belt JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 201 of 521

@ Steering

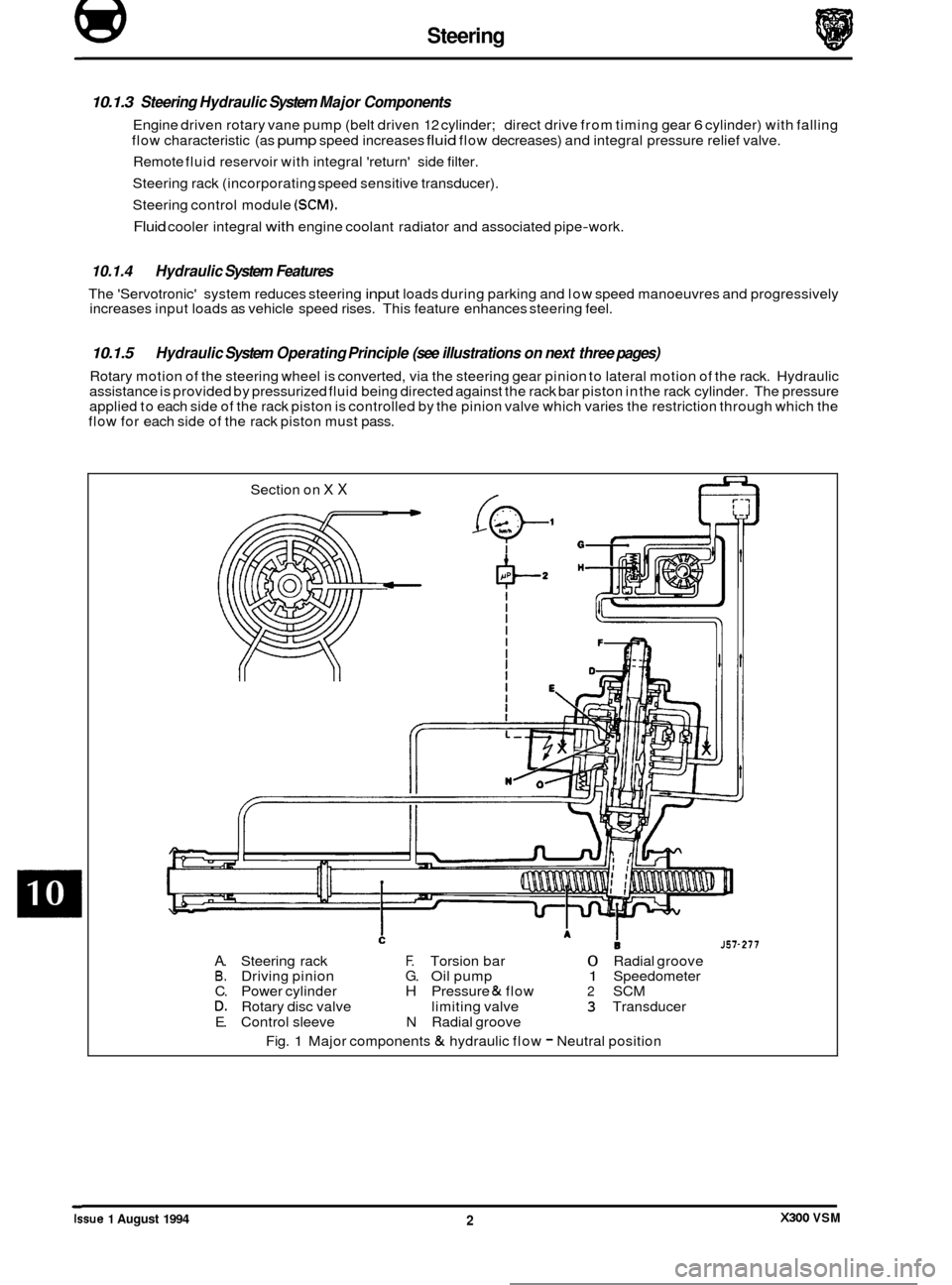

10.1.3 Steering Hydraulic System Major Components

Engine driven rotary vane pump (belt driven 12 cylinder; direct drive from timing gear 6 cylinder) with falling

flow characteristic (as

pump speed increases fluid flow decreases) and integral pressure relief valve.

