index JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1539 of 1784

UNDERBODY COMPONENTS

INDEX

page page

Catalytic Converter/Muffler/Tailpipe Support

Brackets............................. 85

Front Skid Plate......................... 84

Fuel and Brake Fluid Tube Retainer Clip....... 86

Fuel Filler Hose Splash ShieldÐXJ Vehicles.... 86

Fuel Filter Bracket........................ 86Fuel Tank Skid Plate...................... 84

Fuel Tank Support Strap................... 86

Rear Tow HookÐXJ Vehicles............... 87

Service Information....................... 84

Trailer Hitches........................... 88

Transfer Case Skid Plate.................. 84

SERVICE INFORMATION

In some cases, components in the following proce-

dures either support, or are concealed by other com-

ponents. When necessary, refer to component

removal procedure for service access.

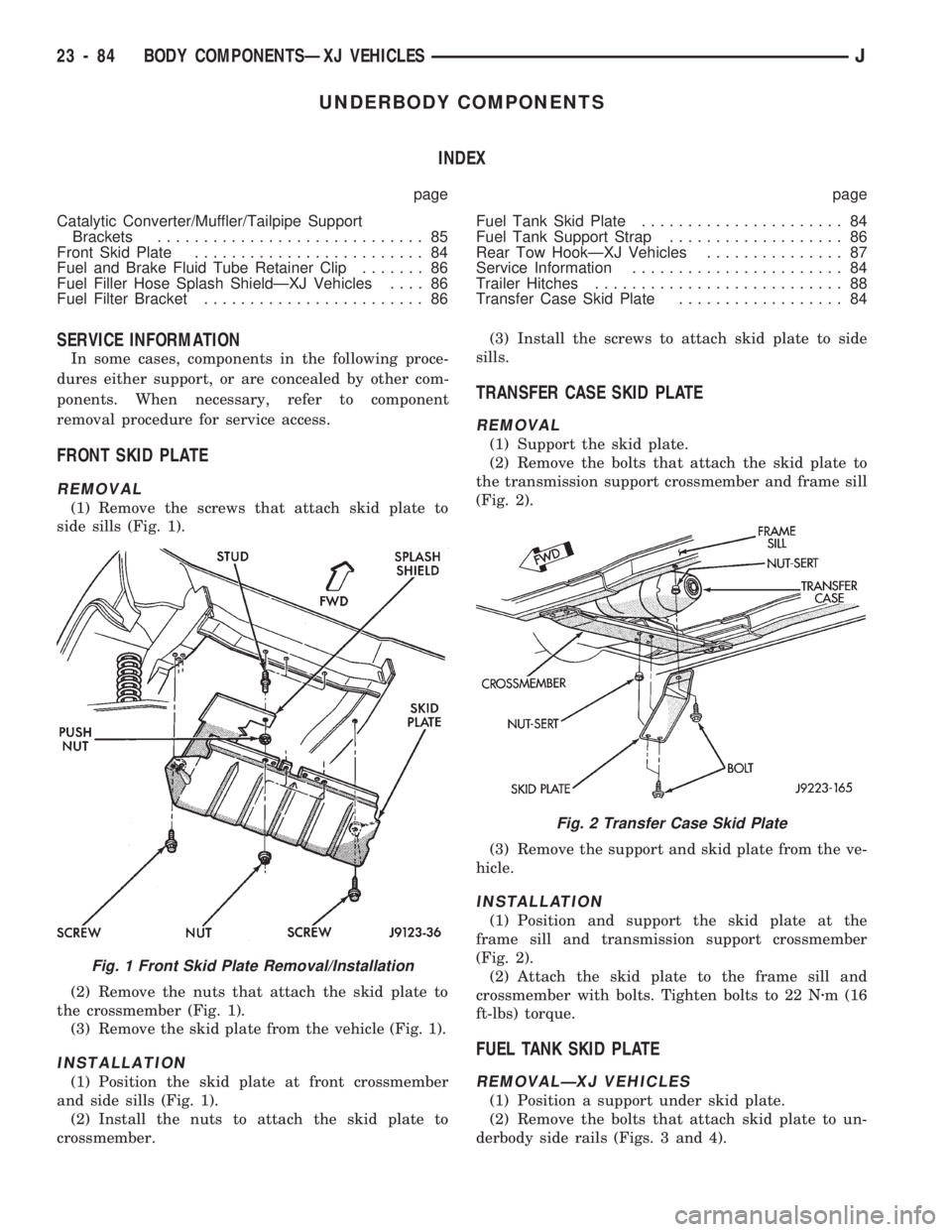

FRONT SKID PLATE

REMOVAL

(1) Remove the screws that attach skid plate to

side sills (Fig. 1).

(2) Remove the nuts that attach the skid plate to

the crossmember (Fig. 1).

(3) Remove the skid plate from the vehicle (Fig. 1).

INSTALLATION

(1) Position the skid plate at front crossmember

and side sills (Fig. 1).

(2) Install the nuts to attach the skid plate to

crossmember.(3) Install the screws to attach skid plate to side

sills.

TRANSFER CASE SKID PLATE

REMOVAL

(1) Support the skid plate.

(2) Remove the bolts that attach the skid plate to

the transmission support crossmember and frame sill

(Fig. 2).

(3) Remove the support and skid plate from the ve-

hicle.

INSTALLATION

(1) Position and support the skid plate at the

frame sill and transmission support crossmember

(Fig. 2).

(2) Attach the skid plate to the frame sill and

crossmember with bolts. Tighten bolts to 22 Nzm (16

ft-lbs) torque.

FUEL TANK SKID PLATE

REMOVALÐXJ VEHICLES

(1) Position a support under skid plate.

(2) Remove the bolts that attach skid plate to un-

derbody side rails (Figs. 3 and 4).

