ad blue JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 22 of 521

(if applicable) term(s) (or Eng-

lish Equivalent)

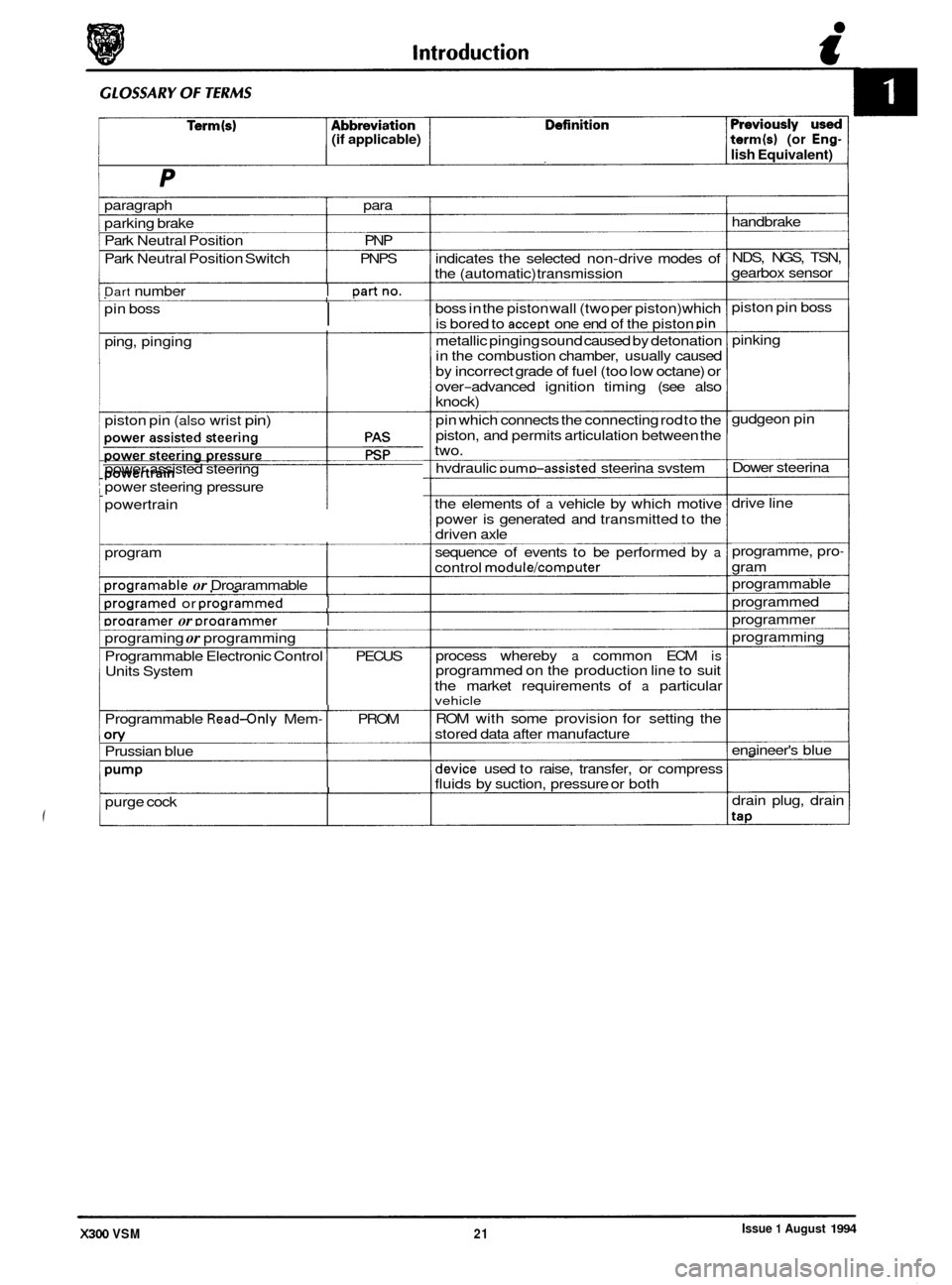

paragraph para

parking brake

Park Neutral Position PNP

Park Neutral Position Switch PNPS

Dart number I Dartno.

I pin boss

ping, pinging

piston pin

(also wrist pin)

power assisted steering

power steering pressure

. powertrain

program

Droaramable or Droarammable I

Droaramed or Droarammed I

Droaramer or Droarammer I

programing or programming

Programmable Electronic Control

I PECUS

Units System

I Programmable Read-only Mem- I PROM

on/ Prussian blue

Pump

purge cock I

indicates the selected non-drive modes of

the (automatic) transmission

boss in the piston wall (two per piston) which

is bored to

accept one end of the piston pin

metallic pinging sound caused by detonation

in the combustion chamber, usually caused

by incorrect grade of fuel (too low octane) or

over

-advanced ignition timing (see also knock)

pin which connects the connecting rod to the

piston, and permits articulation between the

two.