Remote fluid reservoir with integral 'return' side filter.

Steering rack (incorporating speed sensitive transducer).

Steering control module

(SCM).

Fluid cooler integral with engine coolant radiator and associated pipe-work.

10.1.4 Hydraulic System Features

The 'Servotronic' system reduces steering input loads during parking and low speed manoeuvres and progressively

increases input loads as vehicle speed rises. This feature enhances steering feel.

10.1.5

Rotary motion of the steering wheel is converted, via the steering gear pinion to lateral motion of the rack. Hydraulic

assistance is provided by pressurized fluid being directed against the rack bar piston in the rack cylinder. The pressure

applied to each side of the rack piston is controlled by the pinion valve which varies the restriction through which the

flow for each side of the rack piston must pass.

Hydraulic System Operating Principle (see illustrations on next three pages)

Section on X X

J57-277

A. Steering rack F. Torsion bar 0 Radial groove B. Driving pinion G. Oil pump 1 Speedometer

C. Power cylinder H Pressure & flow 2 SCM D. Rotary disc valve limiting valve 3 Transducer

E. Control sleeve N Radial groove

Fig.

1 Major components & hydraulic flow - Neutral position ~

Issue 1 August 1994 X300 VSM 2

Page 205 of 521

@ Steering

Cause

Fluid level low?

Drive belt slack

(V12)

Pump drive loose (6cyl)

center pressures low

Air in system due to loose connection

Pump shaft seal faulty (fluid loss)

Delivery pressure or flow too low

Return flow restricted by blocked reser

-

voir filter

Both check valves blocked

Rack damper too

tight

Lower column incorrectly set

Excessive upper column friction

Faulty rotary valve or seal

Drive belt slack

(VI217

Engine idle speed too low

Pump drive loose

(6cyl)

Air in system due to loose connection

Pump shaft seal faulty (fluid

loss)

Delivery pressure or flow too low

Fluid level low?

tire pressures

high

Air in system due to loose connection

Stiff or seized steering joint

Rack damper too tight

Castor or tracking error

Lower column over extended

Fluid level low?

Air

in system due to loose connection

Pump shaft seal faulty (fluid

loss)

Rack damper loose

Pinion bearing faulty

Rack or column fixings loose

Rack mounting bracket loose

Rack mounting bush loose

Free play in column assembly

10.4 DIAGNOSTIC PROCEDURE

10.4.1 Introduction

The following diagnostic procedures are provided to rapidly pin-point mechanical faults which are not interrogated

by electrical means. Diagnostic procedures which require dedicated electrically operated equipment are dealt with in the 'Electrical Diagnostic Manual' (EDM) but may be mentioned here for reference.

10.4.2 Preliminary Action

Before any problem solving is undertaken it is essential that the fluid level and where applicable, belt tension, is

checked and if required corrected.

CAUTION: It is imperative that the power steering system does not become contaminated in any way. Always de cant fluid from a fresh sealed container and clean the area around the reservoir neck both before and after

topping-up. Never return drained fluid to the system.

