ECU JAGUAR XJ6 1997 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 6 of 227

3261 Jaguar XJ6

0•6Roadside repairs

The following pages are intended to help in dealing with

common roadside emergencies and breakdowns. You will find

more detailed fault finding information at the back of the

manual, and repair information in the main chapters.

If your car won’t start

and the starter motor

doesn’t turn

MIf it’s a model with automatic transmission, make sure the

selector is in ‘P’ or ‘N’.

MOpen the bonnet and make sure that the battery terminals

are clean and tight.

MSwitch on the headlights and try to start the engine. If the

headlights go very dim when you’re trying to start, the

battery is probably flat. Get out of trouble by jump starting

(see next page) using a friend’s car.

If your car won’t start

even though the starter

motor turns as normal

MIs there fuel in the tank?

MIs there moisture on electrical components under the

bonnet? Switch off the ignition, then wipe off any obvious

dampness with a dry cloth. Spray a water-repellent aerosol

product (WD-40 or equivalent) on ignition and fuel system

electrical connectors like those shown in the photos.

Pay special attention to the ignition coil wiring connector

and HT leads.

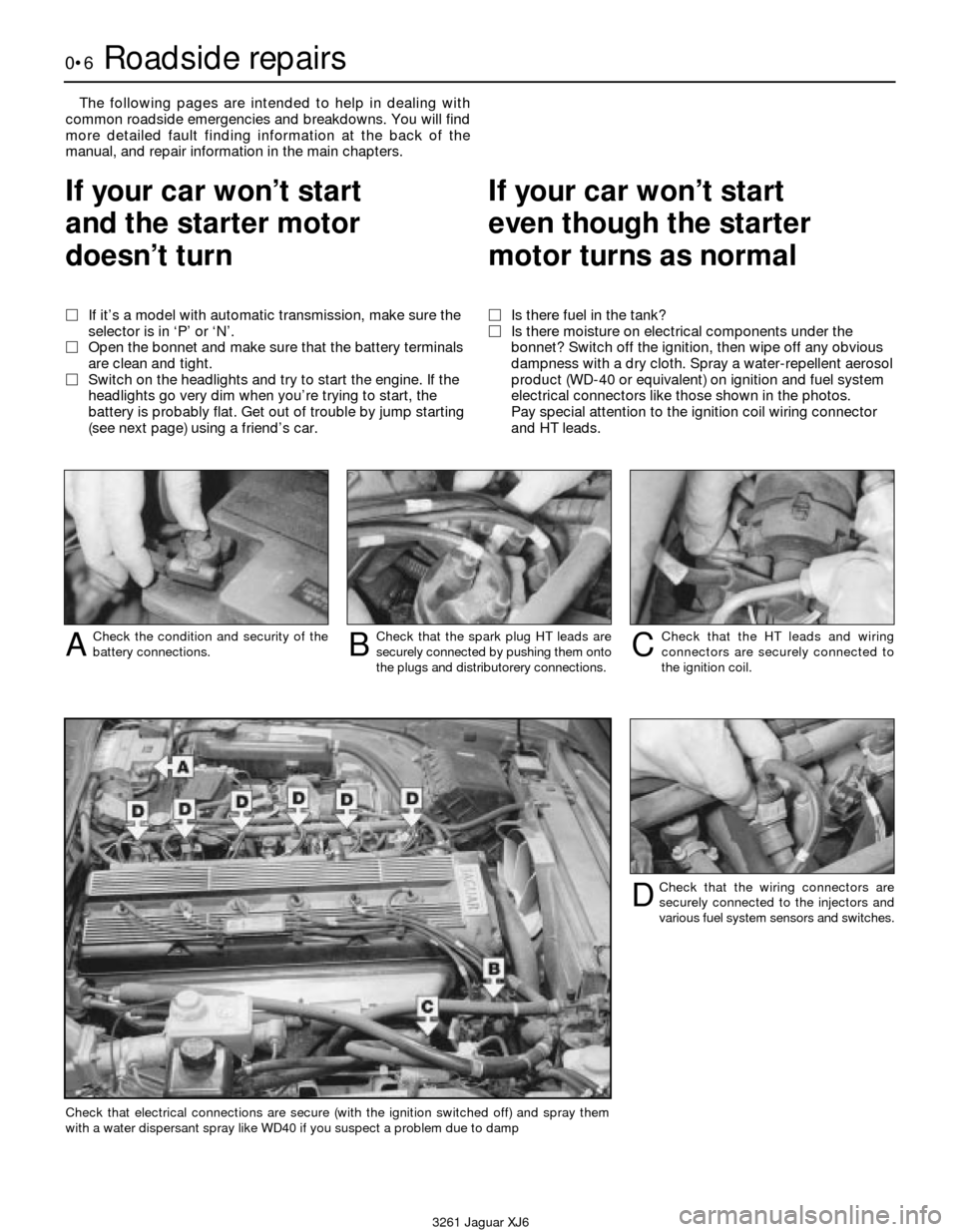

Check the condition and security of the

battery connections.ACheck that the spark plug HT leads are

securely connected by pushing them onto

the plugs and distributorery connections.BCheck that the HT leads and wiring

connectors are securely connected to

the ignition coil.C

Check that the wiring connectors are

securely connected to the injectors and

various fuel system sensors and switches.D

Check that electrical connections are secure (with the ignition switched off) and spray them

with a water dispersant spray like WD40 if you suspect a problem due to damp

Page 8 of 227

3261 Jaguar XJ6

0•8Roadside repairs

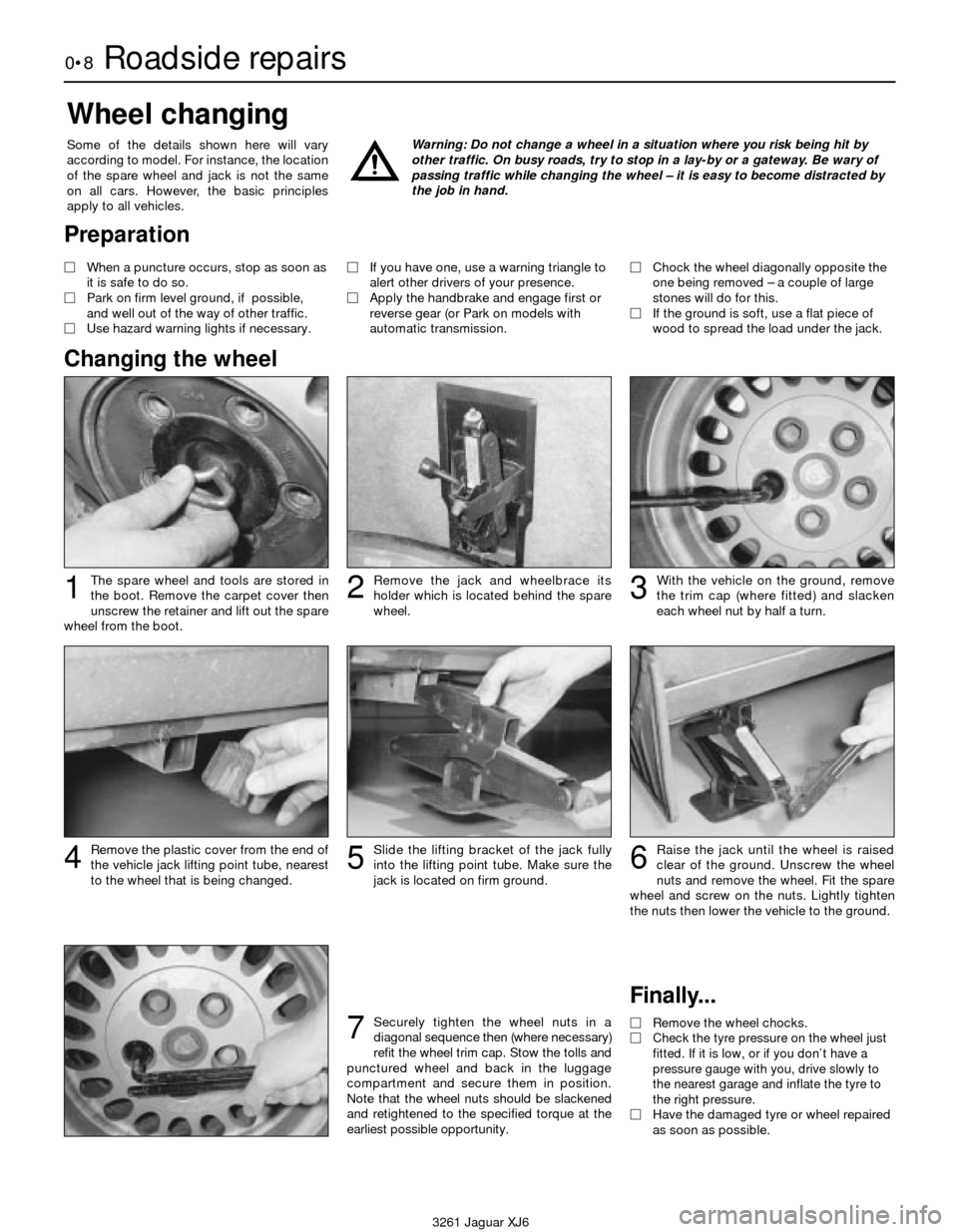

The spare wheel and tools are stored in

the boot. Remove the carpet cover then

unscrew the retainer and lift out the spare

wheel from the boot.

