steering JAGUAR XJ6 1997 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 39 of 227

Torque wrench settings*Nm lbf ft

Camshaft bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Camshaft sprocket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Crankshaft damper-to-crankshaft bolt

3.2 and 3.6 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204 151

4.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 to 220 133 to 162

Crankshaft pulley to damper bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Crankshaft rear oil seal retainer bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Crankshaft sensor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Cylinder head bolts

Step 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 44

Step 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten an additional 90° (1/4 turn)

Driveplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 to 149 91 to 110

Engine mounts

To engine block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 to 66 36 to 39

To chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 24 16 to 18

Exhaust manifold heat shield fasteners . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Exhaust manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Intake manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Sump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Sump bolts, adapter to pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 to 54 36 to 40

Timing chain cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 to 27 16 to 20

Valve cover screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 to 12 7 to 9

*Note:Refer to Part B for additional specifications

2A•2 Engine in-car repair procedures

3261 Jaguar XJ6

1 General information

This Part of Chapter 2 is devoted to in-car

repair procedures for the in-line six-cylinder

engines. All information concerning engine

removal and refitting and engine block and

cylinder head overhaul can be found in Part B

of this Chapter.

The following repair procedures are based

on the assumption that the engine is installed

in the car. If the engine has been removed

from the car and mounted on a stand, many of

the steps outlined in this Part of Chapter 2 will

not apply. We have photographed some in-

car engine procedures with the engine on a

stand for photographic purposes.

The Specifications included in this Part of

Chapter 2 apply only to the procedures

contained in this Part. Part B of Chapter 2

includes the Specifications necessary for

cylinder head and engine block rebuilding.

2 Repair operations possible

with the engine in the car

Many repair operations can be

accomplished without removing the engine

from the car.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier and help keep dirt out of

the internal areas of the engine.

Depending on the components involved, itmay be helpful to remove the bonnet to

improve access to the engine as repairs are

performed (refer to Chapter 11 if necessary).

Cover the wings to prevent damage to the

paint. Special pads are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for gasket or seal

renewal, the repairs can generally be made

with the engine in the car. The intake and

exhaust manifold gaskets, crankshaft oil seals

and cylinder head gasket are all accessible

with the engine in place (although rear oil seal

renewal involves removal of the transmission).

The sump is difficult for a home mechanic to

replace without a hoist and other specialised

equipment, since the front suspension,

steering and crossmember must be lowered

to allow enough clearance for sump removal.

If such equipment is not available, the

alternative would be to remove the engine for

renewal of the sump or oil pump. Note:We

assume that the home mechanic does not

have access to the specialised equipment,

and have photographed our subject engine

out of the car for some procedures.

Exterior engine components, such as the

intake and exhaust manifolds, the water

pump, the starter motor, the alternator, the

distributor and the fuel system components

can be removed for repair with the engine in

place.

Since the cylinder head can be removed

with the engine in-car, camshaft and valve

component servicing can also be

accomplished. Renewal of the timing chains

and sprockets is also possible with the engine

in-car.

3 Top Dead Centre (TDC) for

number one piston- locating

1

Note:The following procedure is based on the

assumption that the distributor is correctly

installed. If you are trying to locate TDC to refit

the distributor correctly, piston position must

be determined by feeling for compression at

the number one spark plug hole, then aligning

the ignition timing marks (see paragraph 8).

1Top Dead Centre (TDC) is the highest point

in the cylinder that each piston reaches as it

travels up the cylinder bore. Each piston

reaches TDC on the compression stroke and

again on the exhaust stroke, but TDC

generally refers to piston position on the

compression stroke.

2Positioning the piston(s) at TDC is an

essential part of many procedures such as

camshaft and timing chain/sprocket removal

and distributor removal.

3Before beginning this procedure, be sure to

place the transmission in Neutral and apply

the handbrake or block the rear wheels. Also,

disable the ignition system by detaching the

coil wire from the centre terminal of the

distributor cap and grounding it on the engine

block with a jumper wire. Remove the spark

plugs (see Chapter 1).

4In order to bring any piston to TDC, the

crankshaft must be turned using one of the

methods outlined below. When looking at the

timing chain end of the engine, normal

crankshaft rotation is clockwise.

a) The preferred method is to turn the

crankshaft with a socket and ratchet

Page 45 of 227

23Clean and lubricate the lower tensioner.

Fill the lower tensioner oil reservoir with engine

oil and refit it on the engine block, aligning the

notch in the tensioner with the lug on the back

of the guide (see illustrations). This should

remove all slack from the lower timing chain. If

not, push the lower tensioner guide back and

forth a few times to prime the tensioner.

24Refit the upper chain tensioner guide and

mounting bracket to the engine block.

Caution: Before fully tightening the

mounting bracket to the engine block,

make sure the mount and chain guide are

clear of the lower chain, auxiliary sprocket

and intermediate sprocket. If necessary,

position the mount for clearance before

tightening the mounting bolts.

25Refit the oil pump drive chain and

sprocket to the crankshaft (see Section 13).

26Refit the upper chain fixed guide to the

engine block and place the upper timing chain

over the intermediate sprocket and auxiliary

shaft sprocket, draping the excess chain over

the top of the fixed guide. Lubricate the chain

and sprockets with clean engine oil.27Gather the loose portion of the upper

timing chain and place it between the upper

guides. Use a large rubber band to hold the

two guides snugly around the chain (see

Section 11).

28If necessary, renew the intermediate shaft

seal (see illustrations).

29Apply a thin coat of RTV sealant to the

engine side of the front cover and RTV sealant

to the oil-pan mating surface (bottom of the

front cover), then refit the front cover. Note:

Make sure the top surface of the cover aligns

with the top surface of the engine block, by

checking with a straightedge(see illustration).

30Refer to Section 11 for refitting of the

cylinder head and Section 10 for refitting of

the camshafts and connection of the upper

timing chain to the two camshaft sprockets.

