fuel pump JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 14 of 521

Introduction c

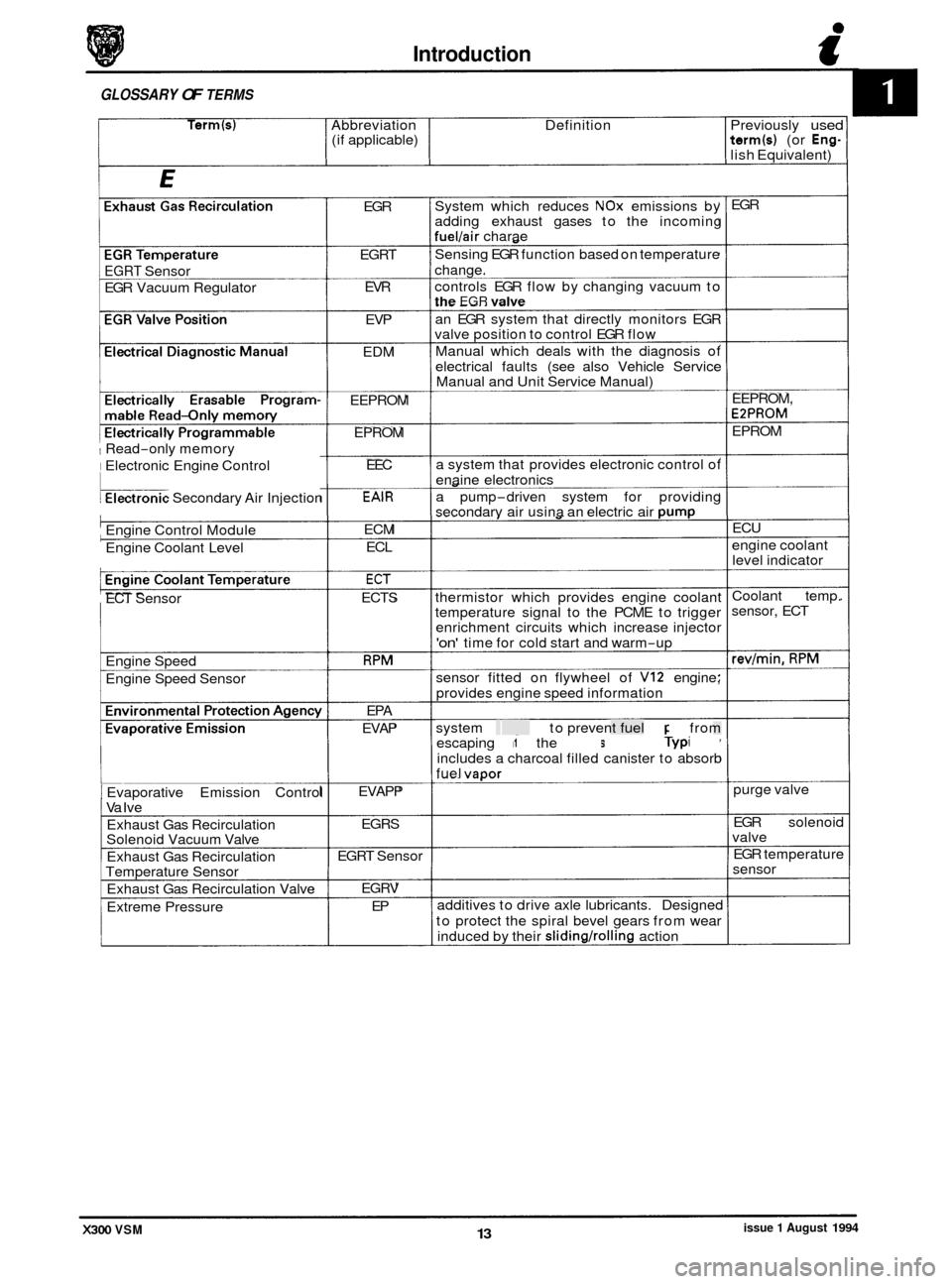

GLOSSARY OF TERMS

Term(s) Abbreviation Definition Previously used (if applicable) term(s) (or Eng- lish Equivalent)

0

EGRT Sensor

EGR Vacuum Regulator

1 Read-only memory

I Electronic Engine Control

kronic Secondary Air Injection

Engine Control Module

Engine Coolant Level

ECT Sensor

Engine Speed

Engine Speed Sensor

1 Evaporative Emission Control

Va Ive

Exhaust Gas Recirculation

Solenoid Vacuum Valve

Exhaust Gas Recirculation

Temperature Sensor

Exhaust Gas Recirculation Valve

Extreme Pressure EGR

EGRT EVR

EVP

EDM

EEPROM EPROM EEC

EAlR

ECM ECL

ECT

ECTS

RPM

EPA

EVAP

EVAPP EGRS

EGRT Sensor

EGRV EP System

which reduces

NOx emissions by

adding exhaust gases to the incoming

fuel/air charae

Sensing EGR function based on temperature

change.

controls EGR flow by changing vacuum to

the EGR valve

an EGR system that directly monitors EGR

valve position to control EGR flow

Manual which deals with the diagnosis of

electrical faults (see also Vehicle Service

Manual and Unit Service Manual)

a system that provides electronic control of

enaine electronics

a pump

-driven system for providing

secondarv air usina an electric air Dump

thermistor which provides engine coolant

temperature signal to the PCME to trigger

enrichment circuits which increase injector

'on' time for cold start and warm-up

sensor fitted on flywheel of

VI2 engine;

provides engine speed information

system designed to prevent fuel vapor from

escaping into the atmosphere. Typically

includes a charcoal filled canister to absorb

fuel

vaoor

additives to drive axle lubricants. Designed

to protect the spiral bevel gears from wear

induced by their

slidingholling action EGR

EEPROM,

EPPROM

EPROM ECU

engine coolant level indicator

Coolant temp.

