fuse box JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 216 of 327

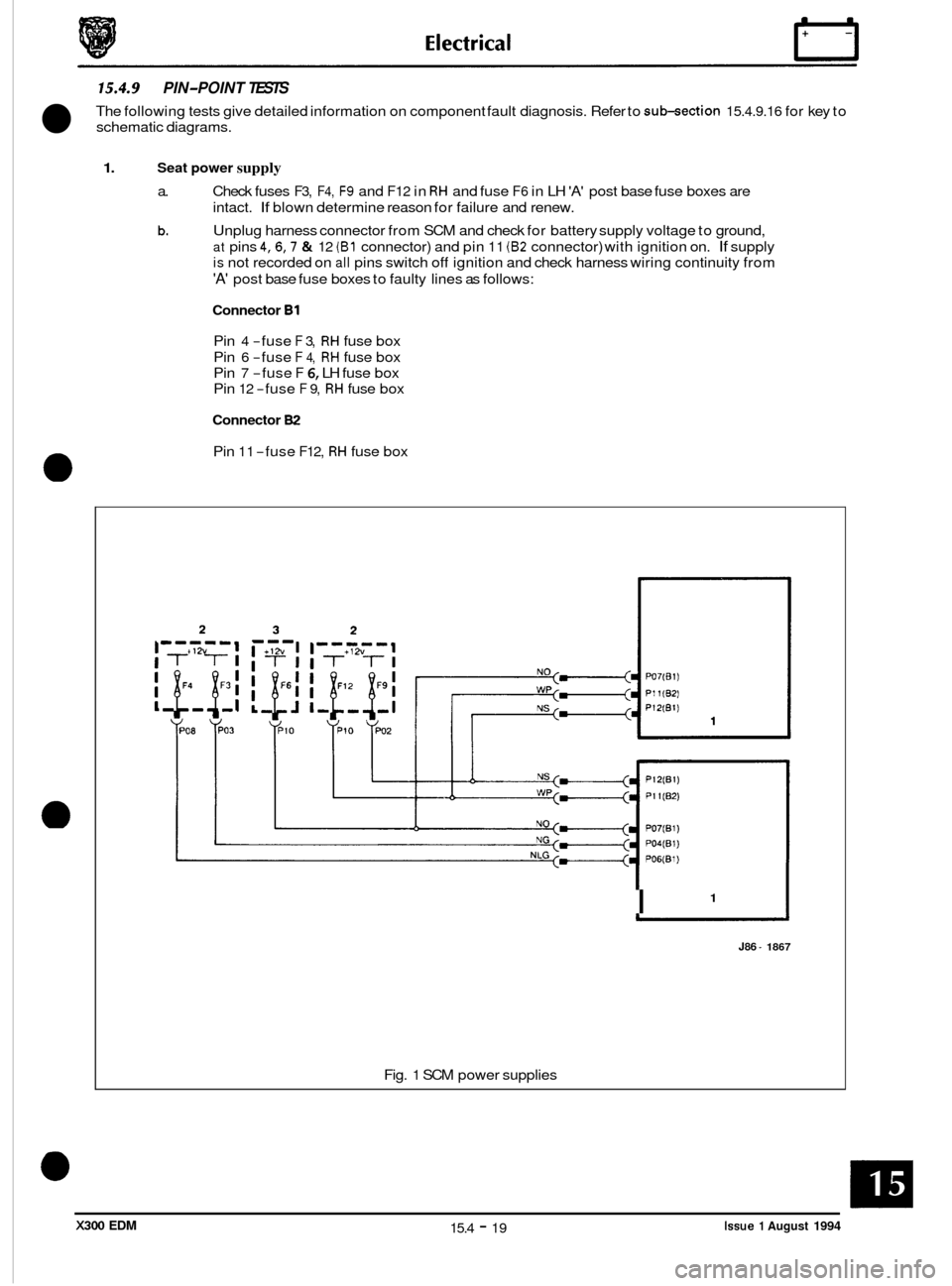

15.4.9 PIN-POINT TESTS

The following tests give detailed information on component fault diagnosis. Refer to sub-section 15.4.9.16 for key to

schematic diagrams.

