index JEEP CHEROKEE 1994 Service Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1051 of 1784

STEERING LINKAGEÐXJ

INDEX

page page

Drag Link.............................. 14

Pitman Arm............................. 15

Service Information....................... 14Steering Dampener....................... 15

Tie Rod ................................ 14

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering dampener. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

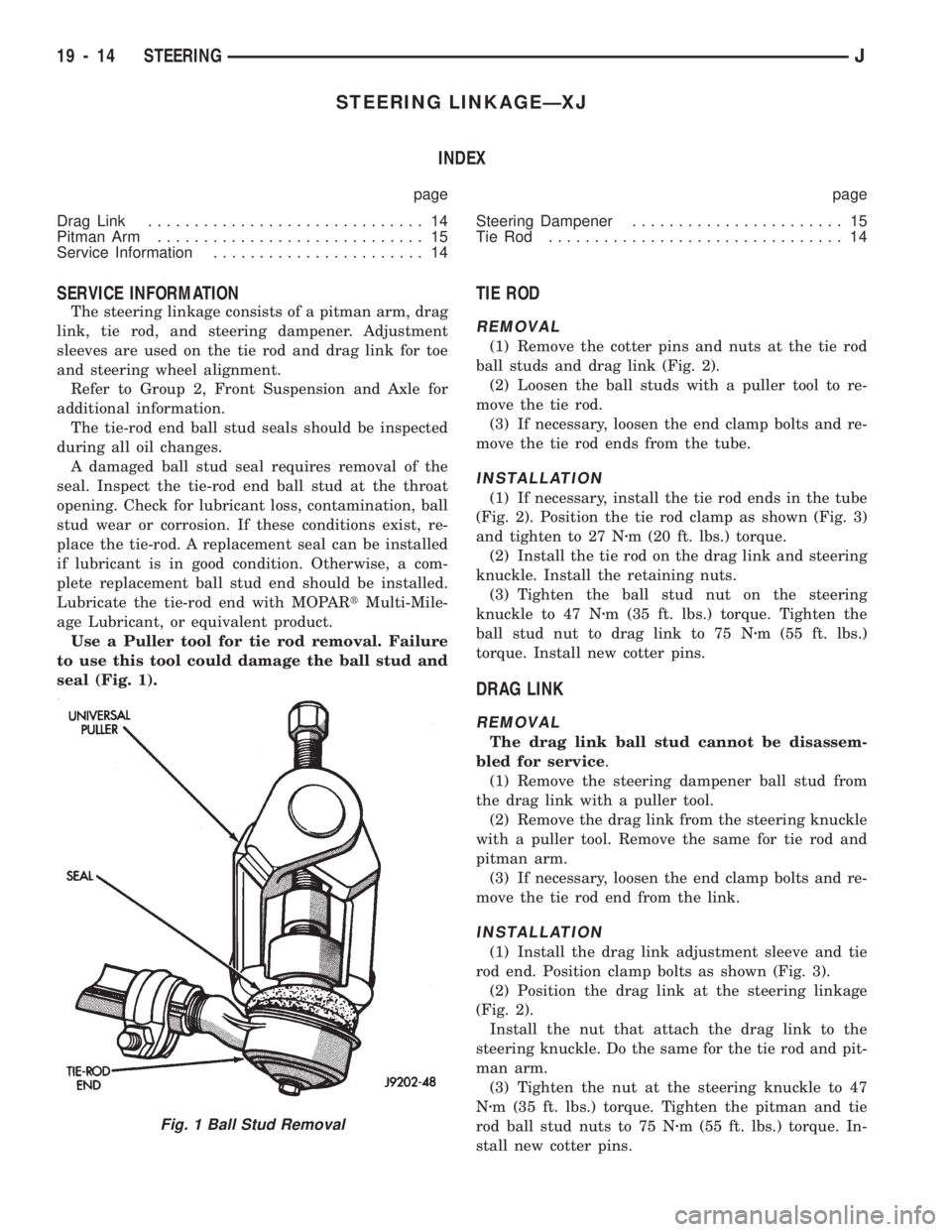

Use a Puller tool for tie rod removal. Failure

to use this tool could damage the ball stud and

seal (Fig. 1).

TIE ROD

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

ball studs and drag link (Fig. 2).

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) If necessary, install the tie rod ends in the tube

(Fig. 2). Position the tie rod clamp as shown (Fig. 3)

and tighten to 27 Nzm (20 ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckle. Install the retaining nuts.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Install new cotter pins.

DRAG LINK

REMOVAL

The drag link ball stud cannot be disassem-

bled for service.

(1) Remove the steering dampener ball stud from

the drag link with a puller tool.

(2) Remove the drag link from the steering knuckle

with a puller tool. Remove the same for tie rod and

pitman arm.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the link.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod end. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the nut that attach the drag link to the

steering knuckle. Do the same for the tie rod and pit-

man arm.

(3) Tighten the nut at the steering knuckle to 47

Nzm (35 ft. lbs.) torque. Tighten the pitman and tie

rod ball stud nuts to 75 Nzm (55 ft. lbs.) torque. In-

stall new cotter pins.

Fig. 1 Ball Stud Removal

19 - 14 STEERINGJ

Page 1054 of 1784

STEERING LINKAGEÐYJ

INDEX

page page

Drag Link.............................. 17

Pitman Arm............................. 18

Service Information....................... 17Steering Dampener....................... 18

Tie Rod ................................ 17

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering dampener. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

