light JAGUAR XJ6 1997 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 79 of 227

17A coolant recovery bottle is used on 1988

and 1989 models, located in the passenger’s

inner wing. The plastic inner wing splash

shield must be removed for access to the

recovery bottle (see Chapter 11). Disconnect

the recovery hose and remove the mounting

screws to renew the recovery bottle (see

illustration). Models from 1990 on do not

have the recovery bottle, but do have a larger

expansion tank.

18Refitting of either expansion tank or

recovery bottle is the reverse of removal.

6 Engine oil cooler- renewal

2

1Models from 1988 through 1991 have a

engine oil cooler, mounted ahead of the

radiator. The engine’s mechanical fan draws

air through the oil cooler, cooling off hot

engine oil that is circulated from the engine by

steel tubes. Access to the cooler is with the

grille removed (refer to Chapter 11 for grille

removal).

2To renew the oil cooler, first disconnect thetwo fittings connecting the lines to the cooler

(see illustration).

Caution: The engine should be cool for this

procedure, and you should have a small

drain pan handy because the fittings are

on the bottom of the cooler and will

probably drip some oil on dismantling.

3Remove the mounting nuts to take the

cooler out of the vehicle (see illustration).

4The other ends of the oil cooler tubes

mount to a block just below the oil filter. With

a drain pan handy, remove the nut retaining

both pipes to the block.

5Refitting the oil cooler and oil lines is the

reverse of removal. When refitting the lines to

the block or the cooler, use new O-rings.7 Water pump- check

1

1A failure in the water pump can cause

serious engine damage due to overheating.

2With the engine running and warmed to

normal operating temperature, squeeze the

upper radiator hose. If the water pump is

working properly, a pressure surge should be

felt as the hose is released.

Warning: Keep hands away from

fan blades!

3Water pumps are equipped with weep or

vent holes (see illustration). If a failure occurs

in the pump seal, coolant will leak from this

hole. In most cases it will be necessary to use

a flashlight to find the hole on the water pump

by looking through the space behind the

pulley just below the water pump shaft.

4If the water pump shaft bearings fail there

may be a howling sound at the front of the

engine while it is running. Bearing wear can be

felt if the water pump pulley is rocked up anddown. Do not mistake drivebelt slippage,

which causes a squealing sound, for water

pump failure. Spray automotive drivebelt

dressing on the belts to eliminate the belt as a

possible cause of the noise.

8 Water pump and pipes-

renewal

3

Warning: Do not start this

procedure until the engine is

completely cool.

1Disconnect the negative battery cable and

drain the cooling system (see Chapter 1).

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Refer to Section 4 to remove the

mechanical fan and clutch (if applicable to

your model).

3Refer to Chapter 1 for removal of the

drivebelts.

3•6 Cooling, heating and air conditioning systems

6.3 Remove the mounting nuts (arrowed)

to take the oil cooler out

7.3 Check the weep hole (arrowed) for

signs of leakage (pump removed for

clarity) - grey discolouration is normal,

large brown stains indicates seal failure

3261 Jaguar XJ6 5.17 The recovery bottle (arrowed) on 1988 and 1989 models is

located in the footwell - disconnect the hoses and the two

mounting screws

6.2 Disconnect the two metal oil lines (arrowed) where they

mount to the bottom of the cooler - use two spanners

Page 84 of 227

4Refitting is the reverse of the removal

procedure.

5Run the engine and check for proper

functioning of the heater (and air conditioning,

if equipped).

Control checks

6The climate-control system uses an all-

electronic control panel that sends digital

information to the climate control computer.

There is little the home mechanic can do to

troubleshoot or test the system. The factory

recommends that diagnosis be performed at a

dealership.

7If there is a problem in just one area of

climate control, put the controls through their

entire range of operation and check the

system responses, i.e. set the controls to

COLD, the fan to low and the temperature to

65° F. In this mode the Manual LED should be

lit and the air conditioning compressor should

engage. Try all of the fan speeds and try the

temperature on HOT, then feel for warm air

coming from the ducts. Note:Between each

try of the different controls, wait 20 seconds or

so for the heater/air conditioning system to

adjust before checking for a response.

8When each control button is pushed two

times, its LED light should go on or off. Renew

the control assembly if any of the warning

lights don’t work.

9On 1988 and 1989 models, if the climate

controls do not respond to any driver input,

check with your Jaguar dealer before

renewing the ECU or control panel. A service

part is available (a resistor, #JLM 1901) that

can be installed at one of the control panel

terminals that may fix the problem without any

other parts being renewed. Instructions are

included with the part.