1. Seat power supply

a.

b.

Check fuses F3, F4, F9 and F12 in RH and fuse F6 in LH 'A' post base fuse boxes are

intact.

If blown determine reason for failure and renew.

Unplug harness connector from SCM and check for battery supply voltage to ground,

at pins 4,6,7 & 12 (B1 connector) and pin 11 (82 connector) with ignition on. If supply

is not recorded on all pins switch off ignition and check harness wiring continuity from

'A' post base fuse boxes to faulty lines as follows:

Connector B1

Pin 4 -fuse F 3, RH fuse box

Pin

6 -fuse F 4, RH fuse box

Pin

7 -fuse F 6, LH fuse box

Pin

12 -fuse F 9, RH fuse box

Connector 82

Pin 11 -fuse F12, RH fuse box

1 I

J86 - 1867

Fig. 1 SCM power supplies

Issue 1 August 1994 15.4 - 19 X300 EDM

Page 217 of 327

n E I ectr ical

2A. Seat movement motors (memory seats)

a.

b.

Check motor operation is not obstructed, and that mechanical linkage is not damaged

or disconnected.

Examine wiring harness, checking continuity between SCM Connector

A1 and motor

unit connector pins as follows:

SCM Motor Function Unit Pin

Pin 8 Seat forward 1

Pin

7 Seat rearward 3

Pin 5 Seat rear raise 1

Pin

6 Seat rear lower 3

Pin 3 Seat front raise 1

Pin

4 Seat front lower 3

Check resistance between motor pins 1 and 3, a value of approximately 2S2 should be

indicated.

Check motor position potentiometer as described in test

4.

C.

d.

28. Seat movement motor (manual seats)

a.

b.

C.

d.

Check motor operation is not obstructed, and that mechanical linkage is not damaged

or disconnected.

Check continuity from motor connector pins (1

& 3) to each relay contact connector

(pin

3, raise relay, pin 8, lower relay) respectively.

Check power supply

(+12V) from LH 'A' post base fuse box, fuse F6, to seat switch

connector pin

9.

Check power supply (+12V) from RH 'A' post base fuse box, fuse F3, to pin 5, raise relay

connector and pin 10, lower relay connector.

Check continuity from switch pack connector pin

4 to raise relay connector pin 5 and

from switch pack connector pin 5 to lower relay connector pin

6

Check continuity to ground from raise relay connector pins 2 and 4 and lower relay

connector pins

7 and 9

e.

f.

3. Seat squab 1 headrest motors

a.

b.

Check motor operation is not obstructed, and that mechanical linkage is not damaged

or disconnected.

Examine wiring harness, checking continuity between SCM Connector

A1 and motor

unit connector pins as follows:

SCM Motor Pin

Pin 1 Squab recline 1 incline +ve 3

Pin 2 Squab recline 1 incline -ve 1

Pin 11 Headrest raise

1 lower +ve 1

Pin 12 Headrest raise

1 lower -ve 3

Check resistance between motor pins 1 and 3; a value of approximately 28 should be

indicated.

Check motor position potentiometers as described in step

4.

C.

d.

