JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1241 of 1784

seal ring is teflon with chamfered ends. The rear

ring is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLING REAR CLUTCH

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

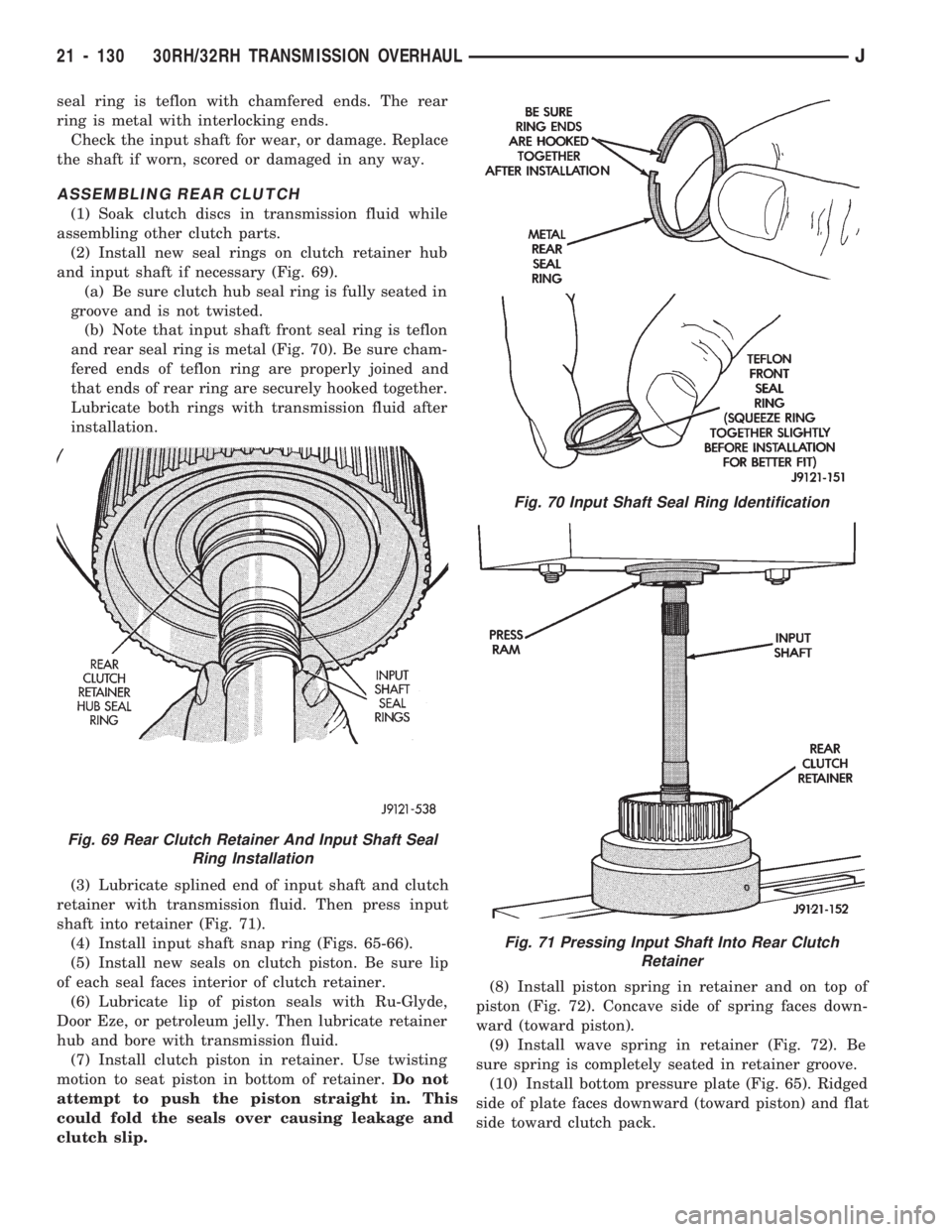

(2) Install new seal rings on clutch retainer hub

and input shaft if necessary (Fig. 69).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(b) Note that input shaft front seal ring is teflon

and rear seal ring is metal (Fig. 70). Be sure cham-

fered ends of teflon ring are properly joined and

that ends of rear ring are securely hooked together.

Lubricate both rings with transmission fluid after

installation.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 71).

(4) Install input shaft snap ring (Figs. 65-66).

(5) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(6) Lubricate lip of piston seals with Ru-Glyde,

Door Eze, or petroleum jelly. Then lubricate retainer

hub and bore with transmission fluid.

