oil type JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 387 of 521

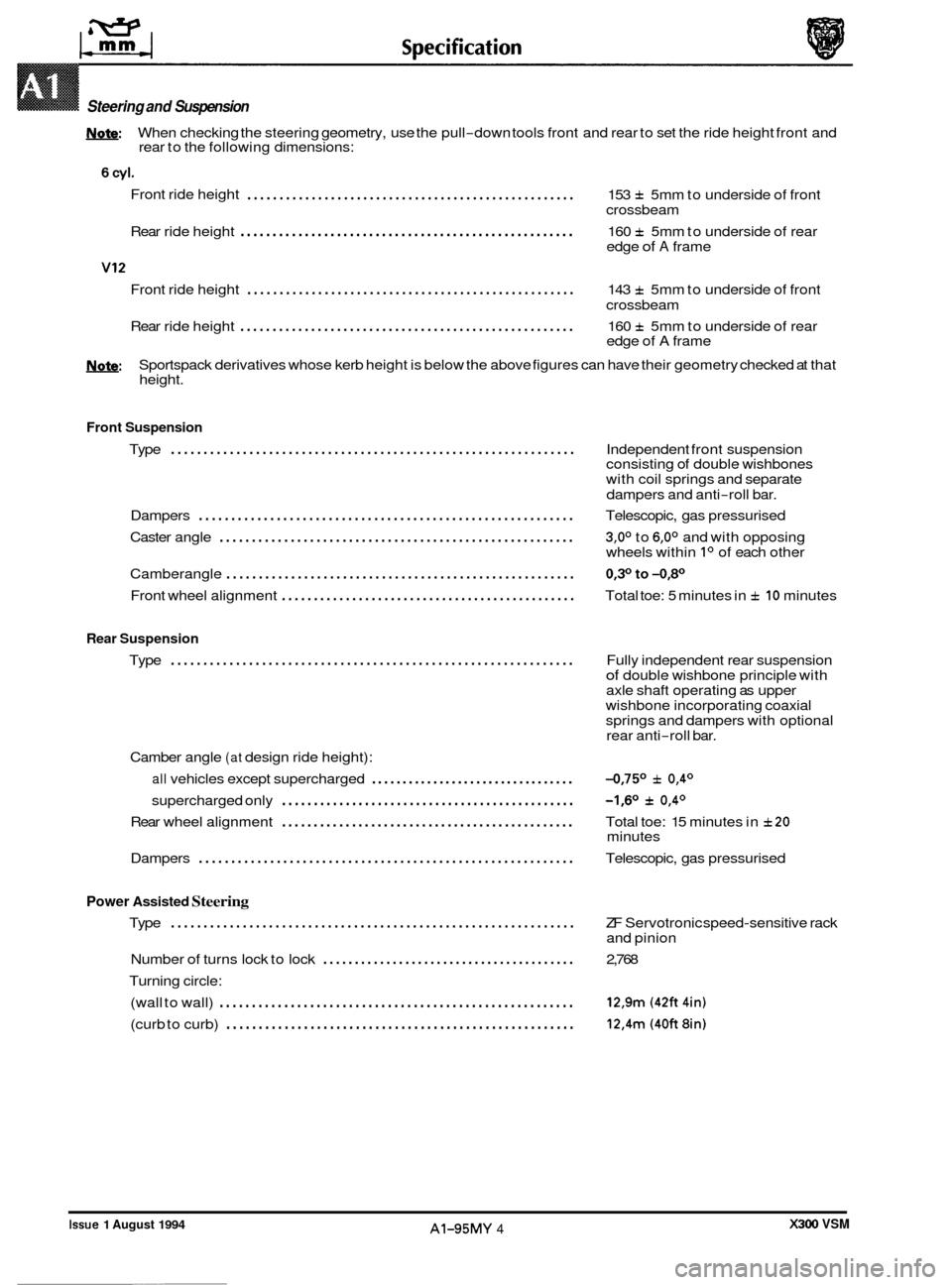

Steering and Suspension

W: When checking the steering geometry, use the pull-down tools front and rear to set the ride height front and

rear to the following dimensions:

Front ride height

................................................... 153 f 5mm to underside of front

crossbeam

Rear ride height

.................................................... 160 f 5mm to underside of rear

edge of A frame

Front ride height

................................................... 143 f 5mm to underside of front

crossbeam

Rear ride height

.................................................... 160 f 5mm to underside of rear

edge of A frame

U: Sportspack derivatives whose kerb height is below the above figures can have their geometry checked at that

height.

