fuse JAGUAR XJ6 1997 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 103 of 227

3261 Jaguar XJ6

5

Chapter 5

Engine electrical systems

Ignition system

Ignition timing (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not adjustable

Ignition coil resistance (at 68°F):

Primary resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 to 0.5 ohms

Secondary resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 to 6.5 k-ohms

Charging system

Charging voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.9 to 15.1 volts

Standard amperage:

No load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 10 amps

Full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 amps or more Amplifier - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Battery cables - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery check, maintenance and charging . . . . . . . . . . . See Chapter 1

Battery - emergency jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Charging system - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Charging system - general information and precautions . . . . . . . . . 10

CHECK ENGINE light . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Distributor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Drivebelt check, adjustment and renewal . . . . . . . . . . . See Chapter 1General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Ignition coil - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ignition system - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ignition system - general information and precautions . . . . . . . . . . . 5

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Spark plug lead, distributor cap and rotor check

and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 15

Starter motor - testing in vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Starter solenoid - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 16

Starting system - general information and precautions . . . . . . . . . . 13

5•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

The engine electrical systems include all

ignition, charging and starting components.

Because of their engine related functions,

these components are discussed separately

from chassis electrical devices such as the

fuses, relays, lights, etc. (which are included in

Chapter 12).

Always observe the following precautions

when working on the electrical systems:

a) Be extremely careful when servicing

engine electrical components. They are

easily damaged if checked, connected or

handled improperly.

b) Never leave the ignition switch on for long

periods of time (10 minutes maximum)

with the engine off.c) Don’t disconnect the battery cables while

the engine is running.

d) Maintain correct polarity when connecting

a battery cable from another vehicle

during jump starting.

e) Always disconnect the negative cable first

and hook it up last or the battery may be

shorted by the tool being used to loosen

the cable clamps.

It’s also a good idea to review the safety-

related information regarding the engine

electrical systems in the Safety first section

near the front of this manual before beginning

any operation included in this Chapter.

2 Battery-

emergency jump starting

1

See “Jump starting”in “Roadside repairs”

at the front of this Manual.

3 Battery- removal and refitting

1

1Disconnect the negative terminal, then the

positive terminal from the battery. On 1989 to

1992 models, the battery is located in the

engine compartment on the passenger side

bulkhead and on 1993 and 1994 models, it is

located in the boot.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Remove the battery hold-down clamp.

3Lift out the battery. Be careful, it’s heavy.

4While the battery is out, inspect the carrier

(tray) for corrosion.

5If you are replacing the battery, make sure

that you get one that’s identical, with the

Page 107 of 227

Refitting

7Insert the distributor into the engine in

exactly the same relationship to the block that

it was in when removed.

8If the distributor does not seat completely,

recheck the alignment marks between the

distributor base and the block to verify that

the distributor is in the same position it was in

before removal. Also check the rotor to see if

it’s aligned with the mark you made on the

edge of the distributor base.

9Refit the distributor hold-down bolt(s).

10The remainder of refitting is the reverse of

removal.

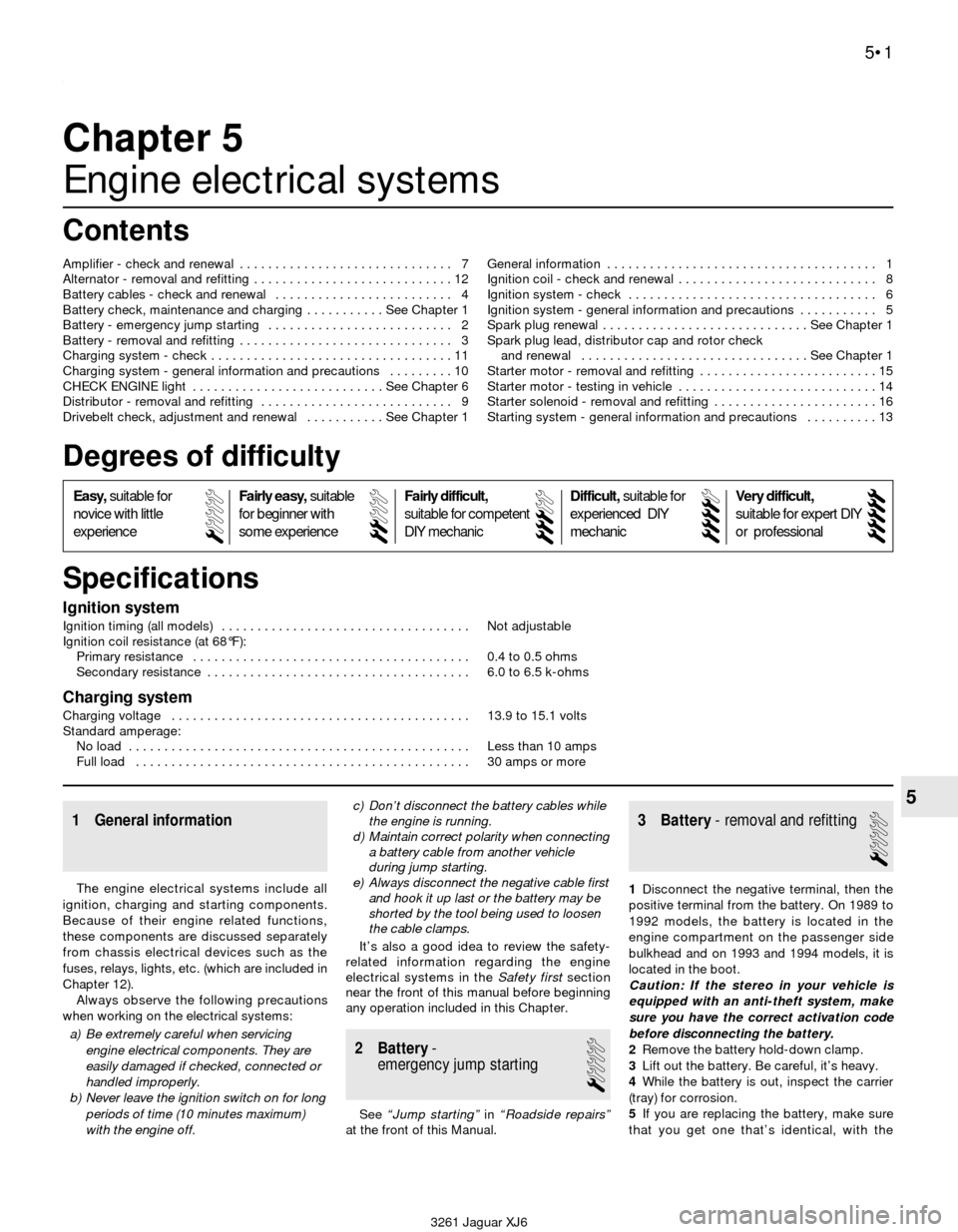

10 Charging system- general

information and precautions

The charging system includes the alternator,

an internal voltage regulator, a charge

indicator light, load dump module, the battery,

an ignition ON relay, an in-line fuse and the

wiring between all the components (see

illustration). The charging system supplies

electrical power for the ignition system, the

lights, the radio, etc. The alternator is driven by

a drivebelt at the front of the engine.

The purpose of the voltage regulator is to

limit the alternator’s voltage to a preset value.

This prevents power surges, circuit overloads,

etc., during peak voltage output.

The alternator load dump module protects

the electrical circuits from excessive voltage

surges. When the battery cables are removed

large amounts of transient voltage is released

through the electrical circuits. This device

diverts up to 30 load volts of excess voltage to

earth by way of a voltage dependent resistor.