(7) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer.Do not

attempt to push the piston straight in. This

could fold the seals over causing leakage and

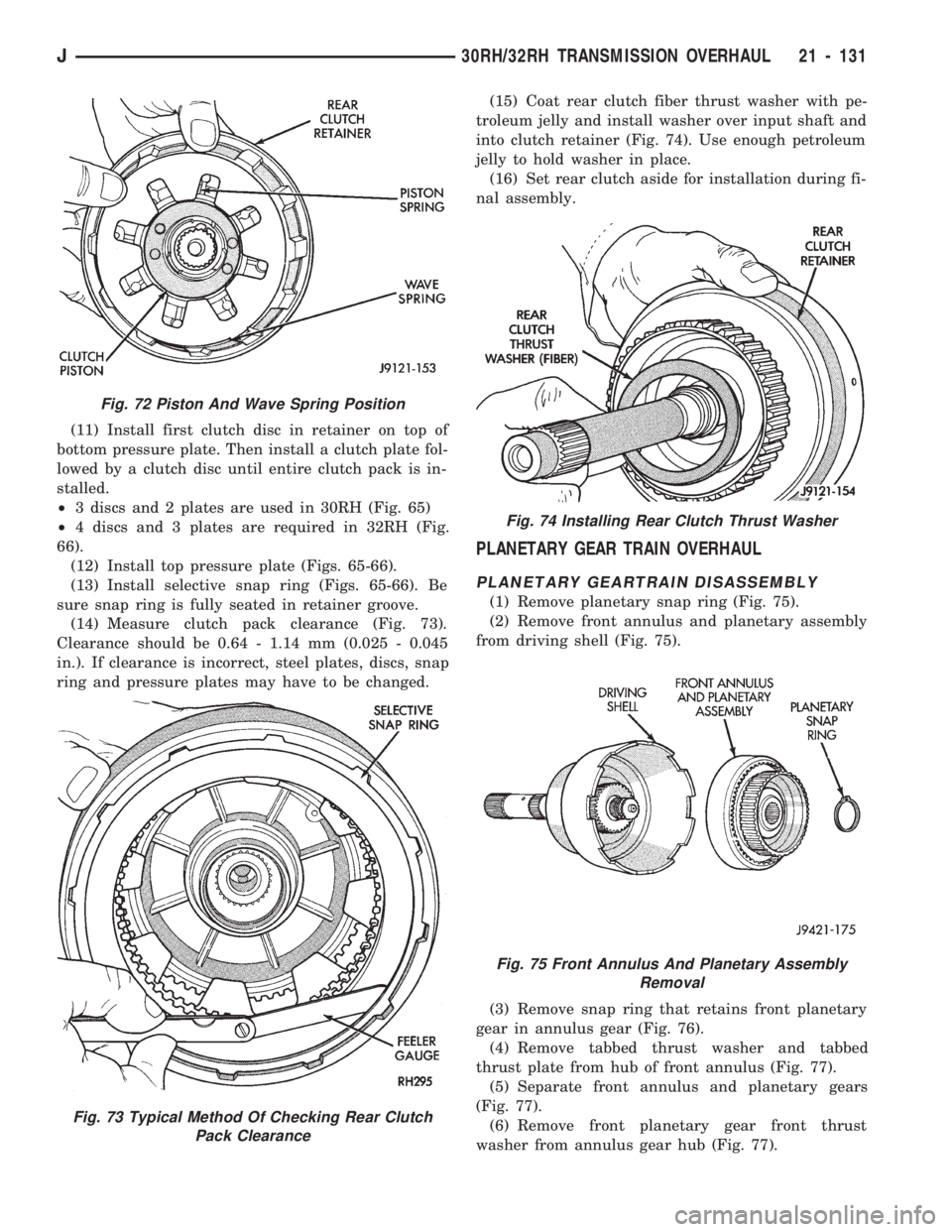

clutch slip.(8) Install piston spring in retainer and on top of

piston (Fig. 72). Concave side of spring faces down-

ward (toward piston).

(9) Install wave spring in retainer (Fig. 72). Be

sure spring is completely seated in retainer groove.

(10) Install bottom pressure plate (Fig. 65). Ridged

side of plate faces downward (toward piston) and flat

side toward clutch pack.

Fig. 69 Rear Clutch Retainer And Input Shaft Seal

Ring Installation

Fig. 70 Input Shaft Seal Ring Identification

Fig. 71 Pressing Input Shaft Into Rear Clutch

Retainer

21 - 130 30RH/32RH TRANSMISSION OVERHAULJ

Page 1242 of 1784

(11) Install first clutch disc in retainer on top of

bottom pressure plate. Then install a clutch plate fol-

lowed by a clutch disc until entire clutch pack is in-

stalled.

²3 discs and 2 plates are used in 30RH (Fig. 65)

²4 discs and 3 plates are required in 32RH (Fig.

66).

(12) Install top pressure plate (Figs. 65-66).

(13) Install selective snap ring (Figs. 65-66). Be

sure snap ring is fully seated in retainer groove.

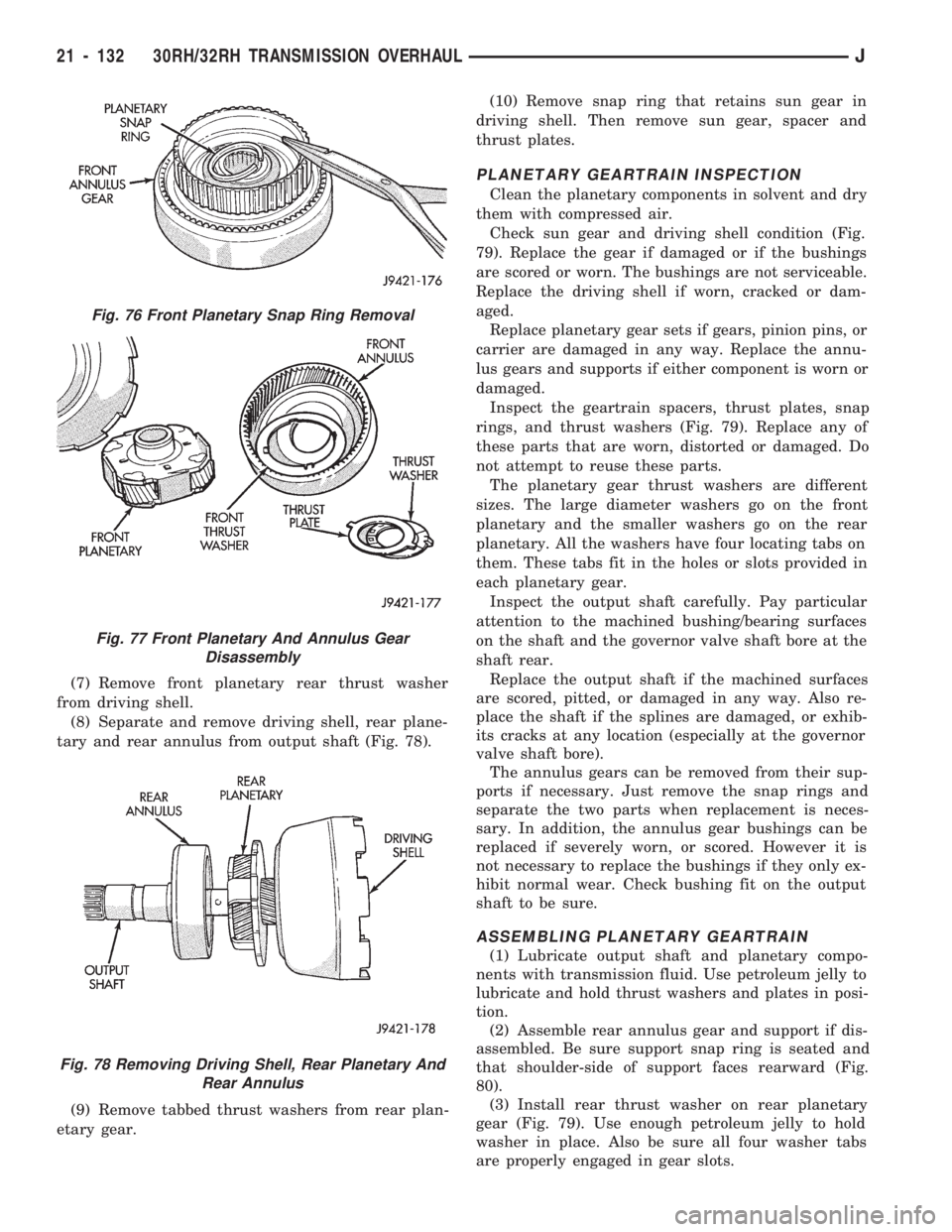

(14) Measure clutch pack clearance (Fig. 73).

