warning JAGUAR XJ6 1997 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 5 of 227

3261 Jaguar XJ6

Safety first!0•5

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle,

always

supplement the

jack with axle

stands, or use

drive-on

ramps.

Never

venture

under a car which

is only supported by a jack.

• Take care if loosening or tightening high-

torque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oil-

soaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Special hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 400

0C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potentially fatal

results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.

Page 8 of 227

3261 Jaguar XJ6

0•8Roadside repairs

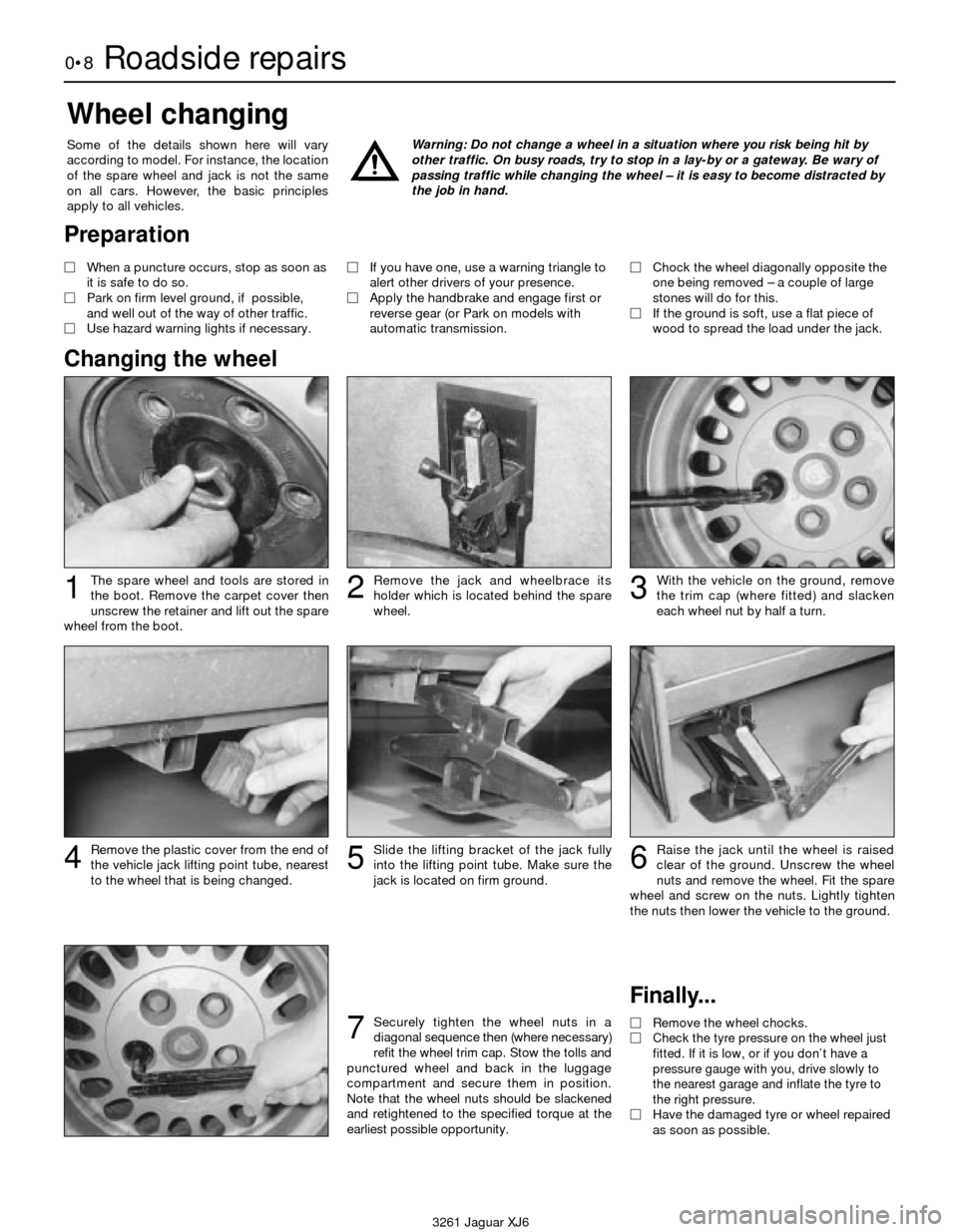

The spare wheel and tools are stored in

the boot. Remove the carpet cover then

unscrew the retainer and lift out the spare

wheel from the boot.

Wheel changing

Some of the details shown here will vary

according to model. For instance, the location

of the spare wheel and jack is not the same

on all cars. However, the basic principles

apply to all vehicles.Warning: Do not change a wheel in a situation where you risk being hit by

other traffic. On busy roads, try to stop in a lay-by or a gateway. Be wary of

passing traffic while changing the wheel – it is easy to become distracted by

the job in hand.

Finally...

MRemove the wheel chocks.

MCheck the tyre pressure on the wheel just

fitted. If it is low, or if you don’t have a

pressure gauge with you, drive slowly to

the nearest garage and inflate the tyre to

the right pressure.

MHave the damaged tyre or wheel repaired

as soon as possible.

Remove the plastic cover from the end of

the vehicle jack lifting point tube, nearest

to the wheel that is being changed.Slide the lifting bracket of the jack fully

into the lifting point tube. Make sure the

jack is located on firm ground.Raise the jack until the wheel is raised

clear of the ground. Unscrew the wheel

nuts and remove the wheel. Fit the spare

wheel and screw on the nuts. Lightly tighten

the nuts then lower the vehicle to the ground.

With the vehicle on the ground, remove

the trim cap (where fitted) and slacken

each wheel nut by half a turn.Remove the jack and wheelbrace its

holder which is located behind the spare

wheel.123

4

Securely tighten the wheel nuts in a

diagonal sequence then (where necessary)

refit the wheel trim cap. Stow the tolls and

punctured wheel and back in the luggage

compartment and secure them in position.

Note that the wheel nuts should be slackened

and retightened to the specified torque at the

earliest possible opportunity.7

56

Preparation

MWhen a puncture occurs, stop as soon as

it is safe to do so.

MPark on firm level ground, if possible,

and well out of the way of other traffic.

MUse hazard warning lights if necessary. MIf you have one, use a warning triangle to

alert other drivers of your presence.

MApply the handbrake and engage first or

reverse gear (or Park on models with

automatic transmission.MChock the wheel diagonally opposite the

one being removed – a couple of large

stones will do for this.

MIf the ground is soft, use a flat piece of

wood to spread the load under the jack.

Changing the wheel

Page 9 of 227

3261 Jaguar XJ6

Roadside repairs0•9

When all else fails, you may find yourself

having to get a tow home – or of course you

may be helping somebody else. Long-distance

recovery should only be done by a garage or

breakdown service. For shorter distances, DIY

towing using another car is easy enough, but

observe the following points:

MUse a proper tow-rope – they are not

expensive. The vehicle being towed must

display an ‘ON TOW’ sign in its rear window.

MAlways turn the ignition key to the ‘on’

position when the vehicle is being towed, so

that the steering lock is released, and that the

direction indicator and brake lights will work.