10Check the vacuum lines to the several

vacuum motors that operate the heater/air

conditioning functions. Look for pinched or

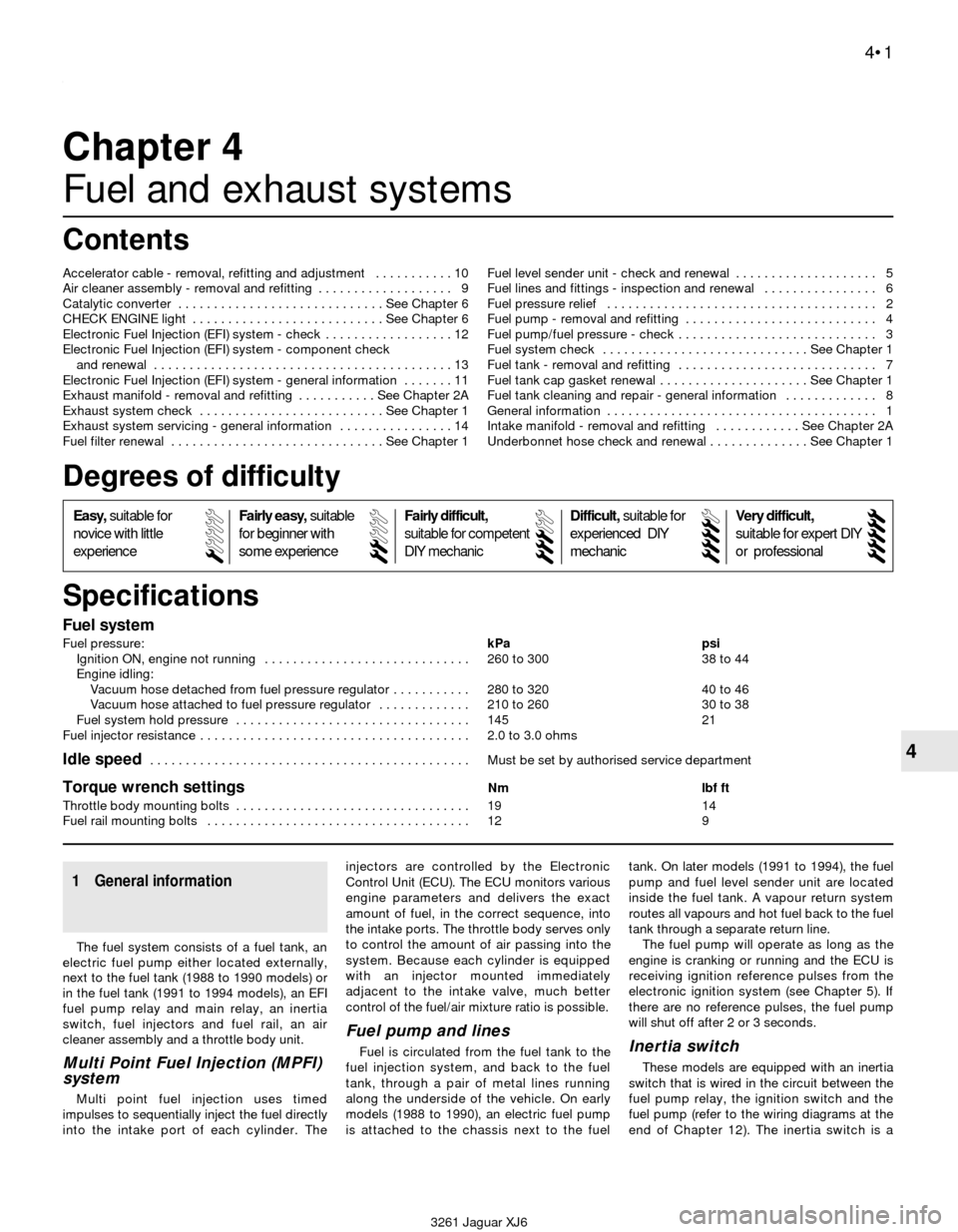

blocked hoses and leaks.11Each of the vacuum “servo motors” in the

system can be checked with a hand-held

vacuum pump (see illustration). Apply vacuum

and watch that the door or control it operates is

working.

12Further diagnosis of the controls or

climate control ECU are best left to a Jaguar

dealership or other qualified repair facility.

13 Air conditioning and heating

system- check and

maintenance

1

Air conditioning system

Warning: The air conditioning

system is under high pressure.

Do not loosen any hose fittings

or remove any components until

the system has been discharged. Air

conditioning refrigerant should be properly

discharged into an EPA-approved

recovery/recycling unit by a dealer service

department or an automotive air

conditioning repair facility. Always wear

eye protection when working near air

conditioning system fittings.

1The following maintenance checks should

be performed on a regular basis to ensure that

the air conditioner continues to operate at

peak efficiency:

a) Inspect the condition of the compressor

drivebelt. If it is worn or deteriorated,

renew it (see Chapter 1).

b) Check the drivebelt tension and, if

necessary, adjust it (see Chapter 1).

c) Inspect the system hoses. Look for

cracks, bubbles, hardening and

deterioration. Inspect the hoses and all

fittings for oil bubbles or seepage. If there

is any evidence of wear, damage or

leakage, renew the hose(s).d) Inspect the condenser fins for leaves,

bugs and any other foreign material that

may have embedded itself in the fins. Use

a “fin comb” or compressed air to remove

debris from the condenser.

e) Make sure the system has the correct

refrigerant charge.

2It’s a good idea to operate the system for

about ten minutes at least once a month. This

is particularly important during the winter

months because long term non-use can

cause hardening, and subsequent failure, of

the seals.

3Leaks in the air conditioning system are

best spotted when the system is brought up

to operating temperature and pressure, by

running the engine with the air conditioning

ON for five minutes. Shut the engine off and

inspect the air conditioning hoses and

connections. Traces of oil usually indicate

refrigerant leaks.

4Because of the complexity of the air

conditioning system and the special

equipment required to effectively work on it,

accurate troubleshooting of the system

should be left to a professional technician.

5If the air conditioning system doesn’t

operate at all, check the fuse panel and the air

conditioning relay (refer to Chapter 12 for

relay locations and testing). See Sections 4, 9

and 12 for electrical checks of heating/air

conditioning system components.

6The most common cause of poor cooling is

simply a low system refrigerant charge. If a

noticeable drop in cool air output occurs, the

following quick check will help you determine

if the refrigerant level is low.

Checking the refrigerant charge

7Warm the engine up to normal operating

temperature.

