JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1121 of 1784

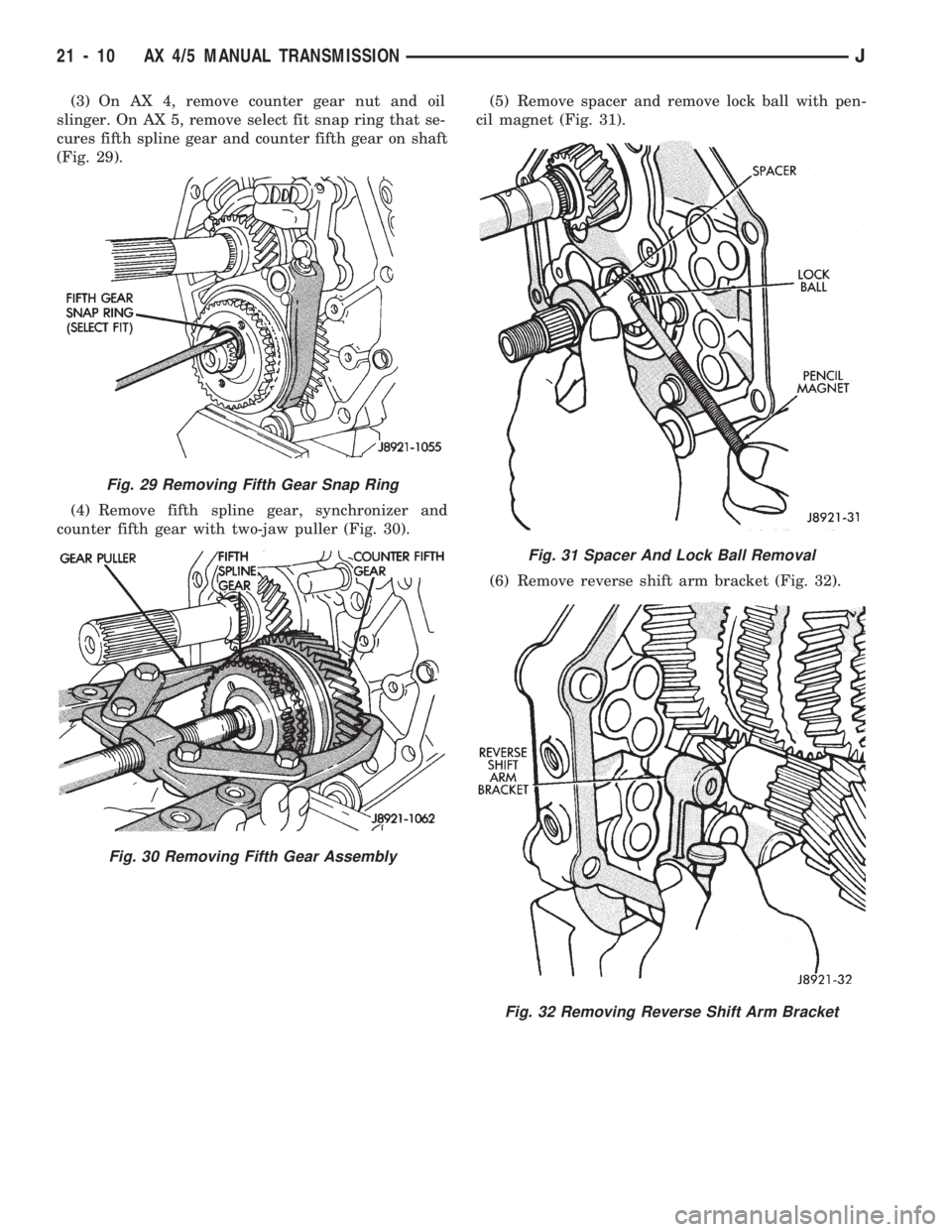

(3) On AX 4, remove counter gear nut and oil

slinger. On AX 5, remove select fit snap ring that se-

cures fifth spline gear and counter fifth gear on shaft

(Fig. 29).

(4) Remove fifth spline gear, synchronizer and

counter fifth gear with two-jaw puller (Fig. 30).(5) Remove spacer and remove lock ball with pen-

cil magnet (Fig. 31).

(6) Remove reverse shift arm bracket (Fig. 32).

