warning JEEP CHEROKEE 1988 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1988, Model line: CHEROKEE, Model: JEEP CHEROKEE 1988Pages: 1378, PDF Size: 19.9 MB

Page 784 of 1378

FUEL PRESSURE REGULATOR

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal

injury, cover fittings with shop towel while disconnecting

fittings.

Removal & Installation

Remove injector fuel rail assembly. Remove 2 pressure

regulator retaining screws. Remove regulator from fuel rail. To

install, reverse removal procedure. Adjust regulator after

installation.

IDLE SPEED STEPPER (ISS) MOTOR

Removal & Installation

1) Disconnect ISS motor connector. Remove ISS motor

retaining screws and ISS motor. To install, reverse removal

procedure. No idle speed adjustment is necessary. Idle speed is

controlled by the Electronic Control Unit (ECU).

THROTTLE POSITION SENSOR

Removal & Installation

Disconnect TPS wire connector. Bend retaining bolts lock

tabs and remove retaining bolts. Remove TPS from throttle plate

assembly. To install, reverse removal procedure. Adjust TPS after

installation. See ADJUSTMENTS in this article.

EGR VALVE

Removal & Installation

Disconnect vacuum hose from EGR valve. Remove bolts which

hold EGR valve to intake manifold. Remove valve and discard gasket.

Clean intake manifold gasket mating surface. To install valve,

reverse removal procedure. Always use new gasket. See Fig. 8.

Page 796 of 1378

IDLE SPEED ACTUATOR (ISA) MOTOR

1) Adjust ISA motor plunger to establish initial position of

plunger only if motor has been removed or replaced. Remove air filter

elbow and start engine. Run engine until engine reaches normal

operating temperature. Turn A/C off (if equipped).

2) Connect tachometer leads to diagnostic connector D1,

attaching negative lead to terminal D1-3 and positive lead to

terminal D1-1. See Fig. 4. Turn ignition off. ISA motor plunger

should move to fully extended position.

3) When ISA motor plunger is fully extended, disconnect ISA

motor wiring connector and start engine. Engine speed should be

3300-3700 RPM. If incorrect, turn hex head screw at end of plunger to

provide engine speed of 3500 RPM.

4) Fully retract ISA motor by holding closed throttle (idle)\

switch plunger inward as throttle is opened. Closed throttle switch

plunger should not touch throttle lever in closed position. If

contact is made, check linkage and/or cable for binding or damage.

Repair as necessary.

5) Connect ISA motor wiring harness connector and turn

ignition off for 10 seconds. ISA motor should move to fully extended

position. Start engine. Engine speed should be 3500 RPM for short

period of time and then decrease to normal idle speed.

6) Turn ignition off. Disconnect tachometer. After final

adjustment of ISA motor, use thread penetrating sealant (Loctite 290)

on adjustment screw to prevent movement and maintain adjustment.

NOTE: If adjustment screw must be moved after thread sealant

hardens, loosen threads by heating screw with flameless heat

such as soldering gun. DO NOT use flame or torch type of

heat as damage to ISA motor will result.

FUEL PRESSURE REGULATOR

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal

injury, cover fittings with shop towel while disconnecting

fittings.

1) Replacement fuel pressure regulator must be adjusted to

establish correct pressure. Remove air filter elbow and hose. Connect

tachometer leads to diagnostic connector D1, attaching negative lead

to terminal D1-3 and positive lead to terminal D1-1. See Fig. 4.

Remove screw plug and install fuel pressure test fitting.

NOTE: Fuel pressure test fitting is not included with throttle

body. Fitting (8983 501 572) must be obtained separately.

2) Connect fuel pressure gauge to test fitting. Start engine

and increase speed to approximately 2000 RPM. Turn Torx head screw at

bottom of regulator to set correct pressure. Turning screw inward

increases pressure and turning screw outward decreases pressure. See

Fig. 3 .

