climate control system JAGUAR XJ6 1994 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 318 of 521

Climate Control Systems

8. AUTO selection display.

9. EXTERIOR temperature selection button. There are two modes:

a) Press and immediate release; provides timed display of four (4) seconds.

b) Press and hold for two (2) seconds; 'latches' the mode until operator over-ride.

10. A/C push-on / push-off button will either engage or disengage (as indicated by the state lamp) the refrigeration

system compressor. The state lamp is also used as a compressor speed fault indicator,see System protection, this

section.

11. AUTO push-on button and state lamp. When selected and the state lamp lit, the A/C mode is selected and control

of demand temperature, fans speed, and air distribution is automatic. AUTO is cancelled by selection of any 'dis- tribution' button, A/C off, or manual FANS SPEED.

12. DEFROST push

-on / push-off button and state lamp. When engaged, air is distributed to the screen at maximum

fans speed and the heated front screen elements (where fitted) are ener ized. The heated front screen is automati- cally timed for a six (6) minute cycle but may be cancelled by pressing tfe HEATED FRONT SCREEN button. Auto- matic temperature control is retained and the fans speed may be manually reduced. Deselection will return the

system to the previous state and selection of AUTO will resume automatic system control.

13. The push

-on / push-off (F) button with state lamp manually controls the HEATED FRONT SCREEN (where fitted).

This facility allows rapid screen de-icing using laminated electrical heating elements to supplement the hot air

defrost.

14. The push-on / push-off (R) button with state lamp manually controls the HEATED REAR SCREEN and door mirror

glass heating elements for a timed cycle of; screen twenty (20) minutes and mirrors eleven (1 1) minutes.

m: The state lamp will remain lit after the mirror timer has gone through its 11 minute cycle and will not go out

until either completion of the 20 minute screen cycle or manual override.

15. TEMPERATURE decrease button

in IoC or I0F steps.

16. TEMPERATURE increase button in

IoC or I0F steps.

w: Automatic temperature control operates over the range 17OC to 31OC (61OF to 90OF). Extreme limits selected

by items 15 and 16 ('Lo' and 'Hi') provide maximum cooling or heating at maximum fans speed.

17. FACE level manual distribution over

-ride push-on / push-off button and state lamp.

0 18. Bi LEVEL (foot and face) manual distribution over-ride push-on / push-off button and state lamp.

19. FOOT level manual distribution over

-ride push-on / push-off button and state lamp.

20. DEMIST (screen and foot) level manual distribution over

-ride push-on / push-off button and state lamp.

!Y&Q: Selection of AUTO will over-ride any manual setting and deselection of any manual distribution will revertthe

system to AUTO distribution.

21. FACE VENTTEMPERATURE CONTROL thumb

-wheel. Situated between dash centre face level vents to reduce face

air outlet temperature relative to that of the foot-well.

