index JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1207 of 1784

30RH/32RH IN-VEHICLE SERVICE

INDEX

page page

Checking Fluid Level and Condition........... 96

Front Band Adjustment.................... 99

Gearshift Linkage Adjustment (YJ)............ 96

Governor and Park Gear Service............ 101

Oil Filter Replacement.................... 100

Park Interlock Cable Adjustment (XJ)......... 97

Park Lock Component Replacement......... 102

Park/Neutral Position Switch Service......... 103

Rear Band Adjustment.................... 99

Recommended Fluid...................... 96

Servicing Transmission Cooler Lines and Fittings. 106

Shift Cable Adjustment (XJ)................ 97

Speedometer Service.................... 103

Transmission Cooler Flow Testing........... 106

Transmission Cooler Reverse Flushing....... 105

Transmission Throttle Cable Adjustment (XJ/YJ) . 98

Valve Body Installation................... 101

Valve Body Removal..................... 100

Valve Body Service...................... 100

RECOMMENDED FLUID

The recommended and preferred fluid for 30RH/

32RH transmissions is Mopar ATF Plus, Type 7176.

Mopar Dexron II is acceptable but should only be

used when ATF Plus is not available.

Transmission fluid capacity is approximately 17

pints (7.9 liters). This is the approximate amount of

fluid required to fill the transmission and torque con-

verter after overhaul.

CHECKING FLUID LEVEL AND CONDITION

(1) Position vehicle on flat, level surface. This is

important in obtaining an accurate fluid level check.

(2) To avoid false readings, which could produce

under or over fill condition, do not check level until

fluid is at normal operating temperature.

(3) Shift transmission into Neutral.

(4) Apply parking brakes.

(5) Operate engine at curb idle speed.

WARNING: WHEN PERFORMING UNDERHOOD OP-

ERATIONS WITH THE ENGINE RUNNING, KEEP

YOUR HANDS WELL AWAY FROM HOT OR ROTAT-

ING ENGINE COMPONENTS. DO NOT WEAR

LOOSE ARTICLES OF CLOTHING WHICH COULD

BECOME ENTANGLED IN ENGINE COMPONENTS

OR ACCESSORIES.

(6) Shift transmission through all gear ranges and

back to Neutral (leave engine running).

(7) Clean exterior of dipstick cap and fill tube be-

fore removing transmission dipstick.

(8) Remove dipstick and inspect fluid level.

²Correct level is to FULL mark

²Acceptable level is between ADD and FULL marks

(9) Check fluid condition. Fluid should be dark to

light red in color and free of dirt or debris.

(10) If fluid is discolored or smells burned but

transmission operation was OK, check cooler flow,

flush cooler and lines and change fluid and filter.

Then road test again to confirm proper operation.(11) If fluid is black or dark brown, burned/turned

to sludge, contains large quantities of metal or fric-

tion material particles, transmission will need over-

haul. Especially if problems were evident during

road test and preliminary diagnosis. Fluid cooler

should also be flow tested and flushed if necessary.

GEARSHIFT LINKAGE ADJUSTMENT (YJ)

(1) Check linkage adjustment by starting engine in

Park and Neutral.

(2) Adjustment is OK if engine starts only in park

and Neutral. Adjustment is incorrect if engine starts

in one but not both positions.

(3) If engine starts in any position other than Park

or Neutral, or if engine will not start at all, park/

neutral position switch may be faulty.

(4) Shift transmission into Park.

(5) Raise vehicle.

(6) Check condition of shift rods, bellcrank, bell-

crank brackets and linkage bushings/grommets (Fig.

1). Tighten, repair, replace worn, damaged parts. Do

not attempt adjustment if linkage components are

worn or damaged.

(7) Loosen shift rod trunnion lock bolt or nut. Be

sure upper shift rod slides freely in trunnion (Fig. 1).

Also be sure shift rods and bellcrank rotate freely

and do not bind at any point.

(8) Verify that manual lever is in Park detent

(Fig. 1). Move lever all the way rearward to be sure

it is in Park.

(9) Check for positive engagement of park lock by

attempting to rotate propeller shaft. Shaft will not

turn when park pawl is engaged.

(10) Adjust shift rod trunnion to a obtain free pin

fit in bellcrank arm and tighten trunnion lock bolt or

nut. Prevent shift rod from turning while tightening

bolt or nut. Gearshift linkage lash must be elimi-

nated to obtain proper adjustment. Eliminate lash by

pulling downward on shift rod and pressing upward

on bellcrank.

21 - 96 30RH/32RH IN-VEHICLE SERVICEJ

Page 1213 of 1784

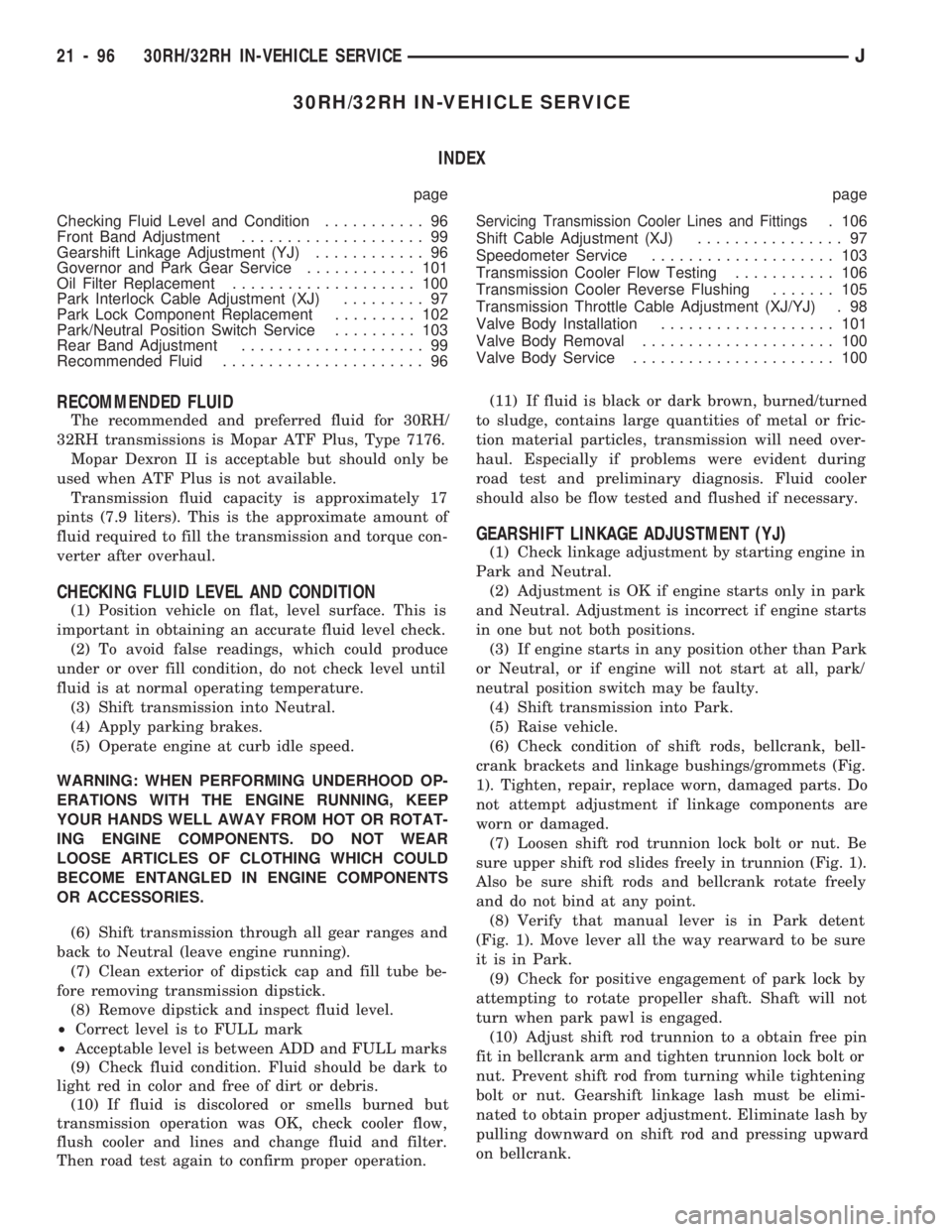

GOVERNOR DISASSEMBLY

(1) Remove governor weights and spring from body

(Fig. 13).

