check engine JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 9 of 327

w Automatic Transmission (AJ16)

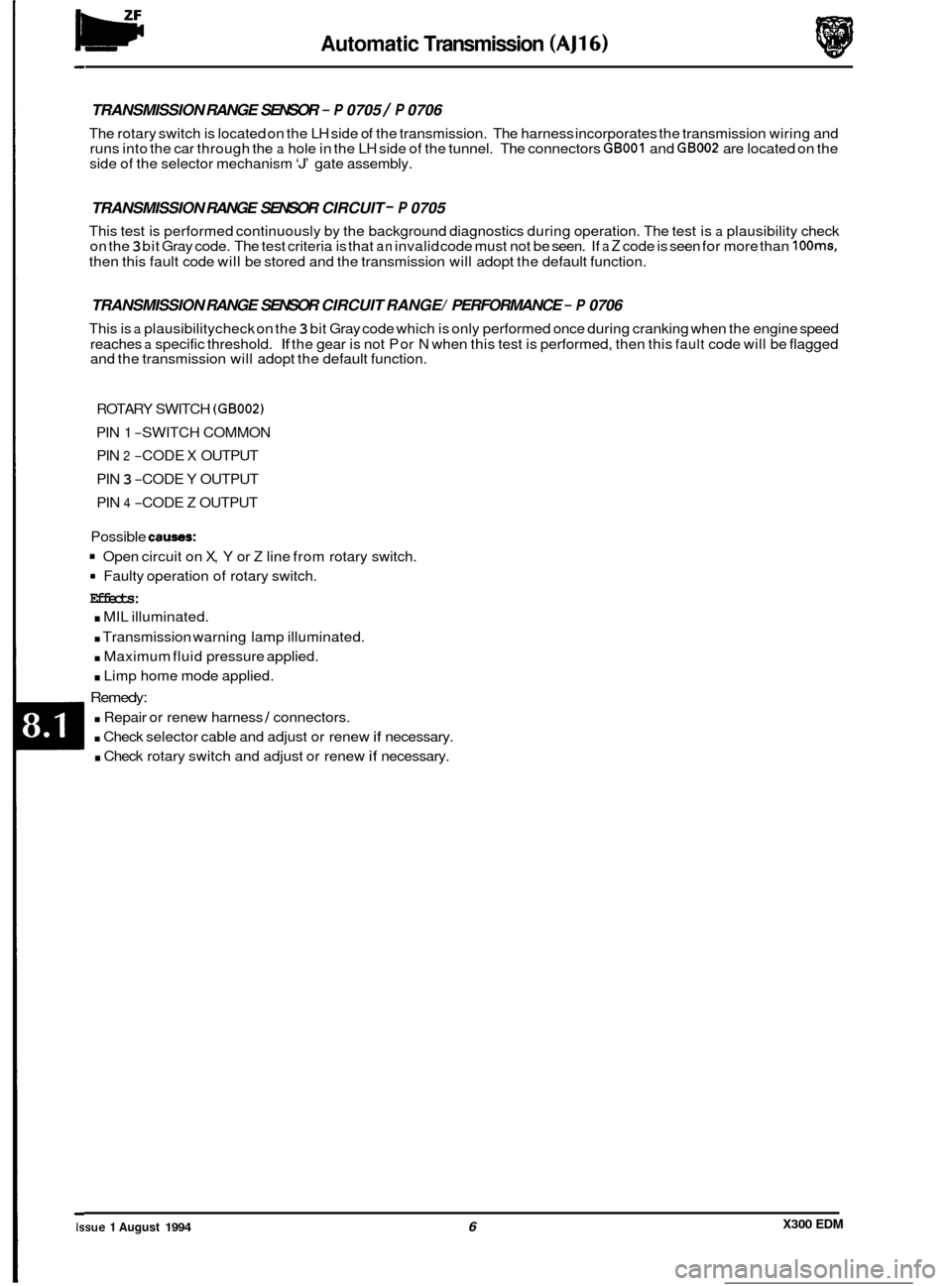

TRANSMISSION RANGE SENSOR - P 0705 / P 0706

The rotary switch is located on the LH side of the transmission. The harness incorporates the transmission wiring and

runs into the car through the a hole in the LH side of the tunnel. The connectors GBOOI and GB002 are located on the

side of the selector mechanism ‘J’ gate assembly.

TRANSMISSION RANGE SENSOR CIRCUIT - P 0705

This test is performed continuously by the background diagnostics during operation. The test is a plausibility check

on the 3 bit Gray code. The test criteria is that an invalid code must not be seen. If a Z code is seen for more than looms,

then this fault code will be stored and the transmission will adopt the default function.

TRANSMISSION RANGE SENSOR CIRCUIT RANGE/ PERFORMANCE - P 0706

This is a plausibilitycheck on the 3 bit Gray code which is only performed once during cranking when the engine speed

reaches

a specific threshold. If the gear is not P or N when this test is performed, then this fault code will be flagged

and the transmission will adopt the default function.

ROTARY SWITCH

(GB002)

PIN 1 -SWITCH COMMON

PIN

2 -CODE X OUTPUT

PIN

3 -CODE Y OUTPUT

PIN

4 -CODE Z OUTPUT

Possible causes

Open circuit on X, Y or Z line from rotary switch.

9 Faulty operation of rotary switch.

Effects:

. MIL illuminated.

. Transmission warning lamp illuminated.

. Maximum fluid pressure applied.

. Limp home mode applied.

Remedy:

. Repair or renew harness I connectors.

. Check selector cable and adjust or renew if necessary.

. Check rotary switch and adjust or renew if necessary.