Issue 1 August 1994 15.4 - 20 X300 EDM

Page 222 of 327

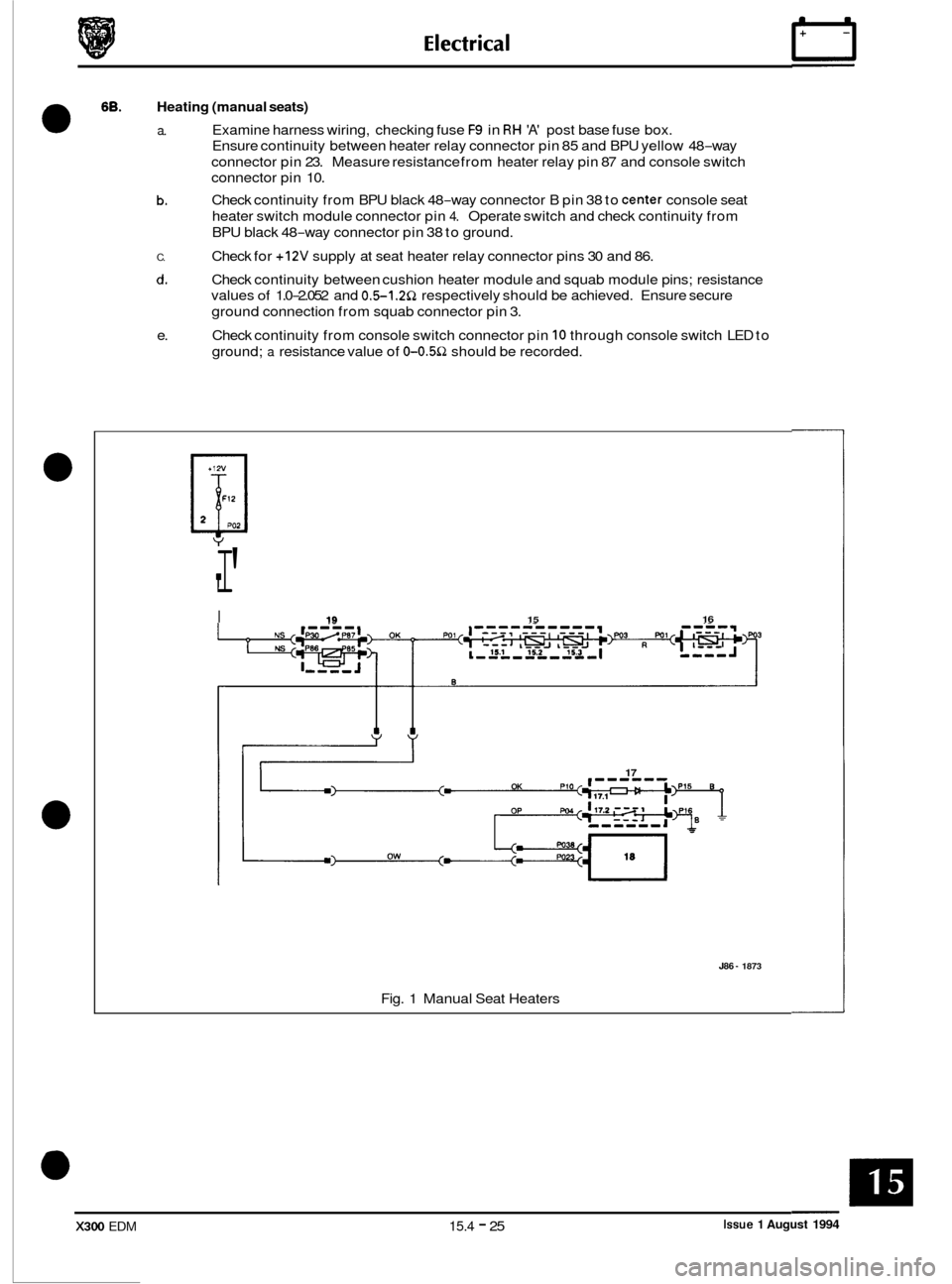

68. Heating (manual seats)

0 a. Examine harness wiring, checking fuse F9 in RH 'A' post base fuse box.

Ensure continuity between heater relay connector pin 85 and BPU yellow 48

-way

connector pin 23. Measure resistance from heater relay pin 87 and console switch

connector pin 10.

Check continuity from BPU black 48

-way connector B pin 38 to center console seat

heater switch module connector pin

4. Operate switch and check continuity from

BPU black 48

-way connector pin 38 to ground.

Check for

+12V supply at seat heater relay connector pins 30 and 86.

Check continuity between cushion heater module and squab module pins; resistance

values

of 1.0-2.052 and 0.5-1.252 respectively should be achieved. Ensure secure

ground connection from squab connector pin 3.

Check continuity from console switch connector pin

10 through console switch LED to

ground;

a resistance value of 0-0.5Q should be recorded.

b.

C.

d.

e.