Issue 1 August 1994 X300 VSM 5

Page 319 of 521

Climate Control Systems

14.4 TEMPERATURE CONTROL

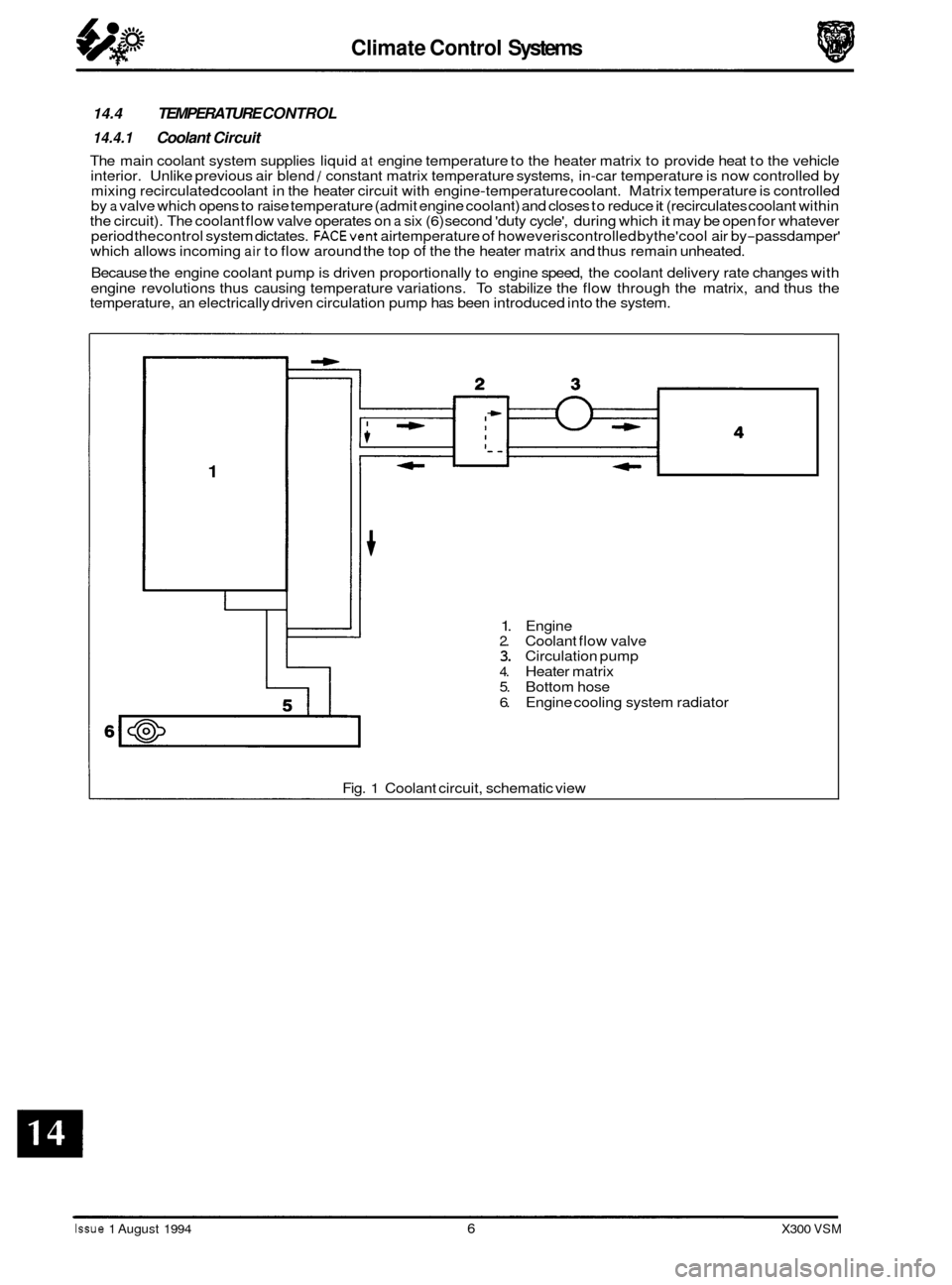

14.4.1 Coolant Circuit

The main coolant system supplies liquid at engine temperature to the heater matrix to provide heat to the vehicle

interior. Unlike previous air blend / constant matrix temperature systems, in-car temperature is now controlled by

mixing recirculated coolant in the heater circuit with engine-temperature coolant. Matrix temperature is controlled

by a valve which opens to raise temperature (admit engine coolant) and closes to reduce it (recirculates coolant within

the circuit). The coolant flow valve operates on a six (6) second 'duty cycle', during which it may be open for whatever

period thecontrol system dictates. FACEvent airtemperature of howeveriscontrolled bythe'cool air by-passdamper'

which allows incoming air to flow around the top of the the heater matrix and thus remain unheated.

Because the engine coolant pump is driven proportionally to engine speed, the coolant delivery rate changes with

engine revolutions thus causing temperature variations. To stabilize the flow through the matrix, and thus the

temperature, an electrically driven circulation pump has been introduced into the system.

1

1. Engine 2. Coolant flow valve 3. Circulation pump

4. Heater matrix

5. Bottom hose

6. Engine cooling system radiator

Fig.