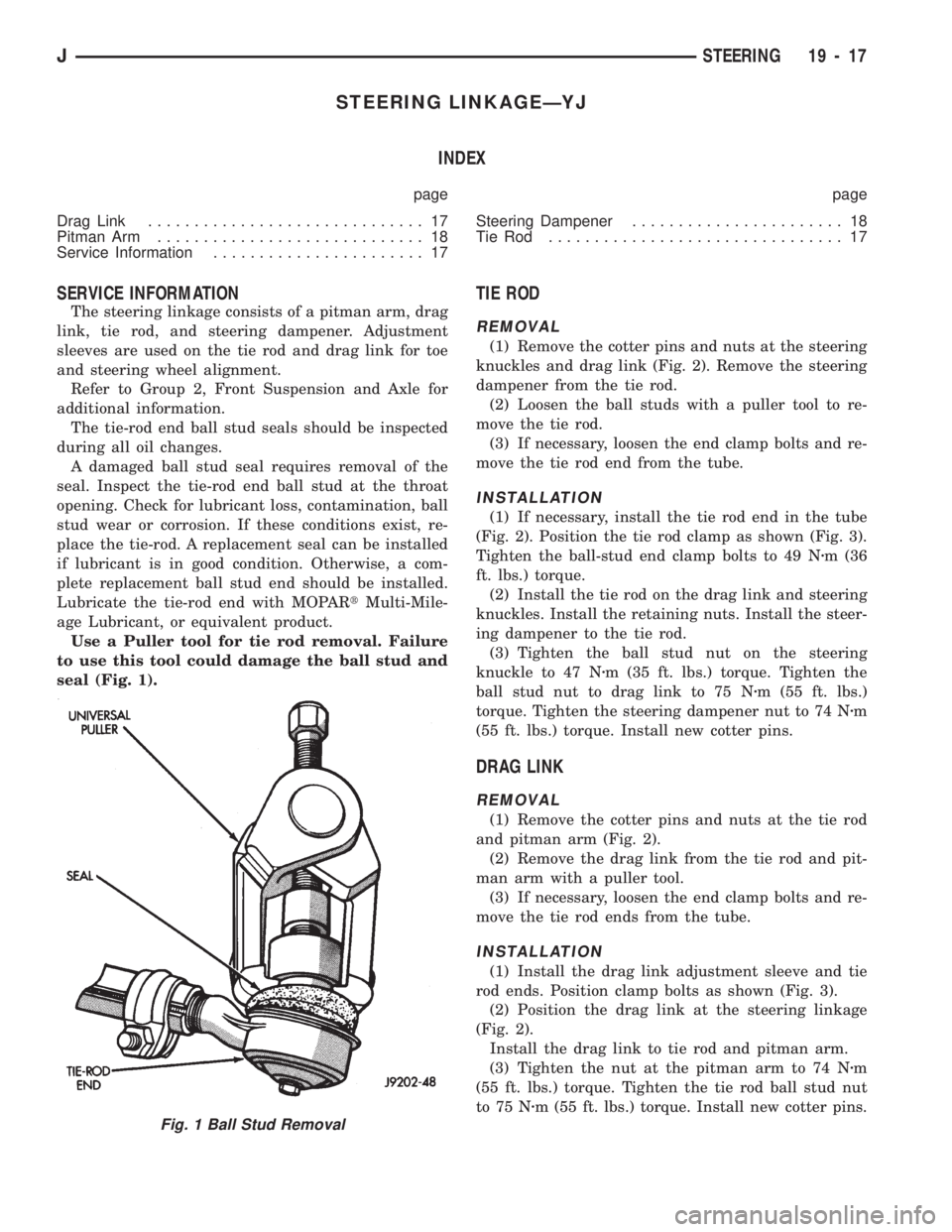

Use a Puller tool for tie rod removal. Failure

to use this tool could damage the ball stud and

seal (Fig. 1).

TIE ROD

REMOVAL

(1) Remove the cotter pins and nuts at the steering

knuckles and drag link (Fig. 2). Remove the steering

dampener from the tie rod.

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the tube.

INSTALLATION

(1) If necessary, install the tie rod end in the tube

(Fig. 2). Position the tie rod clamp as shown (Fig. 3).

Tighten the ball-stud end clamp bolts to 49 Nzm (36

ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckles. Install the retaining nuts. Install the steer-

ing dampener to the tie rod.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Tighten the steering dampener nut to 74 Nzm

(55 ft. lbs.) torque. Install new cotter pins.

DRAG LINK

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

and pitman arm (Fig. 2).

(2) Remove the drag link from the tie rod and pit-

man arm with a puller tool.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod ends. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the drag link to tie rod and pitman arm.

(3) Tighten the nut at the pitman arm to 74 Nzm

(55 ft. lbs.) torque. Tighten the tie rod ball stud nut

to 75 Nzm (55 ft. lbs.) torque. Install new cotter pins.