31The remainder of the refitting is the

reverse of the removal procedure. If your car

is equipped with the hydraulic/self-levelling

suspension, refit the drive coupling and

coupling disc to the intermediate shaft (see

illustrations 8.9a and 8.9b). Coat the

mounting surface of the pump with RTVsealant and make sure the tang on the pump

aligns with the slot in the intermediate shaft

before bolting the pump to the front cover.

Refer to Section 7 for refitting of the

crankshaft spacer, damper and puller.

Caution: DO NOT start the engine until

you’re absolutely certain that the timing

chains are installed correctly. Serious and

costly engine damage could occur if the

chains are installed wrong.

32Run the engine and check for proper

operation.

9 Auxiliary shaft- renewal

3

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Refer to Chapter 10 and remove the power

steering pump, without disconnecting the

hoses. Remove the plastic power steering

pump drive coupling disc.

2A•8 Engine in-car repair procedures

8.28a Drill a small hole in the intermediate

shaft seal, thread a sheet metal screw into

it and use a small slide-hammer pull the

seal out of the cover8.28b Drive the new seal in with a seal-

driver or socket, to the same depth as the

original seal8.29 Bolt the front cover on hand tight, use

a straightedge to make sure the cover’s

top surface is level with the top of the

engine block, then tighten the cover bolts

3261 Jaguar XJ6 8.23a Add oil to the reservoir in the lower tensioner . . .

8.23b . . . and refit the tensioner against the guide -

after it’s installed, push the tensioner guide back and forth

a few times to prime the tensioner

Page 46 of 227

2Refer to Section 8 and remove the front

cover and upper and lower timing chains.

3Remove the power steering drive coupling

from the auxiliary shaft (see illustration).

4Use a small drill to drill holes in the oil seal,

then use a slide-hammer puller to remove the

seal from the rear of the auxiliary shaft

housing (see illustration).

Caution: Drill straight and carefully to avoid

damaging the auxiliary shaft.

5Use a pair of snap-ring pliers to remove the

snap ring from the rear of the auxiliary shaft

(see illustration).

6Pull the auxiliary shaft out toward the front

of the engine.

7Remove the three internal hex-head bolts

and the auxiliary shaft housing.

8Examine the surface of the auxiliary shaft,

it’s sprocket, and the distributor drive-gear. If

there is noticeable wear or damage, replace

the auxiliary shaft assembly with a new one

(see illustration).

9If the auxiliary shaft housing has been

removed, clean it, scrape away the old gasket

material from the housing and the engine

block and refit the housing with a new gasket

(see illustration).

10Clean the auxiliary shaft, lubricate it with

engine oil and refit it through the front of the

block, then refit the washer (see illustration).

Refit the snap-ring(refer to illustration 9.4).11The new oil seal for the rear of the auxiliary

shaft comes with a plastic refitting sleeve that

keeps the seal lip from folding back during

refitting. Keep this sleeve in place until the seal

is fully installed. Tap the new seal into the

housing with a hammer and appropriate-size

socket until the seal is flush, then remove the

plastic sleeve (see illustration).

12The remainder of the refitting is the

reverse of removal. Note:When refitting the

distributor (see Chapter 5), use a new O-ring

to prevent oil leaks at the distributor.

13Run the engine and check for oil leaks at

the power steering pump-to-housing interface.10 Camshafts and valve lifters-

removal, inspection and

refitting

4

Removal

Note:The renewal of the camshafts requires

the use of several special tools. Read through

the procedure and acquire the special tools,

or their equivalent, before beginning work.

1Remove the valve cover (see Section 4).

2Refer to Section 3 and position the engine

at TDC for number 1 cylinder.

3Refer to Chapter 5 and remove the

distributor cap and set it aside along with the

spark plug leads. Mark the positions of the

distributor body and rotor.

4Using a feeler gauge, measure and record

the clearance between the intake and exhaust

camshaft lobes and the lifters for cylinder

number 1 (see illustration). Rotate the

crankshaft until the next cylinder in the firing

order is at TDC and check and record the

valve clearance for that cylinder. Following the

firing order, check and record the valve

clearance for the remaining valves with the

appropriate cylinder at TDC.

5Return the engine to TDC for cylinder

number 1. Using the special tool (Jaguar tool

no. 18G 1433), check the position of each

Engine in-car repair procedures 2A•9

2A

9.3 Use a screwdriver to hold the drive

coupling (arrowed) stationary while

removing the bolt9.4 Remove the auxiliary shaft seal with a

small slide-hammer puller9.5 Use snap-ring pliers to remove the

snap ring (arrowed) from the shaft - note

the three internal hex-head bolts retaining

the housing to the engine block

9.8 Inspect these areas of the auxiliary

shaft for wear

A Oil seal surface

B Bearing journalC Sprocket

D Distributor drive9.9 Refit the auxiliary shaft rear housing

with a new gasket, aligning the oil slot

(arrowed) with the housing

3261 Jaguar XJ6

9.10 Refit the washer before replacing the

snap-ring

9.11 Tap the seal squarely into the bore

with a socket until the seal is flush

with the housing, then remove the

plastic fitting sleeve

Page 55 of 227

6Slowly and carefully press the seal and

retainer squarely onto the crankshaft (see

illustration). The plastic sleeve may be

pushed out as the retainer seats on the engine

block. Remove the plastic sleeve.

7Refit and tighten the retainer bolts to the

torque listed in this Chapter’s Specifications.

8The remaining steps are the reverse of

removal.

16 Engine mounts-

check and renewal

3

1Engine mounts seldom require attention,

but broken or deteriorated mounts should be

renewed immediately or the added strain

placed on the driveline components may

cause damage or wear.

Check

2During the check, the engine must be

raised to remove the weight from the mounts.3Raise the car and support it securely on

axle stands, then position a jack under the

engine sump. Place a large wood block

between the jack head and the sump, then

carefully raise the engine just enough to take

the weight off the mounts. Do not position the

wood block under the drain plug.

Warning: DO NOT place any part

of your body under the engine

when it’s supported by a jack!

4Check the front mounts to see if the rubber

is cracked, hardened or separated from the

metal plates. Sometimes the rubber will split

down the centre.