I' T

I 19 15 16

17 OK

J86 - 1873

Fig. 1 Manual Seat Heaters

Issue 1 August 1994 X300 EDM 15.4 - 25

Page 226 of 327

E I ect r ica I

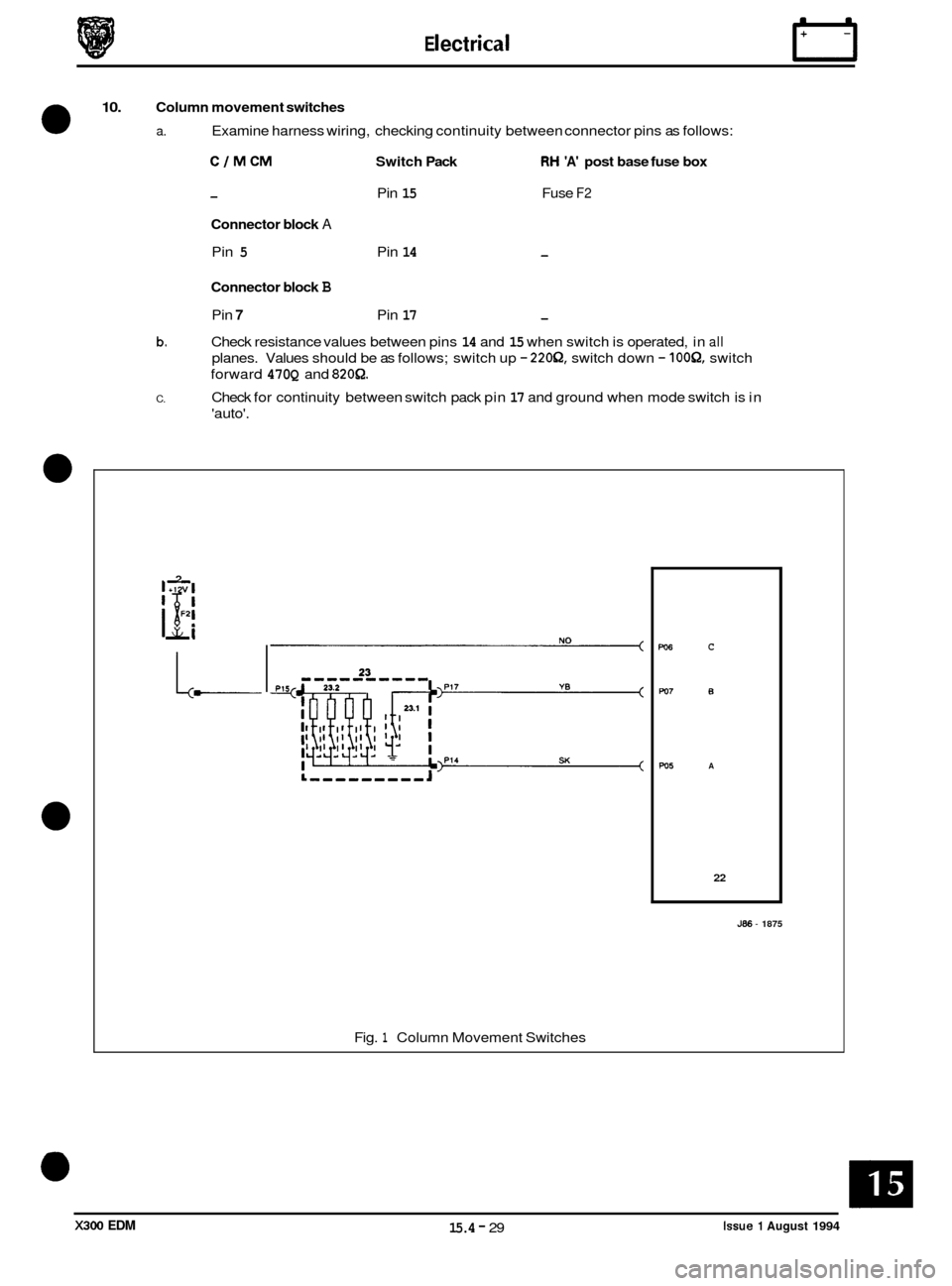

10. Column movement switches

0 a. Examine harness wiring, checking continuity between connector pins as follows:

CIMCM Switch Pack RH 'A' post base fuse box

- Pin 15 Fuse F2

Connector block A

Pin 5 Pin 14 -

Connector block B

Pin 7 Pin 17 -

Check resistance values between pins 14 and 15 when switch is operated, in all

planes. Values should be as follows; switch up - 220Q, switch down - IOOQ, switch

forward

470Q and 8208.