8Place the air conditioning temperature

selector at the coldest setting and put the

Cooling, heating and air conditioning systems 3•11

3

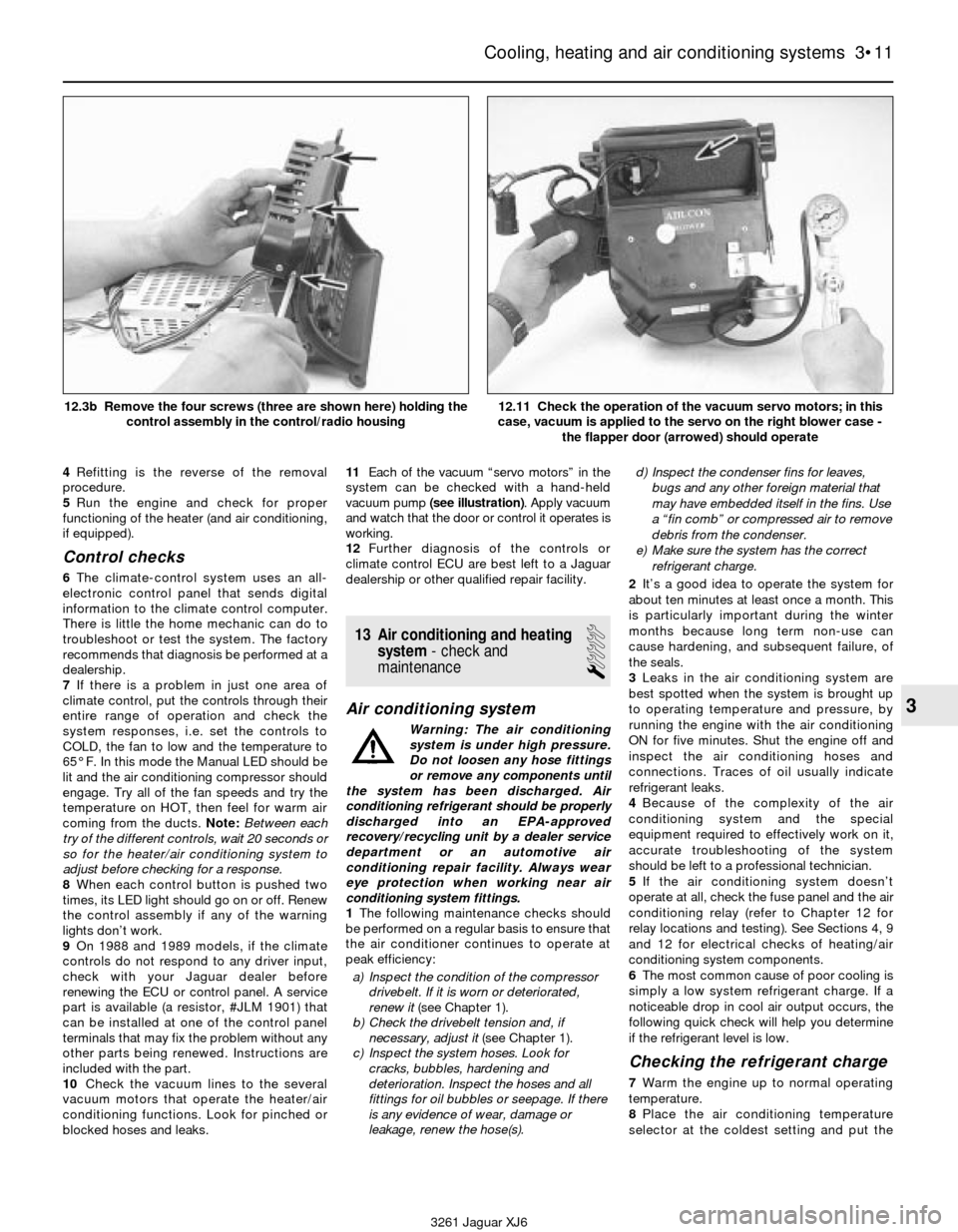

3261 Jaguar XJ6 12.3b Remove the four screws (three are shown here) holding the

control assembly in the control/radio housing

12.11 Check the operation of the vacuum servo motors; in this

case, vacuum is applied to the servo on the right blower case -

the flapper door (arrowed) should operate

Page 85 of 227

blower at the highest setting. Open the doors

(to make sure the air conditioning system

doesn’t cycle off as soon as it cools the

passenger compartment).

9With the compressor engaged - the clutch

will make an audible click and the centre of

the clutch will rotate. After the system reaches

operating temperature, feel the two pipes

connected to the evaporator at the bulkhead

(see illustration).

10The pipe (thinner tubing) leading from the

condenser outlet to the evaporator should be

cold, and the evaporator outlet line (the

thicker tubing that leads back to the

compressor) should be slightly colder (3 to

10° F). If the evaporator outlet is considerably

warmer than the inlet, the system needs a

charge. Insert a thermometer in the centre air

distribution duct while operating the air

conditioning system - the temperature of the

output air should be 35 to 40° F below the

ambient air temperature (down to approxi-

mately 40° F). If the ambient (outside) air

temperature is very high, say 110° F, the duct

air temperature may be as high as 60° F, but

generally the air conditioning is 30 to 50° F

cooler than the ambient air. If the air isn’t as

cold as it used to be, the system probably

needs a charge. Further inspection or testing

of the system is beyond the scope of the

home mechanic and should be left to a

professional.

11Inspect the sight glass (see illustration).

If the refrigerant looks foamy when running,

it’s low. When ambient temperatures are very

hot, bubbles may show in the sight glass even

with the proper amount of refrigerant. With the

proper amount of refrigerant, when the air

conditioning is turned off, the sight glass

should show refrigerant that foams, then

clears. Note:1993 and 1994 models are

equipped with R-134a refrigerant systems and

do not have a sight glass.Heating systems

12If the air coming out of the heater vents

isn’t hot, the problem could stem from any of

the following causes:

a) The thermostat is stuck open, preventing

the engine coolant from warming up

enough to carry heat to the heater core.

Renew the thermostat (see Section 3).

b) A heater hose is blocked, preventing the

flow of coolant through the heater core.

Feel both heater hoses at the bulkhead.

They should be hot. If one of them is cold,

there is an obstruction in one of the hoses

or in the heater core, or the heater control

valve is shut. Detach the hoses and back

flush the heater core with a water hose. If

the heater core is clear but circulation is

impeded, remove the two hoses and flush

them out with a water hose.

c) If flushing fails to remove the blockage

from the heater core, the core must be

renewed.(see Section 11).

13If the blower motor speed does not

correspond to the setting selected on the

blower switch, the problem could be a badfuse, circuit, control panel or climate control

computer (see Sections 10 and 12).

14If there isn’t any air coming out of the

vents:

a) Turn the ignition ON and activate the fan

control. Place your ear at the heating/air

conditioning register (vent) and listen.

Most motors are audible. Can you hear

the motor running?

b) If you can’t (and have already verified that

the blower switch and the blower motor

resistor are good), the blower motor itself

is probably bad (see Section 10).

15If the carpet under the heater core is

damp, or if antifreeze vapour or steam is

coming through the vents, the heater core is

leaking. Remove it (see Section 11) and refit a

new unit (most radiator shops will not repair a

leaking heater core).

16Inspect the drain hose from the heat/AC

assembly at the right side of the bulkhead,

make sure it is not clogged (see illustration).

If there is a humid mist coming from the

system ducts, this hose may be plugged. In

some early models, the hose may have been

pinched during assembly or blocked with

insulation or underseal.

14 Air conditioning

receiver/drier-

removal and refitting

4

Warning: The air conditioning

system is under high pressure.

Do not loosen any hose fittings

or remove any components until

the system has been discharged. Air

conditioning refrigerant should be properly

discharged into an EPA-approved recovery/

recycling unit by a dealer service depart-

ment or an automotive air conditioning

3•12 Cooling, heating and air conditioning systems

13.16 This drain hose (arrowed) from the

heater/air conditioning unit should be kept

clear to allow drainage of condensation

3261 Jaguar XJ6 13.9 Feel the inlet (small arrow) and outlet (large arrow) pipes at

the bulkhead leading to the air conditioning evaporator (battery

removed here for clarity only)