10.4.2 Diagnostic Chart 1

Remedy

Rectify fluid loss and or top up

Re

-tension belt

Renew pump

Set to specification

Secure connection and bleed air out

Renew pump

Renew pump

Renew reservoir

Renew rack

Renew rack

Set to specification

Renew upper column

Renew rack

Retension belt

Reset idle speed

Renew

pump

Secure connection and bleed air out

Renew

pump

Renew pump

Rectify

fluid loss and or top up

Set to specification

Secure connection and bleed air out

Test and renew faulty joint

Renew rack

Check geometry and rectify

if required

Set to specification

Rectify fluid

loss and or top up

Secure connection and bleed air out

Renew pump

Renew rack

Renew rack

Tighten to specification

Renew rack

Renew rack

Check and rectify as required

Trouble

Heavy on both sides

Heavy on one side

Heavy when steering

rapidly

Vague feel about center

Knocking

1 vibration felt

at steering wheel

0

0

0

0

Issue 1 August 1994 6 X300 VSM

Page 207 of 521

@ Steering

10.4.4 Diagnostic chart 3

Trouble

Hydraulic noise when

turning lock to lock

Continuous pressure

relief valve operation

Continuous noise

Cause

Fluid level low?

Air ingress at connections

Air ingress through feed hose lining

or

skin

Air ingress at pump front seal

Water contamination caused by fractured

cooler pipe within engine coolant radi

-

ator

Pump starvation or cavitation caused by

twisted or trapped feed hose

Pump starvation caused by blocked filter

Worn

pump

High pressure hose (pump to rack) dam-

aged or restricted

Fluid level low?

Drive belt loose

(12 cyl only)

Drive pulley loose

Steering pump mounting

(4 loose

Drive 'dog' loose, slipping or incorrectly

fitted

(6 cyl only)-

Hose or pipe fretting on body or chassis

structure

Hose twisted or restricted

Remedy

Rectify fluid loss and or top up

Check and tighten all connections to spec

-

ification

Renew faulty

'0' rings or Dowty washers

Renew porous

1 damaged hoses

Renew

pump

Renew radiator. Flush and drain steering

system twice

minimum, check for noise

and system performance (Pump is most

susceptible to damage due to

loss of lu-

brication and may have to be renewed)