1 Coolant circuit, schematic view

Issue 1 August 1994 6 X300 VSM

Page 320 of 521

Climate Control Systems

Manual Inputs

Automatic inputs

outputs

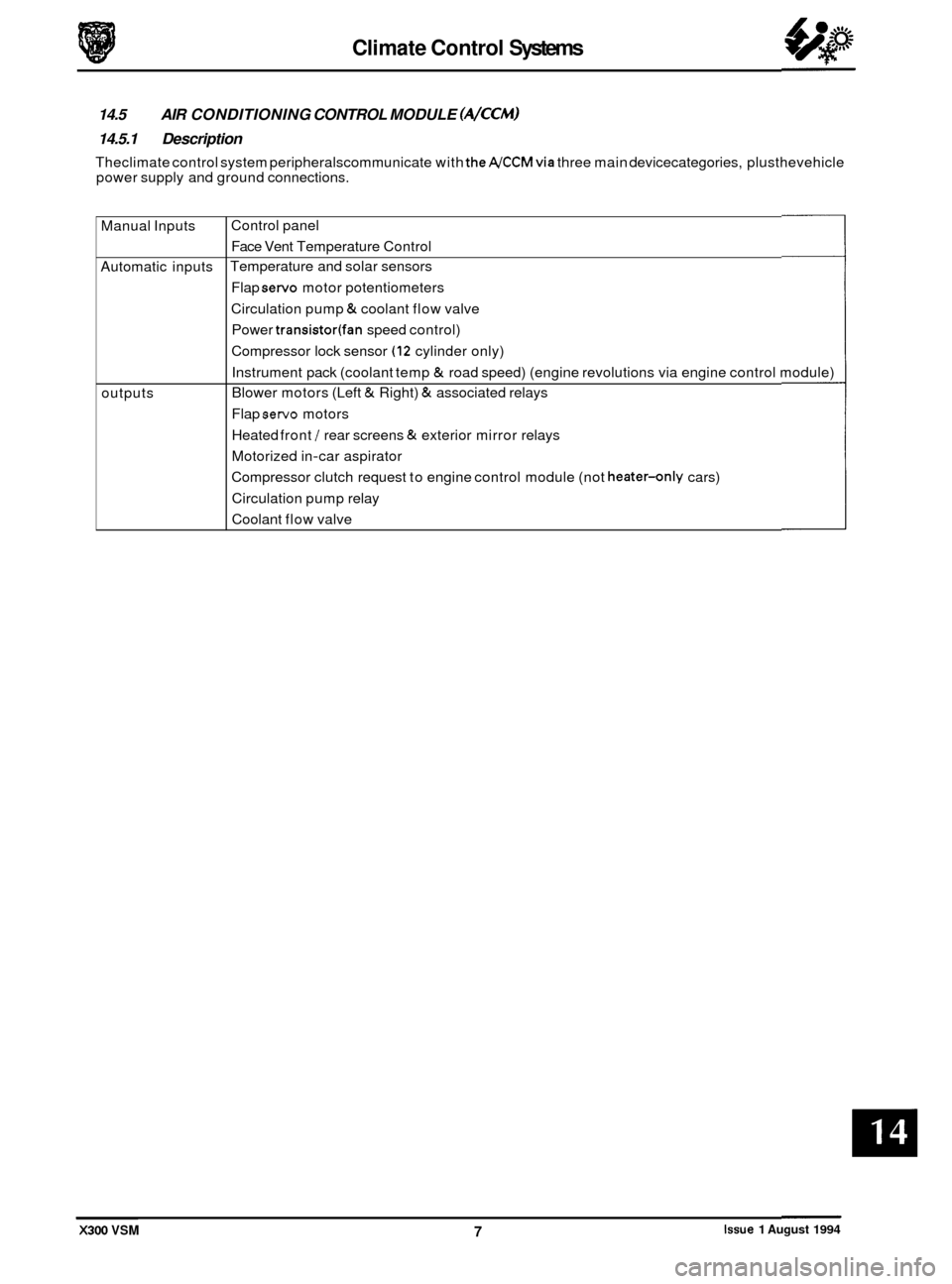

14.5 AIR CONDITIONING CONTROL MODULE (A/CCM)

14.5.1 Description

Theclimate control system peripheralscommunicate with theA/CCMvia three main devicecategories, plusthevehicle

power supply and ground connections.

Control panel Face Vent Temperature Control

Temperature and solar sensors

Flap

servo motor potentiometers

Circulation pump

& coolant flow valve

Power

transistor(fan speed control)

Compressor lock sensor

(12 cylinder only)

Instrument pack (coolant temp

& road speed) (engine revolutions via engine control module)

Blower motors (Left

& Right) & associated relays

Flap

servo motors

Heated front

/ rear screens & exterior mirror relays

Motorized in

-car aspirator

Compressor clutch request to engine control module (not

heater-only cars)