(2) Remove snap ring and separate inner weight

and outer weight and spring (Fig 13).

(3) Remove bolts attaching governor to park gear

(Fig. 13).

(4) Remove park gear from governor body.

(5) Remove filter screen from park gear or gover-

nor body (Fig. 13).

CLEANING AND INSPECTION

Thoroughly clean all the governor parts in a suit-

able cleaning solution but do not use any type of

caustic cleaning agents.

The weights and valves should fall freely in their

bores when clean and dry. Minor surface scratches

and burrs can be removed with crocus cloth.

Inspect the governor weight spring for distortion.

Replace the spring, if damaged. Clean the filter in

solvent and dry it with compressed air. Replace the

filter, if damaged. Inspect the park gear for chipped

or worn gear teeth or damaged ring grooves. Replace

the gear, if damaged.

GOVERNOR ASSEMBLY

The governor valve used in 30RH/31RH/32RH

transmissions built since the 1992 model year, is

made of aluminum. In addition, the output shaft

has been spotfaced to accept the new aluminum

valve. The aluminum valve must not be used in

previous transmissions. The valve can only be

used with an output shaft that has been spot-

faced for valve end clearance. In addition, thegovernor body and output shaft must be prop-

erly indexed during reassembly. Be sure to in-

dex these components as described in the

Transmission Assembly and Adjustment proce-

dures.

(1) Install filter screen in park gear.

(2) Assemble governor body and park gear. Be sure

oil passages in body and gear are aligned.

(3) Install governor-to-park gear bolts finger tight

only at this time.

(4) Install governor weight snap ring in governor

body. Then install governor weight and spring assem-

bly in governor body.

GOVERNOR INSTALLATION

(1) Align and install park gear/governor assembly

on output shaft.

(2) Align valve shaft bore in governor body with

bore in output shaft.Be sure hole in output shaft

for governor valve shaft is aligned with gover-

nor valve bore in governor body. Valve shaft

will bind if misalignment occurs. Remove and

reposition governor body if necessary.

(3) Install governor valve and shaft. Be sure shaft

slides freely in bore before installing E-clip on shaft.

(4) Install governor valve on shaft and in governor

body. Then install remaining shaft retaining snap

ring.

(5) Install components that retain governor body

and park gear on output shaft as follows:

(a) On models with single snap ring, install snap

ring (Fig. 12). Be sure ring is seated in shaft.

(b) On models with thrust washer and two snap

rings, install thin snap ring first. Then install

thrust washer second and thick snap ring last (Fig.

12).

16(c) Verify correct position of snap rings.Be

sure flat side of each snap ring is toward gov-

ernor body.

(6) Tighten governor-to-park gear bolts to 11 Nzm

(95 in. lbs.).

(7) Install adapter and gasket on transmission.

Tighten adapter bolts to 32 Nzm (24 ft. lbs.).

(8) Install transfer case and rear crossmember.

(9) Connect speedometer cable, or vehicle speed

sensor wires exhaust pipe brackets and brake cable,

if removed.

(10) Align and connect propeller shafts. Tighten

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(11) Remove supports and lower vehicle.

(12) Check and adjust transmission fluid level.

PARK LOCK COMPONENT REPLACEMENT

COMPONENT REMOVAL

(1) Raise vehicle and remove transfer case and

adapter housing from transmission.

Fig. 13 Governor Components

21 - 102 30RH/32RH IN-VEHICLE SERVICEJ

Page 1215 of 1784

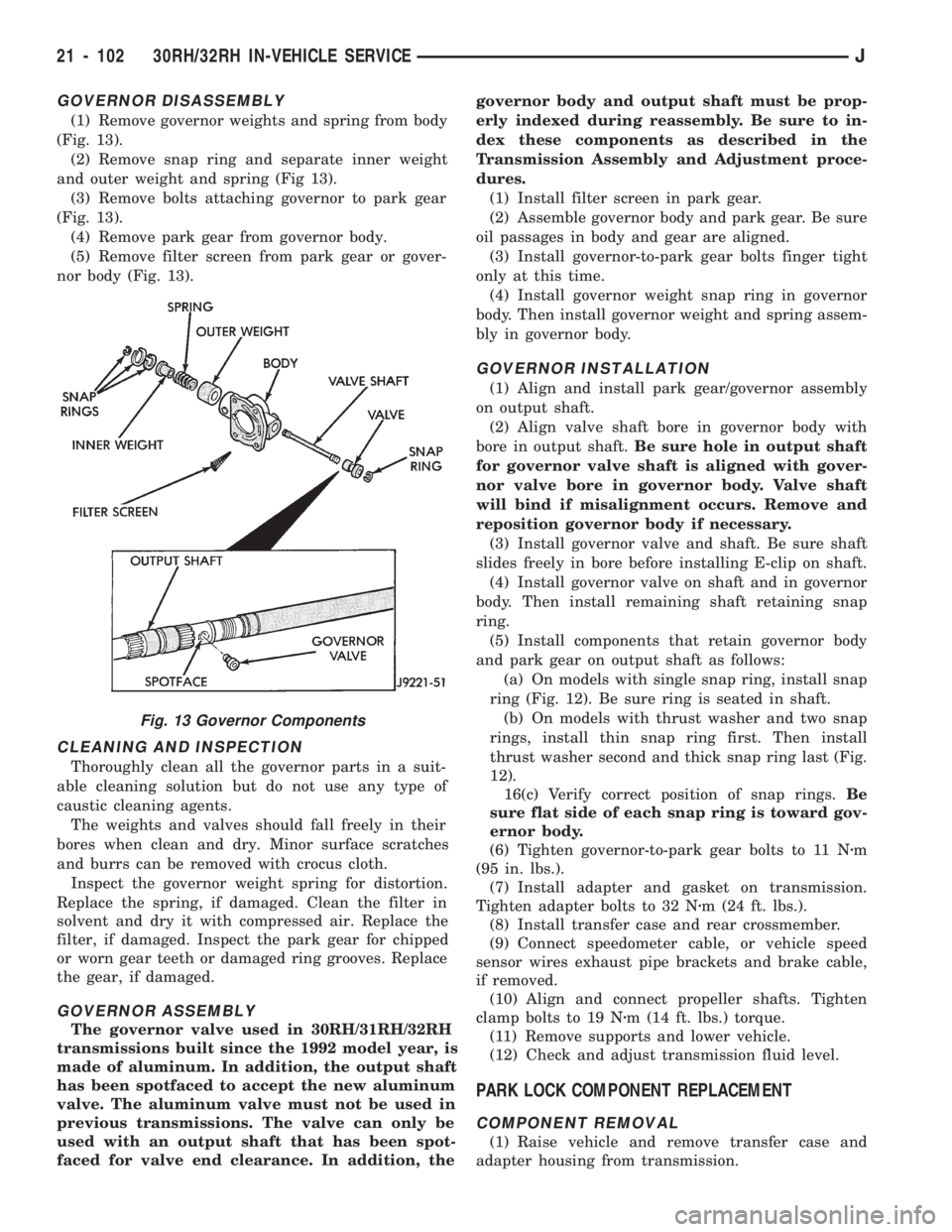

The speedometer assembly used in XJ models is the

new unit type (one-piece) speed sensor (Fig. 16). How-

ever, YJ models may be equipped with either the new

unit style, or the older style that has a two-piece speed

sensor and a metal adapter (Fig. 16). Service procedures

for both styles are described in the following procedures.