3) All models require fuel pressure of 14.5 psi (1.0 kg/cm

�).

Install lead sealing ball to cover regulator adjustment

screw after adjusting fuel pressure. Turn ignition off. Remove

measuring equipment and test fitting. Install original plug screw and

air filter assembly.

Page 802 of 1378

COOLANT TEMPERATURE SENSOR (CTS)

Removal & Installation

Allow engine to cool down. Disconnect CTS wiring harness.

Remove CTS from intake manifold and rapidly plug hole to prevent

coolant loss. Install replacement CTS and connect CTS wiring harness.

FUEL INJECTOR

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal

injury, cover fittings with shop towel while disconnecting

fittings.

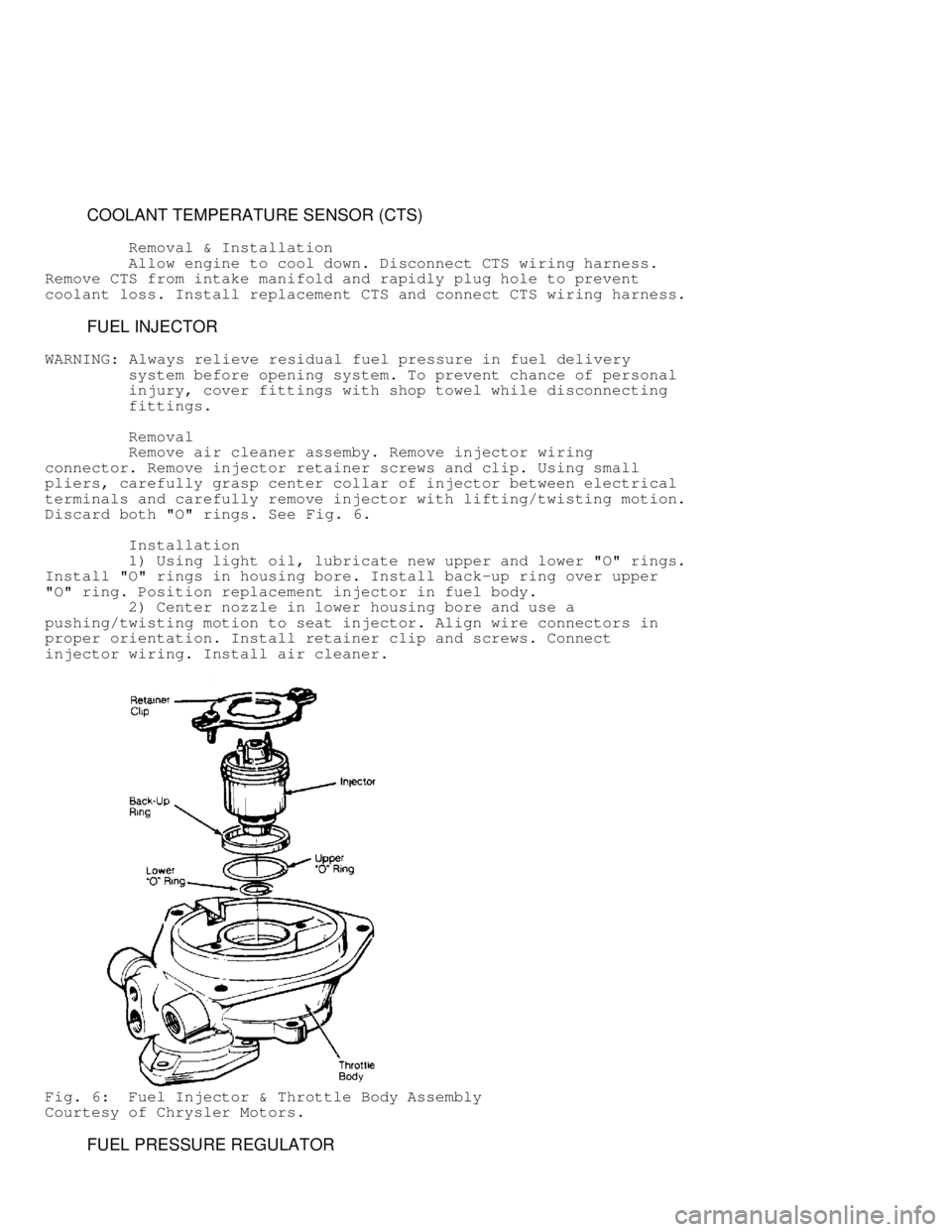

Removal

Remove air cleaner assemby. Remove injector wiring

connector. Remove injector retainer screws and clip. Using small

pliers, carefully grasp center collar of injector between electrical

terminals and carefully remove injector with lifting/twisting motion.

Discard both "O" rings. See Fig. 6.

Installation

1) Using light oil, lubricate new upper and lower "O" rings.

Install "O" rings in housing bore. Install back-up ring over upper

"O" ring. Position replacement injector in fuel body.

2) Center nozzle in lower housing bore and use a

pushing/twisting motion to seat injector. Align wire connectors in

proper orientation. Install retainer clip and screws. Connect

injector wiring. Install air cleaner.

Fig. 6: Fuel Injector & Throttle Body Assembly

Courtesy of Chrysler Motors.

FUEL PRESSURE REGULATOR

Page 803 of 1378

Removal & Installation

WARNING: Always relieve residual fuel pressure in fuel delivery

system before opening system. To prevent chance of personal

injury, cover fittings with shop towel while disconnecting

fittings.

With throttle body assembly removed, remove 3 screws holding

fuel pressure regulator in throttle body. Remove fuel pressure

regulator assembly. Note location of components for installation.

Discard gaskets. To install, reverse removal procedure. Adjust

regulator after installation. See ADJUSTMENTS in this article.

IDLE SPEED ACTUATOR (ISA) MOTOR

Removal & Installation

1) Disconnect throttle return spring. Disconnect wiring

harness connector from ISA motor. Remove ISA motor retaining nuts and

remove ISA motor from bracket.

2) To install ISA motor assembly, reverse removal procedure.

Adjust ISA motor after installation. See ADJUSTMENTS in this article.

