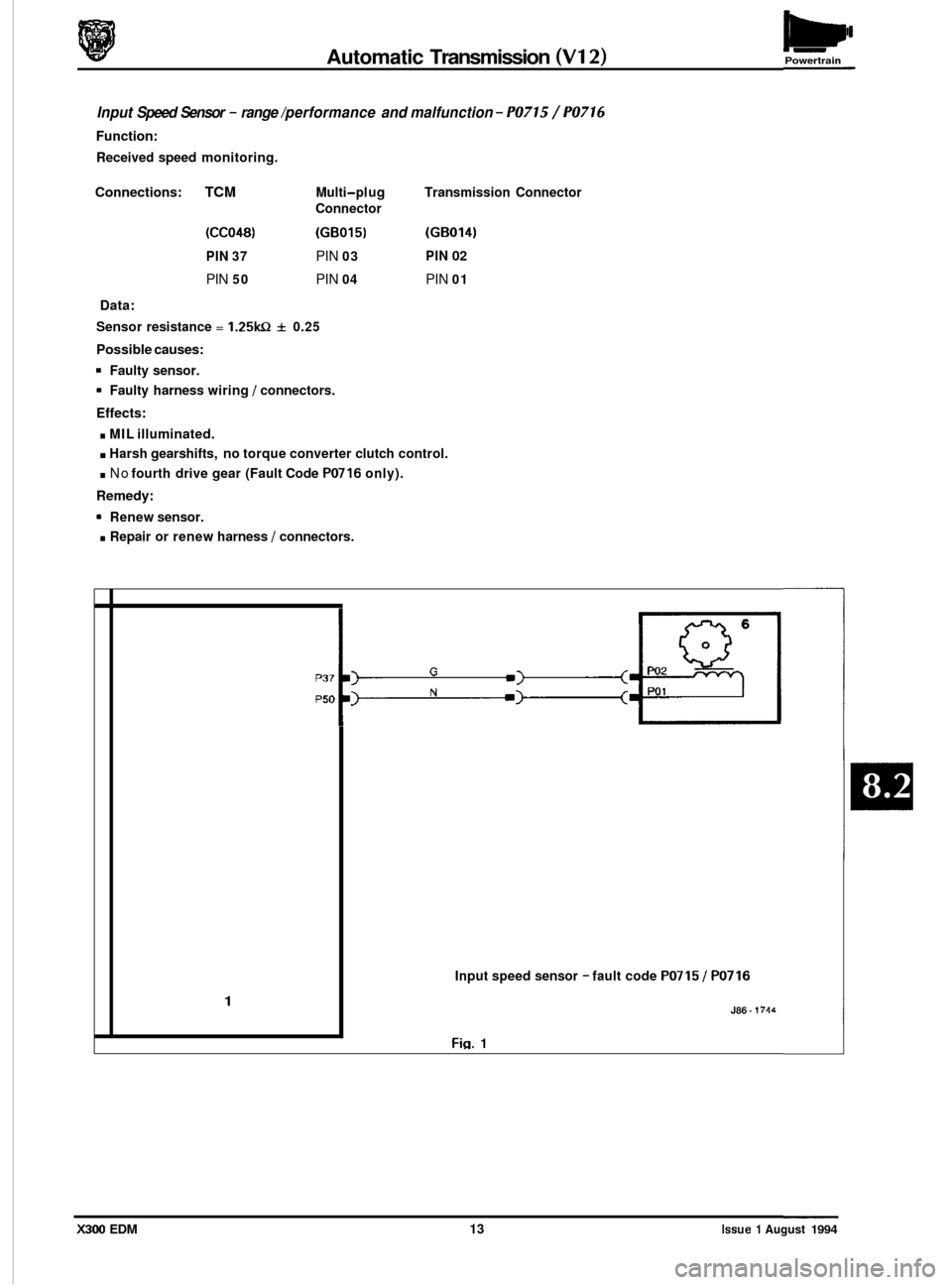

Input Speed Sensor - range /performance and malfunction - PO715 / PO716

Function:

Received speed monitoring.

Transmission Connector

(GB014)

PIN 02

PIN 01

Connections: TCM Multi-pl ug

Connector

(CC048) (GB015)

PIN 37 PIN 03

PIN 50 PIN 04

Data:

Sensor resistance = 1.25kQ f 0.25

Possible causes:

9 Faulty sensor.

9 Faulty harness wiring 1 connectors.

Effects:

. MIL illuminated.

. Harsh gearshifts, no torque converter clutch control.

. No fourth drive gear (Fault Code PO716 only).

Remedy:

. Repair or renew harness 1 connectors.

Renew sensor.