Circulation pump relay

Coolant flow valve

X300 VSM Issue 1 August 1994 7

Page 321 of 521

Climate Control Systems

. Centre vent flap

Foot flap

Defrost flap

I I

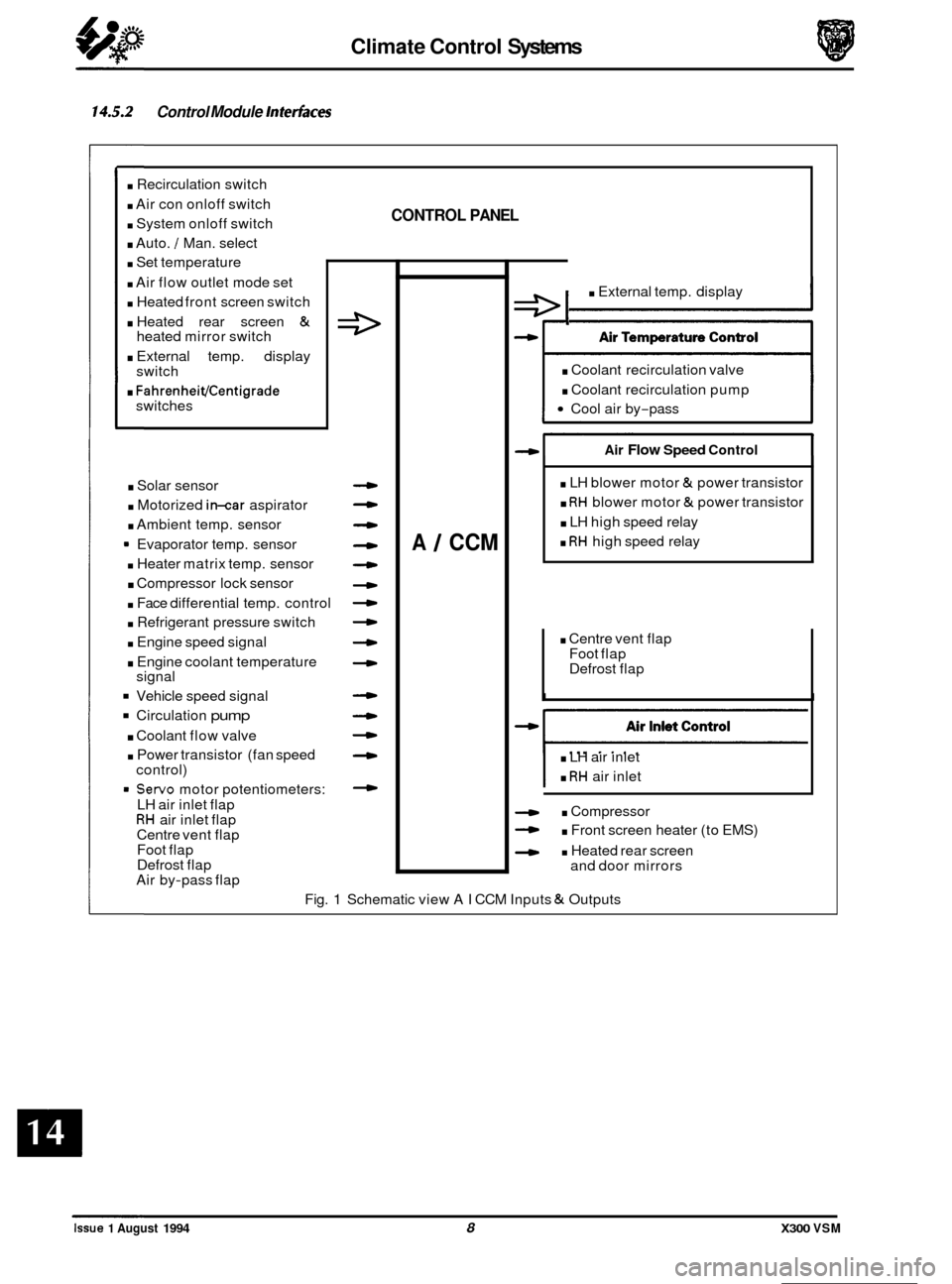

14.5.2 Control Module Interfaces

. Recirculation switch

. Air con onloff switch

. System onloff switch

. Auto. / Man. select

. Set temperature

. Air flow outlet mode set

. Heated front screen switch

. Heated rear screen &

. External temp. display

. FahrenheiVCentigrade

heated mirror switch

switch

switches

. Solar sensor

. Motorized in-car aspirator

. Ambient temp. sensor

9 Evaporator temp. sensor

. Heater matrix temp. sensor

. Compressor lock sensor

. Face differential temp. control

. Refrigerant pressure switch

. Engine speed signal

. Engine coolant temperature

Vehicle speed signal

Circulation pump

. Coolant flow valve

. Power transistor (fan speed

= Servo motor potentiometers:

signal

control)

LH air inlet flap

RH air inlet flap

Centre vent flap

Foot flap

Defrost flap

Air by

-pass flap

CONTROL PANEL

4

-

4

4

4

4

4

4

A 1 CCM

e I . External temp. display

. Coolant recirculation valve

. Coolant recirculation pump

Cool air by-pass

Air Flow Speed Control

. LH blower motor & power transistor

. RH blower motor & power transistor

. LH high speed relay

. RH high speed relay

. LH air inlet

. RH air inlet

. Compressor

- . Front screen heater (to EMS)

- . Heated rear screen

and door mirrors

Fig.

1 Schematic view AI CCM Inputs & Outputs

0

0

0

0

Issue 1 August 1994 8 X300 VSM

Page 322 of 521

Climate Control Systems

CONTROL MODULE FAULT & CONDITION SELF-ANALYSIS

0 14.6 14.6.1 System Health

The climate control system has a 'self-test' facility, accessible from the control panel. The self test sequence has two

basic modes:

0 System error information is stored in the A/CCM up to a maximum of five faults. Should a fault occur there will

be an audible 'beep' and the message 'Er' will be displayed on the control panel LCD for approximately five (5)

seconds after ignition on. Please note that this will happen only once in any ignition switch cycle. The error

source may be accessed by the procedure described in 'Self Test System Diagnosis', this section.

