lug pattern JAGUAR XJ6 1997 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 29 of 227

position, a worn or weak shock absorber is

probably the reason.

4Repeat the above check at each of the

three remaining corners of the vehicle.

Under the vehicle

5Raise the vehicle with a trolley jack and

support it securely on axle stands. See

“Jacking and towing”for proper jacking

points.

6Check the shock absorbers for evidence of

fluid leakage. Make sure that any fluid noted is

from the shocks and not from any other

source. Also check the rubber mounts at each

end for deterioration If the shock absorbers

fail any of the tests above replace the shocks

as a set.

7Check the tyres for irregular wear patterns

and proper inflation. See “Weekly checks”for

information regarding tyre wear.

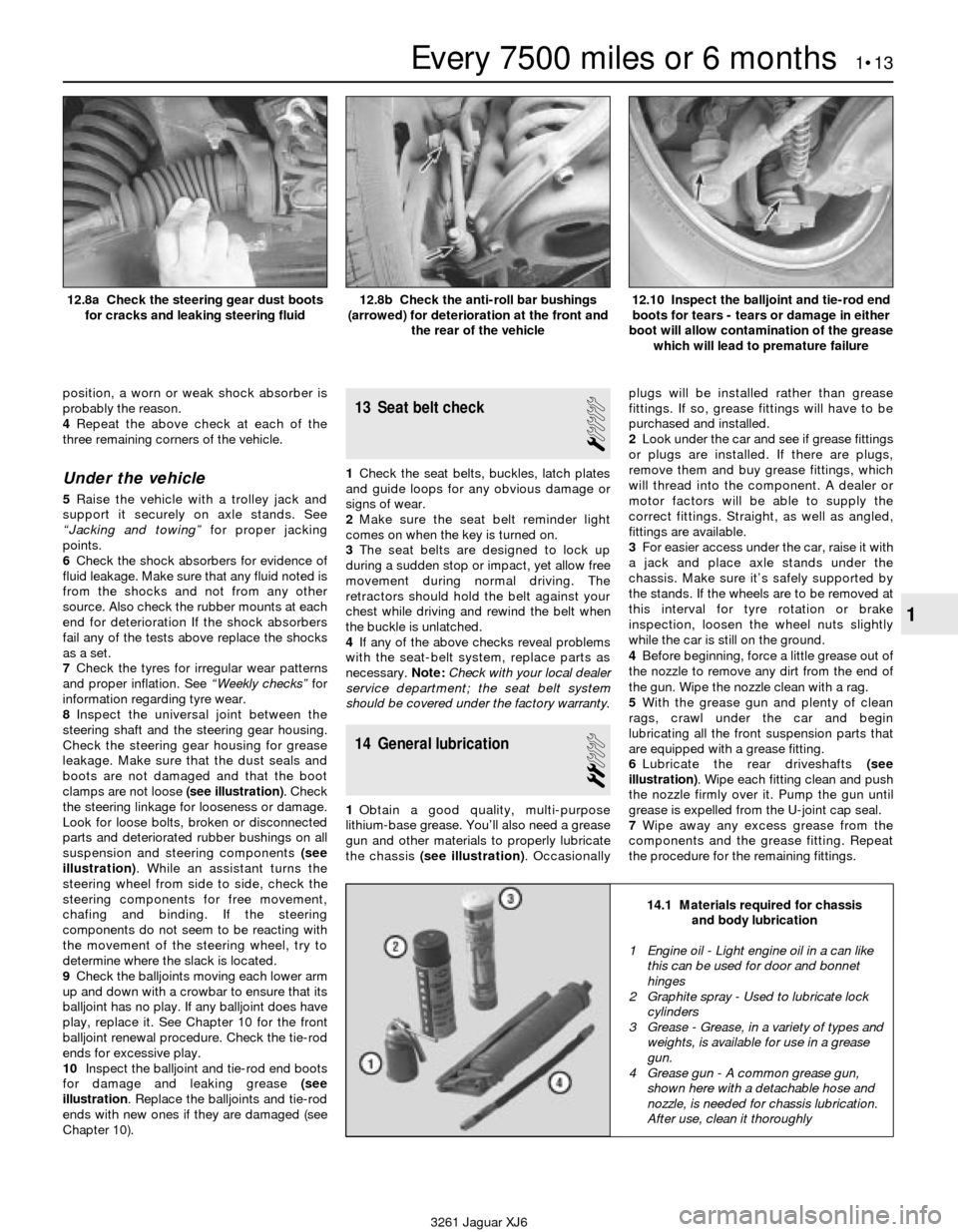

8Inspect the universal joint between the

steering shaft and the steering gear housing.

Check the steering gear housing for grease

leakage. Make sure that the dust seals and

boots are not damaged and that the boot

clamps are not loose (see illustration). Check

the steering linkage for looseness or damage.