Fig. 29 Removing Fifth Gear Snap Ring

Fig. 30 Removing Fifth Gear Assembly

Fig. 31 Spacer And Lock Ball Removal

Fig. 32 Removing Reverse Shift Arm Bracket

21 - 10 AX 4/5 MANUAL TRANSMISSIONJ

Page 1122 of 1784

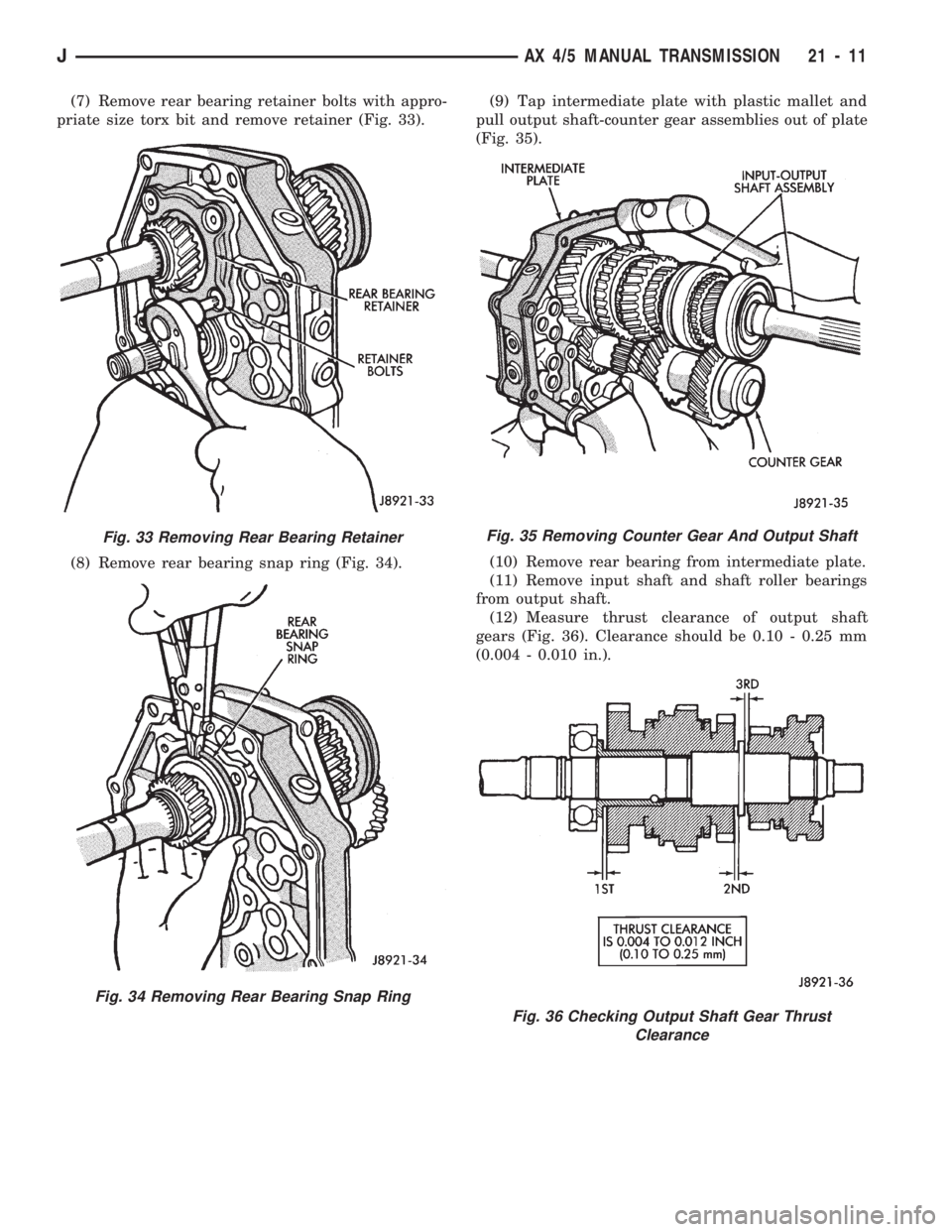

(7) Remove rear bearing retainer bolts with appro-

priate size torx bit and remove retainer (Fig. 33).

(8) Remove rear bearing snap ring (Fig. 34).(9) Tap intermediate plate with plastic mallet and

pull output shaft-counter gear assemblies out of plate

(Fig. 35).

(10) Remove rear bearing from intermediate plate.

(11) Remove input shaft and shaft roller bearings

from output shaft.

(12) Measure thrust clearance of output shaft

gears (Fig. 36). Clearance should be 0.10 - 0.25 mm

(0.004 - 0.010 in.).