13.11 The sight glass (arrowed) is located on the top of the

receiver/drier, to the right of the radiator

Page 89 of 227

3261 Jaguar XJ6

4

Chapter 4

Fuel and exhaust systems

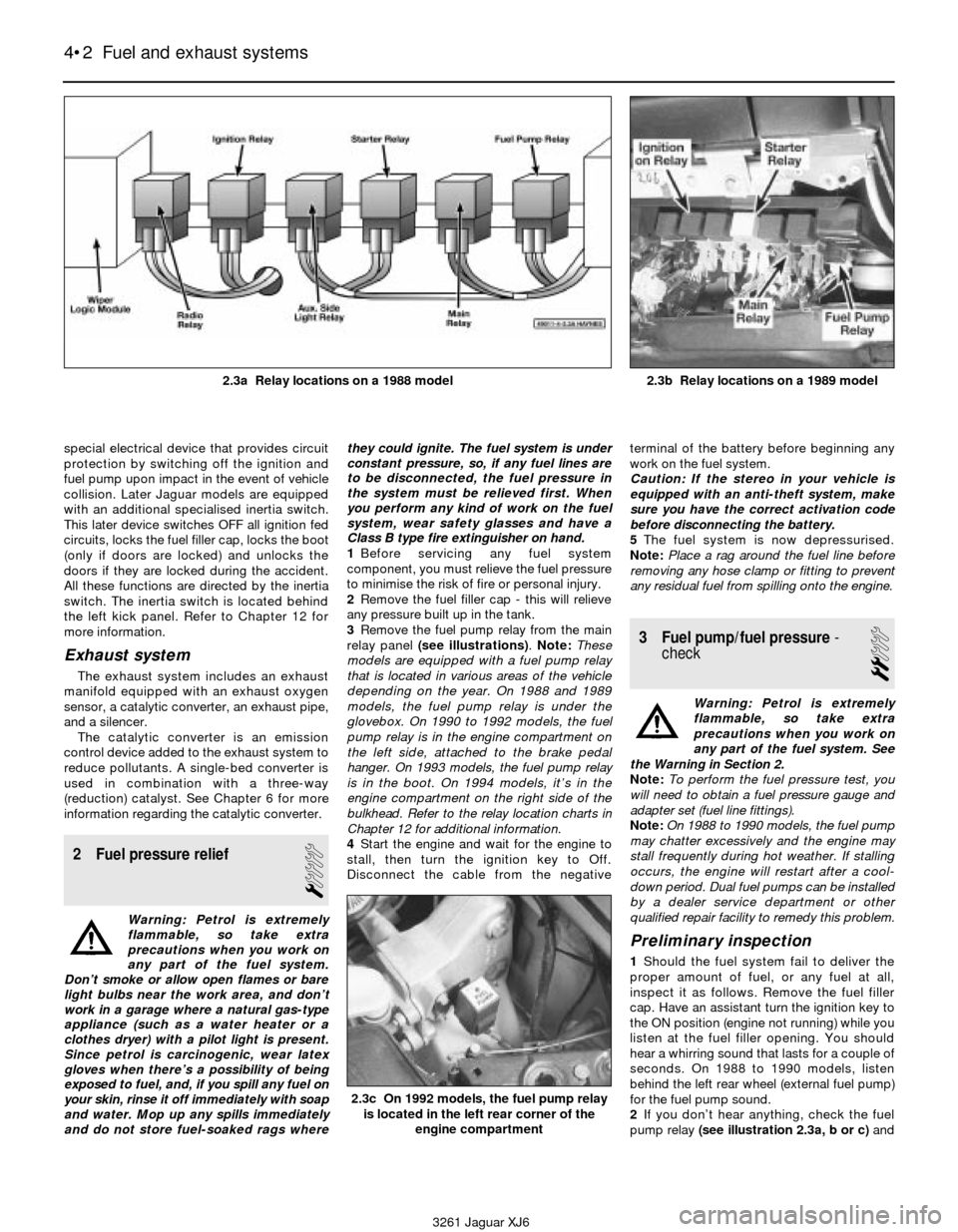

Fuel system

Fuel pressure:kPa psi

Ignition ON, engine not running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260 to 300 38 to 44

Engine idling:

Vacuum hose detached from fuel pressure regulator . . . . . . . . . . . 280 to 320 40 to 46

Vacuum hose attached to fuel pressure regulator . . . . . . . . . . . . . 210 to 260 30 to 38

Fuel system hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145 21

Fuel injector resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 to 3.0 ohms

Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Must be set by authorised service department

Torque wrench settingsNm lbf ft

Throttle body mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 14

Fuel rail mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 9 Accelerator cable - removal, refitting and adjustment . . . . . . . . . . . 10

Air cleaner assembly - removal and refitting . . . . . . . . . . . . . . . . . . . 9

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

CHECK ENGINE light . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Electronic Fuel Injection (EFI) system - check . . . . . . . . . . . . . . . . . . 12

Electronic Fuel Injection (EFI) system - component check

and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electronic Fuel Injection (EFI) system - general information . . . . . . . 11

Exhaust manifold - removal and refitting . . . . . . . . . . . See Chapter 2A

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Exhaust system servicing - general information . . . . . . . . . . . . . . . . 14

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1Fuel level sender unit - check and renewal . . . . . . . . . . . . . . . . . . . . 5

Fuel lines and fittings - inspection and renewal . . . . . . . . . . . . . . . . 6

Fuel pressure relief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Fuel pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel pump/fuel pressure - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fuel system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel tank - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fuel tank cap gasket renewal . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel tank cleaning and repair - general information . . . . . . . . . . . . . 8

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intake manifold - removal and refitting . . . . . . . . . . . . See Chapter 2A

Underbonnet hose check and renewal . . . . . . . . . . . . . . See Chapter 1

4•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

The fuel system consists of a fuel tank, an

electric fuel pump either located externally,

next to the fuel tank (1988 to 1990 models) or

in the fuel tank (1991 to 1994 models), an EFI

fuel pump relay and main relay, an inertia

switch, fuel injectors and fuel rail, an air

cleaner assembly and a throttle body unit.

Multi Point Fuel Injection (MPFI)

system

Multi point fuel injection uses timed

impulses to sequentially inject the fuel directly

into the intake port of each cylinder. Theinjectors are controlled by the Electronic

Control Unit (ECU). The ECU monitors various

engine parameters and delivers the exact

amount of fuel, in the correct sequence, into

the intake ports. The throttle body serves only

to control the amount of air passing into the

system. Because each cylinder is equipped

with an injector mounted immediately

adjacent to the intake valve, much better

control of the fuel/air mixture ratio is possible.

Fuel pump and lines

Fuel is circulated from the fuel tank to the

fuel injection system, and back to the fuel

tank, through a pair of metal lines running

along the underside of the vehicle. On early

models (1988 to 1990), an electric fuel pump

is attached to the chassis next to the fueltank. On later models (1991 to 1994), the fuel

pump and fuel level sender unit are located

inside the fuel tank. A vapour return system

routes all vapours and hot fuel back to the fuel

tank through a separate return line.

The fuel pump will operate as long as the

engine is cranking or running and the ECU is

receiving ignition reference pulses from the

electronic ignition system (see Chapter 5). If

there are no reference pulses, the fuel pump

will shut off after 2 or 3 seconds.Inertia switch

These models are equipped with an inertia

switch that is wired in the circuit between the

fuel pump relay, the ignition switch and the

fuel pump (refer to the wiring diagrams at the

end of Chapter 12). The inertia switch is a

Page 90 of 227

special electrical device that provides circuit

protection by switching off the ignition and

fuel pump upon impact in the event of vehicle

collision. Later Jaguar models are equipped

with an additional specialised inertia switch.

This later device switches OFF all ignition fed

circuits, locks the fuel filler cap, locks the boot

(only if doors are locked) and unlocks the

doors if they are locked during the accident.

All these functions are directed by the inertia

switch. The inertia switch is located behind

the left kick panel. Refer to Chapter 12 for

more information.

Exhaust system

The exhaust system includes an exhaust

manifold equipped with an exhaust oxygen

sensor, a catalytic converter, an exhaust pipe,

and a silencer.

The catalytic converter is an emission

control device added to the exhaust system to

reduce pollutants. A single-bed converter is

used in combination with a three-way

(reduction) catalyst. See Chapter 6 for more

information regarding the catalytic converter.