Fig. 1 Ball Stud Removal

JSTEERING 19 - 17

Page 1056 of 1784

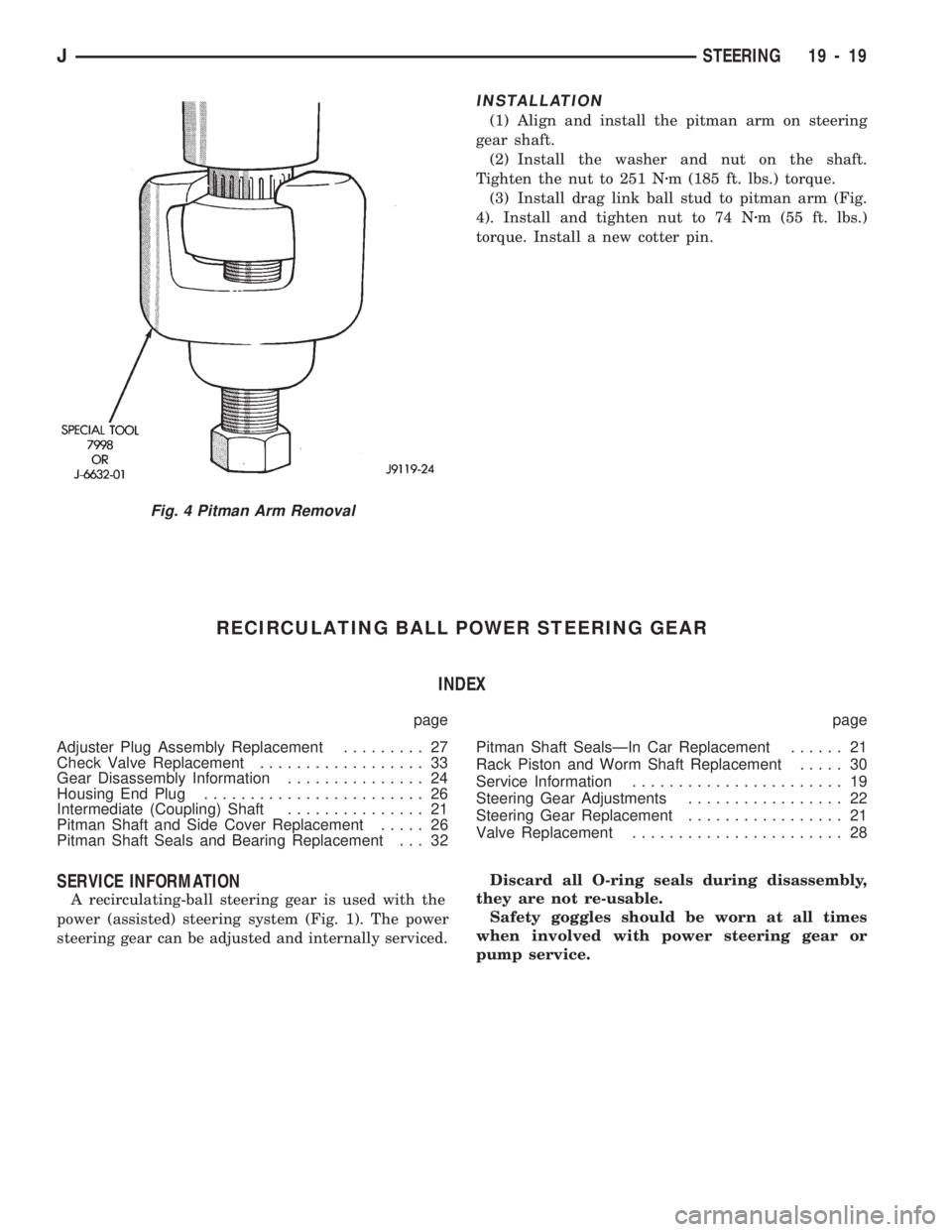

INSTALLATION

(1) Align and install the pitman arm on steering

gear shaft.

(2) Install the washer and nut on the shaft.

Tighten the nut to 251 Nzm (185 ft. lbs.) torque.

(3) Install drag link ball stud to pitman arm (Fig.

4). Install and tighten nut to 74 Nzm (55 ft. lbs.)

torque. Install a new cotter pin.

RECIRCULATING BALL POWER STEERING GEAR

INDEX

page page

Adjuster Plug Assembly Replacement......... 27

Check Valve Replacement.................. 33

Gear Disassembly Information............... 24

Housing End Plug........................ 26

Intermediate (Coupling) Shaft............... 21

Pitman Shaft and Side Cover Replacement..... 26

Pitman Shaft Seals and Bearing Replacement . . . 32Pitman Shaft SealsÐIn Car Replacement...... 21

Rack Piston and Worm Shaft Replacement..... 30

Service Information....................... 19

Steering Gear Adjustments................. 22

Steering Gear Replacement................. 21

Valve Replacement....................... 28

SERVICE INFORMATION

A recirculating-ball steering gear is used with the

power (assisted) steering system (Fig. 1). The power

steering gear can be adjusted and internally serviced.Discard all O-ring seals during disassembly,

they are not re-usable.

Safety goggles should be worn at all times

when involved with power steering gear or

pump service.