SPEEDOMETER ASSEMBLY REMOVAL (WITH

UNIT STYLE SENSOR)

(1) Raise vehicle.

(2) Disconnect wires from vehicle speed sensor.

(3) Remove adapter clamp and screw (Fig. 16).

(4) Remove speed sensor and speedometer adapter

as assembly.

(5) Remove speed sensor retaining screw and re-

move sensor from adapter.

(6) Remove speedometer pinion from adapter.

(7) Inspect sensor and adapter O-rings (Fig. 16).

Remove and discard O-rings if worn or damaged.

(8) Inspect terminal pins in vehicle speed sensor.

Clean pins with Mopar electrical spray cleaner if

dirty or oxidized. Replace sensor if faulty, or pins are

loose, severely corroded, or damaged.

SPEEDOMETER INSTALLATION AND

INDEXING (UNIT STYLE)

(1) Thoroughly clean adapter flange and adapter

mounting surface in housing. Surfaces must be clean

for proper adapter alignment and speedometer oper-

ation.

(2) Install new O-rings on speed sensor and speed-

ometer adapter if necessary (Fig. 17).

(3) Lubricate sensor and adapter O-rings with

transmission fluid.(4) Install vehicle speed sensor in speedometer

adapter. Tighten sensor attaching screw to 2-3 Nzm

(15-27 in. lbs.) torque.

(5) Install speedometer pinion in adapter.

(6) Count number of teeth on speedometer pinion.

Do this before installing assembly in housing. Then

lubricate pinion teeth with transmission fluid.

(7) Note index numbers on adapter body (Fig. 17).

These numbers will correspond to number of teeth on

pinion.

(8) Install speedometer assembly in housing.

(9) Rotate adapter until requiredrange numbers

are at 6 o-clock position. Be sure range index num-

bers correspond to number of teeth on pinion gear.

Fig. 16 Speedometer Components (With Unit Style Sensor)

Fig. 17 Location Of Index Numbers On Speedometer

Adapter (Unit Style Sensor)

21 - 104 30RH/32RH IN-VEHICLE SERVICEJ

Page 1216 of 1784

(10) Install speedometer adapter clamp and retain-

ing screw. Tighten clamp screw to 10-12 Nzm (90-110

in. lbs.) torque.

(11) Connect wires to vehicle speed sensor.

(12) Lower vehicle and top off transmission fluid

level if necessary.

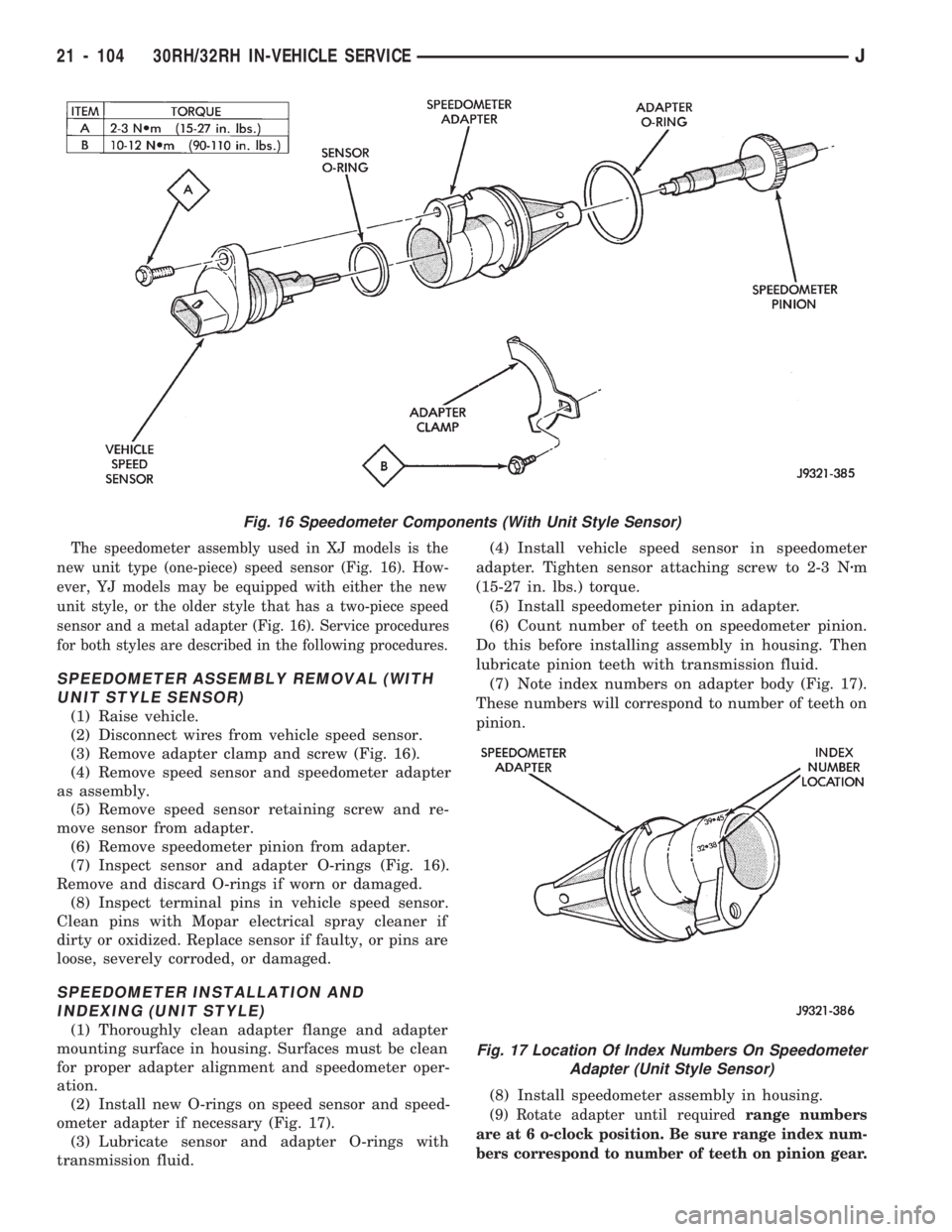

SPEEDOMETER COMPONENT REMOVAL

(TWO-PIECE SENSOR)

(1) Raise vehicle.

(2) Disconnect speed sensor wires.

(3) Remove bolt attaching vehicle speed sensor to

sensor adapter. Then slide sensor out of adapter.

(4) Inspect speed sensor mounting area in sensor

adapter. If transmission fluid is found in this area,

oil seal in metal speedometer adapter is leaking and

will have to be replaced.

(5) Remove speedometer adapter clamp bolt and

remove clamp (Fig. 18).

(6) Remove speedometer adapter, sensor adapter

and speedometer pinion as assembly.

SPEEDOMETER COMPONENT INSTALLATION

AND INDEXING (TWO-PIECE SENSOR)

(1) Replace speedometer O-ring if cut, torn, or worn.