2 Fuel pressure relief

1

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system.

Don’t smoke or allow open flames or bare

light bulbs near the work area, and don’t

work in a garage where a natural gas-type

appliance (such as a water heater or a

clothes dryer) with a pilot light is present.

Since petrol is carcinogenic, wear latex

gloves when there’s a possibility of being

exposed to fuel, and, if you spill any fuel on

your skin, rinse it off immediately with soap

and water. Mop up any spills immediately

and do not store fuel-soaked rags wherethey could ignite. The fuel system is under

constant pressure, so, if any fuel lines are

to be disconnected, the fuel pressure in

the system must be relieved first. When

you perform any kind of work on the fuel

system, wear safety glasses and have a

Class B type fire extinguisher on hand.

1Before servicing any fuel system

component, you must relieve the fuel pressure

to minimise the risk of fire or personal injury.

2Remove the fuel filler cap - this will relieve

any pressure built up in the tank.

3Remove the fuel pump relay from the main

relay panel (see illustrations). Note:These

models are equipped with a fuel pump relay

that is located in various areas of the vehicle

depending on the year. On 1988 and 1989

models, the fuel pump relay is under the

glovebox. On 1990 to 1992 models, the fuel

pump relay is in the engine compartment on

the left side, attached to the brake pedal

hanger. On 1993 models, the fuel pump relay

is in the boot. On 1994 models, it’s in the

engine compartment on the right side of the

bulkhead. Refer to the relay location charts in

Chapter 12 for additional information.

4Start the engine and wait for the engine to

stall, then turn the ignition key to Off.

Disconnect the cable from the negativeterminal of the battery before beginning any

work on the fuel system.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

5The fuel system is now depressurised.

Note:Place a rag around the fuel line before

removing any hose clamp or fitting to prevent

any residual fuel from spilling onto the engine.

3 Fuel pump/fuel pressure-

check

2

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. See

the Warning in Section 2.

Note: To perform the fuel pressure test, you

will need to obtain a fuel pressure gauge and

adapter set (fuel line fittings).

Note: On 1988 to 1990 models, the fuel pump

may chatter excessively and the engine may

stall frequently during hot weather. If stalling

occurs, the engine will restart after a cool-

down period. Dual fuel pumps can be installed

by a dealer service department or other

qualified repair facility to remedy this problem.

Preliminary inspection

1Should the fuel system fail to deliver the

proper amount of fuel, or any fuel at all,

inspect it as follows. Remove the fuel filler

cap. Have an assistant turn the ignition key to

the ON position (engine not running) while you

listen at the fuel filler opening. You should

hear a whirring sound that lasts for a couple of

seconds. On 1988 to 1990 models, listen

behind the left rear wheel (external fuel pump)

for the fuel pump sound.

2If you don’t hear anything, check the fuel

pump relay (see illustration 2.3a, b or c)and

4•2 Fuel and exhaust systems

2.3c On 1992 models, the fuel pump relay

is located in the left rear corner of the

engine compartment

3261 Jaguar XJ6 2.3a Relay locations on a 1988 model

2.3b Relay locations on a 1989 model

Page 93 of 227

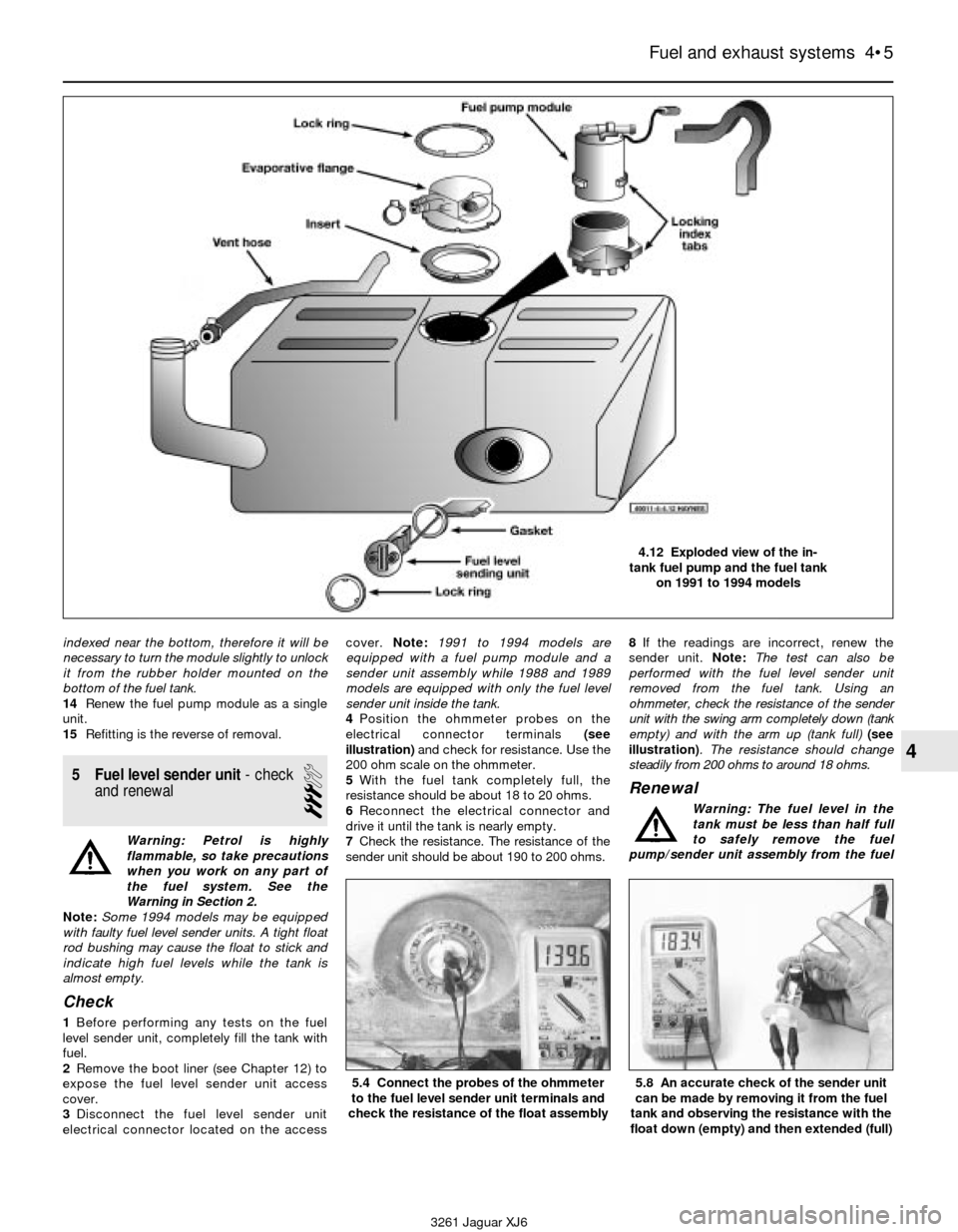

indexed near the bottom, therefore it will be

necessary to turn the module slightly to unlock

it from the rubber holder mounted on the

bottom of the fuel tank.