Fig. 1 Front Skid Plate Removal/Installation

Fig. 2 Transfer Case Skid Plate

23 - 84 BODY COMPONENTSÐXJ VEHICLESJ

Page 1546 of 1784

INTERIOR COMPONENTS

INDEX

page page

Assist HandleÐXJ Vehicles................ 118

B/C-Pillar and Liftgate Pillar Trim CoversÐ

XJ Vehicles.......................... 116

Bucket Seat Cushion and Cover............. 98

Bucket Seat Platform and Tracks........... 105

Bucket Seatback Cover and Frame.......... 100

Bucket Seatback Reconditioning............ 102

Carpets and Floor Mats................... 129

Dash Panel Insulation Panel................ 95

Front Bucket Seats....................... 97

Front Carpet/MatÐXJ Vehicles............. 129

Front Inner Scuff Plate/Cowl Side Trim PanelÐ

XJ Vehicles.......................... 114

Front Shoulder Belt/BuckleÐXJ Vehicles...... 119

Full Floor ConsoleÐXJ Vehicles............ 125

Headliner.............................. 121

I/P Ash Receiver Tray Lamp................ 92

I/P Tweeter Speaker/Courtesy Lamp Support

Bracket.............................. 95

Instrument Cluster Bezel................... 91

Instrument Cluster/Switch/Lighter/Radio/Hevac . . . 91

Instrument Panel......................... 93

Interior Trim Panels and Scuff PlatesÐXJ Vehicles. 112

Jack StorageÐXJ Vehicles................ 127

Mini-Floor ConsoleÐXJ Vehicles............ 124

Outer Scuff PlatesÐXJ Vehicles............ 118

Power Bucket Seat Components............ 106

Quarter and Wheelhouse Trim PanelsÐ

XJ Vehicles.......................... 115

Quarter Trim Panel ExtensionÐXJ Vehicles . . . 115

Rear Carpet/MatÐXJ Vehicles.............. 130

Rear Seat Cushion CoverÐXJ Vehicles...... 107

Rear Seat Cushion ReconditioningÐXJ Vehicles . 108

Rear Seat CushionÐXJ Vehicles............ 107

Rear Seatback CoverÐXJ Vehicles.......... 111

Rear Seatback Latch Striker and BumperÐ

XJ Vehicles.......................... 111

Rear Seatback ReconditioningÐXJ Vehicles . . . 111

Rear SeatbackÐXJ Vehicles............... 109

Rear Shoulder/Lap Belt/BuckleÐXJ Vehicles . . . 120

Spare Tire/Wheel Holddown and Floor BracketsÐ

XJ Vehicles.......................... 128

Sunvisors............................. 124

Windshield Side MouldingÐXJ Vehicles...... 114

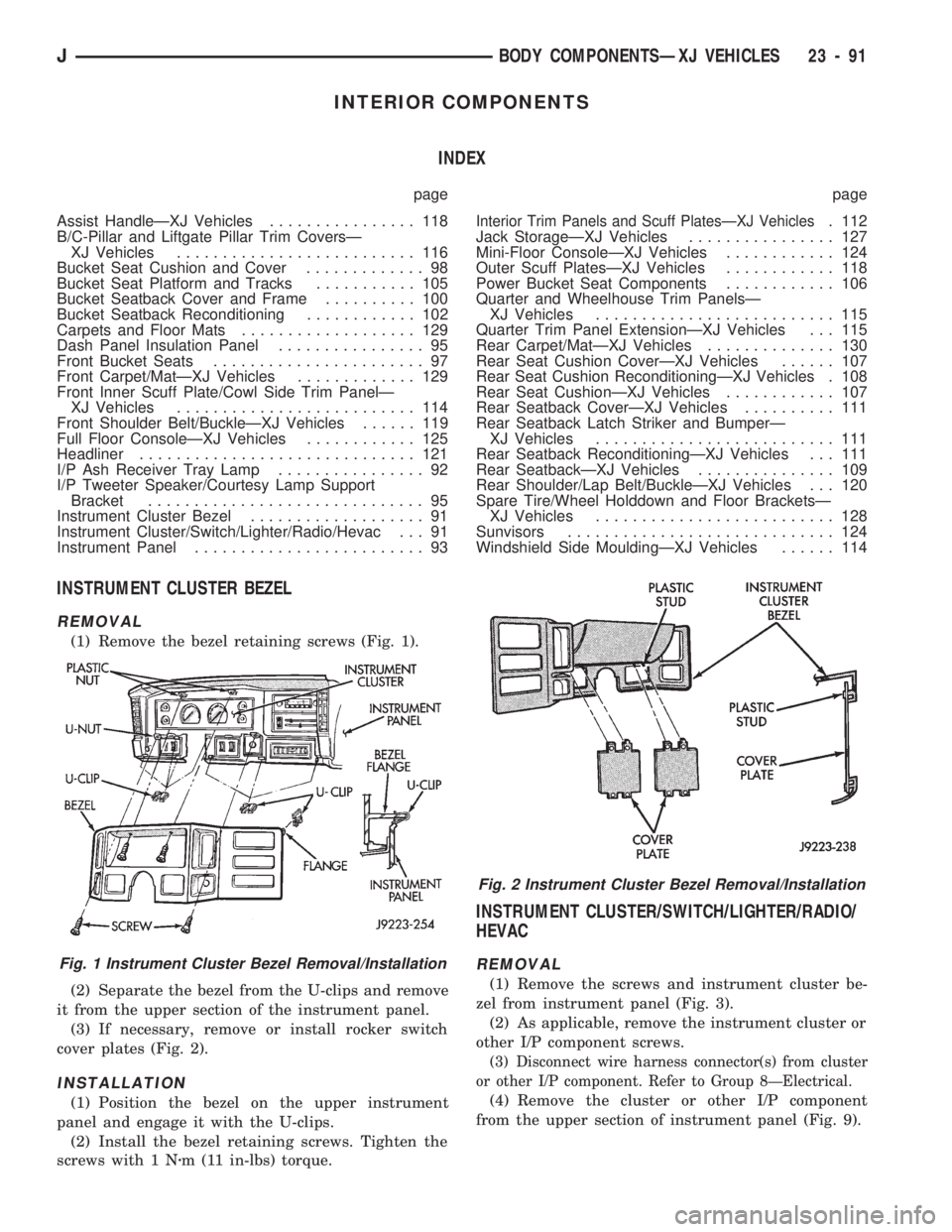

INSTRUMENT CLUSTER BEZEL

REMOVAL

(1) Remove the bezel retaining screws (Fig. 1).

(2) Separate the bezel from the U-clips and remove

it from the upper section of the instrument panel.

(3) If necessary, remove or install rocker switch

cover plates (Fig. 2).

INSTALLATION

(1) Position the bezel on the upper instrument

panel and engage it with the U-clips.

(2) Install the bezel retaining screws. Tighten the

screws with 1 Nzm (11 in-lbs) torque.

INSTRUMENT CLUSTER/SWITCH/LIGHTER/RADIO/

HEVAC

REMOVAL

(1) Remove the screws and instrument cluster be-

zel from instrument panel (Fig. 3).

(2) As applicable, remove the instrument cluster or

other I/P component screws.

(3) Disconnect wire harness connector(s) from cluster

or other I/P component. Refer to Group 8ÐElectrical.

(4) Remove the cluster or other I/P component

from the upper section of instrument panel (Fig. 9).