sensor, ECT

revlmin. RPM

purge valve

EGR solenoid

valve

EGR temperature

sensor

X300 VSM issue 1 August 1994 13

Page 15 of 521

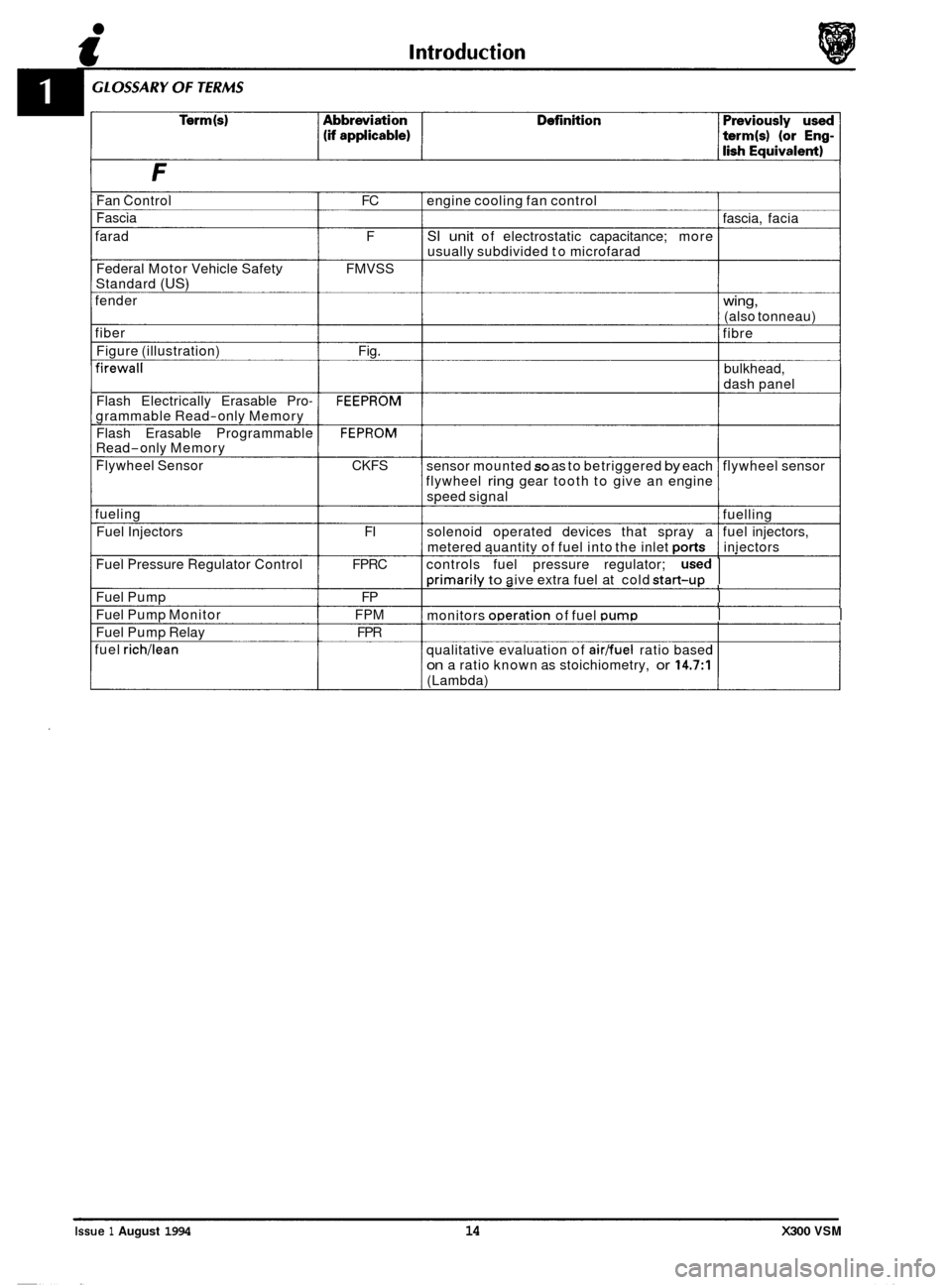

Fan Control FC

Fascia

farad F

I Federal Motor Vehicle Safetv I FMVSS

Standard (US)

fender

fiber

Figure (illustration) Fig.

firewall

Flash Electrically Erasable Pro- FEEPROM grammable Read-only Memory

Flash Erasable Programmable

FEPROM Read-only Memory

Flywheel Sensor CKFS

fueling Fuel Injectors FI

Fuel Pressure Regulator Control FPRC

Fuel Pump FP

Fuel Pump Monitor FPM

Fuel Pump Relay FPR

fuel

rich/lean

engine cooling fan control

SI unit of electrostatic capacitance; more

usually subdivided to microfarad fascia,

facia

wing,

(also tonneau)

fibre

bulkhead,

dash panel

sensor mounted

so as to be triggered by each flywheel sensor

flywheel ring gear tooth to give an engine

speed signal

fuelling

iniectors

solenoid operated

devices that spray a fuel injectors,

metered auantitv of fuel into the inlet

~0rt.s

Drimarilv to aive extra fuel at cold start-uo used I

controls fuel pressure regulator;

I I

monitors oDeration of fuel DumD I I

qualitative evaluation of airbuel ratio based on a ratio known as stoichiometry, or 14.7:l

(Lambda)

Issue 1 August 1994 14 X300 VSM

0

0

Page 22 of 521

(if applicable) term(s) (or Eng-

lish Equivalent)