5Check for relative movement between the

mount plates and the engine or frame (use a

large screwdriver or pry bar to attempt to

move the mounts). If movement is noted,

lower the engine and tighten the mount

fasteners.

6Rubber preservative should be applied to

the mounts to slow deterioration.

Renewal

7Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

8Raise the car and support it securely on

axle stands. Support the engine as described

in paragraph 3.

Caution: Ensure the cooling fan doesn’t hit

the shroud as the engine is raised.

9To remove either engine mount, remove the

nut from the engine bracket, then raise the

engine (see illustration).

10From underneath the car, lower the

steering gear (see Chapter 10) for access to

the nut retaining the insulator to the chassis

bracket.

11Refitting is the reverse of removal. Use

thread-locking compound on the mount

bolts/nuts and be sure to tighten them

securely.

12See Chapter 7 for transmission mount

renewal.

2A•18 Engine in-car repair procedures

3261 Jaguar XJ6 15.6 Refit the retainer and oil seal onto the crankshaft

16.9 Front engine mount (A)

and retaining nut to engine bracket (B)

Page 60 of 227

11Disconnect the throttle linkage,

transmission linkage (and dipstick tube) and

speed control cable, if equipped, from the

engine (see Chapters 4 and 7).

12Refer to Part A of this Chapter and

remove the intake and exhaust manifolds.

13Unbolt the power steering pump (see

Chapter 10). Tie the pump aside without

disconnecting the hoses. Refer to Part A for

removal of the hydraulic pump (if equipped)

from the timing chain cover.

14On air-conditioned models, unbolt the

compressor and set it aside. Do not

disconnect the refrigerant hoses. Note:Wire

the compressor out of the way with a coat

hanger, don’t let the compressor hang on the

hoses.

15Refer to Part A of this Chapter and

remove the drivebelts, water pump pulley and

crankshaft pulley.

16Attach a lifting sling to the engine.

Position a hoist and connect the sling to it.

Take up the slack until there is slight tension

on the hoist.

17With a trolley jack and piece of wood

supporting the bottom of the transmission

sump, refer to Chapter 8 and remove the

driveshaft and rear transmission mount.

Warning: Do not place any part

of your body under the

engine/transmission when it’s

supported only by a hoist or

other lifting device.

18With the hoist taking the weight of the

engine, unbolt the engine mounts (see Part A

of this Chapter).

19Recheck to be sure nothing is still

connecting the engine or transmission to the

vehicle. Disconnect and label anything still

remaining.

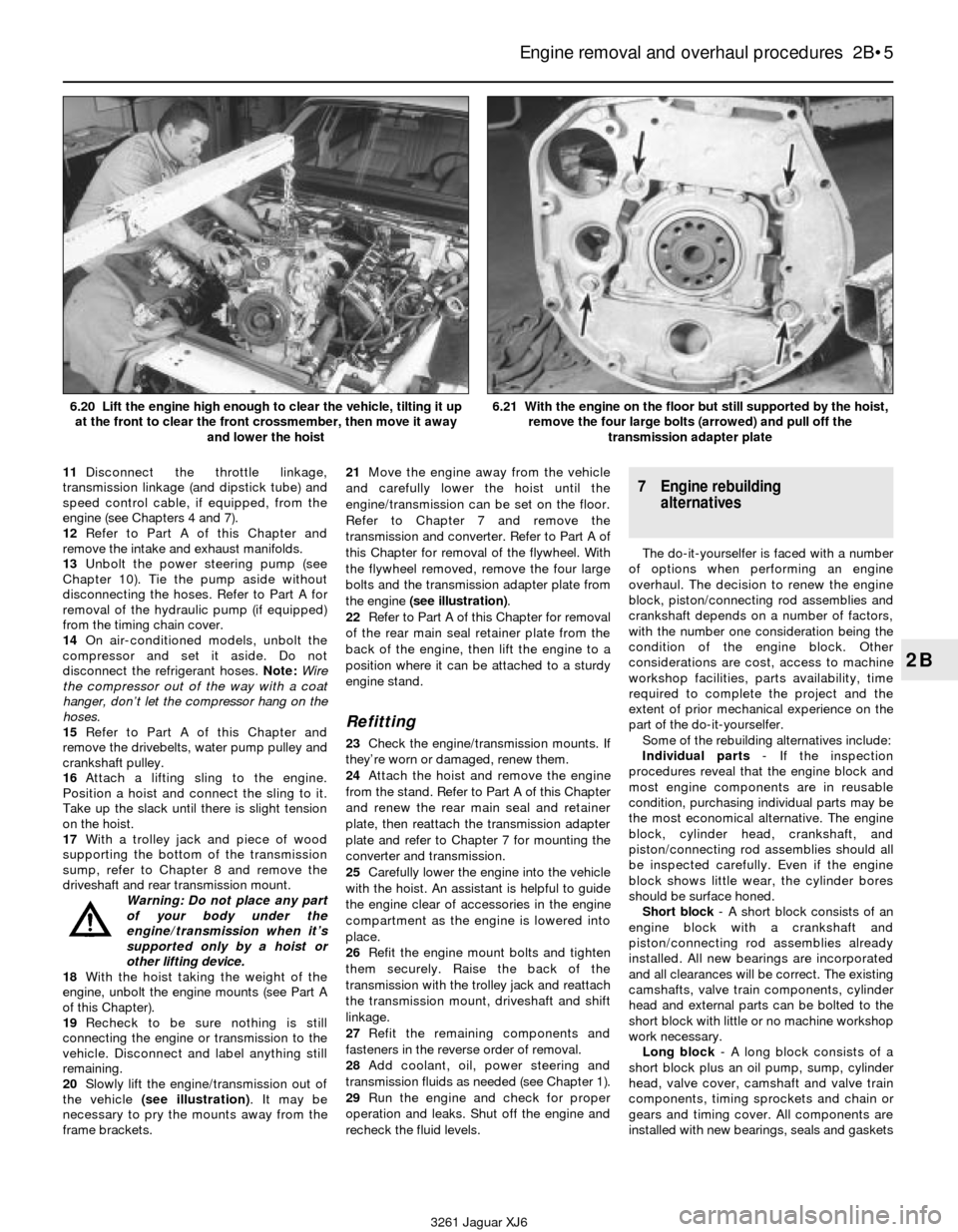

20Slowly lift the engine/transmission out of

the vehicle (see illustration). It may be

necessary to pry the mounts away from the

frame brackets.21Move the engine away from the vehicle

and carefully lower the hoist until the

engine/transmission can be set on the floor.