X300 EDM Issue 1 August 1994 6

Page 27 of 327

lw Automatic Transmission (AJ16)

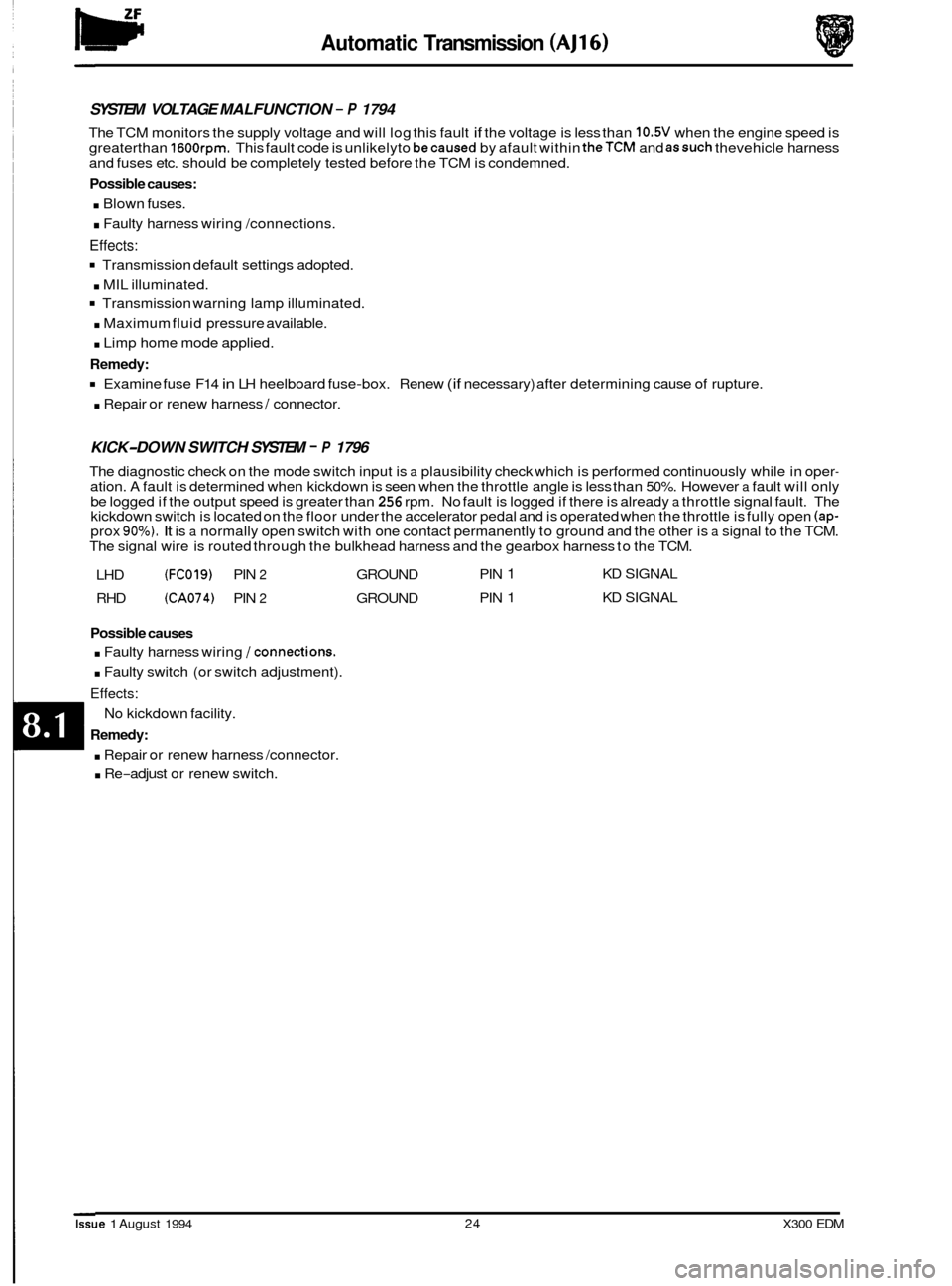

SYSTEM VOLTAGE MALFUNCTION - P 1794

The TCM monitors the supply voltage and will log this fault if the voltage is less than 10.5V when the engine speed is

greaterthan 1600rpm. This fault code is unlikelyto becaused by afault within theTCM and assuch thevehicle harness

and fuses etc. should be completely tested before the TCM is condemned.

Possible causes:

. Blown fuses.

. Faulty harness wiring /connections.

Effects:

Transmission default settings adopted.

. MIL illuminated.

Transmission warning lamp illuminated.

. Maximum fluid pressure available.

. Limp home mode applied.

Remedy:

Examine fuse F14 in LH heelboard fuse-box. Renew (if necessary) after determining cause of rupture.

. Repair or renew harness / connector.

KICK-DOWN SWITCH SYSTEM - P 1796

The diagnostic check on the mode switch input is a plausibility check which is performed continuously while in oper- ation. A fault is determined when kickdown is seen when the throttle angle is less than 50%. However a fault will only

be logged if the output speed is greater than 256 rpm. No fault is logged if there is already a throttle signal fault. The

kickdown switch is located on the floor under the accelerator pedal and is operated when the throttle is fully open (ap- prox 90%). It is a normally open switch with one contact permanently to ground and the other is a signal to the TCM.

The signal wire is routed through the bulkhead harness and the gearbox harness to the TCM.

LHD

(FCO19) PIN 2 GROUND PIN 1 KD

SIGNAL

RHD

(CA074) PIN 2 GROUND PIN 1 KD

SIGNAL

Possible causes

. Faulty harness wiring /connections.

. Faulty switch (or switch adjustment).

Effects:

No kickdown facility.

Remedy:

. Repair or renew harness /connector.

. Re-adjust or renew switch.