14Renew the fuel pump module as a single

unit.

15Refitting is the reverse of removal.

5 Fuel level sender unit- check

and renewal

3

Warning: Petrol is highly

flammable, so take precautions

when you work on any part of

the fuel system. See the

Warning in Section 2.

Note:Some 1994 models may be equipped

with faulty fuel level sender units. A tight float

rod bushing may cause the float to stick and

indicate high fuel levels while the tank is

almost empty.

Check

1Before performing any tests on the fuel

level sender unit, completely fill the tank with

fuel.

2Remove the boot liner (see Chapter 12) to

expose the fuel level sender unit access

cover.

3Disconnect the fuel level sender unit

electrical connector located on the accesscover.Note:1991 to 1994 models are

equipped with a fuel pump module and a

sender unit assembly while 1988 and 1989

models are equipped with only the fuel level

sender unit inside the tank.

4Position the ohmmeter probes on the

electrical connector terminals (see

illustration)and check for resistance. Use the

200 ohm scale on the ohmmeter.

5With the fuel tank completely full, the

resistance should be about 18 to 20 ohms.

6Reconnect the electrical connector and

drive it until the tank is nearly empty.

7Check the resistance. The resistance of the

sender unit should be about 190 to 200 ohms.8If the readings are incorrect, renew the

sender unit. Note:The test can also be

performed with the fuel level sender unit

removed from the fuel tank. Using an

ohmmeter, check the resistance of the sender

unit with the swing arm completely down (tank

empty) and with the arm up (tank full) (see

illustration). The resistance should change

steadily from 200 ohms to around 18 ohms.

Renewal

Warning: The fuel level in the

tank must be less than half full

to safely remove the fuel

pump/sender unit assembly from the fuel

Fuel and exhaust systems 4•5

4

5.4 Connect the probes of the ohmmeter

to the fuel level sender unit terminals and

check the resistance of the float assembly5.8 An accurate check of the sender unit

can be made by removing it from the fuel

tank and observing the resistance with the

float down (empty) and then extended (full)

3261 Jaguar XJ6

4.12 Exploded view of the in-

tank fuel pump and the fuel tank

on 1991 to 1994 models

Page 95 of 227

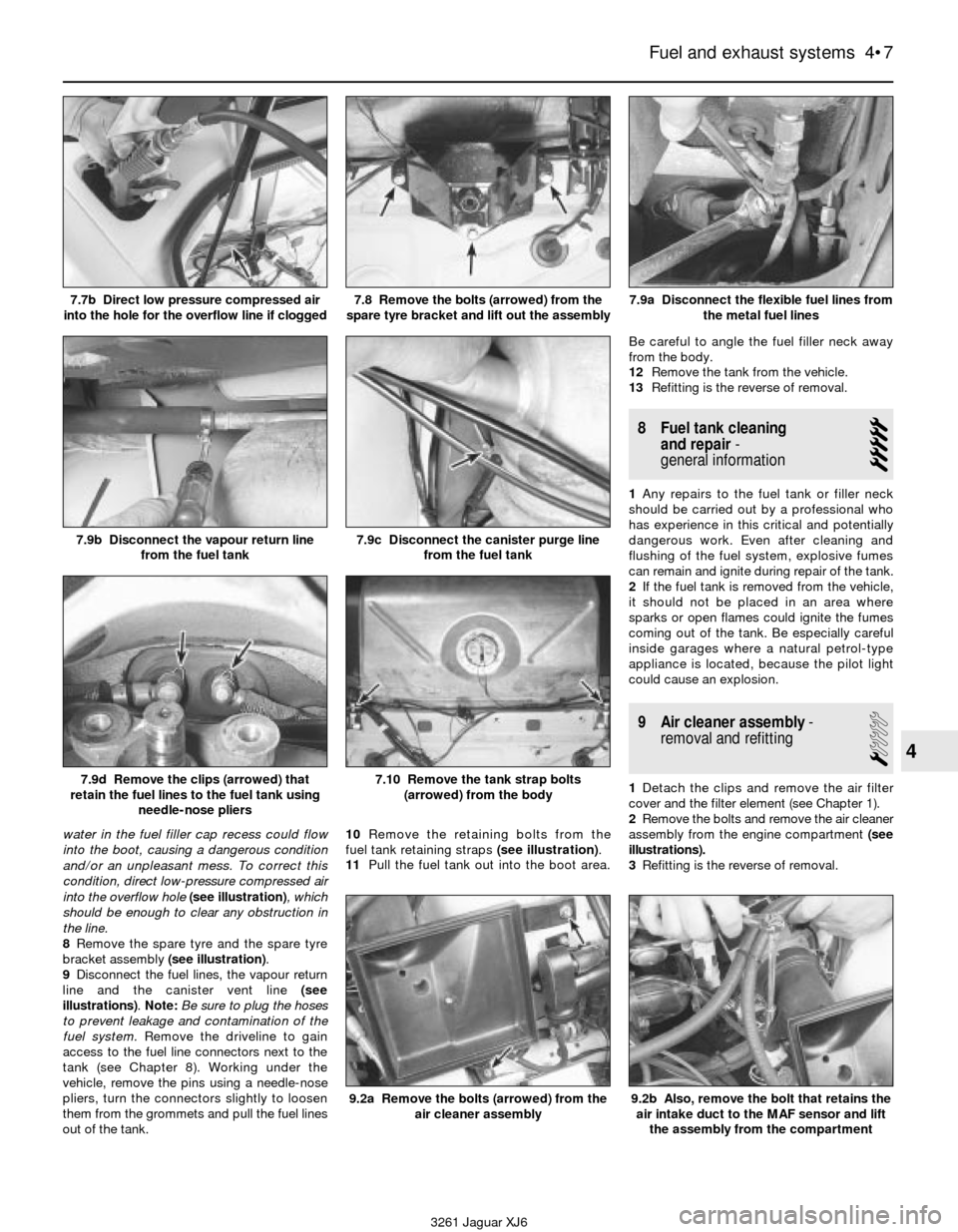

water in the fuel filler cap recess could flow

into the boot, causing a dangerous condition

and/or an unpleasant mess. To correct this

condition, direct low-pressure compressed air

into the overflow hole (see illustration), which

should be enough to clear any obstruction in

the line.

8Remove the spare tyre and the spare tyre

bracket assembly (see illustration).

9Disconnect the fuel lines, the vapour return

line and the canister vent line (see

illustrations). Note:Be sure to plug the hoses

to prevent leakage and contamination of the

fuel system.Remove the driveline to gain

access to the fuel line connectors next to the

tank (see Chapter 8). Working under the

vehicle, remove the pins using a needle-nose

pliers, turn the connectors slightly to loosen

them from the grommets and pull the fuel lines

out of the tank.10Remove the retaining bolts from the

fuel tank retaining straps (see illustration).