Look for loose bolts, broken or disconnected

parts and deteriorated rubber bushings on all

suspension and steering components (see

illustration). While an assistant turns the

steering wheel from side to side, check the

steering components for free movement,

chafing and binding. If the steering

components do not seem to be reacting with

the movement of the steering wheel, try to

determine where the slack is located.

9Check the balljoints moving each lower arm

up and down with a crowbar to ensure that its

balljoint has no play. If any balljoint does have

play, replace it. See Chapter 10 for the front

balljoint renewal procedure. Check the tie-rod

ends for excessive play.

10Inspect the balljoint and tie-rod end boots

for damage and leaking grease (see

illustration. Replace the balljoints and tie-rod

ends with new ones if they are damaged (see

Chapter 10).

13 Seat belt check

1

1Check the seat belts, buckles, latch plates

and guide loops for any obvious damage or

signs of wear.

2Make sure the seat belt reminder light

comes on when the key is turned on.

3The seat belts are designed to lock up

during a sudden stop or impact, yet allow free

movement during normal driving. The

retractors should hold the belt against your

chest while driving and rewind the belt when

the buckle is unlatched.

4If any of the above checks reveal problems

with the seat-belt system, replace parts as

necessary.Note:Check with your local dealer

service department; the seat belt system

should be covered under the factory warranty.

14 General lubrication

2

1Obtain a good quality, multi-purpose

lithium-base grease. You’ll also need a grease

gun and other materials to properly lubricate

the chassis (see illustration). Occasionallyplugs will be installed rather than grease

fittings. If so, grease fittings will have to be

purchased and installed.

2Look under the car and see if grease fittings

or plugs are installed. If there are plugs,

remove them and buy grease fittings, which

will thread into the component. A dealer or

motor factors will be able to supply the

correct fittings. Straight, as well as angled,

fittings are available.

3For easier access under the car, raise it with

a jack and place axle stands under the

chassis. Make sure it’s safely supported by

the stands. If the wheels are to be removed at

this interval for tyre rotation or brake

inspection, loosen the wheel nuts slightly

while the car is still on the ground.

4Before beginning, force a little grease out of

the nozzle to remove any dirt from the end of

the gun. Wipe the nozzle clean with a rag.

5With the grease gun and plenty of clean

rags, crawl under the car and begin

lubricating all the front suspension parts that

are equipped with a grease fitting.

6Lubricate the rear driveshafts (see

illustration). Wipe each fitting clean and push

the nozzle firmly over it. Pump the gun until

grease is expelled from the U-joint cap seal.

7Wipe away any excess grease from the

components and the grease fitting. Repeat

the procedure for the remaining fittings.

Every 7500 miles or 6 months 1•13

1

14.1 Materials required for chassis

and body lubrication

3261 Jaguar XJ6 12.8a Check the steering gear dust boots

for cracks and leaking steering fluid

12.8b Check the anti-roll bar bushings

(arrowed) for deterioration at the front and

the rear of the vehicle12.10 Inspect the balljoint and tie-rod end

boots for tears - tears or damage in either

boot will allow contamination of the grease

which will lead to premature failure

1 Engine oil - Light engine oil in a can like

this can be used for door and bonnet

hinges

2 Graphite spray - Used to lubricate lock

cylinders

3 Grease - Grease, in a variety of types and

weights, is available for use in a grease

gun.

4 Grease gun - A common grease gun,

shown here with a detachable hose and

nozzle, is needed for chassis lubrication.