Refer to Chapter 7 and remove the

transmission and converter. Refer to Part A of

this Chapter for removal of the flywheel. With

the flywheel removed, remove the four large

bolts and the transmission adapter plate from

the engine (see illustration).

22Refer to Part A of this Chapter for removal

of the rear main seal retainer plate from the

back of the engine, then lift the engine to a

position where it can be attached to a sturdy

engine stand.

Refitting

23Check the engine/transmission mounts. If

they’re worn or damaged, renew them.

24Attach the hoist and remove the engine

from the stand. Refer to Part A of this Chapter

and renew the rear main seal and retainer

plate, then reattach the transmission adapter

plate and refer to Chapter 7 for mounting the

converter and transmission.

25Carefully lower the engine into the vehicle

with the hoist. An assistant is helpful to guide

the engine clear of accessories in the engine

compartment as the engine is lowered into

place.

26Refit the engine mount bolts and tighten

them securely. Raise the back of the

transmission with the trolley jack and reattach

the transmission mount, driveshaft and shift

linkage.

27Refit the remaining components and

fasteners in the reverse order of removal.

28Add coolant, oil, power steering and

transmission fluids as needed (see Chapter 1).

29Run the engine and check for proper

operation and leaks. Shut off the engine and

recheck the fluid levels.

7 Engine rebuilding

alternatives

The do-it-yourselfer is faced with a number

of options when performing an engine

overhaul. The decision to renew the engine

block, piston/connecting rod assemblies and

crankshaft depends on a number of factors,

with the number one consideration being the

condition of the engine block. Other

considerations are cost, access to machine

workshop facilities, parts availability, time

required to complete the project and the

extent of prior mechanical experience on the

part of the do-it-yourselfer.

Some of the rebuilding alternatives include:

Individual parts- If the inspection

procedures reveal that the engine block and

most engine components are in reusable

condition, purchasing individual parts may be

the most economical alternative. The engine

block, cylinder head, crankshaft, and

piston/connecting rod assemblies should all

be inspected carefully. Even if the engine

block shows little wear, the cylinder bores

should be surface honed.

Short block- A short block consists of an

engine block with a crankshaft and

piston/connecting rod assemblies already

installed. All new bearings are incorporated

and all clearances will be correct. The existing

camshafts, valve train components, cylinder

head and external parts can be bolted to the

short block with little or no machine workshop

work necessary.

