belt JAGUAR XJ6 1994 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 384 of 521

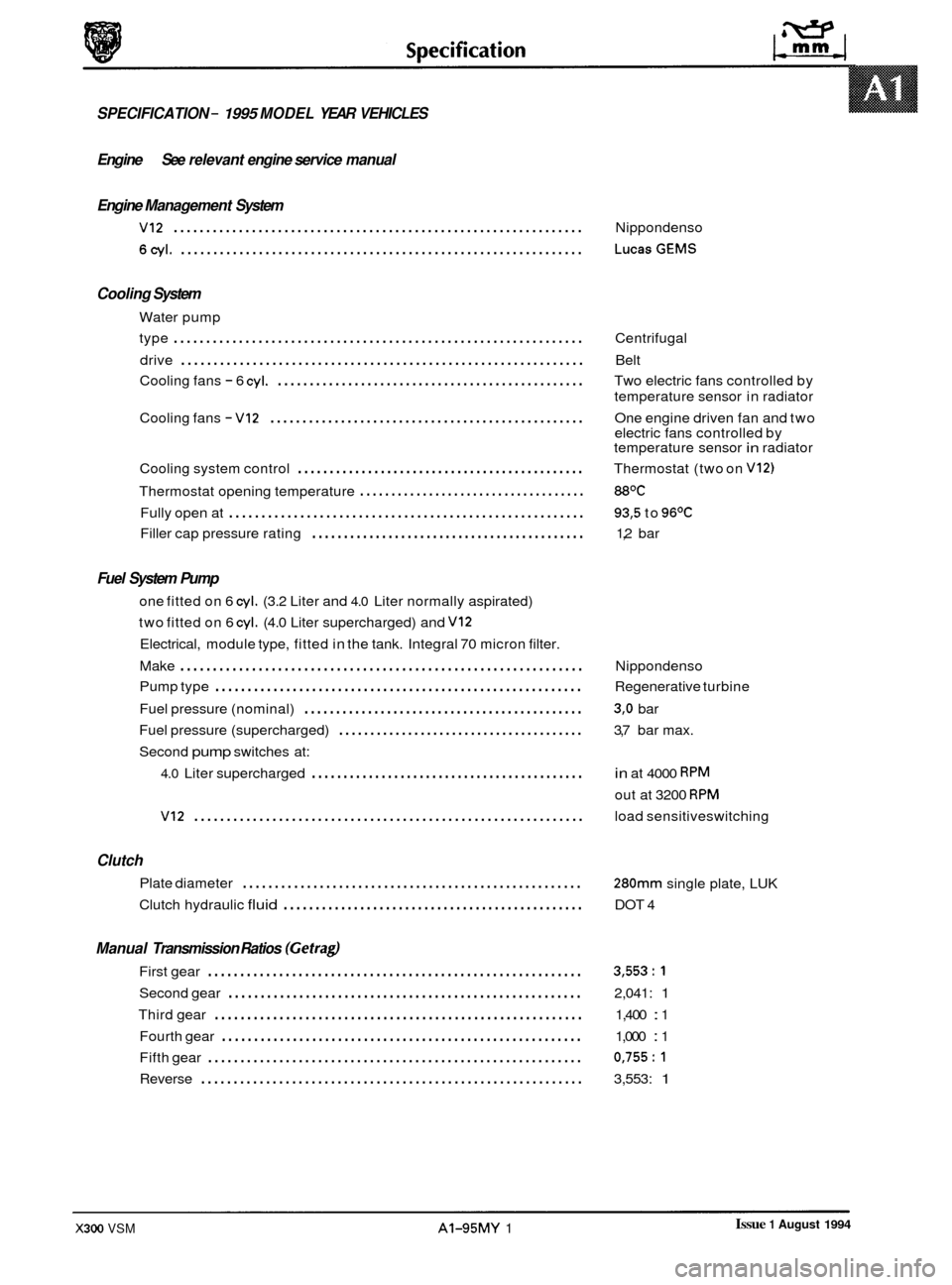

SPECIFICATION - 1995 MODEL YEAR VEHICLES

Engine See relevant engine service manual

Engine Management System

VI2 ............................................................... Nippondenso

6cyl. .............................................................. LucasGEMS

Cooling System

Water pump

type

............................................................... Centrifugal

Cooling fans

- 6 cyl. ................................................ Two electric fans controlled by

Cooling fans

- VI2 ................................................. One engine driven fan and two

Cooling system control

............................................. Thermostat (two on V12)

Thermostat opening temperature .................................... 88OC

Fully open at ....................................................... 93,5 to 96OC

Filler cap pressure rating ........................................... 1,2 bar

drive

.............................................................. Belt

temperature sensor in radiator

electric fans controlled by

temperature sensor

in radiator

Fuel System Pump

one fitted on 6 cyl. (3.2 Liter and 4.0 Liter normally aspirated)

two fitted on 6

cyl. (4.0 Liter supercharged) and VI2

Electrical, module type, fitted in the tank. Integral 70 micron filter.