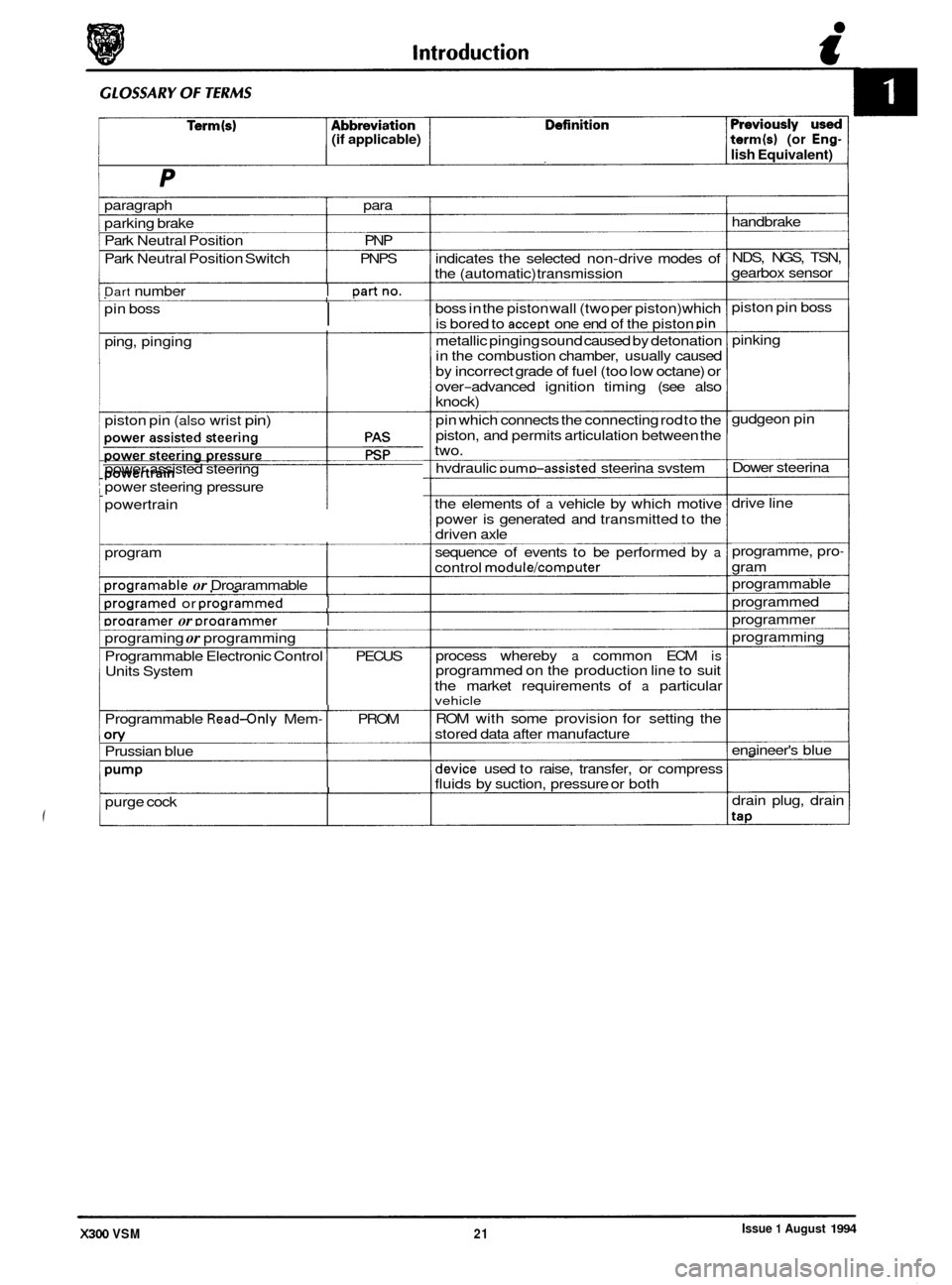

paragraph para

parking brake

Park Neutral Position PNP

Park Neutral Position Switch PNPS

Dart number I Dartno.

I pin boss

ping, pinging

piston pin

(also wrist pin)

power assisted steering

power steering pressure

. powertrain

program

Droaramable or Droarammable I

Droaramed or Droarammed I

Droaramer or Droarammer I

programing or programming

Programmable Electronic Control

I PECUS

Units System

I Programmable Read-only Mem- I PROM

on/ Prussian blue

Pump

purge cock I

indicates the selected non-drive modes of

the (automatic) transmission

boss in the piston wall (two per piston) which

is bored to

accept one end of the piston pin

metallic pinging sound caused by detonation

in the combustion chamber, usually caused

by incorrect grade of fuel (too low octane) or

over

-advanced ignition timing (see also knock)

pin which connects the connecting rod to the

piston, and permits articulation between the

two.