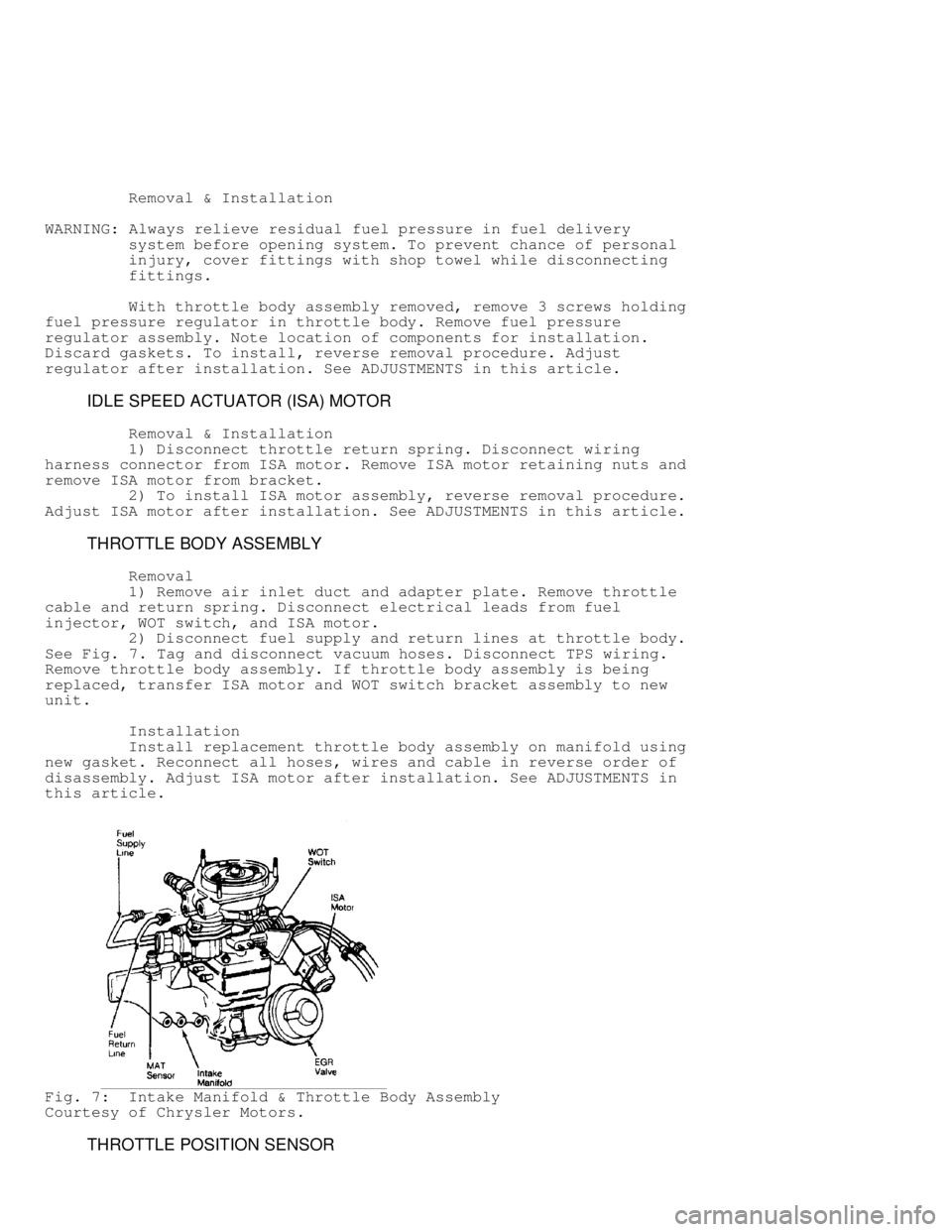

THROTTLE BODY ASSEMBLY

Removal

1) Remove air inlet duct and adapter plate. Remove throttle

cable and return spring. Disconnect electrical leads from fuel

injector, WOT switch, and ISA motor.

2) Disconnect fuel supply and return lines at throttle body.

See Fig. 7 . Tag and disconnect vacuum hoses. Disconnect TPS wiring.

Remove throttle body assembly. If throttle body assembly is being

replaced, transfer ISA motor and WOT switch bracket assembly to new

unit.

Installation

Install replacement throttle body assembly on manifold using

new gasket. Reconnect all hoses, wires and cable in reverse order of

disassembly. Adjust ISA motor after installation. See ADJUSTMENTS in

this article.

Fig. 7: Intake Manifold & Throttle Body Assembly

Courtesy of Chrysler Motors.

THROTTLE POSITION SENSOR

Page 829 of 1378

1 - 25 Amp

Rear Washer/Wiper.

2 - 15 Amp

Radio, Cigarette Lighter.

3 - 25 Amp

Blower Motor.

4 - 20 Amp

Turn Signal, Back-Up Lights, Rear Window Defogger Relay.

5 - 10 Amp

Dome Light, Courtesy Lights, Glove Box Light, Cargo Light,

Radio Memory, Power Mirrors, Teltak Connector.

6 - 15 Amp

Hazard Warning System, Stoplights.

7 - 10 Amp

Parking Lights, Headlight Warning Chime/Buzzer, Instrument

Panel Light Dimmer.

8 - 7.5 Amp

Gauges, Instrument Cluster, Seat Belt Warning, Headlight

Delay, Chime Module, Overhead Console.

9 - 5 Amp

Instrument Panel Illumination.

10 - 25 Amp

Rear Window Defogger.