Make

.............................................................. Nippondenso

Fuel pressure (nominal)

............................................ 3,O bar

Second

pump switches at:

Pump

type

......................................................... Regenerative turbine

Fuel pressure (supercharged)

....................................... 3,7 bar max.

4.0 Liter supercharged ........................................... in at 4000 RPM

out at 3200 RPM

VI2 ............................................................ load sensitiveswitching

Clutch

Plate diameter .....................................................

Clutch hydraulic fluid ............................................... DOT 4

280mm single plate, LUK

Manual Transmission Ratios (Gefragl

First gear .......................................................... 3,553:l

Second gear ....................................................... 2,041: 1

Third gear ......................................................... 1,400 : 1

Fourth gear

........................................................ 1,000 : 1

Fifth gear

.......................................................... 0,755:l

Reverse ........................................................... 3,553: 1

Issue 1 August 1994 X300 VSM AI-95MY 1

Page 395 of 521

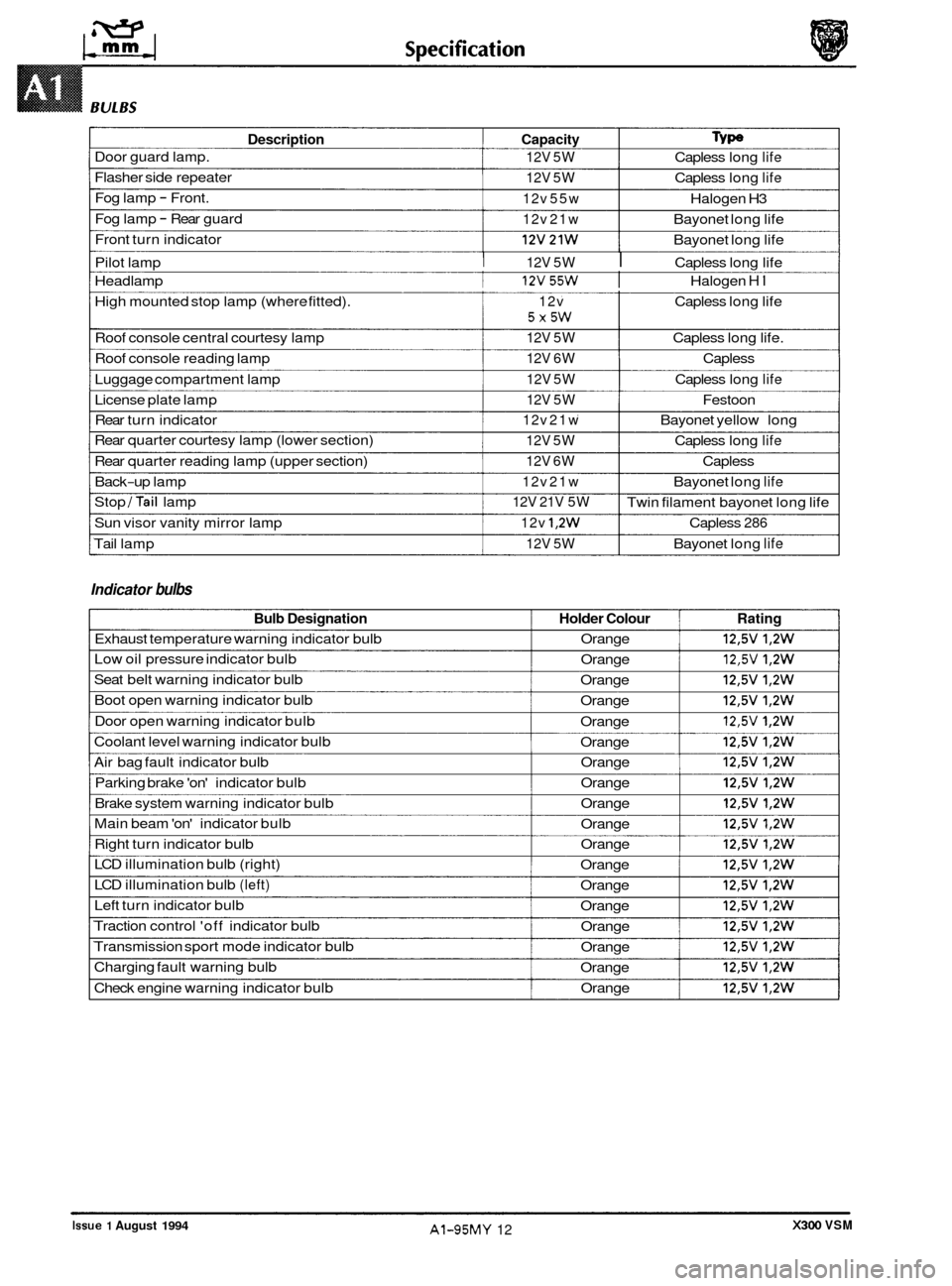

Description Capacity Type

Door guard lamp. 12V 5W Capless long life

Flasher side repeater 12V 5W Capless long life

Fog lamp - Front. 12v 55w Halogen H3

Fog lamp

- Rear guard 12v 21w Bayonet long life

Front turn indicator

I 12v21w I Bayonet long life

Pilot lamp

I 12V 5W I Capless long life

Headlamp

I 12v55w I Halogen HI

High mounted stop lamp (where fitted). 12v Capless long life

Roof console central courtesy lamp

12V 5W Capless long life.