Clearance should be 0.64 - 1.14 mm (0.025 - 0.045

in.). If clearance is incorrect, steel plates, discs, snap

ring and pressure plates may have to be changed.(15) Coat rear clutch fiber thrust washer with pe-

troleum jelly and install washer over input shaft and

into clutch retainer (Fig. 74). Use enough petroleum

jelly to hold washer in place.

(16) Set rear clutch aside for installation during fi-

nal assembly.

PLANETARY GEAR TRAIN OVERHAUL

PLANETARY GEARTRAIN DISASSEMBLY

(1) Remove planetary snap ring (Fig. 75).

(2) Remove front annulus and planetary assembly

from driving shell (Fig. 75).

(3) Remove snap ring that retains front planetary

gear in annulus gear (Fig. 76).

(4) Remove tabbed thrust washer and tabbed

thrust plate from hub of front annulus (Fig. 77).

(5) Separate front annulus and planetary gears

(Fig. 77).

(6) Remove front planetary gear front thrust

washer from annulus gear hub (Fig. 77).

Fig. 72 Piston And Wave Spring Position

Fig. 73 Typical Method Of Checking Rear Clutch

Pack Clearance

Fig. 74 Installing Rear Clutch Thrust Washer

Fig. 75 Front Annulus And Planetary Assembly

Removal

J30RH/32RH TRANSMISSION OVERHAUL 21 - 131

Page 1243 of 1784

(7) Remove front planetary rear thrust washer

from driving shell.

(8) Separate and remove driving shell, rear plane-

tary and rear annulus from output shaft (Fig. 78).

(9) Remove tabbed thrust washers from rear plan-

etary gear.(10) Remove snap ring that retains sun gear in

driving shell. Then remove sun gear, spacer and

thrust plates.

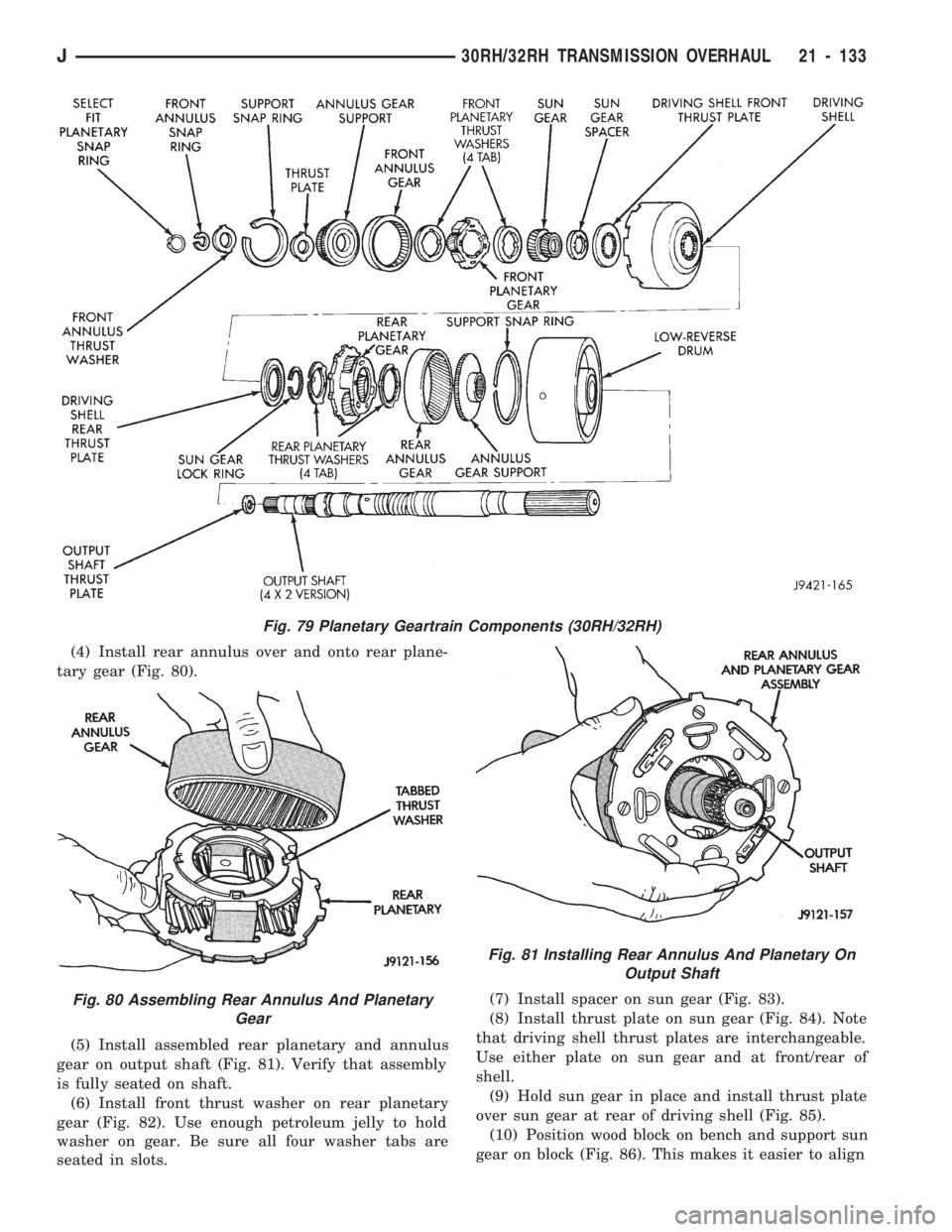

PLANETARY GEARTRAIN INSPECTION

Clean the planetary components in solvent and dry

them with compressed air.

Check sun gear and driving shell condition (Fig.