hvdraulic

DumD-assisted steerina svstem

the elements of

a vehicle by which motive

power is generated and transmitted to the

driven axle

sequence of events to be performed by

a

control module/comDuter

process whereby a common ECM is programmed on the production line to suit

the market requirements of

a particular vehicle

ROM with some provision for setting the

stored data after manufacture

device used to raise, transfer, or compress

fluids by suction, pressure or both handbrake

NDS, NGS, TSN,

gearbox sensor

piston pin boss

pinking

gudgeon pin

Dower steerina

drive line

programme, pro

-

gram

programmable

programmed

programmer

programming

enaineer's blue

drain plug, drain

tap

Issue 1 August 1994 X300 VSM 21

Page 61 of 521

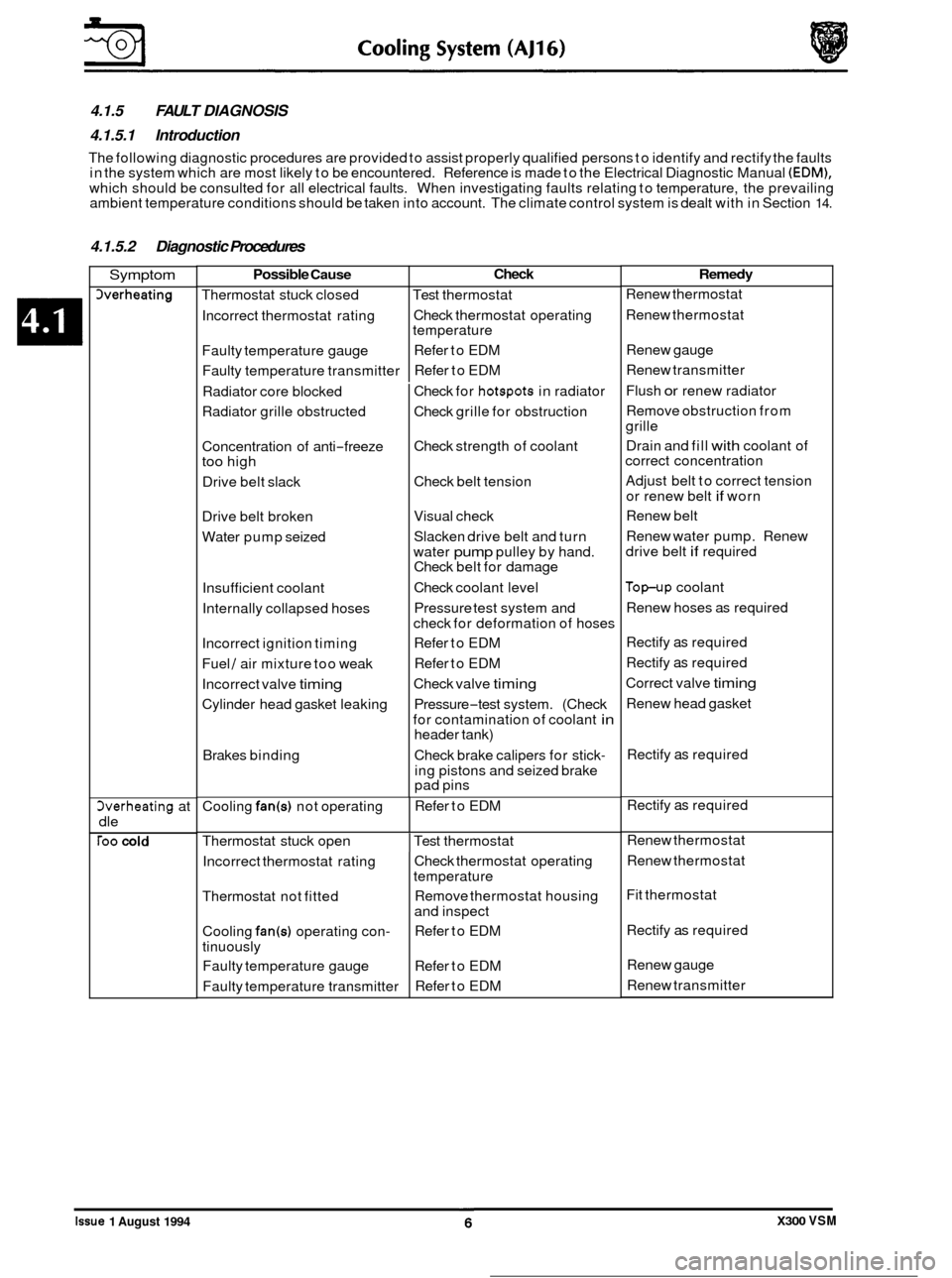

4.1.5 FAULT DIAGNOSIS

4.1.5.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults

in the system which are most likely to be encountered. Reference is made to the Electrical Diagnostic Manual (EDM),

which should be consulted for all electrical faults. When investigating faults relating to temperature, the prevailing

ambient temperature conditions should be taken into account. The climate control system is dealt with in Section 14.

Possible Cause

Thermostat stuck closed

Incorrect thermostat rating

Faulty temperature gauge

Faulty temperature transmitter

4.1.5.2 Diagnostic Procedures

Check

Test thermostat

Check thermostat operating

temperature

Refer to EDM

Refer to EDM

Symptom

herheating

Cooling fan(s) not operating 3verheating at

dle

roo cold

Refer to EDM

Incorrect thermostat rating

Thermostat not fitted

Cooling

fan(s) operating con-

tinuously Faulty temperature gauge

Faulty temperature transmitter

Radiator

core blocked

Radiator grille obstructed

Check thermostat operating

temperature

Remove thermostat housing

and inspect

Refer to EDM

Refer to EDM

Refer to EDM

Concentration of

anti

-freeze too high

Drive belt slack

Drive belt broken

Water pump seized

Insufficient coolant

Internally collapsed hoses

Incorrect ignition timing

Fuel

/ air mixture too weak

Incorrect valve

timing

Cylinder head gasket leaking

Brakes binding Check

for

hotspots in radiator

Check grille for obstruction

Check strength of coolant

Check belt tension

Visual check

Slacken drive belt and turn

water

pump pulley by hand.

Check belt for damage

Check coolant level

Pressure test system and

check for deformation of hoses

Refer to EDM

Refer to EDM

Check valve

timing

Pressure-test system. (Check

for contamination of coolant

in header tank)