The in-line fuse is a special fuse installed

into the circuit with the engine compartment

wiring harness (see Chapter 12). The in-line

fuse protects the electrical system in the

event of excess voltage surges or a power to

earth short circuit. Refer to Chapter 12 for

additional information concerning the in-line

fuses and their locations.

1993 and 1994 models have a Starter Logic

Relay. This microprocessor (computer)

gathers information from the ignition switch,

linear gear position switch, park/neutral

switch, the security switch and the electronic

door lock system. If all the conditions are in

order, the computer allows battery voltage to

be transferred from the ignition switch to the

starter/solenoid assembly.

The charging system doesn’t ordinarily

require periodic maintenance. However, the

drivebelt, battery and wires and connections

should be inspected at the intervals outlined

in Chapter 1.

The dashboard warning light should come

on when the ignition key is turned to Start,

then should go off immediately. If it remains

on, there is a malfunction in the charging

system. Some vehicles are also equipped with

a voltage gauge. If the voltage gaugeindicates abnormally high or low voltage,

check the charging system (see Section 11).

Be very careful when making electrical

circuit connections to a vehicle equipped with

an alternator and note the following:

a) When reconnecting wires to the alternator

from the battery, note their polarity.

b) Before using arc welding equipment to

repair any part of the vehicle, disconnect

the wires from the alternator and the

battery terminals.

c) Never start the engine with a battery

charger connected.

d) Always disconnect both battery leads

before using a battery charger.

e) The alternator is driven by an engine

drivebelt which could cause serious injury

if your hand, hair or clothes become

entangled in it with the engine running.

f) Because the alternator is connected

directly to the battery, it could arc or

cause a fire if overloaded or shorted out.

g) Wrap a plastic bag over the alternator and

secure it with rubber bands before steam

cleaning the engine.

11 Charging system- check

2

Note:1993 and 1994 models are equipped

with a Starter Logic Relay. This microprocessor

(computer) gathers information from theignition switch, linear gear position switch,

park/neutral switch, the security switch and the

electronic door lock system. If all the conditions

are in order, the computer allows battery

voltage to be transferred from the ignition

switch to the starter/solenoid assembly. If all

the components of the charging system are

working properly and the system still does not

charge properly, have the Starter Logic Relay

diagnosed by a dealer service department.

1If a malfunction occurs in the charging

circuit, don’t automatically assume that the

alternator is causing the problem. First check

the following items:

a) Check the drivebelt tension and its

condition. Renew it if worn or damaged.

b) Make sure the alternator mounting and

adjustment bolts are tight.

c) Inspect the alternator wiring harness and

the electrical connectors at the alternator

and voltage regulator. They must be in

good condition and tight.

d) Check the fusible link (if equipped)

located between the starter solenoid and

the alternator or the large main fuses in

the engine compartment. If it’s burned,

determine the cause, repair the circuit

and renew the link or fuse (the vehicle

won’t start and/or the accessories won’t

work if the fusible link or fuse blows).

e) Check all the in-line fuses that are in series

with the charging system circuit (see

Chapter 12).The location of these fuses

and fusible links may vary from year and

Engine electrical systems 5•5

5

10.1 Schematic of a typical charging system

3261 Jaguar XJ6

Page 109 of 227

8After the alternator is installed, adjust the

drivebelt tension (see Chapter 1).

9Check the charging voltage to verify proper

operation of the alternator (see Section 11).

13 Starting system- general

information and precautions

The sole function of the starting system is

to crank the engine over quickly enough to

allow it to start.

The starting system consists of the battery,

the starter motor, the starter solenoid, the

starter relay and the electrical circuit

connecting the components. The solenoid is

mounted directly on the starter motor.

The solenoid/starter motor assembly is

installed on the upper part of the engine, next

to the transmission bellhousing.

When the ignition key is turned to the

START position, the starter solenoid is

actuated through the starter control circuit.

The starter solenoid then connects the battery

to the starter. The battery supplies the

electrical energy to the starter motor, which

does the actual work of cranking the engine.

The starter on a vehicle equipped with an

automatic transmission can be operated only

when the transmission selector lever is in Park

or Neutral.

These vehicles are equipped with either a

Bosch or Lucas starter assembly. The Lucas

unit is distinguished by the separate earth

strap from the solenoid to the starter body.

Bosch starter assemblies are equipped with a

solid metal earthing bar.

The starting system circuit is equipped with

a relay. The relay allows the ignition switch to

power the starter solenoid.

Always observe the following precautions

when working on the starting system:

a) Excessive cranking of the starter motor

can overheat it and cause serious

damage. Never operate the starter motor

for more than 15 seconds at a time

without pausing to allow it to cool for at

least two minutes.

b) The starter is connected directly to the

battery and could arc or cause a fire if

mishandled, overloaded or short circuited.

c) Always detach the cable from the

negative terminal of the battery before

working on the starting system.

Caution:If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

14 Starter motor-

testing in vehicle

2

1Make sure that the battery is charged and

that all cables, both at the battery and starter

solenoid terminals, are clean and secure.2If the starter motor does not turn at all when

the switch is operated, make sure that the

shift lever is in Neutral or Park (automatic

transmission) or that the clutch pedal is

depressed (manual transmission).

3If the starter motor spins but the engine is

not cranking, the overrunning clutch in the

starter motor is slipping and the starter motor

must be renewed.

4If, when the switch is actuated, the starter

motor does not operate at all but the solenoid

clicks, then the problem lies with either the

battery, the main solenoid contacts or the

starter motor itself (or the engine is seized).

5If the solenoid plunger cannot be heard

when the switch is actuated, the battery is

bad, the in-line fuse is burned (the circuit is

open), the starter relay (see illustration)is

defective or the starter solenoid itself is

defective.

6To check the solenoid, connect a jumper

lead between the battery (+) and the ignition

switch terminal (the small terminal) on the

solenoid. If the starter motor now operates,

the solenoid is OK and the problem is in the

ignition switch, linear switch (1988 to 1992),

rotary switch (1993 and 1994) or in the wiring.

7If the starter motor still does not operate,

remove the starter/solenoid assembly for

dismantling, testing and repair.

8If the starter motor cranks the engine at an

abnormally slow speed, first make sure that

the battery is charged and that all terminalconnections are tight. If the engine is partially

seized, or has the wrong viscosity oil in it, it

will crank slowly.

9Run the engine until normal operating

temperature is reached, then disconnect the

coil wire from the distributor cap and earth it

on the engine.

10Connect a voltmeter positive lead to the

battery positive post and connect the

negative lead to the negative post.

11Crank the engine and take the voltmeter

readings as soon as a steady figure is

indicated. Do not allow the starter motor to

turn for more than 15 seconds at a time. A

reading of nine volts or more, with the starter

motor turning at normal cranking speed, is

normal. If the reading is nine volts or more but

the cranking speed is slow, the motor is faulty.

If the reading is less than nine volts and the

cranking speed is slow, the solenoid contacts

are probably burned, the starter motor is bad,

the battery is discharged or there is a bad

connection.

15 Starter motor-

removal and refitting

2

1Detach the cable from the negative terminal

of the battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Raise the vehicle and support it securely

using axle stands.

3Drain the transmission fluid (see Chapter 7)

and remove the transmission fluid filler tube

from the transmission.