79). Replace the gear if damaged or if the bushings

are scored or worn. The bushings are not serviceable.

Replace the driving shell if worn, cracked or dam-

aged.

Replace planetary gear sets if gears, pinion pins, or

carrier are damaged in any way. Replace the annu-

lus gears and supports if either component is worn or

damaged.

Inspect the geartrain spacers, thrust plates, snap

rings, and thrust washers (Fig. 79). Replace any of

these parts that are worn, distorted or damaged. Do

not attempt to reuse these parts.

The planetary gear thrust washers are different

sizes. The large diameter washers go on the front

planetary and the smaller washers go on the rear

planetary. All the washers have four locating tabs on

them. These tabs fit in the holes or slots provided in

each planetary gear.

Inspect the output shaft carefully. Pay particular

attention to the machined bushing/bearing surfaces

on the shaft and the governor valve shaft bore at the

shaft rear.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also re-

place the shaft if the splines are damaged, or exhib-

its cracks at any location (especially at the governor

valve shaft bore).

The annulus gears can be removed from their sup-

ports if necessary. Just remove the snap rings and

separate the two parts when replacement is neces-

sary. In addition, the annulus gear bushings can be

replaced if severely worn, or scored. However it is

not necessary to replace the bushings if they only ex-

hibit normal wear. Check bushing fit on the output

shaft to be sure.

ASSEMBLING PLANETARY GEARTRAIN

(1) Lubricate output shaft and planetary compo-

nents with transmission fluid. Use petroleum jelly to

lubricate and hold thrust washers and plates in posi-

tion.

(2) Assemble rear annulus gear and support if dis-

assembled. Be sure support snap ring is seated and

that shoulder-side of support faces rearward (Fig.

80).

(3) Install rear thrust washer on rear planetary

gear (Fig. 79). Use enough petroleum jelly to hold

washer in place. Also be sure all four washer tabs

are properly engaged in gear slots.

Fig. 76 Front Planetary Snap Ring Removal

Fig. 77 Front Planetary And Annulus Gear

Disassembly

Fig. 78 Removing Driving Shell, Rear Planetary And

Rear Annulus

21 - 132 30RH/32RH TRANSMISSION OVERHAULJ

Page 1244 of 1784

(4) Install rear annulus over and onto rear plane-

tary gear (Fig. 80).

(5) Install assembled rear planetary and annulus

gear on output shaft (Fig. 81). Verify that assembly

is fully seated on shaft.

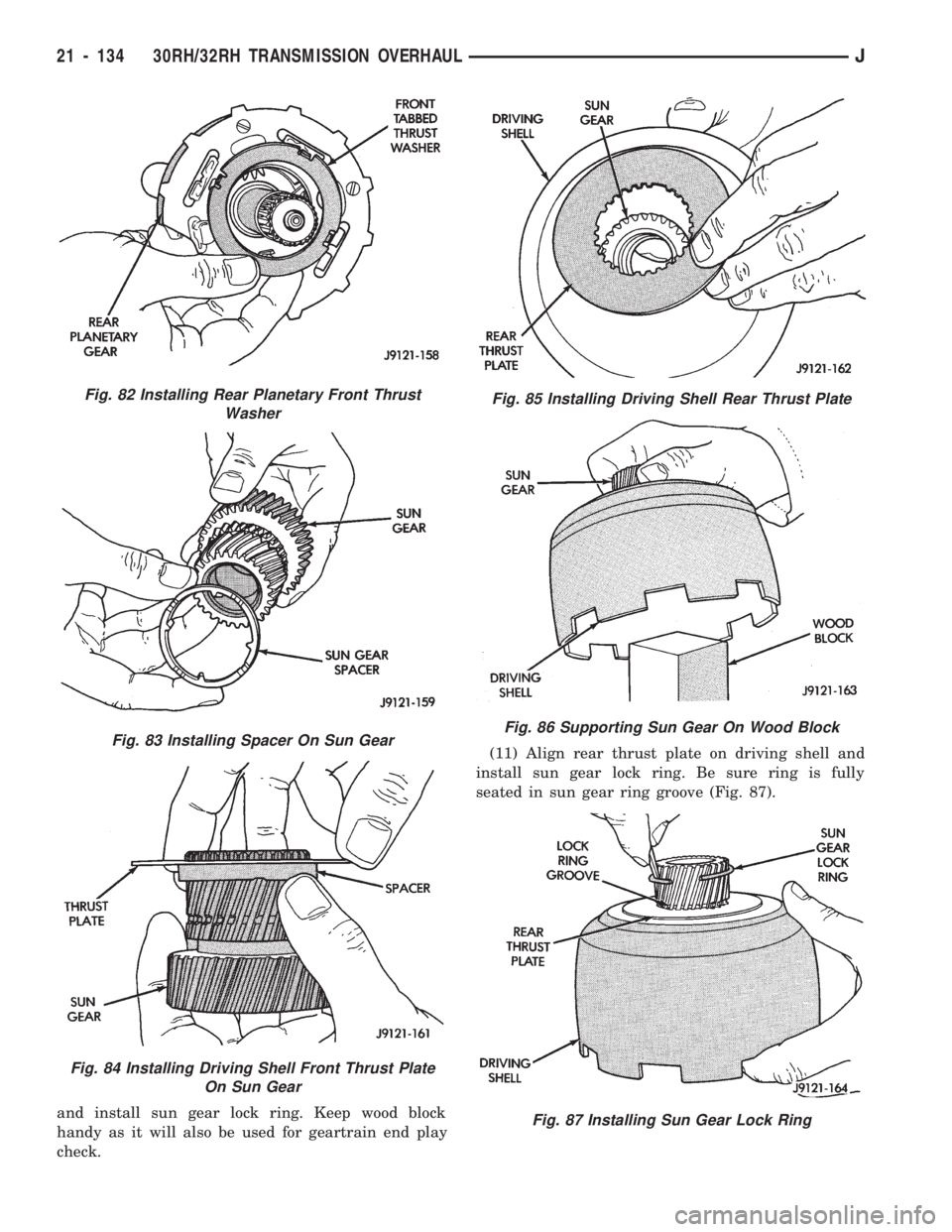

(6) Install front thrust washer on rear planetary

gear (Fig. 82). Use enough petroleum jelly to hold

washer on gear. Be sure all four washer tabs are

seated in slots.(7) Install spacer on sun gear (Fig. 83).