Fig. 1 Instrument Cluster Bezel Removal/Installation

Fig. 2 Instrument Cluster Bezel Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 91

Page 1589 of 1784

EXTERIOR COMPONENTS

INDEX

page page

Battery Tray........................... 140

Body Extension Panels and FasciasÐYJ

Renegade Vehicles..................... 147

Body Side Step Moulding................. 145

Body Stripes/Decals..................... 153

Cowl Grille and Screen................... 139

Cowl Weatherstrip Seal................... 139

Exterior Nameplates (Adhesive-Backed)....... 158

External Spare/Wheel Tire Carrier........... 172

Fender Flare........................... 144

Fender Inner Splash Shields............... 147

Fender Splash Aprons.................... 147

Fenders............................... 141

Fog LampÐYJ Renegade Vehicles.......... 150

Front Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 148

Front Fender Extension PanelÐYJ Renegade

Vehicles............................. 149

Fuel Filler Protector/Nozzle................ 158

Half Metal Door Mirror (External)............ 158

Hard Top Liftgate Glass.................. 162

Hard Top Repair........................ 165

Hard Top Roof Vent..................... 165

Hard Top Service....................... 164

Hard Top Service Information.............. 164Hood................................. 137

Hood Alignment......................... 138

Hood Insulator Panel..................... 138

Hood Safety Latch....................... 139

Liftgate Glass Weatherstrip Seal Replacement . . 163

Radiator Grille Applique................... 134

Rear Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 152

Rear Quarter Extension PanelÐYJ Renegade

Vehicles............................. 151

Rocker Extension PanelÐYJ Renegade

Vehicles............................. 150

Soft Top Service........................ 167

Soft Top Service Information............... 166

Sport Bar............................. 171

Tailgate Adjustment...................... 160

Tailgate Hinge.......................... 159

Tailgate Latch and Release Handle.......... 160

Tailgate Latch Striker..................... 161

Tailgate Lock Cylinder.................... 160

Tailgate Service......................... 159

Tailgate Service Information................ 159

Tailgate Weatherstrip Seal................. 161

Wheelhouse Splash Liners................ 146

RADIATOR GRILLE APPLIQUE

REMOVAL

(1) Raise the hood.

(2) Remove the headlamp bezels (Fig. 1).

(3) Remove the headlamp bulb retainer screws

(Fig. 2).

(4) Disconnect and remove the headlamps and

buckets as a unit (Fig. 2).

(5) Remove the parking lamp retaining screws

(Fig. 2).

(6) Disconnect the wire harness connectors and re-

move the parking lamps (Fig. 2).

(7) Remove the front crossmember cover.

(8) Remove the retaining screws and the bumper

inserts at the top of the grille panel (Fig. 1).

(9) Detach the grille applique from the grille panel

(Fig. 1).

(10) Remove the double faced foam adhesive tape

at the bottom of the grille applique (Fig. 1).

INSTALLATION

(1) Install double faced foam tape at the bottom,

interior side of the grille applique (Fig. 1).

(2) Position the grille applique over the grille

panel and press inward along the bottom where the

tape is located (Fig. 1).

(3) Install the grille applique retaining screws and

the bumper inserts (Fig. 1).(4) Connect the wire harness connectors and posi-

tion the headlamp buckets and headlamps in the

grille panel (Fig. 2).

(5) Install the headlamp bulb retainer and the

screws (Fig. 1). Tighten the screws to 2 Nzm (18 in-

lbs) torque.

(6) Install the headlamp bezels and the retaining

screws (Fig. 1). Tighten the screws securely.

(7) Connect the wire harness connectors and in-

stall the parking lamps (Fig. 2).

(8) Install the parking lamp retaining screws.

Tighten the screws to 2 Nzm (18 in-lbs) torque.

(9) Close the hood.

(10) Install the front crossmember cover.

23 - 134 BODY COMPONENTSÐXJ VEHICLESJ

Page 1612 of 1784

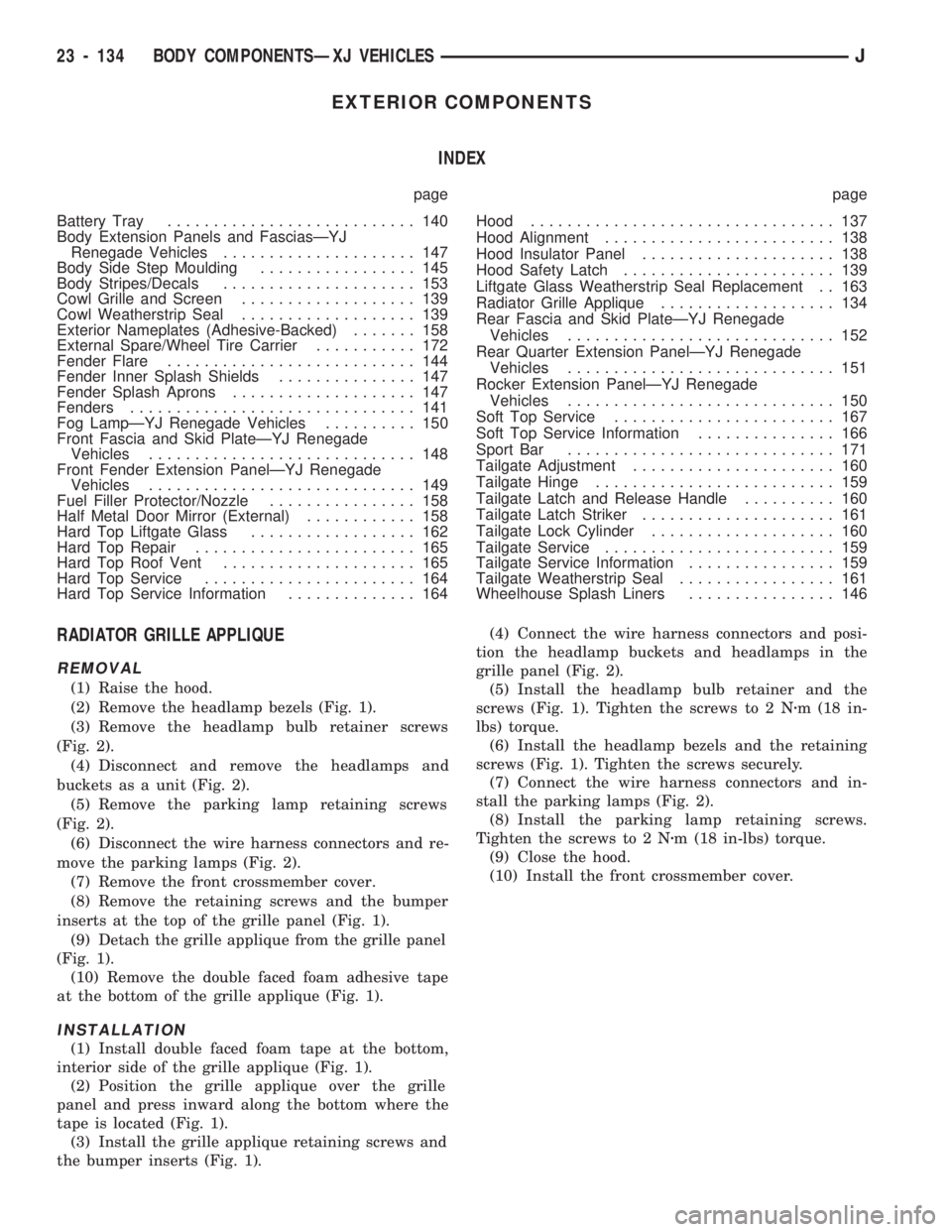

(1) Place the tape stripe/decal on a clean, flat sur-

face with the carrier side facing upward.

(2) Bend a corner of the carrier inward and then,

with a flick of the finger, separate the corner of the

carrier from the tape stripe/decal.

CAUTION: Hold tape stripe/decal at extreme outer

edges of the corners while separating the carrier.(3) Hold tape stripe/decal firmly against the flat

surface and separate the carrier from the tape stripe/

decal.

If hot and humid, a slight jerking motion will

aid separating the carrier from the tape stripe/

decal.