Fig. 4 Pitman Arm Removal

JSTEERING 19 - 19

Page 1060 of 1784

²SECOND - over-center preload adjustment

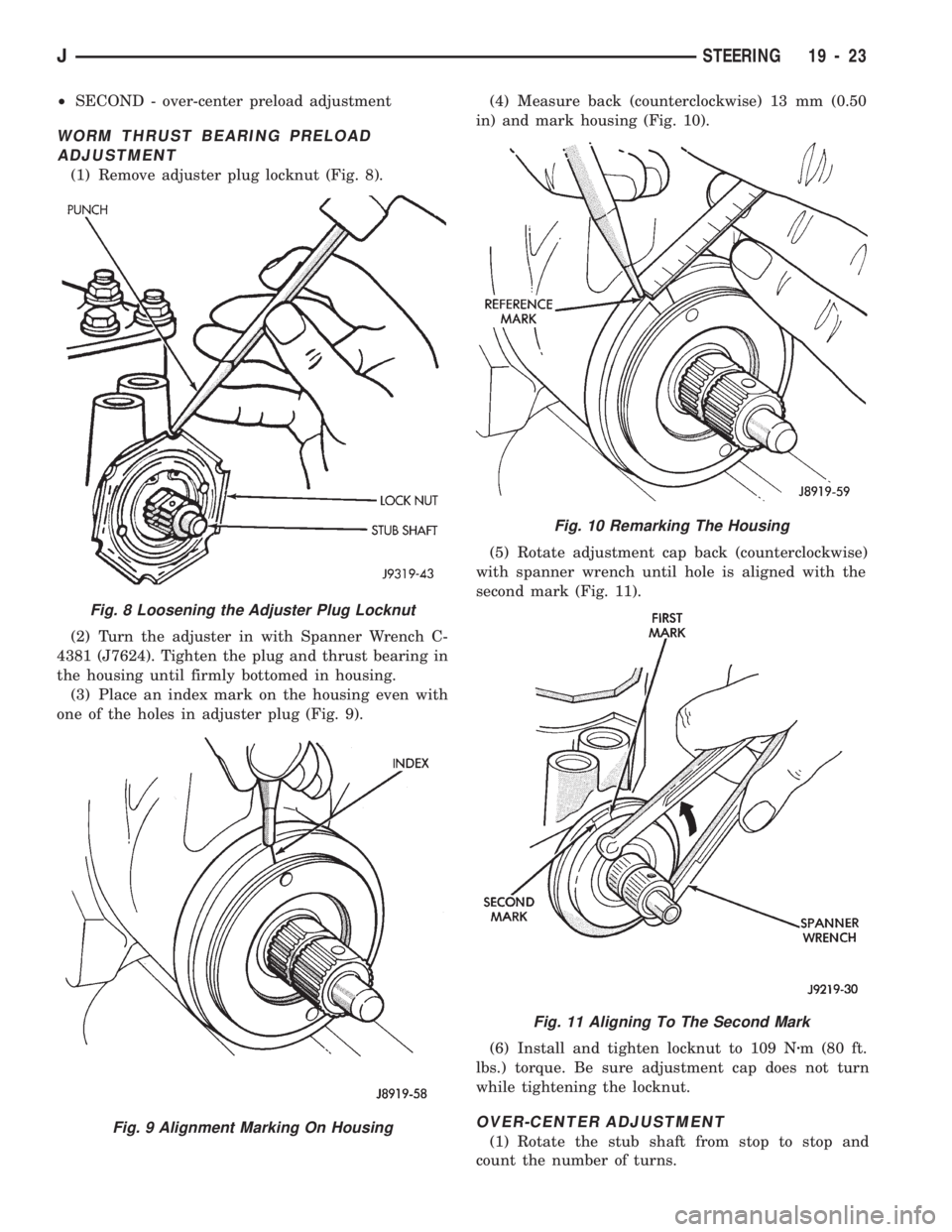

WORM THRUST BEARING PRELOAD

ADJUSTMENT

(1) Remove adjuster plug locknut (Fig. 8).

(2) Turn the adjuster in with Spanner Wrench C-

4381 (J7624). Tighten the plug and thrust bearing in

the housing until firmly bottomed in housing.

(3) Place an index mark on the housing even with

one of the holes in adjuster plug (Fig. 9).(4) Measure back (counterclockwise) 13 mm (0.50

in) and mark housing (Fig. 10).

(5) Rotate adjustment cap back (counterclockwise)

with spanner wrench until hole is aligned with the

second mark (Fig. 11).

(6) Install and tighten locknut to 109 Nzm (80 ft.

lbs.) torque. Be sure adjustment cap does not turn

while tightening the locknut.

OVER-CENTER ADJUSTMENT

(1) Rotate the stub shaft from stop to stop and

count the number of turns.

Fig. 10 Remarking The Housing

Fig. 11 Aligning To The Second Mark

Fig. 8 Loosening the Adjuster Plug Locknut

Fig. 9 Alignment Marking On Housing

JSTEERING 19 - 23

Page 1072 of 1784

MANUAL STEERING GEAR

INDEX

page page

Diagnosis.............................. 35

Gear Adjustments in Vehicle................ 37

Gear Adjustments on Bench................ 42

Gear Assembly.......................... 41

Gear Cleaning and Inspection............... 40Gear Disassembly........................ 37

Information............................. 35

Intermediate (Coupler) Shaft................ 43

Pitman Shaft Seal Replacement............. 35

Steering Gear Replacement................. 43

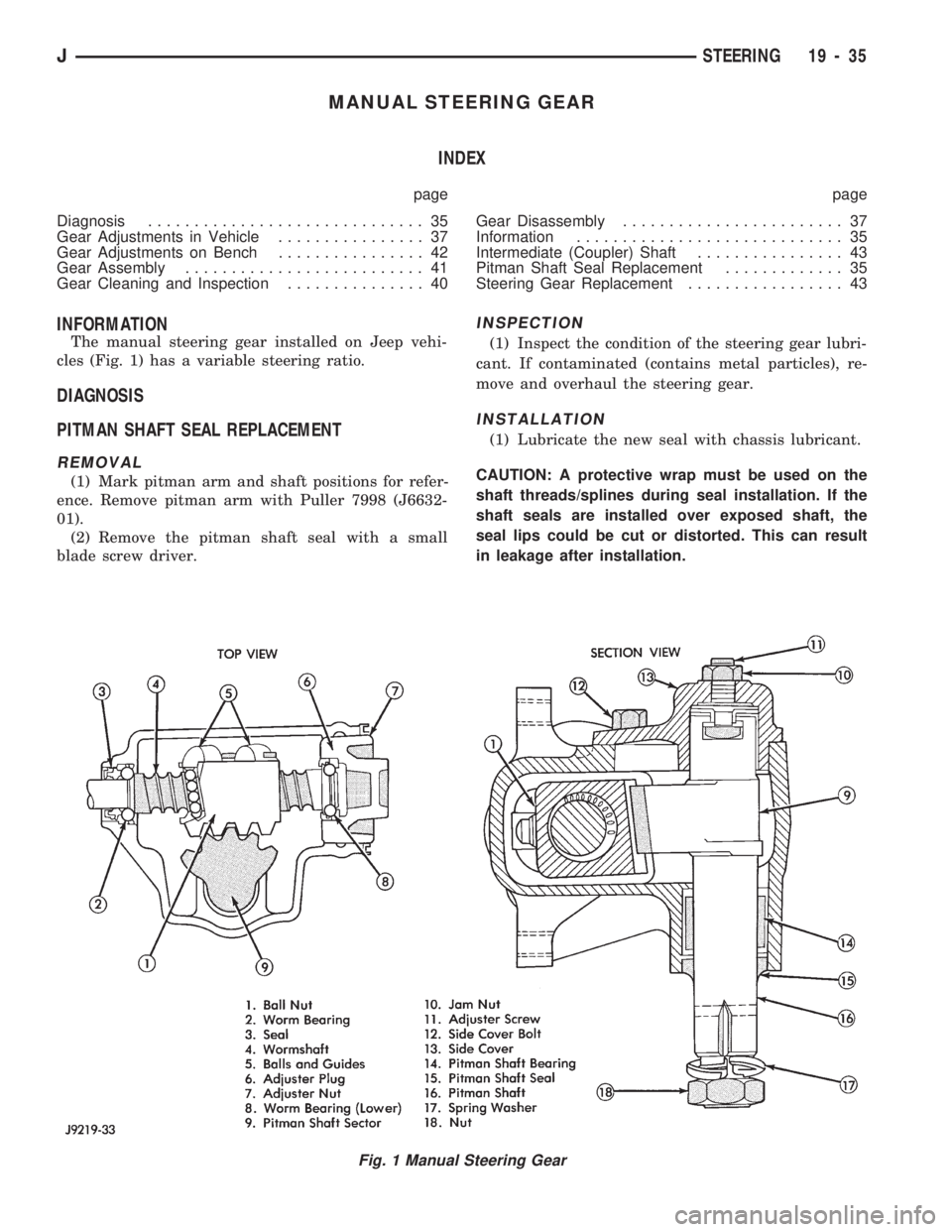

INFORMATION

The manual steering gear installed on Jeep vehi-

cles (Fig. 1) has a variable steering ratio.