Check for continuity between switch pack pin 17 and ground when mode switch is in

'auto'.

b.

C.

2

1

'5i 11 v

L-

L-,,,,,,,,J

Fig. 1 Column Movement Switches

PO6 C

PO7 B

w5 A

22

J86 - 1875

Issue 1 August 1994 15.4 - 29 X300 EDM

Page 232 of 327

E I ect r ica I rl

15.4.9.16 Key to schematic diagrams

I 2

I 3

i 7

, I 13

14

a1 15

j

20

p

23

30

Description

Seat control modules (driver and passenger side)

RH ,'A' post base fuse-box

LH

,'A' post base fuse-box

Head restraint motor and potentiometer

Squab recline motor and potentiometer

Seat movement motor

- fore 1 aft - and potentiometer

Seat movement motor

- rear raise 1 lower - and potentiometer

Seat movement motor

- front raise 1 lower - and potentiometer

Seat raise lower motor (manual seats)

Seat switch pack

Seat raise relay (manual seats)

Seat lower relay (manual seats)

Seat raise

/ lower selector switch (manual seats)

Lumbar pump unit

14.1 Pump

14.2 Solenoid valve

14.3 Pressure switch

Seat cushion heater

15.1 Thermostat

15.2 Inner cushion element

15.3 Outer cushion element

Squab cushion heater

Center console switch unit

17.1 Switch LED

17.2 Heatina select switch

Body processor unit

Heater relay (manual seat)

Column

tilt motor and potentiometer

Column reach motor and potentiometer

Column

I mirror control module

Column switches

23.1 Joystick

23.2 Passenger's rear view mirror up

I down motor and potentiometer

Passenger's rear view mirror left

I right motor and potentiometer

Mode switch (exit

I entry)