Fig. 33 Removing Rear Bearing Retainer

Fig. 34 Removing Rear Bearing Snap Ring

Fig. 35 Removing Counter Gear And Output Shaft

Fig. 36 Checking Output Shaft Gear Thrust

Clearance

JAX 4/5 MANUAL TRANSMISSION 21 - 11

Page 1123 of 1784

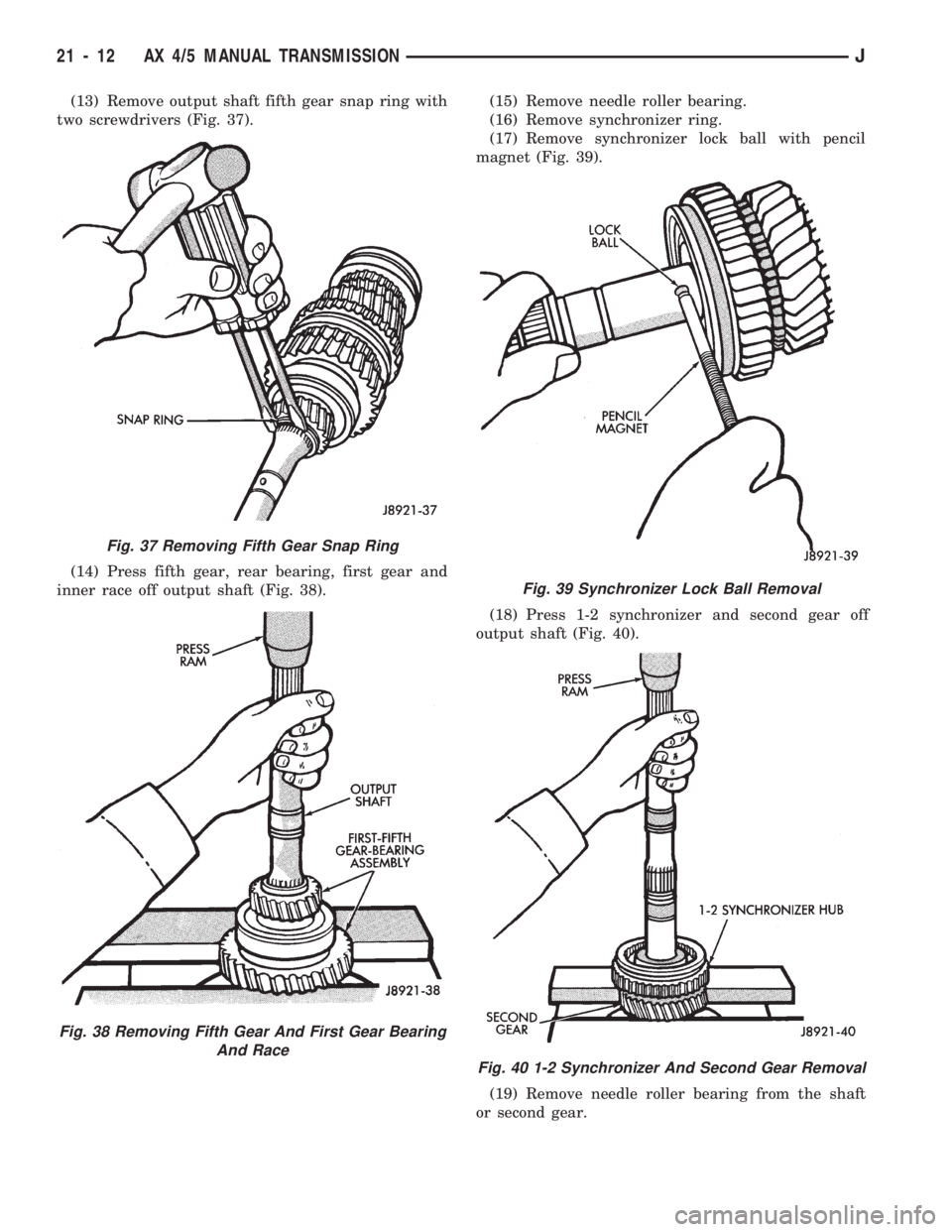

(13) Remove output shaft fifth gear snap ring with

two screwdrivers (Fig. 37).

(14) Press fifth gear, rear bearing, first gear and

inner race off output shaft (Fig. 38).(15) Remove needle roller bearing.

(16) Remove synchronizer ring.

(17) Remove synchronizer lock ball with pencil

magnet (Fig. 39).

(18) Press 1-2 synchronizer and second gear off

output shaft (Fig. 40).

(19) Remove needle roller bearing from the shaft

or second gear.

Fig. 37 Removing Fifth Gear Snap Ring

Fig. 38 Removing Fifth Gear And First Gear Bearing

And Race

Fig. 39 Synchronizer Lock Ball Removal

Fig. 40 1-2 Synchronizer And Second Gear Removal

21 - 12 AX 4/5 MANUAL TRANSMISSIONJ

Page 1124 of 1784

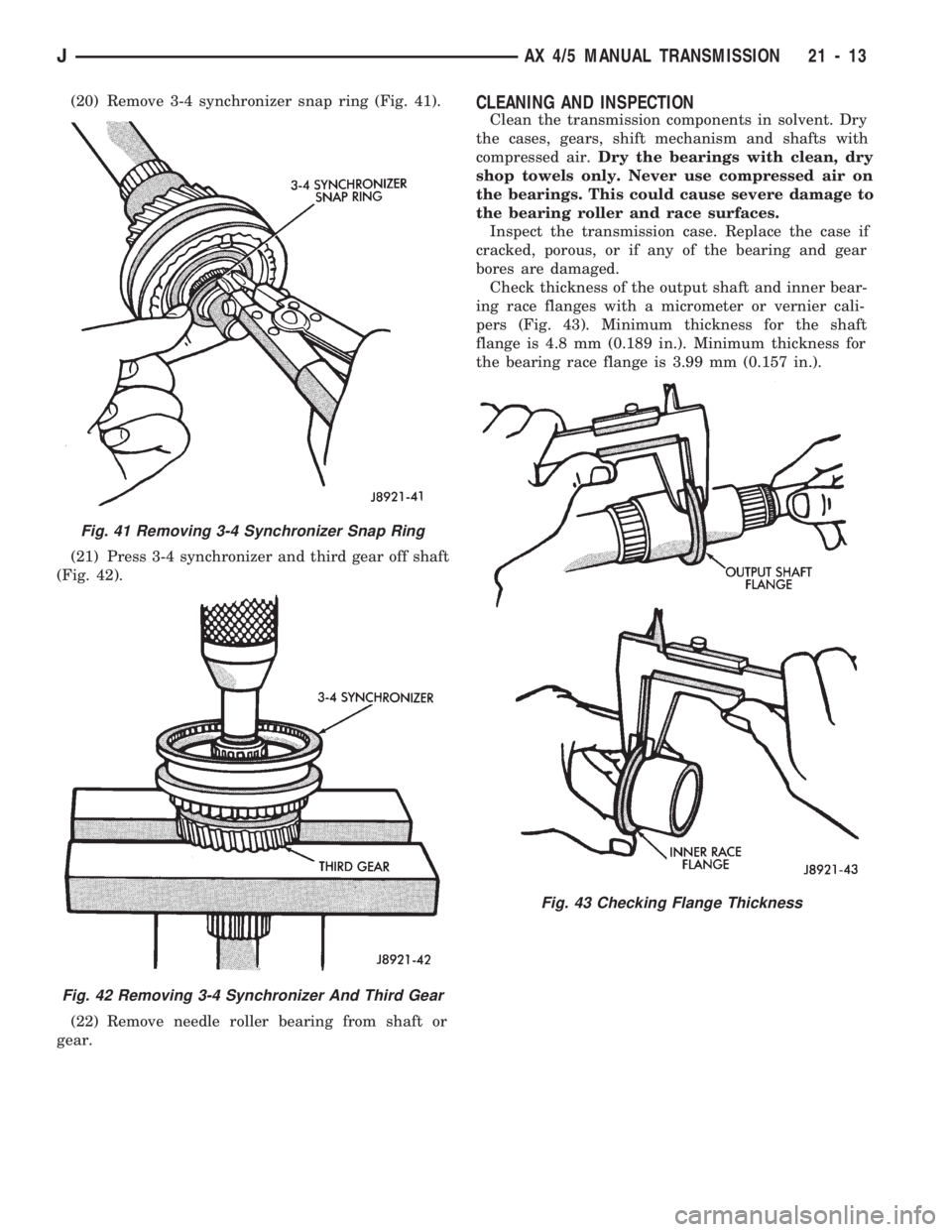

(20) Remove 3-4 synchronizer snap ring (Fig. 41).