Wheel changing

Some of the details shown here will vary

according to model. For instance, the location

of the spare wheel and jack is not the same

on all cars. However, the basic principles

apply to all vehicles.Warning: Do not change a wheel in a situation where you risk being hit by

other traffic. On busy roads, try to stop in a lay-by or a gateway. Be wary of

passing traffic while changing the wheel – it is easy to become distracted by

the job in hand.

Finally...

MRemove the wheel chocks.

MCheck the tyre pressure on the wheel just

fitted. If it is low, or if you don’t have a

pressure gauge with you, drive slowly to

the nearest garage and inflate the tyre to

the right pressure.

MHave the damaged tyre or wheel repaired

as soon as possible.

Remove the plastic cover from the end of

the vehicle jack lifting point tube, nearest

to the wheel that is being changed.Slide the lifting bracket of the jack fully

into the lifting point tube. Make sure the

jack is located on firm ground.Raise the jack until the wheel is raised

clear of the ground. Unscrew the wheel

nuts and remove the wheel. Fit the spare

wheel and screw on the nuts. Lightly tighten

the nuts then lower the vehicle to the ground.

With the vehicle on the ground, remove

the trim cap (where fitted) and slacken

each wheel nut by half a turn.Remove the jack and wheelbrace its

holder which is located behind the spare

wheel.123

4

Securely tighten the wheel nuts in a

diagonal sequence then (where necessary)

refit the wheel trim cap. Stow the tolls and

punctured wheel and back in the luggage

compartment and secure them in position.

Note that the wheel nuts should be slackened

and retightened to the specified torque at the

earliest possible opportunity.7

56

Preparation

MWhen a puncture occurs, stop as soon as

it is safe to do so.

MPark on firm level ground, if possible,

and well out of the way of other traffic.

MUse hazard warning lights if necessary. MIf you have one, use a warning triangle to

alert other drivers of your presence.

MApply the handbrake and engage first or

reverse gear (or Park on models with

automatic transmission.MChock the wheel diagonally opposite the

one being removed – a couple of large

stones will do for this.

MIf the ground is soft, use a flat piece of

wood to spread the load under the jack.

Changing the wheel

Page 11 of 227

3261 Jaguar XJ6

Weekly checks0•11

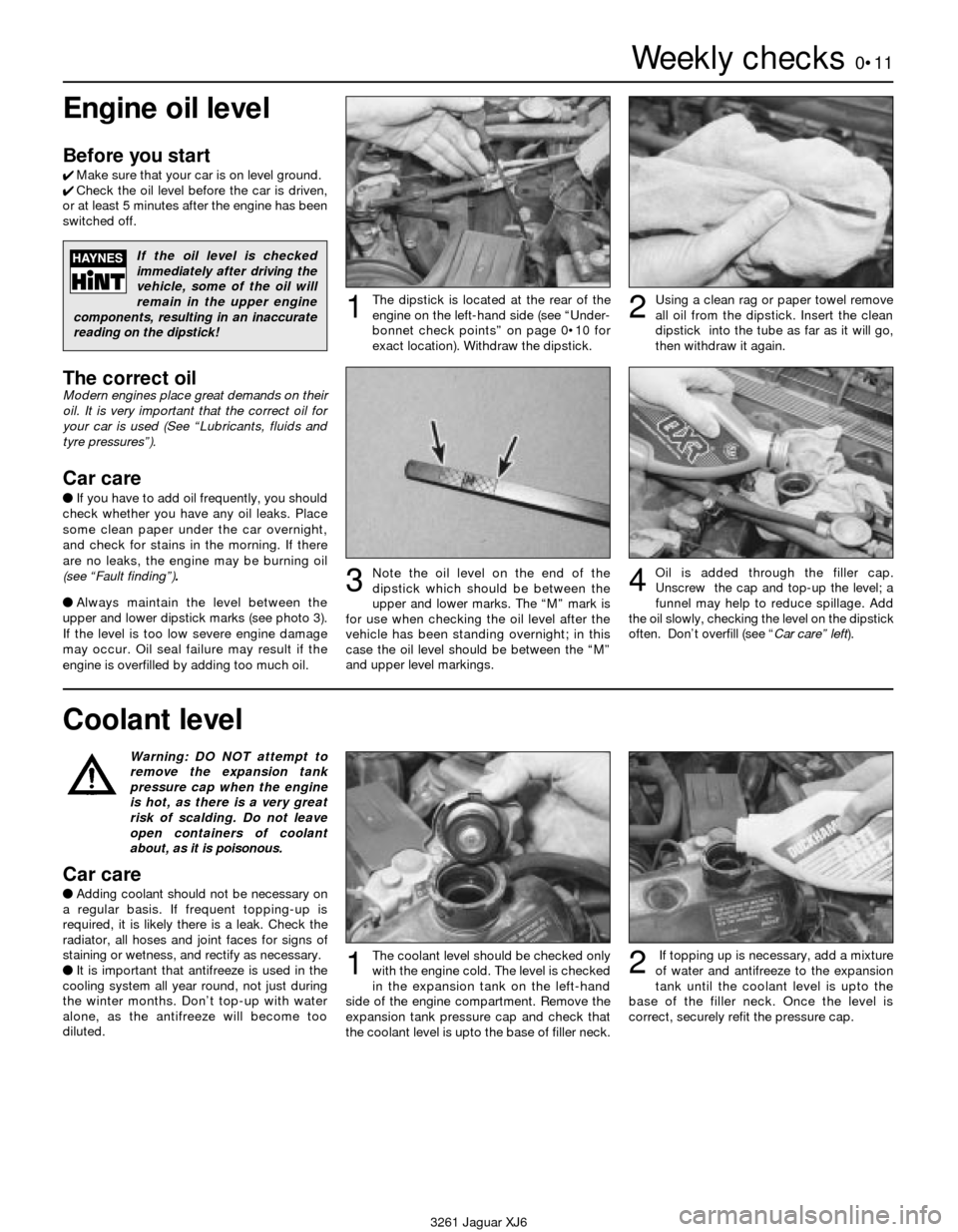

Engine oil level

Before you start

4Make sure that your car is on level ground.

4Check the oil level before the car is driven,

or at least 5 minutes after the engine has been

switched off.

The correct oilModern engines place great demands on their

oil. It is very important that the correct oil for

your car is used (See “Lubricants, fluids and

tyre pressures”).

Car care

l If you have to add oil frequently, you should

check whether you have any oil leaks. Place

some clean paper under the car overnight,

and check for stains in the morning. If there

are no leaks, the engine may be burning oil

(see “Fault finding”).

lAlways maintain the level between the

upper and lower dipstick marks (see photo 3).

If the level is too low severe engine damage

may occur. Oil seal failure may result if the

engine is overfilled by adding too much oil.

If the oil level is checked

immediately after driving the

vehicle, some of the oil will

remain in the upper engine

components, resulting in an inaccurate

reading on the dipstick!

The dipstick is located at the rear of the

engine on the left-hand side (see “Under-

bonnet check points” on page 0•10 for

exact location). Withdraw the dipstick.Using a clean rag or paper towel remove

all oil from the dipstick. Insert the clean

dipstick into the tube as far as it will go,

then withdraw it again.

Note the oil level on the end of the

dipstick which should be between the

upper and lower marks. The “M” mark is

for use when checking the oil level after the

vehicle has been standing overnight; in this

case the oil level should be between the “M”

and upper level markings.Oil is added through the filler cap.

Unscrew the cap and top-up the level; a

funnel may help to reduce spillage. Add

the oil slowly, checking the level on the dipstick

often. Don’t overfill (see “Car care” left).

12

34

Warning: DO NOT attempt to

remove the expansion tank

pressure cap when the engine

is hot, as there is a very great

risk of scalding. Do not leave

open containers of coolant

about, as it is poisonous.

Car care

lAdding coolant should not be necessary on

a regular basis. If frequent topping-up is

required, it is likely there is a leak. Check the

radiator, all hoses and joint faces for signs of

staining or wetness, and rectify as necessary.

lIt is important that antifreeze is used in the

cooling system all year round, not just during

the winter months. Don’t top-up with water

alone, as the antifreeze will become too

diluted.