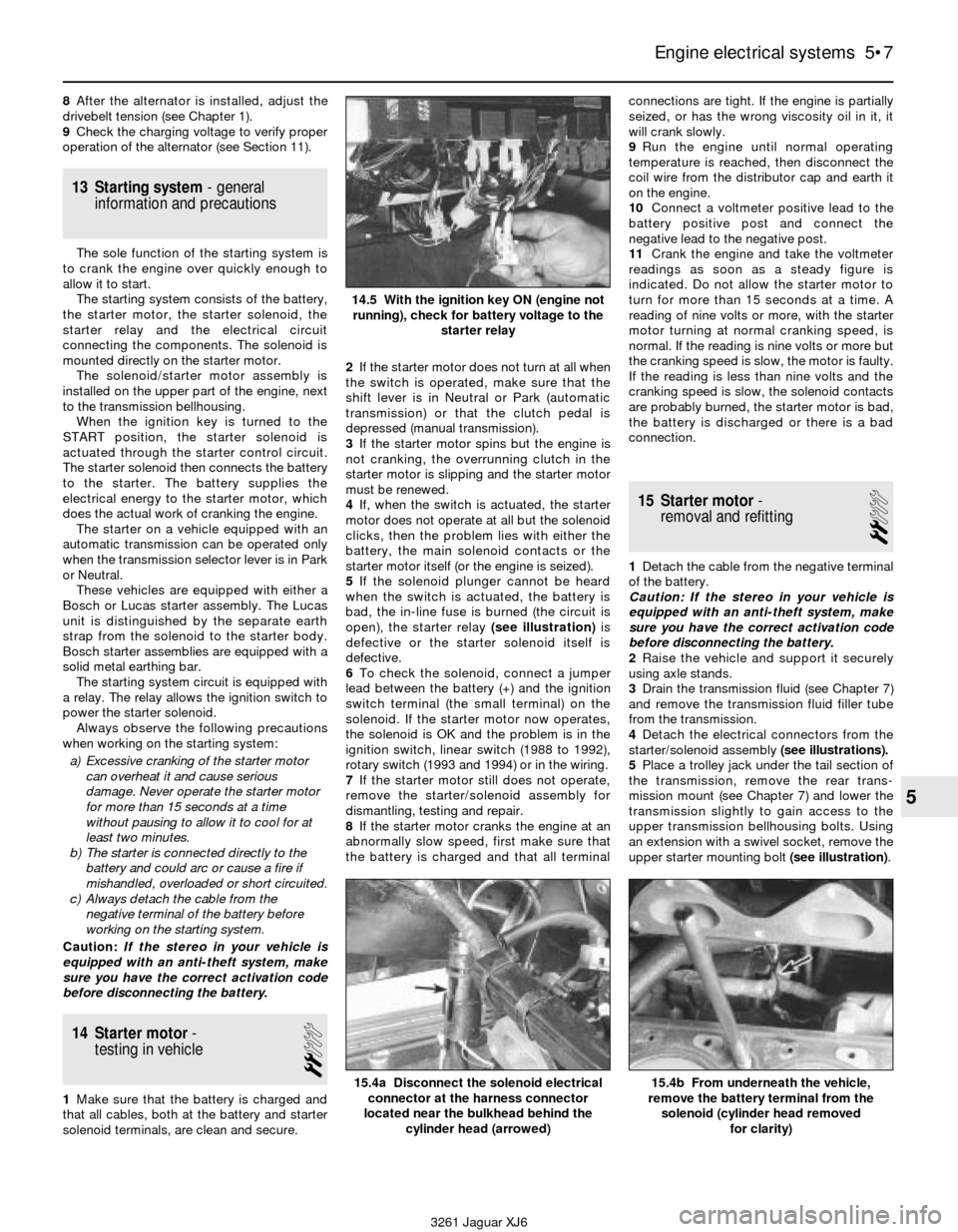

4Detach the electrical connectors from the

starter/solenoid assembly (see illustrations).

5Place a trolley jack under the tail section of

the transmission, remove the rear trans-

mission mount (see Chapter 7) and lower the

transmission slightly to gain access to the

upper transmission bellhousing bolts. Using

an extension with a swivel socket, remove the

upper starter mounting bolt (see illustration).

Engine electrical systems 5•7

5

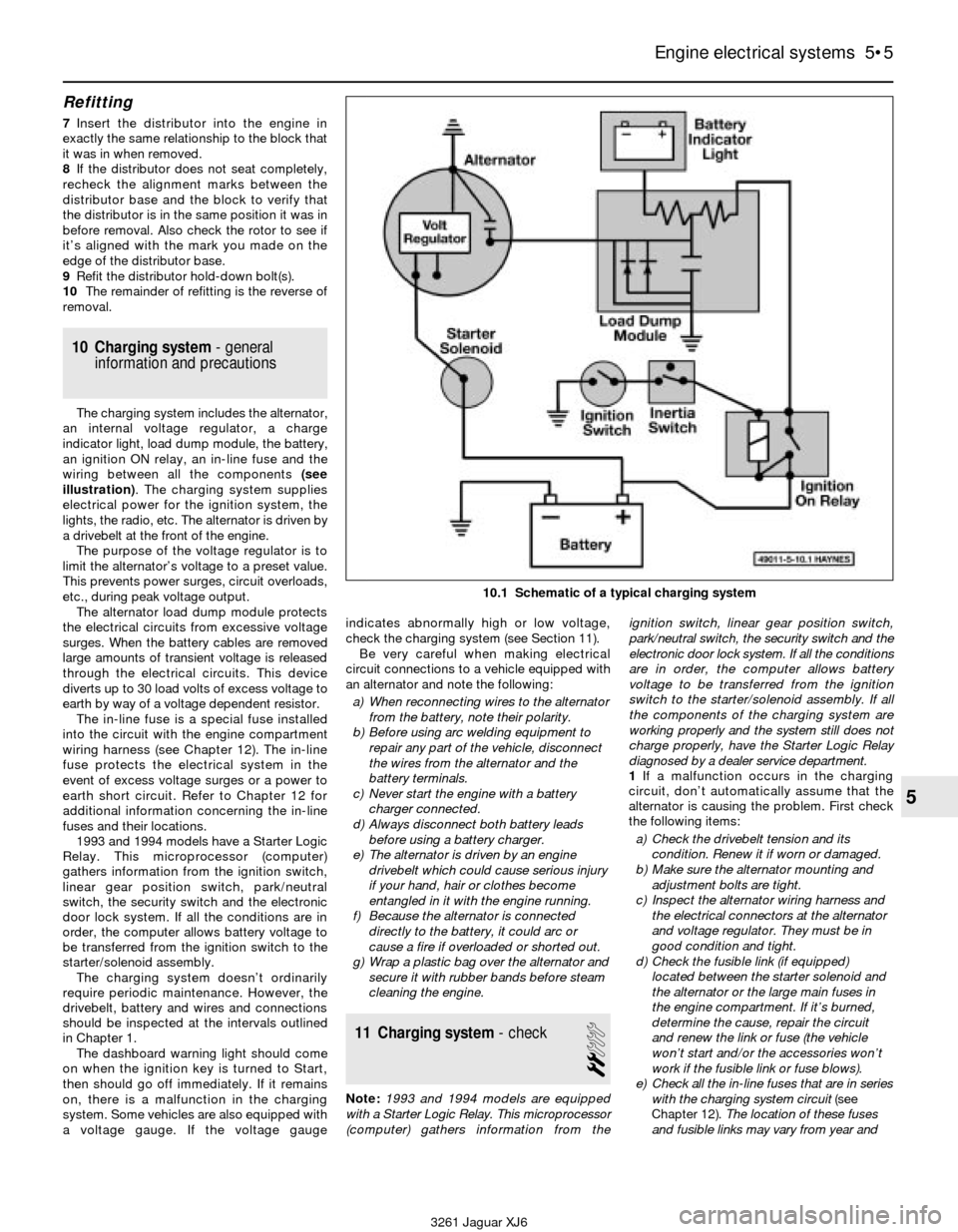

14.5 With the ignition key ON (engine not

running), check for battery voltage to the

starter relay

15.4a Disconnect the solenoid electrical

connector at the harness connector

located near the bulkhead behind the

cylinder head (arrowed)15.4b From underneath the vehicle,

remove the battery terminal from the

solenoid (cylinder head removed

for clarity)

3261 Jaguar XJ6

Page 124 of 227

Test the brakes at various speeds with both

light and heavy pedal pressure. The vehicle

should stop evenly without pulling to one side

or the other. Avoid locking the brakes,

because this slides the tyres and diminishes

braking efficiency and control of the vehicle.