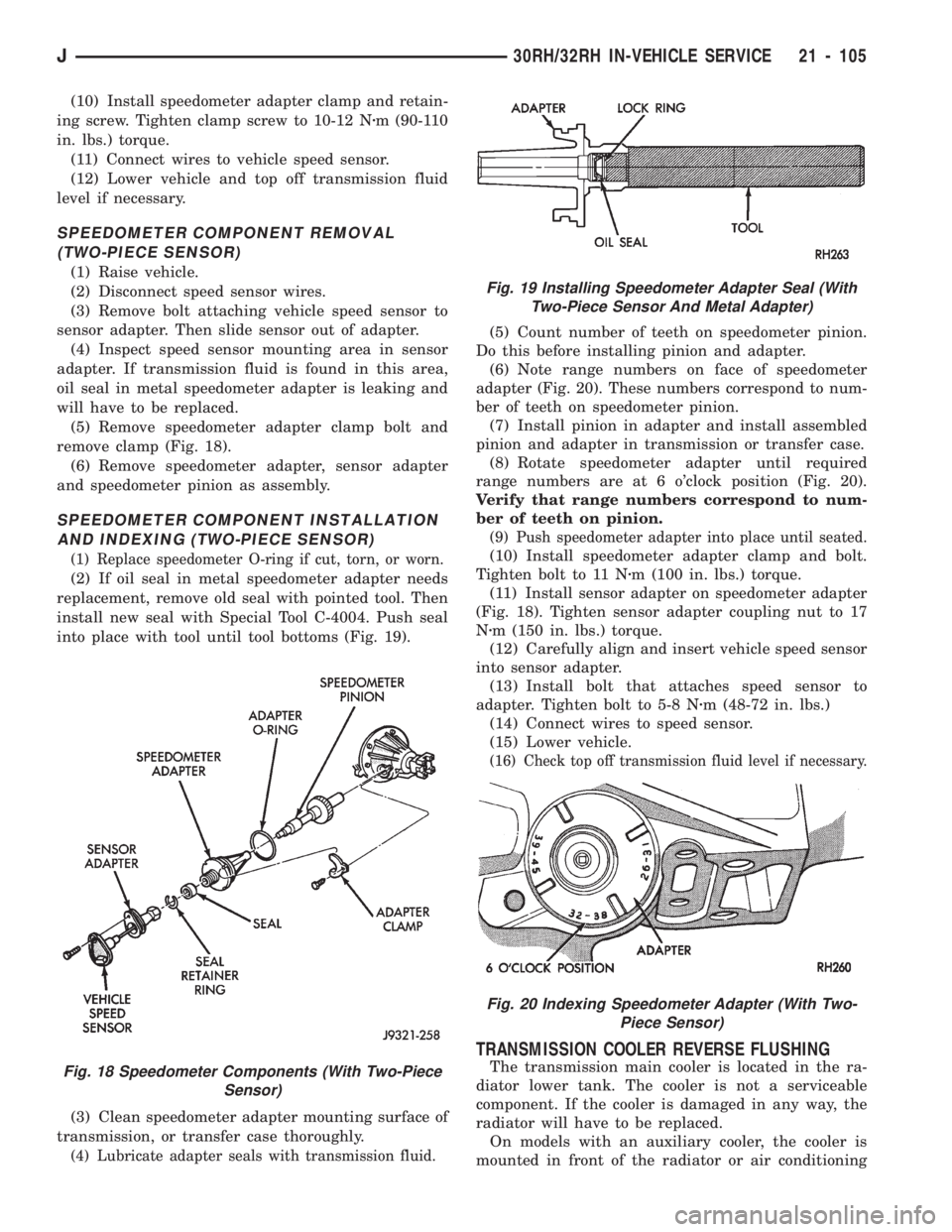

(2) If oil seal in metal speedometer adapter needs

replacement, remove old seal with pointed tool. Then

install new seal with Special Tool C-4004. Push seal

into place with tool until tool bottoms (Fig. 19).

(3) Clean speedometer adapter mounting surface of

transmission, or transfer case thoroughly.

(4) Lubricate adapter seals with transmission fluid.

(5) Count number of teeth on speedometer pinion.

Do this before installing pinion and adapter.

(6) Note range numbers on face of speedometer

adapter (Fig. 20). These numbers correspond to num-

ber of teeth on speedometer pinion.

(7) Install pinion in adapter and install assembled

pinion and adapter in transmission or transfer case.

(8) Rotate speedometer adapter until required

range numbers are at 6 o'clock position (Fig. 20).

Verify that range numbers correspond to num-

ber of teeth on pinion.

(9) Push speedometer adapter into place until seated.

(10) Install speedometer adapter clamp and bolt.

Tighten bolt to 11 Nzm (100 in. lbs.) torque.

(11) Install sensor adapter on speedometer adapter

(Fig. 18). Tighten sensor adapter coupling nut to 17

Nzm (150 in. lbs.) torque.

(12) Carefully align and insert vehicle speed sensor

into sensor adapter.

(13) Install bolt that attaches speed sensor to

adapter. Tighten bolt to 5-8 Nzm (48-72 in. lbs.)

(14) Connect wires to speed sensor.

(15) Lower vehicle.

(16) Check top off transmission fluid level if necessary.

TRANSMISSION COOLER REVERSE FLUSHING

The transmission main cooler is located in the ra-

diator lower tank. The cooler is not a serviceable

component. If the cooler is damaged in any way, the

radiator will have to be replaced.

On models with an auxiliary cooler, the cooler is

mounted in front of the radiator or air conditioningFig. 18 Speedometer Components (With Two-Piece

Sensor)

Fig. 19 Installing Speedometer Adapter Seal (With

Two-Piece Sensor And Metal Adapter)

Fig. 20 Indexing Speedometer Adapter (With Two-

Piece Sensor)

J30RH/32RH IN-VEHICLE SERVICE 21 - 105

Page 1219 of 1784

30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION

INDEX

page page

ConverterÐPump SealÐDrive Plate Service . . . 109

Transmission and Converter Installation....... 109Transmission and Converter Removal........ 108

TRANSMISSION AND CONVERTER REMOVAL

(1) Remove fan shroud attaching bolts.

(2) Disconnect transmission fill tube at upper

bracket.

(3) Raise vehicle.

(4) Remove inspection cover from converter hous-

ing and remove skid plate for access, if necessary.

(5) Remove transmission fill tube and fill tube

O-ring.

(6) Remove starter motor.

(7) Mark propeller shafts and axle yokes for align-

ment reference.

(8) Disconnect propeller shafts at yokes. Secure

shafts to frame rails with wire.

(9) Disconnect exhaust pipes at exhaust manifolds,

if necessary.

(10) Drain transfer case lubricant.

(11) Disconnect vehicle speed sensor wires.

(12) Disconnect transfer case shift linkage.

(13) Disconnect gearshift linkage and throttle ca-

ble at transmission levers.

(14) Disconnect park/neutral position switch wires.

(15) Disconnect and remove crankshaft position

sensor. Retain sensor bolt for reinstallation.

CAUTION: The crankshaft position sensor can be

damaged during transmission removal (or installa-

tion) if the sensor is still bolted to the engine block.

To avoid damage, remove the sensor before remov-

ing the transmission.

(16) Remove converter housing access cover and

mark drive plate and converter for alignment refer-

ence.

(17) Remove bolts attaching converter to drive

plate.

(18) Support engine with support stand.

(19) Support transmission-transfer case assembly

with transmission jack. Secure transmission to jack

with safety chain.