0

0

1

Input speed sensor - fault code PO715 / PO716

J86 - 1714

Fig. 1

X300 EDM 13 Issue 1 August 1994

Page 48 of 327

Powertrain Automatic Transmission (V12)

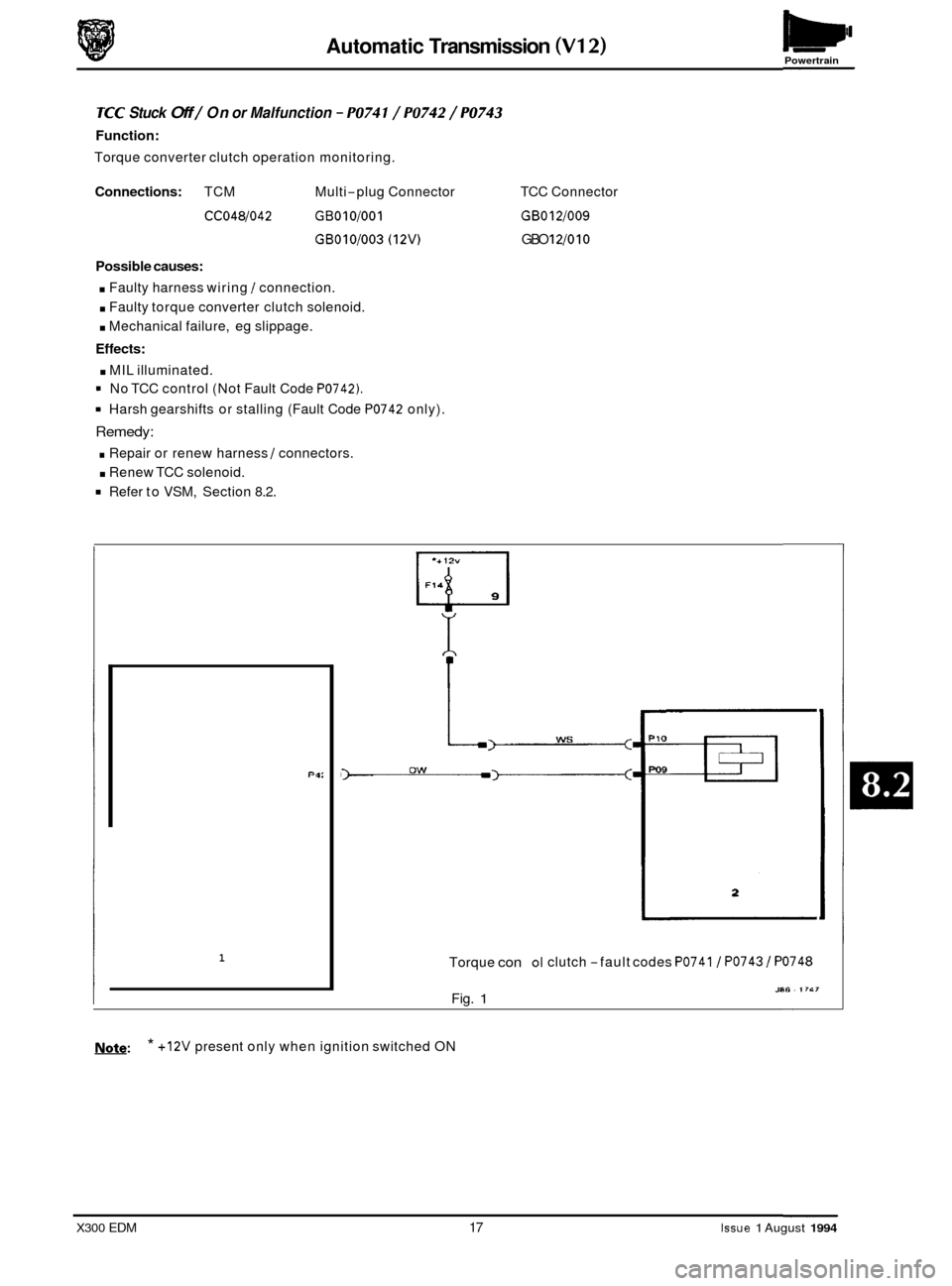

TCC Stuck Off / On or Malfunction - PO74 1 / PO742 / PO743

Function:

Torque converter clutch operation monitoring.

Connections: TCM Multi-plug Connector

CCO48/042 GBOlO/OO1

GB010/003 (12V)

Possible causes:

. Faulty harness wiring 1 connection.

. Faulty torque converter clutch solenoid.

. Mechanical failure, eg slippage.

Effects:

. MIL illuminated.

' No TCC control (Not Fault Code P0742).

Harsh gearshifts or stalling (Fault Code PO742 only).

Remedy:

. Repair or renew harness 1 connectors.

Refer to VSM, Section 8.2.