(8) Install thrust plate on sun gear (Fig. 84). Note

that driving shell thrust plates are interchangeable.

Use either plate on sun gear and at front/rear of

shell.

(9) Hold sun gear in place and install thrust plate

over sun gear at rear of driving shell (Fig. 85).

(10) Position wood block on bench and support sun

gear on block (Fig. 86). This makes it easier to align

Fig. 79 Planetary Geartrain Components (30RH/32RH)

Fig. 80 Assembling Rear Annulus And Planetary

Gear

Fig. 81 Installing Rear Annulus And Planetary On

Output Shaft

J30RH/32RH TRANSMISSION OVERHAUL 21 - 133

Page 1245 of 1784

and install sun gear lock ring. Keep wood block

handy as it will also be used for geartrain end play

check.(11) Align rear thrust plate on driving shell and

install sun gear lock ring. Be sure ring is fully

seated in sun gear ring groove (Fig. 87).

Fig. 82 Installing Rear Planetary Front Thrust

Washer

Fig. 83 Installing Spacer On Sun Gear

Fig. 84 Installing Driving Shell Front Thrust Plate

On Sun Gear

Fig. 85 Installing Driving Shell Rear Thrust Plate

Fig. 86 Supporting Sun Gear On Wood Block

Fig. 87 Installing Sun Gear Lock Ring

21 - 134 30RH/32RH TRANSMISSION OVERHAULJ

Page 1246 of 1784

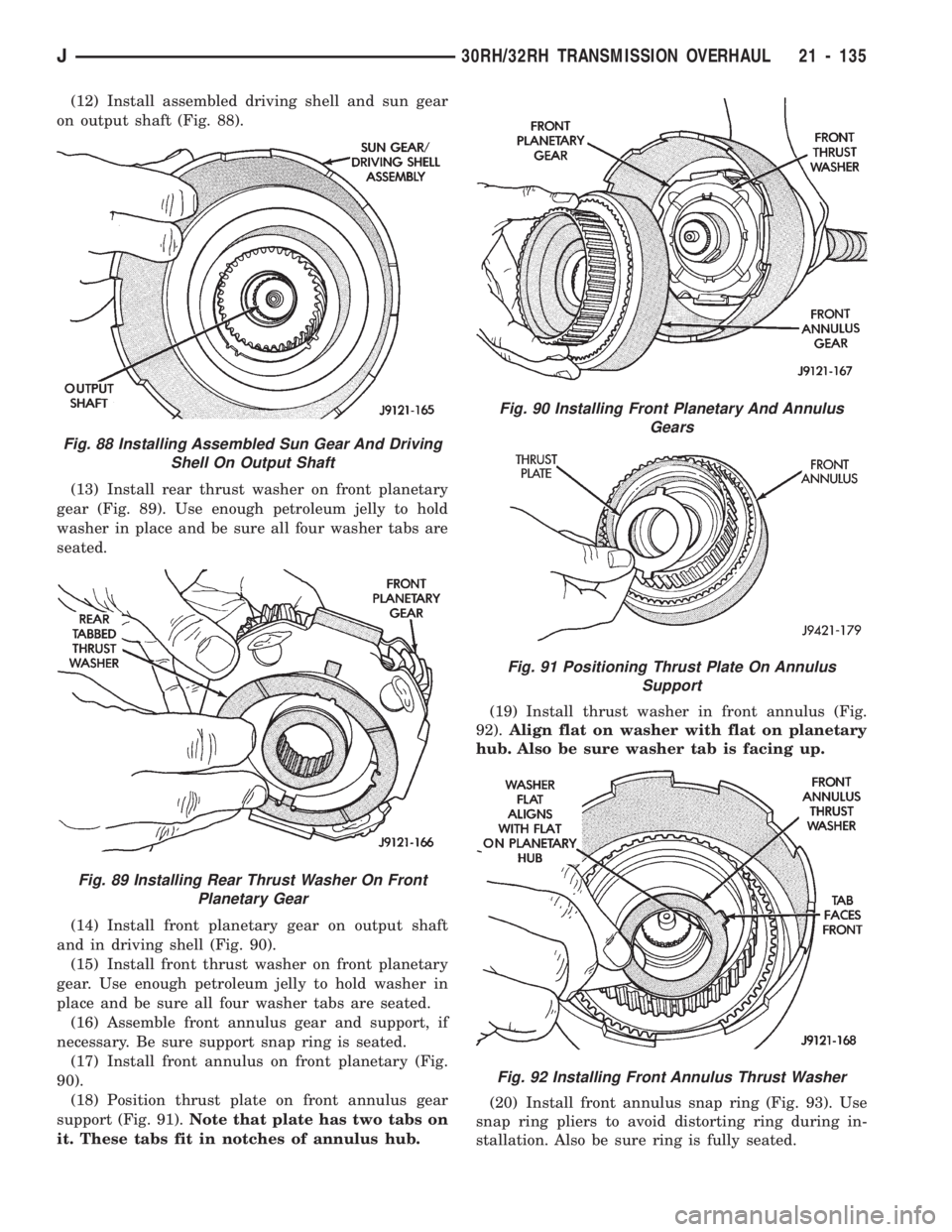

(12) Install assembled driving shell and sun gear

on output shaft (Fig. 88).

(13) Install rear thrust washer on front planetary

gear (Fig. 89). Use enough petroleum jelly to hold

washer in place and be sure all four washer tabs are

seated.

(14) Install front planetary gear on output shaft

and in driving shell (Fig. 90).

(15) Install front thrust washer on front planetary

gear. Use enough petroleum jelly to hold washer in

place and be sure all four washer tabs are seated.

(16) Assemble front annulus gear and support, if

necessary. Be sure support snap ring is seated.

(17) Install front annulus on front planetary (Fig.

90).

(18) Position thrust plate on front annulus gear

support (Fig. 91).Note that plate has two tabs on

it. These tabs fit in notches of annulus hub.(19) Install thrust washer in front annulus (Fig.

92).Align flat on washer with flat on planetary

hub. Also be sure washer tab is facing up.

(20) Install front annulus snap ring (Fig. 93). Use

snap ring pliers to avoid distorting ring during in-

stallation. Also be sure ring is fully seated.