hvdraulic

DumD-assisted steerina svstem

the elements of

a vehicle by which motive

power is generated and transmitted to the

driven axle

sequence of events to be performed by

a

control module/comDuter

process whereby a common ECM is programmed on the production line to suit

the market requirements of

a particular vehicle

ROM with some provision for setting the

stored data after manufacture

device used to raise, transfer, or compress

fluids by suction, pressure or both handbrake

NDS, NGS, TSN,

gearbox sensor

piston pin boss

pinking

gudgeon pin

Dower steerina

drive line

programme, pro

-

gram

programmable

programmed

programmer

programming

enaineer's blue

drain plug, drain

tap

Issue 1 August 1994 X300 VSM 21

Page 332 of 521

Climate Control Systems

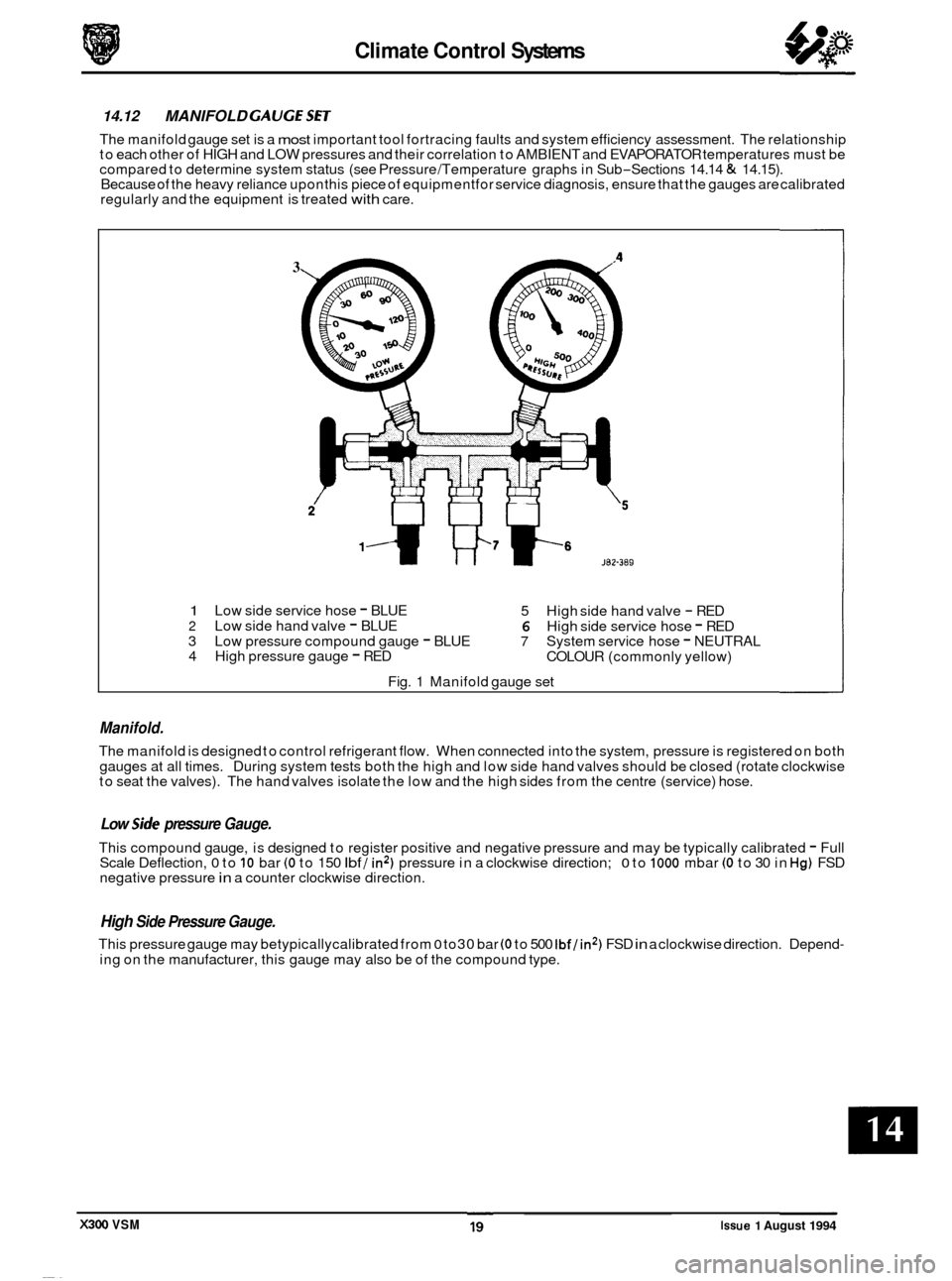

14.12 MANIFOLD GAUGESET

The manifold gauge set is a most important tool fortracing faults and system efficiency assessment. The relationship

to each other of HIGH and LOW pressures and their correlation to AMBIENT and EVAPORATOR temperatures must be

compared to determine system status (see Pressure /Temperature graphs in Sub

-Sections 14.14 & 14.15).

Because of the heavy reliance upon this piece of equipmentfor service diagnosis, ensure that the gauges are calibrated

regularly and the equipment is treated

with care.

3

1 Low side service hose - BLUE

5 High side hand valve - RED 2 Low side hand valve - BLUE 6 High side service hose - RED

3 Low pressure compound gauge - BLUE 7 System service hose - NEUTRAL

4 High pressure gauge - RED

COLOUR (commonly yellow)

Fig. 1 Manifold gauge set

Manifold.

The manifold is designed to control refrigerant flow. When connected into the system, pressure is registered on both

gauges at all times. During system tests both the high and low side hand valves should be closed (rotate clockwise

to seat the valves). The hand valves isolate the low and the high sides from the centre (service) hose.

0 Low side pressure Gauge.

This compound gauge, is designed to register positive and negative pressure and may be typically calibrated - Full

Scale Deflection, 0 to 10 bar (0 to 150 Ibf / in2) pressure in a clockwise direction; 0 to 1000 mbar (0 to 30 in Hg) FSD

negative pressure in a counter clockwise direction.

High Side Pressure Gauge.

This pressure gauge may betypicallycalibrated from 0 to30 bar (0 to 500 Ibf/in2) FSD in a clockwise direction. Depend-

ing on the manufacturer, this gauge may also be of the compound type.