Front Suspension

..............................................................

0

Type Independent front suspension

consisting of double wishbones

with coil springs and separate

dampers and anti

-roll bar.

Dampers

.......................................................... Telescopic, gas pressurised

Caster angle

....................................................... 3,0° to 6,0° and with opposing

wheels within Io of each other

Camberangle

...................................................... 0,3°to-0,80

Front wheel alignment .............................................. Total toe: 5 minutes in f 10 minutes

Rear Suspension

Type .............................................................. Fully independent rear suspension of double wishbone principle with

axle shaft operating as upper

wishbone incorporating coaxial

springs and dampers with optional

rear anti

-roll bar.

Camber angle

(at design ride height):

all vehicles except supercharged ................................. -0,75O f 0,4O

supercharged only -1,6O f 0,4O ..............................................

0 Rear wheel alignment .............................................. Total toe: 15 minutes in f20

Dampers .......................................................... Telescopic, gas pressurised

minutes

Power Assisted Steering

Type .............................................................. ZF

Servotronic speed-sensitive rack

and pinion

Number

of turns lock to lock ........................................ 2,768

Turning circle: (wall to wall)

....................................................... 12,9m (42ft 4in)

(curb to curb) ...................................................... 12,4m (40ft 8in)

0

X300 VSM Issue 1 August 1994 AI-95MY 4 ~~~~

Page 390 of 521

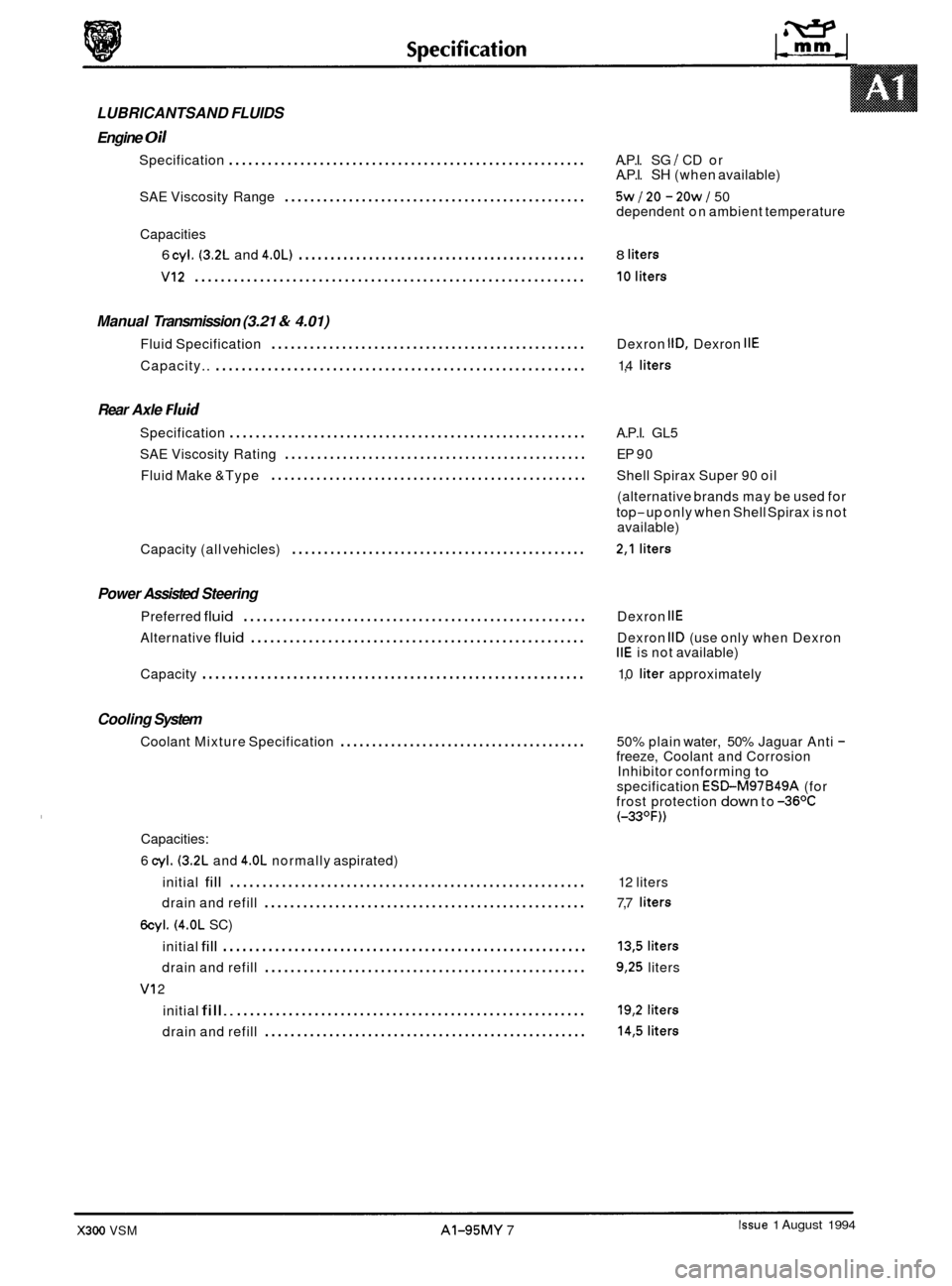

0 LUBRICANTSAND FLUIDS

Engine

Oil