(4) Use a clean sponge and apply ample wetting

solution to the tape stripe/decal adhesive and to the

painted panel surface. The solution will permit ease

of tape stripe/decal movement when positioning it on

the panel.

(5) Position adhesive-coated side of tape stripe/de-

cal on the panel with the bottom aligned with char-

acter line. Where applicable:

²align the end of the replacement tape stripe/decal

with the end of the existing tape stripe/decal, and

²correctly align the index darts and index notches.

(6) If a complete replacement tape stripe/decal is

not being installed:

²position the replacement tape stripe/decal section

at the center of the repair area,

²align it with the existing tape stripe/decal, and

²allow at least 12 mm (1/2 in) of the tape stripe/de-

cal section to overlap the existing tape stripe/decal

edges.

(7) Apply wetting solution to the outer side of the

tape stripe/decal to allow the squeegee to freely slide

while adhering the stripe/decal to the panel.

CAUTION: Avoid unnecessary pulling and stretch-

ing at the ends of the tape stripe/decal because this

could cause it to tear.

(8) Position and slide a squeegee from the center to

the ends of the tape stripe/decal. This will ensure

complete bonding of the tape stripe/decal to the

painted panel surface.

(9) If a wrinkle is trapped in the tape stripe/decal

during the squeegee operation, stop. Lift wrinkled

Fig. 72 Renegade Tape Stripe/Decal Positioning

Fig. 73 Islander Decals

Fig. 74 Sahara Decals

JBODY COMPONENTSÐXJ VEHICLES 23 - 157

Page 1628 of 1784

DOORS

INDEX

page page

Full-Metal Door Assist Handle.............. 175

Full-Metal Door Hinges................... 179

Full-Metal Door Key Lock Cylinder........... 178

Full-Metal Door Latch.................... 179

Full-Metal Door Latch External Release Handle . 178

Full-Metal Door Latch Inside Release and

Lock Handle.......................... 175

Full-Metal Door Service................... 181

Full-Metal Door Trim Panel................ 175Full-Metal Door Vent Window Glass......... 177