0

0

0

Q

Issue 1 August 1994 24 X300 EDM

Page 74 of 327

Climate Control Systems

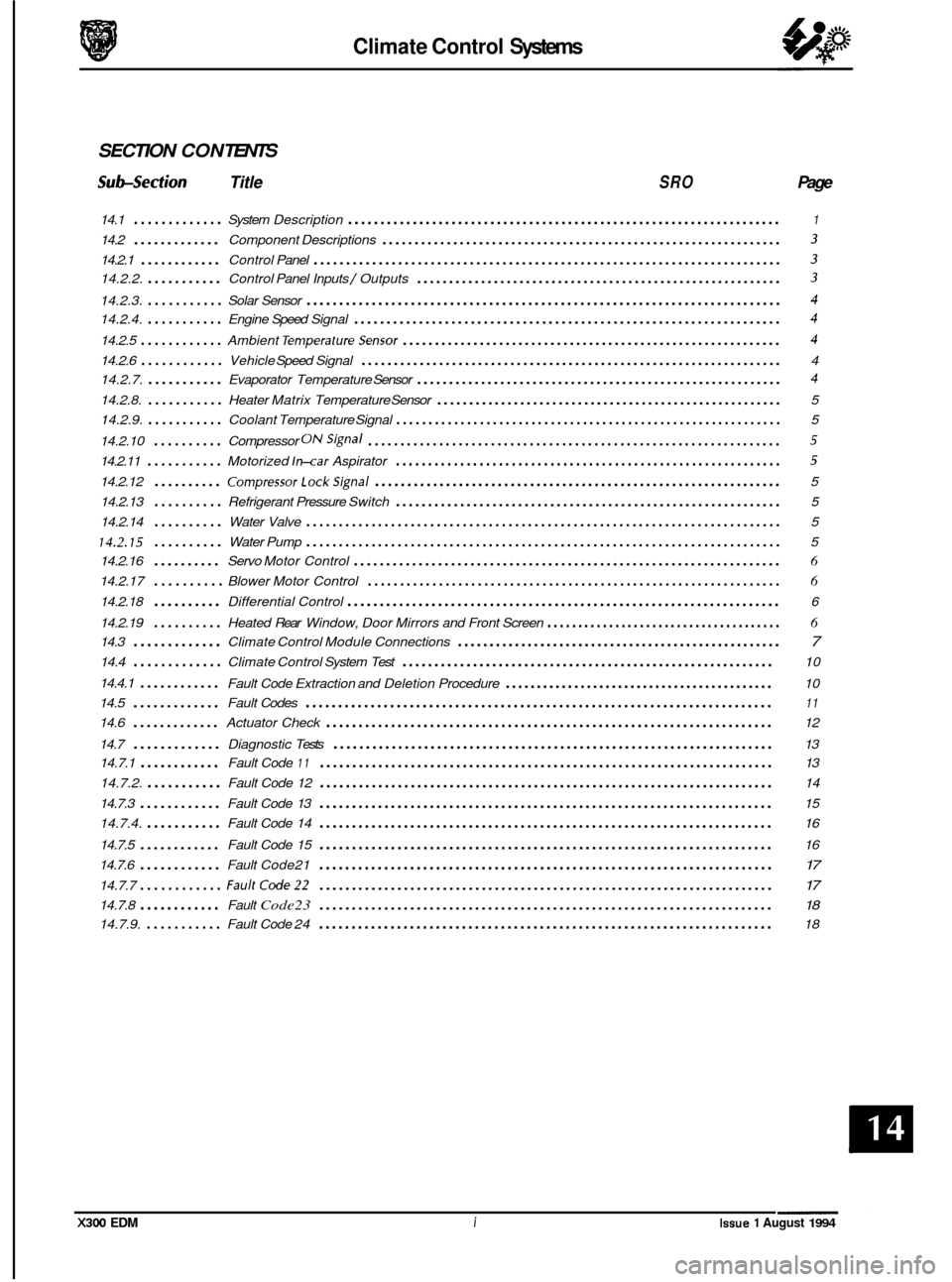

SECTION CON TENTS

Subsection Title SRO Page

14.1 ............. System Description ................................................................... 1

14.2 ............. Component Descriptions .............................................................. 3

14.2.1 ............ Control Panel ........................................................................\

3

14.2.2. ........... Control Panel Inputs / Outputs ......................................................... 3

14.2.3. ........... Solar Sensor ........................................................................\

. 4

14.2.4. ........... Engine Speed Signal .................................................................. 4

14.2.5 ............ Ambient Temperaturesensor ........................................................... 4

14.2.6 ............ Vehicle Speed Signal ................................................................. 4

14.2.7.

........... Evaporator Temperature Sensor ......................................................... 4

14.2.8. ........... Heater Matrix Temperature Sensor ...................................................... 5

14.2.9.

........... Coolant Temperature Signal ............................................................ 5

14.2.10

.......... Compressor ONSignal ................................................................ 5

14.2.11 ........... Motorized ln-car Aspirator ............................................................ 5

14.2.12 .......... CompressorLockSignal ............................................................... 5

14.2.13

.......... Refrigerant Pressure Switch ............................................................ 5

14.2.14

.......... Water Valve ........................................................................\

. 5

14.2.15 .......... Water Pump ........................................................................\

. 5

14.2.16

.......... Servo Motor Control .................................................................. 6

14.2.17 .......... Blower Motor Control ................................................................ 6

14.2.18 .......... Differential Control ................................................................... 6

14.2.19

.......... Heated Rear Window, Door Mirrors and Front Screen ...................................... 6

14.3 ............. Climate Control Module Connections ................................................... 7

14.4 ............. Climate Control System Test .......................................................... 10

14.4.1

............ Fault Code Extraction and Deletion Procedure ........................................... 10

14.5

............. Fault Codes ........................................................................\

11

14.6 ............. Actuator Check ..................................................................... 12

14.7

............. Diagnostic Tests .................................................................... 13

14.7.1

............ Fault Code 11 ...................................................................... 13

14.7.2.

........... Fault Code 12 ...................................................................... 14

14.7.3

............ Fault Code 13 ...................................................................... 15

14.7.4.