Tyres, vehicle load and wheel alignment are

factors which also affect braking performance.

2 Anti-lock Brake system

(ABS)- general information

The Anti-lock Brake System is designed to

maintain vehicle steerability, directional stability

and optimum deceleration under severe

braking conditions on most road surfaces. It

does so by monitoring the rotational speed of

each wheel and controlling the brake line

pressure to each wheel during braking. This

prevents the wheels from locking up.

The ABS system has three main units - the

wheel speed sensors, the electronic control unit

and the modulator (hydraulic control unit). The

sensors - one at each wheel - send a variable

voltage signal to the electronic control unit,

which monitors these signals, compares them

to its program and determines whether a wheel

is about to lock up. When a wheel is about to

lock up, the control unit signals the hydraulic

unit to reduce hydraulic pressure (or not

increase it further) at that wheel’s brake caliper.

Pressure modulation is handled by three

electrically-operated solenoid valves - one for

each front wheel and one for the rear wheels -

inside the modulator.

If a problem develops within the system, an

“ABS” warning light will glow on the dashboard.

Sometimes, a visual inspection of the ABS

system can help you locate the problem.

Carefully inspect the ABS wiring harness. Pay

particularly close attention to the harness and

connections near each wheel. Look for signs of

chafing and other damage caused by

incorrectly routed wires. If a wheel sensor

harness is damaged, the sensor should be

replaced (the harness and sensor are integral).

Warning: Do NOT try to repair an

ABS wiring harness. The ABS

system is sensitive to even thesmallest changes in resistance. Repairing

the harness could alter resistance values

and cause the system to malfunction. If the

ABS wiring harness is damaged in any way,

it must be replaced.

Caution: Make sure the ignition is turned

off before unplugging or reattaching any

electrical connections.

Diagnosis and repair

If a dashboard warning light comes on and

stays on while the vehicle is in operation, the

ABS system requires attention. Although

special electronic ABS diagnostic testing tools

are necessary to properly diagnose the system,

you can perform a few preliminary checks

before taking the vehicle to a dealer service

department or other qualified repair workshop.

a) Check the brake fluid level in the master

cylinder reservoir.

b) Verify that all ABS system electrical

connectors in the engine compartment

are plugged in.

c) Check the fuses.

d) Follow the wiring harness to each front

wheel and to the differential sensor and

verify that all connections are secure and

that the wiring is undamaged.

If the above preliminary checks do not

rectify the problem, the vehicle should be

diagnosed by a dealer service department.

Due to the complex nature of this system, all

actual repair work must be done by a dealer

service department or other qualified repair

workshop.

3 Disc brake pads- renewal

2

Warning: Disc brake pads must

be replaced on both front wheels

or both rear wheels at the same

time - never renew the pads on

only one wheel. Also, the dust created by

the brake system may contain asbestos,

which is harmful to your health. Never blow

it out with compressed air and don’t inhale

any of it. An approved filtering mask should

be worn when working on the brakes. Do

not, under any circumstances, use

petroleum-based solvents to clean brake

parts. Use brake system cleaner only!

Note:The following procedure applies to both

the front and rear brake pads.

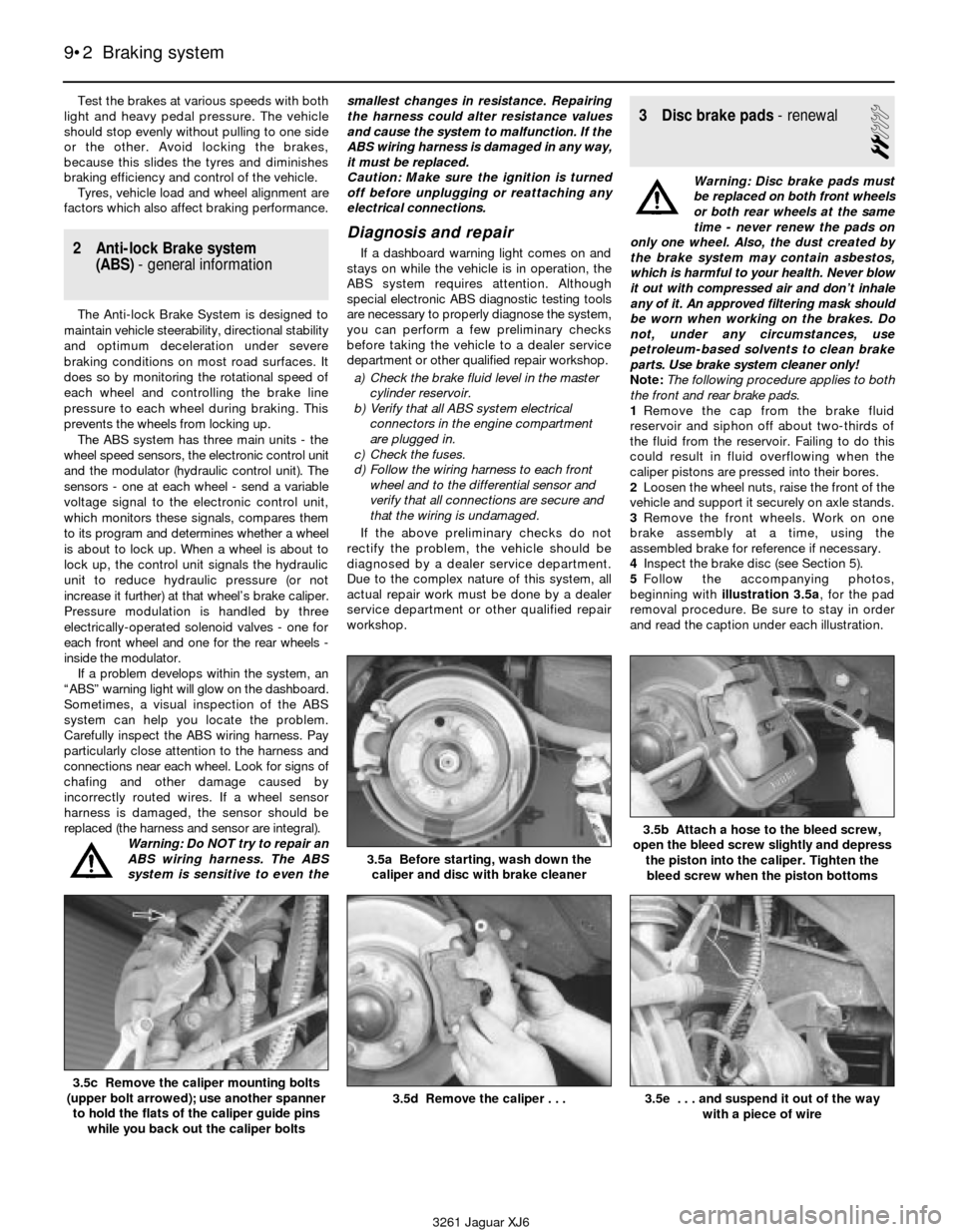

1Remove the cap from the brake fluid

reservoir and siphon off about two-thirds of

the fluid from the reservoir. Failing to do this

could result in fluid overflowing when the

caliper pistons are pressed into their bores.