Specification ....................................................... A.P.I. SG I CD or

A.P.I. SH (when available)

SAE Viscosity Range

............................................... 5w 120 - 20w J 50

dependent on ambient temperature

6 cyi. (3.2L and 4.0L) ............................................. 8 liters

VI2 ............................................................ 10liters

Capacities

Manual Transmission (3.21 & 4.01)

Fluid Specification ................................................. Dexron IlD, Dexron IIE

Capacity.. ......................................................... 1,4 liters

Rear Axle Fluid

Specification ....................................................... A.P.I. GL5

Fluid Make &Type

................................................. Shell Spirax Super 90 oil

SAE

Viscosity Rating

............................................... EP 90

(alternative brands may be used for

top

-up only when Shell Spirax is not

available)

0

Capacity (all vehicles) .............................................. 2,l liters

Power Assisted Steering

Preferred fluid ..................................................... Dexron IIE

Alternative fluid .................................................... Dexron IID (use only when Dexron IIE is not available)

Capacity

........................................................... 1,0 liter approximately

Cooling System

Coolant Mixture Specification ....................................... 50% plain water, 50% Jaguar Anti - freeze, Coolant and Corrosion

Inhibitor conforming to specification ESBM97B49A (for

frost protection down to -36OC (-33OF))

Capacities:

6

cyl. (3.2L and 4.OL normally aspirated)

initial

fill ....................................................... 12 liters

drain and refill

.................................................. 7,7 liters

6cyl. (4.0L SC)