DIAGNOSIS

PITMAN SHAFT SEAL REPLACEMENT

REMOVAL

(1) Mark pitman arm and shaft positions for refer-

ence. Remove pitman arm with Puller 7998 (J6632-

01).

(2) Remove the pitman shaft seal with a small

blade screw driver.

INSPECTION

(1) Inspect the condition of the steering gear lubri-

cant. If contaminated (contains metal particles), re-

move and overhaul the steering gear.

INSTALLATION

(1) Lubricate the new seal with chassis lubricant.

CAUTION: A protective wrap must be used on the

shaft threads/splines during seal installation. If the

shaft seals are installed over exposed shaft, the

seal lips could be cut or distorted. This can result

in leakage after installation.

Fig. 1 Manual Steering Gear

JSTEERING 19 - 35

Page 1082 of 1784

STEERING COLUMN GENERAL SERVICE

INDEX

page page

Column ReplacementÐXJ.................. 46

Column ReplacementÐYJ.................. 48

Park-Lock CableÐConsole Shift Automatic..... 45Service Information....................... 45

Steering Wheel.......................... 45

SERVICE INFORMATION

The column may be disassembled and reassembled.

Also most steering column components can be ser-

viced without removing the column from the vehicle.

For additional information, refer to Group 8H, Elec-

trical.

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any component on the

column.

Safety goggles should be worn at all times

when involved with steering column service.

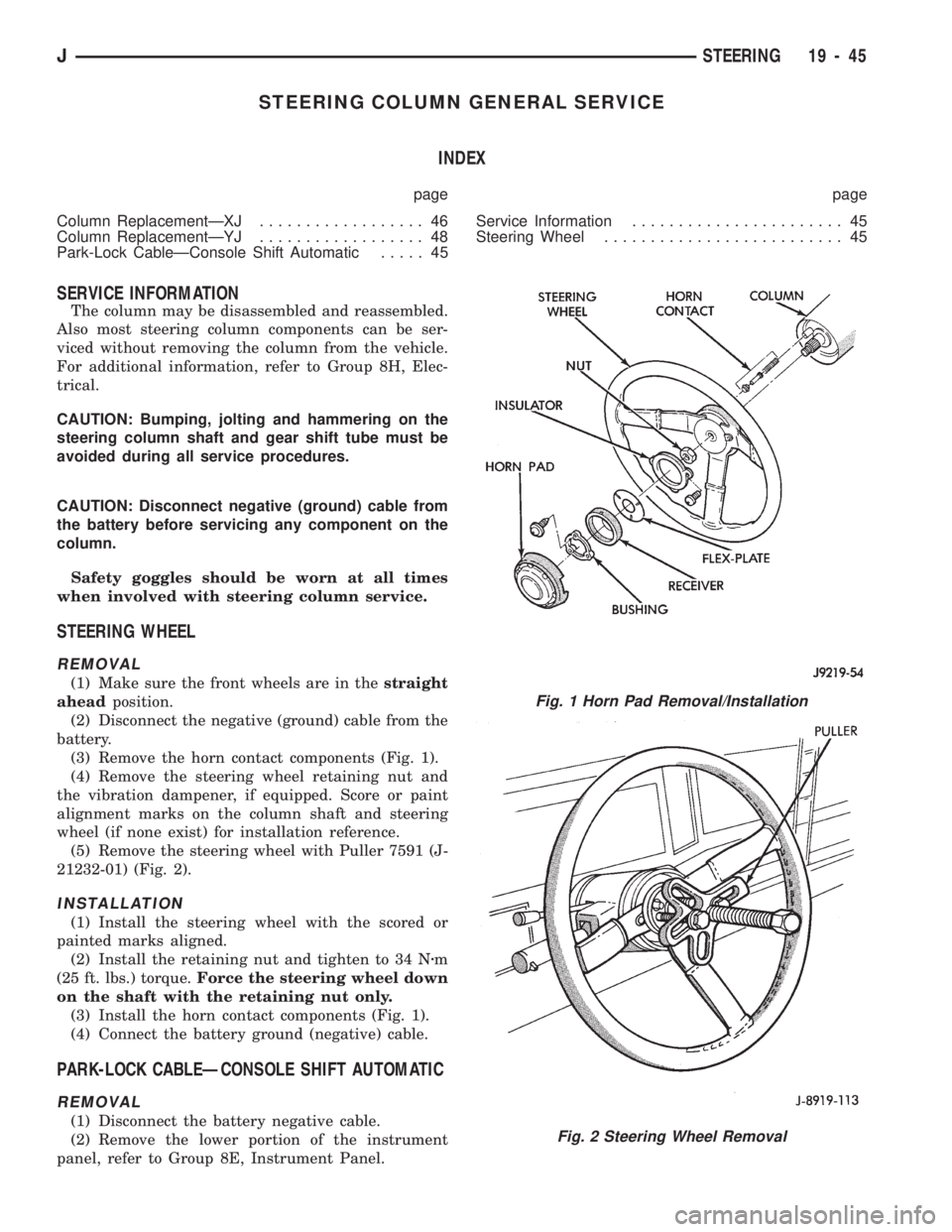

STEERING WHEEL

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition.

(2) Disconnect the negative (ground) cable from the

battery.

(3) Remove the horn contact components (Fig. 1).

(4) Remove the steering wheel retaining nut and

the vibration dampener, if equipped. Score or paint

alignment marks on the column shaft and steering

wheel (if none exist) for installation reference.

(5) Remove the steering wheel with Puller 7591 (J-

21232-01) (Fig. 2).