(21) Press 3-4 synchronizer and third gear off shaft

(Fig. 42).

(22) Remove needle roller bearing from shaft or

gear.CLEANING AND INSPECTION

Clean the transmission components in solvent. Dry

the cases, gears, shift mechanism and shafts with

compressed air.Dry the bearings with clean, dry

shop towels only. Never use compressed air on

the bearings. This could cause severe damage to

the bearing roller and race surfaces.

Inspect the transmission case. Replace the case if

cracked, porous, or if any of the bearing and gear

bores are damaged.

Check thickness of the output shaft and inner bear-

ing race flanges with a micrometer or vernier cali-

pers (Fig. 43). Minimum thickness for the shaft

flange is 4.8 mm (0.189 in.). Minimum thickness for

the bearing race flange is 3.99 mm (0.157 in.).

Fig. 41 Removing 3-4 Synchronizer Snap Ring

Fig. 42 Removing 3-4 Synchronizer And Third Gear

Fig. 43 Checking Flange Thickness

JAX 4/5 MANUAL TRANSMISSION 21 - 13

Page 1125 of 1784

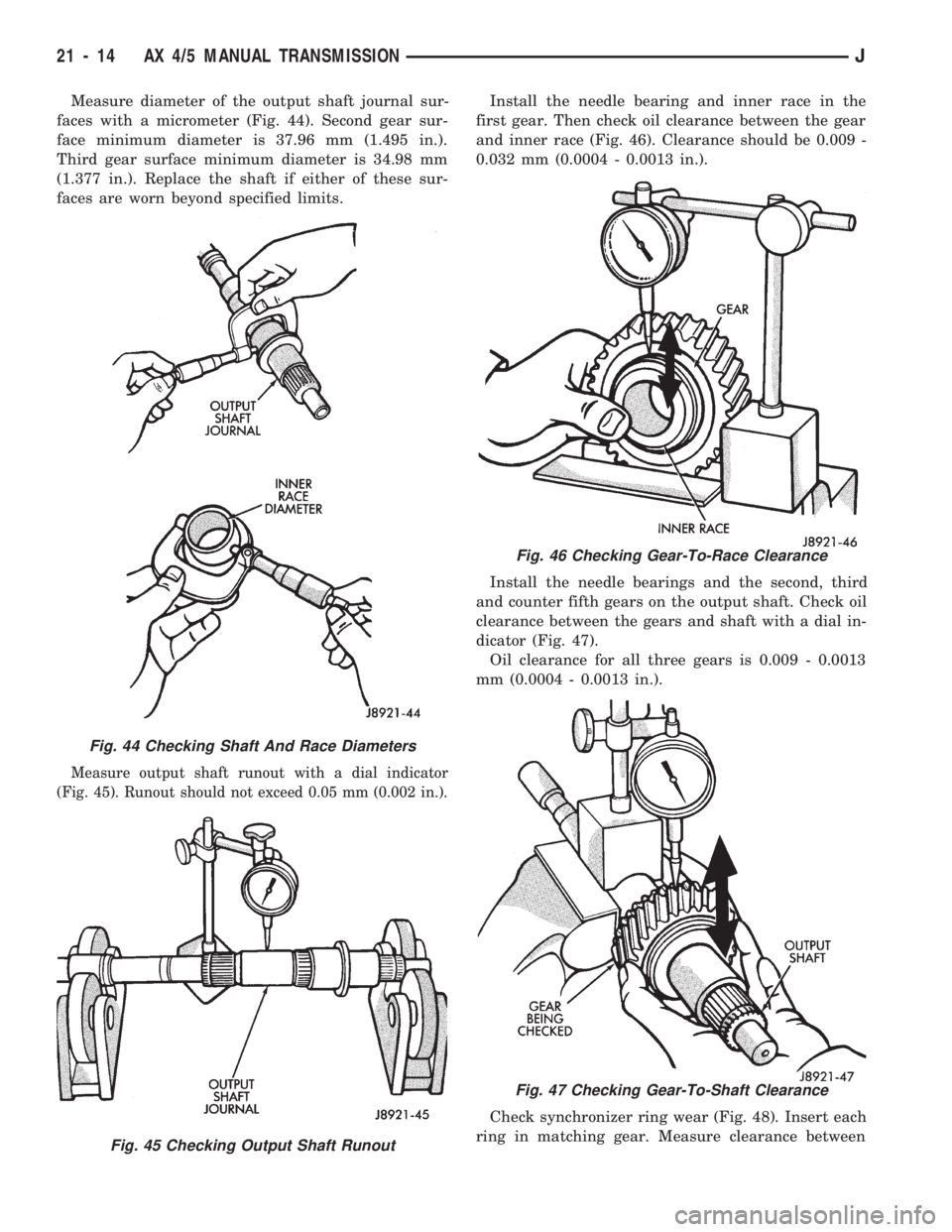

Measure diameter of the output shaft journal sur-

faces with a micrometer (Fig. 44). Second gear sur-

face minimum diameter is 37.96 mm (1.495 in.).

Third gear surface minimum diameter is 34.98 mm

(1.377 in.). Replace the shaft if either of these sur-

faces are worn beyond specified limits.

Measure output shaft runout with a dial indicator

(Fig. 45). Runout should not exceed 0.05 mm (0.002 in.).