11 - 30 Amp (Circuit Breaker)

Power Door Locks, Power Seats, Trailer Towing Wiring Harness.

12 - 10 Amp

ETR Radio, Power Antenna.

13 - Not Used (1984-87); 7.5 Amp (1988)

Transmission Control Unit.

14 - 25 Amp

Headlight Delay, Horns, Security Alarm.

15 - 5.5 Amp (Circuit Breaker)

Front Wiper.

16 - 30 Amp (Circuit Breaker)

Power Windows.

17 - 10 Amp

Clock, Security Alarm (Ign).

CAUTIONS & WARNINGS

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off

all lights and accessories to avoid damaging the electrical system. Be

sure to use fuse with the correct indicated amperage rating. The use

of an incorrect amperage rating fuse may result in a dangerous

Page 830 of 1378

electrical system overload.

BATTERY WARNING

WARNING: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

restored, driveability problems may exist on some

vehicles. These vehicles may require a relearn procedure.

See the COMPUTER RELEARN PROCEDURES article in GENERAL

INFORMATION section.

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

WARNING: Many solid state electrical components can be damaged by

static electricity (ESD). Some will display a warning label,

but many will not. Discharge personal static electricity by

touching a metal ground point on the vehicle prior to

servicing any ESD sensitive component.

HALOGEN BULBS

Halogen bulbs contain pressurized gas which may explode if

overheated. DO NOT touch glass portion of bulb with bare hands. Eye

protection should be worn when handling or working around halogen

bulbs.

RADIATOR CAP

CAUTION: Always disconnect the fan motor when working near the

radiator fan. The fan is temperature controlled and could

start at any time even when the ignition key is in the OFF

position. DO NOT loosen or remove radiator cap when cooling

system is hot.

Page 870 of 1378

WARNING: The knock sensor MUST be tightened to the EXACT torque

specified in order to ensure proper operation.

1) Install the knock sensor to the cylinder block. Tighten

the knock sensor to 89 INCH Lbs. (10 Nm).

2) Connect the knock sensor wire connector.

3) Lower vehicle.