Check brake calipers for stick

-

ing pistons and seized brake

pad pins

Thermostat stuck open

I Test thermostat

Remedy

Renew thermostat

Renew thermostat

Renew gauge

Renew transmitter

Flush

or renew radiator

Remove obstruction from

grille

Drain and fill

with coolant of

correct concentration

Adjust belt to correct tension

or renew belt

if worn

Renew belt

Renew water pump. Renew

drive belt

if required

Top-up coolant

Renew hoses as required

Rectify

as required

Rectify

as required

Correct valve

timing

Renew head gasket

Rectify

as required

Rectify

as required

Renew thermostat

Renew thermostat

Fit thermostat

Rectify

as required

Renew gauge

Renew transmitter

0

e

0

0

Issue 1 August 1994 X300 VSM

Page 70 of 521

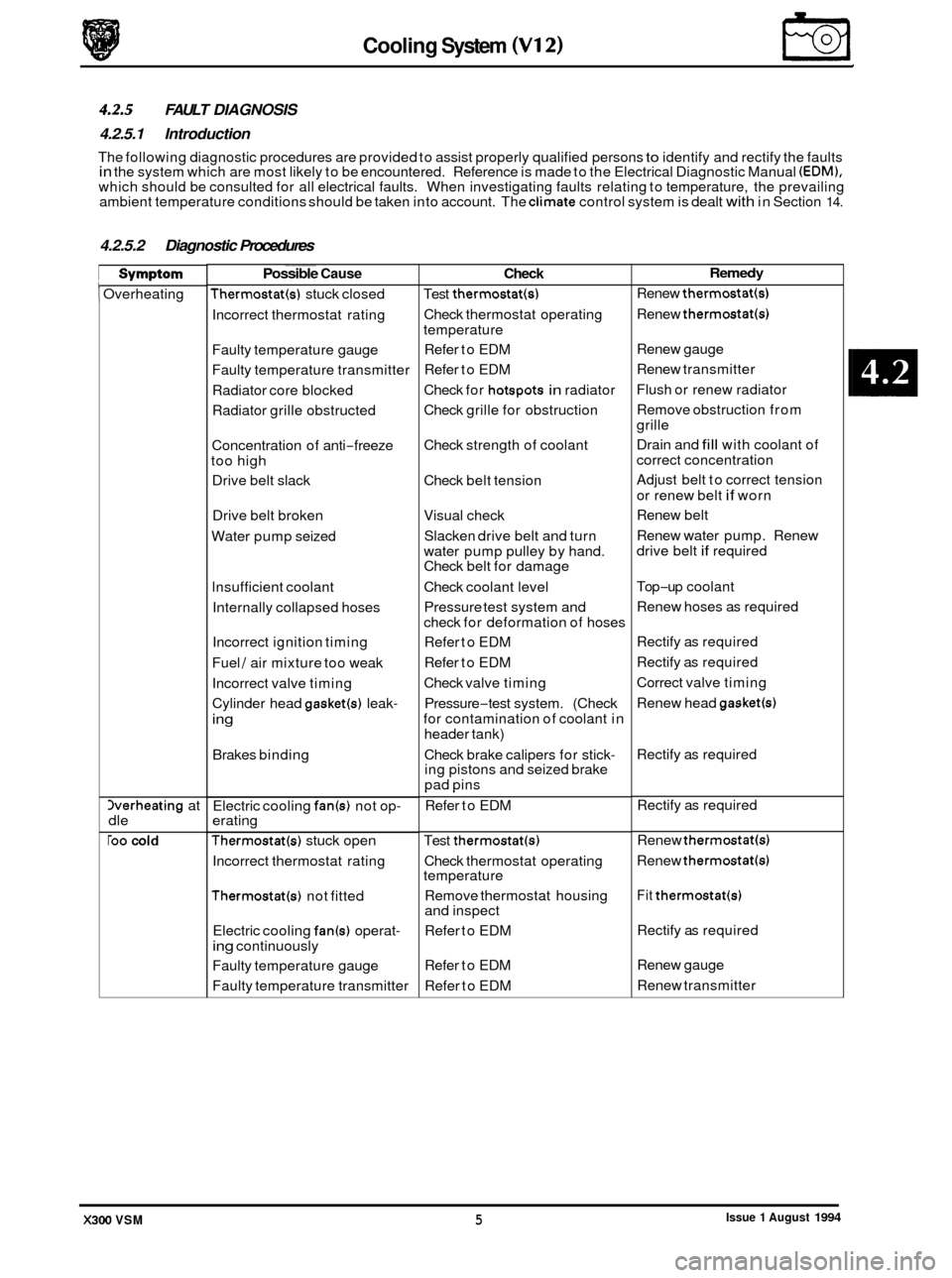

4.2.5.2 Diagnostic Procedures

1

I Symptom ..

Overheating

herheating at

dle

roo cold ~~~

Possible Cause

Thermostat(s) stuck

closed

Incorrect thermostat rating

Faulty temperature gauge

Faulty temperature transmitter

Radiator core blocked

Radiator grille obstructed

Concentration of anti

-freeze

too high

Drive belt slack

Drive belt broken

Water pump seized

lnsuff icient coolant

Internally collapsed hoses

Incorrect ignition timing

Fuel

/ air mixture too weak

Incorrect valve timing

Cylinder head

gasket(s) leak-

ing

Brakes binding

Electric cooling

fan(s) not op- erating

Thermostat(s) stuck open

Incorrect thermostat rating

Thermostatb) not fitted

Electric cooling

fan(s) operat-

ing continuously

Faulty temperature gauge

Faulty temperature transmitter

Check

Cooling System (V12)

4.2.5 FAULT DIAGNOSIS

4.2.5.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults in the system which are most likely to be encountered. Reference is made to the Electrical Diagnostic Manual (EDM), which should be consulted for all electrical faults. When investigating faults relating to temperature, the prevailing

ambient temperature conditions should be taken into account. The climate control system is dealt with in Section 14.

Test thermostat(s)

Check thermostat operating

temperature

Refer to EDM

Refer to EDM

Check for

hotspots in radiator

Check grille for obstruction

Check strength of coolant

Check belt tension

Visual check Slacken drive belt and turn

water pump pulley by hand.

Check belt for damage

Check coolant level

Pressure test system and

check for deformation of hoses

Refer to EDM

Refer to EDM

Check valve timing

Pressure

-test system. (Check

for contamination of coolant in

header tank)

Check brake calipers for stick

- ing pistons and seized brake

pad pins

..

Refer to EDM

Test

thermostat(4

Check thermostat operating

temperature

Remove thermostat housing

and inspect

Refer to EDM

Refer to EDM

Refer to EDM

Remedy

Renew thermostat(s)

Renew thermostat(s1

Renew gauge

Renew transmitter

Flush or renew radiator

Remove obstruction from

grille

Drain and

fill with coolant of

correct concentration

Adjust belt to correct tension

or renew belt

if worn

Renew belt

Renew water pump. Renew

drive belt

if required

Top

-up coolant

Renew hoses as required

Rectify as required

Rectify as required

Correct valve timing

Renew head

gasket(s)

Rectify as required

Rectify as required

Renew

thermostat(s1

Renew thermostatb)

Fit thermostat(s)

Rectify as required

Renew gauge

Renew transmitter

Issue 1 August 1994 X300 VSM 5

Page 75 of 521

Rear deck area

Behind rear bulkhead

Inside fuel tank 1

2

3

Inside fuel tank

Fuel

pump to fuel filter

Above rear axle assembly

Fuel filter to fuel rail

Inlet manifold

Inlet manifold

/fuel rail

Mounted on the fuel rail

Fuel regulator to fuel tank

Fuel tank to running

loss

control valve (NAS 4.0L

normally aspirated engine

only)

Running loss control valve

to primary carbon canister

(NAS 4.0L normally

aspirated engine only)

Left side of the fuel tank

4

5

6

7 8

9

10

11

12

13

14

Fuel tank to tank pressure

control (Rochester) valve

Connected between

emission vent lines as

shown on schematic

Rochester valve

to primary

carbon canister

Primary carbon canister to

secondary carbon canister

(NAS 4.0L normally

aspirated engine only)

15

16

17

18

Primary carbon canister to

atmosphere

Left side of vehicle,

in

front of the rear axle

To the right of the primary

carbon canister on the

other side of the vehicle

(NAS 4.0L normally

aspirated engine only).