........... Fault Code 14 ...................................................................... 16

14.7.5

............ Fault Code 15 ...................................................................... 16

14.7.6

............ Fault Code21 ...................................................................... 17

14.7.7 ............ FaultCode22 ...................................................................... 17

14.7.8 ............ Fault Code23 ...................................................................... 18

14.7.9. ........... Fault Code 24 ...................................................................... 18

X300 EDM i Issue 1 August 1994

Page 86 of 327

Climate Control Systems

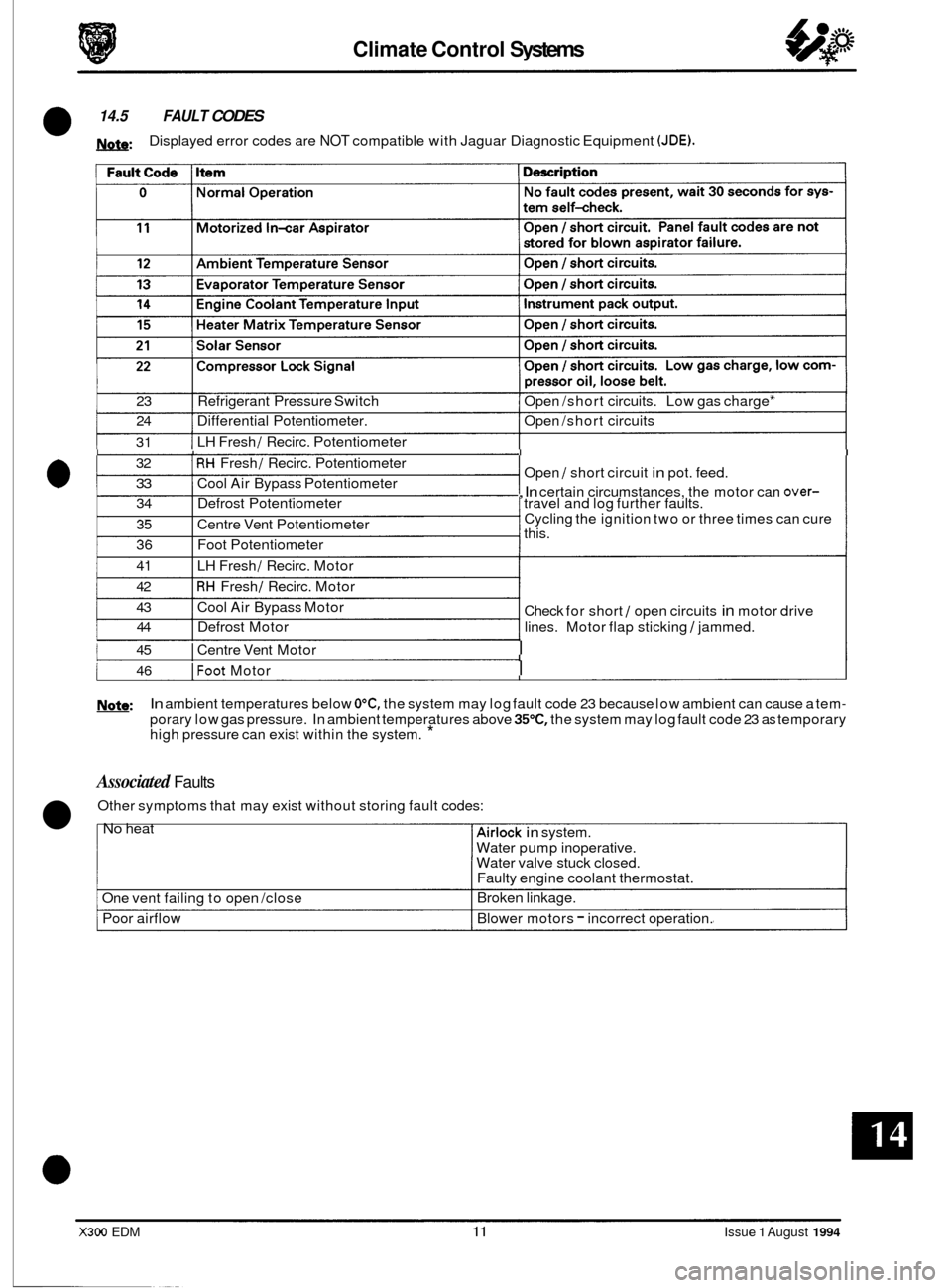

0 14.5 FAULT CODES

J&&: Displayed error codes are NOT compatible with Jaguar Diagnostic Equipment (JDE).

23 Refrigerant Pressure Switch Open /short circuits. Low gas charge*

24 Differential Potentiometer. Open /short circuits

31 LH Fresh

/ Recirc.

Potentiometer I I I I RH Fresh / Recirc. Potentiometer

Open / short circuit in pot. feed.

32

, In certain

circumstances, the motor can over- 0 33 Cool Air Bypass Potentiometer

34 Defrost Potentiometer travel and log further faults.

35

36 Foot Potentiometer Cycling

the ignition two or three times can cure

this.

Centre

Vent Potentiometer

41

42

I LH Fresh / Recirc. Motor

I RH Fresh / Recirc. Motor

43 Cool Air Bypass Motor

44 Defrost Motor lines. Motor flap sticking

/ jammed.

Check

for short

/ open circuits in motor drive

1 45 I Centre Vent Motor I

1 46 IFoot Motor I

W: In ambient temperatures below OOC, the system may log fault code 23 because low ambient can cause a tem-

porary low gas pressure. In ambient temperatures above 35"C, the system may log fault code 23 as temporary

high pressure can exist within the system. *

Associated Faults

Other symptoms that may exist without storing fault codes:

Airlock in system.

Water pump inoperative.

Water valve stuck closed.

Faulty engine coolant thermostat.

Broken linkage.

Blower motors

- incorrect operation.