INSTALLATION

(1) Install the steering wheel with the scored or

painted marks aligned.

(2) Install the retaining nut and tighten to 34 Nzm

(25 ft. lbs.) torque.Force the steering wheel down

on the shaft with the retaining nut only.

(3) Install the horn contact components (Fig. 1).

(4) Connect the battery ground (negative) cable.

PARK-LOCK CABLEÐCONSOLE SHIFT AUTOMATIC

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

Fig. 1 Horn Pad Removal/Installation

Fig. 2 Steering Wheel Removal

JSTEERING 19 - 45

Page 1112 of 1784

TRANSMISSION AND TRANSFER CASE

CONTENTS

page page

30RH/32RH AUTOMATIC TRANSMISSION . . . 66

AW-4 AUTOMATIC TRANSMISSION........ 156AX 15 MANUAL TRANSMISSION.......... 32

AX 4/5 MANUAL TRANSMISSION........... 1

AX 4/5 MANUAL TRANSMISSION

INDEX

page page

Cleaning and Inspection................... 13

Gear Ratios............................. 2

General Information........................ 1

Recommended Lubricant.................... 2

Service Diagnosis......................... 2

Shift Pattern............................. 2Transmission Assembly and Adjustment....... 15

Transmission Disassembly and Overhaul........ 5

Transmission Identification................... 1

Transmission Installation.................... 4

Transmission Removal..................... 3

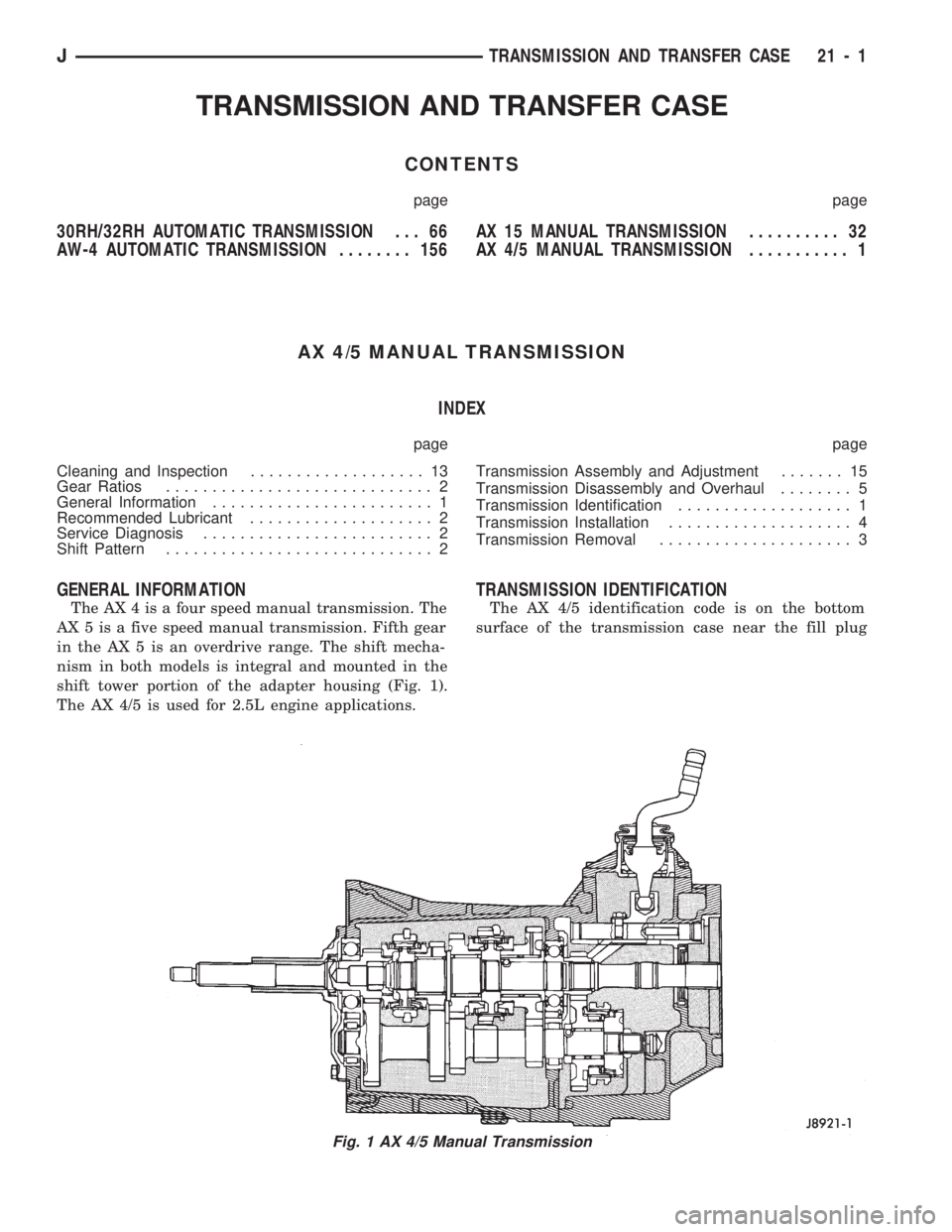

GENERAL INFORMATION

The AX 4 is a four speed manual transmission. The

AX 5 is a five speed manual transmission. Fifth gear

in the AX 5 is an overdrive range. The shift mecha-

nism in both models is integral and mounted in the

shift tower portion of the adapter housing (Fig. 1).

The AX 4/5 is used for 2.5L engine applications.