X300 VSM Issue 1 August 1994

Page 350 of 521

31

30

29

28 27

26

4 26 24 21 23 22 7 20 19 18 18 17 8

a

10

11

12

13

14

1s

1M-137

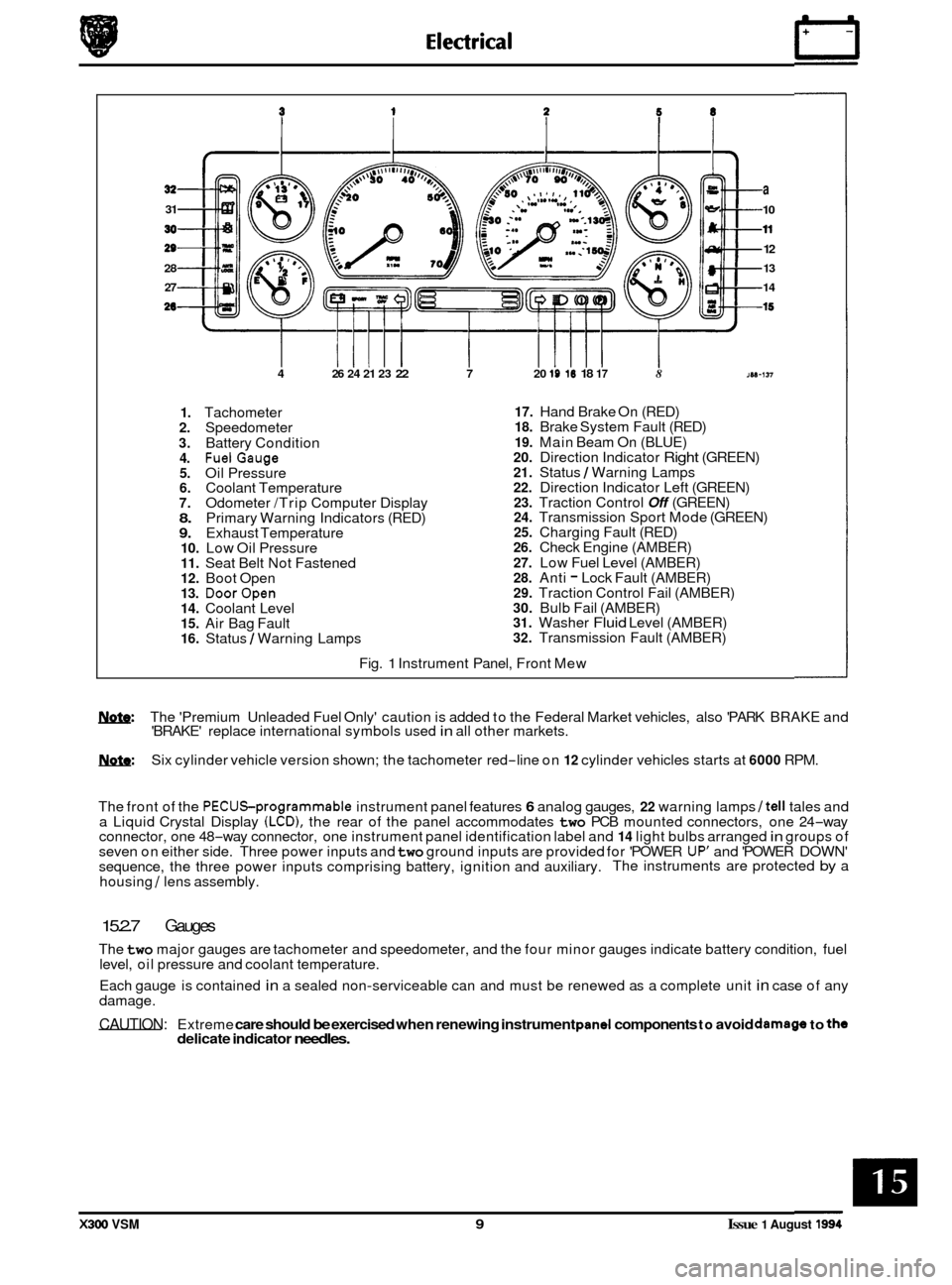

1. Tachometer 2. Speedometer

3. Battery Condition 4. FuelGauge 5. Oil Pressure 6. Coolant Temperature 7. Odometer /Trip Computer Display 8. Primary Warning Indicators (RED) 9. Exhaust Temperature 10. Low Oil Pressure 11. Seat Belt Not Fastened 12. Boot Open 13. DoorOpen 14. Coolant Level 15. Air Bag Fault 16. Status / Warning Lamps

17. Hand Brake On (RED) 18. Brake System Fault (RED)

19. Main Beam On (BLUE) 20. Direction Indicator Right (GREEN) 21. Status / Warning Lamps 22. Direction Indicator Left (GREEN) 23. Traction Control Off (GREEN) 24. Transmission Sport Mode (GREEN) 25. Charging Fault (RED) 26. Check Engine (AMBER)

27. Low Fuel Level (AMBER) 28. Anti - Lock Fault (AMBER) 29. Traction Control Fail (AMBER) 30. Bulb Fail (AMBER) 31. Washer Fluid Level (AMBER) 32. Transmission Fault (AMBER)

Fig.

1 Instrument Panel, Front Mew

w: The 'Premium Unleaded Fuel Only' caution is added to the Federal Market vehicles, also 'PARK BRAKE and

'BRAKE' replace international symbols used in all other markets.

m: Six cylinder vehicle version shown; the tachometer red-line on 12 cylinder vehicles starts at 6000 RPM.

The front of the

PECUSprogrammable instrument panel features 6 analog gauges, 22 warning lamps /tell tales and

a Liquid Crystal Display (LCD), the rear of the panel accommodates two PCB mounted connectors, one 24-way

connector, one 48-way connector, one instrument panel identification label and 14 light bulbs arranged in groups of

seven on either side. Three power inputs and two ground inputs are provided for 'POWER UP' and 'POWER DOWN'

sequence, the three power inputs comprising battery, ignition and auxiliary. The instruments are protected by a

housing

/ lens assembly.

15.2.7 Gauges

The two major gauges are tachometer and speedometer, and the four minor gauges indicate battery condition, fuel

level, oil pressure and coolant temperature.

Each gauge is contained

in a sealed non-serviceable can and must be renewed as a complete unit in case of any

damage.

CAUTION: Extreme care should be exercised when renewing instrument pand components to avoid damago to the delicate indicator needles.

X300 VSM 9 Issue 1 August 1994

Page 376 of 521

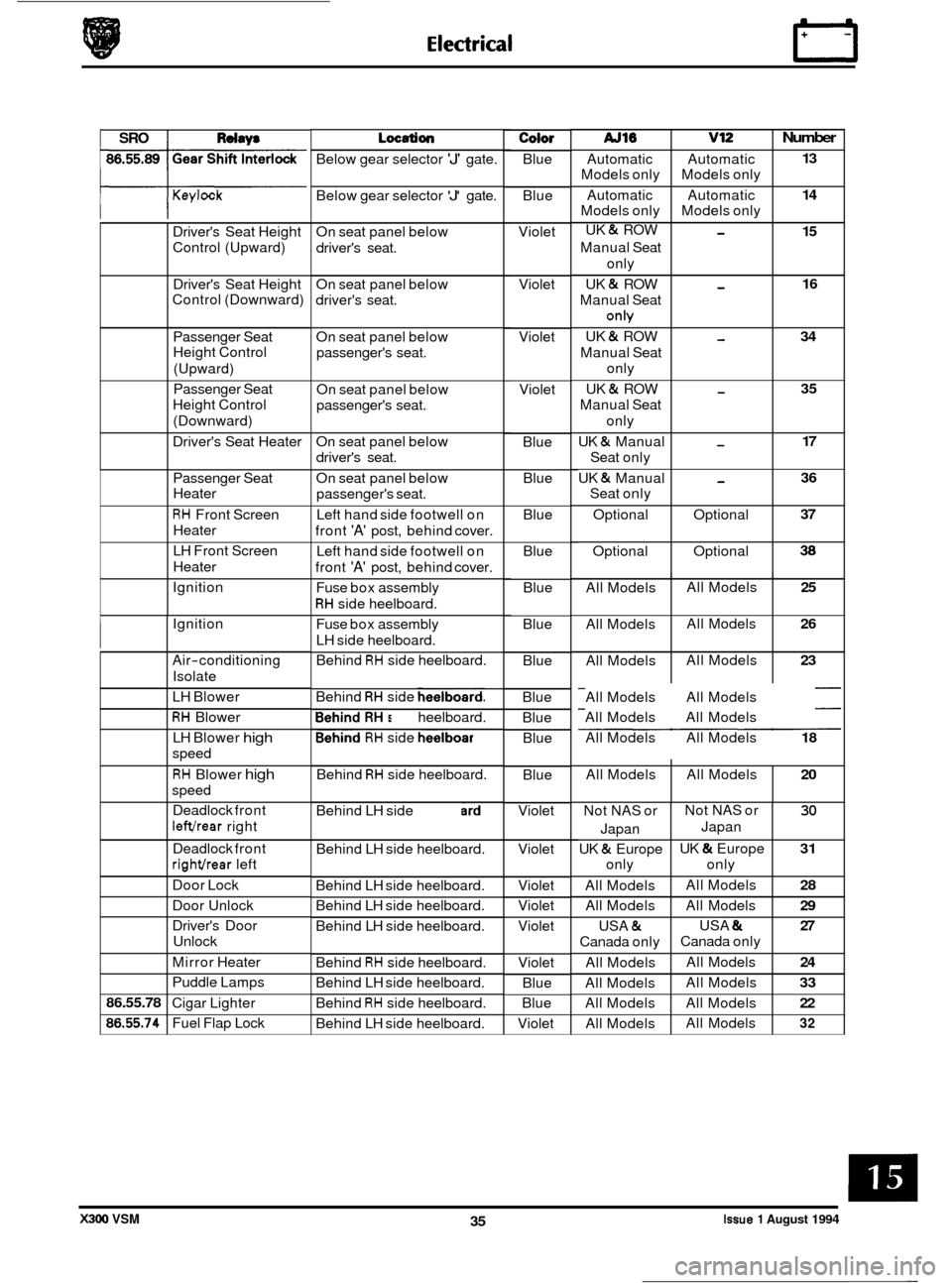

I SRO I Rdw* AJ16 v12

Automatic Automatic

Models only Models only

Automatic Automatic

Models only Models only

UK

& ROW -

Manual Seat

only

UK

& ROW -

Manual Seat

onh/

UK & ROW -

Manual Seat

only

Manual Seat

only

UK

& Manual -

Seat only

UK

& Manual -

Seat only

UK

& ROW -

Optional

Optional

Optional Optional

Keylock

Number

13

14

15

16

34

35

17

36

37

38

Driver's Seat Height

Control (Upward)