Coolant level

The coolant level should be checked only

with the engine cold. The level is checked

in the expansion tank on the left-hand

side of the engine compartment. Remove the

expansion tank pressure cap and check that

the coolant level is upto the base of filler neck.If topping up is necessary, add a mixture

of water and antifreeze to the expansion

tank until the coolant level is upto the

base of the filler neck. Once the level is

correct, securely refit the pressure cap.12

Page 12 of 227

3261 Jaguar XJ6

0•12Weekly checks

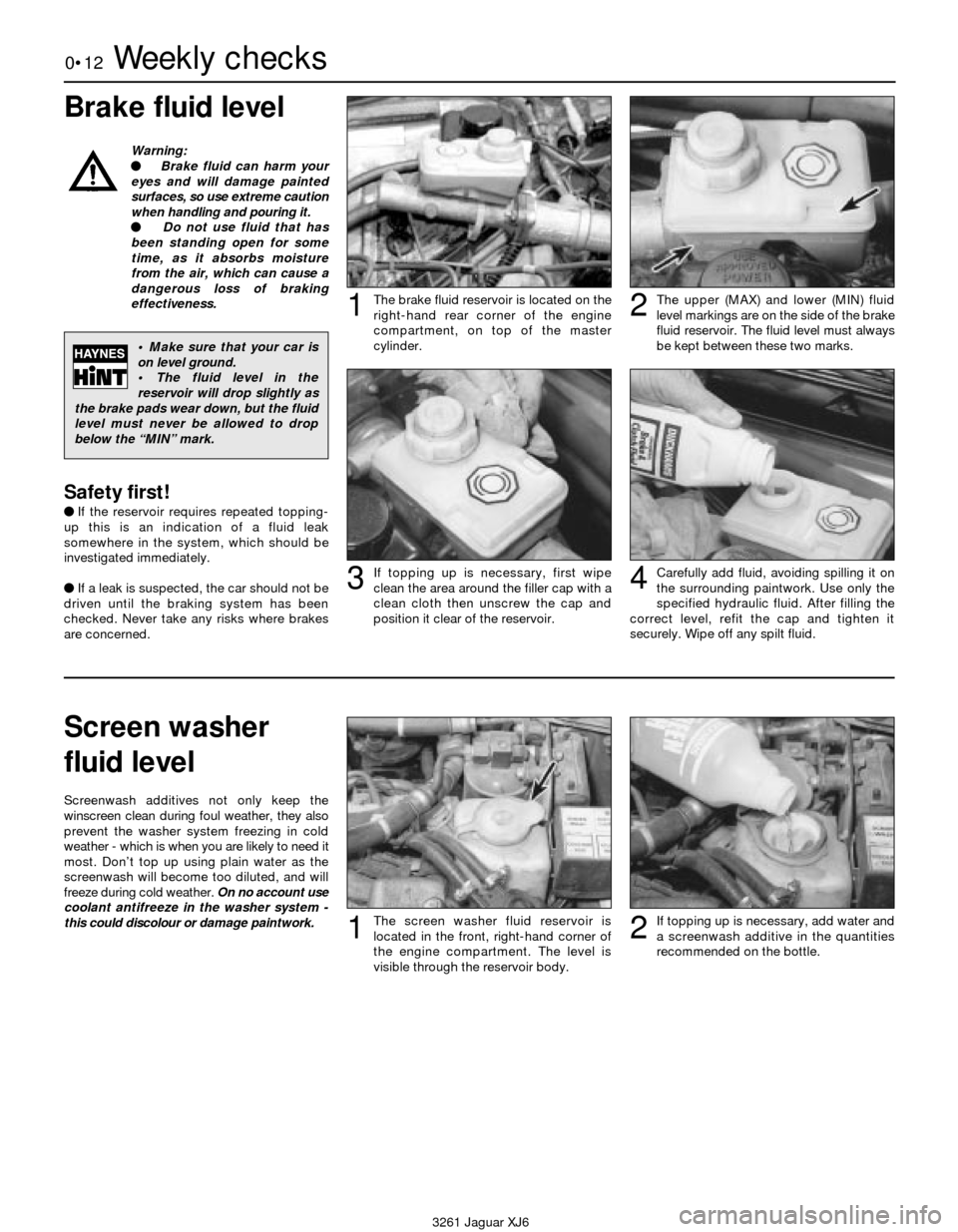

Brake fluid level

Warning:

l Brake fluid can harm your

eyes and will damage painted

surfaces, so use extreme caution

when handling and pouring it.

l Do not use fluid that has

been standing open for some

time, as it absorbs moisture

from the air, which can cause a

dangerous loss of braking

effectiveness.

Safety first!

lIf the reservoir requires repeated topping-

up this is an indication of a fluid leak

somewhere in the system, which should be

investigated immediately.

lIf a leak is suspected, the car should not be

driven until the braking system has been

checked. Never take any risks where brakes

are concerned.

• Make sure that your car is

on level ground.

• The fluid level in the

reservoir will drop slightly as

the brake pads wear down, but the fluid

level must never be allowed to drop

below the “MIN” mark.

The brake fluid reservoir is located on the

right-hand rear corner of the engine

compartment, on top of the master

cylinder.1The upper (MAX) and lower (MIN) fluid

level markings are on the side of the brake

fluid reservoir. The fluid level must always

be kept between these two marks.2

If topping up is necessary, first wipe

clean the area around the filler cap with a

clean cloth then unscrew the cap and

position it clear of the reservoir.3Carefully add fluid, avoiding spilling it on

the surrounding paintwork. Use only the

specified hydraulic fluid. After filling the

correct level, refit the cap and tighten it

securely. Wipe off any spilt fluid.4

Screenwash additives not only keep the

winscreen clean during foul weather, they also

prevent the washer system freezing in cold

weather - which is when you are likely to need it

most. Don’t top up using plain water as the

screenwash will become too diluted, and will

freeze during cold weather. On no account use

coolant antifreeze in the washer system -

this could discolour or damage paintwork.

Screen washer

fluid level

If topping up is necessary, add water and

a screenwash additive in the quantities

recommended on the bottle.2The screen washer fluid reservoir is

located in the front, right-hand corner of

the engine compartment. The level is

visible through the reservoir body.1

Page 13 of 227

3261 Jaguar XJ6

Weekly checks0•13

Power steering

fluid level

Before you start:

4Park the vehicle on level ground.

4Set the steering wheel straight-ahead.

4The engine should be turned off.

Safety first!

lThe need for frequent topping-up indicates

a leak, which should be investigated

immediately.

For the check to be

accurate, the steering must

not be turned once the

engine has been stopped.