TRANSMISSION IDENTIFICATION

The AX 4/5 identification code is on the bottom

surface of the transmission case near the fill plug

Fig. 1 AX 4/5 Manual Transmission

JTRANSMISSION AND TRANSFER CASE 21 - 1

Page 1143 of 1784

AX 15 MANUAL TRANSMISSION

INDEX

page page

General Information....................... 32

Service Diagnosis........................ 33

Transmission Assembly and Adjustment....... 51

Transmission Disassembly and Overhaul....... 36

Transmission Gear Ratios.................. 33

Transmission Identification.................. 32Transmission InstallationÐAX 15............. 35

Transmission Lubricant.................... 33

Transmission RemovalÐAX 15.............. 34

Transmission Shift Pattern.................. 33

Transmission Switch and Plug Locations....... 33

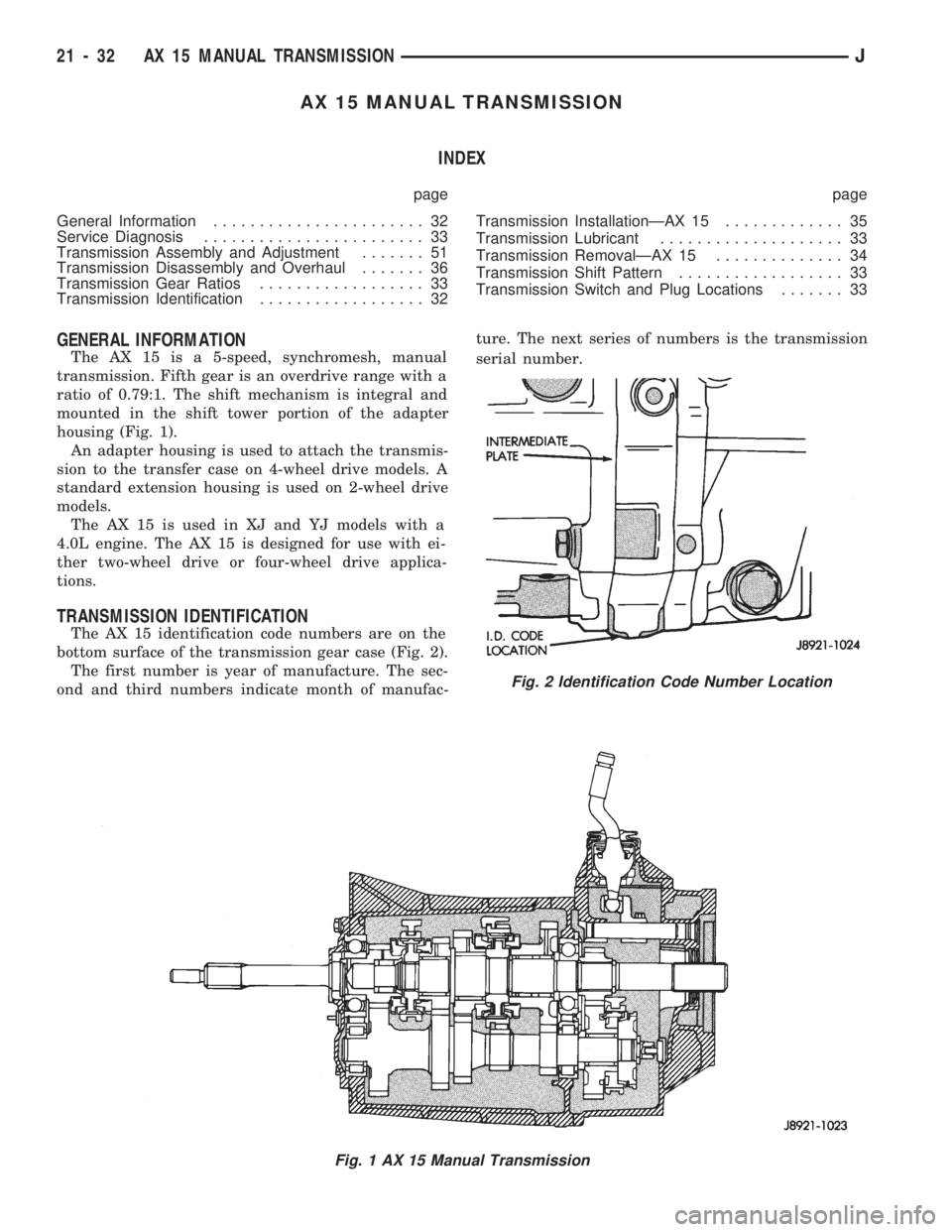

GENERAL INFORMATION

The AX 15 is a 5-speed, synchromesh, manual

transmission. Fifth gear is an overdrive range with a

ratio of 0.79:1. The shift mechanism is integral and

mounted in the shift tower portion of the adapter

housing (Fig. 1).

An adapter housing is used to attach the transmis-

sion to the transfer case on 4-wheel drive models. A

standard extension housing is used on 2-wheel drive

models.

The AX 15 is used in XJ and YJ models with a

4.0L engine. The AX 15 is designed for use with ei-

ther two-wheel drive or four-wheel drive applica-

tions.

TRANSMISSION IDENTIFICATION

The AX 15 identification code numbers are on the

bottom surface of the transmission gear case (Fig. 2).

The first number is year of manufacture. The sec-

ond and third numbers indicate month of manufac-ture. The next series of numbers is the transmission

serial number.

Fig. 1 AX 15 Manual Transmission

Fig. 2 Identification Code Number Location

21 - 32 AX 15 MANUAL TRANSMISSIONJ

Page 1177 of 1784

30RH/32RH AUTOMATIC TRANSMISSION

INDEX

page page

General Information....................... 66

Parts Interchangeability.................... 66

Recommended Fluid...................... 66

Specifications and Band Adjustments......... 66Torque Converter........................ 66

Transmission Application................... 66

Transmission Controls and Components....... 66

Transmission Identification.................. 66

GENERAL INFORMATION

TRANSMISSION APPLICATION

Chrysler 30RH and 32RH automatic transmissions

are used in XJ/YJ models. Both transmissions are

three speed, automatics with a gear-type oil pump,

two clutches and bands and a planetary gear system

(Fig. 1). The 30RH is used with 2.5L engines and the

32RH is used with 4.0L engines.

TORQUE CONVERTER

A three element, torque converter is used for all

applications. The converter consists of the impeller,

stator, and turbine.

The converter used with all 30RH/32RH transmis-

sions is equipped with a converter clutch. The clutch

is engaged by an electrical solenoid and mechanical

clutch module on the valve body. The solenoid is op-

erated by the powertrain control module.