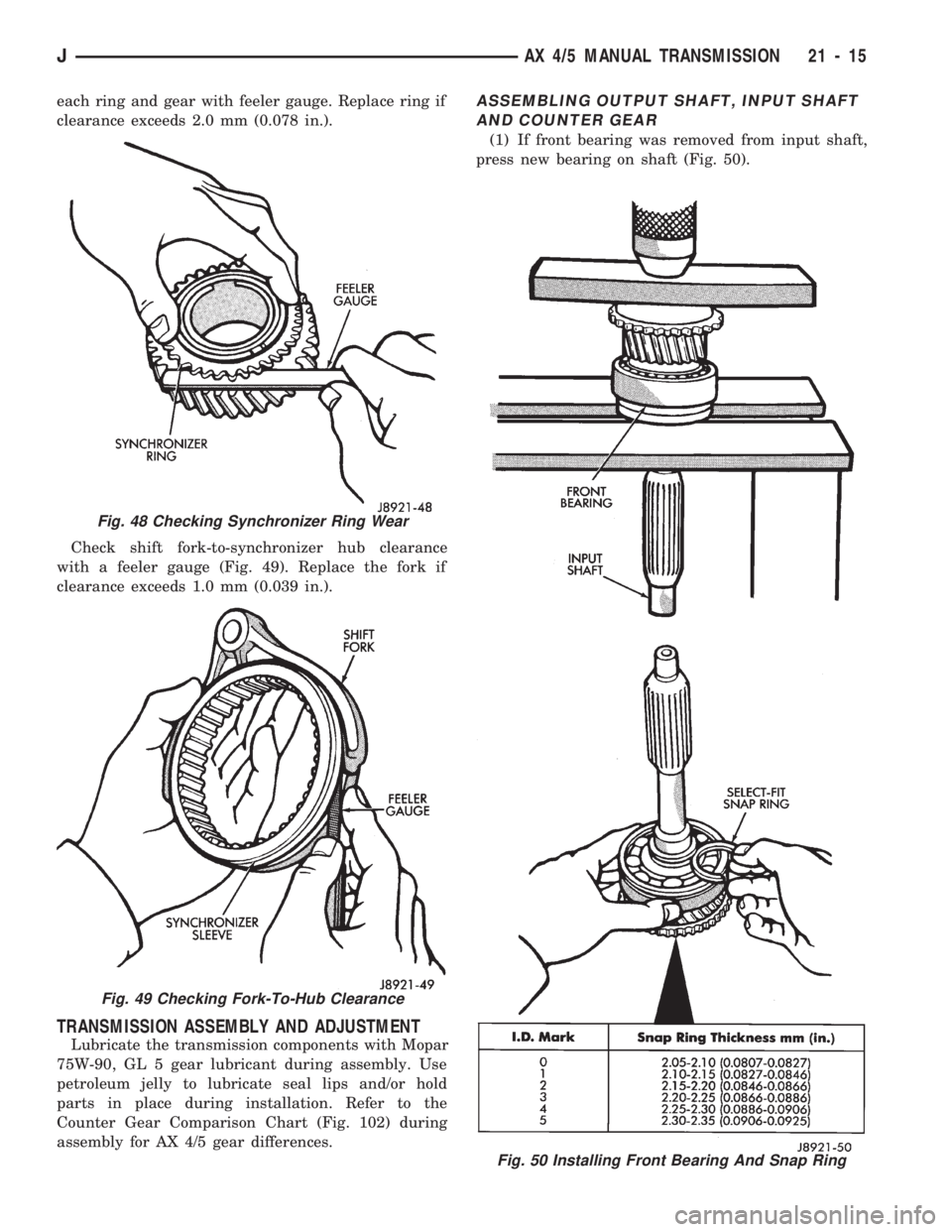

Install the needle bearing and inner race in the

first gear. Then check oil clearance between the gear

and inner race (Fig. 46). Clearance should be 0.009 -

0.032 mm (0.0004 - 0.0013 in.).

Install the needle bearings and the second, third

and counter fifth gears on the output shaft. Check oil

clearance between the gears and shaft with a dial in-

dicator (Fig. 47).

Oil clearance for all three gears is 0.009 - 0.0013

mm (0.0004 - 0.0013 in.).