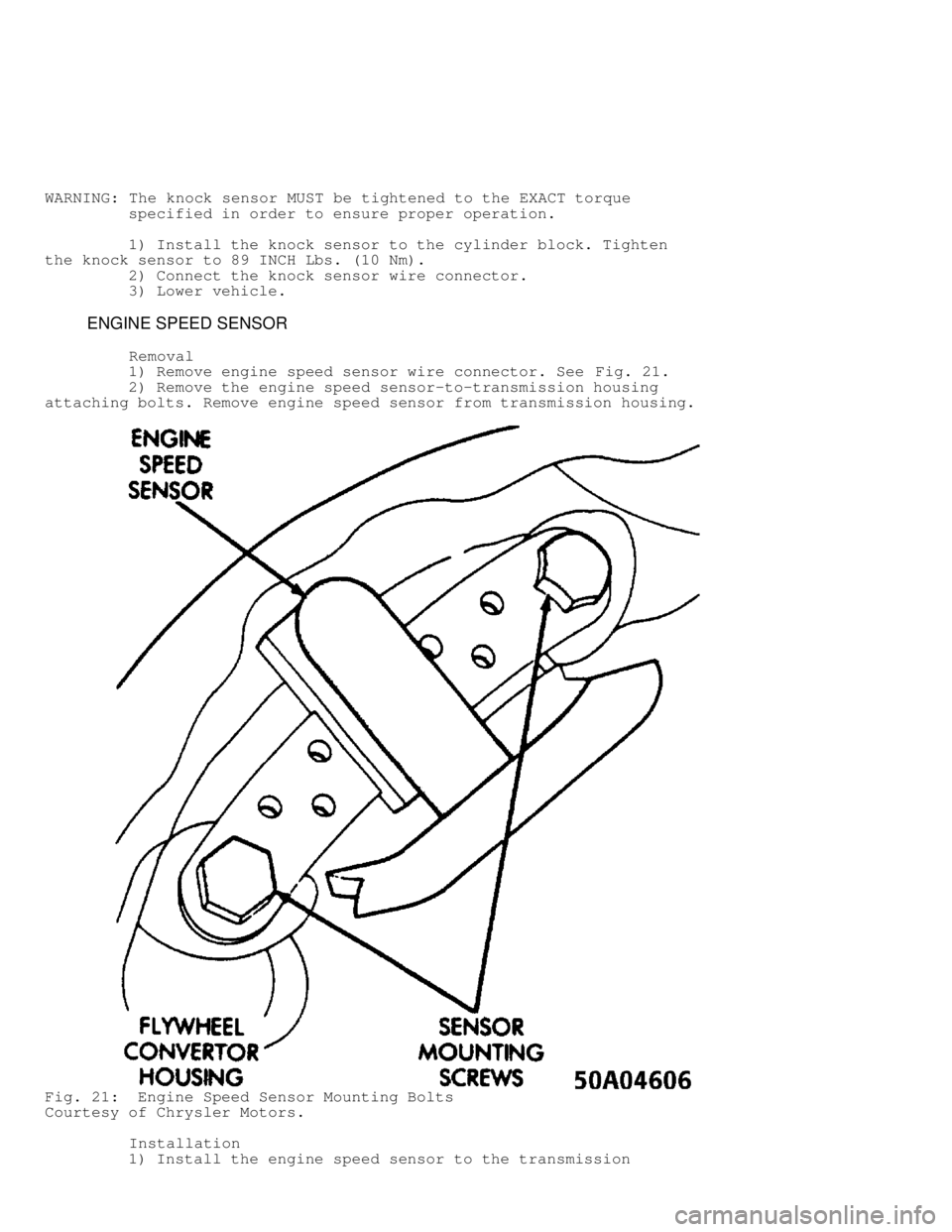

ENGINE SPEED SENSOR

Removal

1) Remove engine speed sensor wire connector. See Fig. 21.

2) Remove the engine speed sensor-to-transmission housing

attaching bolts. Remove engine speed sensor from transmission housing.

Fig. 21: Engine Speed Sensor Mounting Bolts

Courtesy of Chrysler Motors.

Installation

1) Install the engine speed sensor to the transmission

Page 906 of 1378

the ENGINE PERFORMANCE section.

Fuel filter should be drained whenever "WATER IN FUEL"

warning light glows. Diesel fuel can damage asphalt and

painted surfaces. Always place a drain pan under fuel filter

to collect contaminated fuel. See Fig. 2.

1) Stop vehicle and turn engine off. Attach a long piece

of tubing to drain cock outlet. Place end of drain hose into

drain pan. Open filter assembly vent valve (Black + shaped

knob) and drain cock.

2) Drain approximately 1/2 pint (.24 Liters) from fuel

filter. Close vent valve and drain cock. Start engine and

check for leaks. If "WATER IN FUEL" warning lamp comes on

again, remove water contaminated fuel from fuel lines and

fuel tank.

WARNING: DO NOT bleed fuel lines on hot engine, as high exhaust

temperatures could cause fire. Use care when bleeding fuel

lines, as fuel is under extreme pressure and could penetrate

skin, causing personal injury. Wear safety goggles and

protective clothing when bleeding fuel lines.

CAUTION: DO NOT drain fuel/water separator when engine is running or

hot. Allow engine to cool before draining. Verify that the

WATER IN FUEL light on instrument panel is OFF.

Fig. 3: Locking Crankshaft at TDC

Courtesy of American Motors/Jeep Corp.

Page 915 of 1378

BATTERY SPECIFICATIONS

CAUTION: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

restored, driveability problems may exist on some vehicles.