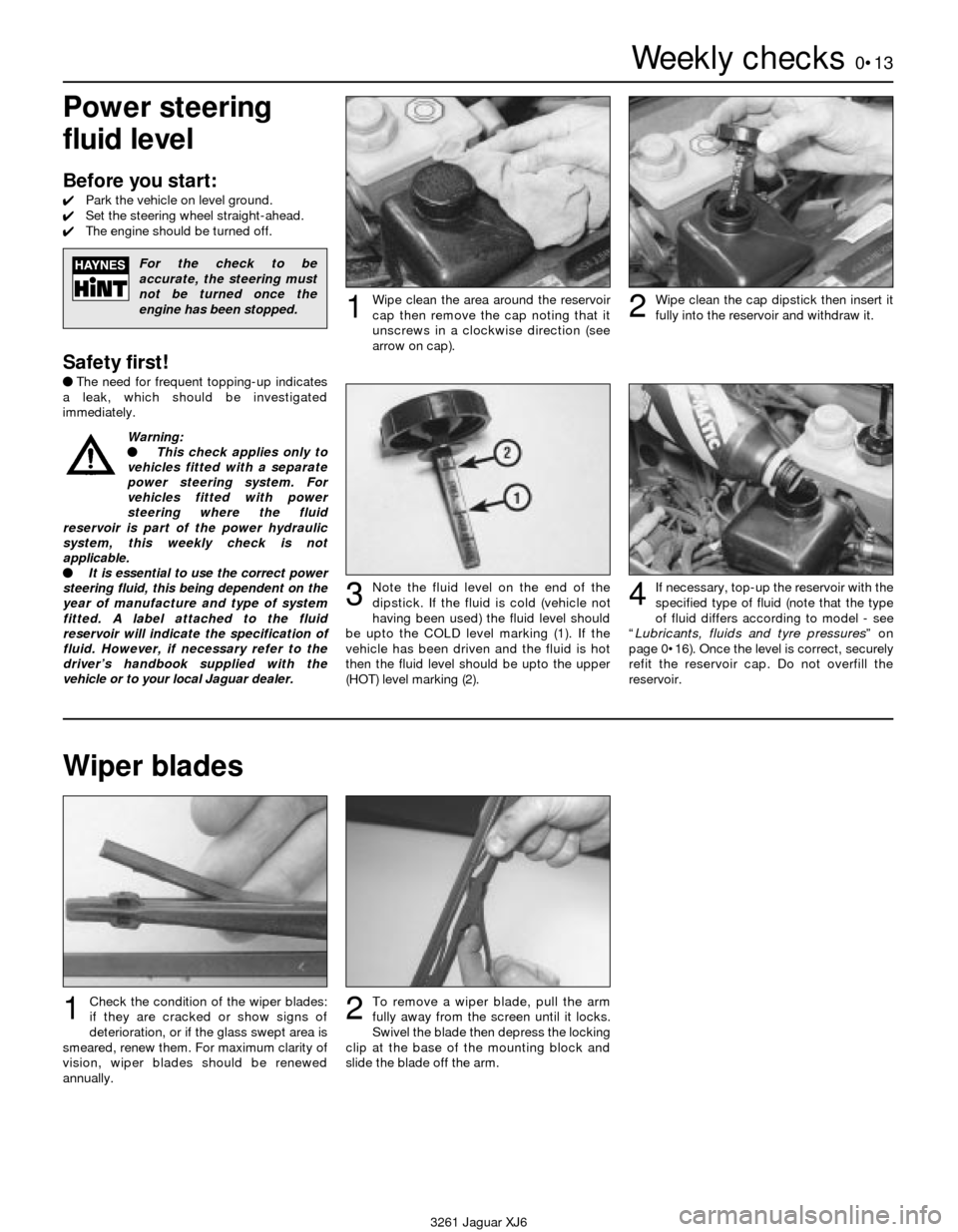

Wipe clean the area around the reservoir

cap then remove the cap noting that it

unscrews in a clockwise direction (see

arrow on cap).1Wipe clean the cap dipstick then insert it

fully into the reservoir and withdraw it.2

Note the fluid level on the end of the

dipstick. If the fluid is cold (vehicle not

having been used) the fluid level should

be upto the COLD level marking (1). If the

vehicle has been driven and the fluid is hot

then the fluid level should be upto the upper

(HOT) level marking (2).3If necessary, top-up the reservoir with the

specified type of fluid (note that the type

of fluid differs according to model - see

“Lubricants, fluids and tyre pressures” on

page 0•16). Once the level is correct, securely

refit the reservoir cap. Do not overfill the

reservoir.4

Wiper blades

Check the condition of the wiper blades:

if they are cracked or show signs of

deterioration, or if the glass swept area is

smeared, renew them. For maximum clarity of

vision, wiper blades should be renewed

annually.1To remove a wiper blade, pull the arm

fully away from the screen until it locks.

Swivel the blade then depress the locking

clip at the base of the mounting block and

slide the blade off the arm.2

Warning:

l This check applies only to

vehicles fitted with a separate

power steering system. For

vehicles fitted with power

steering where the fluid

reservoir is part of the power hydraulic

system, this weekly check is not

applicable.

l It is essential to use the correct power

steering fluid, this being dependent on the

year of manufacture and type of system

fitted. A label attached to the fluid

reservoir will indicate the specification of

fluid. However, if necessary refer to the

driver’s handbook supplied with the

vehicle or to your local Jaguar dealer.

Page 15 of 227

3261 Jaguar XJ6

Weekly checks0•15

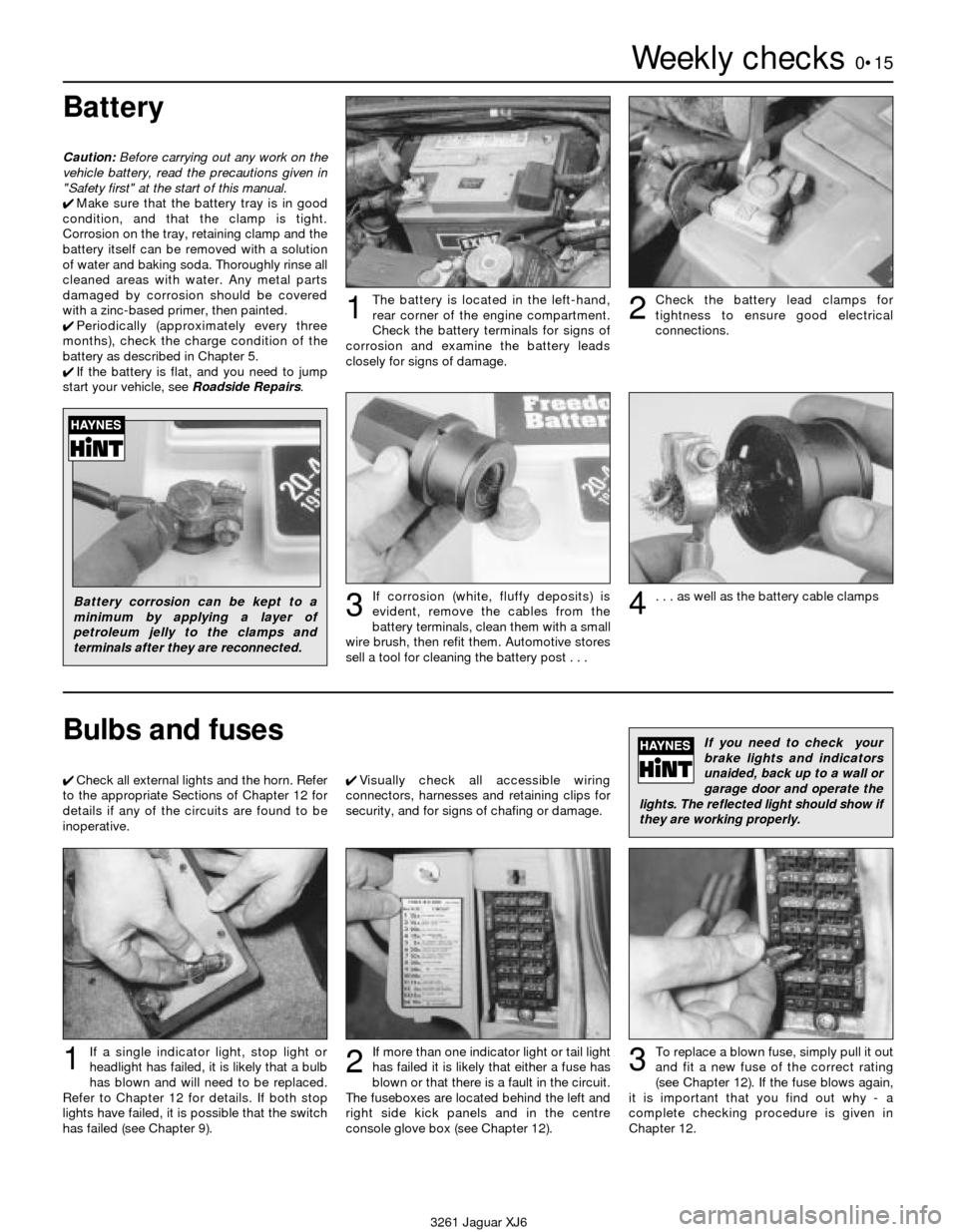

Battery

Caution:Before carrying out any work on the

vehicle battery, read the precautions given in

"Safety first" at the start of this manual.

4Make sure that the battery tray is in good

condition, and that the clamp is tight.

Corrosion on the tray, retaining clamp and the

battery itself can be removed with a solution

of water and baking soda. Thoroughly rinse all

cleaned areas with water. Any metal parts

damaged by corrosion should be covered

with a zinc-based primer, then painted.

4Periodically (approximately every three

months), check the charge condition of the

battery as described in Chapter 5.

4If the battery is flat, and you need to jump

start your vehicle, see Roadside Repairs.

The battery is located in the left-hand,

rear corner of the engine compartment.

Check the battery terminals for signs of

corrosion and examine the battery leads

closely for signs of damage.1Check the battery lead clamps for

tightness to ensure good electrical

connections.2

Battery corrosion can be kept to a

minimum by applying a layer of

petroleum jelly to the clamps and

terminals after they are reconnected.If corrosion (white, fluffy deposits) is

evident, remove the cables from the

battery terminals, clean them with a small

wire brush, then refit them. Automotive stores

sell a tool for cleaning the battery post . . .3. . . as well as the battery cable clamps4

Bulbs and fuses

4Check all external lights and the horn. Refer

to the appropriate Sections of Chapter 12 for

details if any of the circuits are found to be

inoperative.4Visually check all accessible wiring

connectors, harnesses and retaining clips for

security, and for signs of chafing or damage.

If you need to check your

brake lights and indicators

unaided, back up to a wall or

garage door and operate the

lights. The reflected light should show if

they are working properly.

If a single indicator light, stop light or

headlight has failed, it is likely that a bulb

has blown and will need to be replaced.