Fig. 88 Installing Assembled Sun Gear And Driving

Shell On Output Shaft

Fig. 89 Installing Rear Thrust Washer On Front

Planetary Gear

Fig. 90 Installing Front Planetary And Annulus

Gears

Fig. 91 Positioning Thrust Plate On Annulus

Support

Fig. 92 Installing Front Annulus Thrust Washer

J30RH/32RH TRANSMISSION OVERHAUL 21 - 135

Page 1247 of 1784

(21) Install planetary selective snap ring with snap

ring pliers (Fig. 94). Be sure ring is fully seated.

(22) Turn planetary geartrain assembly over so

driving shell is facing workbench. Then support

geartrain on wood block positioned under forward

end of output shaft. This allow geartrain components

to move forward for accurate end play check.

(23) Check planetary geartrain end play with

feeler gauge (Fig. 95). Gauge goes between shoulder

on output shaft and end of rear annulus support.

(24) Geartrain end play should be 0.12 to 1.22 mm

(0.005 to 0.048 in.). If end play is incorrect, snap ring

(or thrust washers) may have to be replaced. Snap

ring is available in three different thicknesses for ad-

justment purposes.

FRONT SERVO AND BAND OVERHAUL

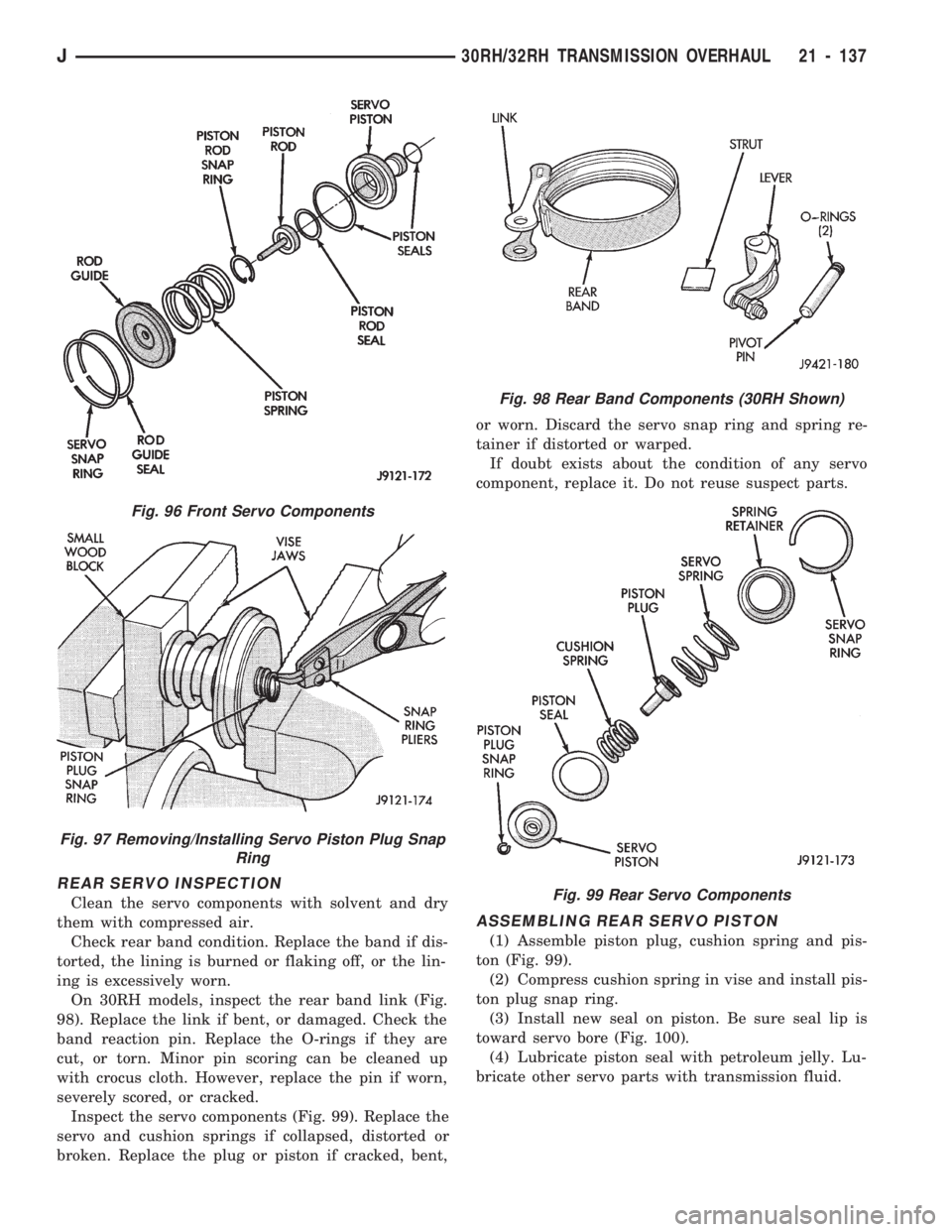

FRONT SERVO DISASSEMBLY (FIG. 96)

(1) Remove small snap ring from servo piston.

(2) Remove piston, rod, springs and guide.

(3) Remove and discard servo piston rings and

O-ring.

FRONT SERVO AND BAND INSPECTION

Clean the servo components with solvent and dry

them with compressed air.

Inspect the servo components. Replace the springs

if collapsed, distorted or broken. Replace the guide,

rod and piston if cracked, bent, or worn. Discard the

servo snap ring if distorted or warped.

Replace the front band if distorted, the lining is

burned or flaking off, or excessively worn.

Check the servo piston bore for wear. Replace the

piston and rod as an assembly if either part is worn

or damaged.

Replace any servo component if doubt exists about

its condition. Do not reuse suspect parts.

ASSEMBLING FRONT SERVO PISTON

(1) Lubricate servo parts with transmission fluid.

(2) Install new O-ring on servo piston rod.

(3) Install new seal on piston rod guide and install

new seal rings on piston.

(4) Assemble rod, piston, servo springs and snap

ring (Fig. 96).

REAR SERVO AND BAND OVERHAUL

REAR SERVO PISTON DISASSEMBLY

(1) Remove seal from servo piston. Note which way

seal lip faces for assembly reference.

(2) Compress cushion spring in vise only enough to

allow piston plug snap ring removal (Fig. 97). Use

wood block between vise jaws and end of piston plug

to keep plug aligned and in position.