2Loosen the wheel nuts, raise the front of the

vehicle and support it securely on axle stands.

3Remove the front wheels. Work on one

brake assembly at a time, using the

assembled brake for reference if necessary.

4Inspect the brake disc (see Section 5).

5Follow the accompanying photos,

beginning with illustration 3.5a, for the pad

removal procedure. Be sure to stay in order

and read the caption under each illustration.

9•2 Braking system

3.5a Before starting, wash down the

caliper and disc with brake cleaner

3.5b Attach a hose to the bleed screw,

open the bleed screw slightly and depress

the piston into the caliper. Tighten the

bleed screw when the piston bottoms

3.5c Remove the caliper mounting bolts

(upper bolt arrowed); use another spanner

to hold the flats of the caliper guide pins

while you back out the caliper bolts3.5d Remove the caliper . . .3.5e . . . and suspend it out of the way

with a piece of wire

3261 Jaguar XJ6

Page 135 of 227

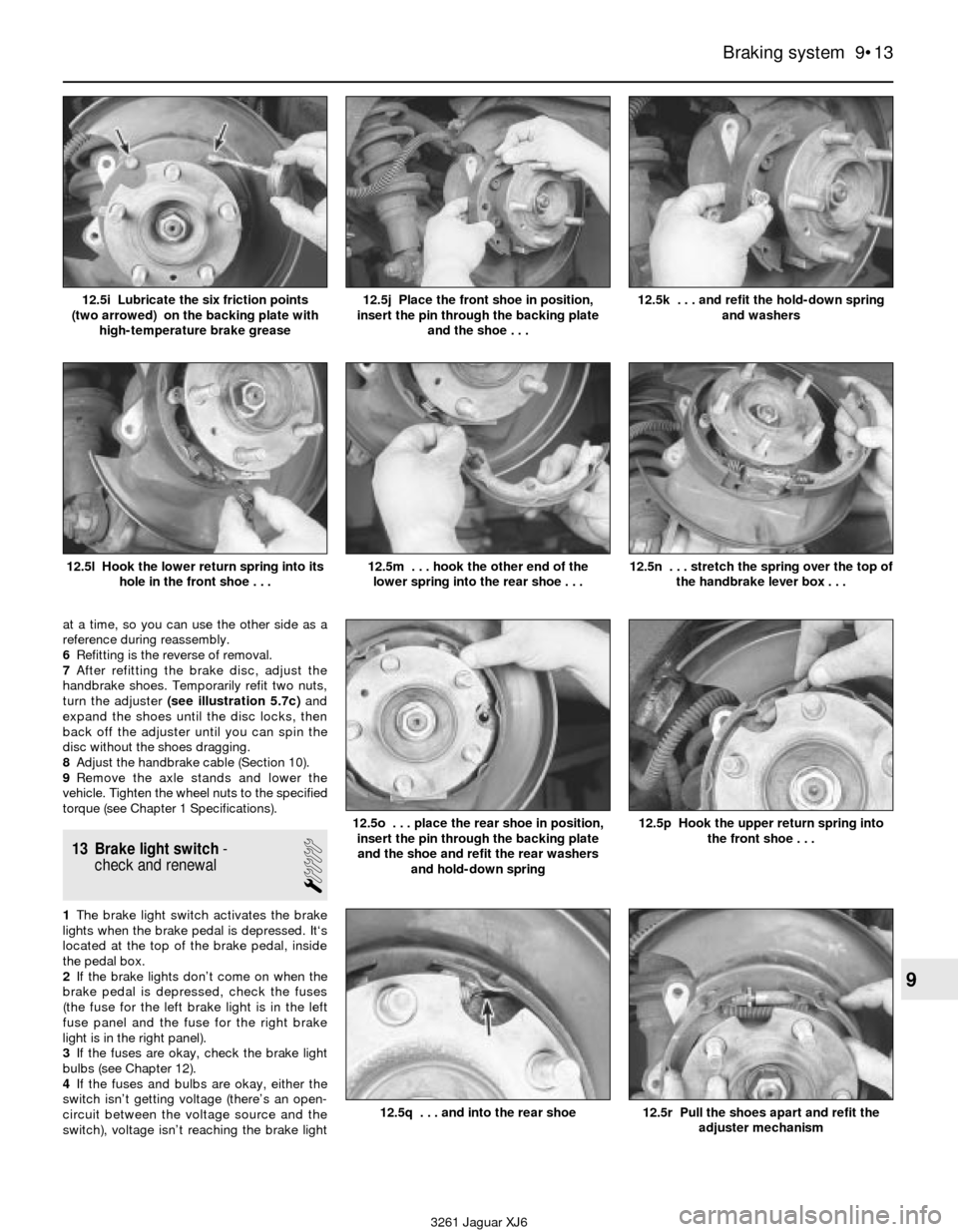

at a time, so you can use the other side as a

reference during reassembly.

6Refitting is the reverse of removal.

7After refitting the brake disc, adjust the

handbrake shoes. Temporarily refit two nuts,

turn the adjuster (see illustration 5.7c)and

expand the shoes until the disc locks, then

back off the adjuster until you can spin the

disc without the shoes dragging.

8Adjust the handbrake cable (Section 10).

9Remove the axle stands and lower the

vehicle. Tighten the wheel nuts to the specified

torque (see Chapter 1 Specifications).

13 Brake light switch-

check and renewal

1

1The brake light switch activates the brake

lights when the brake pedal is depressed. It‘s

located at the top of the brake pedal, inside

the pedal box.

2If the brake lights don’t come on when the

brake pedal is depressed, check the fuses

(the fuse for the left brake light is in the left

fuse panel and the fuse for the right brake

light is in the right panel).

3If the fuses are okay, check the brake light

bulbs (see Chapter 12).

4If the fuses and bulbs are okay, either the

switch isn’t getting voltage (there’s an open-

circuit between the voltage source and the

switch), voltage isn’t reaching the brake light

Braking system 9•13

9

12.5j Place the front shoe in position,

insert the pin through the backing plate

and the shoe . . .12.5k . . . and refit the hold-down spring

and washers12.5i Lubricate the six friction points

(two arrowed) on the backing plate with

high-temperature brake grease

3261 Jaguar XJ6 12.5l Hook the lower return spring into its

hole in the front shoe . . .

12.5m . . . hook the other end of the

lower spring into the rear shoe . . .12.5n . . . stretch the spring over the top of

the handbrake lever box . . .

12.5o . . . place the rear shoe in position,

insert the pin through the backing plate

and the shoe and refit the rear washers

and hold-down spring12.5p Hook the upper return spring into

the front shoe . . .