No heat

One vent failing to open /close

Poor airflow

X300 EDM 11 Issue 1 August 1994

Page 87 of 327

Climate Control Systems

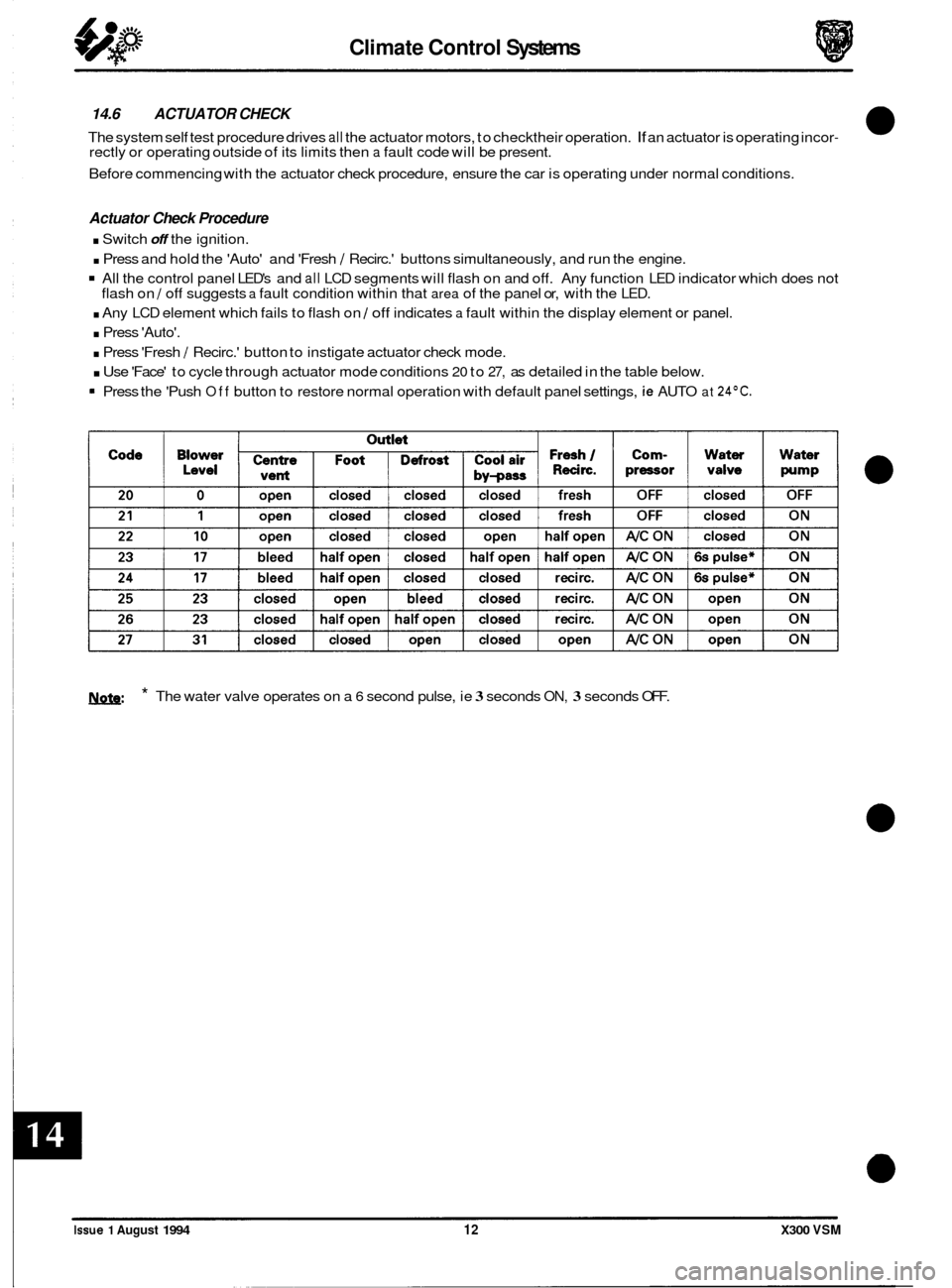

14.6 ACTUATOR CHECK

The system self test procedure drives all the actuator motors, to checktheir operation. If an actuator is operating incor- rectly or operating outside of its limits then a fault code will be present.

Before commencing with the actuator check procedure, ensure the car is operating under normal conditions.

Actuator Check Procedure

. Switch off the ignition.

. Press and hold the 'Auto' and 'Fresh / Recirc.' buttons simultaneously, and run the engine.

All the control panel LED's and all LCD segments will flash on and off. Any function LED indicator which does not

. Any LCD element which fails to flash on / off indicates a fault within the display element or panel.

. Press 'Auto'.

. Press 'Fresh / Recirc.' button to instigate actuator check mode.

. Use 'Face' to cycle through actuator mode conditions 20 to 27, as detailed in the table below.

flash

on

/ off suggests a fault condition within that area of the panel or, with the LED.

Press the 'Push Off button to restore normal operation with default panel settings, ie AUTO at 24OC.

1ynfe: * The water valve operates on a 6 second pulse, ie 3 seconds ON, 3 seconds OFF.

Issue 1 August 1994 12 X300 VSM

Page 91 of 327

Climate Control Systems

14.7.4 Fault Code 14

Coolant Temperature

Input

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A / CCM short circuit to ground.

This input is derived from the instrument pack,

a continuity check can be carried out from pin 22, instrument pack (24-wayconnector), to pin 40 (16-way connector) of the A / C CM.

The instrument pack input from the engine coolant temperature sensor, is covered in the EDM, section 15, Instrument

Pack and Trip Computer.