MOnly attach the tow-rope to the towing

eyes provided. On some models with energy-

absorbing bumpers there are no front towing

eyes; on these vehicles the tow-rope shouldbe attached around the rear arm of the lower

control arm so that the rope passes on the

inside of the coil spring.

MBefore being towed, release the handbrake

and select neutral on the transmission.

MNote that greater-than-usual pedal

pressure will be required to operate the

brakes, since the vacuum servo unit is only

operational with the engine running.

MOn models with power steering, greater-

than-usual steering effort will also be required.

MThe driver of the car being towed must

keep the tow-rope taut at all times to avoid

snatching.

MMake sure that both drivers know the route

before setting off.

MOnly drive at moderate speeds and keep

the distance towed to a minimum. Drivesmoothly and allow plenty of time for slowing

down at junctions.

MOn models with automatic transmission,

special precautions apply. If in doubt, do not

tow, or transmission damage may result.

Caution: On models with automatic

transmission, if the vehicle is to be towed

with its rear wheels on the ground, and

extra 1.7 litres of fluid should be added to

the transmission, prior to towing (this extra

fluid must be drained before driving the

vehicle). Even with the extra fluid added to

the transmission, do not tow the vehicle at

speeds in excess of 30 mph (50 kmh) or for

a distance of greater than 15 miles (25 km).

If towing speed/distance are to exceed

these limits, then the vehicle must be

towed with its rear wheels off the ground.

Towing

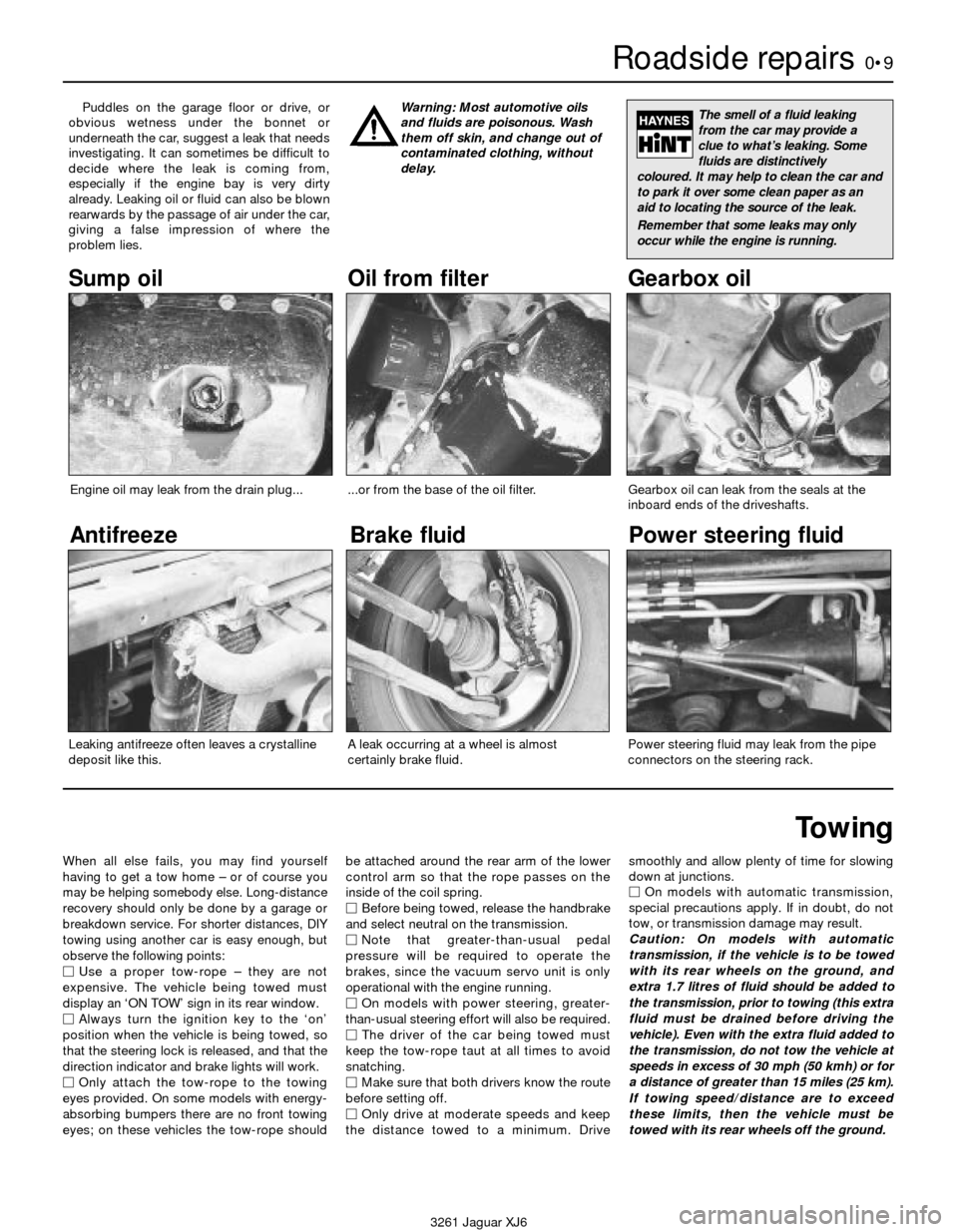

Puddles on the garage floor or drive, or

obvious wetness under the bonnet or

underneath the car, suggest a leak that needs

investigating. It can sometimes be difficult to

decide where the leak is coming from,

especially if the engine bay is very dirty

already. Leaking oil or fluid can also be blown

rearwards by the passage of air under the car,

giving a false impression of where the

problem lies.Warning: Most automotive oils

and fluids are poisonous. Wash

them off skin, and change out of

contaminated clothing, without

delay.The smell of a fluid leaking

from the car may provide a

clue to what’s leaking. Some

fluids are distinctively

coloured. It may help to clean the car and

to park it over some clean paper as an

aid to locating the source of the leak.

Remember that some leaks may only

occur while the engine is running.

Sump oil Gearbox oil

Brake fluid

Power steering fluid

Oil from filter

Antifreeze

Engine oil may leak from the drain plug......or from the base of the oil filter.

Leaking antifreeze often leaves a crystalline

deposit like this.Gearbox oil can leak from the seals at the

inboard ends of the driveshafts.

A leak occurring at a wheel is almost

certainly brake fluid.Power steering fluid may leak from the pipe

connectors on the steering rack.

Page 10 of 227

3261 Jaguar XJ6

0•10Weekly checks

There are some very simple checks which

need only take a few minutes to carry out, but

which could save you a lot of inconvenience

and expense.

These "Weekly checks" require no great skill

or special tools, and the small amount of time

they take to perform could prove to be very

well spent, for example;MKeeping an eye on tyre condition and

pressures, will not only help to stop them

wearing out prematurely, but could also save

your life.

M

Many breakdowns are caused by electrical

problems. Battery-related faults are particularly

common, and a quick check on a regular basis

will often prevent the majority of

these.MIf your car develops a brake fluid leak, the

first time you might know about it is when

your brakes don't work properly. Checking

the level regularly will give advance warning of

this kind of problem.

MIf the oil or coolant levels run low, the cost

of repairing any engine damage will be far

greater than fixing the leak, for example.