12.5q . . . and into the rear shoe12.5r Pull the shoes apart and refit the

adjuster mechanism

Page 163 of 227

3261 Jaguar XJ6

12

Chapter 12

Body electrical system

1 General information

The electrical system is a 12-volt, negative

earth type. Power for the lights and all

electrical accessories is supplied by a

lead/acid-type battery which is charged by

the alternator.

This Chapter covers repair and service

procedures for the various electrical

components not associated with the engine.

Information on the battery, alternator,

distributor and starter motor will be found in

Chapter 5.

It should be noted that when portions of the

electrical system are serviced, the cable

should be disconnected from the negative

battery terminal to prevent electrical shorts

and/or fires.

2 Electrical fault finding-

general information

A typical electrical circuit consists of an

electrical component, any switches, relays,

motors, fuses, fusible links, in-line fuses or

circuit breakers related to that component

and the wiring and electrical connectors that

link the component to both the battery andthe chassis. To help you pinpoint an electrical

circuit problem, wiring diagrams are included

at the end of this Chapter.

Before tackling any troublesome electrical

circuit, first study the appropriate wiring

diagrams to get a complete understanding of

what makes up that individual circuit. Trouble

spots, for instance, can often be narrowed

down by noting if other components related to

the circuit are operating properly. If several

components or circuits fail at one time,

chances are the problem is in a fuse or earth

connection, because several circuits are often

routed through the same fuse and earth

connections.

Electrical problems usually stem from

simple causes, such as loose or corroded

connections, a blown fuse, a melted fusible

link or a bad relay. Visually inspect the

condition of all fuses, wires and connections

in a problem circuit before diagnosing it.

If testing instruments are going to be

utilised, use the diagrams to plan ahead of

time where you will make the necessary

connections in order to accurately pinpoint

the trouble spot.

The basic tools needed for electrical fault

finding include a circuit tester or voltmeter (a

12-volt bulb with a set of test leads can also

be used), a continuity tester, which includes a

bulb, battery and set of test leads, and a

jumper wire, preferably with a circuit breaker

incorporated, which can be used to bypasselectrical components. Before attempting to

locate a problem with test instruments,

use the wiring diagram(s) to decide where to

make the connections.

Voltage checks

Voltage checks should be performed if a

circuit is not functioning properly. Connect

one lead of a circuit tester to either the

negative battery terminal or a known good

earth. Connect the other lead to a electrical

connector in the circuit being tested,

preferably nearest to the battery or fuse. If the

bulb of the tester lights, voltage is present,

which means that the part of the circuit

between the electrical connector and the

battery is problem free. Continue checking the

rest of the circuit in the same fashion. When

you reach a point at which no voltage is

present, the problem lies between that point

and the last test point with voltage. Most of

the time the problem can be traced to a loose

connection. Note:Keep in mind that some

circuits receive voltage only when the ignition

key is in the Accessory or Run position.

Finding a short

One method of finding shorts in a circuit is

to remove the fuse and connect a test light or

voltmeter in its place. There should be no

voltage present in the circuit. Move the wiring

harness from side to side while watching the

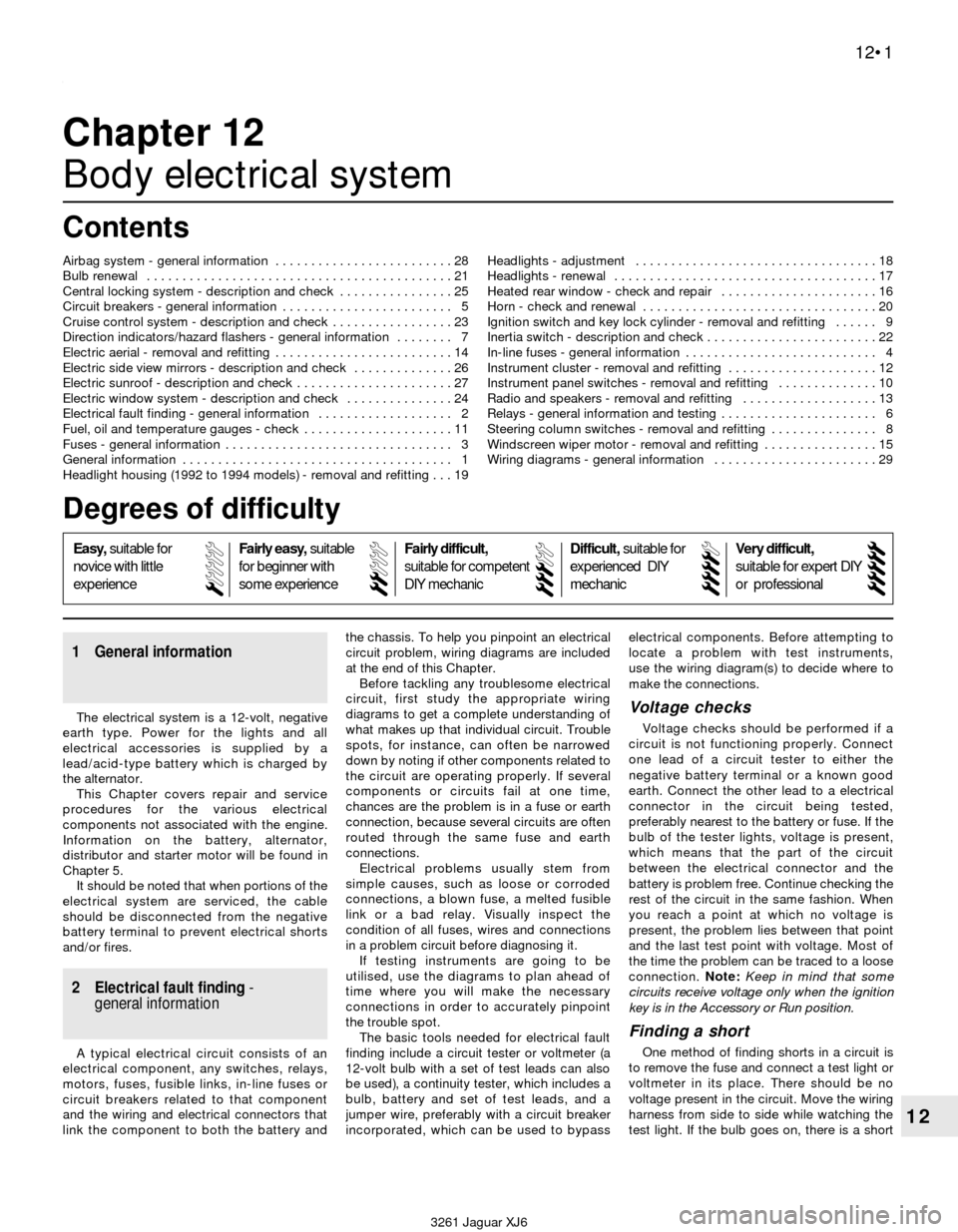

test light. If the bulb goes on, there is a short Airbag system - general information . . . . . . . . . . . . . . . . . . . . . . . . . 28

Bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Central locking system - description and check . . . . . . . . . . . . . . . . 25

Circuit breakers - general information . . . . . . . . . . . . . . . . . . . . . . . . 5

Cruise control system - description and check . . . . . . . . . . . . . . . . . 23

Direction indicators/hazard flashers - general information . . . . . . . . 7

Electric aerial - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electric side view mirrors - description and check . . . . . . . . . . . . . . 26

Electric sunroof - description and check . . . . . . . . . . . . . . . . . . . . . . 27

Electric window system - description and check . . . . . . . . . . . . . . . 24

Electrical fault finding - general information . . . . . . . . . . . . . . . . . . . 2