Reroute or relieve pressure

Renew reservoir

Renew pump

Renew hose

Rectify

fluid loss and or top up

Inspect for damage and renew as required

Tighten pulley to specification

Tighten to specification

Investigate

& rectify as required

Rectify routing

Rectify routing

Issue 1 August 1994 8 X300 VSM

Page 245 of 521

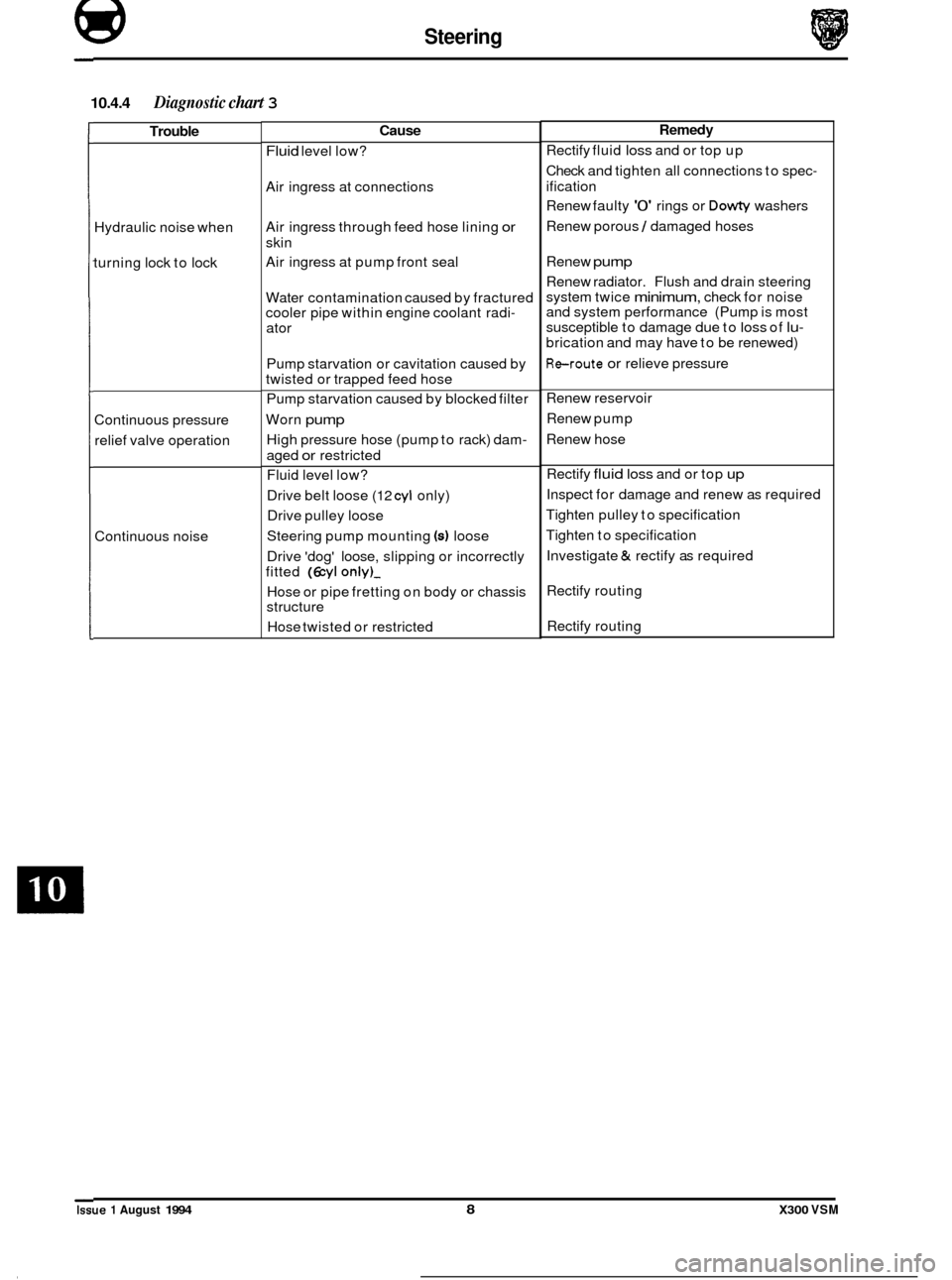

12.6 REAR WHEEL SPEED SENSOR - RENEW

SRO

70.60.04

. Drive the vehicle onto a ramp or raise the back and support

on two stands.

. Cut and remove the ratchet strap securing the speed sen- sor harness to the brake hose.

. Undo and remove the speed sensor to hub carrier secur- ing bolt (Fig. 1).

Remove the speed sensor from the hub carrier and allow

it to hang free, forward of the 'A' frame.

Open both rear doors and displace the rear seat cushion

from the seat pan brackets. Reposition the rear seat

cushion forwards.

9 Push the seat belts/ buckles through the seat cushion slots

and remove the rear seat cushion from the vehicle.

. Displace the RH side of the seat pan sound proofing (1 Fig. 2) to gain access to the speed sensor harness (2 Fig. 2).

9 Displace the speed sensor harness grommet (3 Fig. 2) from the seat pan aperture.

. Feed the speed sensor harness through the seat pan aper- ture and disconnect the multi-plug (4 Fig. 2).

9 Position the new speed sensor harness and connect the

multi-plug.

. Feed the speed sensor harness through the seat pan aper- ture to hang free below the vehicle.

. Refit and fully seat the speed sensor harness grommet to

the seat pan aperture.

Reposition theseat pan sound proofing to its original posi- tion.

Position the rear seat cushion and feed the seat belt / buckles through the slots.

Locate the rear seat cushion into the seat pan brackets (5 Fig. 2).

. Stow the seat belts / buckles.

. Position the speed sensor harness rearwards over the 'A'

Fit and tighten the speed sensor to hub carrier securing

Secure the speed sensor harness to the brake hose using

frame

and locate into the hub carrier.

bolt.

a ratchet strap. Trim the ratchet strap. Fig.