0 Panel communication check may be initiated by following the instruction in 'Self Test System Diagnosis', this

section.

Nsfe: Displayed error codes are NOT directly related to Jaguar Diagnostic Equipment (JDE) but more detailed fault

related information may be accessed using Portable Diagnostic Unit (PDU).

14.6.2 System Protection

Power to the compressor clutch may be cut should either the engine management or air conditioning control systems

detect certain conditions; these conditions may be caused by Fault or Demand and can be classified thus:

0 Engine coolant overheat,

0 Refrigerant excessive pressure.

0 Refrigerant, insufficient pressure or low charge weight.

0 Speed differential between compressor and crankshaft caused by belt slippage or compressor seizure (indi-

cated by A/C state lamp flashing once per second) - 12 cylinder engine only. This feature, 'lock sensing' is fully

explained

in the EDM.

Demand

0 Engine maximum power requirement

0 Electrical system drain at engine idle.

X300 VSM 9 Issue 1 August 1994

Page 323 of 521

Climate Control Systems

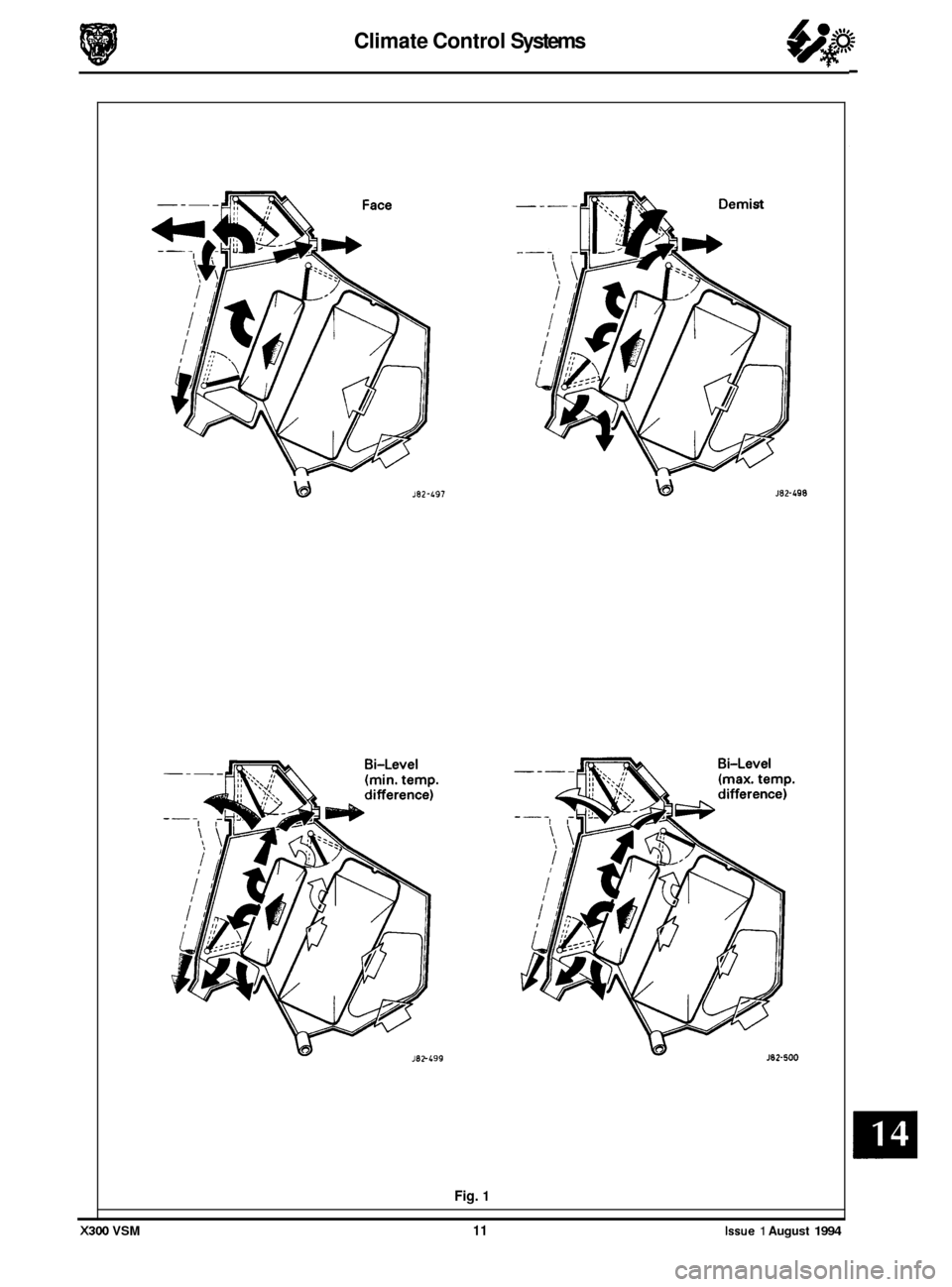

14.7 AIR DlSTRlBUTlON

(Refer to illustrations on this and next page)

Air is drawn from the plenum chamber into the heater/cooler case at the lower front right and left hand sides. All air must first pass through the evaporator (not fitted to heater only cars) and then through the heater matrix for in-car distribution.