Long block- A long block consists of a

short block plus an oil pump, sump, cylinder

head, valve cover, camshaft and valve train

components, timing sprockets and chain or

gears and timing cover. All components are

installed with new bearings, seals and gaskets

Engine removal and overhaul procedures 2B•5

2B

3261 Jaguar XJ6 6.20 Lift the engine high enough to clear the vehicle, tilting it up

at the front to clear the front crossmember, then move it away

and lower the hoist

6.21 With the engine on the floor but still supported by the hoist,

remove the four large bolts (arrowed) and pull off the

transmission adapter plate

Page 78 of 227

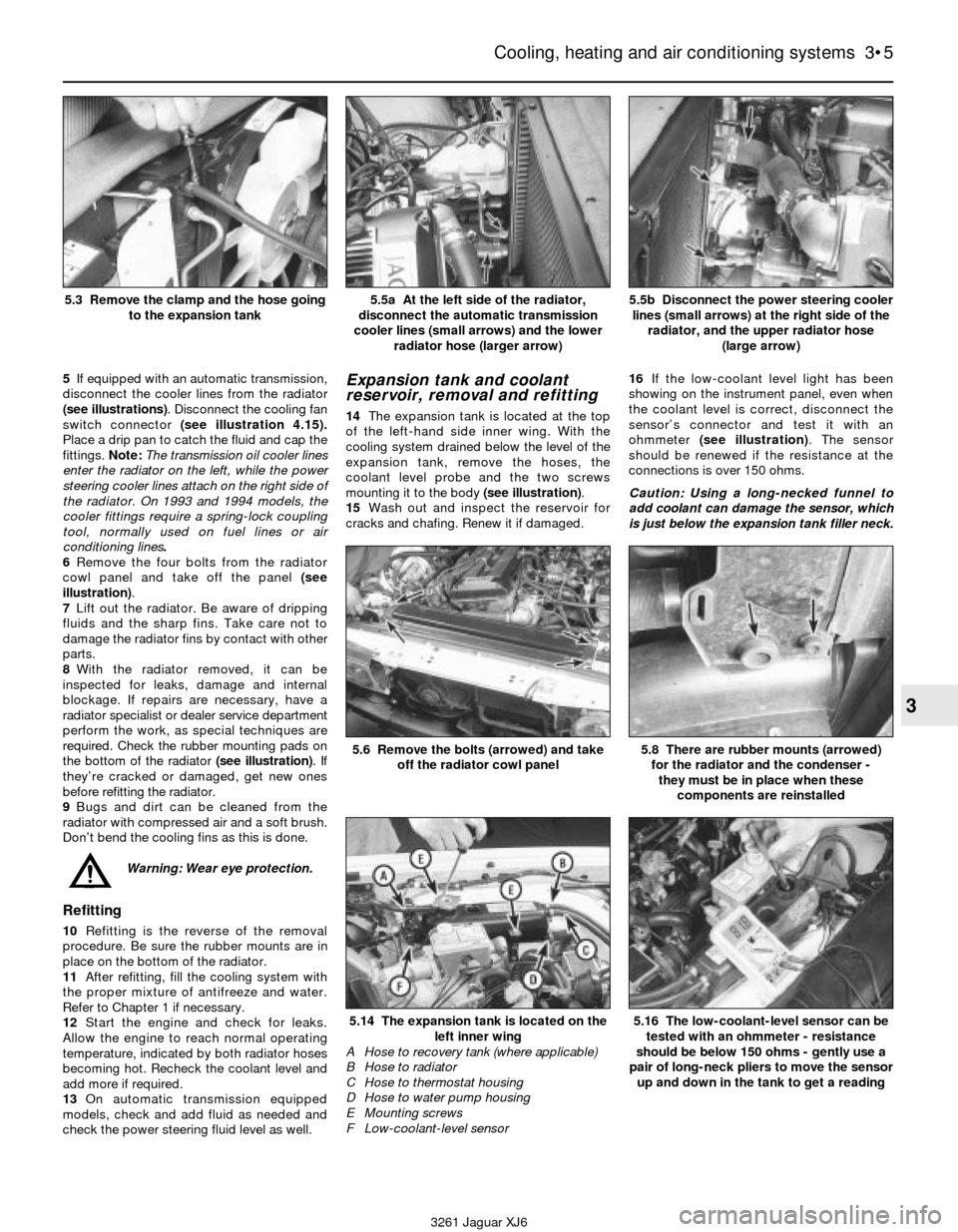

5If equipped with an automatic transmission,

disconnect the cooler lines from the radiator

(see illustrations). Disconnect the cooling fan

switch connector (see illustration 4.15).

Place a drip pan to catch the fluid and cap the

fittings. Note:The transmission oil cooler lines

enter the radiator on the left, while the power

steering cooler lines attach on the right side of

the radiator. On 1993 and 1994 models, the

cooler fittings require a spring-lock coupling

tool, normally used on fuel lines or air

conditioning lines.

6Remove the four bolts from the radiator

cowl panel and take off the panel (see

illustration).

7Lift out the radiator. Be aware of dripping

fluids and the sharp fins. Take care not to

damage the radiator fins by contact with other

parts.

8With the radiator removed, it can be

inspected for leaks, damage and internal

blockage. If repairs are necessary, have a

radiator specialist or dealer service department

perform the work, as special techniques are

required. Check the rubber mounting pads on

the bottom of the radiator (see illustration). If

they’re cracked or damaged, get new ones

before refitting the radiator.

9Bugs and dirt can be cleaned from the

radiator with compressed air and a soft brush.

Don’t bend the cooling fins as this is done.

Warning: Wear eye protection.

Refitting

10Refitting is the reverse of the removal

procedure. Be sure the rubber mounts are in

place on the bottom of the radiator.

11After refitting, fill the cooling system with

the proper mixture of antifreeze and water.

Refer to Chapter 1 if necessary.

12Start the engine and check for leaks.

Allow the engine to reach normal operating

temperature, indicated by both radiator hoses

becoming hot. Recheck the coolant level and

add more if required.

13On automatic transmission equipped

models, check and add fluid as needed and

check the power steering fluid level as well.

Expansion tank and coolant

reservoir, removal and refitting

14The expansion tank is located at the top

of the left-hand side inner wing. With the

cooling system drained below the level of the

expansion tank, remove the hoses, the

coolant level probe and the two screws

mounting it to the body (see illustration).

15Wash out and inspect the reservoir for

cracks and chafing. Renew it if damaged.16If the low-coolant level light has been

showing on the instrument panel, even when

the coolant level is correct, disconnect the

sensor’s connector and test it with an

ohmmeter (see illustration). The sensor

should be renewed if the resistance at the

connections is over 150 ohms.

Caution: Using a long-necked funnel to

add coolant can damage the sensor, which

is just below the expansion tank filler neck.

Cooling, heating and air conditioning systems 3•5

3

5.5a At the left side of the radiator,

disconnect the automatic transmission

cooler lines (small arrows) and the lower

radiator hose (larger arrow)5.5b Disconnect the power steering cooler

lines (small arrows) at the right side of the

radiator, and the upper radiator hose

(large arrow)

3261 Jaguar XJ6 5.3 Remove the clamp and the hose going

to the expansion tank

5.6 Remove the bolts (arrowed) and take

off the radiator cowl panel

5.14 The expansion tank is located on the

left inner wing

A Hose to recovery tank (where applicable)