Driver's Seat Height

Control (Downward)

Passenger Seat

Height Control (Upward)

Passenger Seat

Height Control

(Downward)

Driver's Seat Heater

All Models

All Models

All Models

Passenger Seat

Heater

RH Front

Screen

Heater

LH Front Screen

Heater

Ignition All Models

25

All Models 26

All Models 23

Ignition

Air

-conditioning

Isolate

LH Blower

RH Blower

LH Blower

high

speed

RH Blower high

speed

Deadlock front

lefthear right All

Models All Models

20

Below gear selector 'J' gate.

Not NAS or

Japan

UK

& Europe

only

All Models

All Models

USA

&

Canada only

All Models

All Models

All Models

All Models

Below

gear selector

'J' gate.

Not NAS or

30

UK & Europe 31

All Models 28

All Models 29

USA & 27

All Models 24

All Models 33

All Models 22

All Models 32

Japan

only

Canada only

On

seat panel below

driver's seat.

86.55.78

86.55.74

On seat panel below

driver's seat.

Deadlock front

righthear left

Door Lock

Door Unlock

Driver's Door

Unlock

Mirror Heater

Puddle Lamps

Cigar Lighter

Fuel Flap Lock On

seat panel below

passenger's seat.

On seat panel below

passenger's seat.

On seat panel below

driver's seat.

On seat panel below

passenger's seat.

Left hand side footwell on

front

'A' post, behind cover.

Left hand side footwell on

front

'A' post, behind cover.

Fuse box assembly

RH side heelboard.

Fuse box assembly

LH side heelboard.

Behind

RH side heelboard.

Behind

RH side heelboard.

Behind RH side heelboard.

Behind

RH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Color

Blue

Blue

Violet

Violet

Violet Violet Blue Blue

Blue

Blue

Blue

Blue

Blue

Blue

Blue Blue

Blue

Violet

Violet

Violet

Violet

Violet

Violet Blue

Blue

Violet All

Models All Models

All Models All Models

All Models All Models

18

X300 VSM 35 Issue 1 August 1994

Page 397 of 521

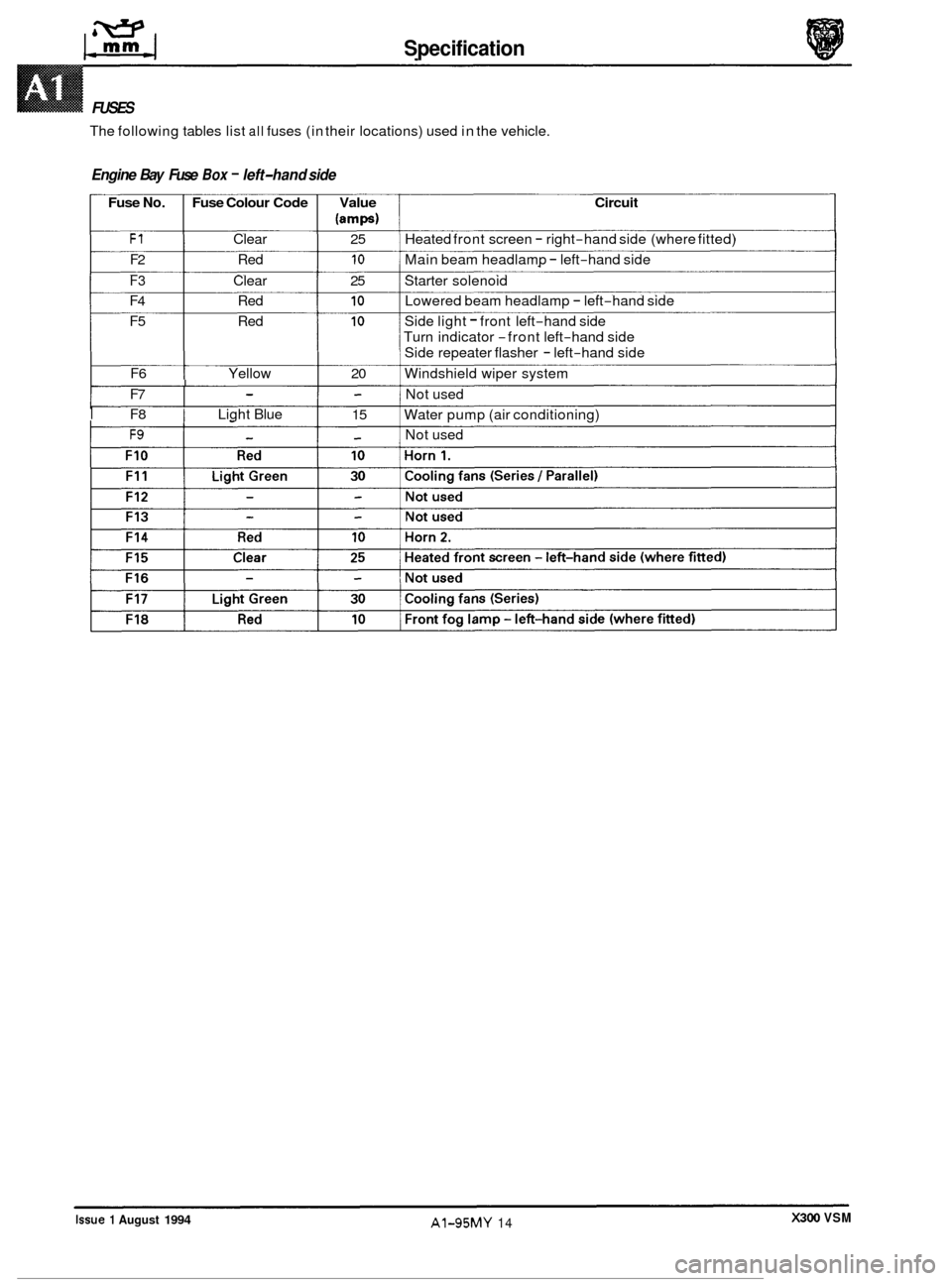

Specification

w IfrnrnJ

FUSES

The following tables list all fuses (in their locations) used in the vehicle.