When cooler air than that available from the other outlets is desired at the FACE vents, air by

-passes the matrix via

the 'cool air by-pass damper' within the range cold to hot.

The flaps for FOOT, COOL AIR, CENTRE VENT, RH & LH RECIRCULATION and DEFROST are electrically driven by indi- vidual motor / potentiometer units.

1. Face outlet

2. Defrost outlet

3. End-of-dash outlet 4. Cool air by-pass damper

5. Evaporator

6. Air in 7. Foot outlet (front)

8. Foot outlet (rear)

9. Rear face outlet 10. Heater matrix

J82-49L

Fig. 1

\d J82-495 \d J82-L96

(Solid arrow = Hot, Line arrow = Cold)

Fig. 2

0

0

0

0

Issue 1 August 1994 10 X300 VSM

Page 324 of 521

0

0

0

Climate Control Systems &j%

\d J82-697

Fig. 1

k9 J82-498

X300 VSM 11 Issue 1 August 1994

Page 325 of 521

Climate Control Systems

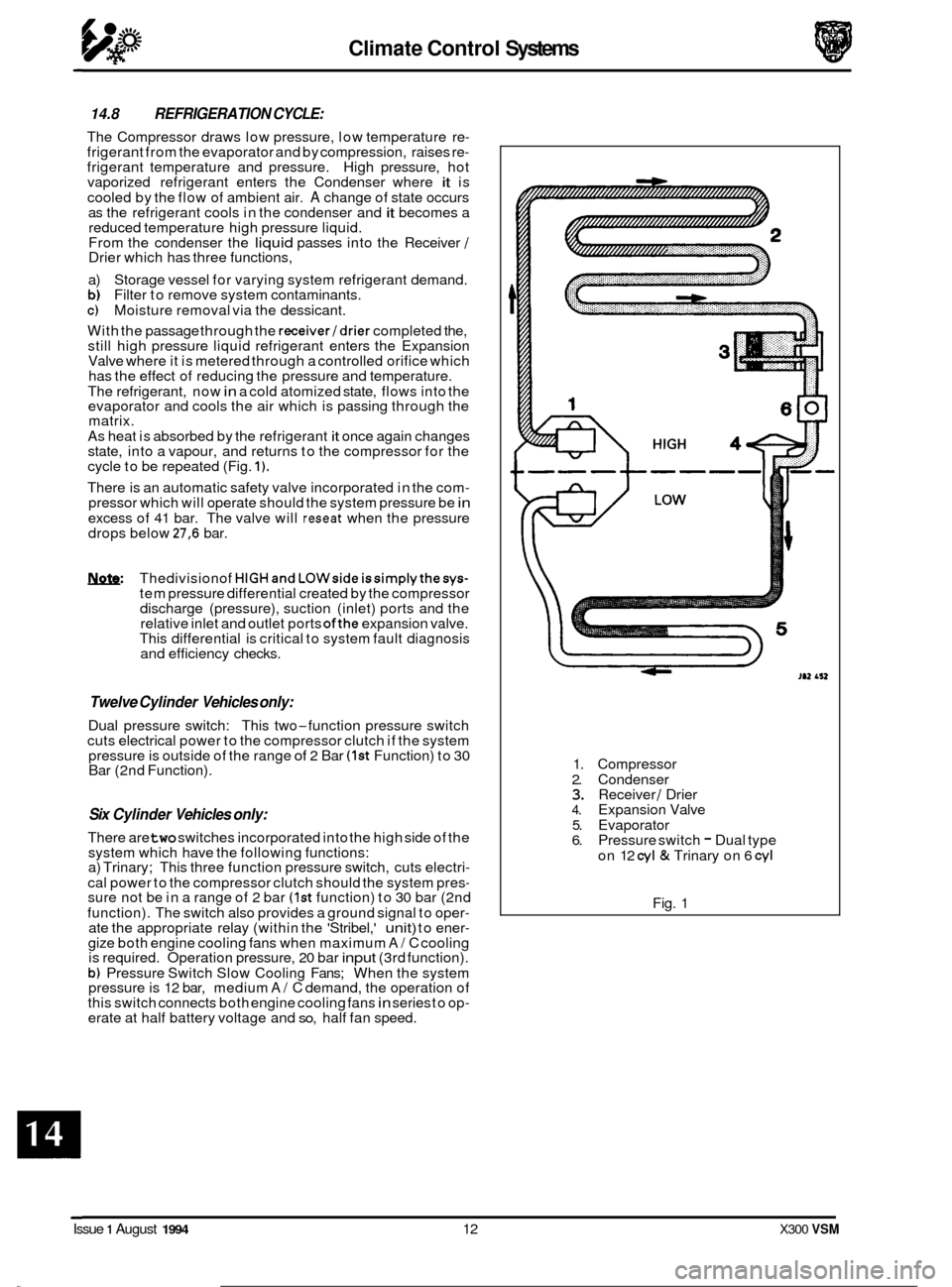

14.8 REFRIGERATION CYCLE:

The Compressor draws low pressure, low temperature re- frigerant from the evaporator and by compression, raises re- frigerant temperature and pressure. High pressure, hot

vaporized refrigerant enters the Condenser where it is

cooled by the flow of ambient air.

A change of state occurs

as the refrigerant cools in the condenser and it becomes a

reduced temperature high pressure liquid.

From the condenser the

liquid passes into the Receiver / Drier which has three functions,

a) Storage vessel for varying system refrigerant demand.

b) Filter to remove system contaminants. c) Moisture removal via the dessicant.

With the passage through the

receiver/drier completed the,

still high pressure liquid refrigerant enters the Expansion

Valve where it is metered through a controlled orifice which

has the effect of reducing the pressure and temperature.

The refrigerant, now

in a cold atomized state, flows into the

evaporator and cools the air which is passing through the

matrix.

As heat is absorbed by the refrigerant

it once again changes

state, into a vapour, and returns to the compressor for the

cycle to be repeated (Fig.

1).

There is an automatic safety valve incorporated in the com- pressor which will operate should the system pressure be in

excess of 41 bar. The valve will reseat when the pressure

drops below 27,6 bar.

W Thedivisionof HIGHandLOWsideissimplythesys- tem pressure differential created by the compressor

discharge (pressure), suction (inlet) ports and the

relative inlet and outlet ports

ofthe expansion valve.

This differential is critical to system fault diagnosis

and efficiency checks.

Twelve Cylinder Vehicles only:

Dual pressure switch: This two-function pressure switch

cuts electrical power to the compressor clutch if the system

pressure is outside of the range

of 2 Bar (1st Function) to 30

Bar (2nd Function).

Six Cylinder Vehicles only:

There are two switches incorporated into the high side of the

system which have the following functions:

a) Trinary; This three function pressure switch, cuts electri

-

cal power to the compressor clutch should the system pres- sure not be in a range of 2 bar (1st function) to 30 bar (2nd

function). The switch also provides a ground signal to oper

- ate the appropriate relay (within the 'Stribel,' unit) to ener- gize both engine cooling fans when maximum A/ C cooling

is required. Operation pressure, 20 bar input (3rd function).

b) Pressure Switch Slow Cooling Fans; When the system

pressure is 12 bar, medium A/ C demand, the operation of

this switch connects both engine cooling fans in series to op- erate at half battery voltage and so, half fan speed. 1.

Compressor

2. Condenser

3. Receiver / Drier 4. Expansion Valve

5. Evaporator

6. Pressure switch - Dual type

on 12

cyl & Trinary on 6 cyl

Fig. 1

0

0

Issue 1 August 1994 12 X300 VSM

Page 326 of 521

Climate Control Systems

0 14.9 GENERAL SYSTEM PROCEDURES

14.9.1 Leak Test

Faults associated with low refrigerant charge weight and low pressure may be caused by leakage. Leaks traced to

mechanical connections may be caused by torque relaxation or joint face contamination. Evidence of oil around such

areas is an indicator of leakage. When checking for non visible leaks use only

a dedicated HFC 134A electronic analyzer

and apply the probe all round the joint / connection.

Should a leak betraced to a joint,checkthatthefixing issecuredtothecorrecttightening torque before any other action

is taken.

Do not forget to check the compressor shaft seal and evaporator.

CAUTION : Never use a dedicated CFC 12 or naked flame type analyzer.

14.9.2 Charge Recovery (System depressurization)

The process of HFC 134A recovery will depend on the basic characteristics of your chosen recovery/ recycle I recharge

equipment, therefore, follow the manufacturer's instructions carefully.

Remember that compressor oil may be drawn

out of the system by this process, take note of the quantity recovered

so that it may be replaced.

CAUTION: Observe all relevant safety requirements.

Wear suitable eye and skin protection

Do not mix HFC 134A with CFC 12. Do not vent refrigerant directly to atmosphere and always use Jaguar approved recovery I recycle I re- charge equipment.