B Hose to radiator

C Hose to thermostat housing

D Hose to water pump housing

E Mounting screws

F Low-coolant-level sensor

5.8 There are rubber mounts (arrowed)

for the radiator and the condenser -

they must be in place when these

components are reinstalled

5.16 The low-coolant-level sensor can be

tested with an ohmmeter - resistance

should be below 150 ohms - gently use a

pair of long-neck pliers to move the sensor

up and down in the tank to get a reading

Page 80 of 227

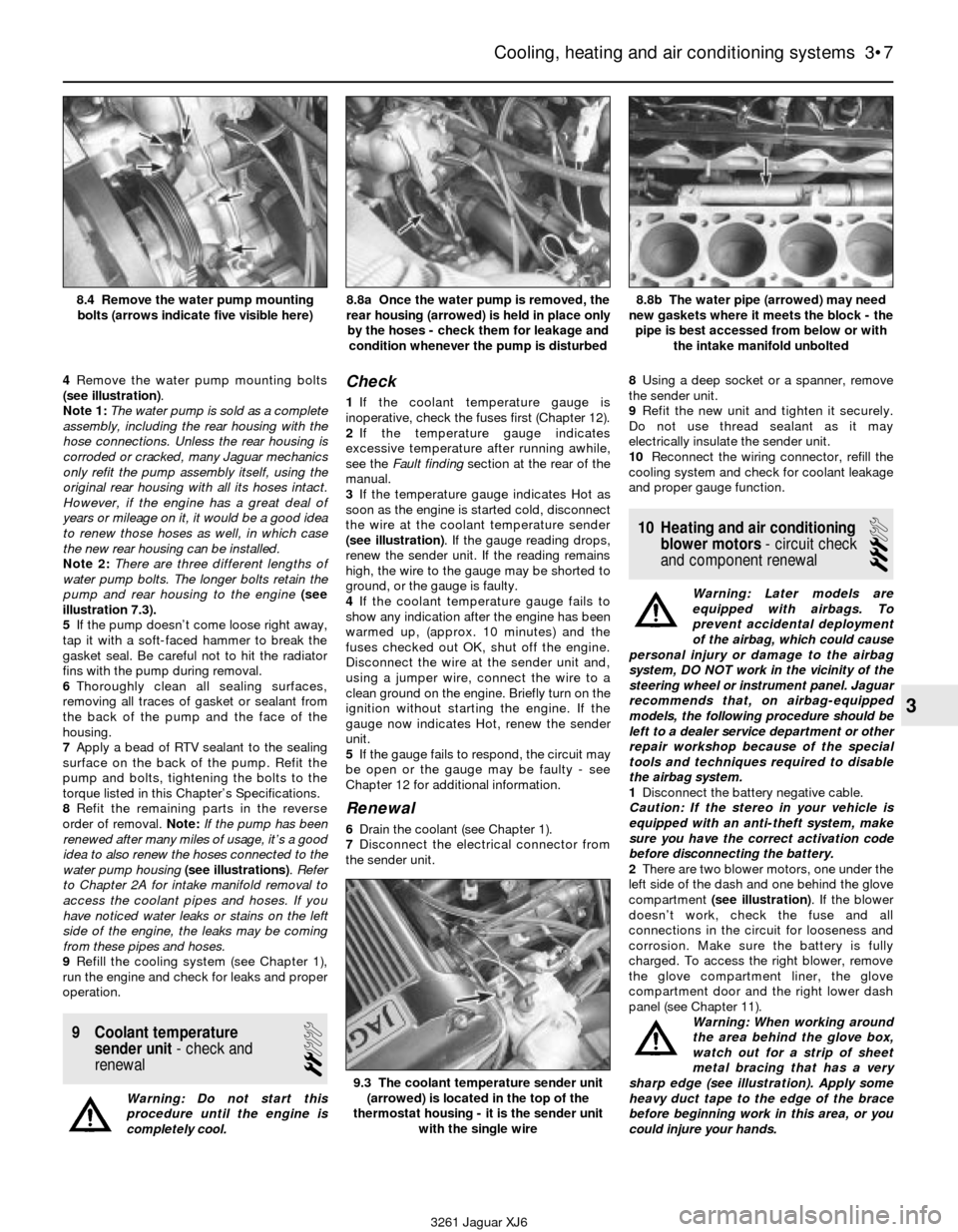

4Remove the water pump mounting bolts

(see illustration).

Note 1:The water pump is sold as a complete

assembly, including the rear housing with the

hose connections. Unless the rear housing is

corroded or cracked, many Jaguar mechanics

only refit the pump assembly itself, using the

original rear housing with all its hoses intact.

However, if the engine has a great deal of

years or mileage on it, it would be a good idea

to renew those hoses as well, in which case

the new rear housing can be installed.

Note 2:There are three different lengths of

water pump bolts. The longer bolts retain the

pump and rear housing to the engine(see

illustration 7.3).

5If the pump doesn’t come loose right away,

tap it with a soft-faced hammer to break the

gasket seal. Be careful not to hit the radiator

fins with the pump during removal.

6Thoroughly clean all sealing surfaces,

removing all traces of gasket or sealant from

the back of the pump and the face of the

housing.

7Apply a bead of RTV sealant to the sealing

surface on the back of the pump. Refit the

pump and bolts, tightening the bolts to the

torque listed in this Chapter’s Specifications.

8Refit the remaining parts in the reverse

order of removal. Note:If the pump has been

renewed after many miles of usage, it’s a good

idea to also renew the hoses connected to the

water pump housing(see illustrations). Refer

to Chapter 2A for intake manifold removal to

access the coolant pipes and hoses. If you

have noticed water leaks or stains on the left

side of the engine, the leaks may be coming

from these pipes and hoses.

9Refill the cooling system (see Chapter 1),

run the engine and check for leaks and proper

operation.

9 Coolant temperature

sender unit- check and

renewal

2

Warning: Do not start this

procedure until the engine is

completely cool.

Check

1If the coolant temperature gauge is

inoperative, check the fuses first (Chapter 12).

2If the temperature gauge indicates

excessive temperature after running awhile,

see the Fault finding section at the rear of the

manual.

3If the temperature gauge indicates Hot as

soon as the engine is started cold, disconnect

the wire at the coolant temperature sender

(see illustration). If the gauge reading drops,

renew the sender unit. If the reading remains

high, the wire to the gauge may be shorted to

ground, or the gauge is faulty.

4If the coolant temperature gauge fails to

show any indication after the engine has been

warmed up, (approx. 10 minutes) and the

fuses checked out OK, shut off the engine.

Disconnect the wire at the sender unit and,

using a jumper wire, connect the wire to a

clean ground on the engine. Briefly turn on the

ignition without starting the engine. If the

gauge now indicates Hot, renew the sender

unit.

5If the gauge fails to respond, the circuit may

be open or the gauge may be faulty - see

Chapter 12 for additional information.

Renewal

6Drain the coolant (see Chapter 1).

7Disconnect the electrical connector from

the sender unit.8Using a deep socket or a spanner, remove

the sender unit.

9Refit the new unit and tighten it securely.

Do not use thread sealant as it may

electrically insulate the sender unit.

10Reconnect the wiring connector, refill the

cooling system and check for coolant leakage

and proper gauge function.

10 Heating and air conditioning

blower motors- circuit check

and component renewal

3

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering wheel or instrument panel. Jaguar

recommends that, on airbag-equipped

models, the following procedure should be

left to a dealer service department or other

repair workshop because of the special

tools and techniques required to disable

the airbag system.

1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2There are two blower motors, one under the

left side of the dash and one behind the glove

compartment (see illustration). If the blower

doesn’t work, check the fuse and all

connections in the circuit for looseness and

corrosion. Make sure the battery is fully

charged. To access the right blower, remove

the glove compartment liner, the glove

compartment door and the right lower dash

panel (see Chapter 11).