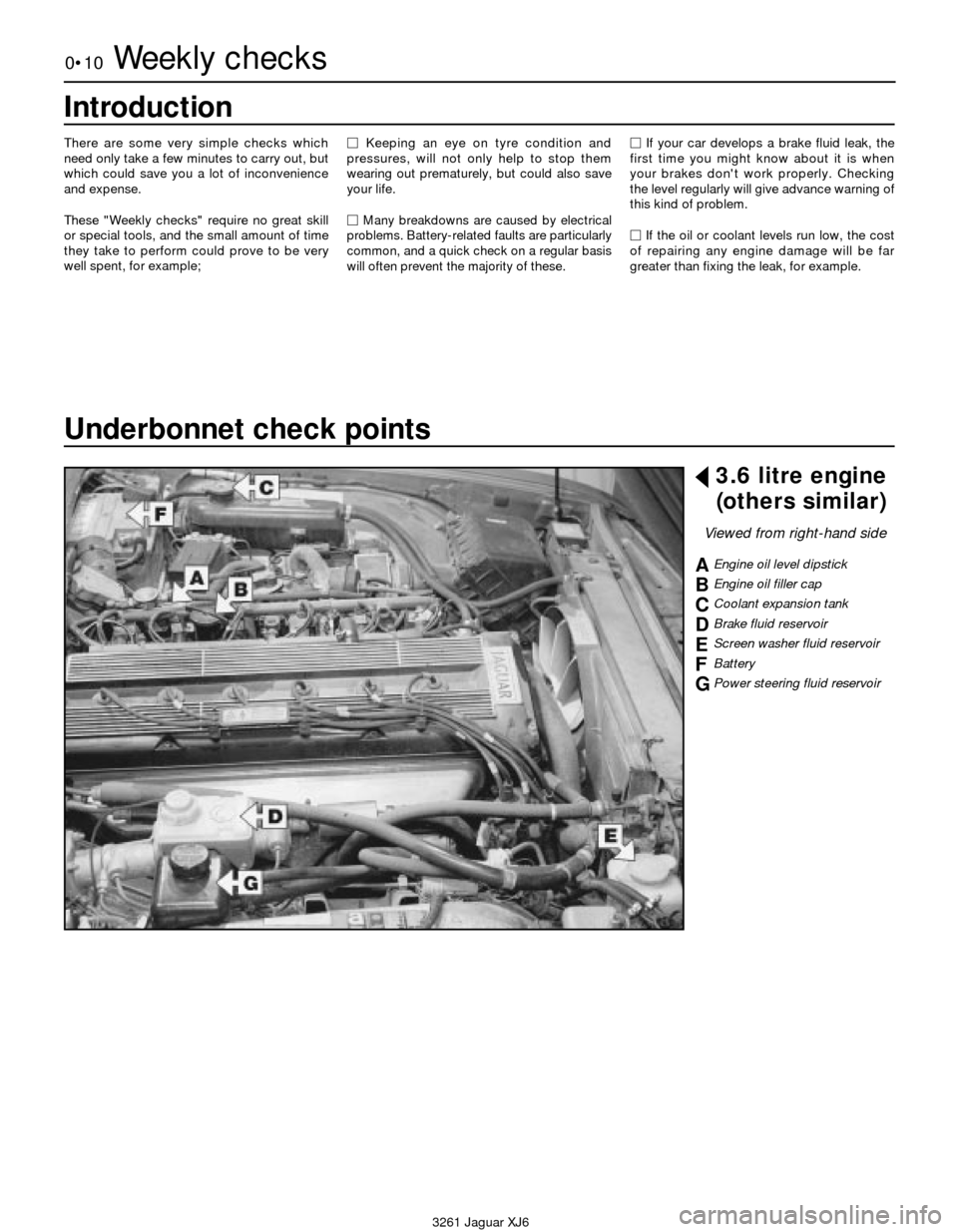

Introduction

§3.6 litre engine

(others similar)

Viewed from right-hand side

AEngine oil level dipstick

BEngine oil filler cap

CCoolant expansion tank

DBrake fluid reservoir

EScreen washer fluid reservoir

FBattery

GPower steering fluid reservoir

Underbonnet check points

Page 11 of 227

3261 Jaguar XJ6

Weekly checks0•11

Engine oil level

Before you start

4Make sure that your car is on level ground.

4Check the oil level before the car is driven,

or at least 5 minutes after the engine has been

switched off.

The correct oilModern engines place great demands on their

oil. It is very important that the correct oil for

your car is used (See “Lubricants, fluids and

tyre pressures”).

Car care

l If you have to add oil frequently, you should

check whether you have any oil leaks. Place

some clean paper under the car overnight,

and check for stains in the morning. If there

are no leaks, the engine may be burning oil

(see “Fault finding”).

lAlways maintain the level between the

upper and lower dipstick marks (see photo 3).

If the level is too low severe engine damage

may occur. Oil seal failure may result if the

engine is overfilled by adding too much oil.

If the oil level is checked

immediately after driving the

vehicle, some of the oil will

remain in the upper engine

components, resulting in an inaccurate

reading on the dipstick!