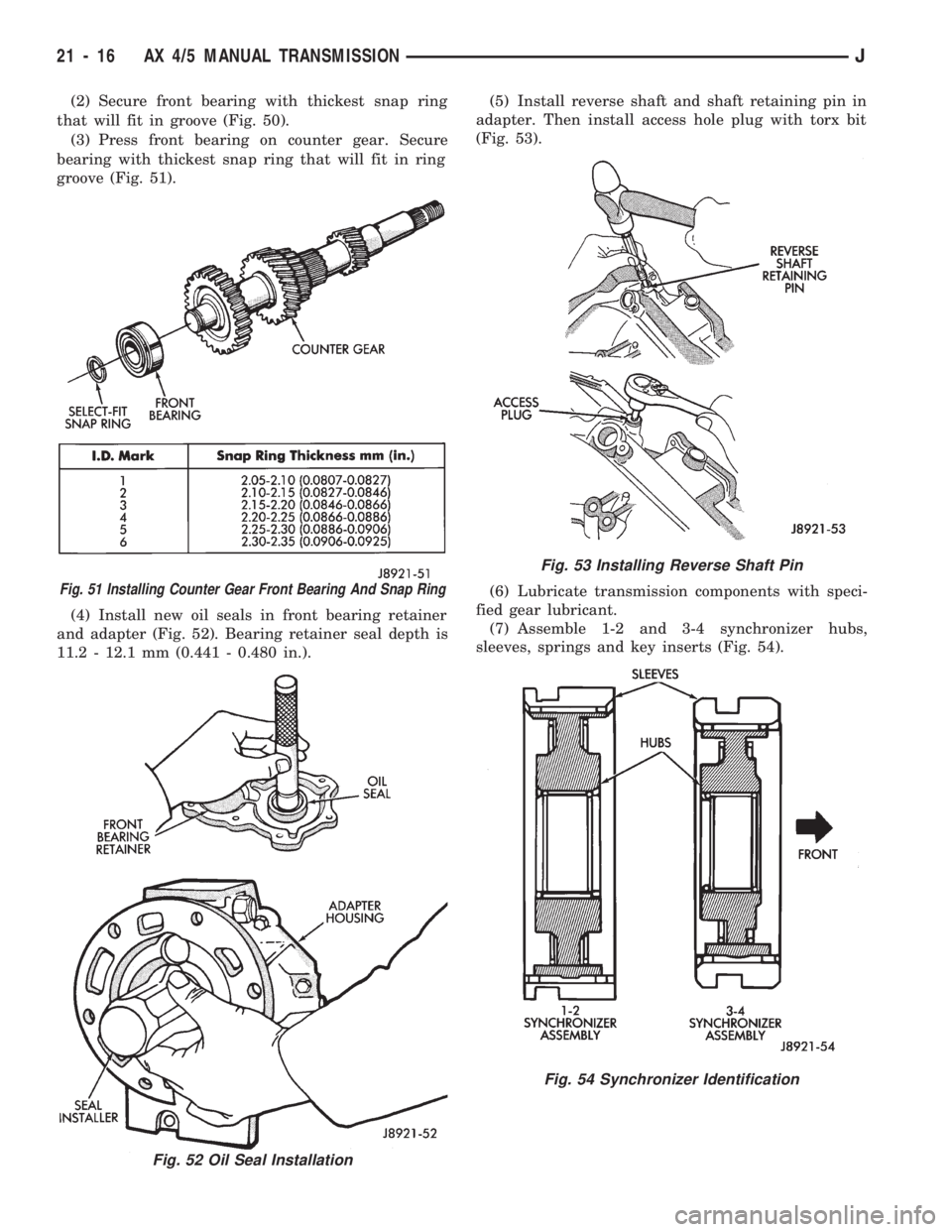

Check synchronizer ring wear (Fig. 48). Insert each

ring in matching gear. Measure clearance between

Fig. 44 Checking Shaft And Race Diameters

Fig. 45 Checking Output Shaft Runout

Fig. 46 Checking Gear-To-Race Clearance

Fig. 47 Checking Gear-To-Shaft Clearance

21 - 14 AX 4/5 MANUAL TRANSMISSIONJ

Page 1126 of 1784

each ring and gear with feeler gauge. Replace ring if

clearance exceeds 2.0 mm (0.078 in.).

Check shift fork-to-synchronizer hub clearance

with a feeler gauge (Fig. 49). Replace the fork if

clearance exceeds 1.0 mm (0.039 in.).

TRANSMISSION ASSEMBLY AND ADJUSTMENT

Lubricate the transmission components with Mopar

75W-90, GL 5 gear lubricant during assembly. Use

petroleum jelly to lubricate seal lips and/or hold

parts in place during installation. Refer to the

Counter Gear Comparison Chart (Fig. 102) during

assembly for AX 4/5 gear differences.

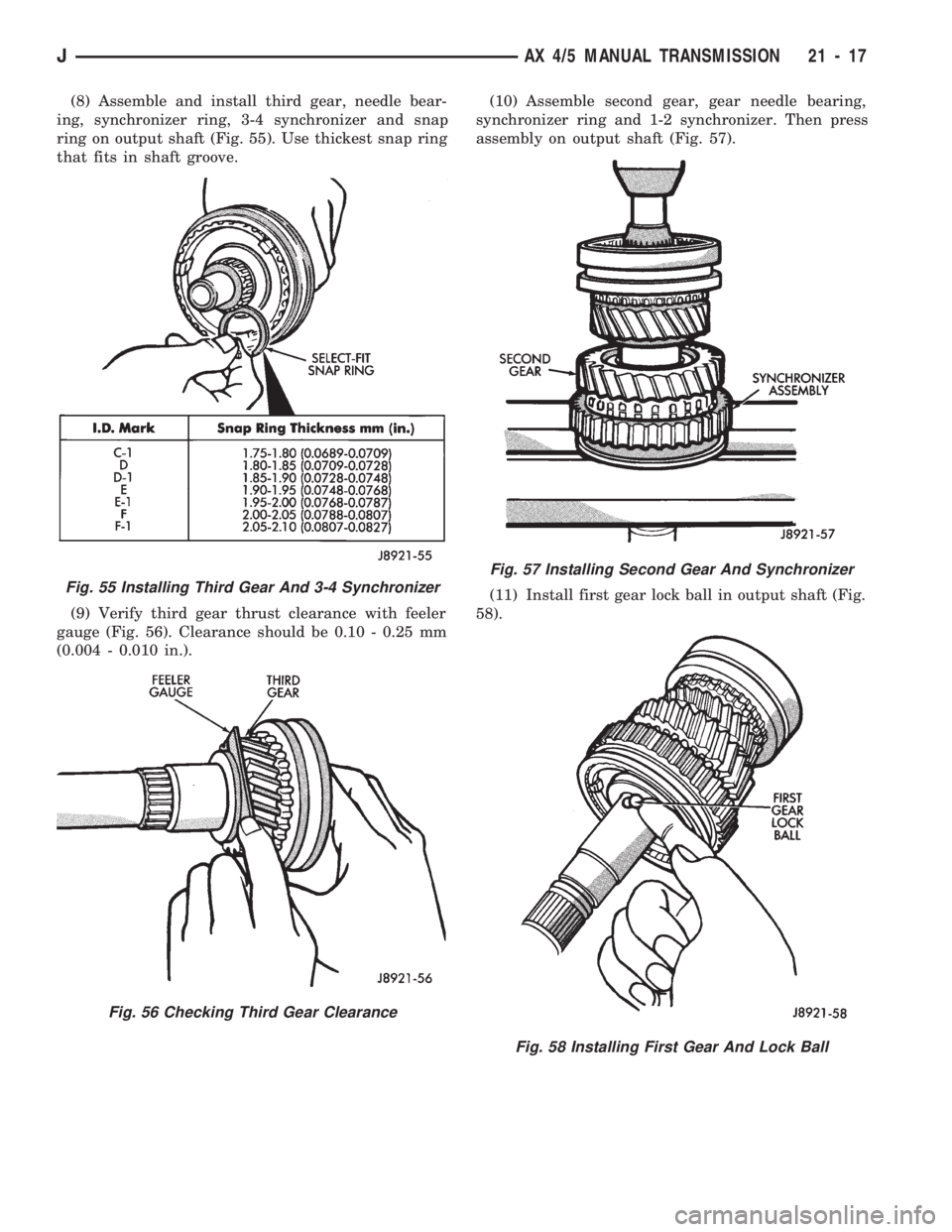

ASSEMBLING OUTPUT SHAFT, INPUT SHAFT

AND COUNTER GEAR

(1) If front bearing was removed from input shaft,

press new bearing on shaft (Fig. 50).