Warning: When working around

the area behind the glove box,

watch out for a strip of sheet

metal bracing that has a very

sharp edge (see illustration). Apply some

heavy duct tape to the edge of the brace

before beginning work in this area, or you

could injure your hands.

Cooling, heating and air conditioning systems 3•7

3

8.4 Remove the water pump mounting

bolts (arrows indicate five visible here)8.8a Once the water pump is removed, the

rear housing (arrowed) is held in place only

by the hoses - check them for leakage and

condition whenever the pump is disturbed8.8b The water pipe (arrowed) may need

new gaskets where it meets the block - the

pipe is best accessed from below or with

the intake manifold unbolted

9.3 The coolant temperature sender unit

(arrowed) is located in the top of the

thermostat housing - it is the sender unit

with the single wire

3261 Jaguar XJ6

Page 81 of 227

3Remove the screws holding the cruise-

control ECU in place (see illustrations), then

remove the four screws holding the ECU

mounting plate in place.

4Disconnect the vacuum lines and electrical

connectors at the blower housing, identifying

each connection with marked masking tape

for reassembly, or write down the colour

codes of the vacuum tubing. Remove the duct

tape connecting the blower housing to the

duct from the heater/air conditioning unit.

5Remove the two bolts holding the top of the

blower housing to the cowl (see illustration).

6Pull down and back on the housing until itsqueezes past the metal brace below it (see

illustration).It will take some force at first.

7To access the left blower motor, remove

the left-hand brace rod from the steering

column forward to the body(see illustration),

then repeat Steps 4 and 5 on the left blower

housing. The blower housing should now drop

straight down and out.

8If the blower motor does not operate,

disconnect the electrical connectors at the

blower motor and connect the black wire

terminal to chassis ground, and the purple

wire terminal to a fused source of battery

voltage. If the blower doesn’t operate, itshould be renewed. If it does operate, there is

a problem in the feed or earth circuit.

9If the motor is good, but doesn’t operate at

any speed, the problem could be in the

heater/air conditioning control assembly or

the heating/air conditioning computer.

Diagnosis either of these electronic com-

ponents is beyond the scope of the home

mechanic, and should be referred to your

Jaguar dealer or other qualified repair facility.

10If either blower motor must be renewed,

remove the five clips and one screw holding

the blower housing halves together (see

illustration).

3•8 Cooling, heating and air conditioning systems

10.2a The right blower housing (arrowed)

is located behind the glove box area

of the dash10.2b Apply heavy duct tape to the sharp

edge of this brace (dotted line) when

working behind the glove box area of the

dash - the metal is very sharp10.3a Remove the screw (A) holding the

wiring harness in place, then remove the

two lower cruise-control ECU screws (B) . . .

10.3b . . . then remove the upper ECU

screw (arrowed) and pull down the ECU,

then remove the ECU mounting plate10.5 Two bolts (arrow indicates the left

bolt) hold the top of the blower housing

to the cowl10.6 Pull down and out on the housing

until it clears the sheet metal brace

below it

3261 Jaguar XJ6 10.7 Remove this brace rod (small arrow)

for clearance to remove the left blower

motor housing (large arrow)

10.10 Remove the five clips (two shown

here with arrows) and one screw holding

the halves of the housing together

Page 82 of 227

11Separate the housing halves and pull up

the plastic plate holding the motor and fan

(see illustration). The fan doesn’t come off

the motor, but loosen the clamp-bolt on the

motor’s mount bracket and slide the motor

and fan out for renewal (see illustration).

Note:Some 1988 models had problems with

cracking of the fan blades and noise from the

blowers. These blowers and fans have been

superseded with improved parts, available

from your Jaguar dealer.

12When either blower housing is separated,

you’ll find two relays mounted inside (see

illustration). These are the blower isolation

relay and blower relay. Before refitting the

blower housing in the car, refer to Chapter 12

for testing of these relays.

13Refitting is the reverse of removal. Check

for proper operation.11 Heater core-

removal and refitting

4

Warning: Later model vehicles

are equipped with airbags. To

prevent the accidental deploy-

ment of the airbag, which could

cause personal injury or damage to the

airbag system, DO NOT work in the vicinity

of the steering wheel or instrument panel.

The manufacturer recommends that, on

airbag-equipped models, the following

procedure should be left to a dealer service

department or other repair workshop

because of the special tools and techniques

required to disable the airbag system.1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Drain the cooling system (see Chapter 1).

Disconnect the heater hoses where they enter

the bulkhead (see illustration). Note:Use

compressed air in one of the pipes to blow out

any remaining coolant and collect it. This will

prevent any spills on the carpeting when the

heater core is removed. Plug the pipes to

prevent any remaining coolant from spilling out.

3Refer to Chapter 11 for removal of the

under-dash panels on both the driver and

passenger sides, and removal of the glovebox.

Warning: When working around

the area behind the glove box,

watch out for a strip of sheet

Cooling, heating and air conditioning systems 3•9

3

3261 Jaguar XJ6 10.11a Separate the housing halves - the blower motor (arrowed)

is attached to a plastic plate sandwiched between the

two housing halves

10.11b Loosen the clamp bolt (arrowed) on the motor bracket and

then pull the motor and fan out as an assembly

10.12 Inside the blower case are the blower and isolation relays

(arrowed) - while the case is apart, test these relays for

proper operation11.2 Disconnect the heater hoses from the pipes at the bulkhead

(small arrows) - the large arrow indicates the evaporator case

retaining nut

Page 83 of 227

metal bracing that has a very sharp edge

(see illustration 10.2b). Apply some heavy

duct tape to the edge of the brace before

beginning work in this area, or you could

injure your hands.