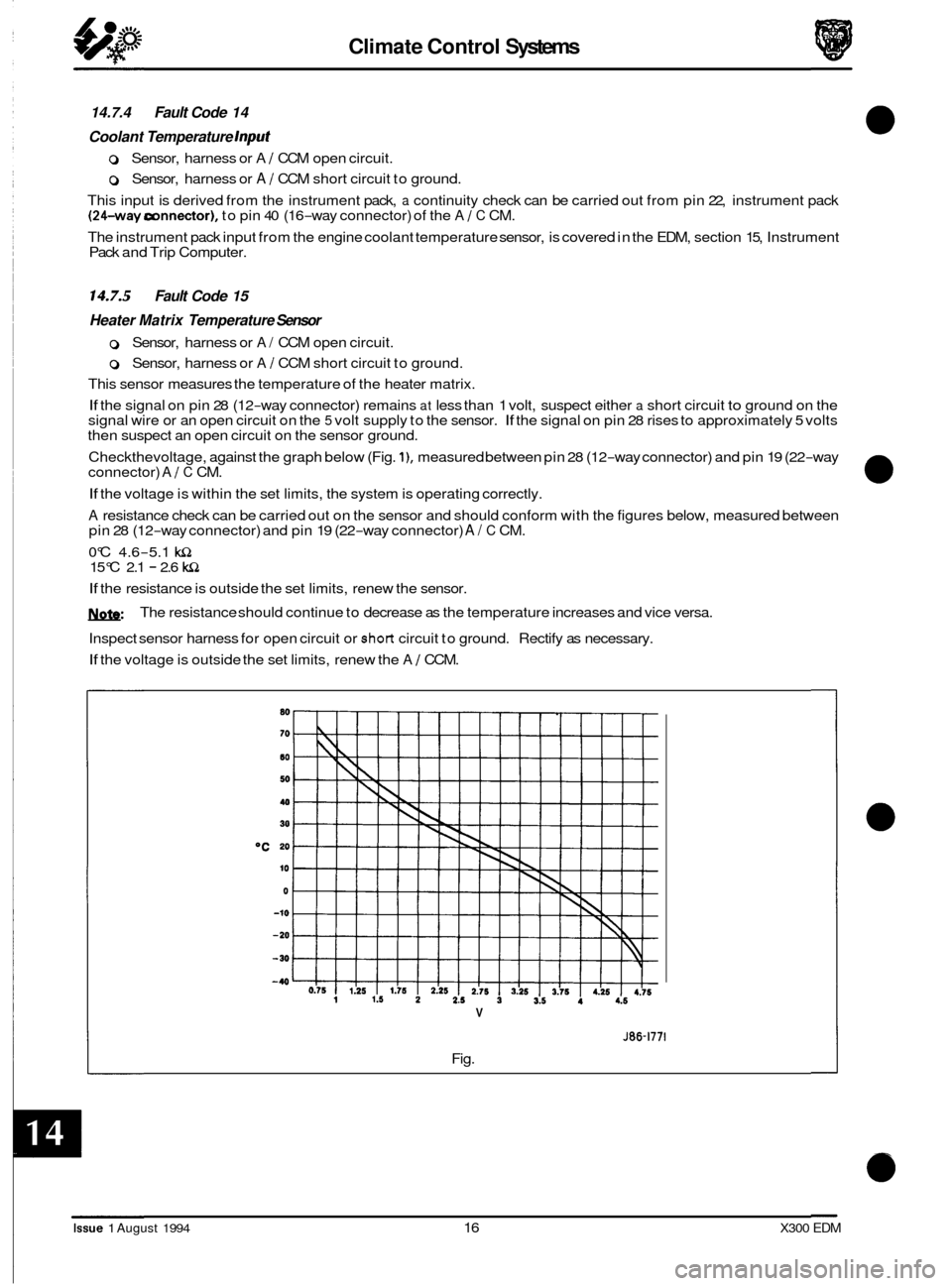

14.7.5 Fault Code 15

Heater Matrix Temperature Sensor

0 Sensor, harness or A/ CCM open circuit.

0 Sensor, harness or A / CCM short circuit to ground.

This sensor measures the temperature of the heater matrix.

If the signal on pin 28 (12-way connector) remains at less than 1 volt, suspect either a short circuit to ground on the

signal wire or an open circuit on the 5 volt supply to the sensor. If the signal on pin 28 rises to approximately 5 volts

then suspect an open circuit on the sensor ground.

Checkthevoltage, against the graph below (Fig.

I), measured between pin 28 (12-way connector) and pin 19 (22-way

connector) A / C CM.

If the voltage is within the set limits, the system is operating correctly.

A resistance check can be carried out on the sensor and should conform with the figures below, measured between

pin 28 (12-way connector) and pin 19 (22-way connector) A/ C CM.

0°C 4.6

-5.1 lclL 15°C 2.1 - 2.6 lclL

If the resistance is outside the set limits, renew the sensor.

1ynfe:

Inspect sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the voltage is outside the set limits, renew the A / CCM.

The

resistance should continue to decrease as the temperature increases and vice versa.

*C

V

J86-1771

Fig.

Issue 1 August 1994 16 X300 EDM

Page 92 of 327

Climate Control Systems

14.7.6 FaulfCode21

Solar Sensor

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A / CCM short circuit to ground.

The sensor provides a linear output response signal to

pin 35 (16-way connector) A/ CCM; the output ranges from 0 to 5 volts, the voltage will drop as light intensity increases.

A resistance check can be carried out on the sensor and should conform with the figures below:

With no light on the sensor, the resistance should read approximately 15

kL2.

With increasing light intensity, the resistance should decrease from 15 kQ.

Inspect the sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the sensor and harness appear correct, suspect the A/ CCM.

14.7.7 Fadf Code 22

Compressor lock Signal

(12 cy/. vehicles only)

0 Sensor, harness or A / CCM open circuit.

0 Sensor, harness or A/ CCM short circuit to ground.

The compressor lock sensor provides an

a.c. signal proportional to engine speed. As engine speed increases the a.c. signal voltage value will increase.

A voltage checkcan be carried out on the sensor and should read approximately 0.5V a.c. whilst the compressor is ON and OV whilst the compressor is OFF, measured between pin 26 (12-way connector) and pin 19 (22-way connector) A

/ C CM.