After use, clean it thoroughly

Page 125 of 227

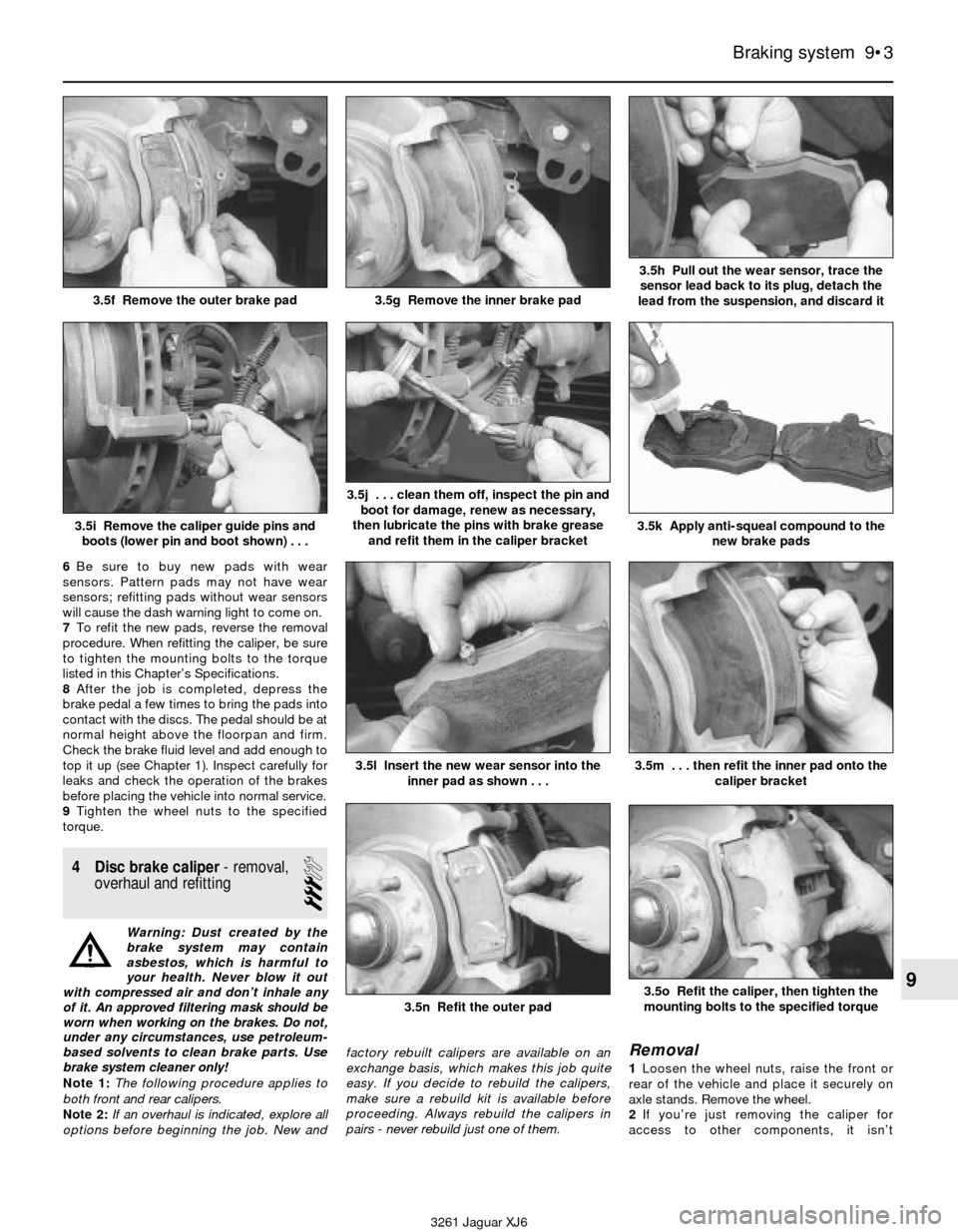

6Be sure to buy new pads with wear

sensors. Pattern pads may not have wear

sensors; refitting pads without wear sensors

will cause the dash warning light to come on.

7To refit the new pads, reverse the removal

procedure. When refitting the caliper, be sure

to tighten the mounting bolts to the torque

listed in this Chapter’s Specifications.

8After the job is completed, depress the

brake pedal a few times to bring the pads into

contact with the discs. The pedal should be at

normal height above the floorpan and firm.

Check the brake fluid level and add enough to

top it up (see Chapter 1). Inspect carefully for

leaks and check the operation of the brakes

before placing the vehicle into normal service.

9Tighten the wheel nuts to the specified

torque.

4 Disc brake caliper- removal,

overhaul and refitting

3

Warning: Dust created by the

brake system may contain

asbestos, which is harmful to

your health. Never blow it out

with compressed air and don’t inhale any

of it. An approved filtering mask should be

worn when working on the brakes. Do not,

under any circumstances, use petroleum-

based solvents to clean brake parts. Use

brake system cleaner only!

Note 1:The following procedure applies to

both front and rear calipers.

Note 2:If an overhaul is indicated, explore all

options before beginning the job. New andfactory rebuilt calipers are available on an

exchange basis, which makes this job quite

easy. If you decide to rebuild the calipers,

make sure a rebuild kit is available before

proceeding. Always rebuild the calipers in

pairs - never rebuild just one of them.

Removal

1Loosen the wheel nuts, raise the front or

rear of the vehicle and place it securely on

axle stands. Remove the wheel.

2If you’re just removing the caliper for

access to other components, it isn’t

Braking system 9•3

9

3.5f Remove the outer brake pad3.5g Remove the inner brake pad

3.5h Pull out the wear sensor, trace the

sensor lead back to its plug, detach the

lead from the suspension, and discard it

3.5i Remove the caliper guide pins and

boots (lower pin and boot shown) . . .

3.5j . . . clean them off, inspect the pin and

boot for damage, renew as necessary,

then lubricate the pins with brake grease

and refit them in the caliper bracket

3.5k Apply anti-squeal compound to the

new brake pads

3261 Jaguar XJ6

3.5l Insert the new wear sensor into the

inner pad as shown . . .

3.5n Refit the outer pad

3.5m . . . then refit the inner pad onto the

caliper bracket

3.5o Refit the caliper, then tighten the

mounting bolts to the specified torque