Engine Bay Fuse Box - left-hand side

Fuse No. Fuse Colour Code Value Circuit

lamps)

F1 Clear 25 Heated front screen - right-hand side (where fitted)

F2 Red 10 Main beam headlamp - left-hand side

F3 Clear 25 Starter solenoid

F4 Red 10 Lowered beam headlamp - left-hand side

F5 Red 10 Side light - front left-hand side

Turn indicator

-front left-hand side

Side repeater flasher

- left-hand side

F6 Yellow 20 Windshield wiper system

I F8 I Light Blue

I Not used

F9 - - Not used

- - F7

15

Water pump (air conditioning) I - -

-l

X300 VSM Issue 1 August 1994 AI-95MY 14

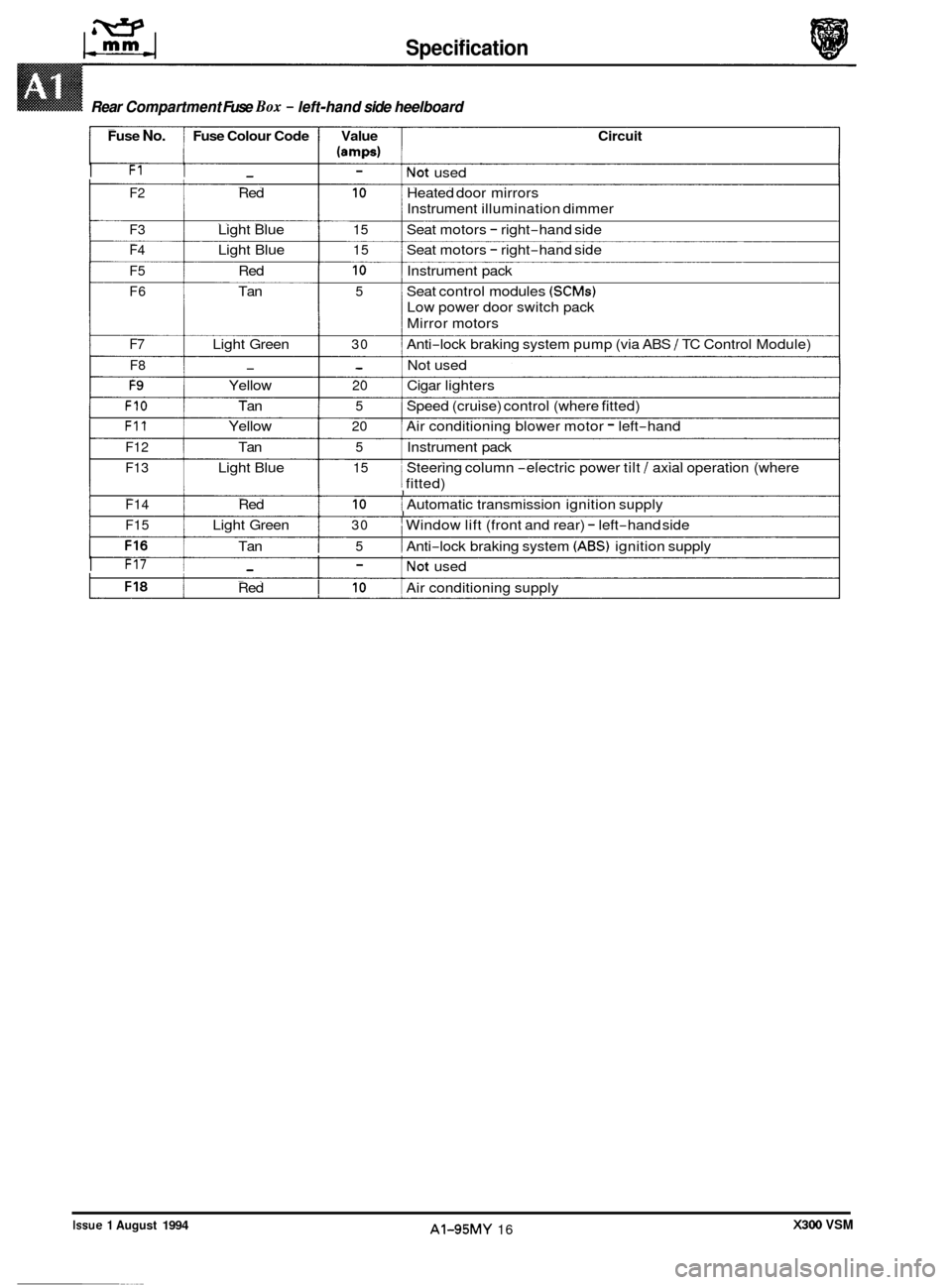

Page 399 of 521

Specification

Rear Compartment Fuse Box - left-hand side heelboard

Fuse No. Fuse Colour Code Value Circuit

(amps)

I F1 I - I - lNot used

F2 Red 10 Heated door mirrors

F3 Light Blue 15 Seat motors - right-hand side

F4 Light Blue 15 Seat motors - right-hand side

F5 Red 10 Instrument pack

F6 Tan 5 Seat control modules (SCMs)

Low power door switch pack

Mirror motors

Instrument

illumination dimmer

F7 Light Green 30 Anti-lock braking system pump (via ABS / TC Control Module)

F8 - - Not used

F9 Yellow 20 Cigar lighters

FIO Tan 5 Speed (cruise) control (where fitted)

F11 Yellow 20 Air conditioning blower motor - left-hand

F12 Tan 5 Instrument pack

F13 Light Blue 15 Steering column -electric power tilt / axial operation (where

j fitted) 1 I I F14 Red 10 i Automatic transmission ignition supply I I I F15 Light Green 30 I Window lift (front and rear) - left-hand side