If the reading is OV whilst the compressor is ON, suspect the sensor or the sensor harness (open circuit or short circuit

to ground).

Check the resistance between pins 1 and 2 of the compressor lock sensor, value should be

190a & 20%.

If the resistance measured falls outside the limits, renew the compressor lock sensor.

Inspect the sensor harness for open circuit or short circuit to ground. Rectify as necessary.

If the sensor and harness appear correct, suspect the AI CCM.

X300 EDM 17 Issue 1 August 1994

Page 102 of 327

Electrical IT

SECTION CONTENTS

Sub

-Section 15.2 lnsfrumenfs

Subsection Title SRO Page

15.2 ............. Instruments .................................................................... 15.2-1

15.2.1

............ Introduction .................................................................... 15.2-1

15.2.2

............ Instrument Pack Connectors - Pin Locations ......................................... 15.2-3

15.2.3

............ Component Description .......................................................... 15.24

15.2.3.1 .......... Speedometer ................................................................... 15.24

15.2.3.2 .......... Tachometer .................................................................... 15.24

15.2.3.3

.......... Engine Oil Pressure and Warning Lamp ............................................. 15.24

15.2.3.4 .......... Engine Coolant Temperature ...................................................... 15.24

15.2.3.5 .......... Fuel Tank Level Gauge and Warning Lamp .......................................... 15.24

15.2.3.6

.......... Battery Voltage Gauge and Warning Lamp .......................................... 15.24

15.2.3.7

.......... Liquid Crystal Display ........................................................... 15.24

15.2.3.8 .......... Trip Computer .................................................................. 15.2-5

15.2.4

............ Primary Warning Lamps (Illuminated Red) .......................................... 15.2-5

15.2.4.1

.......... Exhaust Temperature ............................................................ 15.2-5

15.2.4.2

.......... Low Oil Pressure ................................................................ 15.2-5

15.2.4.3

.......... Seat Belt ....................................................................... \

15.2-5

15.2.4.4

.......... Trunk Lid Open ................................................................. 15.2-5

15.2.4.5

.......... DoorAjar ...................................................................... 15.2-5

15.2.4.6

.......... Engine Coolant LeveL ............................................................ 15.24

15.2.4.7

.......... SRS Airbag Fault ................................................................ 15.24

15.2.4.8 .......... Charging Fault .................................................................. 15.24

15.2.4.9 .......... Brake System Fault .............................................................. 15.24

15.2.4.10 ......... Bark Brake ..................................................................... 15.24

15.2.5. ........... Secondary Warning Lamps (Illuminated Amber) ...................................... 15.2-7

15.2.5.1

.......... Transmission Fault ............................................................... 15.2-7

15.2.5.2

.......... Washer Fluid Level .............................................................. 15.2-7

15.2.5.3

.......... Bulb Fail ....................................................................... \

15.2-7

15.2.5.4

.......... Traction Control Fail ............................................................. 15.2-7

15.2.5.5

.......... Anti-lock Fail .................................................................. 15.2-7

15.2.5.6

.......... Low Fuel Level ................................................................. 15.2-7

15.2.5.7

.......... Check Engine ................................................................... 15.2-7

15.2.6.1

.......... Transmission Sport Mode ......................................................... 15.2-8

15.2.6.2

.......... Traction Control OFF ............................................................ 15.2-8

15.2.6.3

.......... Direction Indicators ............................................................. 15.2-8

15.2.6.4

.......... Main Beam .................................................................... 15.2-8

15.2.6

............ Status

and Warning Lamps ........................................................ 15.2-8

m

a

0

e

0

X300 EDM ii Issue 1 August 1994

Page 103 of 327

Electrical IT

SECTION CON TENTS

Subsection 15.2 Instruments (continued)

Sub-Section Title SRO Page

15.2.7 ............ Fault Diagnosis ................................................................. 15.2-9

15.2.7.1

.......... Active High /Low Inputs ......................................................... 15.2-9

15.2.8.

........... Instrument Pack Pin-point Tests .................................................. 15.2-1 0

15.2.8.1 .......... Oil Pressure, Battery Condition, Coolant Temperature and Fuel Gauges ................. 15.2-1 0

75.2.8.2

.......... Speedometer .................................................................. 15.2-10

15.2.8.4

.......... Liquid Crystal Display .......................................................... 15.2-17

15.2.8.6

.......... Door Open Warning Lamp ...................................................... 15.2-12

15.2.8.7

.......... Exhaust Temperature Warning Lamp .............................................. 15.2-1 3

15.2.8.8 .......... Luggage Compartment Warning Lamp ............................................. 15.2-14

15.2.8.9

.......... Seat Belt Warning Indicator ...................................................... 15.2-1 5

15.2.8.3

.......... Tachometer ................................................................... 15.2-11

15.2.8.5

.......... Trip Computer ................................................................. 15.2-11

15.2.8.70

......... Park Brake Indicator ............................................................ 15.2-16

15.2.8.71

......... Main Beam Indicator ........................................................... 15.2-17

75.2.8.12

......... Direction Indicator Tell Tales ..................................................... 15.2-18

15.2.8.14

......... Washer Fluid Level Indicator ..................................................... 15.2-20

15.2.8.16

......... Brake Fluid Level Indicator ...................................................... 15.2-22

75.2.8.17

......... General Bulb Failure Indicator ................................................... 15.2-23

15.2.8.18

.........

75.2.8.19 .........