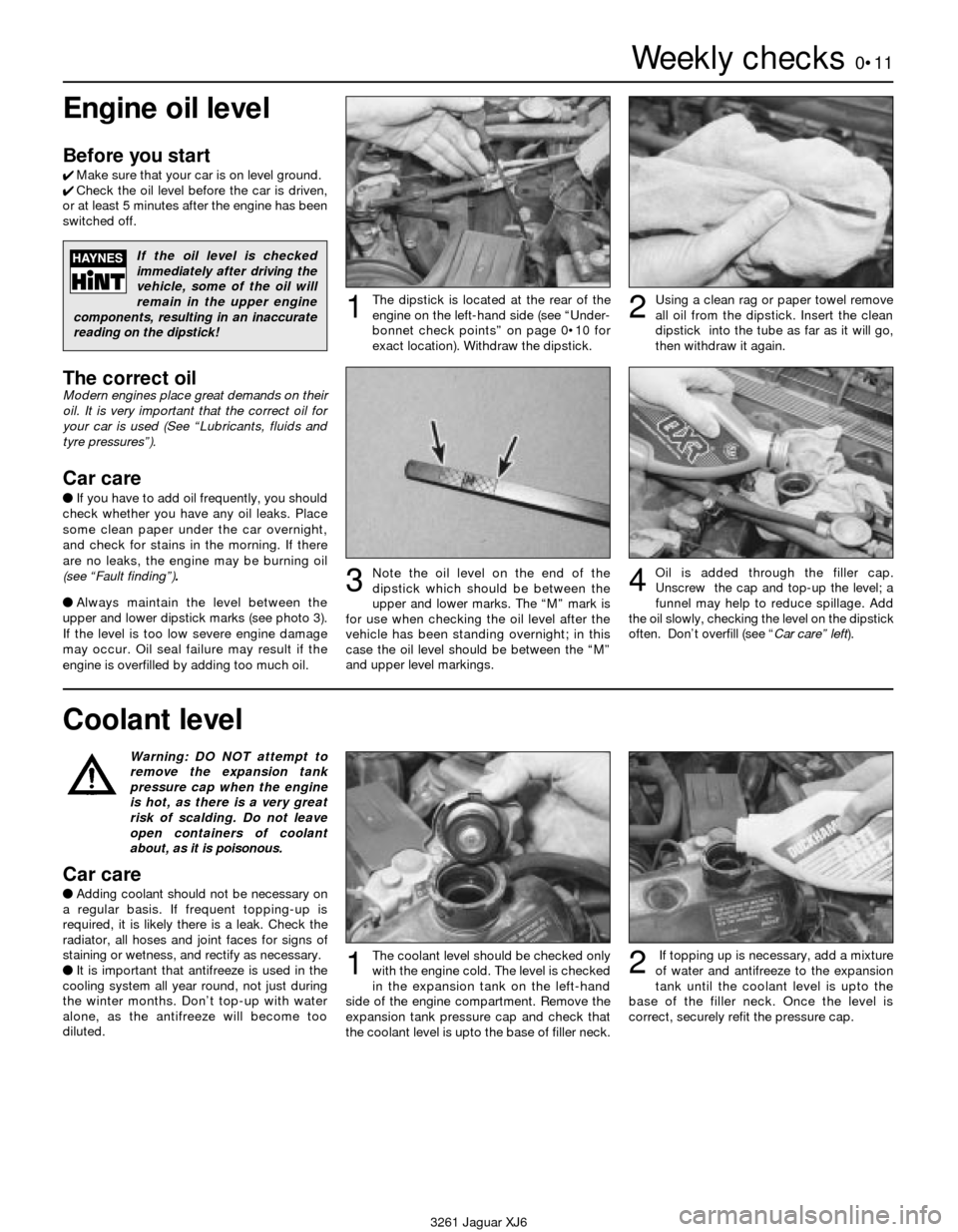

The dipstick is located at the rear of the

engine on the left-hand side (see “Under-

bonnet check points” on page 0•10 for

exact location). Withdraw the dipstick.Using a clean rag or paper towel remove

all oil from the dipstick. Insert the clean

dipstick into the tube as far as it will go,

then withdraw it again.

Note the oil level on the end of the

dipstick which should be between the

upper and lower marks. The “M” mark is

for use when checking the oil level after the

vehicle has been standing overnight; in this

case the oil level should be between the “M”

and upper level markings.Oil is added through the filler cap.

Unscrew the cap and top-up the level; a

funnel may help to reduce spillage. Add

the oil slowly, checking the level on the dipstick

often. Don’t overfill (see “Car care” left).

12

34

Warning: DO NOT attempt to

remove the expansion tank

pressure cap when the engine

is hot, as there is a very great

risk of scalding. Do not leave

open containers of coolant

about, as it is poisonous.

Car care

lAdding coolant should not be necessary on

a regular basis. If frequent topping-up is

required, it is likely there is a leak. Check the

radiator, all hoses and joint faces for signs of

staining or wetness, and rectify as necessary.

lIt is important that antifreeze is used in the

cooling system all year round, not just during

the winter months. Don’t top-up with water

alone, as the antifreeze will become too

diluted.

Coolant level

The coolant level should be checked only

with the engine cold. The level is checked

in the expansion tank on the left-hand

side of the engine compartment. Remove the

expansion tank pressure cap and check that

the coolant level is upto the base of filler neck.If topping up is necessary, add a mixture

of water and antifreeze to the expansion

tank until the coolant level is upto the

base of the filler neck. Once the level is

correct, securely refit the pressure cap.12

Page 12 of 227

3261 Jaguar XJ6

0•12Weekly checks

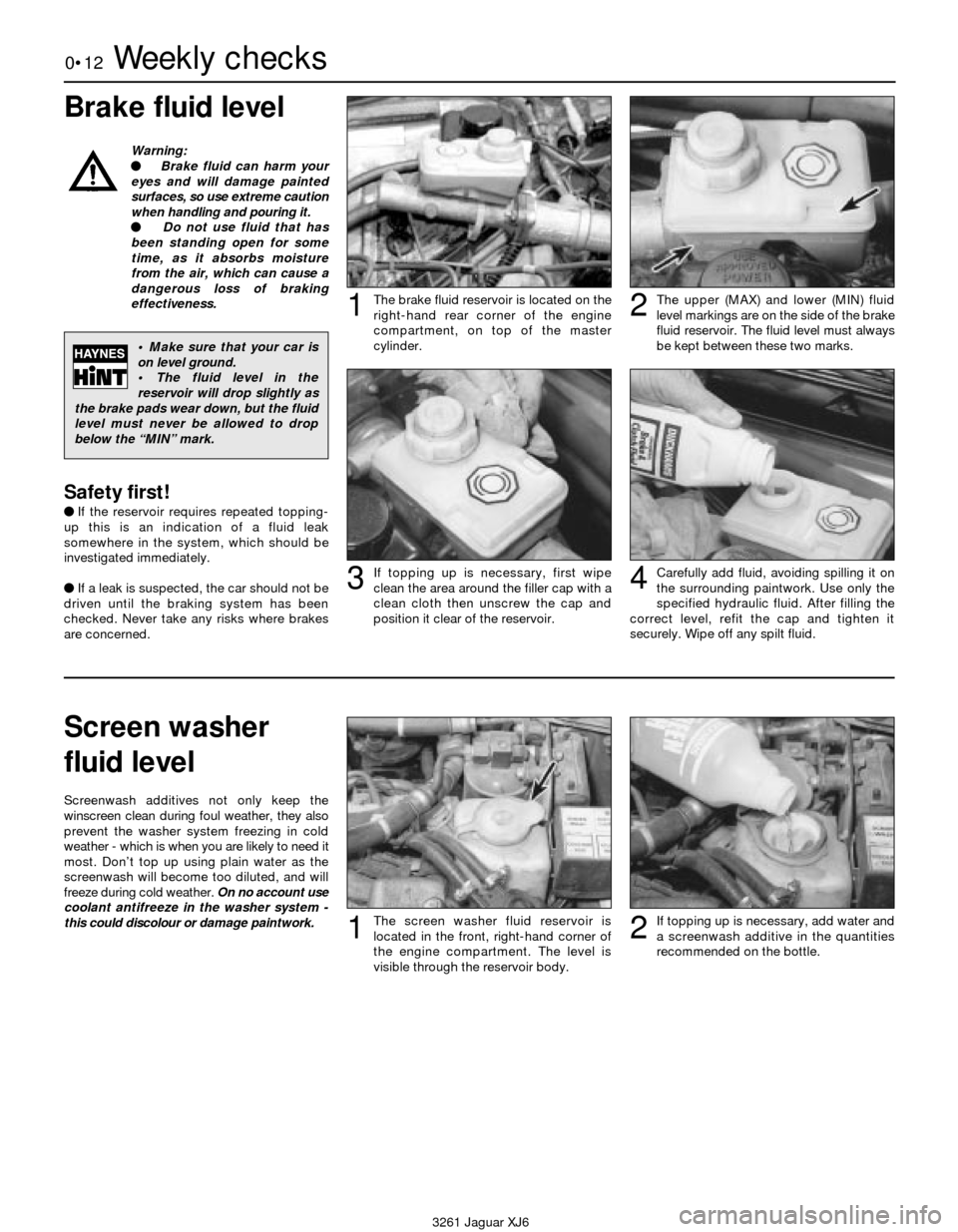

Brake fluid level

Warning:

l Brake fluid can harm your

eyes and will damage painted

surfaces, so use extreme caution

when handling and pouring it.

l Do not use fluid that has

been standing open for some

time, as it absorbs moisture

from the air, which can cause a

dangerous loss of braking

effectiveness.