The impeller is connected to the engine crankshaft

through the front cover which is welded to the impel-

ler. The turbine is splined to the transmission input

shaft and the stator is splined to the transmission re-

action shaft.

The torque converter is a welded assembly and is

not a repairable component. The converter is serviced

as an assembly.

RECOMMENDED FLUID

The recommended (and preferred) fluid for 30RH/

32RH transmissions is Mopar ATF Plus, Type 7176.

Mopar Dexron II can be used but only if ATF Plus

is not available.

Transmission fluid capacity is approximately 17

pints (7.9 liters). This is the approximate amount of

fluid required to fill the transmission and torque con-

verter after overhaul.

TRANSMISSION IDENTIFICATION

The transmission identification numbers are

stamped on the left side of the case just above the oil

pan gasket surface (Fig. 2). The first set of numbers

is the transmission part number. The next set of code

numbers set is the date of build. The final set of code

numbers represents the transmission serial number.

SPECIFICATIONS AND BAND ADJUSTMENTS

Service specifications and torque values are located

at the end of this group. Refer to the specifications

during service operations.

The band adjustment specifications for 1994

transmissions are different. Refer to the front

and rear band adjustment procedures in the In-

Vehicle Service section for details.

PARTS INTERCHANGEABILITY

The 1994 version of the 30RH (A904) transmission

is similar to previous models in appearance only. The

current 30RH is quite different and interchanging

new/old parts is definitely not recommended. Differ-

ent component dimensions, fluid passages, input/out-

put shafts, cases, bands, valve bodies and governor

assemblies are just a few of the changed items. The

32RH transmission is also different from previous

models and the same recommendations apply here as

well.

CAUTION: On YJ models with a 2.5L engine and

30RH transmission, special bolts are used to attach

the driveplate to the crankshaft. These bolts have a

smaller hex head for torque converter clearance.

DO NOT interchange these bolts with similar size

bolts for any reason.

TRANSMISSION CONTROLS AND COMPONENTS

The transmission hydraulic control system per-

forms five basic functions, which are:

²pressure supply

²pressure regulation

²flow control

²clutch/band apply and release

²lubrication

Pressure Supply And Regulation

The oil pump generates the fluid working pressure

needed for operation and lubrication. The pump is

driven by the torque converter. The converter is con-

nected to the engine crankshaft through the drive-

plate.

The pressure regulator valve maintains operating

(line) pressure. The regulator valve is located in the

valve body. The amount of line pressure developed is

21 - 66 30RH/32RH AUTOMATIC TRANSMISSIONJ

Page 1180 of 1784

30RH/32RH TRANSMISSION DIAGNOSIS

INDEX

page page

Air Pressure Test........................ 73

Analyzing the Road Test................... 70

Converter Housing Leak Diagnosis........... 73

Converter Stall Test...................... 72

Diagnosis Guides and Charts............... 76

Fluid Level and Condition.................. 69Gearshift Linkage........................ 70

General Information....................... 69

Hydraulic Pressure Test................... 71

Preliminary Diagnosis..................... 69

Road Test.............................. 70

Transmission Throttle Valve Cable Adjustment . . 70

GENERAL INFORMATION

Automatic transmission problems are generally the

result of:

²poor engine performance

²incorrect fluid level

²incorrect cable/linkage adjustment

²incorrect band adjustment

²incorrect hydraulic control pressure adjustments

²hydraulic component malfunctions

²mechanical component malfunctions.

Begin diagnosis by checking the easily accessible

items such as fluid level, fluid condition and control

linkage adjustment. A road test will determine if fur-

ther diagnosis is necessary.

Procedures outlined in this section should be per-

formed in the following sequence to realize the most

accurate results:

²Preliminary diagnosis

²Check fluid Level and condition

²Check control linkage Adjustment

²Road test

²Stall test

²Hydraulic pressure test

²Air pressure tests

²Leak Tests

²Analyze test results and consult diagnosis charts

PRELIMINARY DIAGNOSIS

Two basic procedures are required. One procedure

for vehicles that are driveable and an alternate pro-

cedure for disabled vehicles (will not back up or

move forward).

Vehicle Is Driveable

(1) Check fluid level and condition.

(2) Adjust throttle cable and gearshift linkage if

complaint was based on delayed, erratic, or harsh

shifts.

(3) Road test vehicle and note transmission operat-

ing characteristics.

(4) Perform stall test if complaint is based on slug-

gish, low speed acceleration or abnormal throttle

opening needed to maintain normal speeds with

properly tuned engine.

(5) Perform hydraulic pressure tests.(6) Perform air pressure test to check clutch-band

operation.

Vehicle Is Disabled

(1) Check fluid level and condition.

(2) Check for broken, disconnected throttle link-

age.

(3) Check for cracked, leaking cooler lines, or

loose, missing pressure port plugs.

(4) Raise vehicle, start engine, shift transmission

into gear and note following:

(a) If propeller shafts turn but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shafts do not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged drive plate, converter,

oil pump or input shaft.

(c) If propeller shafts do not turn and transmis-

sion is not noisy, perform hydraulic pressure test to

determine if problem is a hydraulic or mechanical.

FLUID LEVEL AND CONDITION

(1) Position vehicle on level surface. This is impor-

tant in obtaining an accurate fluid level check.

(2) To avoid false readings, which could produce

under or over fill condition, do not check level until

fluid is at normal operating temperature.

(3) Shift transmission into Neutral.

(4) Apply parking brakes.

(5) Operate engine at curb idle speed.

WARNING: WHEN PERFORMING UNDERHOOD OP-

ERATIONS WITH THE ENGINE RUNNING, KEEP

YOUR HANDS WELL AWAY FROM HOT OR ROTAT-

ING ENGINE COMPONENTS. DO NOT WEAR

LOOSE ARTICLES OF CLOTHING WHICH COULD

BECOME ENTANGLED IN ENGINE COMPONENTS

OR ACCESSORIES.

(6) Clean dipstick filler cap and tube before remov-

ing dipstick.

(7) Remove dipstick and inspect fluid level.

²Correct level is to FULL mark

²Acceptable level is between ADD and FULL marks

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 69