Full-Metal Door Waterdam................. 176

Full-Metal Door Weatherstrip Seals.......... 180

Full-Metal Door Window Glass.............. 178

Full-Metal Door Window Glass Regulator...... 177

Full-Metal Door Window Glass Regulator Handle. 175

Half-Metal Door Latch Striker............... 175

Half-Metal Soft Top Door.................. 173

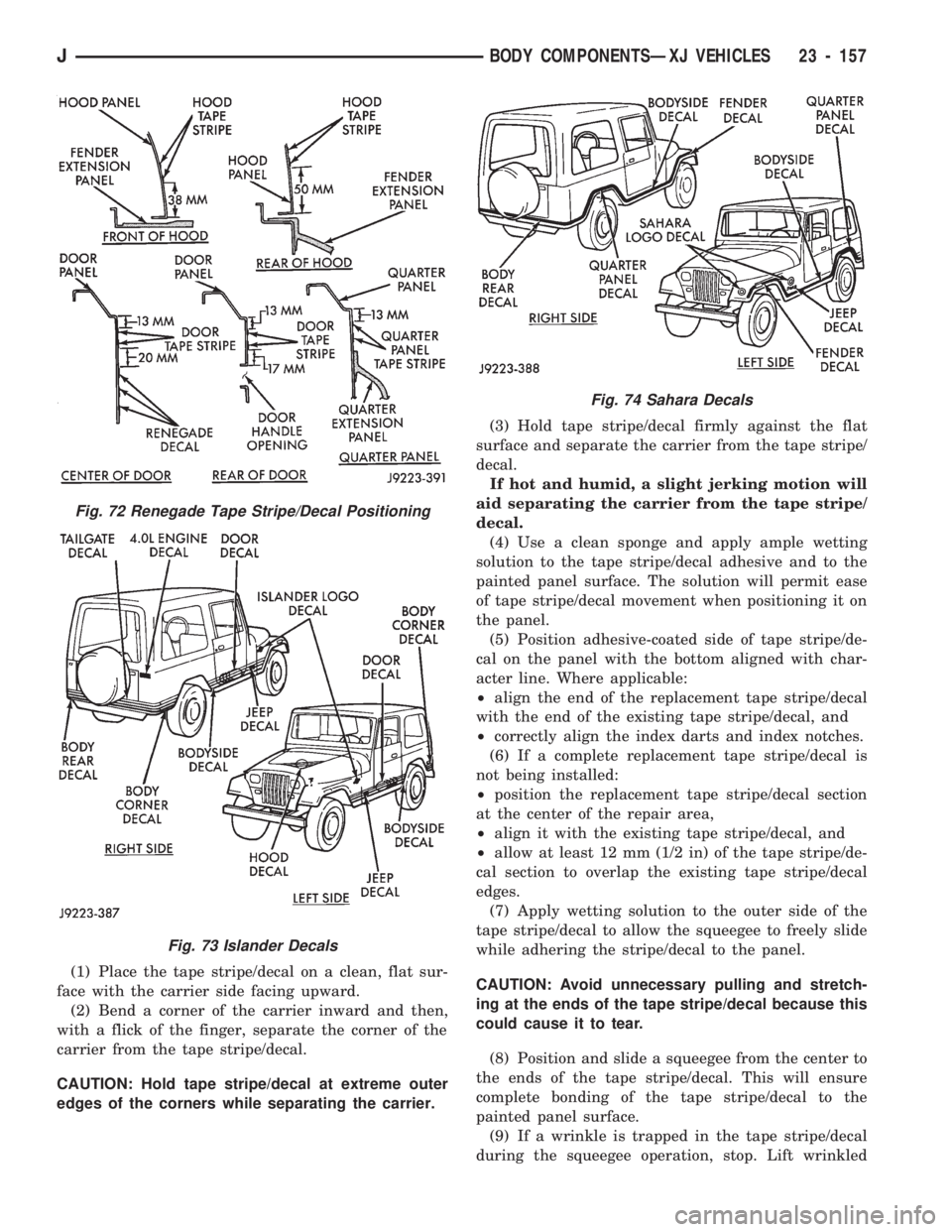

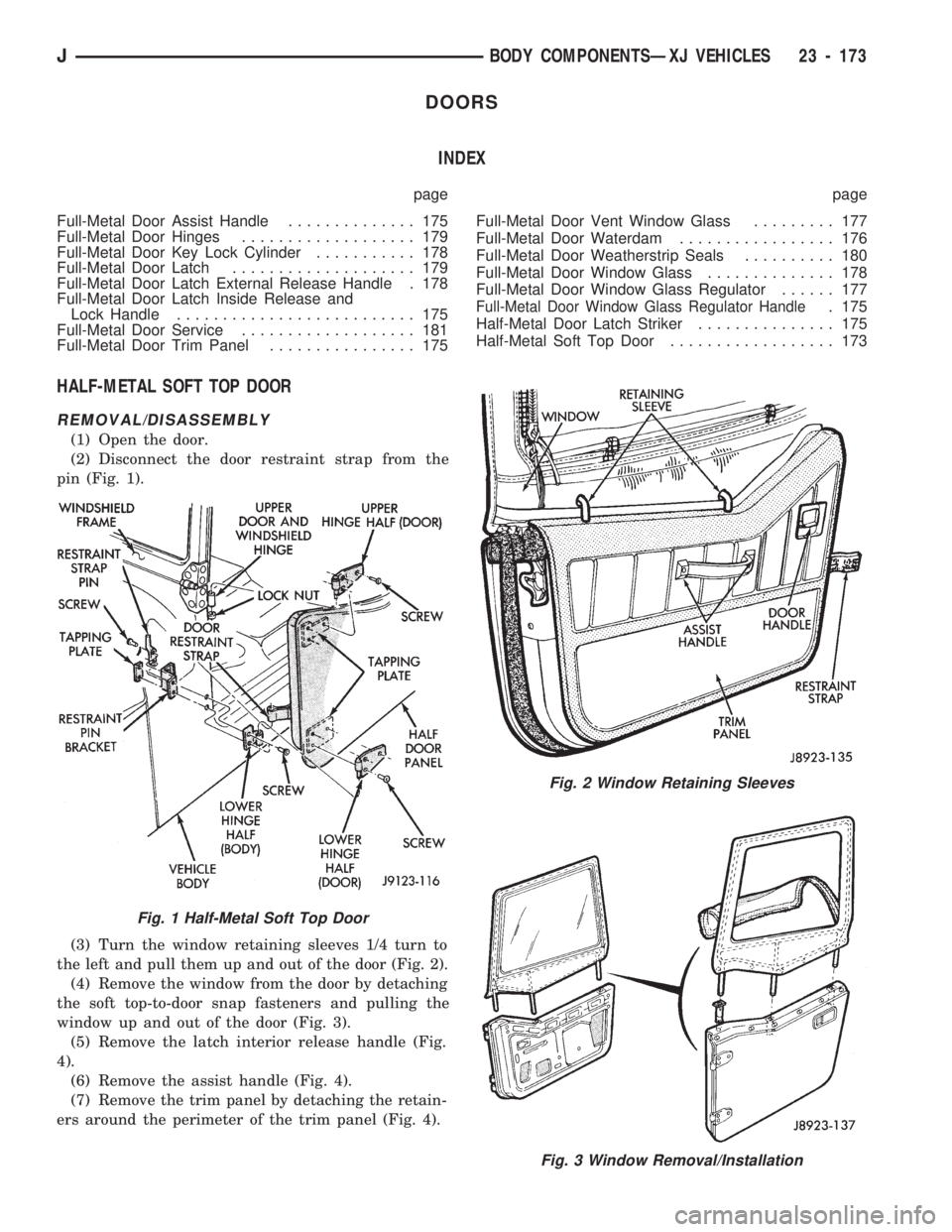

HALF-METAL SOFT TOP DOOR

REMOVAL/DISASSEMBLY

(1) Open the door.

(2) Disconnect the door restraint strap from the

pin (Fig. 1).

(3) Turn the window retaining sleeves 1/4 turn to

the left and pull them up and out of the door (Fig. 2).

(4) Remove the window from the door by detaching

the soft top-to-door snap fasteners and pulling the

window up and out of the door (Fig. 3).

(5) Remove the latch interior release handle (Fig.

4).

(6) Remove the assist handle (Fig. 4).

(7) Remove the trim panel by detaching the retain-

ers around the perimeter of the trim panel (Fig. 4).

Fig. 2 Window Retaining Sleeves

Fig. 3 Window Removal/Installation

Fig. 1 Half-Metal Soft Top Door

JBODY COMPONENTSÐXJ VEHICLES 23 - 173

Page 1638 of 1784

FIXED WINDOW GLASS

INDEX

page page

Fixed Glass Water Leak Detection and Repair . 189

Hard Top Quarter Window Glass............ 188

Rearview Mirror......................... 183

Rearview Mirror Retaining Bracket........... 183

Service Information...................... 183Windshield Frame....................... 184

Windshield Frame Weatherstrip Seal......... 185

Windshield Glass........................ 185

Windshield Reveal Moulding............... 183

SERVICE INFORMATION

The following fixed window service information in-

cludes removal/installation procedures for the:

²windshield reveal moulding,

²rearview mirror,

²windshield frame,

²windshield frame weatherstrip seal,

²windshield glass (using both the short and the ex-

tended installation method), and

²hard top quarter (side) window glass.

WINDSHIELD REVEAL MOULDING

REMOVAL

(1) Disengage the reveal moulding around the pe-

rimeter of the windshield glass with an appropriate

tool.

(2) Remove the mouldings from the windshield

frame.

(3) Inspect the reveal moulding retainers. Replace

the moulding if it has broken, distorted or ineffective

retainers.

INSTALLATION

(1) Position the reveal mouldings on the wind-

shield frame.

(2) Attach the mouldings to the frame by tapping

each moulding with a rubber mallet to seat the re-

tainers.