Take note of the amount of recovered refrigerant, it will indicate the state of the system. 0

14.9.3 Evacuating the System

This process, the removal of unwanted air and moisture, is critical to the correct operation of the air conditioning sys-

tem. The specific procedures will vary depending on the individual characteristics of your chosen recovery I recycle / recharge equipment and must be carried out exactly in accordance with the manufacturers instructions. However,

it is recommended that the initially only the HIGH side valve be opened at the start of the procedure. After a short time a small depression should be seen on the LOW side, at which point the LOW side valve may be opened and the evacu- ation process completed. If a vacuum is not registered on the LOW side it may indicate that the expansion valve is

jammed closed or that the system is blocked. This simple check may save time and effort when the system is re- charged.

Moisture can be highly destructive and may cause internal blockages due to freezing, but more importantly, water sus- pended in the PAG oil will damage the compressor. Once the system has been opened for repairs, or the refrigerant

charge recovered, all traces of moisture MUST be removed before recharging.

14.9.4

The amount of oil drawn out during a recovery procedure will be dependent on the state of the system and the rate

of recovery. The quantity will be approximately 30 to 40 ml; this may vary, and the figure is given only for guidance.

The oil separator vessel in the recovery equipment must be clean and empty

at the start of the process so that the quan- tity of oil which is drawn out may be accurately measured.

Oil may be added by three methods,

1 and 2 being direct into the system and 3 with the compressor off the vehicle;

1. Via the recovery I recycle 1 recharge station.

2. Proprietary oil injector.

Adding Lubricating Oil - Compressor Related

1ynfa: Equipment manufacturer's instructions must be adhered to when using direct oil introduction.

3. Directly into the original, or new unit, because of rectification work to the existing compressor, or the need to fit a new compressor.

Original

From an existing compressor, drain the oil into a measuring cylinder and record the amount. Flush the unit out

with fresh PAG oil and drain thoroughly, Replenish the compressor with the same amount of PAG oil that was

originally drained out and immediately plug all orifices ready for refitting to the vehicle.

X300 VSM 13 Issue 1 August 1994

Page 327 of 521

Climate Control Systems

New

Drain and discard the transit lubricating oil from a new compressor before it is be fitted. An adjustment must

then be made to avoid over-filling the system, by taking into account;

a) the quantity found in the original compressor.

b) the quantity deposited in the recovery equipment oil separator from the charge recovery operation.

Drained from original compressor

50 ml

Recovered from oil separator 40 ml

Quantity to be put in new compressor 50 + 40 = 90 ml

Typical example:

Please note that the discrepancy between the cumulative figure of recovered and drained oil and the nominal capacity

of

180 ml is caused by normally unrecoverable oil being trapped in components such as the condenser, receiver/ drier

or evaporator.

The previous statements apply even

if a problem has occurred due to oil leakage. The amount of oil lost due to leakage

is generally small, so to avoid over-filling please follow the example.

If however the recovery process has not been necessary because refrigerant has also been lost, then ONLY replace the

quantity drained from the original compressor.

14.9.5

Should a major component such as condenser, receiver / drier or evaporator be renewed then an adjustment to the

system oil level must be made. This may be carried out in the same way as the examples for the compressor except

for the fact that trapped oil within any one of these components cannot normally be drained. Therefore, a nominal

amount of oil should be substituted

in addition to that recovered from the recovery station separator.

Adding Lubricating Oil - Component Related

Condenser Add 40 ml

Evaporator Add 40 ml

Receiver / drier NO adjustment

CAUTION: Always decant fresh oil from a sealed container and do not leave oil exposed to the atmosphere. PAG

oil is very hygroscopic (absoh water) and will rapidly attract atmospheric moisture.

PAG oil must NEVER be mixed with mineral based oils.

Do not re-use oil following a recovery cycle, dispose of it safely.

14.9.6 Adding Refrigerant

In order that the air conditioning system may operate efficiently it must contain a full refrigerant charge. The indica- tions of some system defects, and the results of certain tests, will show that a low charge is the most probable cause

of the fault. In such cases the charge should be recovered from the system, the weight noted, and the correct amount

installed.

Should refrigerant be added in liquid form, initial engine start

-up revolutions must NOT exceed 2000 RPM for a period

of (2) two minutes. If the engine speed is excessive, compressor damage may occur due to the lubricating oil and the

liquid refrigerant being initiallyforced around the system as a 'slug', thus taking oil awayfrom the compressor. These

marginal lubrication conditions in the compressor will cease as the refrigerant becomes gaseous.

Never attempt to 'guess' the amount of refrigerant in a system, always recover and recharge with the correct charge

weight; this is the only accurate method.

CAUTION: If oil was drawn out during the recovery process, the corM amount may be added directly from your

recovery / recycle /recharge station (if so equipped) prior to the 'charging process'. It must be stressed that the need to protect compressor oil from moisture is vital, observe the procedures

in HANDLING LUBRICATING OIL and those concerning excessive engine revolutions.

Issue 1 August 1994 14 X300 VSM