Safety first!

lIf the reservoir requires repeated topping-

up this is an indication of a fluid leak

somewhere in the system, which should be

investigated immediately.

lIf a leak is suspected, the car should not be

driven until the braking system has been

checked. Never take any risks where brakes

are concerned.

• Make sure that your car is

on level ground.

• The fluid level in the

reservoir will drop slightly as

the brake pads wear down, but the fluid

level must never be allowed to drop

below the “MIN” mark.

The brake fluid reservoir is located on the

right-hand rear corner of the engine

compartment, on top of the master

cylinder.1The upper (MAX) and lower (MIN) fluid

level markings are on the side of the brake

fluid reservoir. The fluid level must always

be kept between these two marks.2

If topping up is necessary, first wipe

clean the area around the filler cap with a

clean cloth then unscrew the cap and

position it clear of the reservoir.3Carefully add fluid, avoiding spilling it on

the surrounding paintwork. Use only the

specified hydraulic fluid. After filling the

correct level, refit the cap and tighten it

securely. Wipe off any spilt fluid.4

Screenwash additives not only keep the

winscreen clean during foul weather, they also

prevent the washer system freezing in cold

weather - which is when you are likely to need it

most. Don’t top up using plain water as the

screenwash will become too diluted, and will

freeze during cold weather. On no account use

coolant antifreeze in the washer system -

this could discolour or damage paintwork.

Screen washer

fluid level

If topping up is necessary, add water and

a screenwash additive in the quantities

recommended on the bottle.2The screen washer fluid reservoir is

located in the front, right-hand corner of

the engine compartment. The level is

visible through the reservoir body.1

Page 13 of 227

3261 Jaguar XJ6

Weekly checks0•13

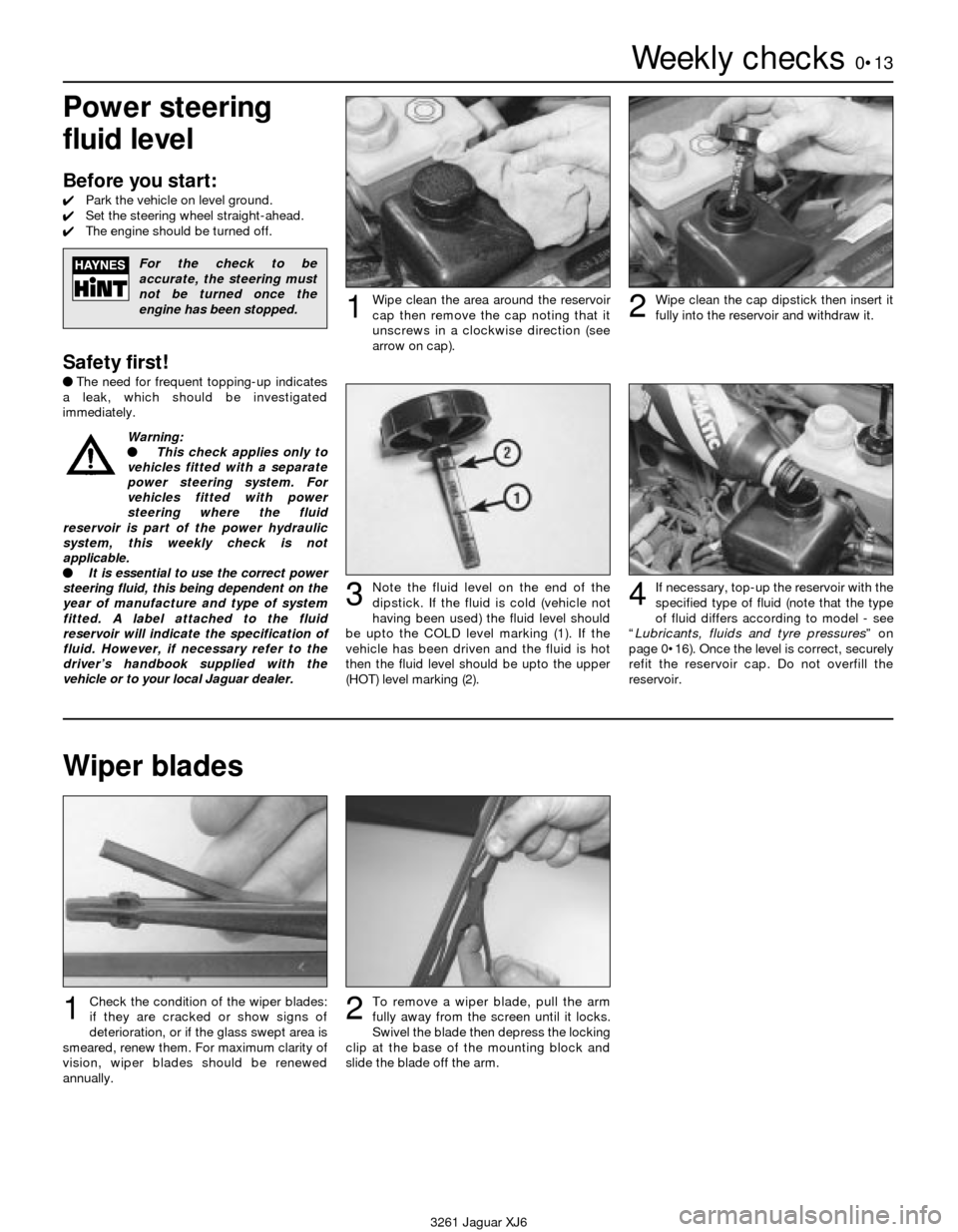

Power steering

fluid level

Before you start:

4Park the vehicle on level ground.

4Set the steering wheel straight-ahead.

4The engine should be turned off.

Safety first!

lThe need for frequent topping-up indicates

a leak, which should be investigated

immediately.

For the check to be

accurate, the steering must

not be turned once the

engine has been stopped.

Wipe clean the area around the reservoir

cap then remove the cap noting that it

unscrews in a clockwise direction (see

arrow on cap).1Wipe clean the cap dipstick then insert it

fully into the reservoir and withdraw it.2

Note the fluid level on the end of the

dipstick. If the fluid is cold (vehicle not

having been used) the fluid level should

be upto the COLD level marking (1). If the

vehicle has been driven and the fluid is hot

then the fluid level should be upto the upper

(HOT) level marking (2).3If necessary, top-up the reservoir with the

specified type of fluid (note that the type

of fluid differs according to model - see

“Lubricants, fluids and tyre pressures” on

page 0•16). Once the level is correct, securely

refit the reservoir cap. Do not overfill the

reservoir.4

Wiper blades

Check the condition of the wiper blades:

if they are cracked or show signs of

deterioration, or if the glass swept area is

smeared, renew them. For maximum clarity of

vision, wiper blades should be renewed

annually.1To remove a wiper blade, pull the arm

fully away from the screen until it locks.