(3)

Remove snap ring from end of piston plug (Fig. 97).

(4) Open vise and remove wood block, piston plug,

cushion spring and servo piston.

Fig. 93 Installing Front Annulus Snap Ring

Fig. 94 Installing Planetary Selective Snap Ring

Fig. 95 Checking Planetary Geartrain End Play

21 - 136 30RH/32RH TRANSMISSION OVERHAULJ

Page 1248 of 1784

REAR SERVO INSPECTION

Clean the servo components with solvent and dry

them with compressed air.

Check rear band condition. Replace the band if dis-

torted, the lining is burned or flaking off, or the lin-

ing is excessively worn.

On 30RH models, inspect the rear band link (Fig.

98). Replace the link if bent, or damaged. Check the

band reaction pin. Replace the O-rings if they are

cut, or torn. Minor pin scoring can be cleaned up

with crocus cloth. However, replace the pin if worn,

severely scored, or cracked.

Inspect the servo components (Fig. 99). Replace the

servo and cushion springs if collapsed, distorted or

broken. Replace the plug or piston if cracked, bent,or worn. Discard the servo snap ring and spring re-

tainer if distorted or warped.

If doubt exists about the condition of any servo

component, replace it. Do not reuse suspect parts.

ASSEMBLING REAR SERVO PISTON

(1) Assemble piston plug, cushion spring and pis-

ton (Fig. 99).

(2) Compress cushion spring in vise and install pis-

ton plug snap ring.

(3) Install new seal on piston. Be sure seal lip is

toward servo bore (Fig. 100).

(4) Lubricate piston seal with petroleum jelly. Lu-

bricate other servo parts with transmission fluid.

Fig. 96 Front Servo Components

Fig. 97 Removing/Installing Servo Piston Plug Snap

Ring

Fig. 98 Rear Band Components (30RH Shown)

Fig. 99 Rear Servo Components

J30RH/32RH TRANSMISSION OVERHAUL 21 - 137

Page 1249 of 1784

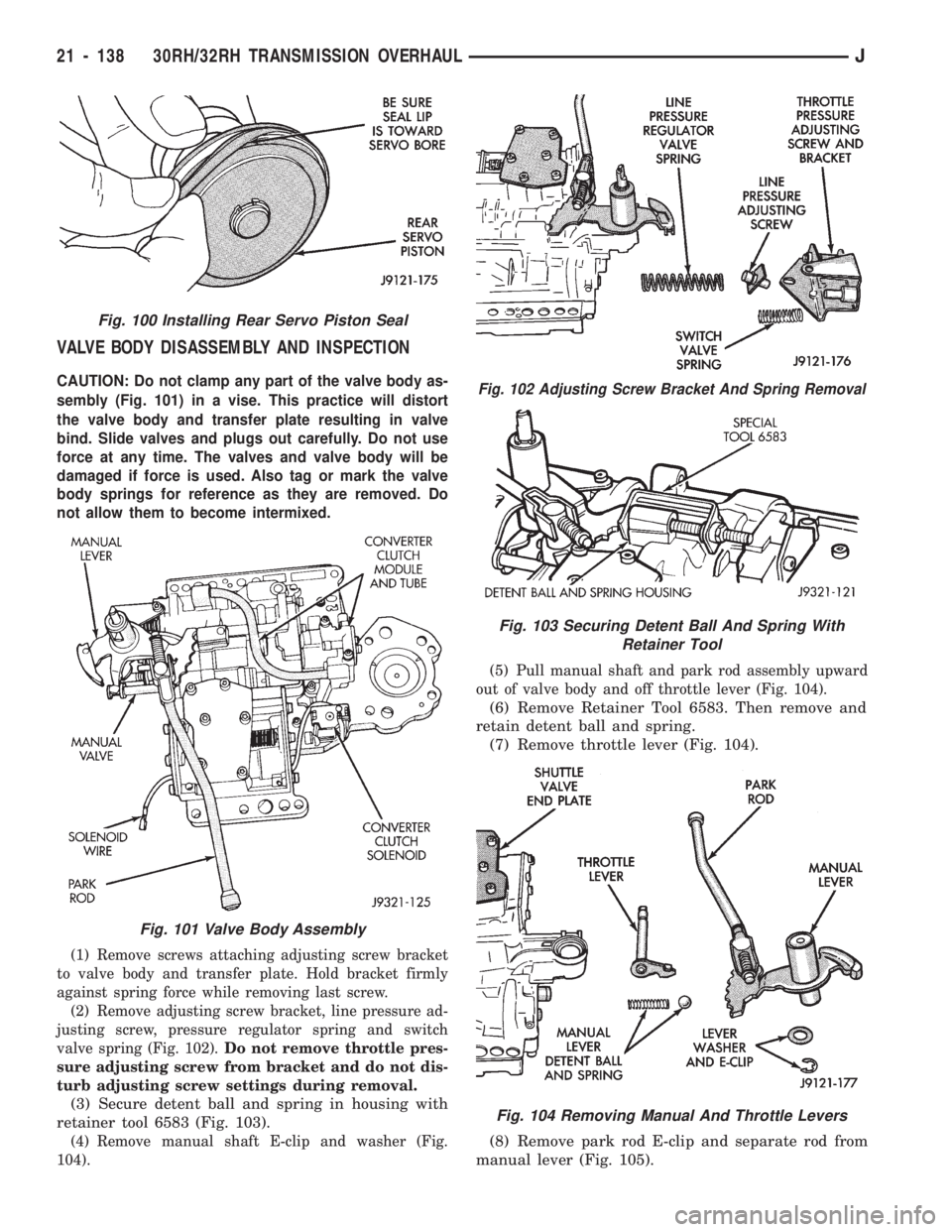

VALVE BODY DISASSEMBLY AND INSPECTION

CAUTION: Do not clamp any part of the valve body as-

sembly (Fig. 101) in a vise. This practice will distort

the valve body and transfer plate resulting in valve

bind. Slide valves and plugs out carefully. Do not use

force at any time. The valves and valve body will be

damaged if force is used. Also tag or mark the valve

body springs for reference as they are removed. Do

not allow them to become intermixed.

(1) Remove screws attaching adjusting screw bracket

to valve body and transfer plate. Hold bracket firmly

against spring force while removing last screw.