15.2.8.20 ......... Traction Control OFF Tell-tale .................................................... 15.2-24

0

75.2.8.13 ......... Generator IND Voltage Indicator ................................................. 15.2-19

7 5.2.8.15 ......... Engine Coolant Level indicator ................................................... 15.2-2 1

Transmission Sport mode Indicator ................................................ 75.2-24

Traction Control Failure Warning Lamp

............................................ 15.2-24

15.2.8.21

......... Anti-lock Failure Warning Lamp .................................................. 15.2-24

15.2.8.22

......... Check Engine Warning Lamp .................................................... 75.2-24

Issue 1 August 1994 iii X300 EDM

Page 156 of 327

Electrical IT

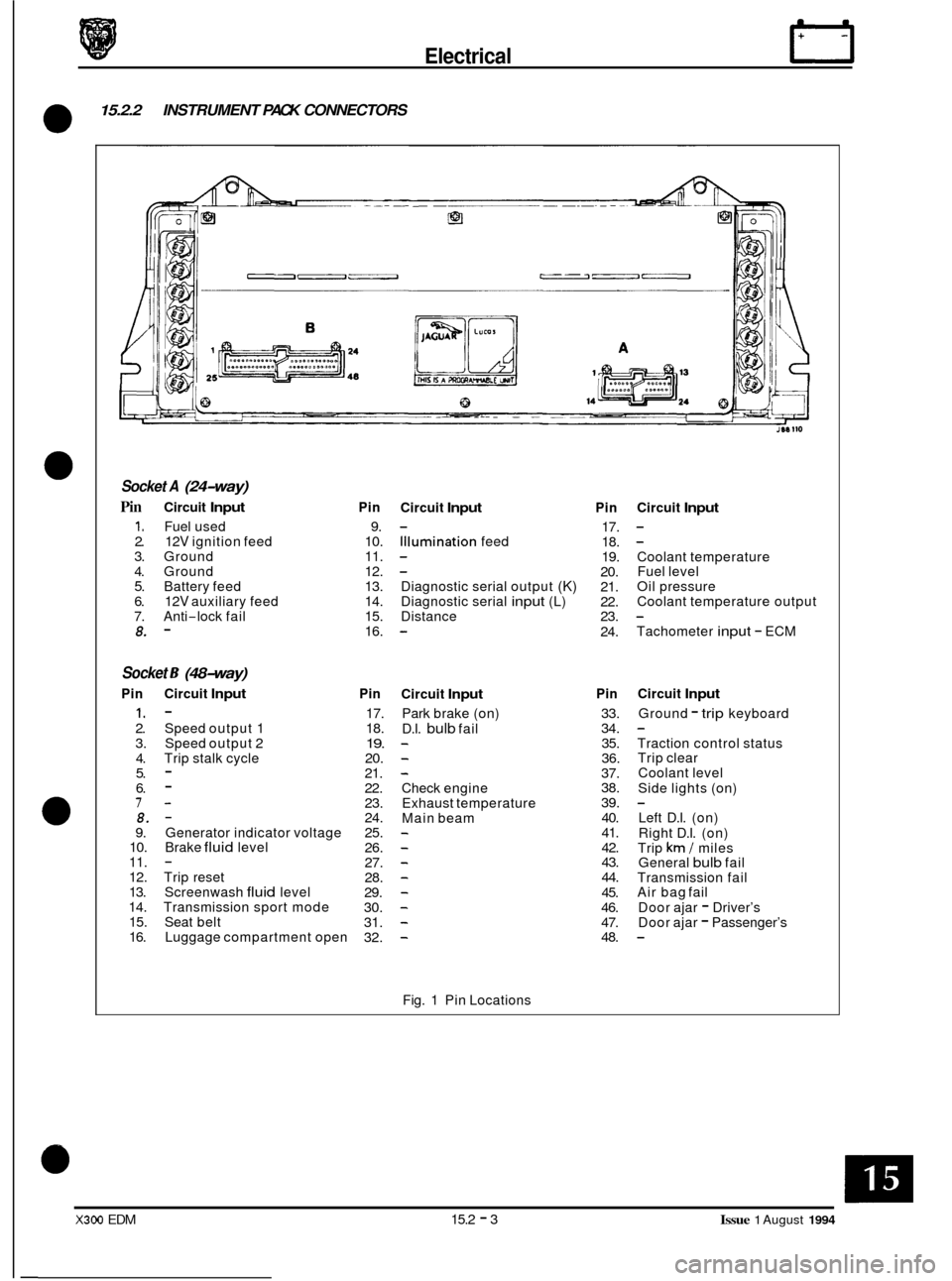

15.2.2 INSTRUMENT PACK CONNECTORS

0

Socket A (24-way)

Pin Circuit Input

1. Fuel used 2. 12V ignition feed 3. Ground 4. Ground 5. Battery feed 6. 12V auxiliary feed 7. Anti-lock fail 8. -

Socket 6 (48-way)

Pin Circuit Input

1. - 2. Speed output 1

3. Speed output 2

4. Trip stalk cycle 5. - 6. - 7- 8. - 9. Generator indicator voltage 10. Brake fluid level 11. - 12. Trip reset 13. Screenwash fluid level 14. Transmission sport mode 15. Seat belt 16. Luggage compartment open

Pin

9.

10.

11.

12.

13.

14.

15.

16.

Pin

17.

18.

19. 20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Circuit Input

Illumination feed

-

- -

Diagnostic serial output (K) Diagnostic serial input (L)

Distance

-

Circuit Input

Park brake (on)

D.I.

bulb fail - - -

Check engine

Exhaust temperature

Main beam

- - - - - - - -

Fig. 1 Pin Locations

Pin

17.

18.

19.

20.

21.

22.

23.

24.

Pin

33.

34. 35.

36.

37.

38.

39. 40.

41.

42.

43.

44.

45.

46.

47.

48.

Circuit Input

-

Coolant temperature

Fuel level

Oil pressure

Coolant temperature output

Tachometer

input - ECM

-

Circuit Input

Ground - trip keyboard

Traction control status

Trip clear

Coolant level

Side lights (on)

Left D.I. (on)

Right D.I. (on)

Trip

km / miles

General bulb fail

Transmission fail

Air bag fail

Door ajar

- Driver’s

Door ajar - Passenger’s

-

X300 EDM 15.2 - 3 Issue 1 August 1994