initial

fill ........................................................ 13,5 liters

drain and refill .................................................. 9,25 liters

initial

fill.. ...................................................... 19,2 liters

drain and refill .................................................. 14,5 liters

VI 2

Issue 1 August 1994 X300 VSM AI-95MY 7

Page 395 of 521

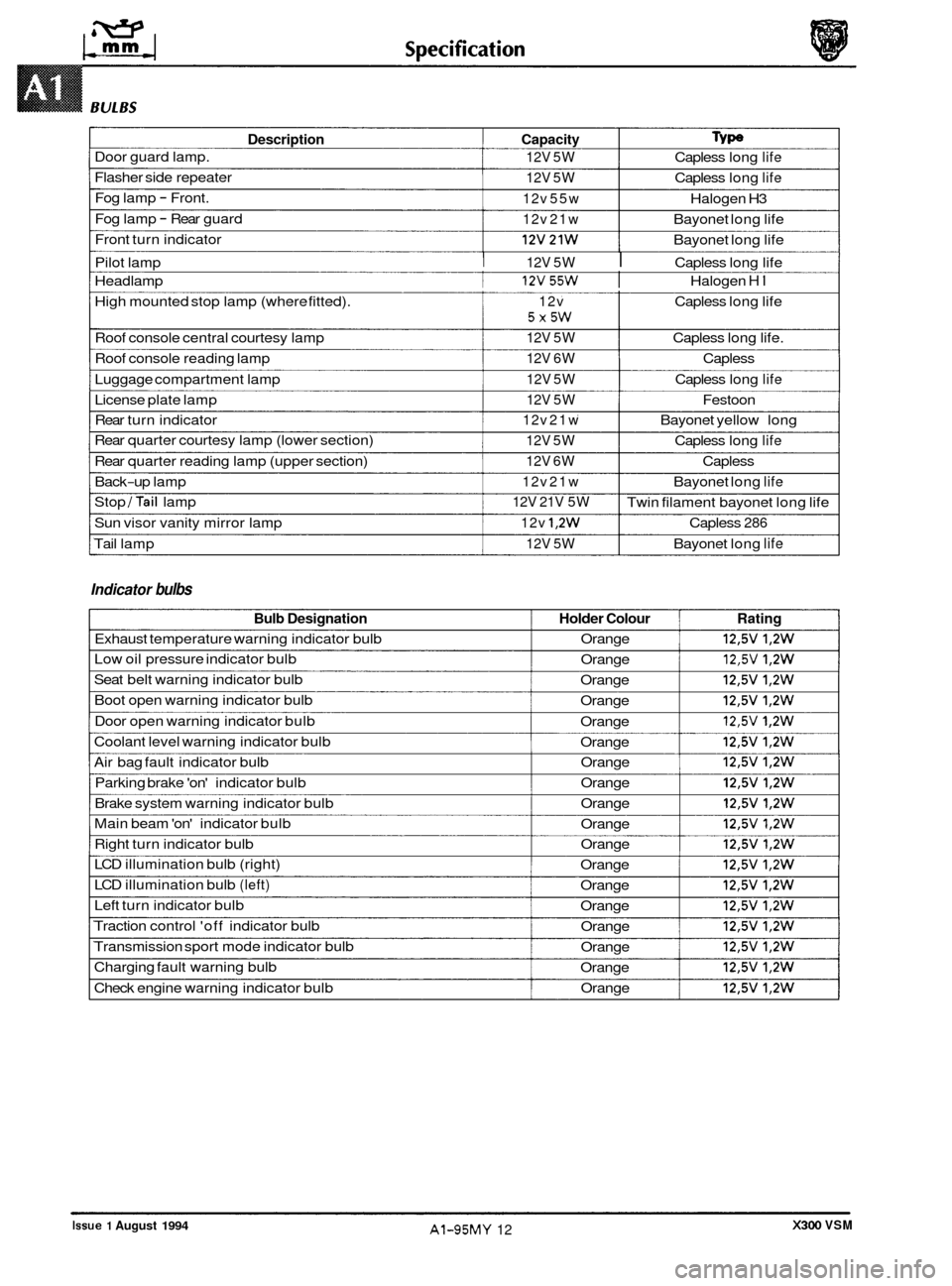

Description Capacity Type

Door guard lamp. 12V 5W Capless long life

Flasher side repeater 12V 5W Capless long life

Fog lamp - Front. 12v 55w Halogen H3

Fog lamp

- Rear guard 12v 21w Bayonet long life

Front turn indicator

I 12v21w I Bayonet long life

Pilot lamp

I 12V 5W I Capless long life

Headlamp

I 12v55w I Halogen HI

High mounted stop lamp (where fitted). 12v Capless long life

Roof console central courtesy lamp

12V 5W Capless long life.

Roof console reading lamp

12V 6W Capless

Luggage compartment lamp

12V 5W Capless long life

License plate lamp 12V 5W Festoon

Rear turn indicator

12v 21w Bayonet yellow long

Rear quarter courtesy lamp (lower section)

12V 5W Capless long life

Rear quarter reading lamp (upper section) 12V 6W Capless

Back

-up lamp 12v 21w Bayonet long life

Stop /Tail lamp

Sun visor vanity mirror lamp

12v 1,2w Capless 286

Tail lamp 12V 5W Bayonet long life

5X5W

12V 21V 5W Twin filament bayonet long life

Indicator bulbs

Bulb Designation Holder Colour Rating

Exhaust temperature warning indicator bulb Orange 12,5V 1,2W

Low oil pressure indicator bulb

Orange 12,5V 1,2W

Seat belt warning indicator bulb

Orange 12,5V 1,2W

Boot open warning indicator bulb

Orange 12,5V 1,2W

Door open warning indicator bulb

Orange 12,5V 1,2W

Coolant level warning indicator bulb

Orange 12,5V 1,2W

Air bag fault indicator bulb Orange 12,5V 1,2W

Parking brake 'on' indicator bulb Orange 12,5V 1,2W

Brake system warning indicator bulb Orange 12,5V 1,2W

Main beam 'on' indicator bulb

Orange 12,5V 1,2W

Right turn indicator bulb Orange 12,5V 1,2W

LCD illumination bulb (right)