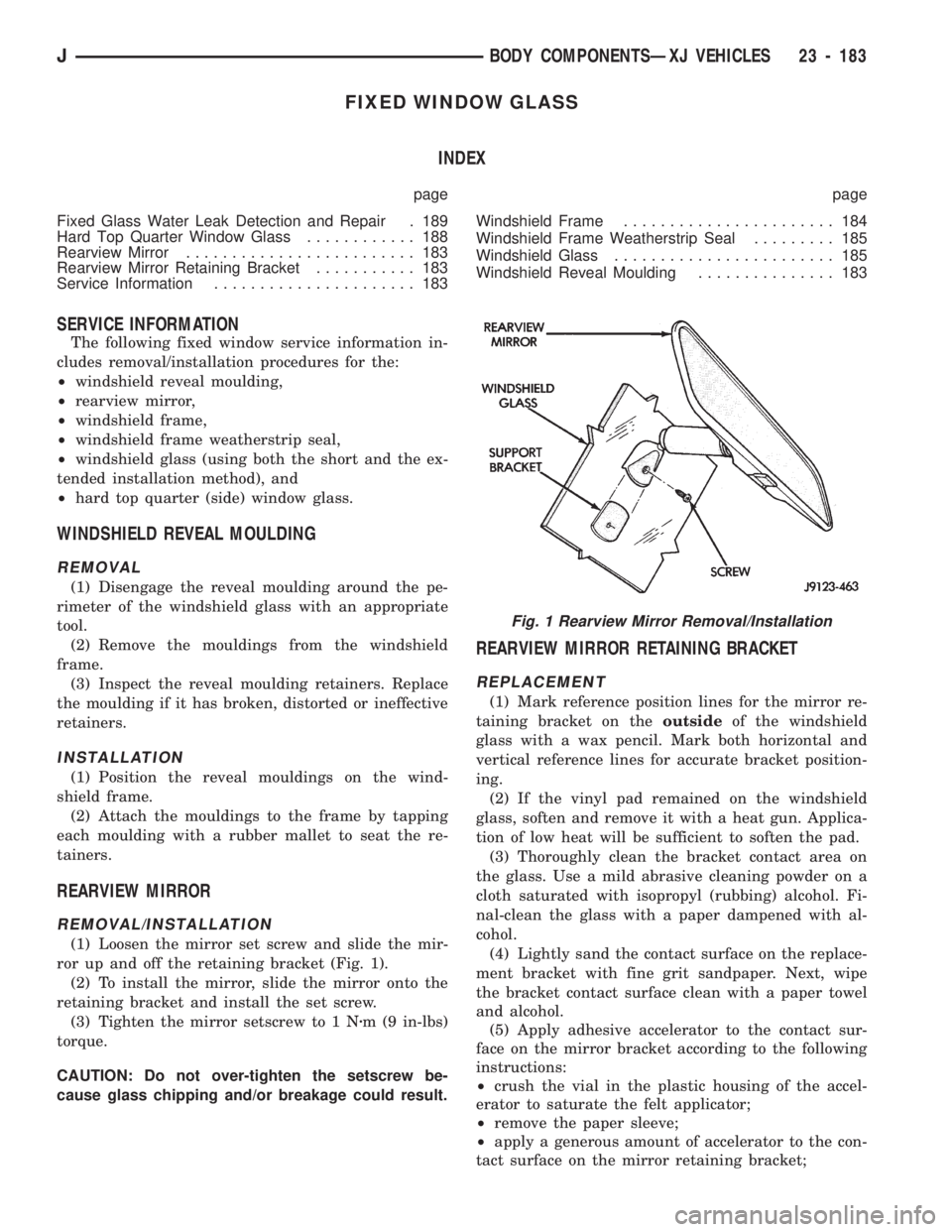

REARVIEW MIRROR

REMOVAL/INSTALLATION

(1) Loosen the mirror set screw and slide the mir-

ror up and off the retaining bracket (Fig. 1).

(2) To install the mirror, slide the mirror onto the

retaining bracket and install the set screw.

(3) Tighten the mirror setscrew to 1 Nzm (9 in-lbs)

torque.

CAUTION: Do not over-tighten the setscrew be-

cause glass chipping and/or breakage could result.

REARVIEW MIRROR RETAINING BRACKET

REPLACEMENT

(1) Mark reference position lines for the mirror re-

taining bracket on theoutsideof the windshield

glass with a wax pencil. Mark both horizontal and

vertical reference lines for accurate bracket position-

ing.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun. Applica-

tion of low heat will be sufficient to soften the pad.

(3) Thoroughly clean the bracket contact area on

the glass. Use a mild abrasive cleaning powder on a

cloth saturated with isopropyl (rubbing) alcohol. Fi-

nal-clean the glass with a paper dampened with al-

cohol.

(4) Lightly sand the contact surface on the replace-

ment bracket with fine grit sandpaper. Next, wipe

the bracket contact surface clean with a paper towel

and alcohol.

(5) Apply adhesive accelerator to the contact sur-

face on the mirror bracket according to the following

instructions:

²crush the vial in the plastic housing of the accel-

erator to saturate the felt applicator;

²remove the paper sleeve;

²apply a generous amount of accelerator to the con-

tact surface on the mirror retaining bracket;

Fig. 1 Rearview Mirror Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 183

Page 1645 of 1784

INTERIOR COMPONENTS

INDEX

page page

Carpet/Floor Mats....................... 198

Floor Consoles......................... 197

Front Shoulder Belts..................... 196

Glove Box............................. 194

Instrument Cluster and Gauge Housings...... 190

Instrument Cluster Bezel.................. 191Instrument Panel........................ 190

Instrument Panel Components.............. 191

Instrument Panel Service.................. 192

Rear Shoulder Belts..................... 196

Seats................................ 195

Sunvisors............................. 196

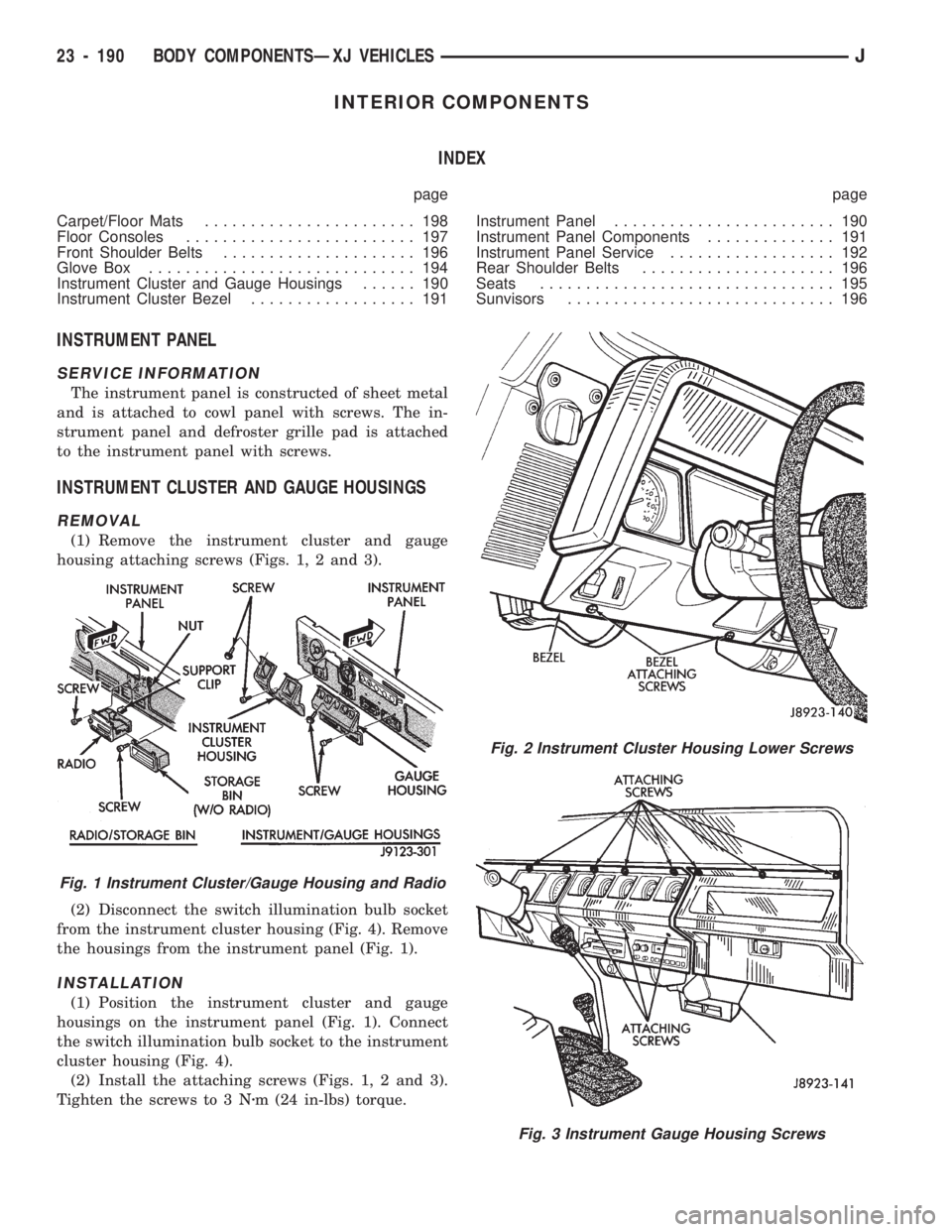

INSTRUMENT PANEL

SERVICE INFORMATION

The instrument panel is constructed of sheet metal

and is attached to cowl panel with screws. The in-

strument panel and defroster grille pad is attached

to the instrument panel with screws.