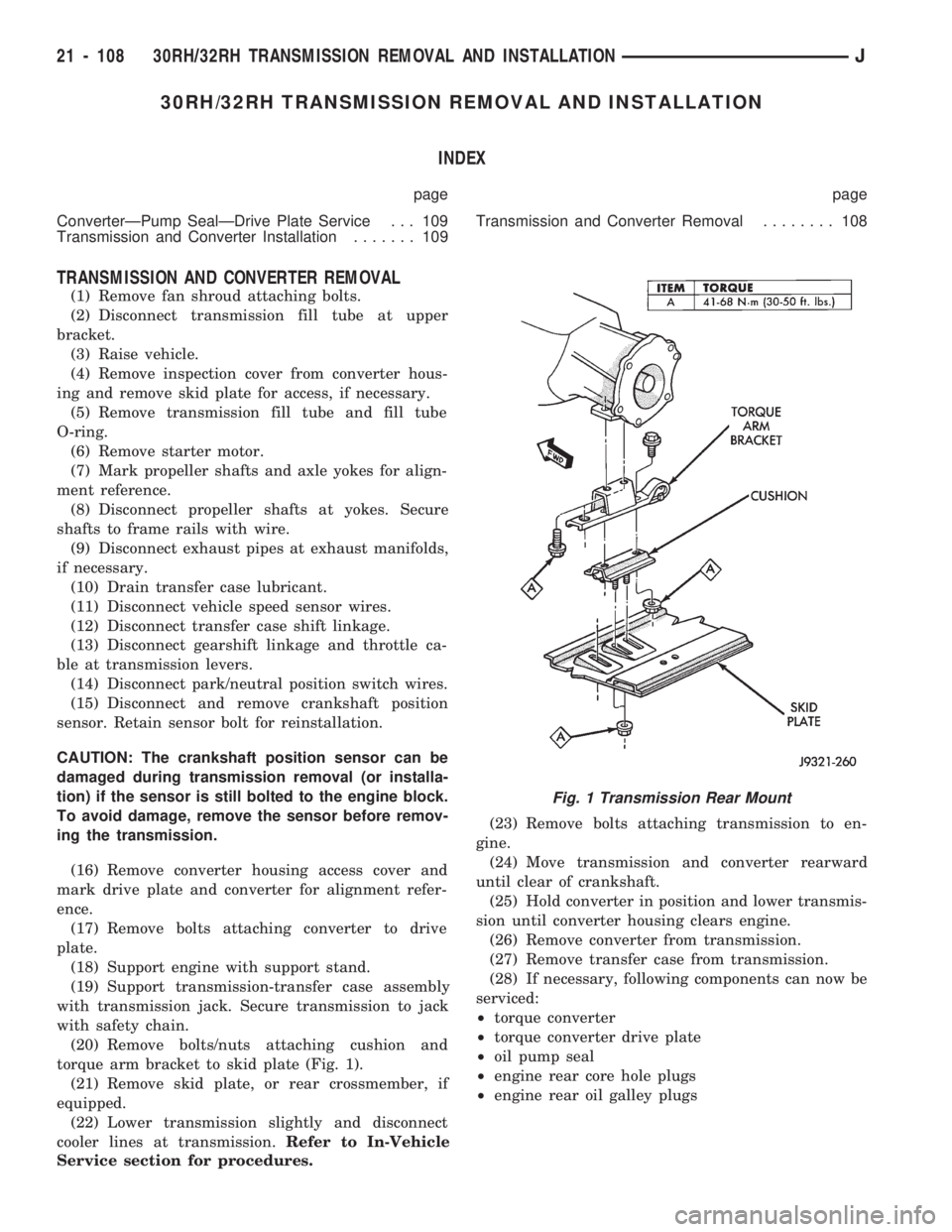

(20) Remove bolts/nuts attaching cushion and

torque arm bracket to skid plate (Fig. 1).

(21) Remove skid plate, or rear crossmember, if

equipped.

(22) Lower transmission slightly and disconnect

cooler lines at transmission.Refer to In-Vehicle

Service section for procedures.(23) Remove bolts attaching transmission to en-

gine.

(24) Move transmission and converter rearward

until clear of crankshaft.

(25) Hold converter in position and lower transmis-

sion until converter housing clears engine.

(26) Remove converter from transmission.

(27) Remove transfer case from transmission.

(28) If necessary, following components can now be

serviced:

²torque converter

²torque converter drive plate

²oil pump seal

²engine rear core hole plugs

²engine rear oil galley plugs

Fig. 1 Transmission Rear Mount

21 - 108 30RH/32RH TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1223 of 1784

30RH/32RH TRANSMISSION OVERHAUL

INDEX

page page

Adapter Housing and Park Lock Component

Overhaul............................ 120

Front Clutch Overhaul.................... 125

Front Servo and Band Overhaul............ 136

Governor and Park Gear Overhaul.......... 121

Oil Pump Overhaul...................... 122

Overhaul Service Information............... 118

Overrunning ClutchÐLow-Reverse DrumÐRear

Support Overhaul...................... 118

Planetary Gear Train Overhaul............. 131Rear Clutch Overhaul.................... 128

Rear Servo and Band Overhaul............. 136

Transmission Assembly and Adjustment

Procedures........................... 146

Transmission Assembly Tips............... 146

Transmission Case Cleaning and Inspection . . . 118

Transmission Disassembly................. 112

Valve Body Assembly and Adjustment........ 144

Valve Body Disassembly and Inspection...... 138

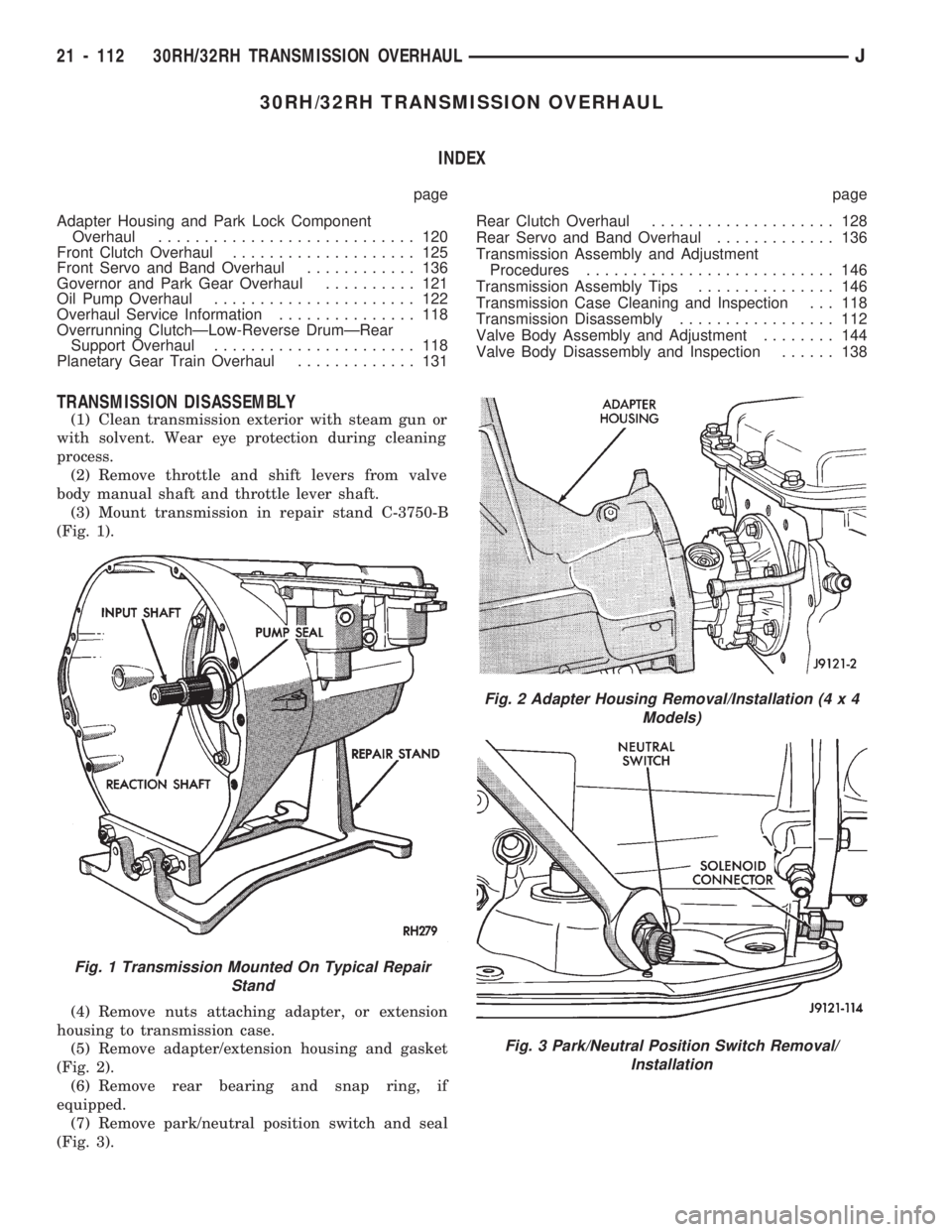

TRANSMISSION DISASSEMBLY

(1) Clean transmission exterior with steam gun or

with solvent. Wear eye protection during cleaning

process.