Orange 12,5V 1,2W

LCD illumination bulb (left) Orange 12,5V 1,2W

Left turn indicator bulb

Orange 12,5V 1,2W

Traction control 'off indicator bulb

Orange 12,5V 1,2W

Transmission sport mode indicator bulb

Orange 12,5V 1,2W

Charging fault warning bulb

Orange 12,5V 1,2W

Check engine warning indicator bulb Orange 12,5V 1,2W

0

0

0

X300 VSM Issue 1 August 1994 AI-95MY 12

Page 413 of 521

General Fitting Instructions

A3.2 GENERAL FITTING INSTRUCTIONS

A3.2.1

Always fit covers to protect the wings before commencing work in the engine compartment. Cover the seats and

carpets, wear clean overalls and wash hands or wear gloves before working inside the car. Avoid spilling hydraulic

fluid, anti

-freeze or battery acid on the paintwork. In the event of spillage, wash off with water immediately. Use poly- thene sheets in the boot to protect carpets. Always use the recommended service tool, or a satisfactory equivalent,

where specified. Protect temporarily exposed screw threads by replacing nuts or fitting caps.

Precautions Against Damage To The Vehicle

A3.2.2 Preparation

Before disassembly, clean the surrounding area as thoroughly as possible. When components have been removed,

blank off any exposed openings using greaseproof paper and masking tape. Immediately seal fuel, oil and hydraulic

lines when separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends

of oilways, exposed by component removal, with tapered hardwood plugs or readily visible plastic plugs. Immediately

a component is removed, place

it in a suitable container; use a separate container for each component and its asso- ciated parts. Before dismantling a component, clean it thoroughly with a recommended cleaning agent: check that the

agent will not damage any of the materials within the component. Clean the bench and obtain marking materials, la-

bels, containers and locking wire before dismantling a component.

A3.2.3 Dismantling

Observe scrupulous cleanliness when dismantling components, particularly when parts of the brake, fuel or hydraulic

system are being worked on. A particle of dirt or a fragment of cloth could cause a dangerous malfunction if trapped in these systems. Clean all tapped holes, crevices, oilways and fluid passages with compressed air.

WRNIFLG: DO NOT PERMIT COMPRESSED AIR TO ENTER AN OPEN WOUND. ALWAYS USE EVE PROTECTION

WHEN USING COMPRESSED AIR.

Ensure that any 'O'-rings used for sealing are correctly refitted or renewed if disturbed. Mark mating parts to ensure

that they are replaced as dismantled. Whenever possible use marking materials which avoid the possibilities of caus- ing distortion or the initiation of cracks, which could occur if a center punch or scriber were used. Wire together mating

parts where necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to

be renewed and to parts requiring further inspection before being passed for reassembly.

Place labelled parts and other parts for rebuild

in separate containers.

Do not discard a part which is due for renewal until it has been compared with the new part, to ensure that the correct

part has been obtained.

A3.2.4 Inspection

Before inspecting a component for wear or performing a dimensional check, ensure that it is absolutely clean; a slight

smear of grease can conceal an incipient failure. When a component is to be checked dimensionally against figures

quoted for

it, use the correct equipment (surface plates, micrometers, dial gauges etc.) in serviceable condition. The

use of makeshift equipment can be dangerous. Reject a component if its dimensions are outside the limits quoted,

or if damage is apparent. A part may be refitted if its critical dimension is exactly to the limit size and it is otherwise

satisfactory. Use Plastigauge 12 Type PG-1 for checking bearing surface clearance e.g. big end bearing shell to crank

journal. Instructions for the use of Plastigauge and a scale giving bearing clearances in steps of

0,0025 mm (0.0001

in) are supplied with the package.