INSTRUMENT CLUSTER AND GAUGE HOUSINGS

REMOVAL

(1) Remove the instrument cluster and gauge

housing attaching screws (Figs. 1, 2 and 3).

(2) Disconnect the switch illumination bulb socket

from the instrument cluster housing (Fig. 4). Remove

the housings from the instrument panel (Fig. 1).

INSTALLATION

(1) Position the instrument cluster and gauge

housings on the instrument panel (Fig. 1). Connect

the switch illumination bulb socket to the instrument

cluster housing (Fig. 4).

(2) Install the attaching screws (Figs. 1, 2 and 3).

Tighten the screws to 3 Nzm (24 in-lbs) torque.

Fig. 2 Instrument Cluster Housing Lower Screws

Fig. 3 Instrument Gauge Housing Screws

Fig. 1 Instrument Cluster/Gauge Housing and Radio

23 - 190 BODY COMPONENTSÐXJ VEHICLESJ

Page 1656 of 1784

PAINT APPLICATION

INDEX

page page

Accent Paint........................... 202

Base/Color Coat........................ 201

Basecoat/Clearcoat...................... 202

Body Undercoat......................... 203

Buffing and Polishing..................... 203

Exterior Body Colors..................... 204Paint Repair on Galvanized Metals.......... 202

Plastic Components...................... 203

Primer................................ 201

Stone Chip Protection.................... 201

Surface Preparation...................... 201

SURFACE PREPARATION

Proper surface preparation is the key to top-quality

body panel refinishing. The bare metal must be

cleaned, de-greased, de-waxed and treated with phos-

phate.

Always clean the panel surface with a wax and

grease removal solution, and then wipe the surface

with a tack rag before applying primer or paint.

Cleaning will also remove any residual silicone from

the painted surface.

Body putty that is procured from a major supplier

is highly recommended. If a synthetic body filler is to

be used, it should also be a quality product.

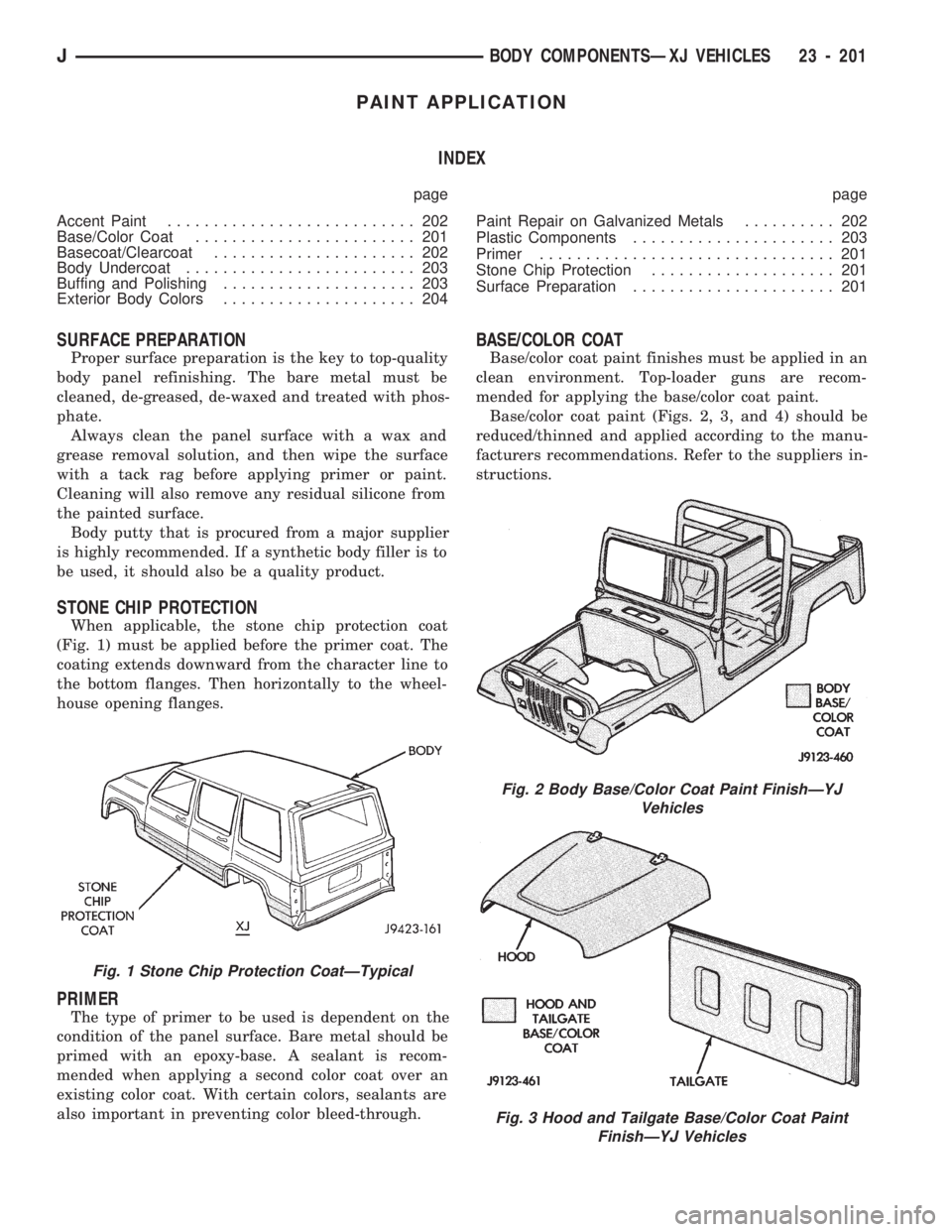

STONE CHIP PROTECTION

When applicable, the stone chip protection coat

(Fig. 1) must be applied before the primer coat. The

coating extends downward from the character line to

the bottom flanges. Then horizontally to the wheel-

house opening flanges.

PRIMER

The type of primer to be used is dependent on the

condition of the panel surface. Bare metal should be

primed with an epoxy-base. A sealant is recom-

mended when applying a second color coat over an

existing color coat. With certain colors, sealants are

also important in preventing color bleed-through.

BASE/COLOR COAT

Base/color coat paint finishes must be applied in an

clean environment. Top-loader guns are recom-

mended for applying the base/color coat paint.

Base/color coat paint (Figs. 2, 3, and 4) should be

reduced/thinned and applied according to the manu-

facturers recommendations. Refer to the suppliers in-

structions.