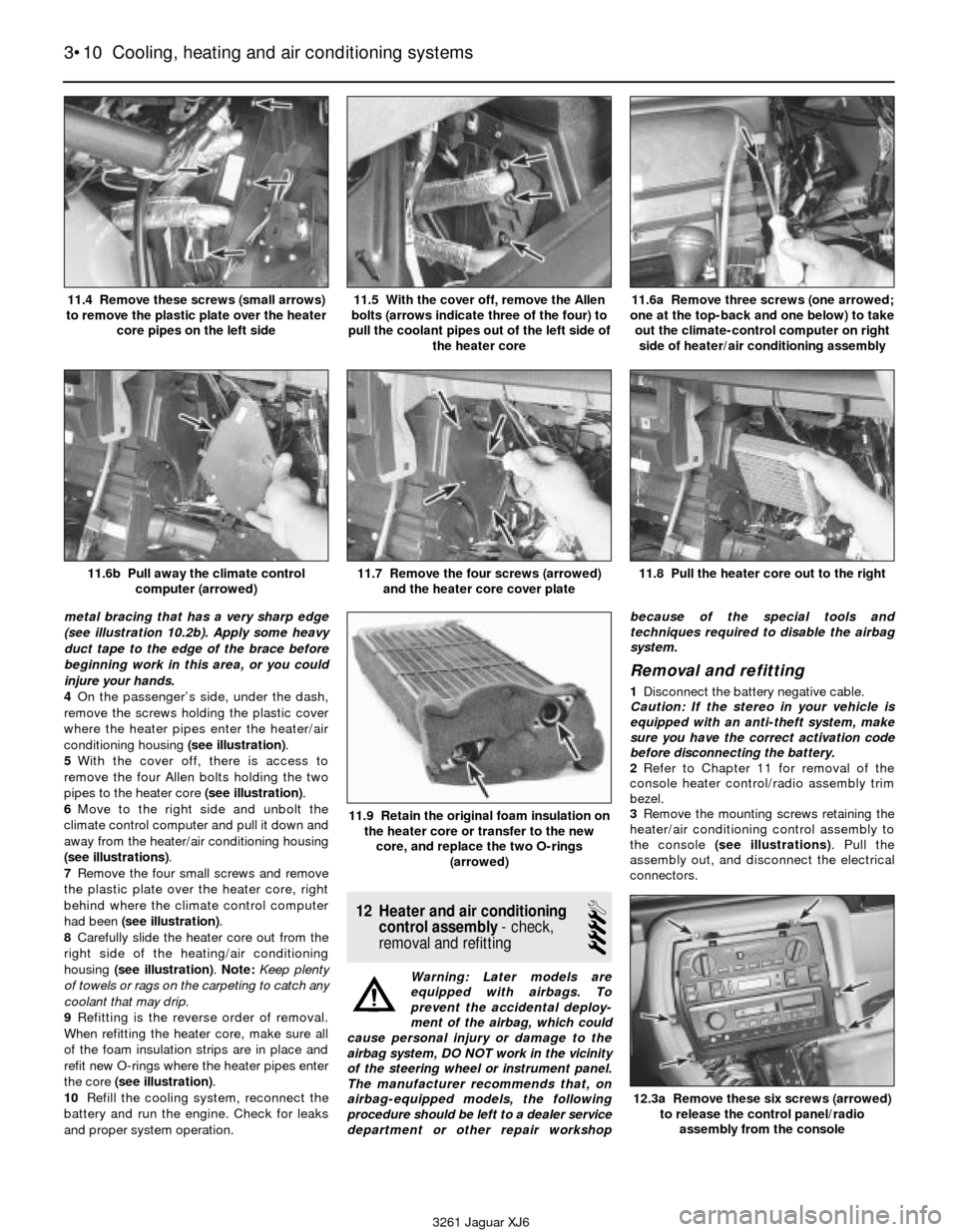

4On the passenger’s side, under the dash,

remove the screws holding the plastic cover

where the heater pipes enter the heater/air

conditioning housing (see illustration).

5With the cover off, there is access to

remove the four Allen bolts holding the two

pipes to the heater core (see illustration).

6Move to the right side and unbolt the

climate control computer and pull it down and

away from the heater/air conditioning housing

(see illustrations).

7Remove the four small screws and remove

the plastic plate over the heater core, right

behind where the climate control computer

had been (see illustration).

8Carefully slide the heater core out from the

right side of the heating/air conditioning

housing (see illustration). Note:Keep plenty

of towels or rags on the carpeting to catch any

coolant that may drip.

9Refitting is the reverse order of removal.

When refitting the heater core, make sure all

of the foam insulation strips are in place and

refit new O-rings where the heater pipes enter

the core (see illustration).

10Refill the cooling system, reconnect the

battery and run the engine. Check for leaks

and proper system operation.

12 Heater and air conditioning

control assembly- check,

removal and refitting

4

Warning: Later models are

equipped with airbags. To

prevent the accidental deploy-

ment of the airbag, which could

cause personal injury or damage to the

airbag system, DO NOT work in the vicinity

of the steering wheel or instrument panel.

The manufacturer recommends that, on

airbag-equipped models, the following

procedure should be left to a dealer service

department or other repair workshopbecause of the special tools and

techniques required to disable the airbag

system.

Removal and refitting

1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Refer to Chapter 11 for removal of the

console heater control/radio assembly trim

bezel.

3Remove the mounting screws retaining the

heater/air conditioning control assembly to

the console (see illustrations). Pull the

assembly out, and disconnect the electrical

connectors.

3•10 Cooling, heating and air conditioning systems

11.4 Remove these screws (small arrows)

to remove the plastic plate over the heater

core pipes on the left side11.5 With the cover off, remove the Allen

bolts (arrows indicate three of the four) to

pull the coolant pipes out of the left side of

the heater core11.6a Remove three screws (one arrowed;

one at the top-back and one below) to take

out the climate-control computer on right

side of heater/air conditioning assembly

11.6b Pull away the climate control

computer (arrowed)11.7 Remove the four screws (arrowed)

and the heater core cover plate11.8 Pull the heater core out to the right

3261 Jaguar XJ6

11.9 Retain the original foam insulation on

the heater core or transfer to the new

core, and replace the two O-rings

(arrowed)

12.3a Remove these six screws (arrowed)

to release the control panel/radio

assembly from the console