0

0

0

X300 VSM Issue 1 August 1994 2

Page 418 of 521

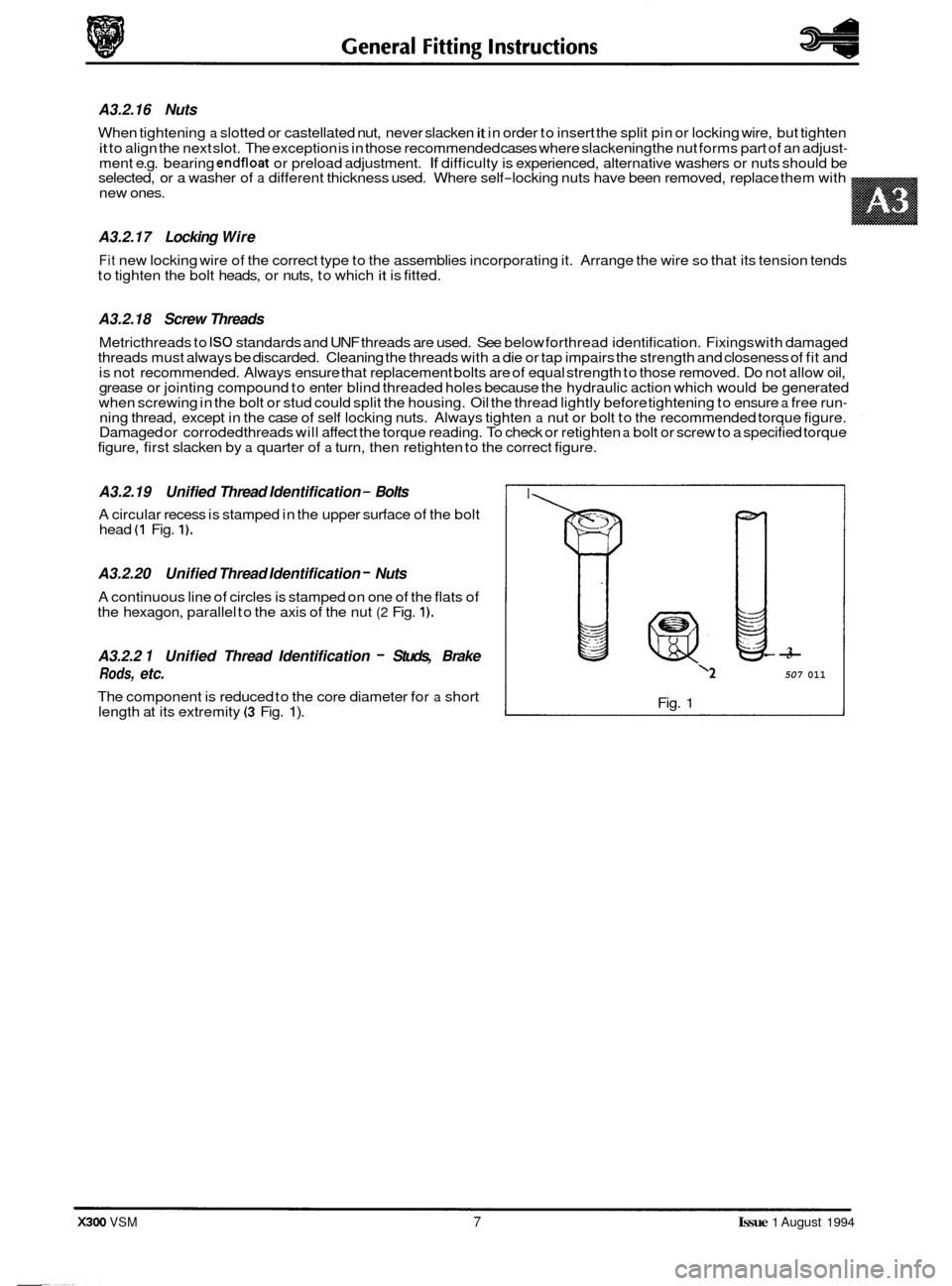

- A3.2.19 Unified Thread Identification - Bolts

A circular recess is stamped in the upper surface of the bolt

head (1 Fig. 1).

A3.2.20 Unified Thread Identification - Nuts

A continuous line of circles is stamped on one of the flats of

the hexagon, parallel to the axis of the nut (2 Fig. 1).

A3.2.2 1 Unified Thread Identification - Studs, Brake

Rods, etc.

The component is reduced to the core diameter for a short

length at its extremity (3 Fig. 1).

A3.2.16 Nuts

When tightening a slotted or castellated nut, never slacken it in order to insert the split pin or locking wire, but tighten

it to align the next slot. The exception is in those recommended cases where slackening the nut forms part of an adjust- ment e.g. bearing endfloat or preload adjustment. If difficulty is experienced, alternative washers or nuts should be

selected, or a washer of a different thickness used. Where self-locking nuts have been removed, replace them with

new ones.