Swivel the blade then depress the locking

clip at the base of the mounting block and

slide the blade off the arm.2

Warning:

l This check applies only to

vehicles fitted with a separate

power steering system. For

vehicles fitted with power

steering where the fluid

reservoir is part of the power hydraulic

system, this weekly check is not

applicable.

l It is essential to use the correct power

steering fluid, this being dependent on the

year of manufacture and type of system

fitted. A label attached to the fluid

reservoir will indicate the specification of

fluid. However, if necessary refer to the

driver’s handbook supplied with the

vehicle or to your local Jaguar dealer.

Page 23 of 227

exhaust components will be warm during the

actual work, so try to anticipate any potential

problems before the engine and accessories

are hot.

5Park the vehicle on a level spot. Start the

engine and allow it to reach its normal

operating temperature (the needle on the

temperature gauge should be at least above

the bottom mark). Warm oil and contaminates

will flow out more easily. Turn off the engine

when it’s warmed up. Remove the oil filler cap

located next to the valve cover.

6Raise the vehicle and support it on axle

stands.

Warning: To avoid personal

injury, never get beneath the

vehicle when it is supported by

only by a jack. The jack provided

with your vehicle is designed solely for

raising the vehicle to remove and replace

the wheels. Always use axle stands to

support the vehicle when it becomes

necessary to place your body underneath

the vehicle.

7Being careful not to touch the hot exhaust

components, place the drain pan under the

drain plug in the bottom of the pan and

remove the plug (see illustration). You may

want to wear gloves while unscrewing the

plug the final few turns if the engine is really

hot.

8Allow the old oil to drain into the pan. It may

be necessary to move the pan farther under

the engine as the oil flow slows to a trickle.

Inspect the old oil for the presence of metal

shavings and chips.

9After all the oil has drained, wipe off the

drain plug with a clean rag. Even minute metal

particles clinging to the plug would

immediately contaminate the new oil.

10Clean the area around the drain plug

opening, refit the plug and tighten it securely,

but do not strip the threads.

11Move the drain pan into position under the

oil filter.

12Remove all tools, rags, etc. from under

the vehicle, being careful not to spill the oil in

the drain pan, then lower the vehicle.

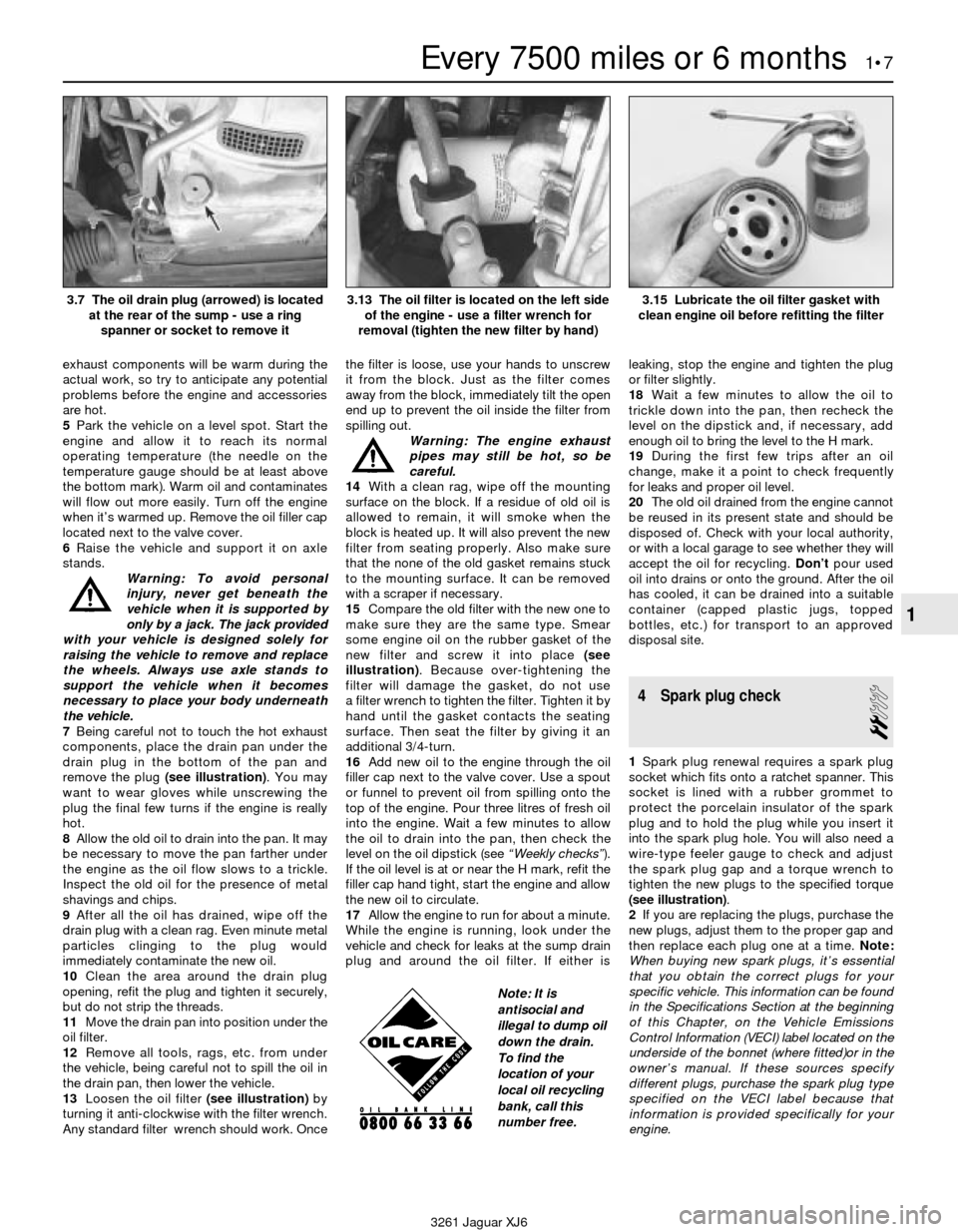

13Loosen the oil filter (see illustration)by

turning it anti-clockwise with the filter wrench.

Any standard filter wrench should work. Oncethe filter is loose, use your hands to unscrew

it from the block. Just as the filter comes

away from the block, immediately tilt the open

end up to prevent the oil inside the filter from

spilling out.

Warning: The engine exhaust

pipes may still be hot, so be

careful.

14With a clean rag, wipe off the mounting

surface on the block. If a residue of old oil is

allowed to remain, it will smoke when the

block is heated up. It will also prevent the new

filter from seating properly. Also make sure

that the none of the old gasket remains stuck

to the mounting surface. It can be removed

with a scraper if necessary.

15Compare the old filter with the new one to

make sure they are the same type. Smear

some engine oil on the rubber gasket of the

new filter and screw it into place (see

illustration). Because over-tightening the

filter will damage the gasket, do not use

a filter wrench to tighten the filter. Tighten it by

hand until the gasket contacts the seating

surface. Then seat the filter by giving it an

additional 3/4-turn.

16Add new oil to the engine through the oil

filler cap next to the valve cover. Use a spout

or funnel to prevent oil from spilling onto the

top of the engine. Pour three litres of fresh oil

into the engine. Wait a few minutes to allow

the oil to drain into the pan, then check the

level on the oil dipstick (see “Weekly checks”).

If the oil level is at or near the H mark, refit the

filler cap hand tight, start the engine and allow

the new oil to circulate.

17Allow the engine to run for about a minute.