1

Fig. 2

Issue 1 August 1994 22 X300 VSM

0

0

0

Page 252 of 521

Body Components & Trim .

SECTION CONTENTS

Sub-Section Title SRO Page

13.5.6 ............ Hood lock Control Cable RH or LH, Renew ............................................. 43

13.5.7.

........... Hood Striker Assembly, Renew ........................................................ 43

Hood lock Release Handle. Renew

.................................................... 43

13.5.8 ............

13.6 ............. Glazing (Fixed) ..................................................................... 44

13.6.1

............ Glazing (Fixed). Description .......................................................... 44

13.6.2.

........... Interior Mirror, Renew ............................................................... 44

13.6.3.

........... Sun Visor Mirror Assembly, Renew ..................................................... 44

13.6.4.

........... Exterior Mirror, Renew ............................................................... 44

13.6.5

............ Exterior Mirror Glass, Renew .......................................................... 44

13.7

............. Carpets ........................................................................\

.... 45

13.7.1

............ Carpets, Description ................................................................. 45

13.7.2.

........... Removal of Stains - General Information ................................................ 45

13.7.3.

........... Powder Cleaning - Removal of Small Spillage Stains ...................................... 45

13.7.4

............ Spot Cleaning- LocalizedStains ...................................................... 46

13.7.6

............ RepairofDamagedCarpet ........................................................... 47

e

13.7.5. ........... Carpet Cleaning and Stain Removal Materials ........................................... 47

13.8

............. Seating and Seat Belts ................................................................ 48

13.8.1

............ Seating, Description ................................................................. 48

Front Manual Seat, Renew

............................................................ 48

13.8.3.

........... Front Seat (Power Operated), Renew ................................................... 48

13.8.2

............

13.8.4 ............ Front

Seat Head Restraint (Power Operated), Renew ...................................... 49

13.8.5.

........... Front Seat Head Restraint (Power Operated), Renew ...................................... 49

13.8.6

............ RearSeat Cushion. Renew ............................................................ 49

13.8.7 ............ RearSeatSquab. Renew ............................................................. 49

73.8.8 ............ Seat Belts, Description ............................................................... 50

13.8.9 ............ Emergency Locking Retractor/ Automatic Locking Retractor Seat Belts ...................... 50

13.8.10

.......... Tear loop Seat Belts, Description ...................................................... 51

13.8.1 I ........... Front Seat Belt Buckle Unit, Renew .................................................... 52

13.8.12

.......... Front Seat Belt, Renew ............................................................... 52

13.8.13

.......... Rear Inertia Seat Belt, Renew ......................................................... 52

13.8.14

.......... Rear, Center, Static Seat Belt, Renew ................................................... 53