A3.2.17 Locking Wire

Fit new locking wire of the correct type to the assemblies incorporating it. Arrange the wire so that its tension tends

to tighten the bolt heads, or nuts, to which it is fitted.

A3.2.18 Screw Threads

Metricthreads to IS0 standards and UNF threads are used. See below forthread identification. Fixings with damaged

threads must always be discarded. Cleaning the threads with a die or tap impairs the strength and closeness of fit and

is not recommended. Always ensure that replacement bolts are of equal strength to those removed. Do not allow oil,

grease or jointing compound to enter blind threaded holes because the hydraulic action which would be generated

when screwing in the bolt or stud could split the housing. Oil the thread lightly before tightening to ensure

a free run- ning thread, except in the case of self locking nuts. Always tighten a nut or bolt to the recommended torque figure.

Damaged or corroded threads will affect the torque reading. To check or retighten a bolt or screw to a specified torque

figure, first slacken by a quarter of a turn, then retighten to the correct figure.

I

7

-3

‘2 507 011

Fig. 1

X300 VSM 7 Issue 1 August 1994

Page 430 of 521

Systems Repair Body & Body -

A4.1.3. POTENTIAL RISKS I

A4.1.3. Paint

Organic solvents, found in paints, may cause damage or severe irritation to liver, kidneys, digestive tracts and respira- tory system if inhaled over long periods of time.

Prolonged exposure to isocyanates may cause lung sensitization. Asthma

-like symptoms may develop with subse-

quent exposure to very low concentrations of isocyanates.

Solvent inhalation can cause dizziness or loss of consciousness.

Splashes of solvents, paint activators and additives can cause damage to the eyes and may cause dermatitis. Peroxide

and acid catalysts may cause burns.

Inhalation of

spray dust and sanding debris may cause lung damage.

I

A4.1.3.2 Applied Heat (Welding)

There is considerable risk of damage to eyes and skin when welding or flame cutting.

Fire is a serious danger and many materials or fluids within the vehicle are highly flammable.

Toxic and dangerous fumes may be liberated when any of the following are subjected to heat:

0 Expanded foam

0 Corrosion protection

0 Trim and seat materials

0 Paints which contain isocyanates

0 Adhesive and sealing compounds

When heated to a temperature of 3OO0C, polyurethane based compounds may liberate small quantities of isocyanate.

Many types of nitrogen containing chemicals may be liberated as breakdown products; these chemicals can contain

isocyanates, oxides of nitrogen and hydrogen cyanide.

Potentially toxic or asphyxiant fumes and gases are produced by welding, for example; zinc oxide with zinc coated

panels, and ozone gas from the MIG process.

A4.1.3.3 Metal Repair

There is considerable risk of damage to eyes, ears and skin when metal cutting, forming, or dressing is being carried

out.

Soldering may be hazardous because of heat generated fumes and skin contact with the materials.

A4.1.4. PRECAUTIONS

A4.1.4.1 Paint

The inhalation of sprays, fumes, or dust during paint application or sanding processes should always be avoided. En- sure that there is efficient ventilation / extraction at all times. Paint spraying should be confined as far as possible to

spray booths. Personnel with a history of asthma should not be engaged in any process which involves the use of

isocyanates. Any operator working inside

a spray booth where isocyanate material is present must use air-fed breath- ing equipment. Supplied air to the visor should be fed at the recommended pressure and filtered to remove oil, water,

and fumes. Operators involved in handling mixing or spraying should wear protective clothing - gloves and goggles,

to avoid skin and eye contact.

A particle mask or canister type respirator should be worn when sanding.

A4.1.4.2 Applied Heat

When welding, flame cutting, brazing etc, the operator should use as appropriate, goggles, mask/fume extractor and

flameproof protective clothing. It is especially important when working with polyurethane compounds to use air-fed

breathing equipment.

Ensure that

at all times the appropriate fire fighting equipment is available and that personnel are trained in its use.

A4.1.4.3 Metal Repair

Appropriate eye and hand protection should be worn when sanding, drilling, cutting, chiselling, flatting or welding.

Operators should wear

a face mask or air-fed visor when sanding or flatting either body solder or fillers.

When

a soldering operation has been completed, swarf must be removed from the work area and the operator must

wash his hands thoroughly.

X300 VSM 3 Issue 1 August 1994