(2) Remove throttle and shift levers from valve

body manual shaft and throttle lever shaft.

(3) Mount transmission in repair stand C-3750-B

(Fig. 1).

(4) Remove nuts attaching adapter, or extension

housing to transmission case.

(5) Remove adapter/extension housing and gasket

(Fig. 2).

(6) Remove rear bearing and snap ring, if

equipped.

(7) Remove park/neutral position switch and seal

(Fig. 3).

Fig. 1 Transmission Mounted On Typical Repair

Stand

Fig. 2 Adapter Housing Removal/Installation (4 x 4

Models)

Fig. 3 Park/Neutral Position Switch Removal/

Installation

21 - 112 30RH/32RH TRANSMISSION OVERHAULJ

Page 1231 of 1784

before final assembly, install cam only as de-

scribed in Transmission Assembly And Adjust-

ment section. Clutch cam must be properly

indexed in case to fit and operate properly.

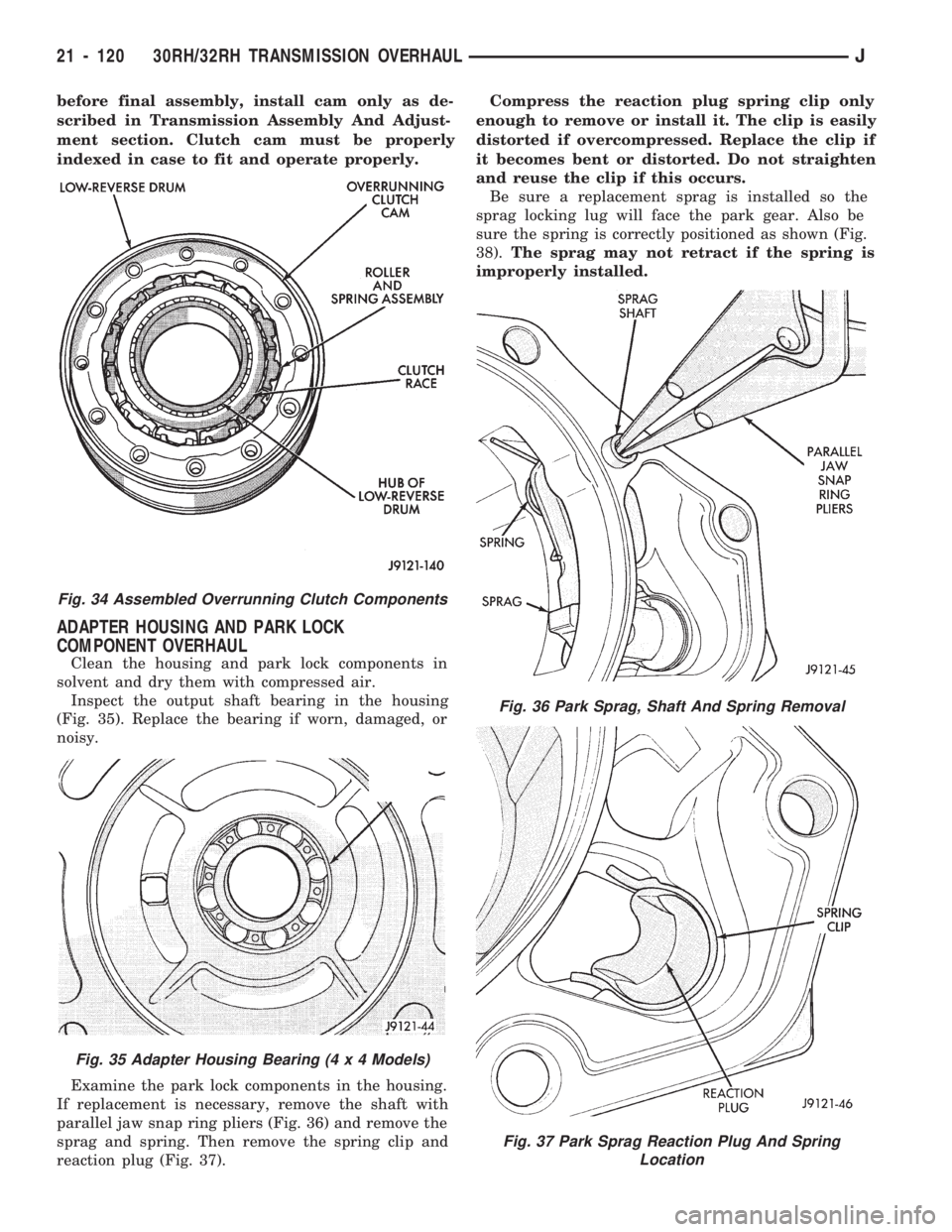

ADAPTER HOUSING AND PARK LOCK

COMPONENT OVERHAUL

Clean the housing and park lock components in

solvent and dry them with compressed air.

Inspect the output shaft bearing in the housing

(Fig. 35). Replace the bearing if worn, damaged, or

noisy.

Examine the park lock components in the housing.

If replacement is necessary, remove the shaft with

parallel jaw snap ring pliers (Fig. 36) and remove the

sprag and spring. Then remove the spring clip and

reaction plug (Fig. 37).Compress the reaction plug spring clip only

enough to remove or install it. The clip is easily

distorted if overcompressed. Replace the clip if

it becomes bent or distorted. Do not straighten

and reuse the clip if this occurs.

Be sure a replacement sprag is installed so the

sprag locking lug will face the park gear. Also be

sure the spring is correctly positioned as shown (Fig.

38).The sprag may not retract if the spring is

improperly installed.

Fig. 34 Assembled Overrunning Clutch Components

Fig. 35 Adapter Housing Bearing (4 x 4 Models)