. Renew TCC solenoid. TCC

Connector

GBOl2/009

GBO 1210 10

PQ:

1 Torque con

Fig. 1

01 clutch -fault codes PO741 1 PO743 I PO748

J80 - IT47

Note: * +12V present only when ignition switched ON

X300 EDM 17 Issue 1 August 1994

Page 51 of 327

Automatic Transmission (V12) Powertrain

Shift Malfunction (Max- Adapt) - PO780

Function:

Transmission internal operation monitoring.

Possible causes:

. Mechanical wear 1 failure.

Effects:

. Harsher shifts.

Remedy:

. Refer to VSM, Section 8.2.

Transmission Component Slipping - PI 739

Function:

Transmission internal operation monitoring.

Possible causes:

Faulty harness wiring /connection.

. Fuse blown.

. Faulty torque converter clutch.

Mechanical wear.

Effects:

. MIL lamp illuminated.

. Harsh shifts.

Remedy:

. Repair or renew harness 1 connector.

Renew fuse F14 in LH heelboard fuse-box on determining reason for rupture.

Refer to VSM, Section 8.2.

0

0

Issue 1 August 1994 20 X300 EDM

Page 52 of 327

Automatic Transmission (V12) Powertrain

Torque Reduction Signal Malfunction - P1780

Function:

ECM signal monitor.

Connections: TCM PI Harness ECM

CC048/007 P1063/008 P1044/006

Possible causes:

. Faulty harness wiring /connection.

. Faulty ECM signal.

Effects:

. Harsh gearshifts.

Remedy:

. Repair or renew harness / connector.

Examine ECM fault diagnosis (refer to EDM, section 5.2).

Transmission

warning lamp illuminated.

Engine Torque Signal Malfunction - P1781

Function:

ECM signal monitor.

Connections: TCM PI Harness

CC048/0 12 P1063/007

ECM

P1044/005

Possible causes:

. Faulty harness wiring /connection.

. Faulty ECM signal.

Effects:

. Transmission warning lamp illuminated.

. Harsh gearshifts.

Remedy:

Repair or renew harness / connector.

Examine ECM fault diagnosis (refer

to EDM, section 5.2).