While the engine is running, look under the

vehicle and check for leaks at the sump drain

plug and around the oil filter. If either isleaking, stop the engine and tighten the plug

or filter slightly.

18Wait a few minutes to allow the oil to

trickle down into the pan, then recheck the

level on the dipstick and, if necessary, add

enough oil to bring the level to the H mark.

19During the first few trips after an oil

change, make it a point to check frequently

for leaks and proper oil level.

20The old oil drained from the engine cannot

be reused in its present state and should be

disposed of. Check with your local authority,

or with a local garage to see whether they will

accept the oil for recycling. Don’tpour used

oil into drains or onto the ground. After the oil

has cooled, it can be drained into a suitable

container (capped plastic jugs, topped

bottles, etc.) for transport to an approved

disposal site.

4 Spark plug check

2

1Spark plug renewal requires a spark plug

socket which fits onto a ratchet spanner. This

socket is lined with a rubber grommet to

protect the porcelain insulator of the spark

plug and to hold the plug while you insert it

into the spark plug hole. You will also need a

wire-type feeler gauge to check and adjust

the spark plug gap and a torque wrench to

tighten the new plugs to the specified torque

(see illustration).

2If you are replacing the plugs, purchase the

new plugs, adjust them to the proper gap and

then replace each plug one at a time. Note:

When buying new spark plugs, it’s essential

that you obtain the correct plugs for your

specific vehicle. This information can be found

in the Specifications Section at the beginning

of this Chapter, on the Vehicle Emissions

Control Information (VECI) label located on the

underside of the bonnet (where fitted)or in the

owner’s manual. If these sources specify

different plugs, purchase the spark plug type

specified on the VECI label because that

information is provided specifically for your

engine.

Every 7500 miles or 6 months 1•7

1

3.7 The oil drain plug (arrowed) is located

at the rear of the sump - use a ring

spanner or socket to remove it3.13 The oil filter is located on the left side

of the engine - use a filter wrench for

removal (tighten the new filter by hand)3.15 Lubricate the oil filter gasket with

clean engine oil before refitting the filter

3261 Jaguar XJ6

Note: It is

antisocial and

illegal to dump oil

down the drain.

To find the

location of your

local oil recycling

bank, call this

number free.

Page 25 of 227

5 Power hydraulic system

fluid level check

1

Caution: Use only Castrol or Jaguar

hydraulic system mineral oil (HSMO) in the

power hydraulic system (available at

Jaguar dealer service departments).

1The power hydraulic system controls the ride

levelling and the brake servo systems. The

fluid reservoir also supplies the power

steering system on some models. The level

of the fluid should be carefully maintained. Low

fluid levels can adversely affect the riding and

braking capabilities of your vehicle. The power

hydraulic system fluid reservoir is located on

the right inner wing of the engine compartment.

1988 and 1989 models

2The fluid level can easily be checked by

viewing the reservoir sight glass. A green

indicator in the sight glass indicates an OK

condition, while a red indicator in the sight glass

requires fluid to be added (see illustration).

3If additional fluid is required, pop open the

plastic tab located on top of the reservoir cap

(see illustration).

4Insert the mineral oil dispensing tube into

the reservoir filler hole. Push down and turn

until the dispensing tube is locked in place.

5Add fluid until the green indicator in the

sight glass appears, then release the

dispensing tube by pushing downward and

turning the opposite direction of refitting.

1990 to 1994 models

6The fluid level can be checked by removing

the cap and observing the level of fluid on the

dipstick.

7Wipe off the fluid with a clean rag, reinsert

it, then withdraw it and read the fluid level

(see illustration). The dipstick is marked so

the fluid can be checked either cold or hot.

The level should be at the HOT mark if the

fluid was hot to the touch. It should be at the

COLD mark if the fluid was cool to the touch.

At no time should the fluid level drop below

the add mark.8If additional fluid is required, pour the

specified type directly into the reservoir, using

a funnel to prevent spills.

6 Battery check

and general information

1

Warning: Certain precautions

must be followed when working

with the battery. Hydrogen gas,

which is highly flammable, is

always present in the battery cells, so don’t

smoke, and keep naked flames and sparks

away from the battery. The electrolyte in

the battery is actually dilute sulphuric acid,

which will cause injury if splashed on your

skin or in your eyes. It will also ruin clothes

and painted surfaces. When removing the

battery cables, always detach the negative

cable first and hook it up last!1A routine preventive maintenance program

for the battery in your vehicle is the only way

to ensure quick and reliable starts. But before

performing any battery maintenance, make

sure that you have the proper equipment

necessary to work safely around the battery

(see illustration).

2There are also several precautions that

should be taken whenever battery

maintenance is performed. Before servicing

the battery, always turn the engine and all

accessories off and disconnect the cable from

the negative terminal of the battery.

3The battery produces hydrogen gas, which

is both flammable and explosive. Never create

a spark, smoke or light a match around the

battery. Always charge the battery in a

ventilated area.

4Electrolyte contains poisonous and corrosive

sulphuric acid. Do not allow it to get in your

eyes, on your skin or on your clothes, and

Every 7500 miles or 6 months 1•9

1

5.2 The power hydraulic system reservoir

is located on the right-hand inner wing -

to check the fluid level on 1988 and 1989

models simply look through the sight glass

and note the colour of the indicator5.3 To add fluid, remove the filler hole

dust cap (arrowed)5.7 On 1990 and later models remove the

cap and check the fluid level on the dipstick

6.1 Tools and materials required for

battery maintenance

1 Face shield/safety goggles - When

removing corrosion with a brush, the

acidic particles can fly up into your eyes

2 Baking soda - A solution of baking soda

and water can be used to neutralise

corrosion

3 Petroleum jelly - A layer of this on the

battery posts will help prevent corrosion

4 Battery post/cable cleaner - This wire

brush cleaning tool will remove all traces

of corrosion from the battery posts and

cable clamps

5 Treated felt washers - Placing one of

these on each post, directly under the

cable clamps, will help prevent corrosion

6 Puller - Sometimes the cable clamps are

difficult to pull off the posts, even after the

nut/bolt has been completely loosened.

This tool pulls the clamp straight up and

off the post without damage

7 Battery post/cable cleaner - Here is

another cleaning tool which is a slightly

different version of number 4 above, but

it does the same thing

8 Rubber gloves - Another safety item to

consider when servicing the battery;

remember that’s acid inside the battery!

3261 Jaguar XJ6

Page 26 of 227

never ingest it. Wear protective safety glasses

when working near the battery. Keep children

away from the battery.

5Note the external condition of the battery. If

the positive terminal and cable clamp on your

vehicle’s battery is equipped with a rubber

protector, make sure it isn’t torn or damaged.

It should completely cover the terminal. Look

for any corroded or loose connections, cracks

in the case or cover or loose hold-down

clamps. Also check the entire length of each

cable for cracks and frayed conductors.