Fig. 36 Park Sprag, Shaft And Spring Removal

Fig. 37 Park Sprag Reaction Plug And Spring

Location

21 - 120 30RH/32RH TRANSMISSION OVERHAULJ

Page 1232 of 1784

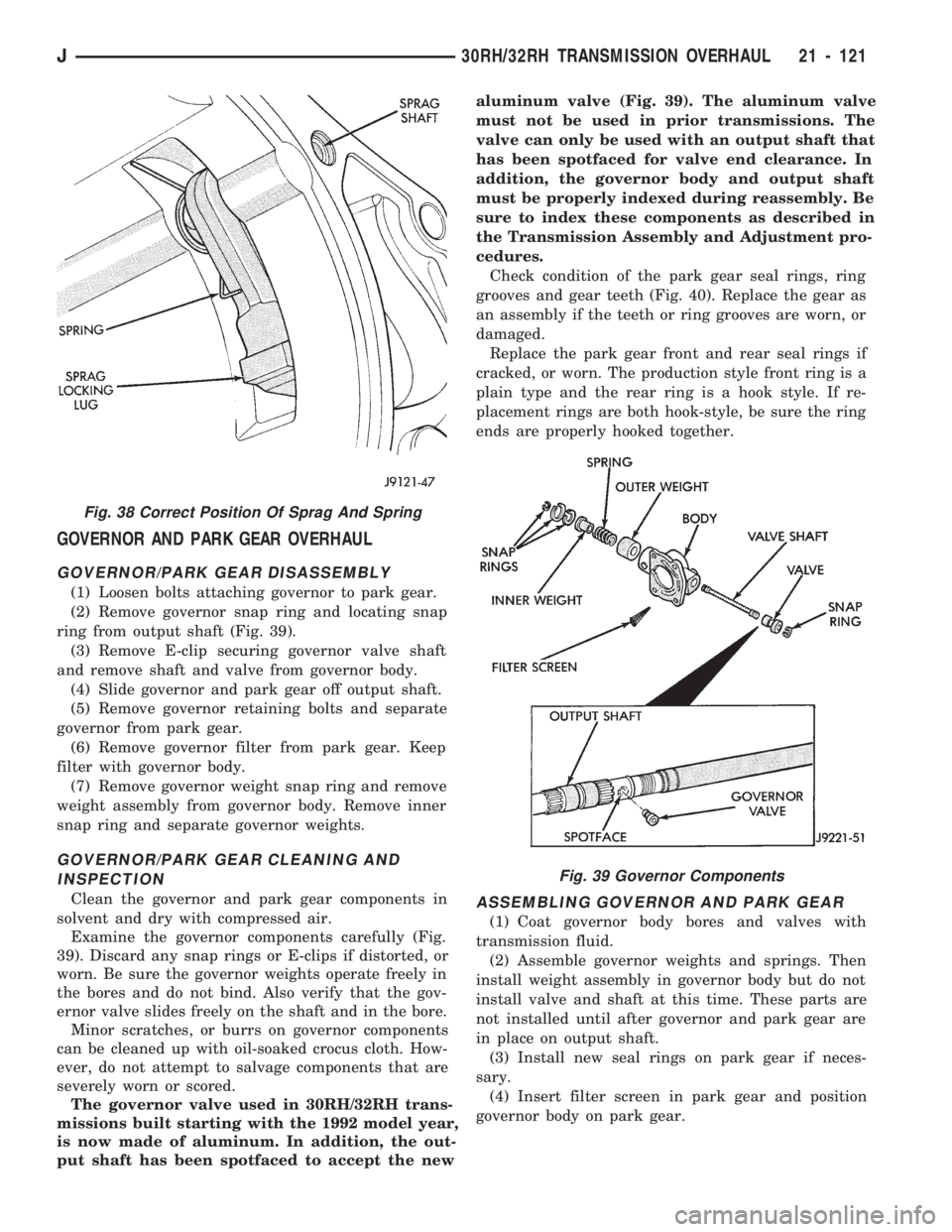

GOVERNOR AND PARK GEAR OVERHAUL

GOVERNOR/PARK GEAR DISASSEMBLY

(1) Loosen bolts attaching governor to park gear.

(2) Remove governor snap ring and locating snap

ring from output shaft (Fig. 39).

(3) Remove E-clip securing governor valve shaft

and remove shaft and valve from governor body.

(4) Slide governor and park gear off output shaft.

(5) Remove governor retaining bolts and separate

governor from park gear.

(6) Remove governor filter from park gear. Keep

filter with governor body.

(7) Remove governor weight snap ring and remove

weight assembly from governor body. Remove inner

snap ring and separate governor weights.

GOVERNOR/PARK GEAR CLEANING AND

INSPECTION

Clean the governor and park gear components in

solvent and dry with compressed air.

Examine the governor components carefully (Fig.

39). Discard any snap rings or E-clips if distorted, or

worn. Be sure the governor weights operate freely in

the bores and do not bind. Also verify that the gov-

ernor valve slides freely on the shaft and in the bore.

Minor scratches, or burrs on governor components

can be cleaned up with oil-soaked crocus cloth. How-

ever, do not attempt to salvage components that are

severely worn or scored.

The governor valve used in 30RH/32RH trans-

missions built starting with the 1992 model year,

is now made of aluminum. In addition, the out-

put shaft has been spotfaced to accept the newaluminum valve (Fig. 39). The aluminum valve

must not be used in prior transmissions. The

valve can only be used with an output shaft that

has been spotfaced for valve end clearance. In

addition, the governor body and output shaft

must be properly indexed during reassembly. Be

sure to index these components as described in

the Transmission Assembly and Adjustment pro-

cedures.

Check condition of the park gear seal rings, ring

grooves and gear teeth (Fig. 40). Replace the gear as

an assembly if the teeth or ring grooves are worn, or

damaged.

Replace the park gear front and rear seal rings if

cracked, or worn. The production style front ring is a

plain type and the rear ring is a hook style. If re-

placement rings are both hook-style, be sure the ring

ends are properly hooked together.ASSEMBLING GOVERNOR AND PARK GEAR

(1) Coat governor body bores and valves with

transmission fluid.

(2) Assemble governor weights and springs. Then

install weight assembly in governor body but do not

install valve and shaft at this time. These parts are

not installed until after governor and park gear are

in place on output shaft.

(3) Install new seal rings on park gear if neces-

sary.

(4) Insert filter screen in park gear and position

governor body on park gear.

Fig. 38 Correct Position Of Sprag And Spring

Fig. 39 Governor Components

J30RH/32RH TRANSMISSION OVERHAUL 21 - 121

Page 1261 of 1784

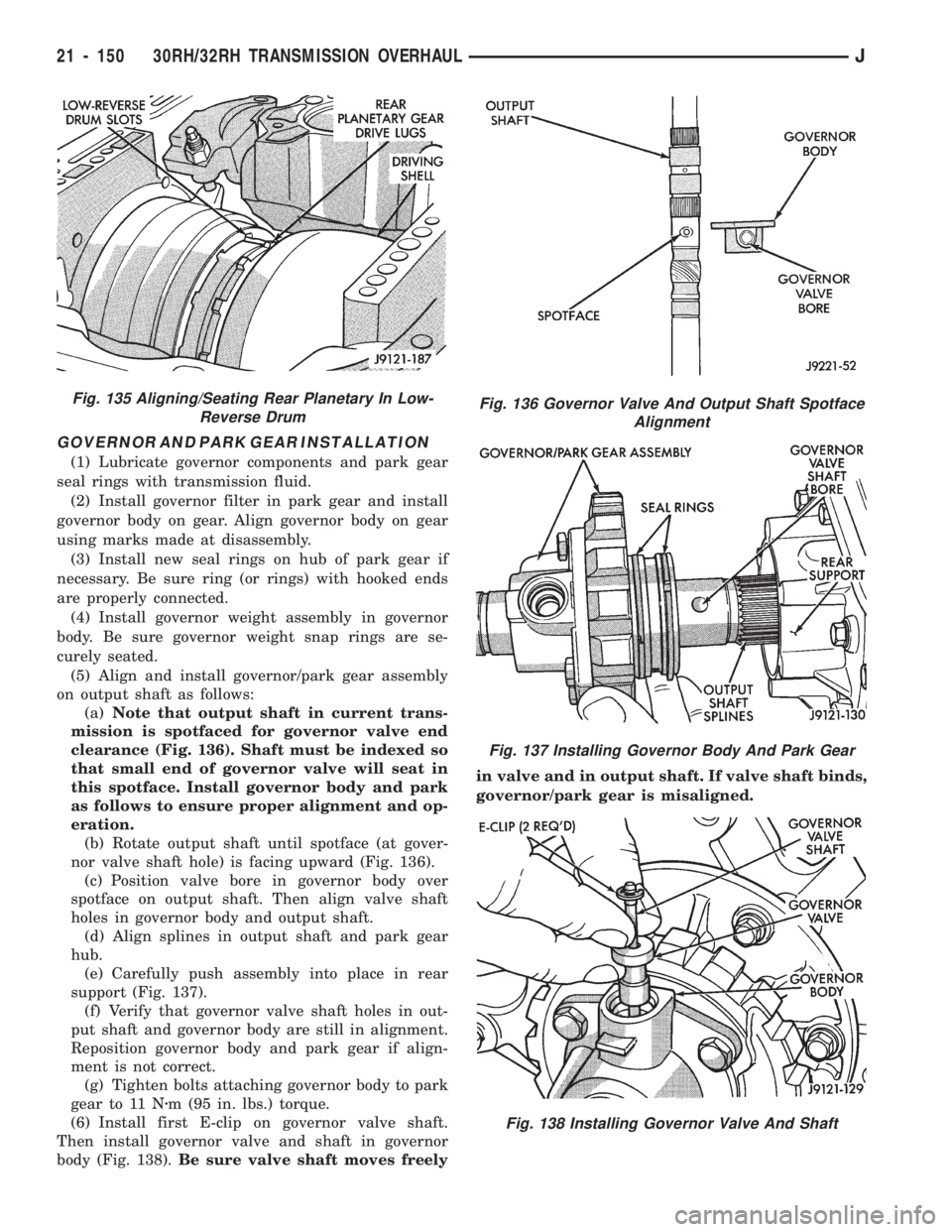

GOVERNOR AND PARK GEAR INSTALLATION

(1) Lubricate governor components and park gear

seal rings with transmission fluid.