Primary carbon canister

to

purge valve

Below the left head lamp

module

18

19

20

21

22

m Fuel, Emission Contro & Engine Management (AJ16) - .

0

0

0

0

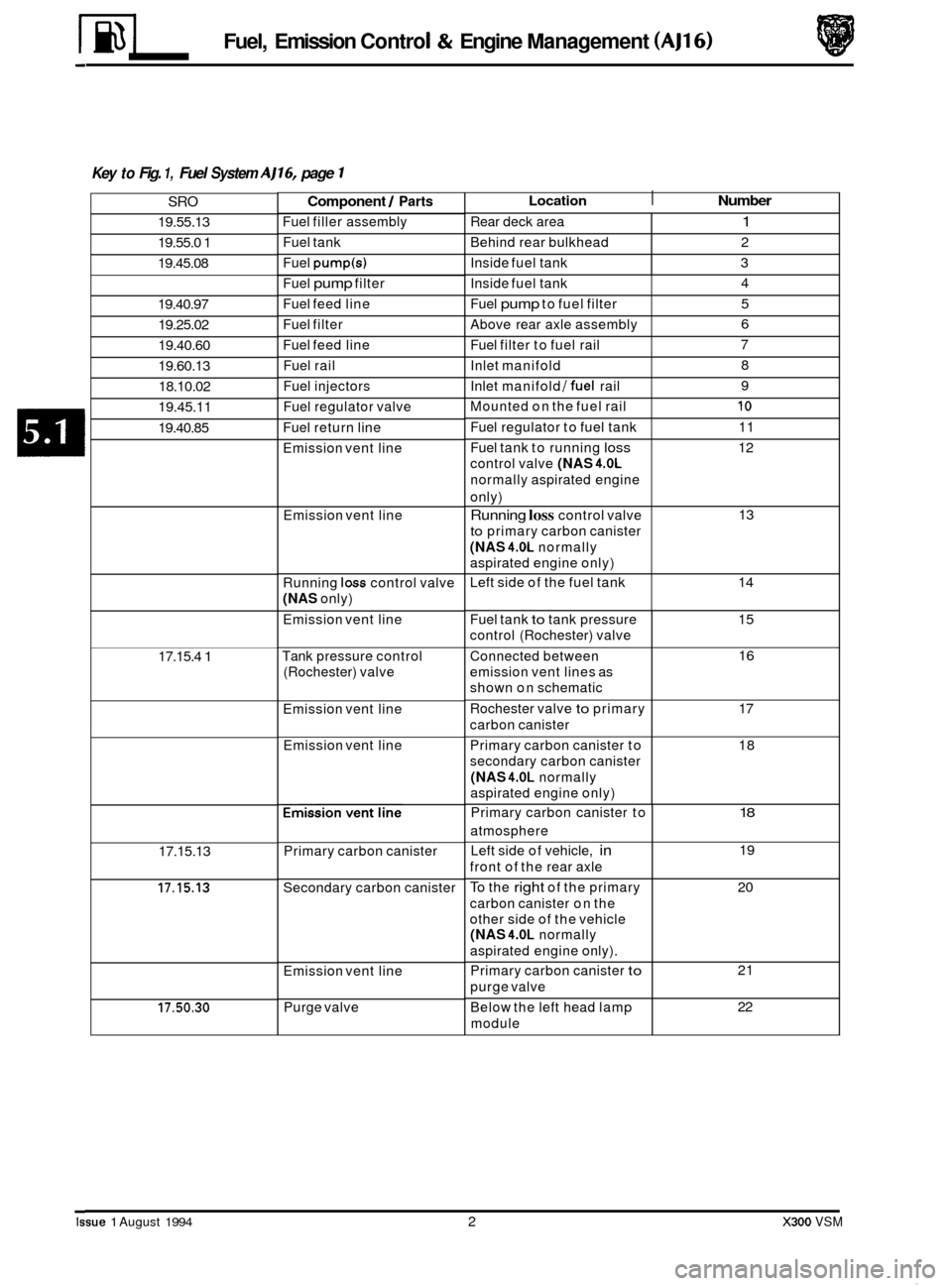

Key to Fig. 1, Fuel System AJ16, page 1

Location I Number Component / Parts

Fuel filler assembly

SRO

19.55.13

19.55.0 1

19.45.08

Fuel tank

Fuel

pump(s)

Fuel pump filter

Fuel feed line

Fuel filter

Fuel feed line

19.40.97

19.25.02

19.40.60

19.60.13 18.10.02

19.45.11

Fuel rail

Fuel injectors

Fuel regulator valve

19.40.85 Fuel return line

Emission vent line

Emission vent line

Running

loss control valve

(NAS only)

Emission vent line

Tank pressure control

(Rochester) valve

17.15.4 1

Emission vent line

Emission vent line

Emission vent line

Primary carbon canister

17.15.13

Secondary carbon canister 17.15.13

Emission vent line

Purge valve

17.50.30

Issue 1 August 1994 2 X300 VSM

Page 76 of 521

striker and the-fuel cap stowage magnet.

The fuel bowl, retained around the filler neck by a clip, containing a drain tube filter located over the mating drain tube,

is rubber moulded onto a steel armature and fitted to the BIW decking panel by five M5 nuts.

The fuel lid latching assembly fitted to the metal armature of the fuel bowl by an M5 nut, includes the locking pin and

the operating actuator.

The actuator operates from the central locking system driven by the security and locking control module

(SLCM).

The fuel tank, mounted across thevehicle behind the passenger compartment rear bulkhead, is held in position by two

retaining straps, tightened by two M5 fixing arrangements.

The fuel tank of AJ16 engined vehicles contains one fuel pump, supplying fuel to the normally aspirated engine and

two fuel pumps, supplyingfuel to the supercharged engine. They are regenerative turbine pumps supplied by

Nippon- Denso. Nominal operating pressure is 3 bar (3.7 bar for supercharged engine) above the manifold depression and

pump delivery is 90 litredhour minimum at 13.2 volts, 3 bar outlet pressure. The pump(s) draw a nominal current of 7 amperes at 13 volts, 3 bar outlet pressure, ambient temperatures. Built in to the pump assembly is a over-pressure

relief valve which blows at 4.5 - 8.5 bar.