These vehicles may require a relearn procedure. See COMPUTER

RELEARN PROCEDURES article in the GENERAL INFORMATION

section.

All gasoline engine equipped models use group 58 batteries

with 390 or 475 amp cold crank rating. Models with 2.1L Turbo Diesel

engine use group 24 batteries with a 815 amp cold crank rating.

CAUTIONS & WARNINGS

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off

all lights and accessories to avoid damaging the electrical system. Be

sure to use fuse with the correct indicated amperage rating. The use

of an incorrect amperage rating fuse may result in a dangerous

electrical system overload.

BATTERY WARNING

WARNING: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

restored, driveability problems may exist on some vehicles.

These vehicles may require a relearn procedure. See COMPUTER

RELEARN PROCEDURES article in GENERAL INFORMATION section.

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning

that brake pads need replacement.

DIESEL FUEL ANTI-FUNGAL ADDITIVES

CAUTION: If fuel contamination due to fungi or other microorganisms is

suspected a fuel additive with a biocide may be used. Follow

the manufacturers dosage as recommended on product label. Use

biocides ONLY when necessary, excessive use can may cause

other fuel system problems.

DIESEL FUEL CONTAMINATION

WARNING: Diesel fuel system may be contaminated with fungi or other

microorganisms. Keep contaminated fuel away from open skin

cuts or sores to prevent skin irritation or infection.

DIESEL FUEL REQUIREMENTS

CAUTION: All diesel engines are to use Diesel Fuel #2 when the outside

temperature is above 20\bF (-7\bC). In temperatures that are

below 20\bF (-7\bC) use Diesel Fuel #1, this will reduce the

chance of the fuel thickening and forming wax.

Note: A Diesel Fuel #1 & #2 combination (Blended Fuel) may be\

used, and is recommended for mild winter driving.

Page 916 of 1378

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

WARNING: Many solid state electrical components can be damaged by

static electricity (ESD). Some will display a warning label,

but many will not. Discharge personal static electricity by

touching a metal ground point on the vehicle prior to

servicing any ESD sensitive component.

ENGINE OIL

CAUTION: Never use non-detergent or straight mineral oil.

CAUTION: Do not use reclaimed fluid, mineral oil, fluid that was

stored in old or open containers, or fluid inferior to AMC

Standard AM 4101. Be sure to handle the fluid in clean

containers that will not introduce even a slight amount of

foreign liquids or particles. Such contamination of fluid

could lead to hydraulic system failure.

ENGINE OIL FILTER (GASOLINE)

CAUTION: Verify that proper Oil Filter is being used. Filters with

metric threads (M20 x 1.5) must be used with some engines.

Other engines use SAE type (3/4" x 16) threads, and must

use an oil filter with these threads. Possible engine damage

can occur with improper oil filter.

ENGINE OIL FILTER (TURBO DIESEL ONLY)

CAUTION: The engine oil filter has METRIC threads. Use of a filter

with improper threads can result in oil leakage and

possible engine damage. Look for thread size symbol M20x1.5

on filter.

FUEL SYSTEM SERVICE

WARNING: DO NOT bleed fuel lines on hot engine, as high exhaust

temperatures could cause fire. Use care when bleeding fuel

lines, as fuel is under extreme pressure and could penetrate

skin, causing personal injury. Wear safety goggles and

protective clothing when bleeding fuel lines.

WARNING: Relieve fuel system pressure prior to servicing any fuel

system component.

HALOGEN BULBS

Halogen bulbs contain pressurized gas which may explode if

overheated. DO NOT touch glass portion of bulb with bare hands. Eye

protection should be worn when handling or working around halogen

bulbs.

RADIATOR CAP

CAUTION: Always disconnect the fan motor when working near the

radiator fan. The fan is temperature controlled and could

start at any time even when the ignition key is in the OFF

position. DO NOT loosen or remove radiator cap when cooling

system is hot.

STARTING FLUID USE (TURBO DIESEL)