(2) Install governor filter in park gear and install

governor body on gear. Align governor body on gear

using marks made at disassembly.

(3) Install new seal rings on hub of park gear if

necessary. Be sure ring (or rings) with hooked ends

are properly connected.

(4) Install governor weight assembly in governor

body. Be sure governor weight snap rings are se-

curely seated.

(5) Align and install governor/park gear assembly

on output shaft as follows:

(a)Note that output shaft in current trans-

mission is spotfaced for governor valve end

clearance (Fig. 136). Shaft must be indexed so

that small end of governor valve will seat in

this spotface. Install governor body and park

as follows to ensure proper alignment and op-

eration.

(b) Rotate output shaft until spotface (at gover-

nor valve shaft hole) is facing upward (Fig. 136).

(c) Position valve bore in governor body over

spotface on output shaft. Then align valve shaft

holes in governor body and output shaft.

(d) Align splines in output shaft and park gear

hub.

(e) Carefully push assembly into place in rear

support (Fig. 137).

(f) Verify that governor valve shaft holes in out-

put shaft and governor body are still in alignment.

Reposition governor body and park gear if align-

ment is not correct.

(g) Tighten bolts attaching governor body to park

gear to 11 Nzm (95 in. lbs.) torque.

(6) Install first E-clip on governor valve shaft.

Then install governor valve and shaft in governor

body (Fig. 138).Be sure valve shaft moves freelyin valve and in output shaft. If valve shaft binds,

governor/park gear is misaligned.

Fig. 136 Governor Valve And Output Shaft Spotface

Alignment

Fig. 137 Installing Governor Body And Park Gear

Fig. 138 Installing Governor Valve And Shaft

Fig. 135 Aligning/Seating Rear Planetary In Low-

Reverse Drum

21 - 150 30RH/32RH TRANSMISSION OVERHAULJ

Page 1267 of 1784

AW-4 AUTOMATIC TRANSMISSION

CONTENTS

page page

AW-4 IN-VEHICLE SERVICE............. 173

AW-4 TRANSMISSION DIAGNOSIS........ 167

AW-4 TRANSMISSION OVERHAUL........ 192

AW-4 TRANSMISSION REMOVAL AND

INSTALLATION....................... 189GENERAL INFORMATION................ 156

TRANSMISSION/TRANSFER CASE

SPECIFICATIONS..................... 320

GENERAL INFORMATION

INDEX

page page

Components and Operation................ 157

Description............................ 156

FirstÐThirdÐReverse Gear Components...... 159

Fourth Gear Overdrive Components......... 158

Geartrain Operation and Application Charts.... 159Hydraulic System........................ 160

Torque Converter........................ 158

Transmission Identification................. 157

Transmission Ranges and Shift Lever Positions . 157

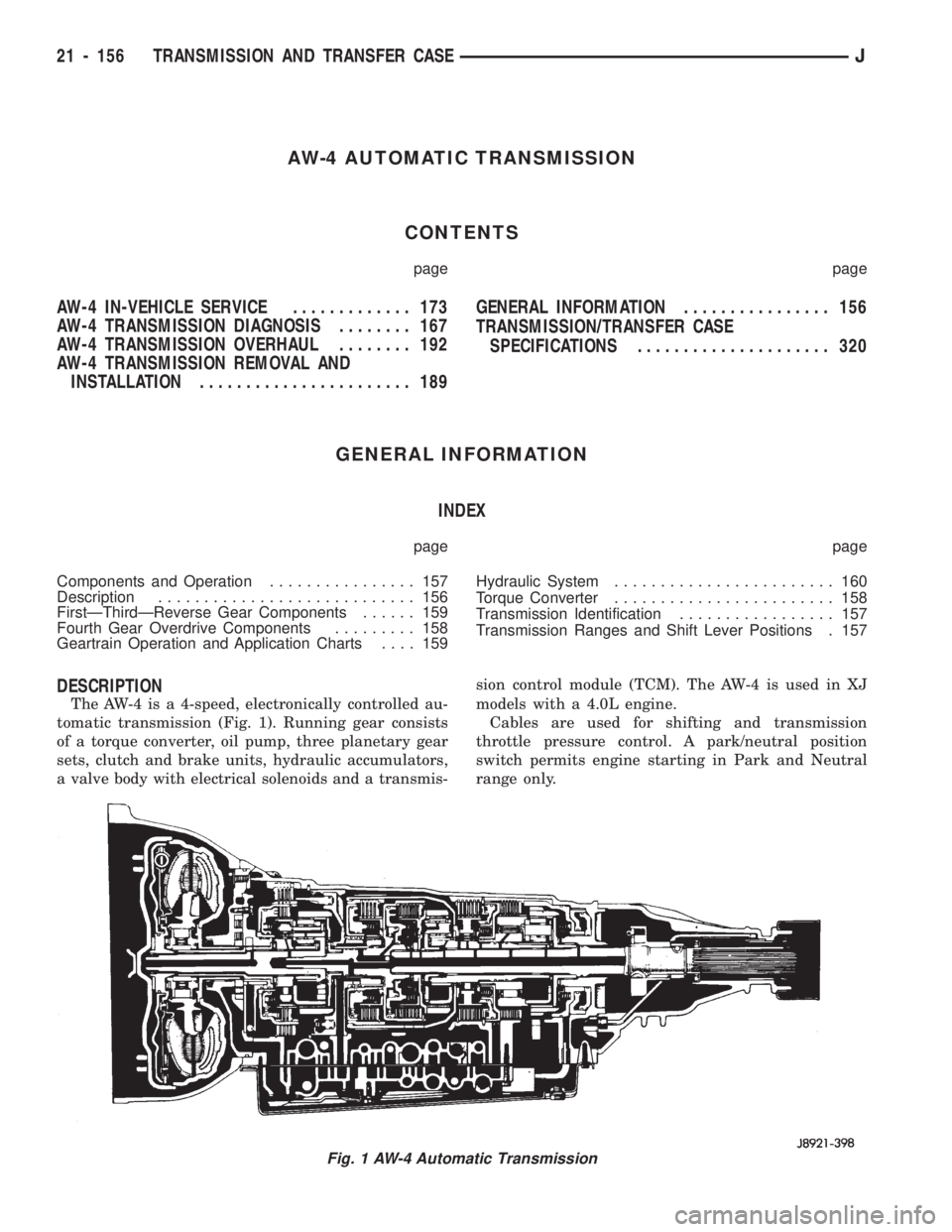

DESCRIPTION

The AW-4 is a 4-speed, electronically controlled au-

tomatic transmission (Fig. 1). Running gear consists

of a torque converter, oil pump, three planetary gear

sets, clutch and brake units, hydraulic accumulators,

a valve body with electrical solenoids and a transmis-sion control module (TCM). The AW-4 is used in XJ

models with a 4.0L engine.

Cables are used for shifting and transmission

throttle pressure control. A park/neutral position

switch permits engine starting in Park and Neutral

range only.

Fig. 1 AW-4 Automatic Transmission

21 - 156 TRANSMISSION AND TRANSFER CASEJ