11Pull the fuel tank out into the boot area.Be careful to angle the fuel filler neck away

from the body.

12Remove the tank from the vehicle.

13Refitting is the reverse of removal.

8 Fuel tank cleaning

and repair-

general information

5

1Any repairs to the fuel tank or filler neck

should be carried out by a professional who

has experience in this critical and potentially

dangerous work. Even after cleaning and

flushing of the fuel system, explosive fumes

can remain and ignite during repair of the tank.

2If the fuel tank is removed from the vehicle,

it should not be placed in an area where

sparks or open flames could ignite the fumes

coming out of the tank. Be especially careful

inside garages where a natural petrol-type

appliance is located, because the pilot light

could cause an explosion.

9 Air cleaner assembly-

removal and refitting

1

1Detach the clips and remove the air filter

cover and the filter element (see Chapter 1).

2Remove the bolts and remove the air cleaner

assembly from the engine compartment (see

illustrations).

3Refitting is the reverse of removal.

Fuel and exhaust systems 4•7

4

7.7b Direct low pressure compressed air

into the hole for the overflow line if clogged7.8 Remove the bolts (arrowed) from the

spare tyre bracket and lift out the assembly7.9a Disconnect the flexible fuel lines from

the metal fuel lines

7.9b Disconnect the vapour return line

from the fuel tank7.9c Disconnect the canister purge line

from the fuel tank

7.9d Remove the clips (arrowed) that

retain the fuel lines to the fuel tank using

needle-nose pliers

3261 Jaguar XJ6

7.10 Remove the tank strap bolts

(arrowed) from the body

9.2a Remove the bolts (arrowed) from the

air cleaner assembly9.2b Also, remove the bolt that retains the

air intake duct to the MAF sensor and lift

the assembly from the compartment

Page 96 of 227

10 Accelerator cable- removal,

refitting and adjustment

3

Removal

1Detach the cable from the negative terminal

of the battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Loosen the locknut on the threaded portion

of the throttle cable at the throttle body (see

illustration).

3Rotate the throttle lever, then slip the

throttle cable end out of the slot in the lever

(see illustration).

4Detach the throttle cable from the

accelerator pedal (see illustration).

5From inside the vehicle, pull the cable

through the bulkhead.

Refitting and adjustment

6Refitting is the reverse of removal.

7To adjust the cable, fully depress the

accelerator pedal and check that the throttle

is fully opened.

8If not fully opened, loosen the locknuts,

depress accelerator pedal and adjust the

cable until the throttle is fully open.

9Tighten the locknuts and recheck the

adjustment. Make sure the throttle closes fully

when the pedal is released (see illustration).

10After the cable is adjusted, check the

adjustment of the bellcrank. Use a small

clamp and a straight rod or stiff wire (coat

hanger) and attach it to the brake master

cylinder in such a way that the tip acts as a

pointer. Align the pointer with “A” (automatic

transmission) or “M” (manual transmission) on

the bellcrank (see illustration),depending on

what type of transmission is installed in the

vehicle.

11Slowly rotate the bellcrank until it reaches

the throttle stop (wide open throttle) andcheck to make sure the pointer aligns with the

notch in the bellcrank (see illustration).

12If necessary, adjust the position of

the throttle stop using a spanner and turn the

throttle stop screw until the bellcrank reaches

the correct position. Lock the throttle stop

screw in place.

4•8 Fuel and exhaust systems

3261 Jaguar XJ6 10.4 Remove circlip (arrowed) and separate cable from the

accelerator pedal by pulling the pin from the pedal assembly

10.2 Loosen the locknuts on the accelerator cable10.3 Rotate the bellcrank and remove the cable end from the slot

10.9 Make sure the throttle closes completely and there is a

slight amount of flex in the cable

10.10 Attach a strong wire (coat hanger)

to the master cylinder using a clamp and

align it with the notch on the bellcrank

Page 98 of 227

of these sensors and their corresponding

ECU-controlled relays are not contained

within EFI components, but are located

throughout the engine compartment. For

further information regarding the ECU and its

relationship to the engine electrical and

ignition system, see Chapter 6.

12 Electronic Fuel Injection

(EFI) system- check

2

1Check the earth wire connections for

tightness. Check all wiring and electrical

connectors that are related to the system.

Loose electrical connectors and poor grounds

can cause many problems that resemble

more serious malfunctions.

2Check to see that the battery is fully

charged, as the control unit and sensors

depend on an accurate supply voltage in

order to properly meter the fuel.

3Check the air filter element - a dirty or

partially blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for a shorted

wire in the harness related to the system.

5Check the air intake duct from the MAF

sensor to the intake manifold for leaks, which

will result in an excessively lean mixture. Also

check the condition of the vacuum hoses

connected to the intake manifold.

6Remove the air intake duct from the throttle

body and check for carbon and residue build-

up. If it’s dirty, clean with aerosol carburettor

cleaner (make sure the can says it’s safe for

use with oxygen sensors and catalytic

converters) and a toothbrush.

7With the engine running, place a

stethoscope against each injector, one at a

time, and listen for a clicking sound, indicating

operation (see illustration).8If there is a problem with an injector,

purchase a special injector test light (noid

light) and refit it into the injector electrical

connector (see illustration). Start the engine

and make sure that each injector connector

flashes the noid light. This will test for the

proper voltage signal to the injector.Caution:

If the engine will not start and the noid

light indicates that each injector is

receiving the proper signal, there is a good

possibility that the injector(s) is stuck open

and allowing fuel into the combustion

chamber in excessive amounts. If the spark

plugs are fouled, detach the primary (low

voltage) wires from the ignition coil, disable

the fuel pump by removing the fuel pump

relay (see Section 2), remove the spark plugs

and crank the engine over. If fuel sprays from

the spark plug holes, the engine is flooded

and the fuel must be removed from the

combustion chambers.

9With the engine OFF and the fuel injector

electrical connectors disconnected, measure

the resistance of each injector (see

illustration). Each injector should measure

about 2.0 to 3.0 ohms. If not, the injector is

probably faulty.10The remainder of the system checks

should be left to a Jaguar service department

or other qualified repair workshop, as there is

a chance that the control unit may be

damaged if not performed properly.

13 Electronic Fuel Injection

(EFI) system- component

check and renewal

3

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. See

the Warning in Section 2.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

Throttle body

Check

1Verify that the throttle linkage operates

smoothly.

2Start the engine, detach each vacuum hose

and, using your finger, check the vacuum at

each port on the throttle body with the engine

at idle and above idle. The vacuum available

from the throttle body is ported. Raise the

engine rpm and watch as vacuum increases.

It may be necessary to use a vacuum gauge.

Refer to Chapter 2B for additional information

concerning vacuum checks.

Renewal

Warning: Wait until the engine is

completely cool before

beginning this procedure.