Driver's rear view mirror up

I down motor and potentiometer

Driver's rear view mirror left

1 right motor and potentiometer

Driver's door switch pack

Mirror polarity select switch

Mirror joystick

X300 EDM 15.4 - 35 Issue 1 August 1994

Page 233 of 327

E I ect r ica I

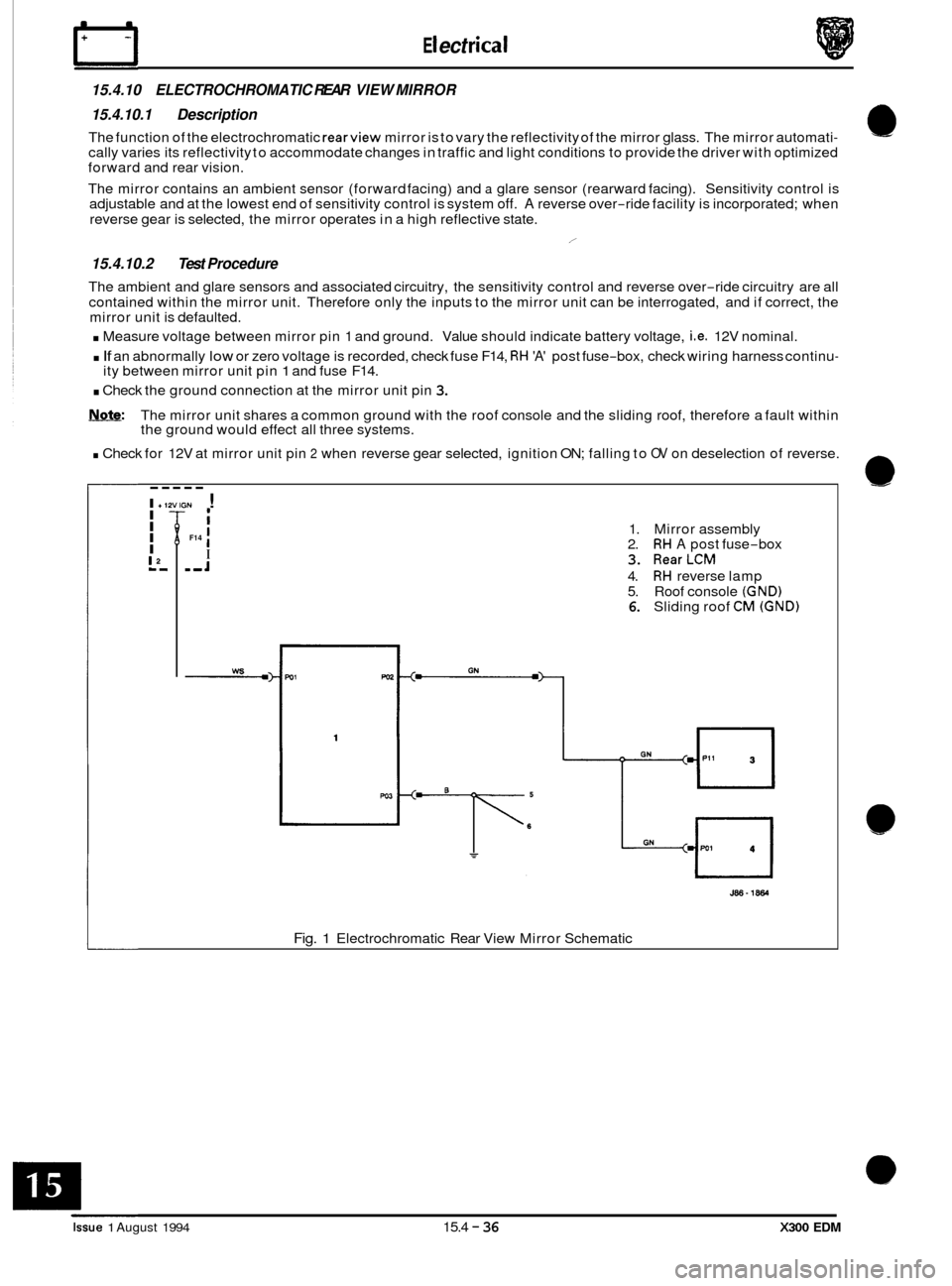

15.4.10 ELECTROCHROMATIC REAR VIEW MIRROR

15.4.10.1 Description

The function of the electrochromatic rearview mirror is to vary the reflectivity of the mirror glass. The mirror automati- cally varies its reflectivity to accommodate changes in traffic and light conditions to provide the driver with optimized

forward and rear vision.

The mirror contains an ambient sensor (forward facing) and

a glare sensor (rearward facing). Sensitivity control is

adjustable and at the lowest end of sensitivity control is system off. A reverse over-ride facility is incorporated; when

reverse gear is selected, the mirror operates in a high reflective state.

15.4.10.2 Test Procedure

The ambient and glare sensors and associated circuitry, the sensitivity control and reverse over-ride circuitry are all

contained within the mirror unit. Therefore only the inputs to the mirror unit can be interrogated, and if correct, the

mirror unit is defaulted.

. Measure voltage between mirror pin 1 and ground. Value should indicate battery voltage, i.e. 12V nominal.

. If an abnormally low or zero voltage is recorded, check fuse F14, RH 'A' post fuse-box, check wiring harness continu-

. Check the ground connection at the mirror unit pin 3.

Note: The mirror unit shares a common ground with the roof console and the sliding roof, therefore a fault within

the ground would effect all three systems.

. Check for 12V at mirror unit pin 2 when reverse gear selected, ignition ON; falling to OV on deselection of reverse.

/

ity between mirror unit pin 1 and fuse F14.

----- I +12VIGN ! I I I

I

L',

I I

I ,,J

F14 1. Mirror assembly

2. RH A post fuse-box

3. RearLCM

4. RH reverse lamp

5. Roof console (GND) 6. Sliding roof CM (GND)

J86-1864

Fig. 1 Electrochromatic Rear View Mirror Schematic

Issue 1 August 1994 15.4 - 36 X300 EDM