X300 EDM 21 Issue 1 August 1994

Page 53 of 327

Automatic Transmission (V12) W Powertrain

1

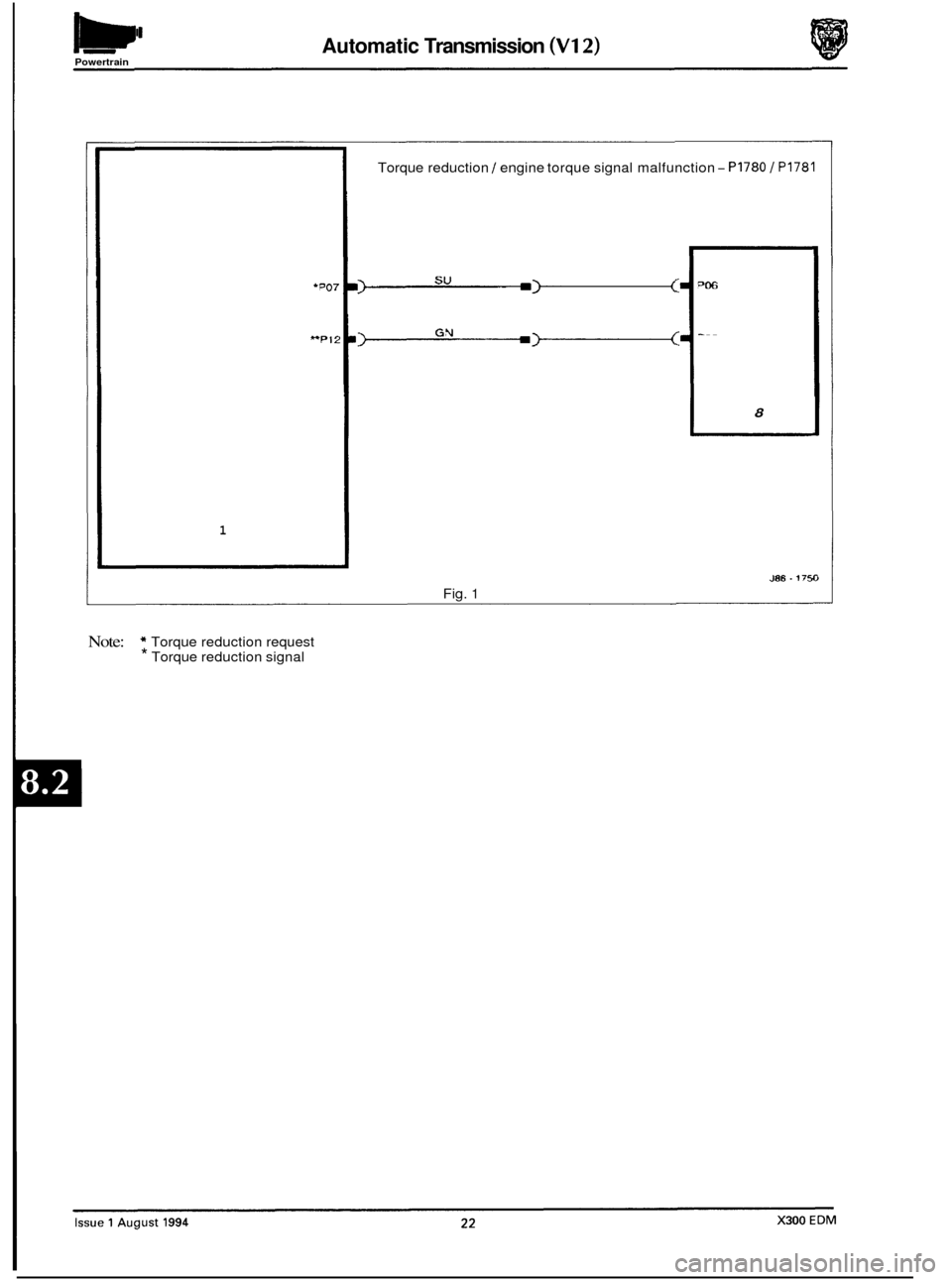

Torque reduction / engine torque signal malfunction - PI780 / PI781

-

8

J86.175~3

Fig. 1

Note: * Torque reduction request * Torque reduction signal

0

0

0

Page 109 of 327

Electrical rl

15.1.3 AIR BAG DISARMING/ ARMING PROCEDURE

warnings and cautions

WARNING: DISARM SRS BEFORE SERVICING ANY SRS OR STEERING COLUMN COMPONENT.

ALLOW A MINIMUM OF ONE MINUTE TIME DELAY FOR THE BACK

-UP POWER SUPPLY TO DISCHARGE,

AFTER THE BATTERY GROUND LEAD HAS BEEN DISCONNECTED.

THE SYSTEM COMPONENTS ARE NON

-SERVICEABLE, IF FAULTS ARE SUSPECTED, CHANGE COMPO- NENTS FOR NEW ITEMS ONLY.

NEVER PROBE THE CONNECTORS OF AN AIR BAG MODULE.

FAILURE TO OBSERVE THE ABOVE PROCEDURES MAY RESULT

IN ACCIDENTAL DEPLOYMENT OF AIR

BAG.

ALWAYS WEAR SAFETY GLASSES WHEN WORKING ON AIR BAG EQUIPPED VEHICLES.

PERSONNEL CARRYING AN AIR BAG MODULE MUST ENSURE THAT THE MODULE AND TRIM COVER

ARE POINTED AWAY FROM THE BODY. WHEN POSITIONED ON A BENCH

OR WORK SURFACE ENSURE

THAT THE AIR BAG MODULE AND TRIM COVER FACE UPWARDS, LIMITING MOTION ON ACCIDENTAL

DEPLOYMENT.

ALWAYS WEAR GLOVES WHEN HANDLING DEPLOYED AIR BAG MODULE, DEPOSITS OF SODIUM HY

- DROXIDE MAY BE PRESENT ON THE MODULE SURFACE. IF SODIUM HYDROXIDE CONTACTS ANY

AREA OF SKIN, WASH THE AFFECTED AREA IMMEDIATELY WITH MILD SOAP AND WATER. DISPOSE OF

THE DEPLOYED AIR BAG USING THE CORRECT PROCEDURES, REFER TO SECTION

15 OF THE VSM.

CAUTION:

When scrapping vehicles ensure air bags have been deployed.

If

a component has been renewed and the fault does not clear, refit original item and repeat diagnostic

procedure.

After servicing repeat diagnostic procedures to ensure correct system operation.

Renew air bag module if surrounding trim panels are damaged.

Do not attempt to repaint trim covers as paint may damage cover material.

Disarming

. Allow a minimum 1 minute time delay before attempting to diagnose or renew any component in the SRS system.

Remove driver-side air bag module and connect air bag simulator to cable reel cassette multi-plug.

. Remove passenger-side air bag module and connect air bag simulator to harness.

. Re-connect battery ground lead.

Disconnect

the battery ground lead.

This delay allows the DM back

-up power supply to discharge, preventing accidental firing of the air bag.

0

Arming

Disconnect the battery ground lead.

. Remove air bag simulators and install driver and passenger-side air bag modules. Ensure fasteners are tightened

. Re-connect battery ground lead.

Switch ignition 'on' and ensure air bag MIL Lamp extinguishes.

to specified torque.

X300 EDM 15.1 -3 Issue 1 August 1994