Refer to Chapter 12 for details. If both stop

lights have failed, it is possible that the switch

has failed (see Chapter 9).If more than one indicator light or tail light

has failed it is likely that either a fuse has

blown or that there is a fault in the circuit.

The fuseboxes are located behind the left and

right side kick panels and in the centre

console glove box (see Chapter 12).

2

To replace a blown fuse, simply pull it out

and fit a new fuse of the correct rating

(see Chapter 12). If the fuse blows again,

it is important that you find out why - a

complete checking procedure is given in

Chapter 12.31

Page 16 of 227

0•16Lubricants, fluids and tyre pressures

3261 Jaguar XJ6

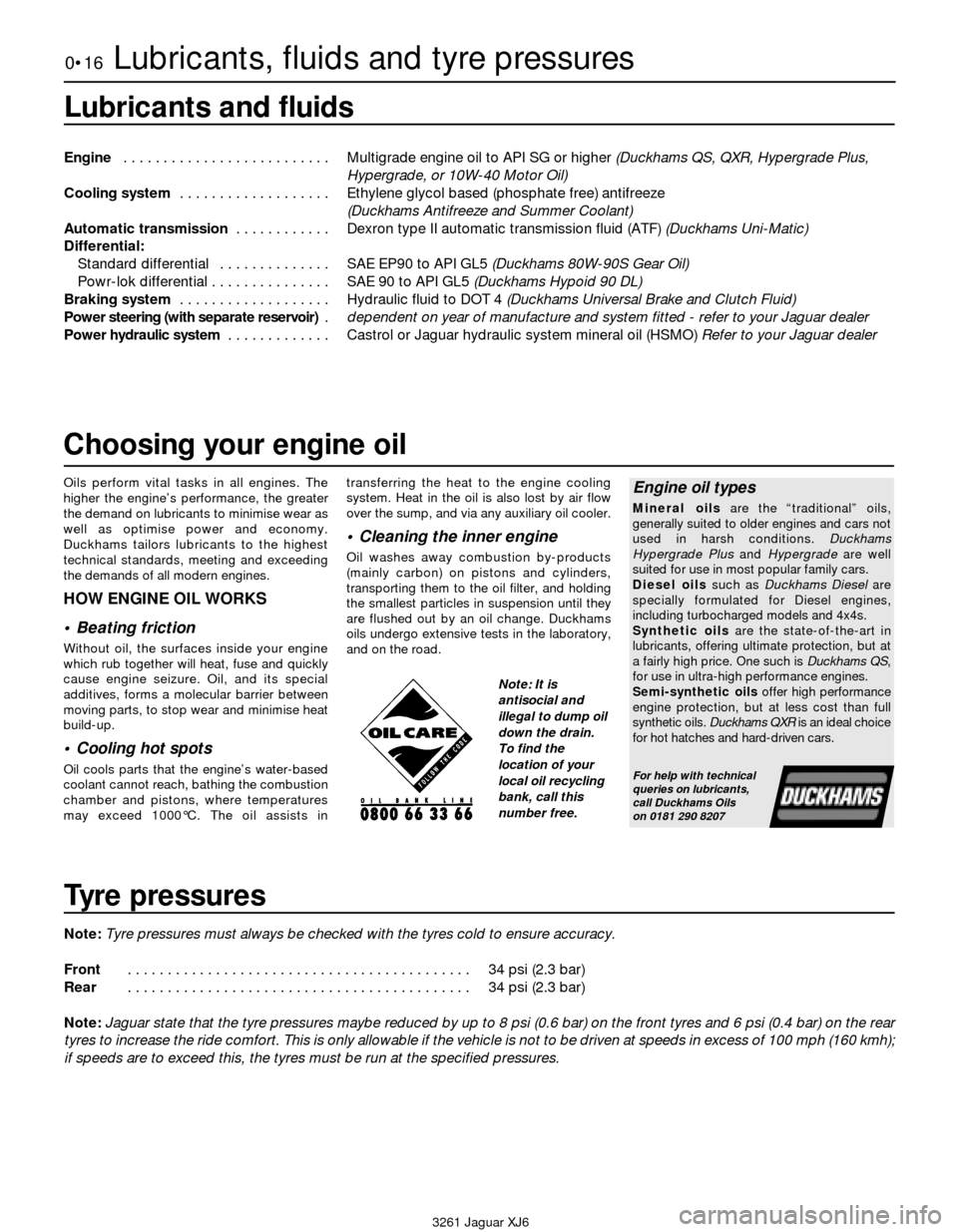

Lubricants and fluids

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . Multigrade engine oil to API SG or higher (Duckhams QS, QXR, Hypergrade Plus,

Hypergrade, or 10W-40 Motor Oil)

Cooling system . . . . . . . . . . . . . . . . . . . Ethylene glycol based (phosphate free) antifreeze

(Duckhams Antifreeze and Summer Coolant)

Automatic transmission . . . . . . . . . . . . Dexron type II automatic transmission fluid (ATF) (Duckhams Uni-Matic)

Differential:

Standard differential . . . . . . . . . . . . . . SAE EP90 to API GL5 (Duckhams 80W-90S Gear Oil)

Powr-lok differential . . . . . . . . . . . . . . . SAE 90 to API GL5 (Duckhams Hypoid 90 DL)

Braking system . . . . . . . . . . . . . . . . . . . Hydraulic fluid to DOT 4 (Duckhams Universal Brake and Clutch Fluid)

Power steering (with separate reservoir) .dependent on year of manufacture and system fitted - refer to your Jaguar dealer

Power hydraulic system . . . . . . . . . . . . . Castrol or Jaguar hydraulic system mineral oil (HSMO) Refer to your Jaguar dealer

Tyre pressures

Note:Tyre pressures must always be checked with the tyres cold to ensure accuracy.

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 psi (2.3 bar)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 psi (2.3 bar)

Note:Jaguar state that the tyre pressures maybe reduced by up to 8 psi (0.6 bar) on the front tyres and 6 psi (0.4 bar) on the rear

tyres to increase the ride comfort. This is only allowable if the vehicle is not to be driven at speeds in excess of 100 mph (160 kmh);

if speeds are to exceed this, the tyres must be run at the specified pressures.

Oils perform vital tasks in all engines. The

higher the engine’s performance, the greater

the demand on lubricants to minimise wear as

well as optimise power and economy.

Duckhams tailors lubricants to the highest

technical standards, meeting and exceeding

the demands of all modern engines.

HOW ENGINE OIL WORKS

• Beating friction

Without oil, the surfaces inside your engine

which rub together will heat, fuse and quickly

cause engine seizure. Oil, and its special

additives, forms a molecular barrier between

moving parts, to stop wear and minimise heat

build-up.

• Cooling hot spots

Oil cools parts that the engine’s water-based

coolant cannot reach, bathing the combustion

chamber and pistons, where temperatures

may exceed 1000°C. The oil assists intransferring the heat to the engine cooling

system. Heat in the oil is also lost by air flow

over the sump, and via any auxiliary oil cooler.

• Cleaning the inner engine

Oil washes away combustion by-products

(mainly carbon) on pistons and cylinders,

transporting them to the oil filter, and holding

the smallest particles in suspension until they

are flushed out by an oil change. Duckhams

oils undergo extensive tests in the laboratory,

and on the road.

Engine oil types

Mineral oilsare the “traditional” oils,

generally suited to older engines and cars not

used in harsh conditions. Duckhams

Hypergrade Plus and Hypergradeare well

suited for use in most popular family cars.

Diesel oilssuch as Duckhams Dieselare

specially formulated for Diesel engines,

including turbocharged models and 4x4s.

Synthetic oilsare the state-of-the-art in

lubricants, offering ultimate protection, but at

a fairly high price. One such is Duckhams QS,

for use in ultra-high performance engines.

Semi-synthetic oilsoffer high performance

engine protection, but at less cost than full

synthetic oils. Duckhams QXRis an ideal choice

for hot hatches and hard-driven cars.

For help with technical

queries on lubricants,

call Duckhams Oils

on 0181 290 8207

Choosing your engine oil

Note: It is

antisocial and

illegal to dump oil

down the drain.

To find the

location of your

local oil recycling

bank, call this

number free.

Page 23 of 227

exhaust components will be warm during the

actual work, so try to anticipate any potential

problems before the engine and accessories

are hot.

5Park the vehicle on a level spot. Start the

engine and allow it to reach its normal

operating temperature (the needle on the

temperature gauge should be at least above

the bottom mark). Warm oil and contaminates

will flow out more easily. Turn off the engine

when it’s warmed up. Remove the oil filler cap

located next to the valve cover.

6Raise the vehicle and support it on axle

stands.