Fuel is drawn by the pumps from the fuel tank and is then supplied to the fuel rail via a

70 micron filter and the fuel

feed line connected in series by fuel filter.

The amount of fuel being injected into the engine

is controlled by the fuel injectors combined with the engine control module (ECM). - Any excessive fuel flowing through the system, is returned to the fuel tankvia the fuel regulator valve mounted on the

fuel rail, the fuel return line and the check valve also located inside the tank.

The two filters prevent contaminants from entering the fuel rail and possible damage to the fuel injectors, the engine,

the pump and the underfloor filter.

The fuel pumps are switched on and off by relays controlled by the engine control module

(ECM).

The second fuel pump for the supercharged engine operates only in the higher speed range, switching on at 4000rpm and off at 3200rpm.

The fuel lines are made up of an assembly, combining steel under floor pipes and flexible conductive anti-permeation

tubing. In orderto perform speedy remove and refit operations, the underfloor steel lines are linked through the engine

bay bulkhead to the flexible tubing, leading to the fuel rail and the fuel regulator by using positive sealing, quick-fit

type connectors. The same type connectors, are used to connect the fuel feed and return line to the fuel tank.

Connectors used inside the engine bay are of different sizes tocorrespond with the difference in pipe diameter, whereas

the connectors for the feed and return lines at the fuel tank are the same size.

Except for the return line connector at the fuel tank, two release tools, one for each size of connector are required to

release all remaining connectors.

-~

Fuel, Emission Control & Engine Management (AJ16)

5.1.2 GENERAL DESCRIPTION

m: WORKING ON THE FUEL SYSTEM MAY RESULT IN FUEL AND FUEL VAPOUR BEING PRESENT IN THE

ATMOSPHERE. FUEL VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHllST WORKING ON THE FUEL SYSTEM. ADHERE STRICTLY TO THE FOLLOWING PRECAUTIONS:

DO NOT

SMOEIN THE WORK AREA.

DISPLAY 'NO SMOKING

' SIGNS AROUND THE AREA.

ENSURE THAT A

CO2 FIRE EXTINGUISHER IS CLOSE AT HAND.

ENSURE THAT DRY SAND

IS AVAILABLE TO SOAK UP ANY FUEL SPILLAGE.

EMPTY FUEL USING SUITABLE FIRE

PROOF EQUIPMENT INTO AN AUTHORIZED EXPLOSIOWROOF

CONTAINER.

DO NOT EMPTY FUEL

INTO A PIT.

ENSURE THAT WORKING AREA

IS WELL VENTILATED.

ENSURE THAT ANY WORK ON THE FUEL SYSTEM

IS ONLY CARRIED OUT BY EXPERIENCED AND WELL

QUALIFIED MAINTENANCE PERSONNEL.

The fuel filler assembly, supplied complete with serviceable lid, hinge and hinge spring, is fixed to the Body-in-White

(BIW) decking panel by two M5 nuts. Additional parts of the assembly comprise a adjustable rubber buffer, a snap-in

X300 VSM 3 Issue 1 August 1994

Page 91 of 521

+ 17.15.13

17.50.30

Component / parts

Fuel filler assembly

Fuel tank

Fuel pumps

Fuel

pump filter

Fuel feed line

Fuel filter

Fuel feed line

Fuel rail

Fuel injectors

Fuel regulator valve

Fuel return line

Emission vent line

Tank pressure control

(Rochester) valve

Emission vent line

Primary carbon canister

Emission vent line

Purge valve

Emission vent line

Location Number

Rear deck area

1

Behind rear bulkhead 2

Inside fuel tank 3

Inside fuel tank 4

Fuel

pump to fuel filter 5

Above rear axle assembly 6

Fuel filter to fuel rail 7

Inlet manifold

8

Inlet manifold /fuel rail 9

Mounted on the fuel rail 10

Fuel regulator to fuel tank 11

Fuel tank to tank pressure 12

control (Rochester) valve

Connected between

emission vent lines as

shown on schematic 13

Rochester valve to primary 14

carbon canister

Left side

of vehicle, in 15

front of the rear axle

Primary carbon canister to 16

purge valve

Below the left head lamp 17

module

Primary carbon canister

to at-

mosphere

18

0

0

0

Issue 1 August 1994 2 X300 VSM

Page 92 of 521

striker and the fuel cap stowage magnet.

The fuel bowl, retained around the filler neck by a clip, containing a drain tube filter located

overthe mating drain tube,

is rubber moulded onto a steel armature and fitted to the BIW decking panel. by five M5 nuts.

The fuel lid latching assembly fitted to the metal armature of the fuel bowl by an M5 nut, includes the locking pin and

the operating actuator.

The actuator operates from the central locking system driven by the Security and Locking Control Module (SLCM).

The fuel tank, mounted across the vehicle behind the passenger compartment rear bulkhead, is held in position by two

retaining straps, tightened by two M5 fixing arrangements.

VI2 engined vehicles are equipped with two fuel pumps located inside the tank. They are regenerative turbine pumps

supplied by Nippon Denso. Nominal operating pressure is 3 bar above the manifold depression and pump delivery

is 90 litres/hour minimum at 13.2 volts, 3 bar outlet pressure. The pump draws a nominal current of 7 amperes at 13 volts, 3 bar outlet pressure, ambient temperatures. Built in to the pump assembly is a over-pressure relief valve which

blows at 4.5 - 8.5 bar.

Fuel is drawn by the pumps from the fuel tank and is then supplied to the fuel rail via a

70 micron filter and the fuel

feed line connected in series by fuel filter.

The amount of fuel being injected into the engine is controlled by the fuel injectors combined with the engine control

module (ECM).

Any excessive fuel flowing through the system, is returned to thefuel tankvia the fuel regulator valve mounted on the

fuel rail, the fuel return line and the check valve also located inside the tank.

The two filters prevent contaminants from entering the fuel rail and possible damage to the fuel injectors, the engine,

the pump and underfloor filter.