Fuel, oil and temperature gauges - check . . . . . . . . . . . . . . . . . . . . . 11

Fuses - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlight housing (1992 to 1994 models) - removal and refitting . . . 19Headlights - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Headlights - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Heated rear window - check and repair . . . . . . . . . . . . . . . . . . . . . . 16

Horn - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ignition switch and key lock cylinder - removal and refitting . . . . . . 9

Inertia switch - description and check . . . . . . . . . . . . . . . . . . . . . . . . 22

In-line fuses - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Instrument cluster - removal and refitting . . . . . . . . . . . . . . . . . . . . . 12

Instrument panel switches - removal and refitting . . . . . . . . . . . . . . 10

Radio and speakers - removal and refitting . . . . . . . . . . . . . . . . . . . 13

Relays - general information and testing . . . . . . . . . . . . . . . . . . . . . . 6

Steering column switches - removal and refitting . . . . . . . . . . . . . . . 8

Windscreen wiper motor - removal and refitting . . . . . . . . . . . . . . . . 15

Wiring diagrams - general information . . . . . . . . . . . . . . . . . . . . . . . 29

12•1

Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 164 of 227

to earth somewhere in that area, probably

where the insulation has rubbed through. The

same test can be performed on each

component in the circuit, even a switch.

Earth check

Perform an earth test to check whether a

component is properly earthed. Disconnect

the battery and connect one lead of a self-

powered test light, known as a continuity

tester, to a known good earth. Connect the

other lead to the wire or earth connection

being tested. If the bulb goes on, the earth is

good. If the bulb does not go on, the earth is

not good.

Continuity check

A continuity check is done to determine if

there are any breaks in a circuit - if it is

passing electricity properly. With the circuit off

(no power in the circuit), a self-powered

continuity tester can be used to check the

circuit. Connect the test leads to both ends of

the circuit (or to the “power” end and a good

earth), and if the test light comes on the circuit

is passing current properly. If the light doesn’t

come on, there is a break somewhere in the

circuit. The same procedure can be used

to test a switch, by connecting the continuity

tester to the power in and power out sides of

the switch. With the switch turned On, the test

light should come on.

Finding an open circuit

When diagnosing for possible open circuits,

it is often difficult to locate them by sight

because oxidation or terminal misalignment

are hidden by the electrical connectors.

Merely wiggling an electrical connector on a

sensor or in the wiring harness may correct

the open circuit condition. Remember this

when an open circuit is indicated when

diagnosing a circuit. Intermittent problems

may also be caused by oxidised or loose

connections.Electrical fault finding is simple if you keep

in mind that all electrical circuits are basically

electricity running from the battery, through

the wires, switches, relays, fuses and fusible

links to each electrical component (light bulb,

motor, etc.) and to earth, from which it is

passed back to the battery. Any electrical

problem is an interruption in the flow of

electricity to and from the battery.

3 Fuses- general information

The electrical circuits of the vehicle are

protected by a combination of fuses, circuit

breakers and In-line fuses. The fuse blocks

are located in the left and right side kick

panels and in the centre console glove box

(see illustrations).

Each of the fuses is designed to protect a

specific circuit, and the various circuits are

identified on the fuse panel cover.

Miniaturised fuses are employed in the fuse

blocks. These compact fuses, with blade

terminal design, allow fingertip removal and

renewal. If an electrical component fails,

always check the fuse first. The best way tocheck the fuses is with a test light. Check for

power at the exposed terminal tips of each

fuse. If power is present on one side of the

fuse but not the other, the fuse is blown. A

blown fuse can be confirmed by visual

inspection (see illustration).

Be sure to renew blown fuses with the

correct type. Fuses of different ratings are

physically interchangeable, but only fuses of

the proper rating should be used. Replacing a

fuse with one of a higher or lower value than

specified is not recommended. Each electrical

circuit needs a specific amount of protection.

The amperage value of each fuse is moulded

into the fuse body.

If the renewal fuse immediately fails, don’t

renew it again until the cause of the problem

is isolated and corrected. In most cases, this

will be a short circuit in the wiring caused by a

broken or deteriorated wire.

4 In-line fuses-

general information

Some circuits are protected by in-line

fuses. In-line fuses are used in such circuits

as the windscreen wiper system, headlight

12•2 Body electrical system

3261 Jaguar XJ6 3.1a The left side fusebox is located in the passenger’s side kick

panel, behind the fuse panel cover

3.1b The right side fusebox is located in the driver’s side kick

panel, behind the fuse panel cover

3.1c A third fusebox is located in the

centre console glove box3.3 When a fuse blows, the metal element

between the terminals melts - the fuse on

the left is blown, the one on the right is ok

Page 165 of 227

wash system, radio memory and the ABS

main feed and pump circuits.

In-line fuses are located through out the

vehicle depending on the year, make and

model. Consult the wiring diagrams at the end

of this Chapter for further information.

In-line fuses also have a blade terminal

design, which allow fingertip removal and

renewal. If an electrical component fails,

always check the fuse first. A blown fuse is

easily identified through the clear plastic

body. Inspect the element for evidence of

damage (see illustration 3.3).

Be sure to renew blown fuses with the

correct type. Fuses are usually colour-coded

to indicate their rating. Fuses of different

ratings are physically interchangeable, but

only fuses of the proper rating should be

used. Replacing a fuse with one of a different

value than specified is not recommended.

Each electrical circuit needs a specific

amount of protection. The amperage value of

each fuse is moulded into the fuse body.If the renewal fuse immediately fails, don’t

renew it again until the cause of the problem

is isolated and corrected. Don’t substitute

anything else for the fuse. In most cases, this

will be a short circuit in the wiring caused by a

broken or deteriorated wire.

5 Circuit breakers-

general information

Circuit breakers generally protect

components such as electric windows, central

locking and headlights. On some models the

circuit breaker resets itself automatically, so

an electrical overload in the circuit will cause it

to fail momentarily, then come back on. If the

circuit doesn’t come back on, check it

immediately. Once the condition is corrected,

the circuit breaker will resume its normal

function. Some circuit breakers have a button

on top and must be reset manually.To test a circuit breaker, use an ohmmeter

to check continuity between the terminals. A

reading of zero to 1.0 ohms indicates a good

circuit breaker. An open circuit reading on the

meter indicates a bad circuit breaker.