Roof console reading lamp

12V 6W Capless

Luggage compartment lamp

12V 5W Capless long life

License plate lamp 12V 5W Festoon

Rear turn indicator

12v 21w Bayonet yellow long

Rear quarter courtesy lamp (lower section)

12V 5W Capless long life

Rear quarter reading lamp (upper section) 12V 6W Capless

Back

-up lamp 12v 21w Bayonet long life

Stop /Tail lamp

Sun visor vanity mirror lamp

12v 1,2w Capless 286

Tail lamp 12V 5W Bayonet long life

5X5W

12V 21V 5W Twin filament bayonet long life

Indicator bulbs

Bulb Designation Holder Colour Rating

Exhaust temperature warning indicator bulb Orange 12,5V 1,2W

Low oil pressure indicator bulb

Orange 12,5V 1,2W

Seat belt warning indicator bulb

Orange 12,5V 1,2W

Boot open warning indicator bulb

Orange 12,5V 1,2W

Door open warning indicator bulb

Orange 12,5V 1,2W

Coolant level warning indicator bulb

Orange 12,5V 1,2W

Air bag fault indicator bulb Orange 12,5V 1,2W

Parking brake 'on' indicator bulb Orange 12,5V 1,2W

Brake system warning indicator bulb Orange 12,5V 1,2W

Main beam 'on' indicator bulb

Orange 12,5V 1,2W

Right turn indicator bulb Orange 12,5V 1,2W

LCD illumination bulb (right)

Orange 12,5V 1,2W

LCD illumination bulb (left) Orange 12,5V 1,2W

Left turn indicator bulb

Orange 12,5V 1,2W

Traction control 'off indicator bulb

Orange 12,5V 1,2W

Transmission sport mode indicator bulb

Orange 12,5V 1,2W

Charging fault warning bulb

Orange 12,5V 1,2W

Check engine warning indicator bulb Orange 12,5V 1,2W

0

0

0

X300 VSM Issue 1 August 1994 AI-95MY 12

Page 431 of 521

Body Systems & Body Repair

A4.1.5 GENERAL REPAIR NOTES

The following advice should be noted before ANY repair work is carried out.

0 Disconnect the vehicle battery ground lead (disconnect the alternator where electric welding is used) and take

note of the reconnection procedures as detailed in Section 15.

0 Where structural parts are straightened or renewed, a body alignment / straightening jig must be used.

0 Where appropriate, structural sections should be straightened by cold processes. Heat, especially excessive

heat, will reduce the strength of steels.

0 Repairs may only be carried out successfully, and any warranties protected, if genuine Jaguar replacement parts

and Jaguar approved materials are used.

0 Tools, procedures and facilities must be right for the job. Do not compromise the quality of the work by using

inappropriate methods.

0 All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel

removal / replacement; this is especially important where hollow sections may contain harnesses, tubes or

foam, see section

A4.3.5.

0 The welding and gas processes detailed in the following sections are the only ones recommended by Jaguar

Cars Ltd.

0 Ensure that you have read and understood the safety related procedures in this and other relevant sections.

WARNING: DO NOT WORK

IN THE VICINITY OF A LIVE AIR BAG, REMOVE IT COMPLETELY. READ WORKING PRAC- TICES AIR BAG, SECTION 15. ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT MUST BE RENEWED. PLEASE SEE SECTION

AGE LOCATIONS. 13 FOR IMPORTANT INFORMATION REGARDING 'TEAR LOOP' SEAT BELTS / BUCKLES AND ANCHOR-

CAUTION: Electric arc welding should not be used on Jaguar vehicles. The high vottages produced by this process will cause irreparable damage to the electrical control and microprocessor systems.

A4.1.5.1 Welding and Gas Processes Special Notes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated,

metal.

The flanges of panels which are to be welded together must be clean, corrosion free and treated as appropriate,

with either weld-through primer or inter-weld sealer; use only materials and processes in accordance with the 'Body Seal-

ing and Preservation Manual' and relevant application areas in section A4.3.1.1.

See 'Zinc Coated Panels' section A4.2.

Generally, the resistance spot welding equipment used in the motor vehicle repair industry does not produce a weld

of equivalent strength to that of the manufacturer. Therefore, the expression 'single row of resistance spot welds'

means that the spots should be spaced on a pitch of

19mm to 25mm. This will usually result in more spot welds than

found in the original factory joint.

To remove resistance spot welds, a resistance spot weld cutter should be used.

If the new joint is to be MIG plug welded, the old resistance spot welds should be cut from the panel which is to be

retained and those holes used for plug welding.

Suitable holes may also be drilled or punched;

8,O mm dia for sections up to 1,6 mm, and 10,O mm dia for thicker sec- tions.

0

0

0

X300 VSM Issue 1 August 1994 4