Fig. 50 Installing Front Bearing And Snap Ring

Fig. 48 Checking Synchronizer Ring Wear

Fig. 49 Checking Fork-To-Hub Clearance

JAX 4/5 MANUAL TRANSMISSION 21 - 15

Page 1127 of 1784

(2) Secure front bearing with thickest snap ring

that will fit in groove (Fig. 50).

(3) Press front bearing on counter gear. Secure

bearing with thickest snap ring that will fit in ring

groove (Fig. 51).

(4) Install new oil seals in front bearing retainer

and adapter (Fig. 52). Bearing retainer seal depth is

11.2 - 12.1 mm (0.441 - 0.480 in.).(5) Install reverse shaft and shaft retaining pin in

adapter. Then install access hole plug with torx bit

(Fig. 53).

(6) Lubricate transmission components with speci-

fied gear lubricant.

(7) Assemble 1-2 and 3-4 synchronizer hubs,

sleeves, springs and key inserts (Fig. 54).

Fig. 51 Installing Counter Gear Front Bearing And Snap Ring

Fig. 52 Oil Seal Installation

Fig. 53 Installing Reverse Shaft Pin

Fig. 54 Synchronizer Identification

21 - 16 AX 4/5 MANUAL TRANSMISSIONJ

Page 1128 of 1784

(8) Assemble and install third gear, needle bear-

ing, synchronizer ring, 3-4 synchronizer and snap

ring on output shaft (Fig. 55). Use thickest snap ring

that fits in shaft groove.

(9) Verify third gear thrust clearance with feeler

gauge (Fig. 56). Clearance should be 0.10 - 0.25 mm

(0.004 - 0.010 in.).(10) Assemble second gear, gear needle bearing,

synchronizer ring and 1-2 synchronizer. Then press

assembly on output shaft (Fig. 57).

(11) Install first gear lock ball in output shaft (Fig.

58).

Fig. 55 Installing Third Gear And 3-4 Synchronizer

Fig. 56 Checking Third Gear Clearance

Fig. 57 Installing Second Gear And Synchronizer

Fig. 58 Installing First Gear And Lock Ball

JAX 4/5 MANUAL TRANSMISSION 21 - 17

Page 1129 of 1784

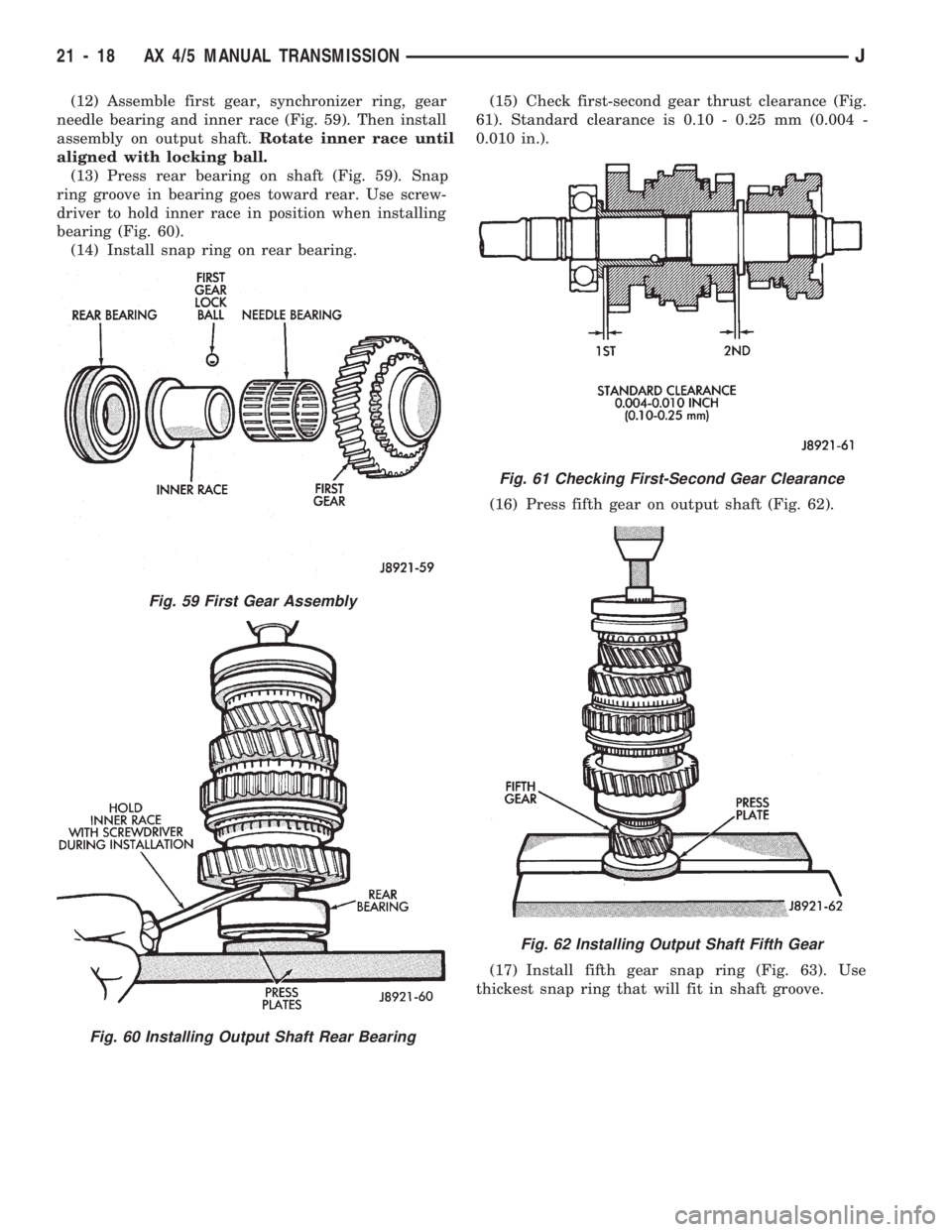

(12) Assemble first gear, synchronizer ring, gear

needle bearing and inner race (Fig. 59). Then install

assembly on output shaft.Rotate inner race until

aligned with locking ball.