3Detach the cable from the negative terminal

of the battery (see the Cautionat the

beginning of this Section).

4Drain the radiator (see Chapter 1).

4•10 Fuel and exhaust systems

12.9 Using an ohmmeter, measure the

resistance across both terminals

of the injector

3261 Jaguar XJ6 12.7 Use a stethoscope or a screwdriver to determine if the

injectors are working properly - they should make a steady

clicking sound that rises and falls with engine speed changes

12.8 Refit the “noid” light into the fuel injector electrical

connector and check to see that it blinks with the engine running

Page 100 of 227

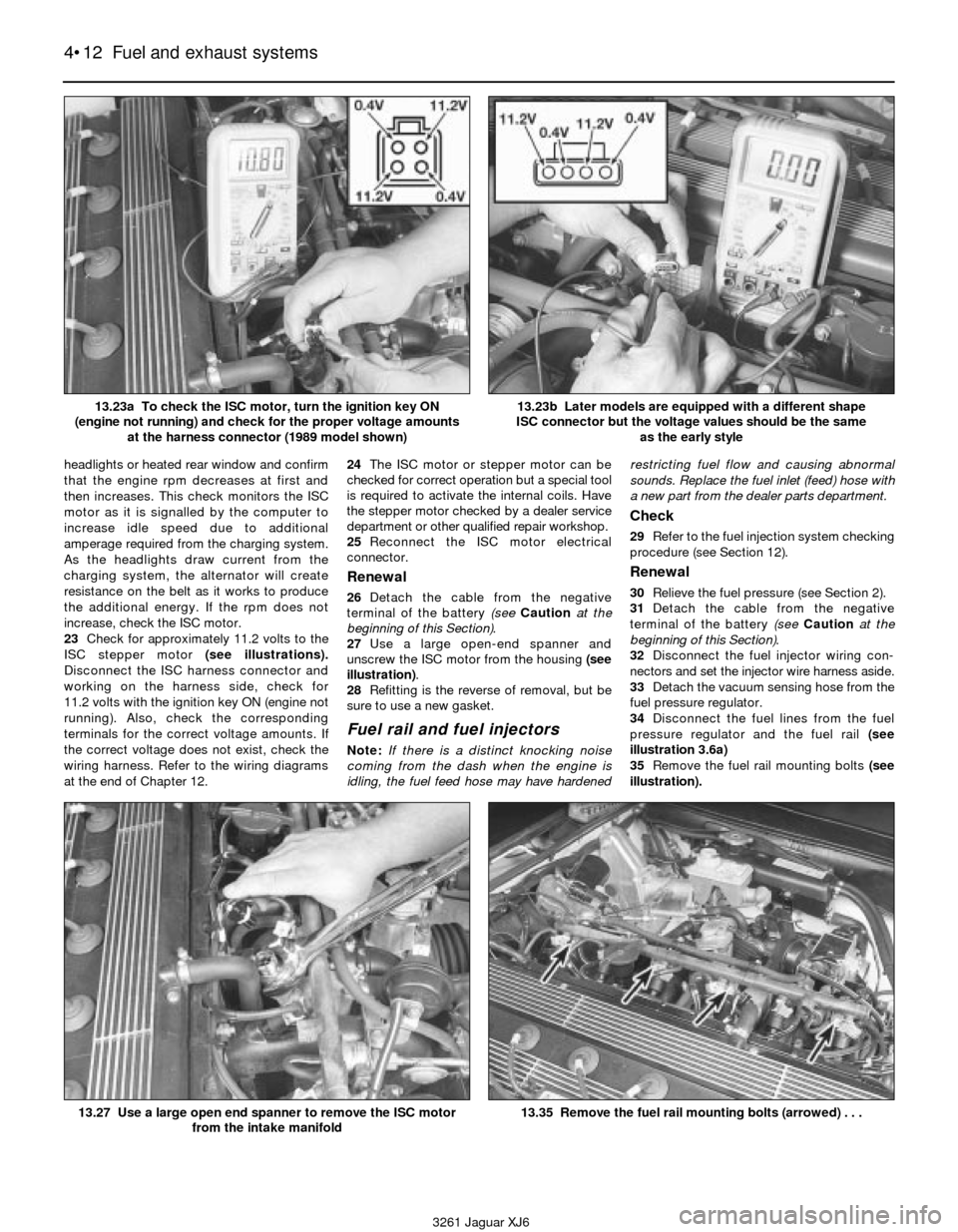

headlights or heated rear window and confirm

that the engine rpm decreases at first and

then increases. This check monitors the ISC

motor as it is signalled by the computer to

increase idle speed due to additional

amperage required from the charging system.

As the headlights draw current from the

charging system, the alternator will create

resistance on the belt as it works to produce

the additional energy. If the rpm does not

increase, check the ISC motor.

23Check for approximately 11.2 volts to the

ISC stepper motor (see illustrations).

Disconnect the ISC harness connector and

working on the harness side, check for

11.2 volts with the ignition key ON (engine not

running). Also, check the corresponding

terminals for the correct voltage amounts. If

the correct voltage does not exist, check the

wiring harness. Refer to the wiring diagrams

at the end of Chapter 12.24The ISC motor or stepper motor can be

checked for correct operation but a special tool

is required to activate the internal coils. Have

the stepper motor checked by a dealer service

department or other qualified repair workshop.

25Reconnect the ISC motor electrical

connector.

Renewal

26Detach the cable from the negative

terminal of the battery (see Cautionat the

beginning of this Section).

27Use a large open-end spanner and

unscrew the ISC motor from the housing (see

illustration).

28Refitting is the reverse of removal, but be

sure to use a new gasket.

Fuel rail and fuel injectors

Note:If there is a distinct knocking noise

coming from the dash when the engine is

idling, the fuel feed hose may have hardenedrestricting fuel flow and causing abnormal

sounds. Replace the fuel inlet (feed) hose with

a new part from the dealer parts department.

Check

29Refer to the fuel injection system checking

procedure (see Section 12).

Renewal

30Relieve the fuel pressure (see Section 2).

31Detach the cable from the negative

terminal of the battery (see Cautionat the

beginning of this Section).

32Disconnect the fuel injector wiring con-

nectors and set the injector wire harness aside.

33Detach the vacuum sensing hose from the

fuel pressure regulator.

34Disconnect the fuel lines from the fuel

pressure regulator and the fuel rail (see

illustration 3.6a)

35Remove the fuel rail mounting bolts (see

illustration).

4•12 Fuel and exhaust systems

3261 Jaguar XJ6 13.23a To check the ISC motor, turn the ignition key ON

(engine not running) and check for the proper voltage amounts

at the harness connector (1989 model shown)

13.23b Later models are equipped with a different shape

ISC connector but the voltage values should be the same

as the early style

13.27 Use a large open end spanner to remove the ISC motor

from the intake manifold13.35 Remove the fuel rail mounting bolts (arrowed) . . .