Tan

I 5 1 Anti-lock braking system (ABS) ignition supply

I F17 1 - I - lNot used

Red

I 10 I Air conditioning supply

Rear Compartment Fuse Box - left-hand side heelboard ~~

X300 VSM Issue 1 August 1994 AI-95MY 16

0

0

0

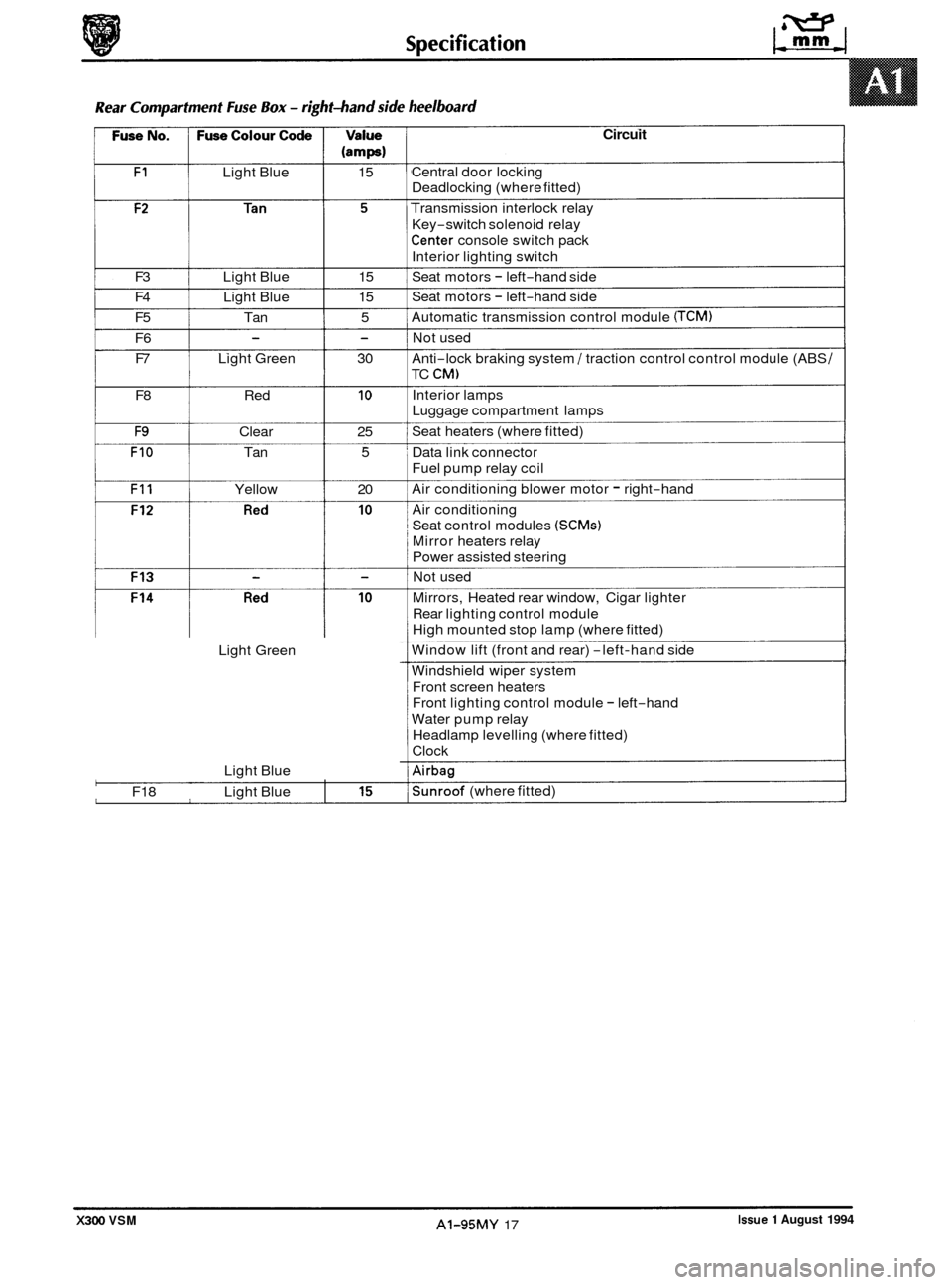

Page 400 of 521

(amps)

F1 Light Blue 15

F3 Light Blue 15

F4 Light Blue 15

F5 Tan 5

F6 F7 Light Green 30

- -

F8 Red 10

F9 Clear 25

FIO Tan 5

F11 Yellow 20 0

Light Green

Light Blue

F18 Light Blue

0'

I

Circuit

Central door locking

Deadlocking (where fitted)

Transmission interlock relay

Key

-switch solenoid relay

Center console switch pack

Interior lighting switch

Seat motors

- left-hand side

Seat motors

- left-hand side

Automatic transmission control module

(TCM)

Not used

Anti

-lock braking system / traction control control module (ABS /

TC CM)

Interior lamps

Luggage compartment lamps

Seat heaters (where fitted)

Data link connector

Fuel pump relay coil

Air conditioning blower motor

- right-hand

Air conditioning

Seat control modules

(SCMs)

Mirror heaters relay

Power assisted steering

Not used

Mirrors, Heated rear window, Cigar lighter

Rear lighting control module

High mounted stop lamp (where fitted)

Window lift (front and rear)

-left-hand side

Windshield wiper system Front screen heaters

Front lighting control module

- left-hand

Water pump relay

Headlamp levelling (where fitted)

Clock

Airbag

Sunroof (where fitted)

Issue 1 August 1994 AI-95MY 17 X300 VSM

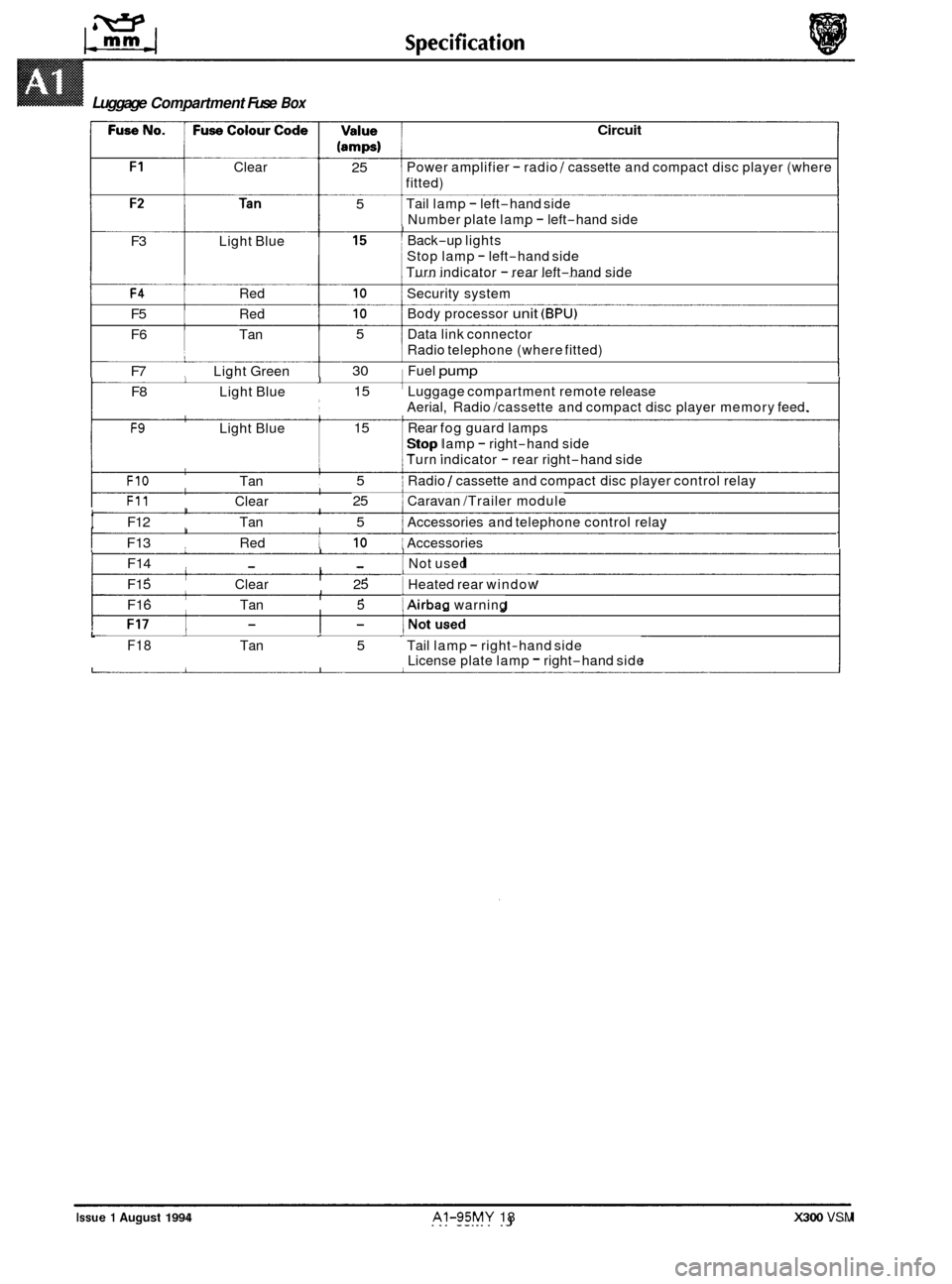

Page 401 of 521

Clear

(amps) 1

Circuit

I

25 5 Power amplifier - radio / cassette and compact disc player (where

fitted)