(13) Press rear bearing on shaft (Fig. 59). Snap

ring groove in bearing goes toward rear. Use screw-

driver to hold inner race in position when installing

bearing (Fig. 60).

(14) Install snap ring on rear bearing.(15) Check first-second gear thrust clearance (Fig.

61). Standard clearance is 0.10 - 0.25 mm (0.004 -

0.010 in.).

(16) Press fifth gear on output shaft (Fig. 62).

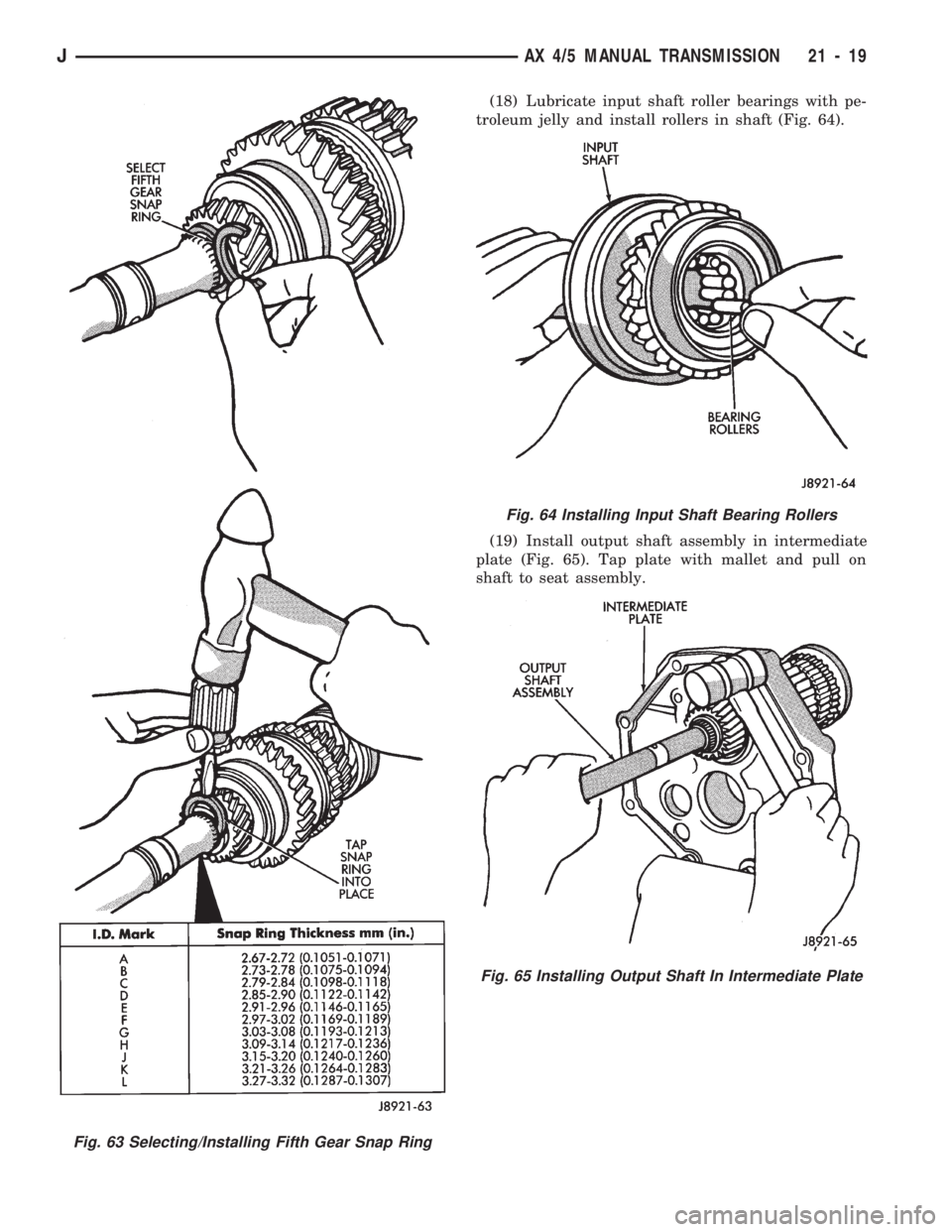

(17) Install fifth gear snap ring (Fig. 63). Use

thickest snap ring that will fit in shaft groove.

Fig. 59 First Gear Assembly

Fig. 60 Installing Output Shaft Rear Bearing

Fig. 61 Checking First-Second Gear Clearance

Fig. 62 Installing Output Shaft Fifth Gear

21 - 18 AX 4/5 MANUAL TRANSMISSIONJ

Page 1130 of 1784

(18) Lubricate input shaft roller bearings with pe-

troleum jelly and install rollers in shaft (Fig. 64).

(19) Install output shaft assembly in intermediate

plate (Fig. 65). Tap plate with mallet and pull on

shaft to seat assembly.

Fig. 63 Selecting/Installing Fifth Gear Snap Ring

Fig. 64 Installing Input Shaft Bearing Rollers

Fig. 65 Installing Output Shaft In Intermediate Plate

JAX 4/5 MANUAL TRANSMISSION 21 - 19