iii Issue 1 August 1994

Page 254 of 521

Body Components & Trim -

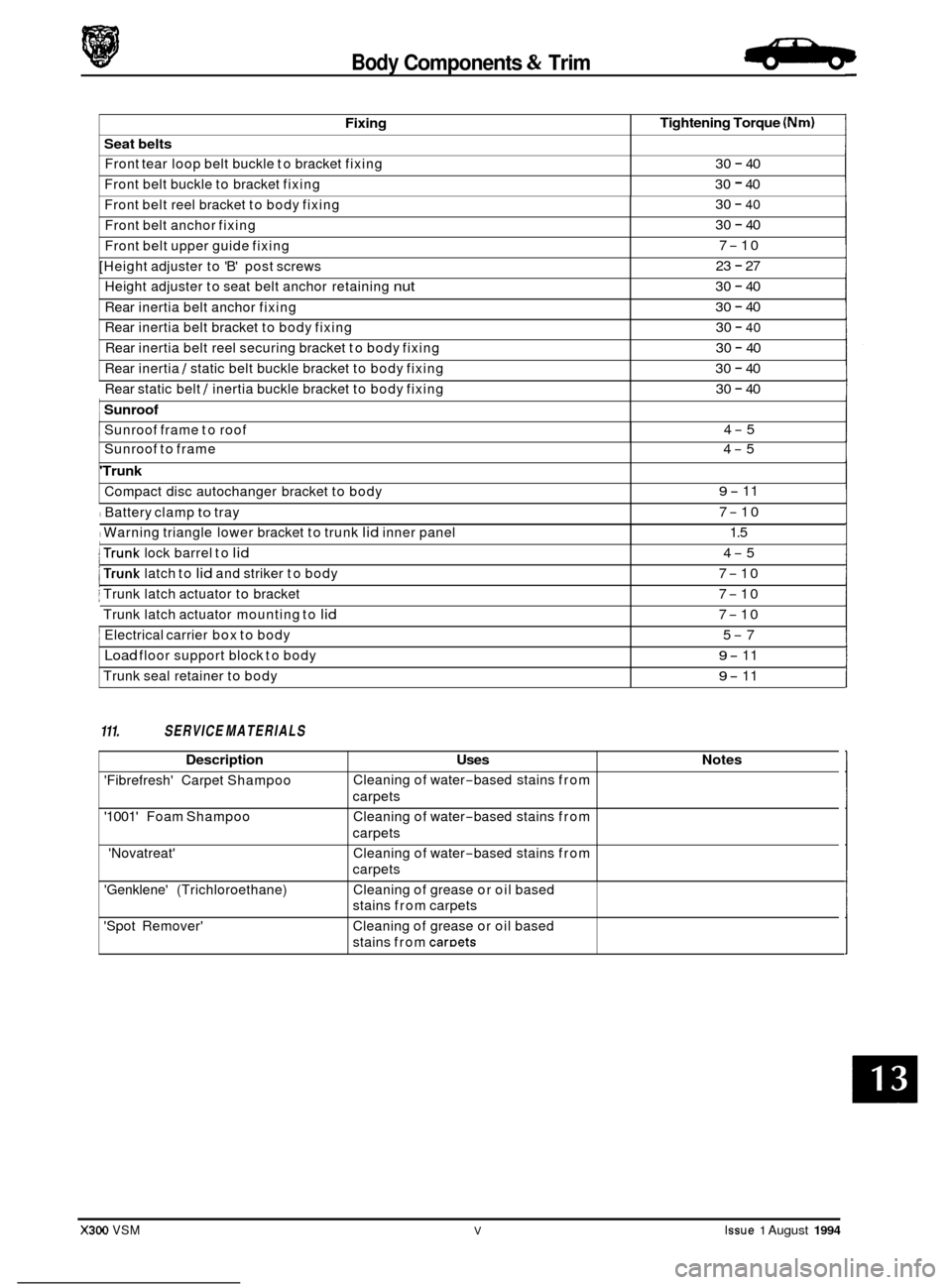

Fixing

Seat belts

Front tear loop belt buckle to bracket fixing

Front belt buckle to bracket fixing

Tightening Torque (Nm)