Warning: To avoid personal

injury, never get beneath the

vehicle when it is supported by

only by a jack. The jack provided

with your vehicle is designed solely for

raising the vehicle to remove and replace

the wheels. Always use axle stands to

support the vehicle when it becomes

necessary to place your body underneath

the vehicle.

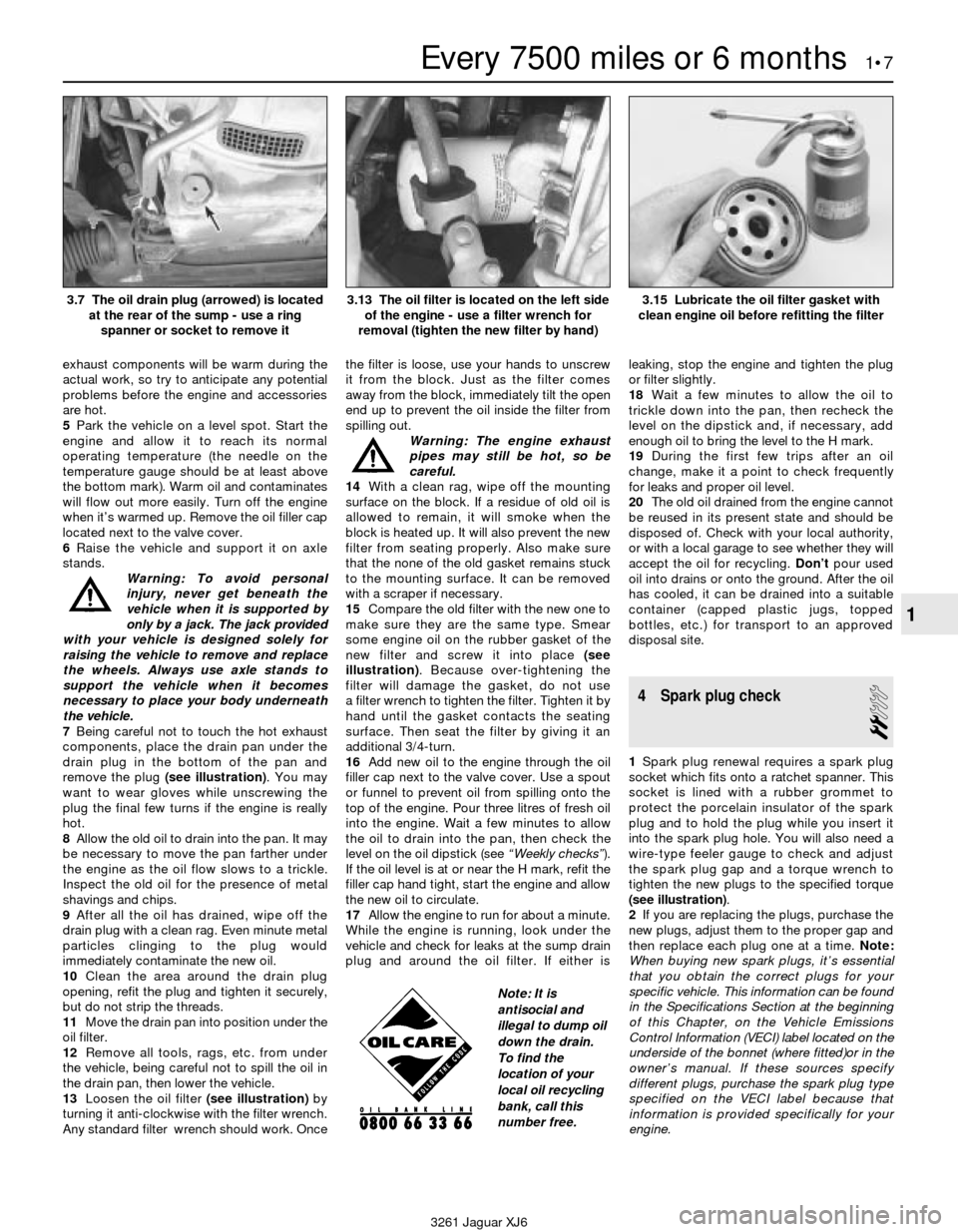

7Being careful not to touch the hot exhaust

components, place the drain pan under the

drain plug in the bottom of the pan and

remove the plug (see illustration). You may

want to wear gloves while unscrewing the

plug the final few turns if the engine is really

hot.

8Allow the old oil to drain into the pan. It may

be necessary to move the pan farther under

the engine as the oil flow slows to a trickle.

Inspect the old oil for the presence of metal

shavings and chips.

9After all the oil has drained, wipe off the

drain plug with a clean rag. Even minute metal

particles clinging to the plug would

immediately contaminate the new oil.

10Clean the area around the drain plug

opening, refit the plug and tighten it securely,

but do not strip the threads.

11Move the drain pan into position under the

oil filter.

12Remove all tools, rags, etc. from under

the vehicle, being careful not to spill the oil in

the drain pan, then lower the vehicle.

13Loosen the oil filter (see illustration)by

turning it anti-clockwise with the filter wrench.

Any standard filter wrench should work. Oncethe filter is loose, use your hands to unscrew

it from the block. Just as the filter comes

away from the block, immediately tilt the open

end up to prevent the oil inside the filter from

spilling out.

Warning: The engine exhaust

pipes may still be hot, so be

careful.

14With a clean rag, wipe off the mounting

surface on the block. If a residue of old oil is

allowed to remain, it will smoke when the

block is heated up. It will also prevent the new

filter from seating properly. Also make sure

that the none of the old gasket remains stuck

to the mounting surface. It can be removed

with a scraper if necessary.

15Compare the old filter with the new one to

make sure they are the same type. Smear

some engine oil on the rubber gasket of the

new filter and screw it into place (see

illustration). Because over-tightening the

filter will damage the gasket, do not use

a filter wrench to tighten the filter. Tighten it by

hand until the gasket contacts the seating

surface. Then seat the filter by giving it an

additional 3/4-turn.

16Add new oil to the engine through the oil

filler cap next to the valve cover. Use a spout

or funnel to prevent oil from spilling onto the

top of the engine. Pour three litres of fresh oil

into the engine. Wait a few minutes to allow

the oil to drain into the pan, then check the

level on the oil dipstick (see “Weekly checks”).

If the oil level is at or near the H mark, refit the

filler cap hand tight, start the engine and allow

the new oil to circulate.

17Allow the engine to run for about a minute.

While the engine is running, look under the

vehicle and check for leaks at the sump drain

plug and around the oil filter. If either isleaking, stop the engine and tighten the plug

or filter slightly.

18Wait a few minutes to allow the oil to

trickle down into the pan, then recheck the

level on the dipstick and, if necessary, add

enough oil to bring the level to the H mark.

19During the first few trips after an oil

change, make it a point to check frequently

for leaks and proper oil level.

20The old oil drained from the engine cannot

be reused in its present state and should be

disposed of. Check with your local authority,

or with a local garage to see whether they will

accept the oil for recycling. Don’tpour used

oil into drains or onto the ground. After the oil

has cooled, it can be drained into a suitable

container (capped plastic jugs, topped

bottles, etc.) for transport to an approved

disposal site.

4 Spark plug check

2

1Spark plug renewal requires a spark plug

socket which fits onto a ratchet spanner. This

socket is lined with a rubber grommet to

protect the porcelain insulator of the spark

plug and to hold the plug while you insert it

into the spark plug hole. You will also need a

wire-type feeler gauge to check and adjust

the spark plug gap and a torque wrench to

tighten the new plugs to the specified torque

(see illustration).

2If you are replacing the plugs, purchase the

new plugs, adjust them to the proper gap and

then replace each plug one at a time. Note:

When buying new spark plugs, it’s essential

that you obtain the correct plugs for your

specific vehicle. This information can be found

in the Specifications Section at the beginning

of this Chapter, on the Vehicle Emissions

Control Information (VECI) label located on the

underside of the bonnet (where fitted)or in the

owner’s manual. If these sources specify

different plugs, purchase the spark plug type

specified on the VECI label because that

information is provided specifically for your

engine.

Every 7500 miles or 6 months 1•7

1

3.7 The oil drain plug (arrowed) is located

at the rear of the sump - use a ring

spanner or socket to remove it3.13 The oil filter is located on the left side

of the engine - use a filter wrench for

removal (tighten the new filter by hand)3.15 Lubricate the oil filter gasket with

clean engine oil before refitting the filter

3261 Jaguar XJ6

Note: It is

antisocial and

illegal to dump oil

down the drain.

To find the

location of your

local oil recycling

bank, call this

number free.

Page 27 of 227

leak be found, renew the offending gasket or

oil seal by referring to the appropriate

Chapters in this manual.

2Also check the security and condition of all

the engine-related pipes and hoses. Ensure

that all cable ties or securing clips are in place

and in good condition. Clips which are broken

or missing can lead to chafing of the hoses,

pipes or wiring, which could cause more

serious problems in the future.