(2) Remove adjusting screw bracket, line pressure ad-

justing screw, pressure regulator spring and switch

valve spring (Fig. 102).Do not remove throttle pres-

sure adjusting screw from bracket and do not dis-

turb adjusting screw settings during removal.

(3) Secure detent ball and spring in housing with

retainer tool 6583 (Fig. 103).

(4) Remove manual shaft E-clip and washer (Fig.

104).(5) Pull manual shaft and park rod assembly upward

out of valve body and off throttle lever (Fig. 104).

(6) Remove Retainer Tool 6583. Then remove and

retain detent ball and spring.

(7) Remove throttle lever (Fig. 104).

(8) Remove park rod E-clip and separate rod from

manual lever (Fig. 105).

Fig. 102 Adjusting Screw Bracket And Spring Removal

Fig. 103 Securing Detent Ball And Spring With

Retainer Tool

Fig. 104 Removing Manual And Throttle Levers

Fig. 100 Installing Rear Servo Piston Seal

Fig. 101 Valve Body Assembly

21 - 138 30RH/32RH TRANSMISSION OVERHAULJ

Page 1250 of 1784

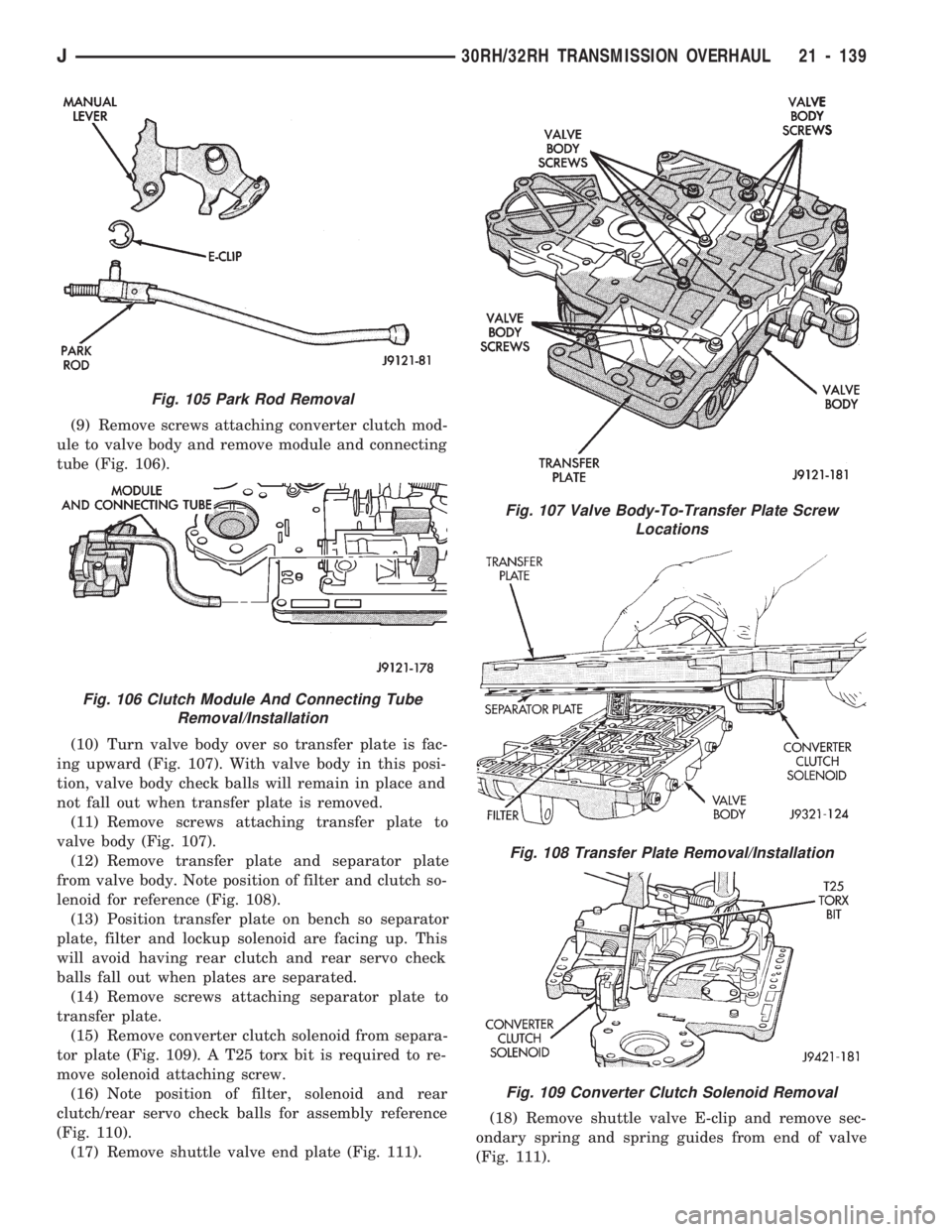

(9) Remove screws attaching converter clutch mod-

ule to valve body and remove module and connecting

tube (Fig. 106).

(10) Turn valve body over so transfer plate is fac-

ing upward (Fig. 107). With valve body in this posi-

tion, valve body check balls will remain in place and

not fall out when transfer plate is removed.

(11) Remove screws attaching transfer plate to

valve body (Fig. 107).

(12) Remove transfer plate and separator plate

from valve body. Note position of filter and clutch so-

lenoid for reference (Fig. 108).

(13) Position transfer plate on bench so separator

plate, filter and lockup solenoid are facing up. This

will avoid having rear clutch and rear servo check

balls fall out when plates are separated.

(14) Remove screws attaching separator plate to

transfer plate.

(15) Remove converter clutch solenoid from separa-

tor plate (Fig. 109). A T25 torx bit is required to re-

move solenoid attaching screw.

(16) Note position of filter, solenoid and rear

clutch/rear servo check balls for assembly reference

(Fig. 110).

(17) Remove shuttle valve end plate (Fig. 111).(18) Remove shuttle valve E-clip and remove sec-

ondary spring and spring guides from end of valve

(Fig. 111).

Fig. 105 Park Rod Removal

Fig. 106 Clutch Module And Connecting Tube

Removal/Installation

Fig. 107 Valve Body-To-Transfer Plate Screw

Locations

Fig. 108 Transfer Plate Removal/Installation

Fig. 109 Converter Clutch Solenoid Removal

J30RH/32RH TRANSMISSION OVERHAUL 21 - 139