Tail lamp

- left-hand side

Number plate lamp

- left-hand side I Back-up lights

Stop lamp

- left-hand side

Turn indicator

- rear left-hand side

F3 Light Blue

F4 Red 10 Security system

F5 Red 10 Body processor unit (BPU)

F6 Tan 5 Data link connector

F7 Light Green 30 Fuel pump

F8 Light Blue 15 Luggage compartment remote release

F9 Light Blue 15 i Rear fog guard lamps

Radio

telephone (where fitted)

1

Aerial, Radio /cassette and compact disc player memory feed.

Stop lamp

- right-hand side

1 Turn indicator - rear right-hand side I.

I FIO Tan 5 i Radio / cassette and compact disc player control relay

F11 Clear 25 1 Caravan /Trailer module I

t F12 Tan 5 ~ Accessories

and telephone control relay I I

I I I F13 Red 10 ~ Accessories 1 1 I I F14 - - I Not used 1 I I F15 Clear 25 1 Heated

rear window I I I F16 Tan 5 1 Airbag warning

Luggage Compartment Fuse Box

Issue 1 August 1994 AI-95MY 18 X300 VSM

L F18 Tan 5 Tail lamp - right-hand side

License plate lamp - right-hand side

Page 417 of 521

General Fitting Instructions

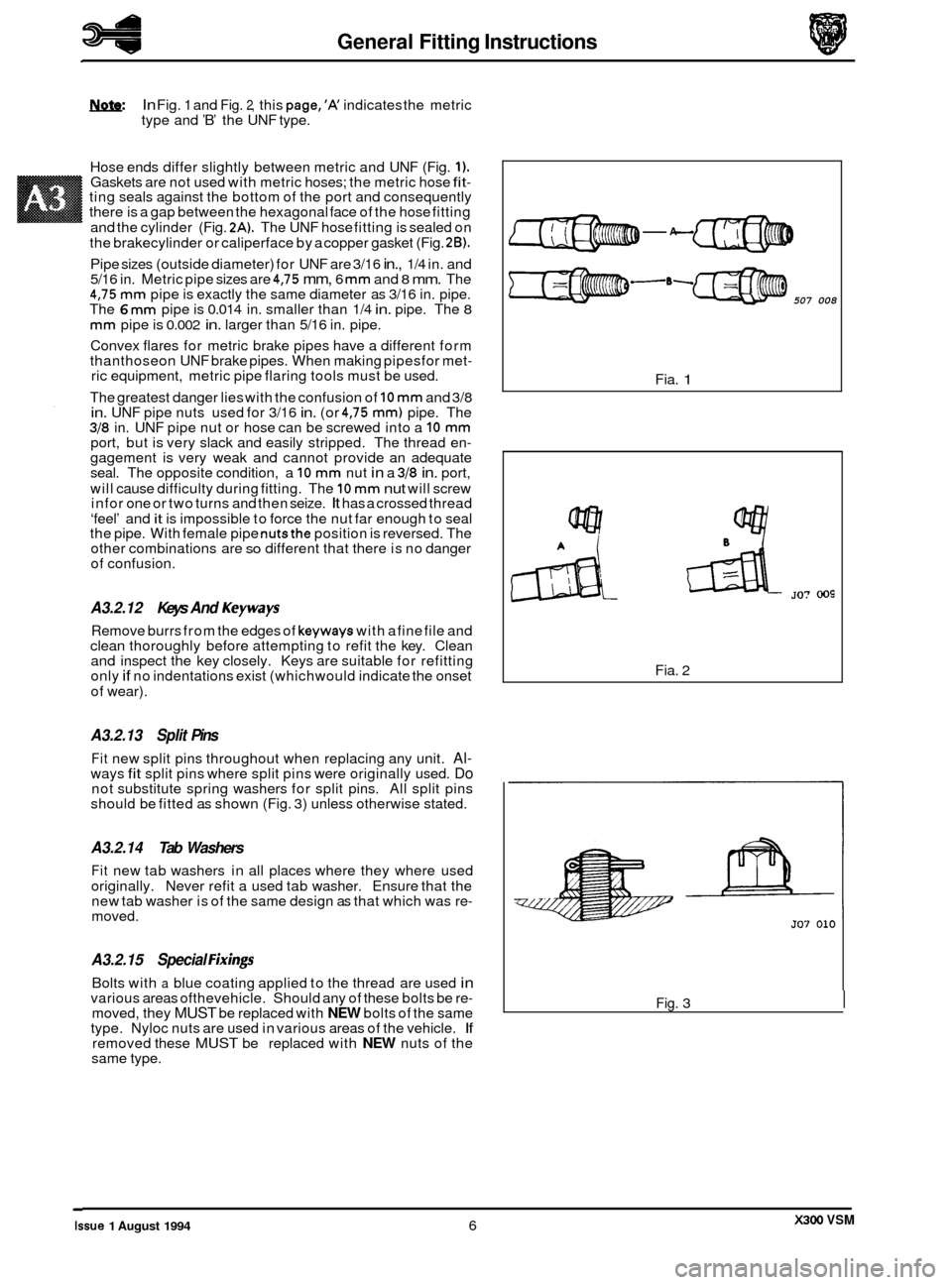

In Fig. 1 and Fig. 2, this page,’K indicates the metric

type and ’B’ the UNF type.

Hose ends differ slightly between metric and UNF (Fig.

1). Gaskets are not used with metric hoses; the metric hose fit- ting seals against the bottom of the port and consequently

there is a gap between the hexagonal face of the hose fitting

and the cylinder (Fig.

2A). The UNF hose fitting is sealed on

the brakecylinder or caliperface by a copper gasket (Fig.

2B).

Pipe sizes (outside diameter) for UNF are 3/16 in., 1/4 in. and

5/16 in. Metric pipe sizes are 4,75 mm, 6 mm and 8 mm. The 4,75 mm pipe is exactly the same diameter as 3/16 in. pipe.

The 6 mm pipe is 0.014 in. smaller than 1/4 in. pipe. The 8

mm pipe is 0.002 in. larger than 5/16 in. pipe.