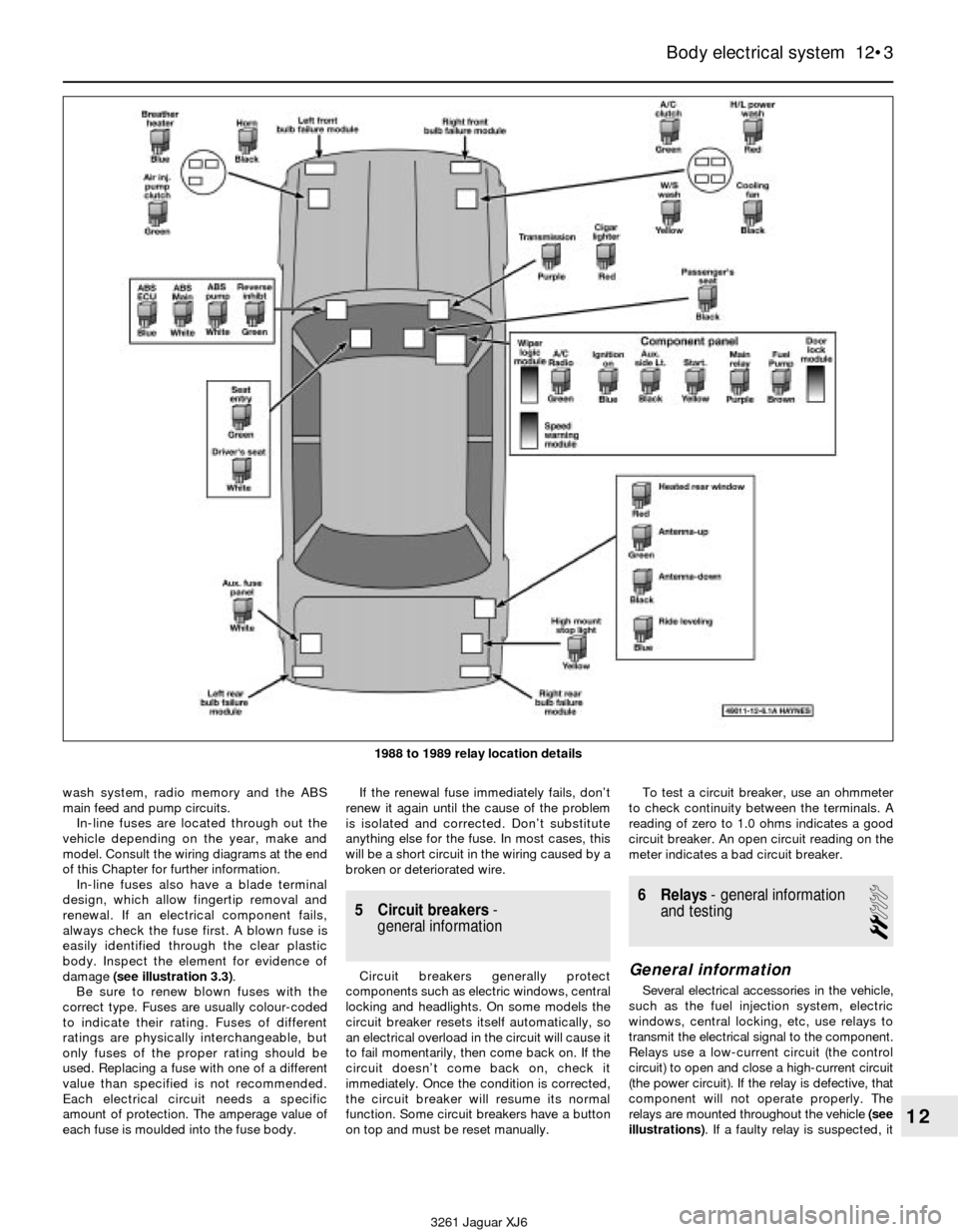

6 Relays- general information

and testing

2

General information

Several electrical accessories in the vehicle,

such as the fuel injection system, electric

windows, central locking, etc, use relays to

transmit the electrical signal to the component.

Relays use a low-current circuit (the control

circuit) to open and close a high-current circuit

(the power circuit). If the relay is defective, that

component will not operate properly. The

relays are mounted throughout the vehicle (see

illustrations). If a faulty relay is suspected, it

Body electrical system 12•3

12

3261 Jaguar XJ6 1988 to 1989 relay location details

Page 166 of 227

can be removed and tested using the

procedure below or by a dealer service

department or a repair workshop. Defective

relays must be replaced as a unit.

Testing

1It’s best to refer to the wiring diagram for

the circuit to determine the proper

connections for the relay you’re testing.

However, if you’re not able to determine the

correct connection from the wiring diagrams,

you may be able to determine the test

connections from the information that follows.

2On most relays, two of the terminals are the

relay’s control circuit (they connect to the

relay coil which, when energised, closes the

large contacts to complete the circuit). The

other terminals are the power circuit (they are

connected together within the relay when the

control-circuit coil is energised).

3Relays are sometimes marked as an aid to

help you determine which terminals are the

control circuit and which are the powercircuit (see illustration). As a general rule,

the two thicker wires connected to the relay

are the power circuit; the thinner wires are

the control circuit.

4Remove the relay from the vehicle and check

for continuity between the relay power circuit

terminals. There should be no continuity.5Connect a fused jumper wire between one

of the two control circuit terminals and the

positive battery terminal. Connect another

jumper wire between the other control circuit

terminal and earth. When the connections are

made, the relay should click. On some relays,

polarity may be critical, so, if the relay doesn’t

click, try swapping the jumper wires on the

control circuit terminals.

6With the jumper wires connected, check for

continuity between the power circuit

terminals. Now, there should be continuity.

8If the relay fails any of the above tests,

renew it.

7 Direction indicator/hazard

flasher- general information

Warning: Later model vehicles

are equipped with airbags. To

prevent accidental deployment6.3 Most relays are marked on the outside

to easily identify the control circuit and

power circuits

12•4 Body electrical system

3261 Jaguar XJ6 1990 to 1992 relay location details

Page 169 of 227

11 Fuel, oil and temperature

gauges- check

1

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbag

equipped models, the following procedure

be performed at a dealer service

department or other properly equipped

repair facility because of the special tools

and techniques required to disable the

airbag system.

1All tests below require the ignition switch to

be turned to ON position when testing.

2Check the fuse if the gauge pointer does

not move from the empty, low or cold

positions. If the fuse is OK, locate the

particular sender unit for the circuit you’re

working on (see Chapter 4 for fuel sender unit

location, Chapter 2 for oil sender unit location,

or Chapter 3 for temperature sender unit

location). Connect the sender unit connector

to earth If the pointer goes to the full, high or

hot position renew the sender unit. If the

pointer stays in same position use a jumper

wire to earth the terminal on the back of the

gauge. If the pointer moves with the back of

the gauge earthed the problem lies in the wire

between the gauge and the sender unit. If the

pointer does not moves with the back of the

gauge earthed check for voltage at the other

terminal of the gauge. If voltage is present

renew the gauge.

12 Instrument cluster-

removal and refitting

1

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbag

equipped models, the following procedure

be performed at a dealer service

department or other properly equipped

repair facility because of the special tools

and techniques required to disable the

airbag system.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Disconnect the negative battery cable.

2Remove the instrument cluster housing (see

Chapter 11).

3Remove the instrument cluster mounting

screws (see illustration). Separate the

instrument cluster from the cluster housing.

4Refitting is the reverse of removal.

13 Radio and speakers-

removal and refitting

2

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbagequipped models, the following procedure

be performed at a dealer service

department or other properly equipped

repair facility because of the special tools

and techniques required to disable the

airbag system.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Disconnect the negative battery cable.

Radio

2Remove the radio trim bezel (Chapter 11).

3Remove the retaining screws (see

illustration), pull the radio/control panel

outward to access the backside and

disconnect the electrical connectors and

aerial lead. Detach the retaining clips and

separate the radio from the control panel.

4Refitting is the reverse of removal.

Speakers

5Remove the door trim panel (Chapter 11).

6Remove the nuts from the speaker

mounting studs (see illustration). Disconnect

the electrical connector and remove the

speaker from the vehicle.

7Refitting is the reverse of removal.

Body electrical system 12•7

12

3261 Jaguar XJ6 12.3 Remove the instrument cluster retaining screws (arrowed)

then separate the instrument cluster from the cluster housing

13.3 Remove the retaining screws (arrowed) and pull the

radio/control panel out enough to unplug the connectors

13.6 Remove the nuts from the retaining

studs (arrowed) to remove the speaker