3Carefully check the radiator hoses and

heater hoses along their entire length. Renew

any hose which is cracked, swollen or

deteriorated. Cracks will show up better if

the hose is squeezed. Pay close attention

to the hose clips that secure the hoses to the

cooling system components. Hose clips can

pinch and puncture hoses, resulting in cooling

system leaks.

4Inspect all the cooling system components

(hoses, joint faces etc.) for leaks. A leak in the

cooling system will usually show up as white-

or rust-coloured deposits on the area

adjoining the leak. Where any problems of this

nature are found on system components,

renew the component or gasket with

reference to Chapter 3.

5From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

6Also check the condition of the power

steering fluid hoses and pipes.

8 Automatic transmission

fluid level check

1

1The level of the automatic transmission fluid

should be carefully maintained. Low fluid level

can lead to slipping or loss of drive, while

overfilling can cause foaming, loss of fluid and

transmission damage.

2The transmission fluid level should only be

checked when the transmission is at its

normal operating temperature.

Caution: If the vehicle has just been driven

for a long time at high speed or in city

traffic in hot weather, or if it has been

pulling a trailer, an accurate fluid level

reading cannot be obtained. Allow the fluid

to cool down for about 30 minutes.

3If the vehicle has not been driven, park the

vehicle on level ground, set the handbrake,

then start the engine and bring it to operating

temperature. While the engine is idling,

depress the brake pedal and move the

selector lever through all the gear ranges,

beginning and ending in Park.

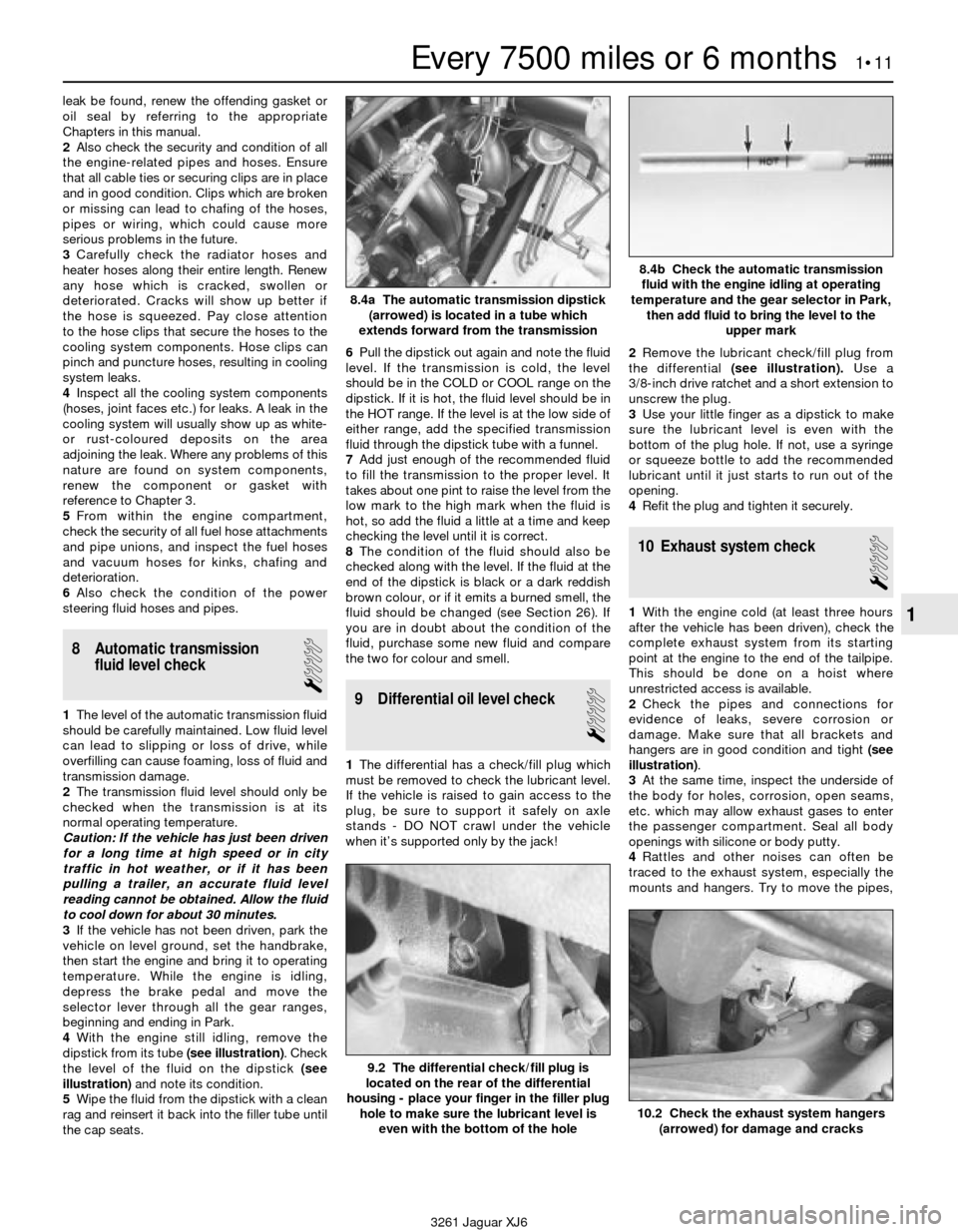

4With the engine still idling, remove the

dipstick from its tube (see illustration). Check

the level of the fluid on the dipstick (see

illustration)and note its condition.

5Wipe the fluid from the dipstick with a clean

rag and reinsert it back into the filler tube until

the cap seats.6Pull the dipstick out again and note the fluid

level. If the transmission is cold, the level

should be in the COLD or COOL range on the

dipstick. If it is hot, the fluid level should be in

the HOT range. If the level is at the low side of

either range, add the specified transmission

fluid through the dipstick tube with a funnel.

7Add just enough of the recommended fluid

to fill the transmission to the proper level. It

takes about one pint to raise the level from the

low mark to the high mark when the fluid is

hot, so add the fluid a little at a time and keep

checking the level until it is correct.

8The condition of the fluid should also be

checked along with the level. If the fluid at the

end of the dipstick is black or a dark reddish

brown colour, or if it emits a burned smell, the

fluid should be changed (see Section 26). If

you are in doubt about the condition of the

fluid, purchase some new fluid and compare

the two for colour and smell.9 Differential oil level check

1

1The differential has a check/fill plug which

must be removed to check the lubricant level.

If the vehicle is raised to gain access to the

plug, be sure to support it safely on axle

stands - DO NOT crawl under the vehicle

when it’s supported only by the jack!2Remove the lubricant check/fill plug from

the differential (see illustration).Use a

3/8-inch drive ratchet and a short extension to

unscrew the plug.

3Use your little finger as a dipstick to make

sure the lubricant level is even with the

bottom of the plug hole. If not, use a syringe

or squeeze bottle to add the recommended

lubricant until it just starts to run out of the

opening.

4Refit the plug and tighten it securely.

10 Exhaust system check

1

1With the engine cold (at least three hours

after the vehicle has been driven), check the

complete exhaust system from its starting

point at the engine to the end of the tailpipe.

This should be done on a hoist where

unrestricted access is available.

2Check the pipes and connections for

evidence of leaks, severe corrosion or

damage. Make sure that all brackets and

hangers are in good condition and tight (see

illustration).

3At the same time, inspect the underside of

the body for holes, corrosion, open seams,

etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with silicone or body putty.

4Rattles and other noises can often be

traced to the exhaust system, especially the

mounts and hangers. Try to move the pipes,

Every 7500 miles or 6 months 1•11

1

9.2 The differential check/fill plug is

located on the rear of the differential

housing - place your finger in the filler plug

hole to make sure the lubricant level is

even with the bottom of the hole

10.2 Check the exhaust system hangers

(arrowed) for damage and cracks

3261 Jaguar XJ6

8.4a The automatic transmission dipstick

(arrowed) is located in a tube which

extends forward from the transmission

8.4b Check the automatic transmission

fluid with the engine idling at operating

temperature and the gear selector in Park,

then add fluid to bring the level to the

upper mark

Page 28 of 227

silencer and catalytic converter. If the

components can come in contact with the

body or suspension parts, secure the exhaust

system with new mounts.

5Check the running condition of the engine

by inspecting inside the end of the tailpipe.

The exhaust deposits here are an indication of

engine state-of-tune. If the pipe is black and

sooty or coated with white deposits, the

engine is in need of a tune-up, including a

thorough fuel system inspection.

11 Braking system - general

check and adjustment

2

Warning: The dust created by

the brake system may contain

asbestos, which is harmful to

your health. Never blow it out

with compressed air and don’t inhale any

of it. An approved filtering mask should be

worn when working on the brakes. Do not,

under any circumstances, use petroleum-

based solvents to clean brake parts. Use

brake system cleaner only! Try to use non-

asbestos replacement parts whenever

possible.