Fig. 2 Body Base/Color Coat Paint FinishÐYJ

Vehicles

Fig. 3 Hood and Tailgate Base/Color Coat Paint

FinishÐYJ Vehicles

Fig. 1 Stone Chip Protection CoatÐTypical

JBODY COMPONENTSÐXJ VEHICLES 23 - 201

Page 1664 of 1784

HEATING AND AIR CONDITIONING

CONTENTS

page page

CLIMATE CONTROL SYSTEMÐXJ VEHICLES . 22

CLIMATE CONTROL SYSTEMÐYJ VEHICLES . 37

COMPRESSOR OVERHAUL............... 17

GENERAL INFORMATION.................. 1SERVICE DIAGNOSISÐELECTRICAL........ 14

SERVICE DIAGNOSISÐMECHANICAL........ 8

TORQUE SPECIFICATIONS................ 45

GENERAL INFORMATION

INDEX

page page

A/C Operation............................ 1

Compressor Oil Level...................... 6

Pressure Gauge and Manifold Assembly........ 2

Refrigerant (R-12)......................... 1

Service Precautions........................ 2Service Valves........................... 3

System Charge........................... 5

System Discharge......................... 4

System Evacuation........................ 4

A/C OPERATION

The compressor increases the pressure and temper-

ature of the refrigerant. The heated refrigerant vapor

is then pumped into the condenser where it cools by

the air passing over the condenser fins. As the refrig-

erant cools in the condenser, it condenses into a liq-

uid. Still under high pressure, the liquid refrigerant

passes into the receiver. The receiver acts as a reser-

voir to furnish refrigerant to the expansion (H) valve

at all times. From the receiver, the high pressure liq-

uid refrigerant passes to the expansion (H) valve.

The expansion (H) valve meters refrigerant into the

evaporator where a low pressure is maintained by

the suction side of the compressor. As it enters the

evaporator, the refrigerant immediately begins to

boil by absorbing heat from the air passing over the

evaporator core. Having given up its heat to boil the

refrigerant, the air is cooled and passes into the pas-

senger compartment of the vehicle. From the evapo-

rator the vaporized refrigerant is drawn back to the

compressor to repeat the cycle.

REFRIGERANT (R-12)

It is illegal to release R-12 into the atmosphere.

SAFETY PRECAUTIONS

WARNING: EXTREME CARE MUST BE TAKEN TO

PREVENT ANY LIQUID REFRIGERANT FROM COM-

ING IN CONTACT WITH THE SKIN AND ESPE-

CIALLY THE EYES. ALWAYS WEAR SAFETYGOGGLES WHEN SERVICING ANY PART OF THE

REFRIGERANT SYSTEM. IF EYE CONTACT IS

MADE, APPLY A FEW DROPS OF MINERAL OIL TO

THE EYES AND FLUSH WITH WATER FOR SEV-

ERAL MINUTES. SEEK MEDICAL ATTENTION IMME-

DIATELY.

The refrigerant used in the air conditioner system

is Refrigerant-12 (R-12). R-12 is nonexplosive, non-

flammable, non-corrosive, has practically no odor and

is heavier than air. Although it is classified as a safe

refrigerant, certain precautions must be observed to

protect the parts involved and the person who is

working on the unit. Liquid R-12, at normal atmo-

sphere pressures and temperatures, evaporates so

quickly that it has the tendency to freeze anything it

contacts.

WARNING: TO AVOID A DANGEROUS EXPLOSION,

NEVER WELD OR STEAM CLEAN NEAR AIR CON-

DITIONING LINES OR COMPONENTS. DO NOT

HEAT R-12 ABOVE 52ÉC (125ÉF).

The R-12 in the system is always under pressure.

Because the system is tightly sealed, heat applied to

any part could cause this pressure to build up exces-

sively.

JHEATING AND AIR CONDITIONING 24 - 1

Page 1680 of 1784

COMPRESSOR OVERHAUL

INDEX

page page

Compressor............................. 17

Compressor Isolation...................... 17

Description............................. 17Magnetic Clutch......................... 18

Purging Compressor of Air................. 17

DESCRIPTION

The A/C system uses a Sanden compressor. This

compressor is a 7 piston design. Designated the SD-

709, the compressor is mounted on the front right

side of the engine and is driven by a serpentine belt.

System lubrication is provided by 135cc615cc (4.6

cu. in.60.5 cu. in.) of 500 viscosity refrigerant oil.

The clutch used on the compressor consists of 3 ba-

sic components: the pulley, front plate and the field

coil. The pulley and field coil are attached to the

front head of the compressor with tapered snap rings.

The hub is keyed to the compressor shaft and is re-

tained on the shaft with a self-locking nut. Special

service tools are required to remove and install the

clutch plate on the compressor shaft.

COMPRESSOR ISOLATION

It is not necessary to discharge the system for com-

pressor removal. The compressor can be isolated from

the remainder of the system and eliminate the need

for recharging when performing compressor service.

(1) Connect pressure gauge and manifold.

(2) Close both gauge hand valves.

(3) Mid-position both service valves.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A DI-

RECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(4) Start the engine and operate the air condition-

ing system.

(5) Turn the suction service valve slowly clockwise

toward the front seated position.

(6) When pressure drops to zero, stop the engine

and compressor and quickly finish front-seating the

suction service valve.

(7) Front-seat the discharge service valve.

(8) Loosen the oil level check plug slowly to re-

lease any internal pressure in the compressor.

The compressor is now isolated from the remainder

of the system.

The service valves can be removed from the com-

pressor.

PURGING COMPRESSOR OF AIR

The compressor must be purged of air whenever it

has been isolated for an oil level check or other ser-

vice procedures without discharging the entire sys-

tem.

(1) Cap the service gauge ports on both of the ser-

vice valves.

(2) Back-seat the suction service valve to allow the

system refrigerant to enter the compressor.

(3) Place the discharge service valve in the mid-po-

sition or cracked-position.

(4) Loosen the discharge service valve gauge port

cap to permit the refrigerant to force any air out of

the compressor.

(5) Back-seat the discharge service valve and

tighten the gauge port cap.

(6) The compressor is now ready for service.

COMPRESSOR

REMOVAL

(1) Isolate the compressor.

(2) Disconnect negative cable from battery.

(3) Disconnect the clutch lead wire.

(4) Remove the discharge and inlet (suction) ser-

vice valves from the compressor. Plug or tape all the

openings.

(5) Remove the serpentine drive belt (refer to

Group 7, Cooling System for the proper procedure).

(6) Remove the bolts and lift the compressor from

the mounting bracket (Figs. 1 and 2).

INSTALLATION

If a replacement compressor is being installed;

check the oil level. Add or subtract oil as neces-

sary and install the magnetic clutch on the com-

pressor.

(1) If the mounting bracket was removed, install

the bracket to the block. Tighten the mounting bolts

to 27 NIm (20 ft. lbs.) torque.

(2) Install the compressor on the mounting

bracket. Tighten the bolts to 27 NIm (20 ft. lbs.)

torque.

(3) Install the serpentine drive belt (refer to Group

7, Cooling System for the proper procedure).

(4) Tighten the serpentine drive belt to the speci-

fied tension.

²New belt tensionÐ800-900 N (180-200 lb-f).

JHEATING AND AIR CONDITIONING 24 - 17