30 - 40

30

- 40

Front belt reel bracket to body fixing

Front belt anchor fixing 30 - 40

30 - 40

7

-10

23

- 27

30

- 40

30 - 40

30

- 40

30 - 40

30

- 40

Front belt upper guide fixing

[Height adjuster to 'B' post screws

Height adjuster to seat belt anchor retaining

nut

Rear inertia belt anchor fixing

Rear inertia belt bracket to body fixing

Rear inertia belt reel securing bracket to body fixing

Rear inertia

/ static belt buckle bracket to body fixing ~

Rear

static belt / inertia buckle bracket to body fixing

: Sunroof ~

Sunroof frame

to roof

30 - 40

4

-5

111. SERVICE MATERIALS

Sunroof to frame 4-5

'Trunk

Compact disc autochanger bracket to body

I Battery clamp to tray

I Warning triangle lower bracket to trunk lid inner panel

9- 11

7

-10

1.5

X300 VSM V Issue 1 August 1994

I trunk lock barrel to lid

j Trunk latch actuator to bracket

Trunk latch actuator mounting to

lid

j Electrical carrier box to body

Load floor support block to body

Trunk seal retainer to body

trunk latch to lid and striker to body

4-5

7

-10

7

-10

7

-10

5

-7

9- 11

9- 11

Description Uses

'Fibrefresh' Carpet Shampoo

'1001' Foam Shampoo

'Novatreat' Cleaning

of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Notes

'Genklene' (Trichloroethane)

'Spot Remover' Cleaning

of grease or oil based

stains from carpets

Cleaning of grease or oil based

stains from

caroets

Page 256 of 521

Body Components & Trim

13.1 GENERAL DESCRIPTION

This section covers the following areas of the vehicle body:

0 Battery cover

0 Carpets - passenger compartment, trunk

0 Console - including radio, glovebox

0 Doors -frames, sealing, locks, trim, glazing

0 Fascia

0 Fuel filler flap assembly

0 Footrest

0 Hood - liners, gas strut, locking,

0 Illuminated sunvisor - inc mirror

0 Interior trim - trim pads, finishers, veneers

0 Mirrors - internal, external

0 Rear parcel tray

0 Roof console

0 Roof lining (headlining)

o Seats -front, rear -

0 Seat belts - front, rear

0 Sliding roof

0 Steering column cowl

0 Underscuttle pad

Refer to Appendix

A4 - Body Systems & Body Repair for information relating to crash-damage repairs and to the fol- lowing external components: exterior trim, bumpers, windscreen and rear screen, closures and sealing.

Refer to Section 15, Electrical for details of the following motors and solenoids: driver's and interior mirrors, window

lift, sunroof, seat / headrest and locking mechanisms (doors, trunk and filler cap).

Refer to Section 15, Electrical and Electrical Diagnostic Manual (EDM) for details of the passenger and driver airbags.

X300 VSM 1 Issue 1 August 1994

Page 290 of 521

Body Components & Trim -

13.3.32 'A' Post lower Trim Pad, Renew

SRO 76.13.30

. Locally displace the draught welting from the front door

= Undo and remove the 'A' post lower trim pad quarter turn

. Displace and remove the 'A' post lower trim pad by pulling

. Fit and seat the new 'A' post lower trim pad, engaging the

. Fit and secure the 'A' post lower trim pad quarter turn fas-

Reposition and fully seat the draught welting to the front

aperture

flange.

fastener. rearwards to disengage clips and place aside.

clips on the front door flange.

tener. door aperture flange.

13.3.33 Rear Quarter Upper Trim Pad, Renew

. Remove the rear seat belt upper anchorage RH or LH.

. Remove the trim pad securing screw.

. Slacken but do not remove thecombined grab handle and

. Unclip the rear quarter trim pad and remove.

. To refit, carry out reversal of the above procedure, noting

that seat belt fixings must be tightened to the specified

torque.

coat hook securing screws.

13.3.34 'B' Post Upper Trim Pad, Renew

. Position front seat and squab fully forward.

. Remove seat belt lower anchorage and feed the belt

through the lower trim aperture.

. Remove seat belt upper anchorage.

. Remove trim finisher upper seat belt aperture and door

. Release upper trim pad from its fixings by exerting down-

. To refit, carry out reversal of the above procedure.

aperture edge

trim.

ward pressure.

WARNING: ENSURE THAT THE SEAT BELT IS CORRECTLY

ASSEMBLED AND FlXlNGS TORQUE TIGH-

0 TENED.

13.3.35 'B' Post lower Trim Pad, Renew

. Position front seat and squab fully forward.

Remove seat belt lower anchorage and feed the belt

. Release trim pad quarter turn fasteners and remove trim

Remove fasteners from trim pad as required.