Note: For detailed photographs of the brake

system, refer to Chapter 9.

1In addition to the specified intervals, the

brakes should be inspected every time the

wheels are removed or whenever a defect is

suspected. Any of the following symptoms

could indicate a potential brake system

defect: The vehicle pulls to one side when the

brake pedal is depressed; the brakes make

squealing or dragging noises when applied;

brake pedal travel is excessive; the pedal

pulsates; brake fluid leaks, usually onto the

inside of the tyre or wheel.

2The disc brakes have built-in electrical wear

indicators which cause a warning lamp to

illuminate on the instrument panel when

they’re worn to the renewal point. When the

warning light comes on, replace the pads

immediately or expensive damage to the

discs can result.

3Loosen the wheel nuts.

4Raise the vehicle and place it securely on

axle stands.

5Remove the wheels.

Disc brakes

6There are two pads (an outer and an inner)

in each caliper. The pads are visible through

inspection holes in each caliper (see Haynes

Hint).

7Check the pad thickness by looking at each

end of the caliper and through the inspection

hole in the caliper body. If the lining material is

less than the thickness listed in this Chapter’s

Specifications, replace the pads. Note:Keep

in mind that the lining material is riveted or

bonded to a metal backing plate and the metal

portion is not included in this measurement.8If it is difficult to determine the exact

thickness of the remaining pad material by the

above method, or if you are at all concerned

about the condition of the pads, remove the

caliper(s), then remove the pads from the

calipers for further inspection (see Chapter 9).

9Once the pads are removed from the

calipers, clean them with brake cleaner and

re-measure them with a ruler or a vernier

caliper.

10Measure the disc thickness with a

micrometer to make sure that it still has

service life remaining. If any disc is thinner

than the specified minimum thickness,

replace it (refer to Chapter 9). Even if the disc

has service life remaining, check its condition.

Look for scoring, gouging and burned spots. If

these conditions exist, remove the disc and

have it resurfaced (see Chapter 9).

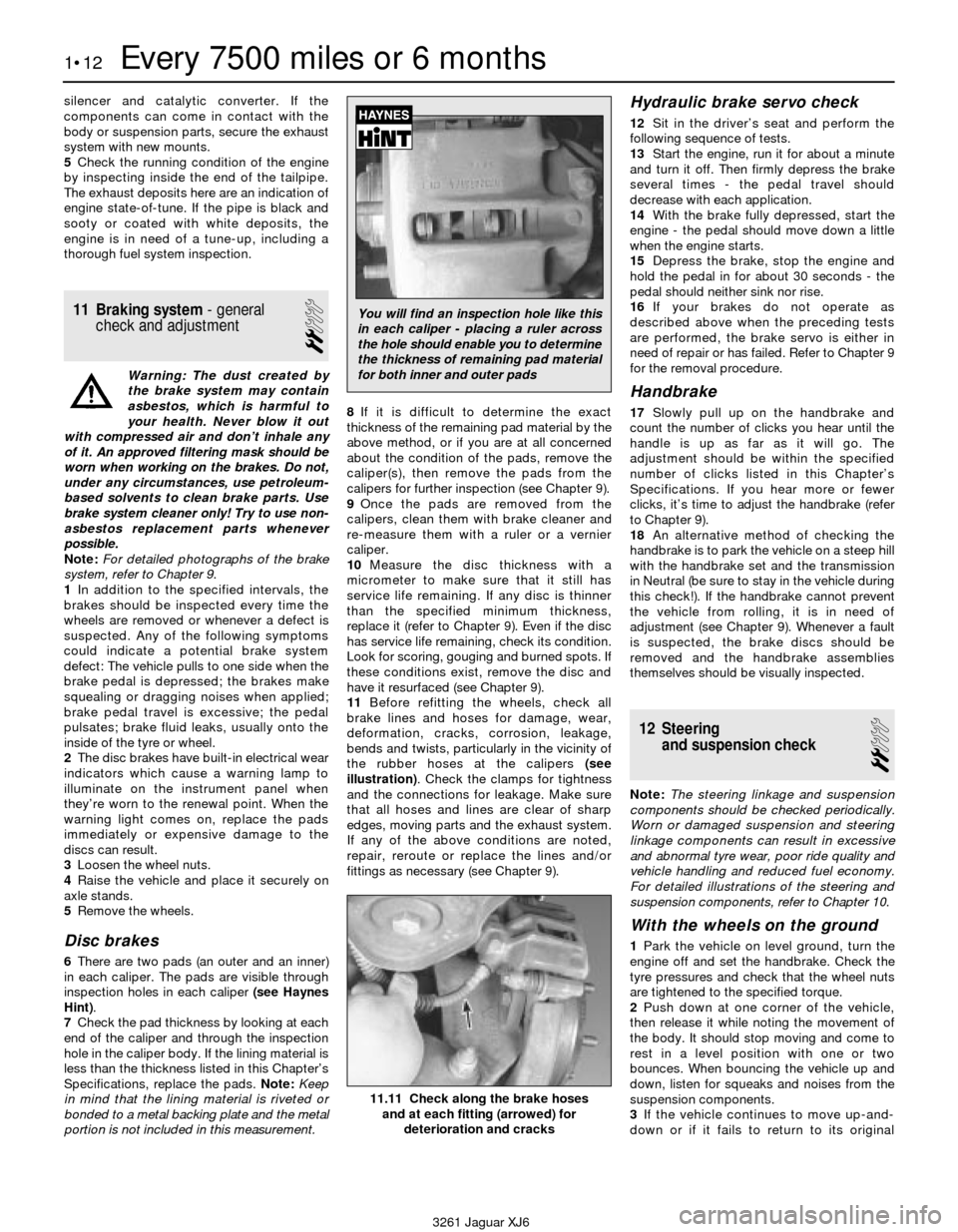

11Before refitting the wheels, check all

brake lines and hoses for damage, wear,

deformation, cracks, corrosion, leakage,

bends and twists, particularly in the vicinity of

the rubber hoses at the calipers (see

illustration). Check the clamps for tightness

and the connections for leakage. Make sure

that all hoses and lines are clear of sharp

edges, moving parts and the exhaust system.

If any of the above conditions are noted,

repair, reroute or replace the lines and/or

fittings as necessary (see Chapter 9).

Hydraulic brake servo check

12Sit in the driver’s seat and perform the

following sequence of tests.

13Start the engine, run it for about a minute

and turn it off. Then firmly depress the brake

several times - the pedal travel should

decrease with each application.

14With the brake fully depressed, start the

engine - the pedal should move down a little

when the engine starts.

15Depress the brake, stop the engine and

hold the pedal in for about 30 seconds - the

pedal should neither sink nor rise.

16If your brakes do not operate as

described above when the preceding tests

are performed, the brake servo is either in

need of repair or has failed. Refer to Chapter 9

for the removal procedure.

Handbrake

17Slowly pull up on the handbrake and

count the number of clicks you hear until the

handle is up as far as it will go. The

adjustment should be within the specified

number of clicks listed in this Chapter’s

Specifications. If you hear more or fewer

clicks, it’s time to adjust the handbrake (refer

to Chapter 9).

18An alternative method of checking the

handbrake is to park the vehicle on a steep hill

with the handbrake set and the transmission

in Neutral (be sure to stay in the vehicle during

this check!). If the handbrake cannot prevent

the vehicle from rolling, it is in need of

adjustment (see Chapter 9). Whenever a fault

is suspected, the brake discs should be

removed and the handbrake assemblies

themselves should be visually inspected.

12 Steering

and suspension check

2

Note: The steering linkage and suspension

components should be checked periodically.

Worn or damaged suspension and steering

linkage components can result in excessive

and abnormal tyre wear, poor ride quality and

vehicle handling and reduced fuel economy.

For detailed illustrations of the steering and

suspension components, refer to Chapter 10.

With the wheels on the ground

1Park the vehicle on level ground, turn the

engine off and set the handbrake. Check the

tyre pressures and check that the wheel nuts

are tightened to the specified torque.

2Push down at one corner of the vehicle,

then release it while noting the movement of

the body. It should stop moving and come to

rest in a level position with one or two

bounces. When bouncing the vehicle up and

down, listen for squeaks and noises from the

suspension components.

3If the vehicle continues to move up-and-

down or if it fails to return to its original

1•12Every 7500 miles or 6 months

11.11 Check along the brake hoses

and at each fitting (arrowed) for

deterioration and cracks

3261 Jaguar XJ6

You will find an inspection hole like this

in each caliper - placing a ruler across

the hole should enable you to determine

the thickness of remaining pad material

for both inner and outer pads