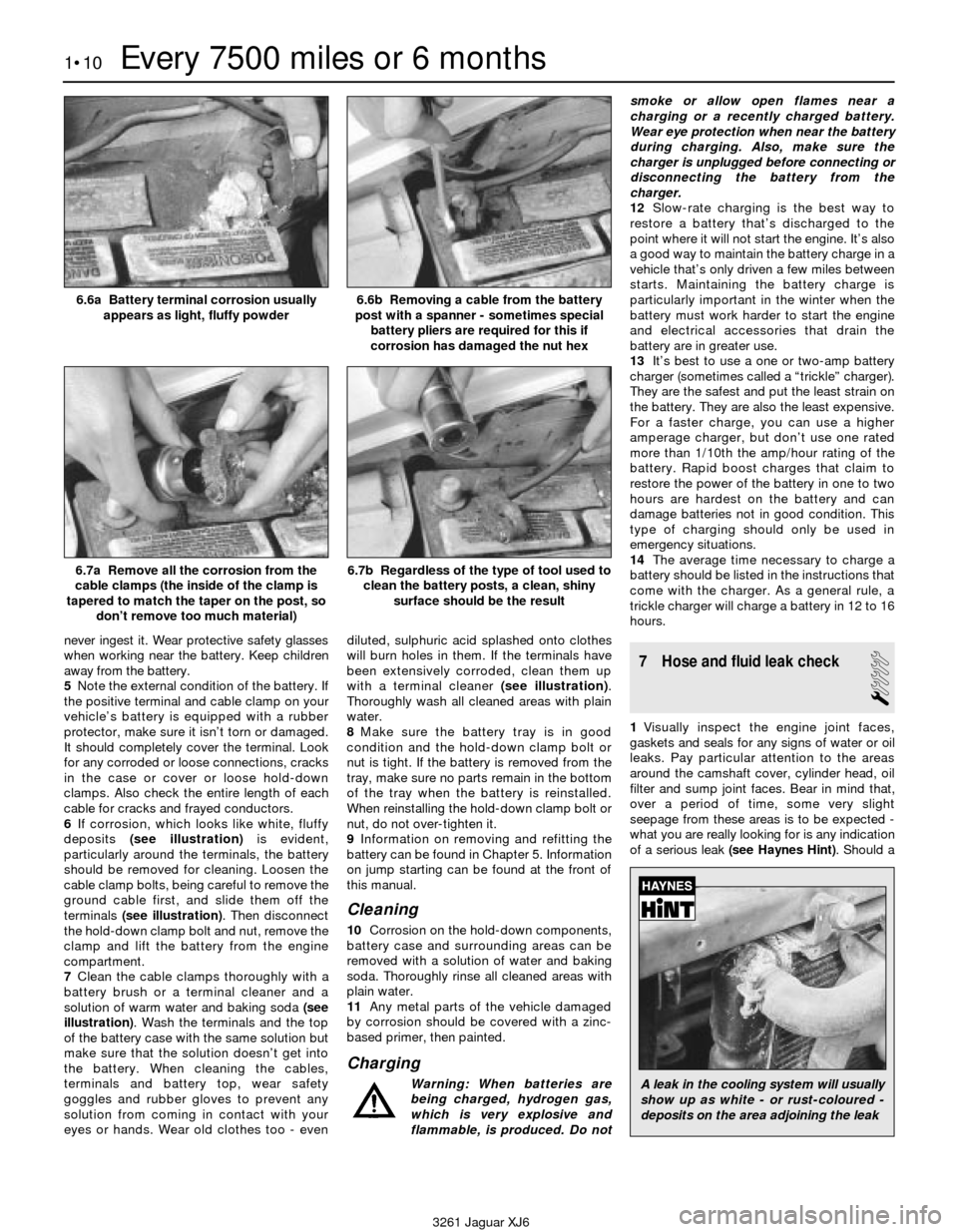

6If corrosion, which looks like white, fluffy

deposits (see illustration)is evident,

particularly around the terminals, the battery

should be removed for cleaning. Loosen the

cable clamp bolts, being careful to remove the

ground cable first, and slide them off the

terminals (see illustration). Then disconnect

the hold-down clamp bolt and nut, remove the

clamp and lift the battery from the engine

compartment.

7Clean the cable clamps thoroughly with a

battery brush or a terminal cleaner and a

solution of warm water and baking soda (see

illustration). Wash the terminals and the top

of the battery case with the same solution but

make sure that the solution doesn’t get into

the battery. When cleaning the cables,

terminals and battery top, wear safety

goggles and rubber gloves to prevent any

solution from coming in contact with your

eyes or hands. Wear old clothes too - evendiluted, sulphuric acid splashed onto clothes

will burn holes in them. If the terminals have

been extensively corroded, clean them up

with a terminal cleaner (see illustration).

Thoroughly wash all cleaned areas with plain

water.

8Make sure the battery tray is in good

condition and the hold-down clamp bolt or

nut is tight. If the battery is removed from the

tray, make sure no parts remain in the bottom

of the tray when the battery is reinstalled.

When reinstalling the hold-down clamp bolt or

nut, do not over-tighten it.

9Information on removing and refitting the

battery can be found in Chapter 5. Information

on jump starting can be found at the front of

this manual.

Cleaning

10Corrosion on the hold-down components,

battery case and surrounding areas can be

removed with a solution of water and baking

soda. Thoroughly rinse all cleaned areas with

plain water.

11Any metal parts of the vehicle damaged

by corrosion should be covered with a zinc-

based primer, then painted.

Charging

Warning: When batteries are

being charged, hydrogen gas,

which is very explosive and

flammable, is produced. Do notsmoke or allow open flames near a

charging or a recently charged battery.

Wear eye protection when near the battery

during charging. Also, make sure the

charger is unplugged before connecting or

disconnecting the battery from the

charger.

12Slow-rate charging is the best way to

restore a battery that’s discharged to the

point where it will not start the engine. It’s also

a good way to maintain the battery charge in a

vehicle that’s only driven a few miles between

starts. Maintaining the battery charge is

particularly important in the winter when the

battery must work harder to start the engine

and electrical accessories that drain the

battery are in greater use.

13It’s best to use a one or two-amp battery

charger (sometimes called a “trickle” charger).

They are the safest and put the least strain on

the battery. They are also the least expensive.

For a faster charge, you can use a higher

amperage charger, but don’t use one rated

more than 1/10th the amp/hour rating of the

battery. Rapid boost charges that claim to

restore the power of the battery in one to two

hours are hardest on the battery and can

damage batteries not in good condition. This

type of charging should only be used in

emergency situations.

14The average time necessary to charge a

battery should be listed in the instructions that

come with the charger. As a general rule, a

trickle charger will charge a battery in 12 to 16

hours.

7 Hose and fluid leak check

1

1Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the camshaft cover, cylinder head, oil

filter and sump joint faces. Bear in mind that,

over a period of time, some very slight

seepage from these areas is to be expected -

what you are really looking for is any indication

of a serious leak (see Haynes Hint). Should a

1•10Every 7500 miles or 6 months

6.6a Battery terminal corrosion usually

appears as light, fluffy powder6.6b Removing a cable from the battery

post with a spanner - sometimes special

battery pliers are required for this if

corrosion has damaged the nut hex

6.7a Remove all the corrosion from the

cable clamps (the inside of the clamp is

tapered to match the taper on the post, so

don’t remove too much material)6.7b Regardless of the type of tool used to

clean the battery posts, a clean, shiny

surface should be the result

3261 Jaguar XJ6

A leak in the cooling system will usually

show up as white - or rust-coloured -

deposits on the area adjoining the leak