Convex flares for metric brake pipes have a different form

thanthoseon UNF brake pipes. When making pipesfor met

- ric equipment, metric pipe flaring tools must be used.

The greatest danger lies with the confusion of

10 mm and 3/8 in. UNF pipe nuts used for 3/16 in. (or 4,75 mm) pipe. The 318 in. UNF pipe nut or hose can be screwed into a 10 mm port, but is very slack and easily stripped. The thread en- gagement is very weak and cannot provide an adequate

seal. The opposite condition, a 10 mm nut in a 318 in. port,

will cause difficulty during fitting. The

10 mm nut will screw

in for one or two turns and then seize. It has a crossed thread

‘feel’ and

it is impossible to force the nut far enough to seal

the pipe. With female pipe nutsthe position is reversed. The

other combinations are so different that there is no danger

of confusion.

A3.2.12 Keys And Keyways

Remove burrs from the edges of keyways with a fine file and

clean thoroughly before attempting to refit the key. Clean

and inspect the key closely. Keys are suitable for refitting

only

if no indentations exist (which would indicate the onset

of wear).

A3.2.13 Split Pins

Fit new split pins throughout when replacing any unit. Al- ways fit split pins where split pins were originally used. Do not substitute spring washers for split pins. All split pins

should be fitted as shown (Fig. 3) unless otherwise stated.

A3.2.14 Tab Washers

Fit new tab washers in all places where they where used

originally. Never refit a used tab washer. Ensure that the

new tab washer is of the same design as that which was re

- moved.

A3.2.15 Special Fixing

Bolts with a blue coating applied to the thread are used in various areas ofthevehicle. Should any of these bolts be re- moved, they MUST be replaced with NEW bolts of the same

type. Nyloc nuts are used in various areas of the vehicle. If removed these MUST be replaced with NEW nuts of the

same type.

-A

507 008

Fia. 1

Fia. 2

Fig. 3 I

X300 VSM Issue 1 August 1994 6

Page 421 of 521

General Fitting Instructions

I

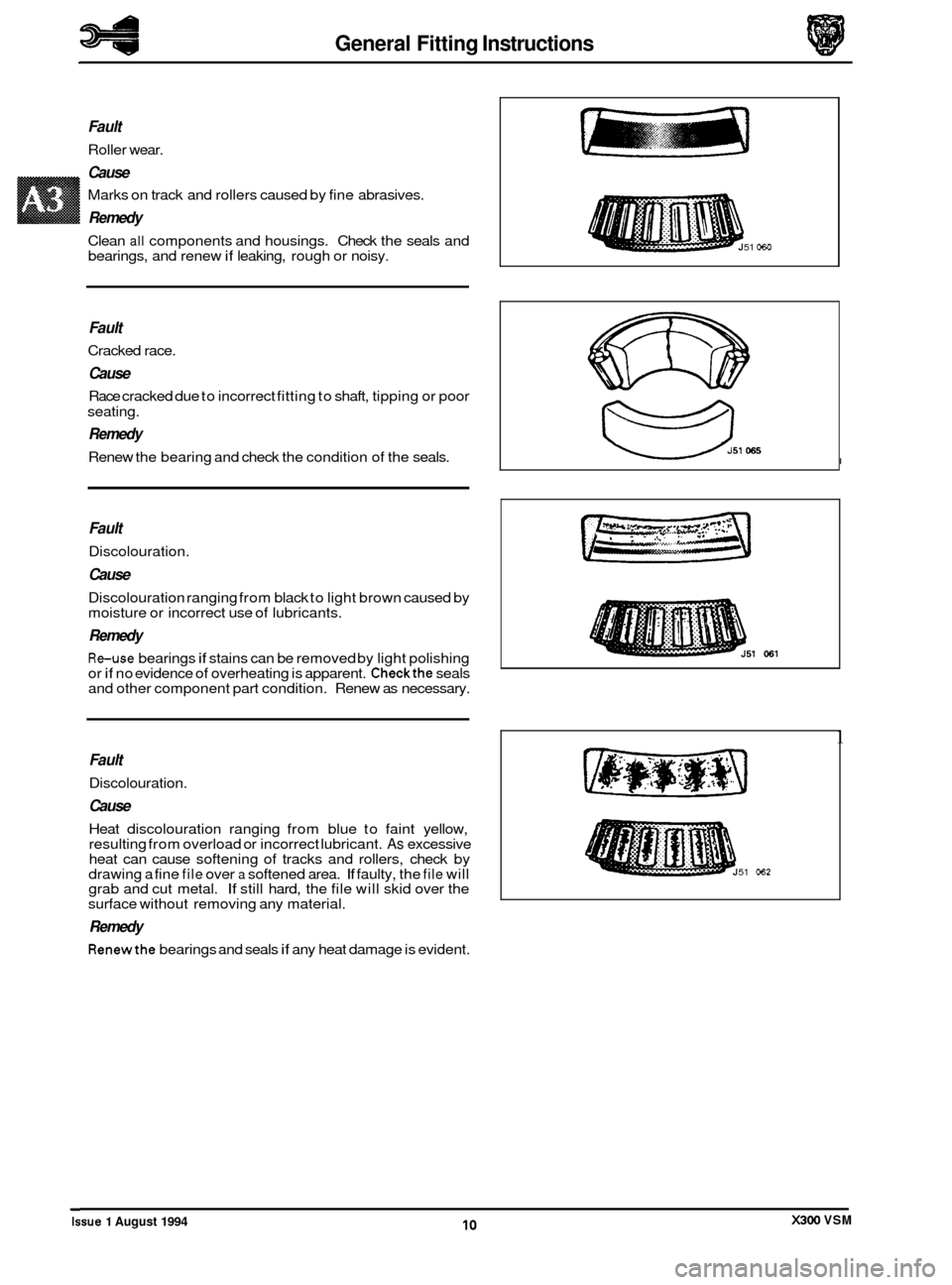

Fault

Roller wear.

Cause

Marks on track and rollers caused by fine abrasives.

Remedy

Clean all components and housings. Check the seals and

bearings, and renew if leaking, rough or noisy.

Fault

Cracked race.

Cause

Race cracked due to incorrect fitting to shaft, tipping or poor

seating.

Remedy

Renew the bearing and check the condition of the seals.

Fault

Discolouration.

Cause

Discolouration ranging from black to light brown caused by

moisture or incorrect use of lubricants.

Remedy

Reuse bearings if stains can be removed by light polishing

or if no evidence of overheating is apparent. Checkthe seals

and other component part condition. Renew as necessary.

51 060

[pzq-j - ..., .... *au

....... ........ e L. U

1

Fault

Discolouration.

Cause

Heat discolouration ranging from blue to faint yellow,

resulting from overload or incorrect lubricant. As excessive

heat can cause softening of tracks and rollers, check by

drawing a fine

file over a softened area. If faulty, the file will

grab and cut metal. If still hard, the file will skid over the

surface without removing any material.

Remedy

Renewthe bearings and seals if any heat damage is evident.

51 062

Issue 1 August 1994 X300 VSM 10