The second fuel pump is controlled by the engine control module

(ECM) and works of a mapped fuel map. The pumps

'switch on' time depends on the fuel requirement which is depending on the engine load.

The fuel lines are made up of an assembly, combining steel underfloor pipes and flexible conductive anti

-permeation

tubing. In order to perform speedy remove and refit operations, the underfloor steel lines are linked through the engine

bay bulkhead to theflexibletubing, leading to the fuel rail and the fuel regulator by using positive sealing, quick

fit type

connectors. The same type connectors, are used to connect the fuel feed and return line to the fuel tank.

Connectors used inside the engine bay, are of different sizes to correspond with the difference in pipe diameter, where

- as the connectors for the feed and return lines at the fuel tank are the same size.

Except for the return line connector at the fuel tank, two release tools, one for each size of connector, are required to

release all remaining connectors.

Fuel, Emission Control & Engine Management (V12)

5.2.2 GENERAL DESCRIPTION

WARNING: WORKING ON THE FUEL SYSTEM RESULTS IN FUEL AND FUEL VAPOUR BEING PRESENT IN THE AT- MOSPHERE. FUEL VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST

WORKING ON THE FUEL SYSTEM. ADHERE STRICTLY TO THE FOLLOWING PRECAUTIONS:

PO NOT SMOKF, IN THE WORK AREA.

DISPLAY 'NO SMOKING

' SIGNS AROUND THE AREA.

ENSURE THAT A

CO2 FIRE EXTINGUISHER IS CLOSE AT HAND.

ENSURE THAT DRY SAND

IS AVAILABLE TO SOAK UP ANY FUEL SPILLAGE.

EMPTY FUEL USING SUITABLE FIRE PROOF EQUIPMENT INTO AN AUTHORIZED EXPLOSION PROOF

CONTAINER.

DO NOT EMPTY FUEL INTO A PIT.

ENSURE THAT WORKING AREA IS WELL VENTILATED.

ENSURE THAT ANY WORK ON THE FUEL SYSTEM

IS ONLY CARRIED OUT BY EXPERIENCED AND WELL

QUALIFIED MAINTENANCE PERSONNEL.

The fuel filler assembly, supplied complete with serviceable lid, hinge and hinge spring, is fixed to the Body-in-White (BIW) decking panel by two M5 nuts. Additional parts of the assembly comprise a adjustable rubber buffer, a snap-in

X300 VSM 3 Issue 1 August 1994

Page 156 of 521

Automatic Transmission (V12 & AJl6 Supercharged) Pomrtrain

8.2.1 GENERAL DESCRIPTION

This section provides information relating to the Powertrain 4L80-E transmissions fitted to the 4,O liter supercharged

engine (4,OL SC) and to the 6,O liter engine (6,OL).

The Powertrain 4L80-E is a four-speed, high torque capacity, electronically controlled automatic transmission, which

comprises a torque converter with lock-up direct drive clutch and three planetary gear sets. Five multiple diskclutches,

one intermediate sprag clutch assembly, two roller clutch assemblies and two band assemblies provide the drive el- ements necessary for correct sequential gear engagement and operation.

The torque converter containing

a pump, a turbine (rotor), a stator assembly, and a clutch pressure disksplined to the

turbine, acts as a fluid coupling for smooth torque transmission from the engine. The converter also supplies addi- tional torque multiplication when necessary, and the torque converter clutch (TCC) pressure disk provides a mechan- ical direct drive or 'lock-up' above a certain speed in top gear for greater fuel economy.

Gearshift operations are controlled from the Transmission Control Module (TCM), which governs the electronically

controlled valve body situated within the transmission.

Three planetary gear sets provide reverse and the four forward ratios, the changing of which is fully automatic in rela

- tion to load, vehicle speed and throttle opening. The Transmission Control Module receives and integrates various ve- hicle sensor input signals, and transmits operating signals to the solenoids located in the control valve assembly.

These solenoids govern the transmission operating pressures, up-shift and down-shift gear selection patterns and

also the torque converter clutch operation by pulse width modulated control.

8.2.1.1 Gear Ranges

Selectable gear positions are: P - Park, R - Reverse, N - Neutral, D - Drive, 3, 2.

P - Park position of the shift lever provides a mechanical locking of the output shaft of the transmission, and as such,

must only be engaged when the the vehicle is stationary. In addition, and for

extra safety, the handbrake should also

be applied. It is necessary to have the ignition ON and the footbrake applied to move the shift lever from the Park

position. For ignition key removal the shift lever must be in the Park position. The engine can be started in the Park

position.

R - Reverse enables the vehicle to be operated in a rearwards direction. The engine cannot be started in the Reverse

position.

N

-Neutral position enables the engine to be started and operated without driving the vehicle. It also allows the vehicle

to be moved manually for access, ie for removal of the propeller shaft.

D

-Drive position allows the automatic selection of all four forward gear ratios during normal driving conditions for

maximum efficiency and fuel economy. On acceleration, down-shifts are obtained by depressing the accelerator pedal

or by manual selection. The engine cannot be started in this position.

3

- Manual third position allows automatic operation of the three lower gear ratios but inhibits selection of the fourth

ratio. This position is used for towing a trailer or negotiating hilly terrain when greater engine braking control is re- quired. The engine cannot be started in this position.

2 - Manual second position allows automatic operation of the two lower gear ratios but inhibits selection of the third

and fourth ratios. This position is used for heavy traffic congestion or negotiating hilly terrain when even greater en

- gine braking control is required than is provided by manual third. This ratio may be selected at any vehicle speed - even if the transmission is in third or fourth ratio, the transmission will immediately down-shift to second gear pro- vided the vehicle speed is below 137 km / h (85 mile / h). The engine cannot be started in this position.

N.g!b: With the Performance Mode switch in the NORMAL position, the vehicle will pull away in second gear. How- ever, if more than 75 per cent of throttle is applied when the vehicle speed is between zero and 13 km/ h (8 mile / h), then first gear will be selected. From 13 to 61 km/ h (8 to 38 mile/ h) first gear is obtainable by 'kick-down'.

In 'sport' mode thevehicle pulls away in first gear and the transmission operatesfully in all four forward gears.

X300 VSM 1 Issue 1 August 1994