= To refit, carry out reversal of the above procedure.

through the lower

trim aperture.

pad.

WARNING: ENSURE THAT THE SEAT BELT IS CORRECTLY

ASSEMBLED AND FlXlNGS TORQUE TIGH- TENED.

X300 VSM 35 Issue 1 August 1994

Page 303 of 521

Body Components & Trim a

13.8 SEATING AND SEAT BELTS

13.8.1 Seating, Description

The front seats are available in a range of materials consisting of sculptured fabric / leather, leather, sports cloth / leather, embossed leather / leather and autolux. Both seats are available as 'manual', ie manually adjustable with elec- tric rise and fall, manual height adjustment headrests, 'power', ie 12-way electric adjustment, 'power with memory', ie memory controlled, 12-way electric adjustment of seat, steering column and exterior rear view mirrors and 'heated',

ie with integral heating.

Front seats are based on a non

-handed, one-piece frame which includes cushion and squab frames and seat adjuster

mechanisms. The seat switchpacks (powerseats) are fitted to the outboard side of driver and passenger seats; on 'man- ual'seats, the seat height adjustment switch is similarly located. Seat control modules SCMs are contained within the

seat assemblies. The seats are secured through four mounting points to the vehicle floor.

Rear seats are of the bench type with

full width removable cushion and individual seat squabs.

Electrical components installed on the heel board below the rear passenger seat are protected

by two covers secured

by two locating brackets on the floor and by two latches on the cover. The latches are released by pushing down on

the two recesses in the top edge of the cover.

13.8.2 Front Manual Seat, Renew

. Disconnect vehicle battery ground lead.

. Disconnect electrical connections as required.

. Remove the seat forward fixings.

Move the seat fully forward.

. Remove the rear fixing / slide covers.

. Remove the seat rear fixings.

. Reposition seat for access and remove seat from vehicle.

. To refit seat, carry out reversal of above procedure.

13.8.3

. Disconnect vehicle battery ground lead.

. Move the seat fully forward to gain access to squab back

Remove squab side fixings, disconnect lamp harness and

. To refit, carry out reversal of the above procedure.

Front Seat (Power Operated) Squab Back

Cover, Renew

cover outer fixings.

remove squab back cover.

13.8.4

. Position seat as required for access.

. Disconnect vehicle battery ground lead.

. Release sound insulation retainers and displace insula-

. Remove SCM cover, move SCM aside and remove seat

. Remove the seat forward fixings and move the seat fully

. Remove the seat rearward fixing covers and remove the

. Disconnect multi-plugs, seat switch and motor harness to

. Release harness tie strap and remove seat assembly from

Front Seat (Power Operated), Renew

tion.

switch

multi-plug from its mounting bracket.

forward. seat rearward fixings.

SCM.

vehicle.

. To refit, carry out reversal of the above procedure, ensur- ing that fixings are tightened to the correct torque.

Issue 1 August 1994 48 X300 VSM

0

0

0

Page 304 of 521

Body Components & Trim

13.8.5

Renew

Front Seaf Head Restraint (Power Operated),

. Recline the seat to give access to the head restraint from

. Disengage the head restraint from its retainers with a

= To refit, carry out reversal of the above procedure, ensur-

the rear.

sharp upward

pull.

ing that the restraint is fully locked in position.

13.8.6 Rear Seaf Cushion, Renew

. Release the seat cushion quick release fittings.

. Remove the seat cushion from the vehicle.

To refit, carry out reversal of the above procedure.

13.8.7 Rear Seat Squab, Renew

. Release the rear seat cushion quick release fittings and re-

. Release the rear squab fixings and remove the squab.

. Move the rear seat belts aside and remove the squab as-

. Remove the armrest from the squab assembly.

. Remove the seat belt stowage pocket.

To refit, carry out reversal of the above procedure.

move

the cushion.

sembly from the vehicle.

Issue 1 August 1994 X300 VSM 49